Evolution of Microstructure and Performance in Polyacrylonitrile Precursor Fibers: A Comparison of Spinning Processes

Abstract

1. Introduction

2. Materials and Methods

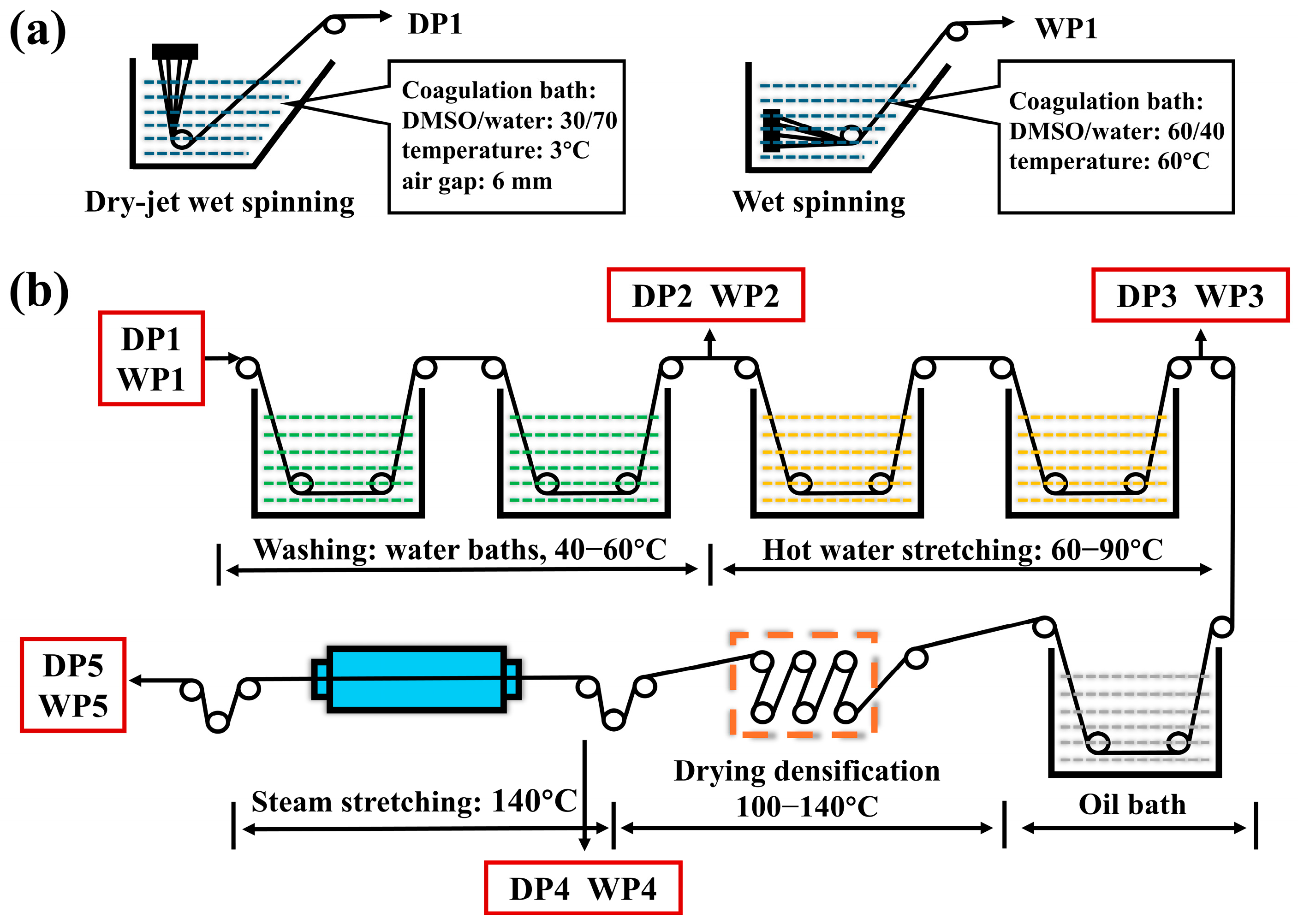

