Diffusion Behavior of Polyurethane Slurry for Simultaneous Enhancement of Reservoir Strength and Permeability Through Splitting Grouting Technology

Abstract

1. Introduction

2. Modeling and Parameterization

2.1. Finite-Discrete Element Methods

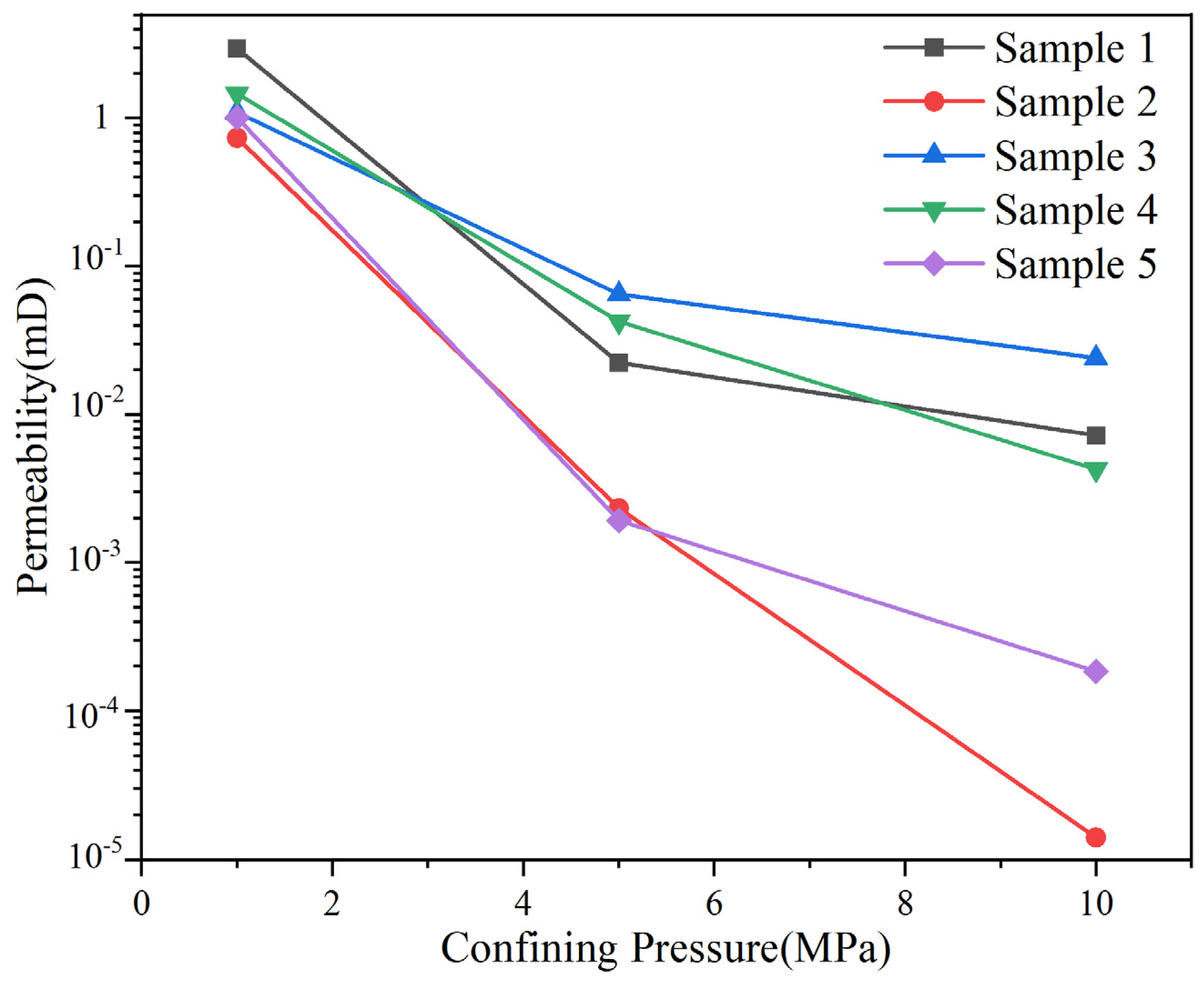

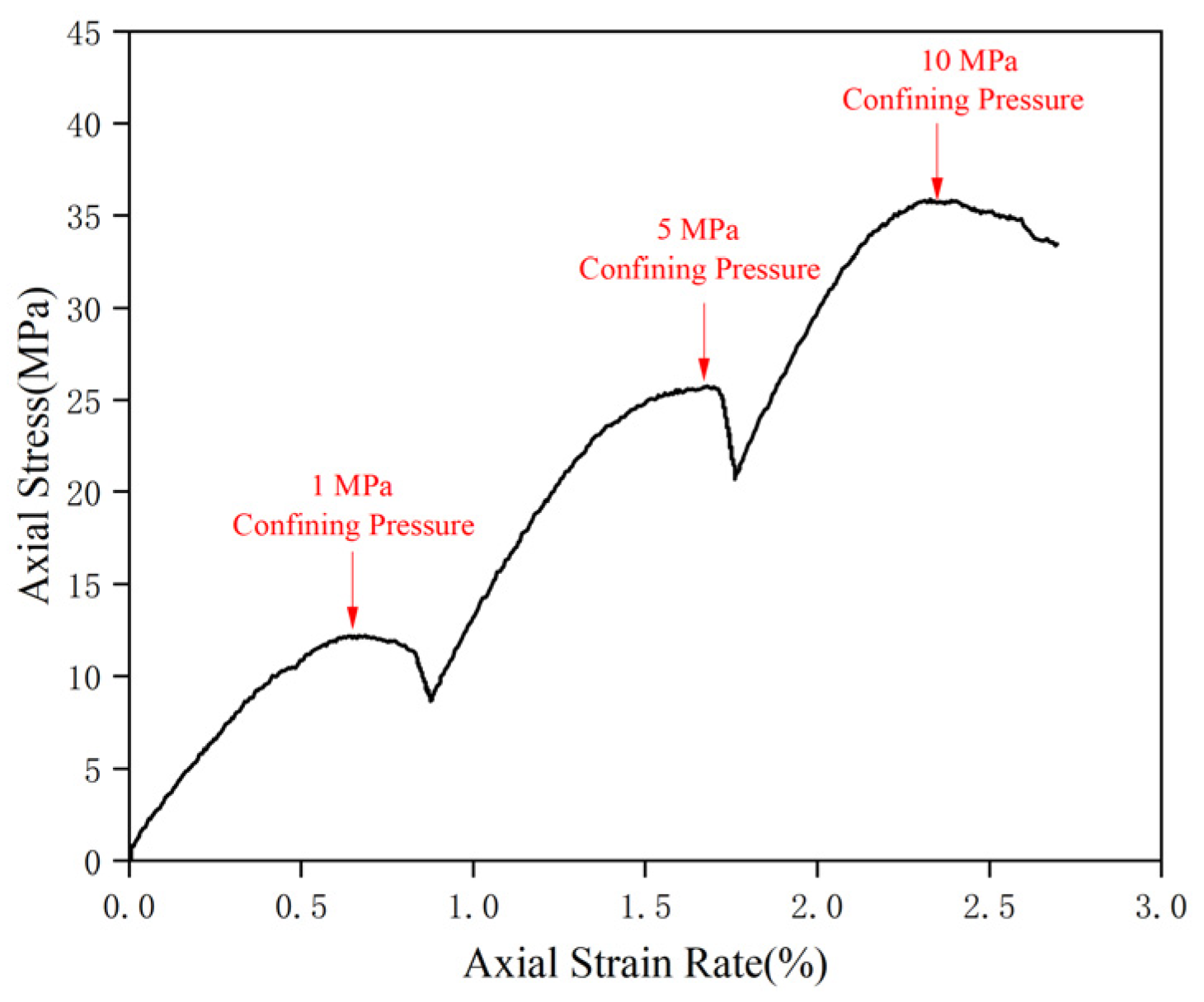

2.2. Parameterization

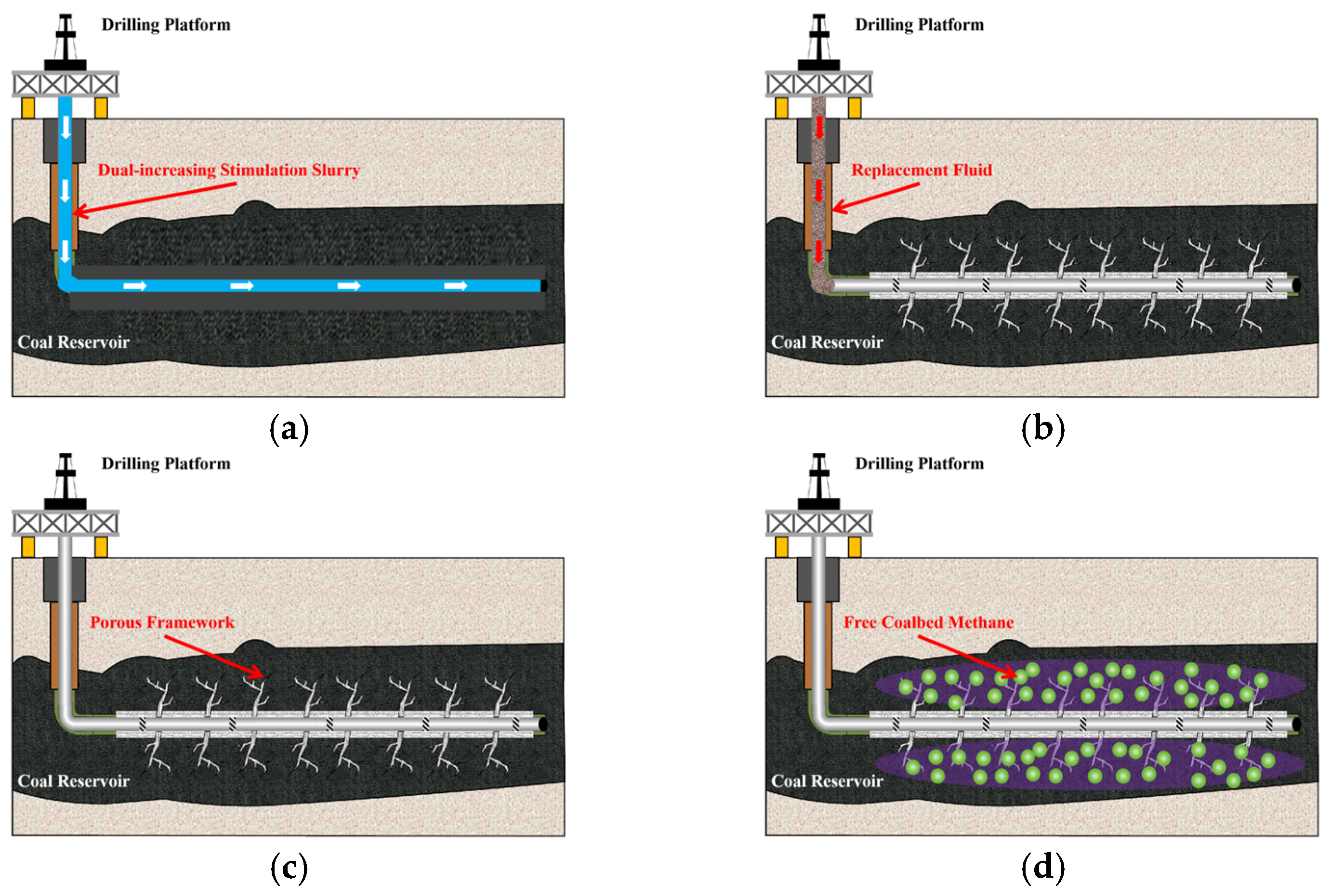

2.3. Dual-Enhanced Stimulation Model for Deep CBM Reservoirs

3. Results and Discussion

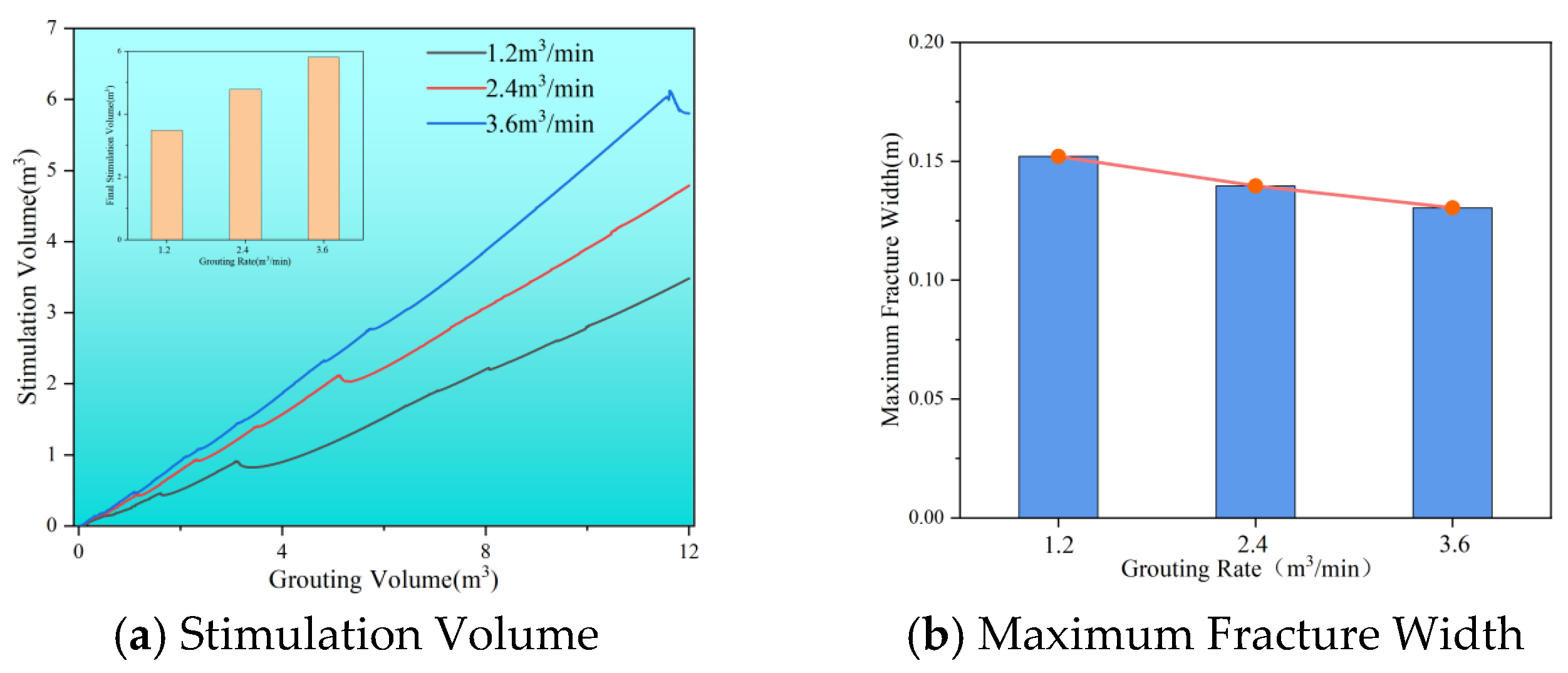

3.1. Influence of Engineering Parameters on Diffusion Behavior of Polyurethane Slurry

3.2. Influence of Geologic Factors on Diffusion Behavior of Polyurethane Polymer Slurry

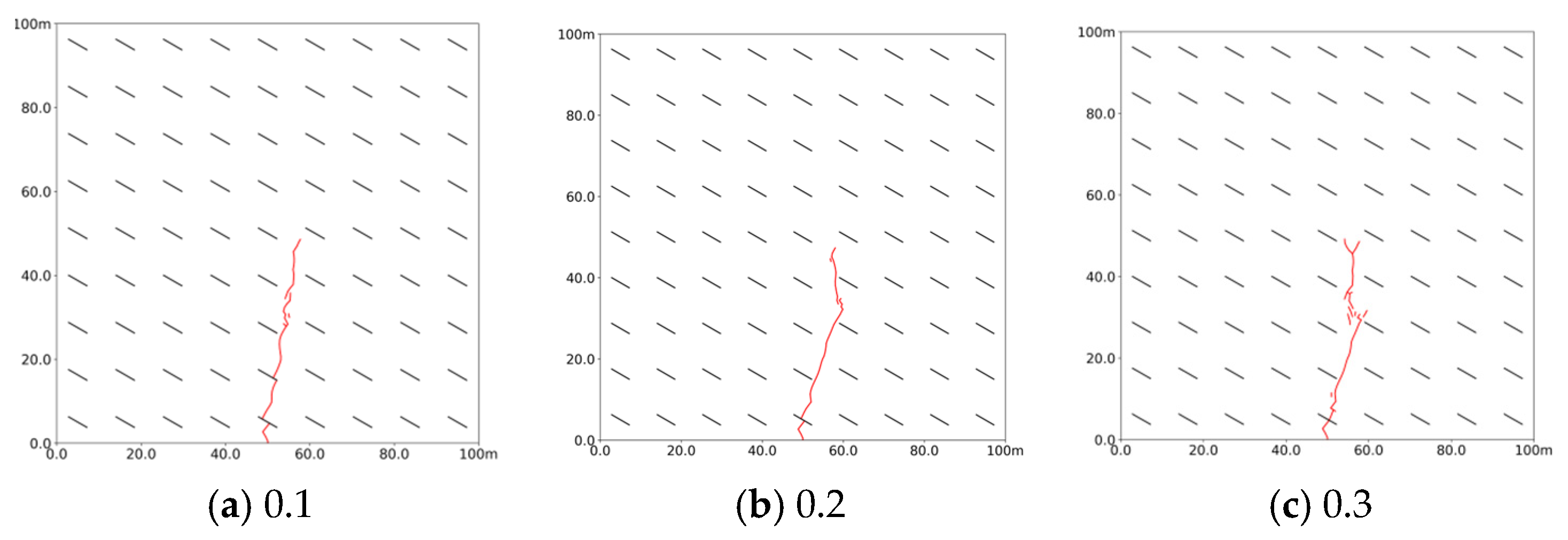

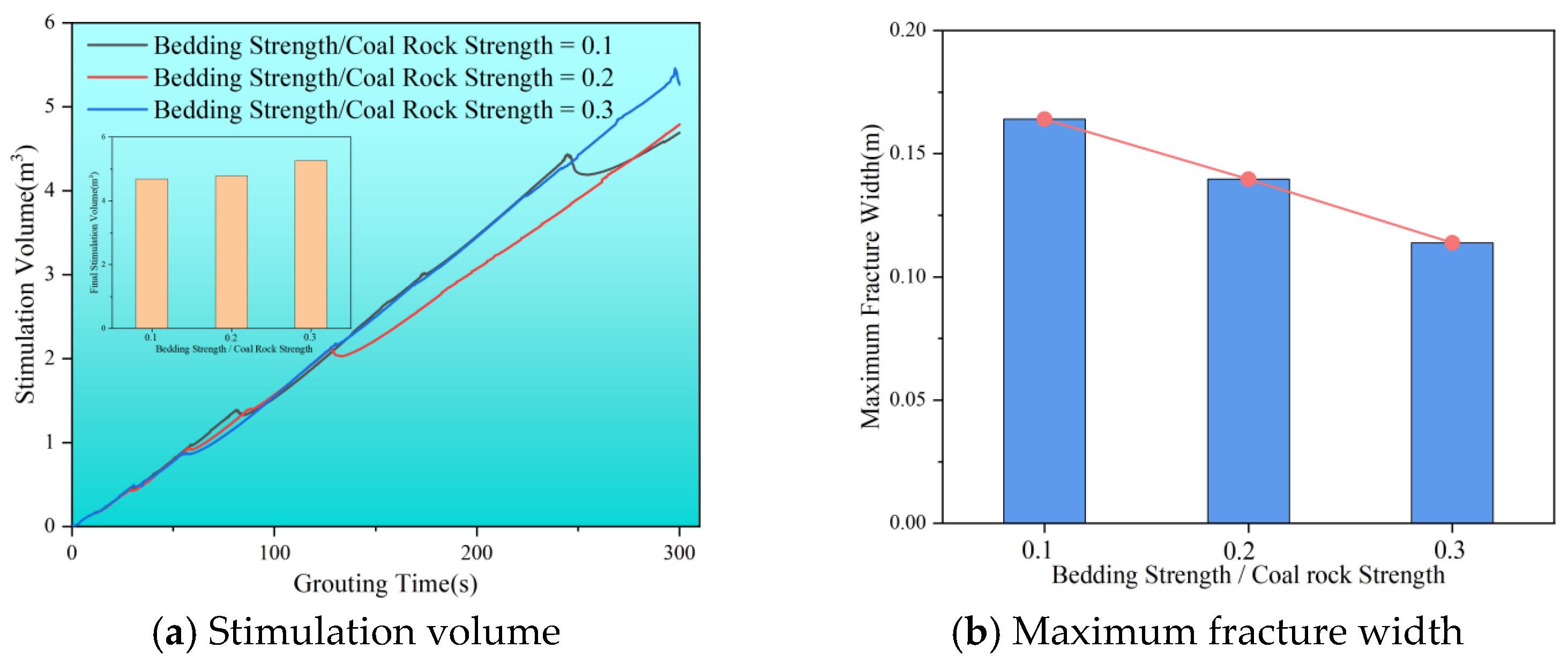

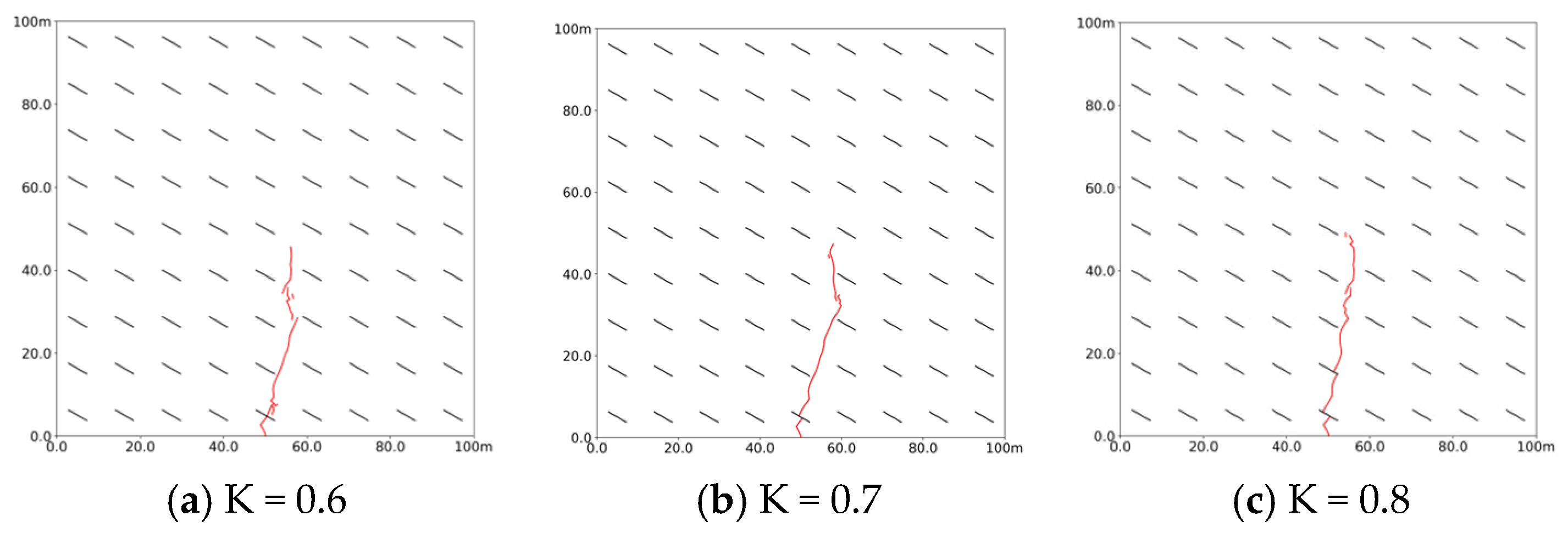

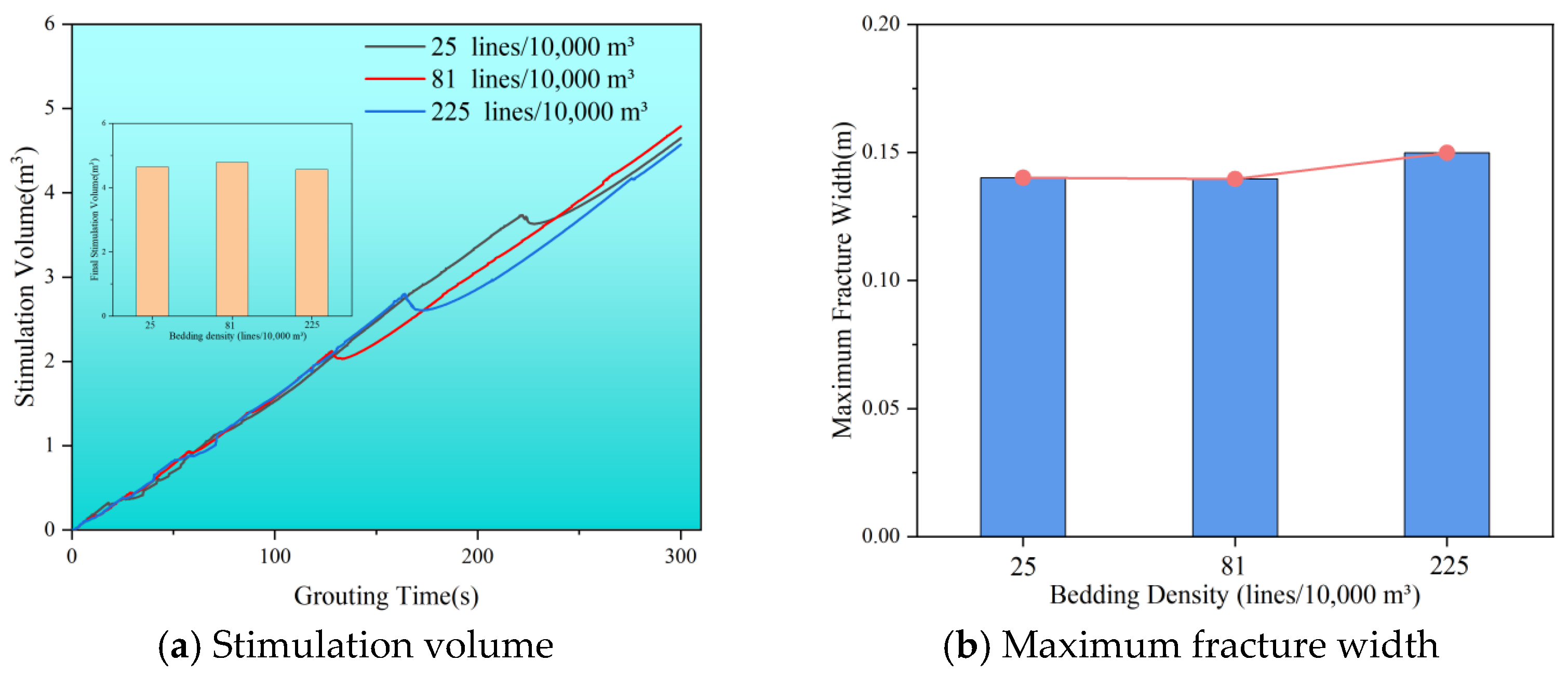

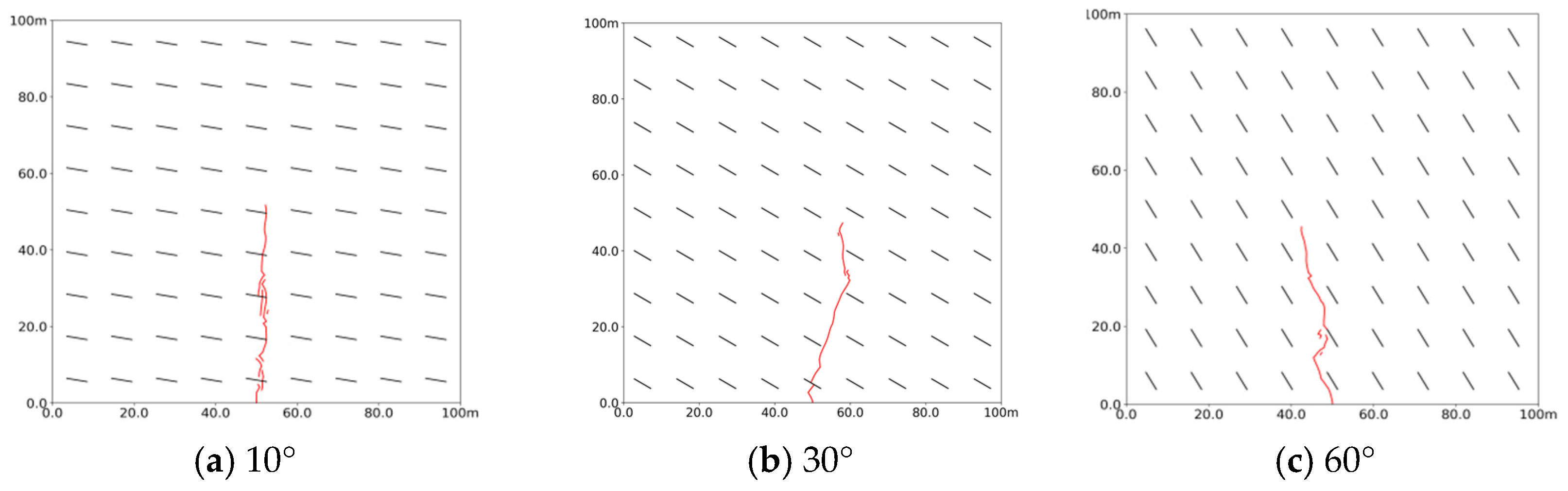

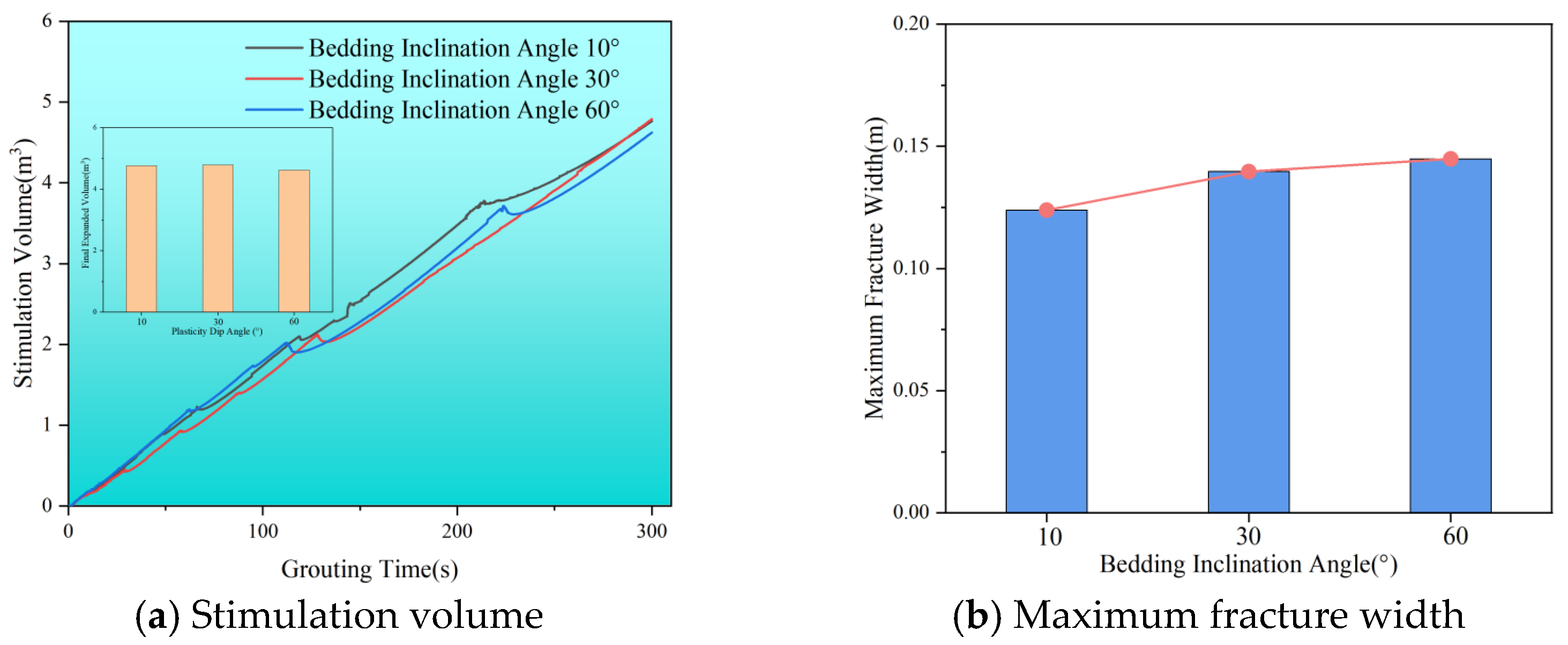