2.1. Preparation of Fiber Samples

2.2. Characterization

3. Results and Discussion

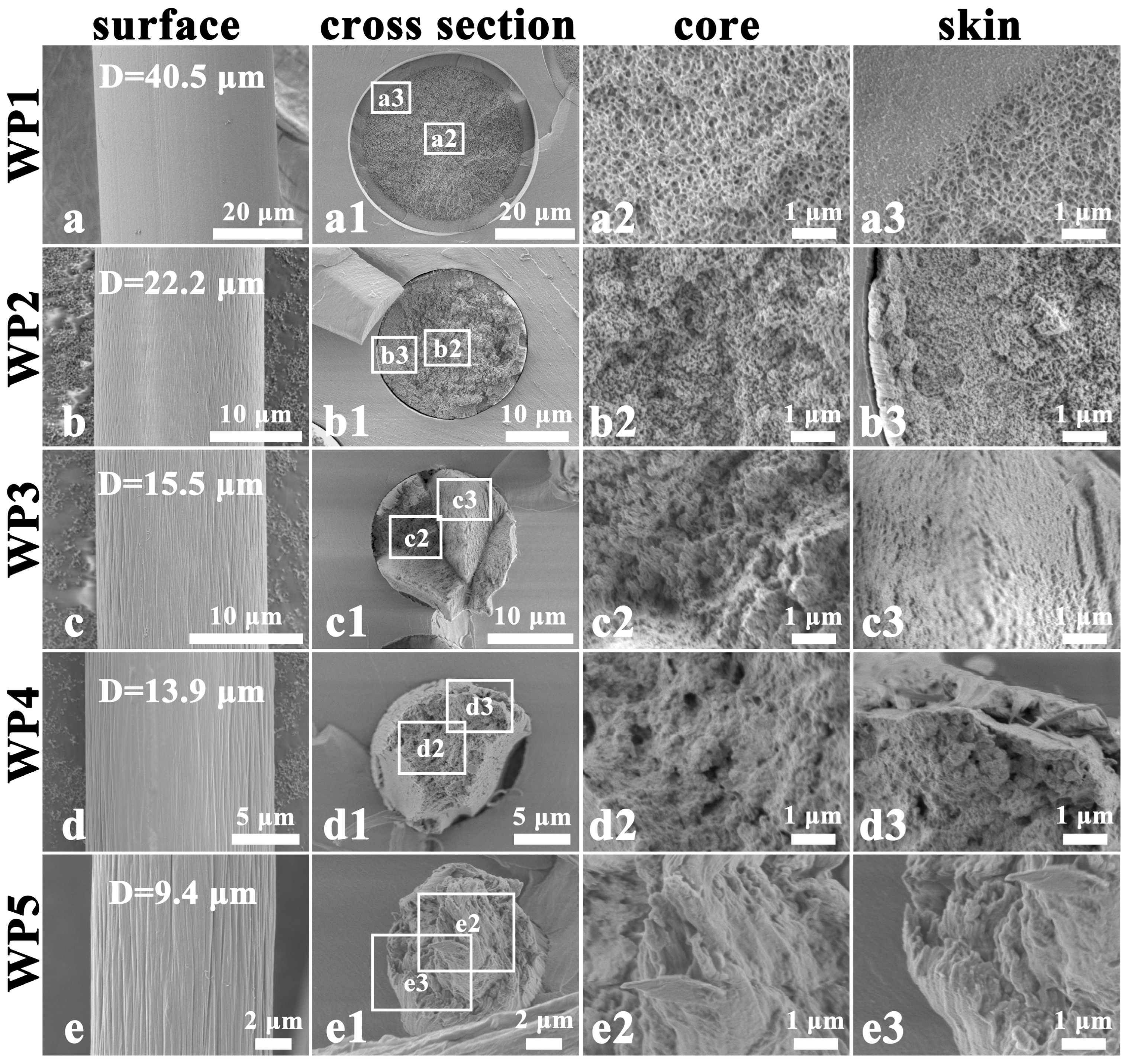

3.1. Morphology

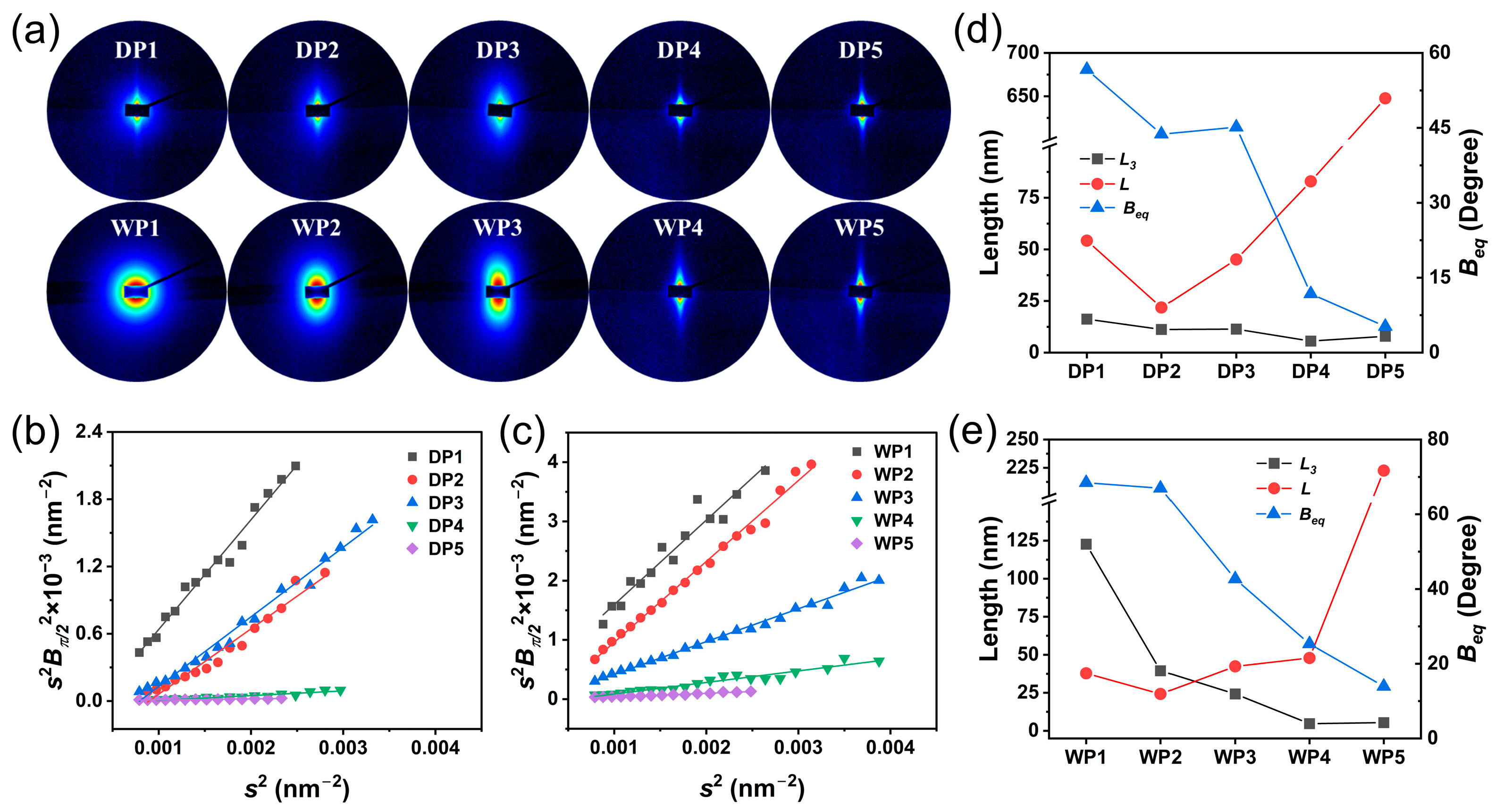