3.3. Influence of Bedding Characteristics on Diffusion Behavior of Polyurethane Polymer Slurry

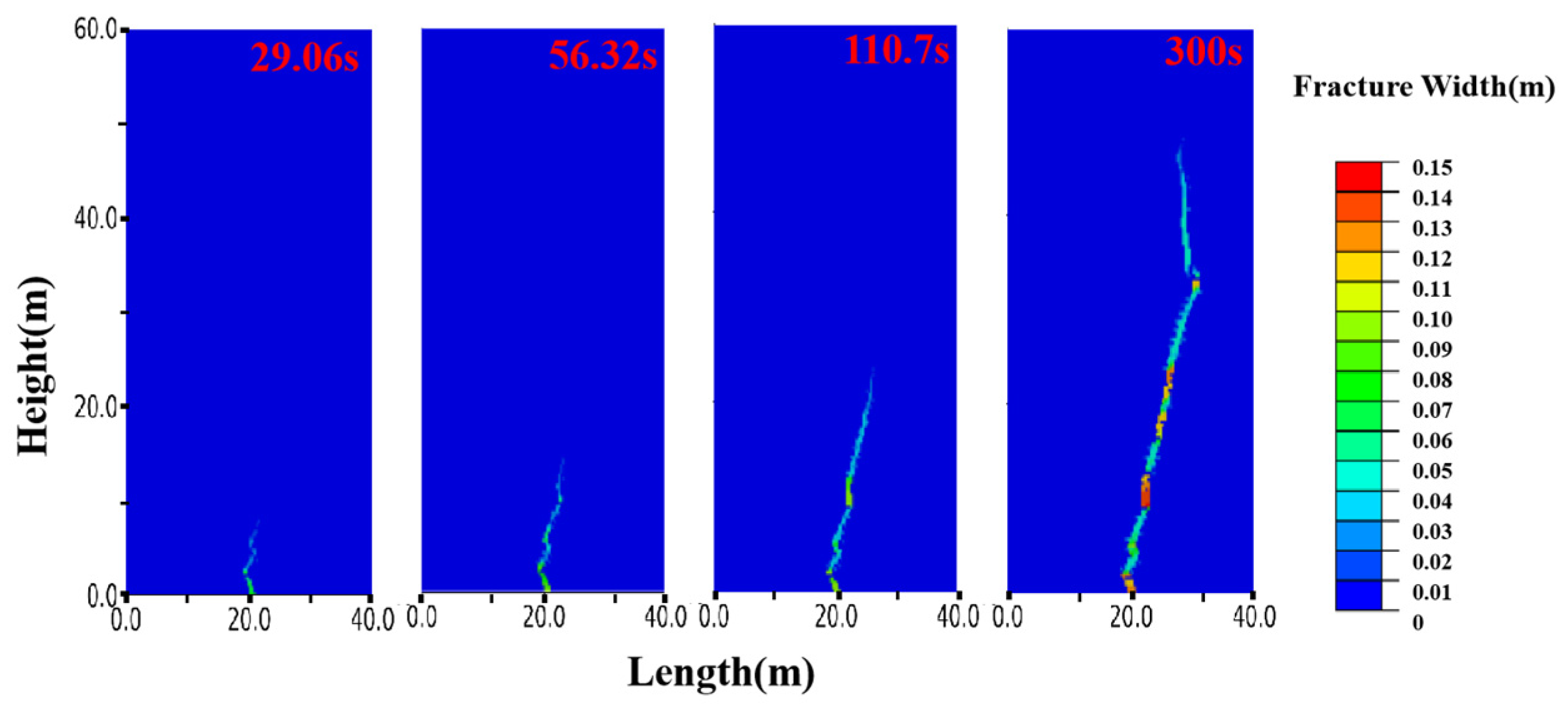

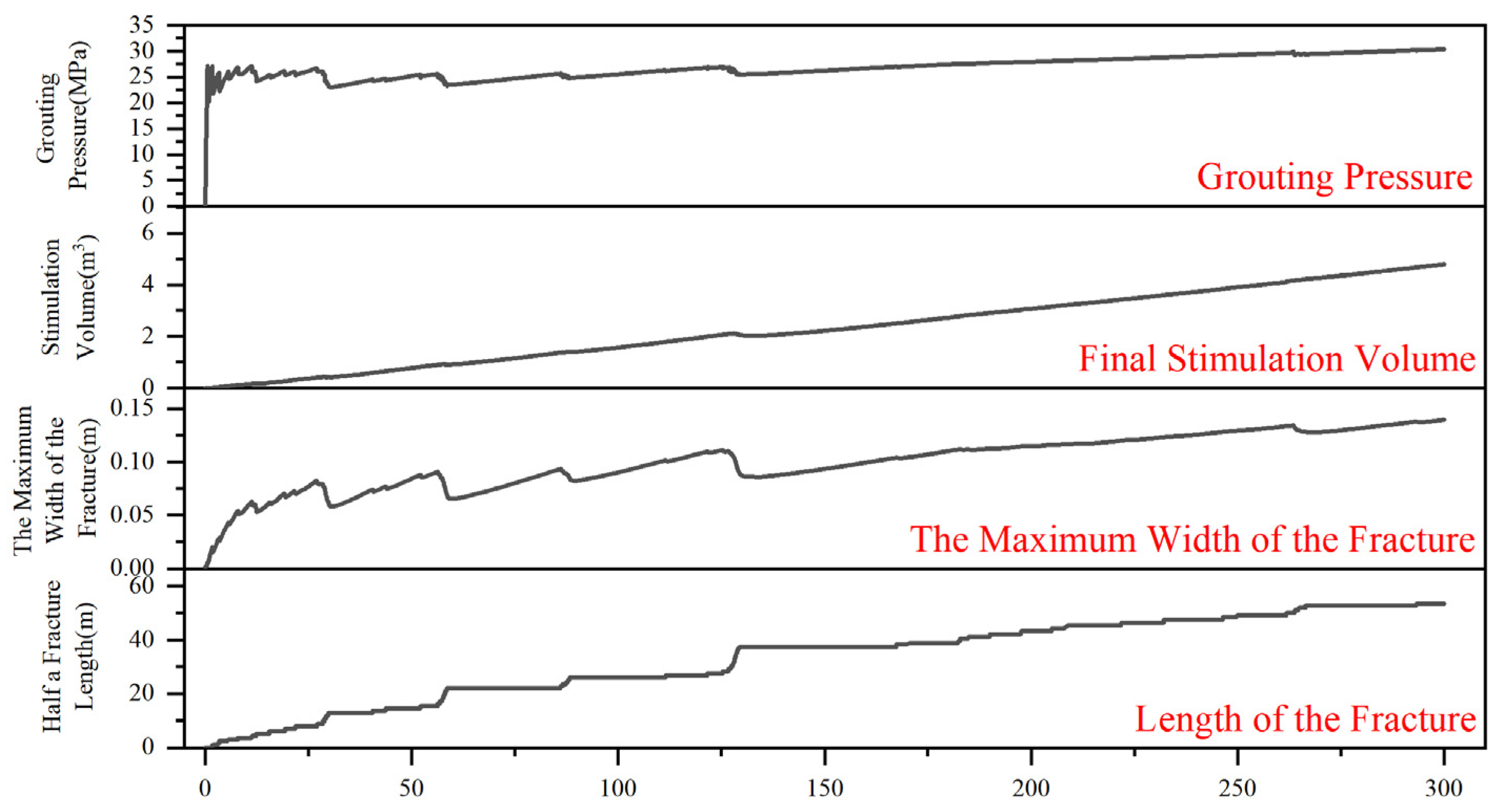

3.4. Analysis of Dual-Enhanced Stimulation Process

3.5. Analysis of the Main Controlling Factors of Splitting Pressure

4. Conclusions

- As the grouting rate increases, the volume of dual-enhanced stimulation also rises, resulting in a wider maximum width of the slurry vein. Specifically, at a grouting rate of 3.6 m3/min, the volume of dual-enhanced stimulation can reach 5.8 m3, with the maximum width of the slurry vein measuring approximately 0.15 m. When the slurry viscosity is low, the slurry tends to expand into multiple veins. However, as the viscosity increases, the volume of dual-enhanced stimulation decreases, while the maximum width of the slurry veins expands further. This trend indicates that compaction grouting is more likely to occur at higher viscosities.