3.2. Void Structure

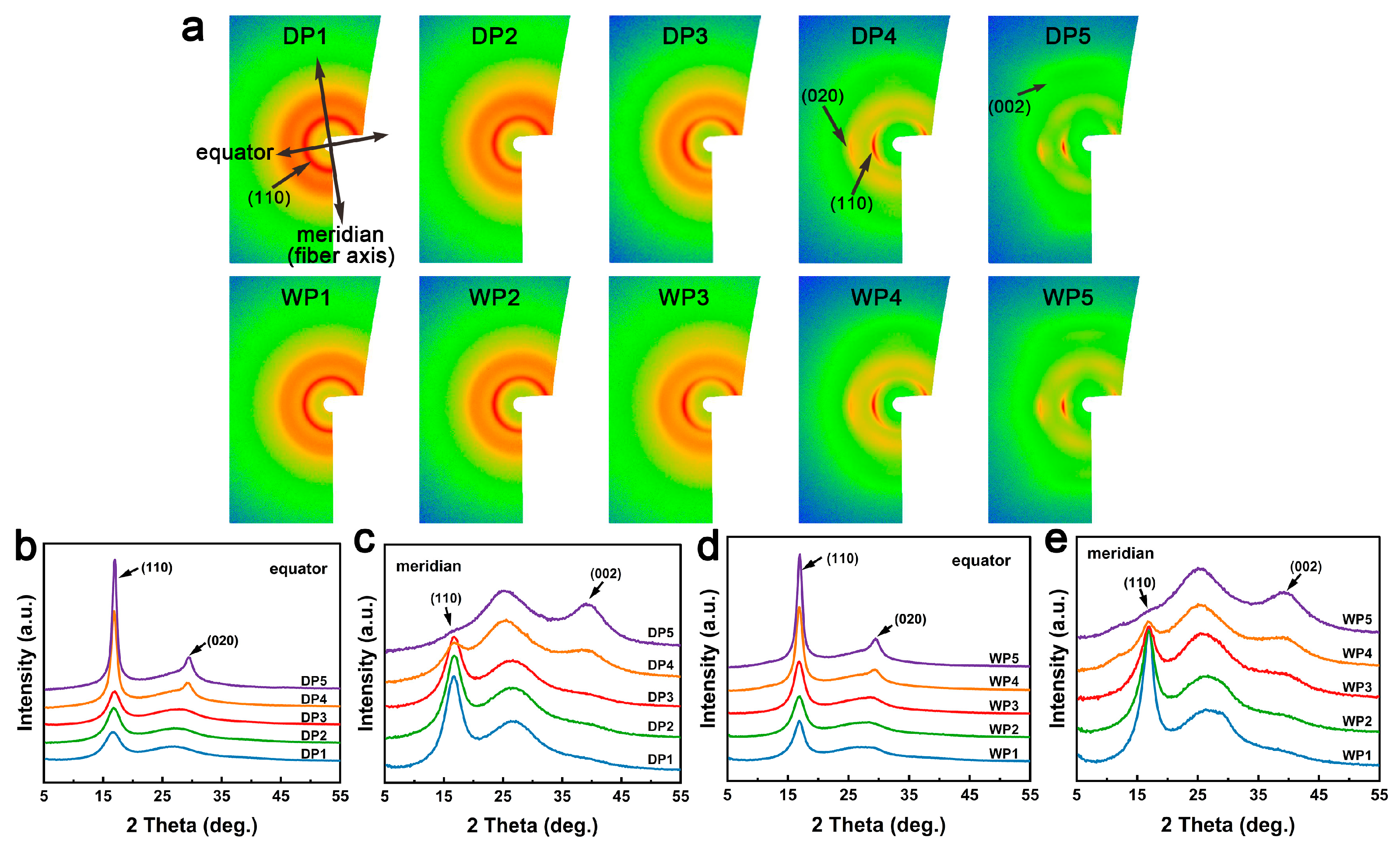

3.3. Crystallinity and Orientation

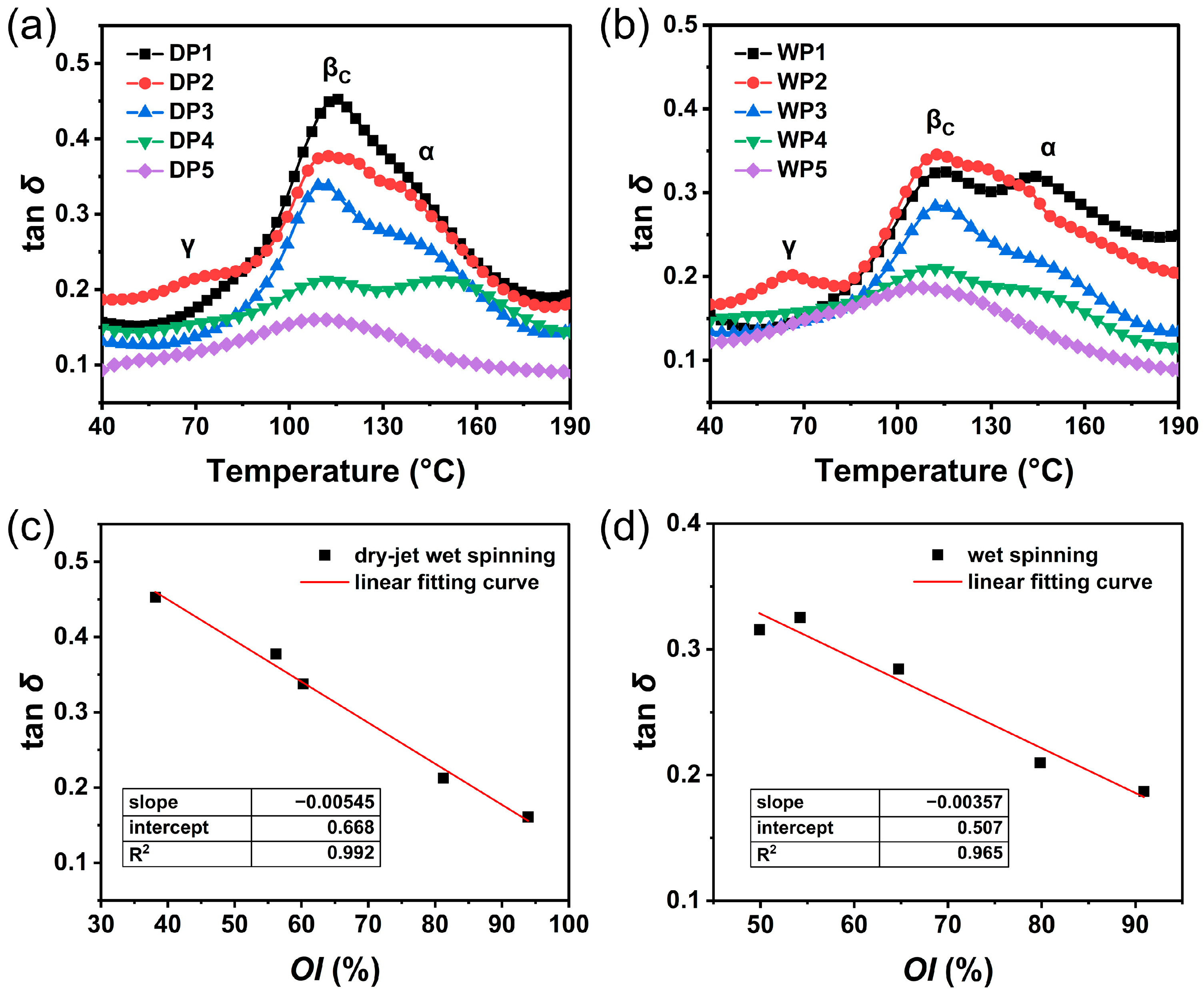

3.4. Thermomechanical Transitions

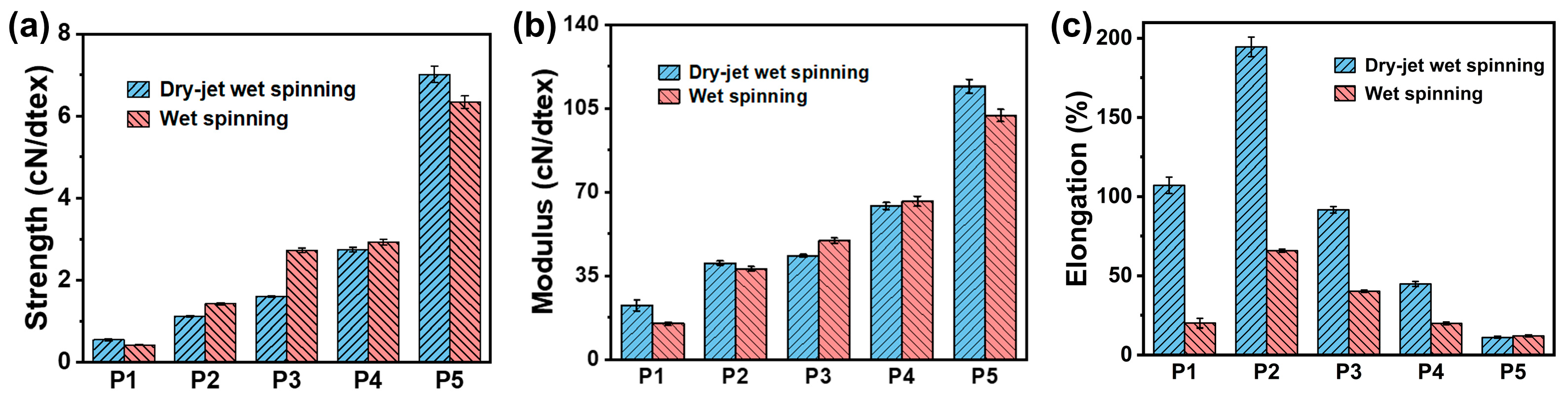

3.5. Mechanical Properties

3.6. Structural Evolution Sketch

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Karaboğa, F.; Göleç, F.; Yunus, D.E.; Toros, S.; Öz, Y. Mechanical response of carbon fiber reinforced epoxy composite parts joined with varying bonding techniques for aerospace applications. Compos. Struct. 2024, 331, 117920. [Google Scholar] [CrossRef]