- When bedding strength is high, the slurry tends to penetrate through the beddings. In contrast, a lower bedding strength allows the slurry to expand along the bedding, which decreases the maximum width of the slurry vein as the bedding strength increases. Additionally, as the lateral pressure coefficient rises, the volume of dual-enhanced stimulation decreases, making it more likely for the slurry to expand along the beddings. Natural bedding promotes directional flow; denser bedding results in more pronounced directional changes, creating a more complex network of slurry veins. As the angle of inclination increases, the slurry veins are more likely to change direction. At low bedding angles of 10°, the slurry expands almost vertically, while the maximum width of the slurry vein increases with steeper bedding inclinations.

- During the grouting process, the directional flow of the slurry may be caused by localized stress concentration at the tip of the slurry, leading to its release along the direction of the maximum principal stress in the reservoir. Pressure fluctuations primarily occur in the early stages of grouting, when the slurry continuously accumulates, releases, and fills within the reservoir, resulting in fracturing damage. In the later stages of grouting, the pressure stabilizes around 30 MPa, with compaction damage becoming predominant. Under these reservoir conditions, both fracturing and compaction grouting modes coexist, with fracturing grouting being more prevalent initially and compaction grouting taking precedence later. Furthermore, the grouting rate significantly affects the fracturing pressure of the reservoir; as the grouting rate increases, the time to achieve fracturing decreases, and the fracturing pressure increases.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Burnham, A.K.; McConaghy, J.R. Comparison of the Acceptability of Various Oil Shale Processes. In Proceedings of the 26th Oil Shale Symposium, Golden, CO, USA, 16–20 October 2006. [Google Scholar]