- Li, P.; Yan, Z.; Yang, Y. Progress in automobile body processing technology: Multi-material and lightweight strategies for saving energy and reducing emissions. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 324. [Google Scholar] [CrossRef]

- Yu, W.; Jiang, L. Application of Carbon Fiber Reinforced Aluminum Matrix Composites in Automotive Industry. IJAMM 2024, 3, 3. [Google Scholar] [CrossRef]

- Hiremath, N.; Young, S.; Ghossein, H.; Penumadu, D.; Vaidya, U.; Theodore, M. Low cost textile-grade carbon-fiber epoxy composites for automotive and wind energy applications. Compos. Part B 2020, 198, 108156. [Google Scholar] [CrossRef]

- Khayyam, H.; Jazar, R.N.; Nunna, S.; Golkarnarenji, G.; Badii, K.; Fakhrhoseini, S.M.; Kumar, S.; Naebe, M. PAN precursor fabrication, applications and thermal stabilization process in carbon fiber production: Experimental and mathematical modelling. Prog. Mater. Sci. 2020, 107, 100575. [Google Scholar] [CrossRef]

- Boyano, A.; Lopez-Guede, J.M.; Torre-Tojal, L.; Fernandez-Gamiz, U.; Zulueta, E.; Mujika, F. Delamination Fracture Behavior of Unidirectional Carbon Reinforced Composites Applied to Wind Turbine Blades. Materials 2021, 14, 593. [Google Scholar] [CrossRef] [PubMed]

- Nachtane, M.; Tarfaoui, M.; Abichou, M.a.; Vetcher, A.; Rouway, M.; Aâmir, A.; Mouadili, H.; Laaouidi, H.; Naanani, H. An Overview of the Recent Advances in Composite Materials and Artificial Intelligence for Hydrogen Storage Vessels Design. J. Compos. Sci. 2023, 7, 119. [Google Scholar] [CrossRef]

- Jang, D.; Lee, M.E.; Choi, J.; Cho, S.Y.; Lee, S. Strategies for the production of PAN-Based carbon fibers with high tensile strength. Carbon 2022, 186, 644–677. [Google Scholar] [CrossRef]

- Ahn, H.; Yeo, S.Y.; Lee, B.-S. Designing Materials and Processes for Strong Polyacrylonitrile Precursor Fibers. Polymers 2021, 13, 2863. [Google Scholar] [CrossRef]

- Liu, Y.; Kumar, S. Recent Progress in Fabrication, Structure, and Properties of Carbon Fibers. Polym. Rev. 2012, 52, 234–258. [Google Scholar] [CrossRef]

- Frank, E.; Steudle, L.M.; Ingildeev, D.; Spörl, J.M.; Buchmeiser, M.R. Carbon Fibers: Precursor Systems, Processing, Structure, and Properties. Angew. Chem. Int. Ed. 2014, 53, 5262–5298. [Google Scholar] [CrossRef]

- Kaur, J.; Millington, K.; Smith, S. Producing high-quality precursor polymer and fibers to achieve theoretical strength in carbon fibers: A review. J. Appl. Polym. Sci. 2016, 133, 43963. [Google Scholar] [CrossRef]

- Wu, T.; Lu, C.; Sun, T.; Li, Y.; Yuan, S.; Li, D.; Wang, G.; Ren, X. New discovery on the relationship between microstructure and tensile strength of PAN-based carbon fibers. Microporous Mesoporous Mater. 2022, 330, 111584. [Google Scholar] [CrossRef]

- Kunzmann, C.; Moosburger-Will, J.; Horn, S. High-resolution imaging of the nanostructured surface of polyacrylonitrile-based fibers. J. Mater. Sci. 2016, 51, 9638–9648. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, C. New insight into structure-property correlation of polyacrylonitrile precursor fibers and resultant carbon fibers. J. Polym. Res. 2022, 29, 233. [Google Scholar] [CrossRef]