- Esen, O.; Fişne, A. A comprehensive study on methane adsorption capacities and pore characteristics of coal seams: Implications for efficient coalbed methane development in the Soma Basin, Türkiye. Rock Mech. Rock Eng. 2024, 57, 6355–6375. [Google Scholar] [CrossRef]

- Lei, Q.; Wang, H.-y.; Zhao, Q.; Liu, D. Status analysis and advices on exploration and development of unconventional hydrocarbon resources. Nat. Gas Ind. 2008, 28, 7–10. [Google Scholar]

- Song, Y.; Zhang, X.; Liu, S.; Song, Y.; Zhang, X.; Liu, S. Status Quo and Research of CBM Exploration and Development. In Coalbed Methane in China; Geological Theory and Development; Springer: Singapore, 2021; pp. 1–12. [Google Scholar]

- Yao, G.; Wang, J. A glimpse of coalbed methane production overseas and reflections on accelerating coalbed methane development in China. Sino-Glob. Energy 2010, 15, 25–33. [Google Scholar]

- Xie, H.; Gao, F.; Ju, Y.; Gao, M.; Zhang, R.; Gao, Y.; Liu, J.; Xie, L. Quantitative definition and investigation of deep mining. J. China Coal Soc. 2015, 40, 1–10. [Google Scholar]

- Zhang, S.; Tang, S.; Tang, D.; Pan, Z.; Yang, F. The characteristics of coal reservoir pores and coal facies in Liulin district, Hedong coal field of China. Int. J. Coal Geol. 2010, 81, 117–127. [Google Scholar] [CrossRef]

- Liu, C.; Zhu, J.; Che, C.; Yang, H.; Fan, M. Methodologies and results of the latest assessment of coalbed methane resources in China. Nat. Gas Ind. 2009, 29, 130–132. [Google Scholar]

- Geng, M.; Chen, H.; Chen, Y.; Zeng, L.; Chen, S.; Jiang, X. Methods and results of the fourth round national CBM resources evaluation. Coal Sci. Technol. 2018, 36, 64–68. [Google Scholar]

- Shen, J.; Qin, Y.; Fu, X.; Chen, G.; Run, C. Properties of deep coalbed methane reservoir-forming conditions and critical depth discussion. Nat. Gas Geosci. 2014, 25, 1470–1476. [Google Scholar]

- Li, S.; Tang, D.; Xu, H.; Tao, S.; Shao, G.; Ren, P. Evolution of physical differences in various buried depth of coal reservoirs under constraint of stress. Acta Pet. Sin. 2015, 36, 68–75. [Google Scholar]

- Ye, J.-p.; Zhang, S.-r.; Ling, B.-c.; Zheng, G.-q.; Wu, J.L. Study on variation law of coalbed methane physical property parameters with seam depth. Coal Sci. Technol. 2014, 42, 35–39. [Google Scholar]

- Li, S.; Tang, D.; Xu, H.; Tao, S. Progress in geological researches on the deep coalbed methane reservoirs. Earth Sci. Front. 2016, 23, 10. [Google Scholar]

- Zhong, L.; Zheng, Y.; Yun, Z.; Lei, C.; Zhang, H. The adsorption capability of coal under integrated influence of temperature and pressure and predicted content quantity of coal bed gas. Mei T’an Hsueh Pao (J. China Coal Soc.) 2002, 27, 581–585. [Google Scholar]

- Pan, Z.; Wood, D.A. Coalbed methane (CBM) exploration, reservoir characterisation, production, and modelling: A collection of published research (2009–2015). J. Nat. Gas Sci. Eng. 2015, 26, 1472–1484. [Google Scholar] [CrossRef]

- Yuan, L.; Lin, B.Q.; Yang, W. Research progress and development direction of gas control with mine hydraulic technology in China coal mine. Coal Sci. Technol. 2015, 43, 45–49. [Google Scholar]

- Lv, H.; Cheng, Z.; Xie, F.; Pan, J.; Liu, F. Study on hydraulic fracturing prevention and control of rock burst in roof of deep extra-thick coal seam roadway group. Sci. Rep. 2024, 14, 29537. [Google Scholar] [CrossRef]

- Gang, C. The adsorption characteristics and affecting factors of deep low-rank coal in Cainan area of Junggar basin. Coal Geol. Explor. 2016, 44, 50–54. [Google Scholar]

- Hu, S.; Wang, X.; Cao, Z.; Li, J.; Cong, D.; Xu, Y. Formation conditions and exploration direction of large and medium gas reservoirs in the Junggar Basin, NW China. Pet. Explor. Dev. 2020, 47, 266–279. [Google Scholar] [CrossRef]

- Shen, P.; Lv, S.; Li, G.; Ren, B.; Bai, J.; Jia, J.; Chen, Z. Hydraulic fracturing technology for deep coalbed methane horizontal wells: A case study in North Changzhi area of Qinshui Basin. J. China Coal Soc. 2021, 46, 2488–2500. [Google Scholar]

- Sun, P.; Liu, H.; Chao, H.; Wang, Y. Exploration direction of coalbed methane in low-rank coals. Nat. Gas Ind. 2008, 28, 19–22. [Google Scholar]

- Wu, C.; Qin, Y.; Fu, X. Macroscopic dynamic energies for the formation of coalbed gas reservoirs and their geological evolution—A case study from Qinshui Basin in Shanxi Province. Earth Sci. Front. 2005, 12, 299–308. [Google Scholar]

- Li, Y.; Jia, D.; Liu, J.; Fu, C.; Ai, C. The calculation method based on the equivalent continuum for the fracture initiation pressure of fracturing of coalbed methane well. J. Pet. Sci. Eng. 2016, 146, 909–920. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, J.; Huang, G. Experimental study of fracture geometry during hydraulic fracturing in coal. Rock Soil Mech. 2018, 39, 3677–3684. [Google Scholar]

- Zangeneh, N.; Eberhardt, E.; Bustin, R. Application of the distinct-element method to investigate the influence of natural fractures and in-situ stresses on hydrofrac propagation. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Chicago, IL, USA, 24–27 June 2012; p. ARMA-2012-223. [Google Scholar]

- Wang, T.; Hu, W.; Elsworth, D.; Zhou, W.; Zhou, W.; Zhao, X.; Zhao, L. The effect of natural fractures on hydraulic fracturing propagation in coal seams. J. Pet. Sci. Eng. 2017, 150, 180–190. [Google Scholar] [CrossRef]

- Ma, G.; Zhang, F.; Liu, X.; Feng, D. Experimental study on hydraulic fracture propagation in fractured reservoir. J. Min. Saf. Eng. 2017, 34, 993999. [Google Scholar]

- Liu, X.; Ding, Y.; Luo, P.; Liang, L. Influence of natural fracture on hydraulic fracture propagation. Spec. Oil Gas Reserv. 2018, 2, 148–153. [Google Scholar]

- Nikam, A.; Awoleke, O.O.; Ahmadi, M. Modeling the interaction between natural and hydraulic fractures using 3D finite-element analysis. SPE Prod. Oper. 2019, 34, 703–724. [Google Scholar] [CrossRef]

- Li, B.; Ma, X.; Zhang, G.; Guo, W.; Xu, T.; Yuan, Y.; Sun, Y. Enhancement of gas production from natural gas hydrate reservoir by reservoir stimulation with the stratification split grouting foam mortar method. J. Nat. Gas Sci. Eng. 2020, 81, 103473. [Google Scholar] [CrossRef]

- Desai, A.; Auad, M.L.; Shen, H.; Nutt, S.R. Mechanical behavior of hybrid composite phenolic foam. J. Cell. Plast. 2008, 44, 15–36. [Google Scholar] [CrossRef]

- Sun, Y.; Shen, Y.; Zhang, G.; Li, B.; Huang, F.; Qi, Y.; Shan, H.; Jin, F. Performance of dual-increasing stimulation slurry and its consolidating body for submarine hydrate reservoir. J. China Univ. Pet. (Ed. Nat. Sci.) 2022, 46, 1–10. [Google Scholar]

- Wang, X.; Sun, Y.; Guo, W.; Chen, H.; Peng, S. An environmental-benign method to enhance hydrate production in clayey silty reservoir via splitting grouting. J. Clean. Prod. 2024, 449, 141780. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, J.; Li, B.; Sun, Y. Analysis of the hydraulic fracturing mechanism and fracture propagation law with a new extended finite element model for the silty hydrate reservoir in the South China Sea. J. Nat. Gas Sci. Eng. 2022, 101, 104535. [Google Scholar] [CrossRef]

- Munjiza, A.; Owen, D.; Bicanic, N. A combined finite-discrete element method in transient dynamics of fracturing solids. Eng. Comput. 1995, 12, 145–174. [Google Scholar] [CrossRef]

- Donzé, F.V.; Richefeu, V.; Magnier, S.-A. Advances in discrete element method applied to soil, rock and concrete mechanics. Electron. J. Geotech. Eng. 2009, 8, 44. [Google Scholar]

- Zhu, H.; Tang, X.; Liu, Q.; Li, K.; Xiao, J.; Jiang, S.; McLennan, J.D. 4D multi-physical stress modelling during shale gas production: A case study of Sichuan Basin shale gas reservoir, China. J. Pet. Sci. Eng. 2018, 167, 929–943. [Google Scholar] [CrossRef]

- Liu, Z.; Pan, Z.; Li, S.; Zhang, L.; Wang, F.; Han, L.; Zhang, J.; Ma, Y.; Li, H.; Li, W. Study on the effect of cemented natural fractures on hydraulic fracture propagation in volcanic reservoirs. Energy 2022, 241, 122845. [Google Scholar] [CrossRef]

- Park, K.; Paulino, G.H. Cohesive zone models: A critical review of traction-separation relationships across fracture surfaces. Appl. Mech. Rev. 2011, 64, 060802. [Google Scholar] [CrossRef]

- Ma, C.; Dong, C.; Luan, G.; Lin, C.; Liu, X.; Elsworth, D. Types, characteristics and effects of natural fluid pressure fractures in shale: A case study of the Paleogene strata in Eastern China. Pet. Explor. Dev. 2016, 43, 634–643. [Google Scholar] [CrossRef]