- Gao, Q.; Jing, M.; Zhao, S.; Wang, Y.; Qin, J.; Yu, M.; Wang, C. From Microfibrillar Network to Lamellae during the Coagulation Process of Polyacrylonitrile Fiber: Visualization of Intermediate Structure Evolution. Macromolecules 2020, 53, 8663–8673. [Google Scholar] [CrossRef]

- Li, J.; Yu, Y.; Li, H.; Liu, Y. Polyacrylonitrile based carbon fibers: Spinning technology dependent precursor fiber structure and its successive transformation. J. Appl. Polym. Sci. 2021, 138, 50988. [Google Scholar] [CrossRef]

- Gao, Q.; Jing, M.; Zhao, S.; Wang, Y.; Qin, J.; Yu, M.; Wang, C. Effect of spinning speed on microstructures and mechanical properties of polyacrylonitrile fibers and carbon fibers. Ceram. Int. 2020, 46, 23059–23066. [Google Scholar] [CrossRef]

- Dong, R.; Zhao, J.; Zhang, Y.; Pan, D. Morphology control of polyacrylonitrile (PAN) fibers by phase separation technique. J. Polym. Sci. Part B Polym. Phys. 2009, 47, 261–275. [Google Scholar] [CrossRef]

- Sun, L.; Shang, L.; Xiao, L.; Zhang, M.; Li, M.; Ao, Y. Structural changes of polyacrylonitrile fibers in the process of wet spinning. J. Appl. Polym. Sci. 2020, 137, 48905. [Google Scholar] [CrossRef]

- He, J.; Chen, Q.; Zhu, H.; Wang, Y.; Malik, H.; Ma, B.; Wang, X.; Zhang, H.; Liu, Y.; Yu, J. Microstructural Evolution during Dry-Jet Wet Spinning Postprocessing from Coagulation Bath Fiber to High-Performance Polyacrylonitrile Precursor Fiber. ACS Appl. Polym. Mater. 2024, 6, 1781–1789. [Google Scholar] [CrossRef]

- Gao, Q.; Jing, M.; Chen, M.; Zhao, S.; Wang, W.; Qin, J.; Wang, C. Microfibril alignment induced by stretching fields during the dry-jet wet spinning process: Reinforcement on polyacrylonitrile fiber mechanical properties. Polym. Test. 2020, 81, 106191. [Google Scholar] [CrossRef]

- Gao, Q.; Jing, M.; Chen, M.; Zhao, S.; Wang, Y.; Qin, J.; Yu, M.; Wang, C. Force field in coagulation bath at low temperature induced microfibril evolution within PAN nascent fiber and precursor fiber. J. Appl. Polym. Sci. 2020, 137, 49380. [Google Scholar] [CrossRef]

- Moskowitz, J.D.; Jackson, M.B.; Tucker, A.; Cook, J.D. Evolution of polyacrylonitrile precursor fibers and the effect of stretch profile in wet spinning. J. Appl. Polym. Sci. 2021, 138, 50967. [Google Scholar] [CrossRef]

- Oh, S.C.; Wang, Y.S.; Yeo, Y.-K. Modeling and Simulation of the Coagulation Process of Poly(acrylonitrile) Wet-Spinning. Ind. Eng. Chem. Res. 1996, 35, 4796–4800. [Google Scholar] [CrossRef]

- Wang, J.; Wang, T.; Xu, J.; Yu, J.; Zhang, Y.; Wang, H. Study on spinnability of polyacrylonitrile solution based on dynamics simulation of dry-jet wet spinning. J. Appl. Polym. Sci. 2018, 135, 46377. [Google Scholar] [CrossRef]

- Wang, H.; Yi, Z.; Zhao, Z.; Zhang, S.; Su, F.; Zhang, X. Evolution of Radial Aggregated Structure Within Polyacrylonitrile-Based Fibers During Stretching. J. Appl. Polym. Sci. 2025, 142, e57310. [Google Scholar] [CrossRef]

- Shioya, M.; Takaku, A. Characterization of microvoids in carbon fibers by absolute small-angle x-ray measurements on a fiber bundle. J. Appl. Phys. 1985, 58, 4074–4082. [Google Scholar] [CrossRef]