- Xiong, D.; He, J.; Ma, X.; Qu, Z.; Guo, T.; Ma, S. Fracturing simulation with different perforation positions at deep coal seam and roof/floor rock—Case study at the No. 8 deep coal seam of a gas field in the Ordos basin. J. China Coal Soc. 2024, 49, 4897–4914. [Google Scholar]

- Peng, W.; Mi, H.; Xu, L.; Wu, J. Fracability evaluation and classification of deep coal reservoirs in the Shenfu block. Coal Sci. Technol. 2025, 53, 238–247. [Google Scholar]

- Wan, Y.; Wang, Z.; Han, S.; Qiao, Y.; Gao, H. Geological characteristics and resource potential of deep coalbed methane accumulation in Yan’an Gas Field, southeastern margin of Ordos Basin. Nat. Gas Geosci. 2024, 35, 1724–1739. [Google Scholar]

- Wu, S.; Tang, D.; Li, S.; Wu, H.; Hu, X.; Zhu, X. Effects of geological pressure and temperature on permeability behaviors of middle-low volatile bituminous coals in eastern Ordos Basin, China. J. Pet. Sci. Eng. 2017, 153, 372–384. [Google Scholar] [CrossRef]

- Meng, Y.; Li, Z. Experimental study on the porosity and permeability of coal in net confining stress and its stress sensitivity. J. China Coal Soc. 2015, 40, 154–159. [Google Scholar]

- Qi, Y.; Sun, Y.; Li, B.; Liu, X.; Zhang, G. Fracture Initiation and Slurry Diffusion in Marine Hydrate Reservoirs during Dual-Enhanced Stimulation. Energy Fuels 2025, 39, 6849–6864. [Google Scholar] [CrossRef]

- Chandra, N.; Li, H.; Shet, C.; Ghonem, H. Some issues in the application of cohesive zone models for metal–ceramic interfaces. Int. J. Solids Struct. 2002, 39, 2827–2855. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, J.; Wu, H. Experimental and numerical study on hydraulic fracture propagation in coalbed methane reservoir. J. Nat. Gas Sci. Eng. 2016, 35, 455–467. [Google Scholar] [CrossRef]

- Zou, J.; Chen, W.; Yuan, J.; Yang, D.; Yang, J. 3-D numerical simulation of hydraulic fracturing in a CBM reservoir. J. Nat. Gas Sci. Eng. 2017, 37, 386–396. [Google Scholar] [CrossRef]

- Wang, P.-t.; Yang, T.-h.; Yu, Q.-l.; Shi, W.-h. Uniaxial compression test and numerical simulation of stratified biotite granulite. J. Northeast. Univ. (Nat. Sci.) 2015, 36, 1633–1637. [Google Scholar]

- Zhou, X.; Yong, R.; Fan, Y.; Zeng, B.; Song, Y.; Guo, X.; Zhou, N.; Duan, X.; Zhu, Z. Influence of natural fractures on fracturing of horizontal shale gas wells and process adjustment. China Pet. Explor. 2020, 25, 94–104. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, G.; Yang, K.; Xu, D. Numerical simulation on volumetric fracturing for shale gas reservoir considering natural fractures. China Sci. 2018, 13, 286–290. [Google Scholar]

- Zhu, B.; Tang, S.; Yan, Z.; Zhang, J. Effects of crustal stresses and natural fractures on fracture pressure of coal reservoirs. J. China Coal Soc. 2009, 34, 1199–1202. [Google Scholar]

- Guo, J.; Wang, Y. Mechanism of natural fracture reactivation and propagation by hydraulic fracture. J. Eng. Geol. 2018, 26, 1523–1533. [Google Scholar]

| Form | Parameters | Value | Data Sources |

|---|---|---|---|

| CBM reservoirs | Modulus of elasticity/GPa | 1.7 | on-the-spot survey |

| Poisson’s ratio | 0.25 | [41] | |

| Permeability/mD | 1.27 | on-the-spot survey | |

| Failure strength/MPa | 9.95 | on-the-spot survey | |

| porosity | 0.06 | [43] | |

| Vertical effective geostress/MPa | 20 | [41,42] | |

| Dual-enhanced slurry | Upper and lower surface loss coefficient/m/(Pa·s) | 2.3 × 10−8 | [46] |

| Density/g/cm3 | 1.68 | [32] |

| Runs | Grouting Rate (m3/min) | Slurry Viscosity (mPa·s) | Lateral Pressure Coefficients | Bedding Strength/Coal Rock Strength | Layer Density (Lines/10,000 m3) | Bedding Inclination Angles |

|---|---|---|---|---|---|---|

| 1 | 1.2 | 300 | 0.7 | 0.2 | 81 | 30° |

| 2 | 2.4 | 300 | 0.7 | 0.2 | 81 | 30° |

| 3 | 3.6 | 300 | 0.7 | 0.2 | 81 | 30° |

| 4 | 2.4 | 100 | 0.7 | 0.2 | 81 | 30° |

| 5 | 2.4 | 300 | 0.7 | 0.2 | 81 | 30° |

| 6 | 2.4 | 500 | 0.7 | 0.2 | 81 | 30° |

| 7 | 2.4 | 300 | 0.6 | 0.2 | 81 | 30° |

| 8 | 2.4 | 300 | 0.7 | 0.2 | 81 | 30° |

| 9 | 2.4 | 300 | 0.8 | 0.2 | 81 | 30° |

| 10 | 2.4 | 300 | 0.7 | 0.1 | 81 | 30° |

| 11 | 2.4 | 300 | 0.7 | 0.2 | 81 | 30° |

| 12 | 2.4 | 300 | 0.7 | 0.3 | 81 | 30° |

| 13 | 2.4 | 300 | 0.7 | 0.2 | 25 | 30° |

| 14 | 2.4 | 300 | 0.7 | 0.2 | 81 | 30° |

| 15 | 2.4 | 300 | 0.7 | 0.2 | 225 | 30° |

| 16 | 2.4 | 300 | 0.7 | 0.2 | 81 | 10° |

| 17 | 2.4 | 300 | 0.7 | 0.2 | 81 | 30° |

| 18 | 2.4 | 300 | 0.7 | 0.2 | 81 | 60° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zhang, F.; Wu, J.; Qiang, S.; Li, B.; Zhang, G. Diffusion Behavior of Polyurethane Slurry for Simultaneous Enhancement of Reservoir Strength and Permeability Through Splitting Grouting Technology. Polymers 2025, 17, 2513. https://doi.org/10.3390/polym17182513

Wang X, Zhang F, Wu J, Qiang S, Li B, Zhang G. Diffusion Behavior of Polyurethane Slurry for Simultaneous Enhancement of Reservoir Strength and Permeability Through Splitting Grouting Technology. Polymers. 2025; 17(18):2513. https://doi.org/10.3390/polym17182513

Chicago/Turabian StyleWang, Xiangzeng, Fengsan Zhang, Jinqiao Wu, Siqi Qiang, Bing Li, and Guobiao Zhang. 2025. "Diffusion Behavior of Polyurethane Slurry for Simultaneous Enhancement of Reservoir Strength and Permeability Through Splitting Grouting Technology" Polymers 17, no. 18: 2513. https://doi.org/10.3390/polym17182513

APA StyleWang, X., Zhang, F., Wu, J., Qiang, S., Li, B., & Zhang, G. (2025). Diffusion Behavior of Polyurethane Slurry for Simultaneous Enhancement of Reservoir Strength and Permeability Through Splitting Grouting Technology. Polymers, 17(18), 2513. https://doi.org/10.3390/polym17182513