- Thünemann, A.F.; Ruland, W. Microvoids in Polyacrylonitrile Fibers: A Small-Angle X-ray Scattering Study. Macromolecules 2000, 33, 1848–1852. [Google Scholar] [CrossRef]

- Li, D.; Lu, C.; Yang, Y.; Wang, L.; Cui, D.; Liu, Z.; Guo, Y. Characterization of the Microstructure of Carbon Fibers: Small Angle X-ray Scattering. Mater. Rep. 2021, 35, 7077–7086. [Google Scholar] [CrossRef]

- Qian, B.; Pan, D.; Wu, Z. The mechanism and characterstics of dry-jet wet-spinning of acrylic fibers. Adv. Polym. Technol. 1986, 6, 509–529. [Google Scholar] [CrossRef]

- Law, S.J.; Mukhopadhyay, S.K. Investigation of wet-spun acrylic fiber morphology by membrane technology techniques. J. Appl. Polym. Sci. 1996, 62, 33–47. [Google Scholar] [CrossRef]

- Zeng, X.; Hu, J.; Zhao, J.; Zhang, Y.; Pan, D. Investigating the jet stretch in the wet spinning of PAN fiber. J. Appl. Polym. Sci. 2007, 106, 2267–2273. [Google Scholar] [CrossRef]

- Chen, R.; Li, Z.; Shi, Y.; Liu, L.-Z.; Li, D.; Zhao, Y.; Lv, B. In situ study of the preoxidation of polyacrylonitrile fibers. J. Appl. Crystallogr. 2022, 55, 901–910. [Google Scholar] [CrossRef]

- Allen, R.A.; Ward, I.M.; Bashir, Z. The variation of the d-spacings with stress in the hexagonal polymorph of polyacrylonitrile. Polymer 1994, 35, 4035–4040. [Google Scholar] [CrossRef]

- Liu, X.D.; Ruland, W. X-ray studies on the structure of polyacrylonitrile fibers. Macromolecules 1993, 26, 3030–3036. [Google Scholar] [CrossRef]

- Bashir, Z. Co-crystallization of solvents with polymers: The x-ray diffraction behavior of solvent-containing and solvent-free polyacrylonitrile. J. Polym. Sci. Part B Polym. Phys. 1994, 32, 1115–1128. [Google Scholar] [CrossRef]

- Bashir, Z. The Hexagonal Mesophase in Atactic Polyacrylonitrile: A New Interpretation of the Phase Transitions in the Polymer. J. Macromol. Sci. Part B Phys. 2001, 40, 41–67. [Google Scholar] [CrossRef]

- Sawai, D.; Kanamoto, T.; Yamazaki, H.; Hisatani, K. Dynamic Mechanical Relaxations in Poly(acrylonitrile) with Different Stereoregularities. Macromolecules 2004, 37, 2839–2846. [Google Scholar] [CrossRef]

- Kalashnik, A.T.; Smirnova, T.N.; Chernova, O.P.; Kozlov, V.V. Properties and Structure of Polyacrylonitrile Fibers. Polym. Sci. Ser. A 2010, 52, 1233–1238. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, L.; Zhang, L.; Zhao, Z.; Wang, S.; Li, Z.; Jing, D.; Zhang, S. Evolution of Microstructure and Performance in Polyacrylonitrile Precursor Fibers: A Comparison of Spinning Processes. Polymers 2025, 17, 2504. https://doi.org/10.3390/polym17182504

Cao L, Zhang L, Zhao Z, Wang S, Li Z, Jing D, Zhang S. Evolution of Microstructure and Performance in Polyacrylonitrile Precursor Fibers: A Comparison of Spinning Processes. Polymers. 2025; 17(18):2504. https://doi.org/10.3390/polym17182504

Chicago/Turabian StyleCao, Liang, Lili Zhang, Zhenbo Zhao, Shaowei Wang, Zhaowei Li, Deqi Jing, and Shouchun Zhang. 2025. "Evolution of Microstructure and Performance in Polyacrylonitrile Precursor Fibers: A Comparison of Spinning Processes" Polymers 17, no. 18: 2504. https://doi.org/10.3390/polym17182504

APA StyleCao, L., Zhang, L., Zhao, Z., Wang, S., Li, Z., Jing, D., & Zhang, S. (2025). Evolution of Microstructure and Performance in Polyacrylonitrile Precursor Fibers: A Comparison of Spinning Processes. Polymers, 17(18), 2504. https://doi.org/10.3390/polym17182504