Effect of ZnCl2 Treatment Parameters on the Thermo-Hydrolysis of Recycled MDF for Epoxy Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

2.2. Methods

2.2.1. Recycling

2.2.2. Recycling Fiber Qualities

2.2.3. Epoxy Composites and Their Properties

3. Results and Discussion

3.1. Recycled Fiber Characterization

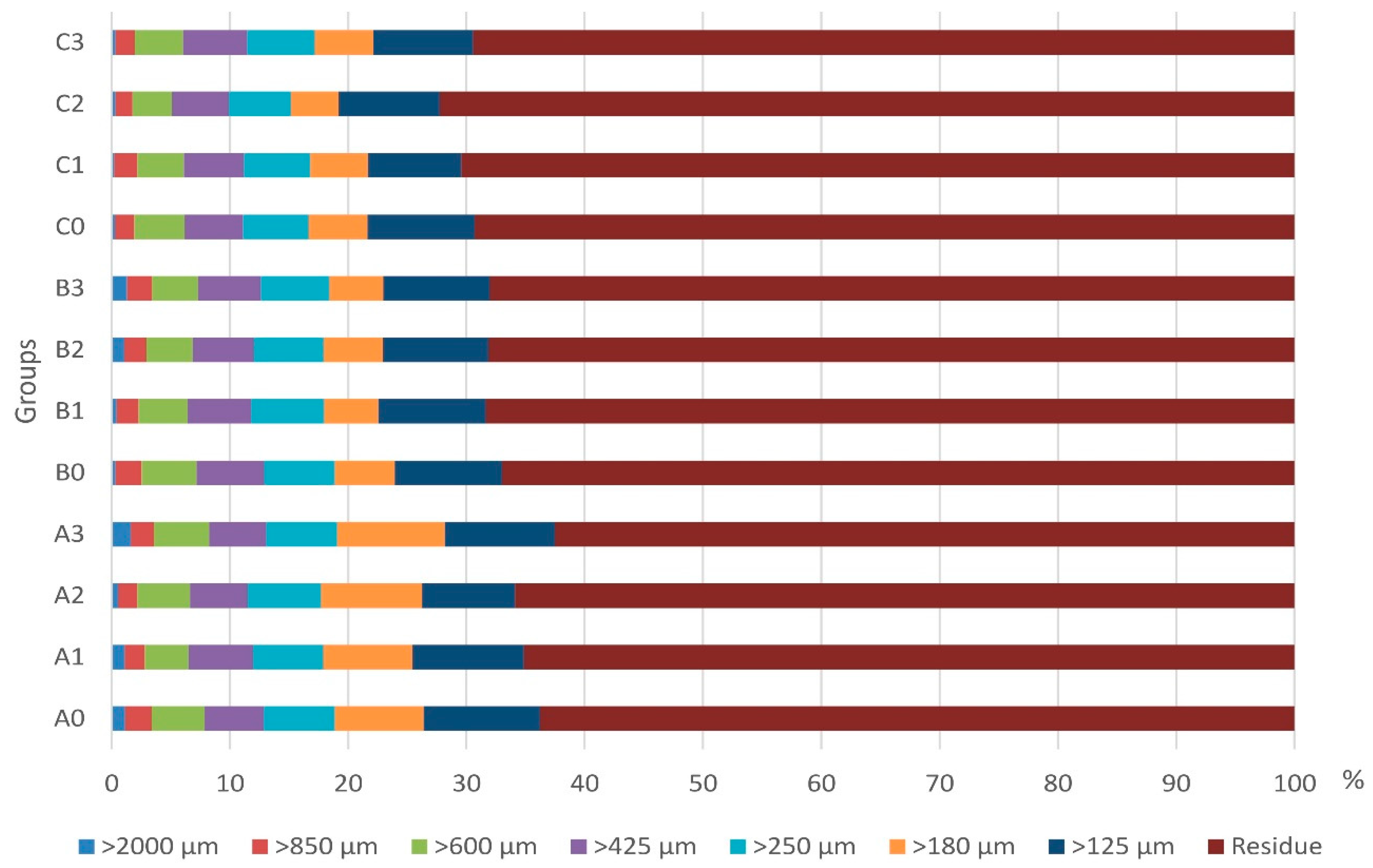

3.1.1. Particle Size Distributions

3.1.2. FT-IR Analysis of Recycled Fibers

3.1.3. Elemental Analysis of Recycled Fibers

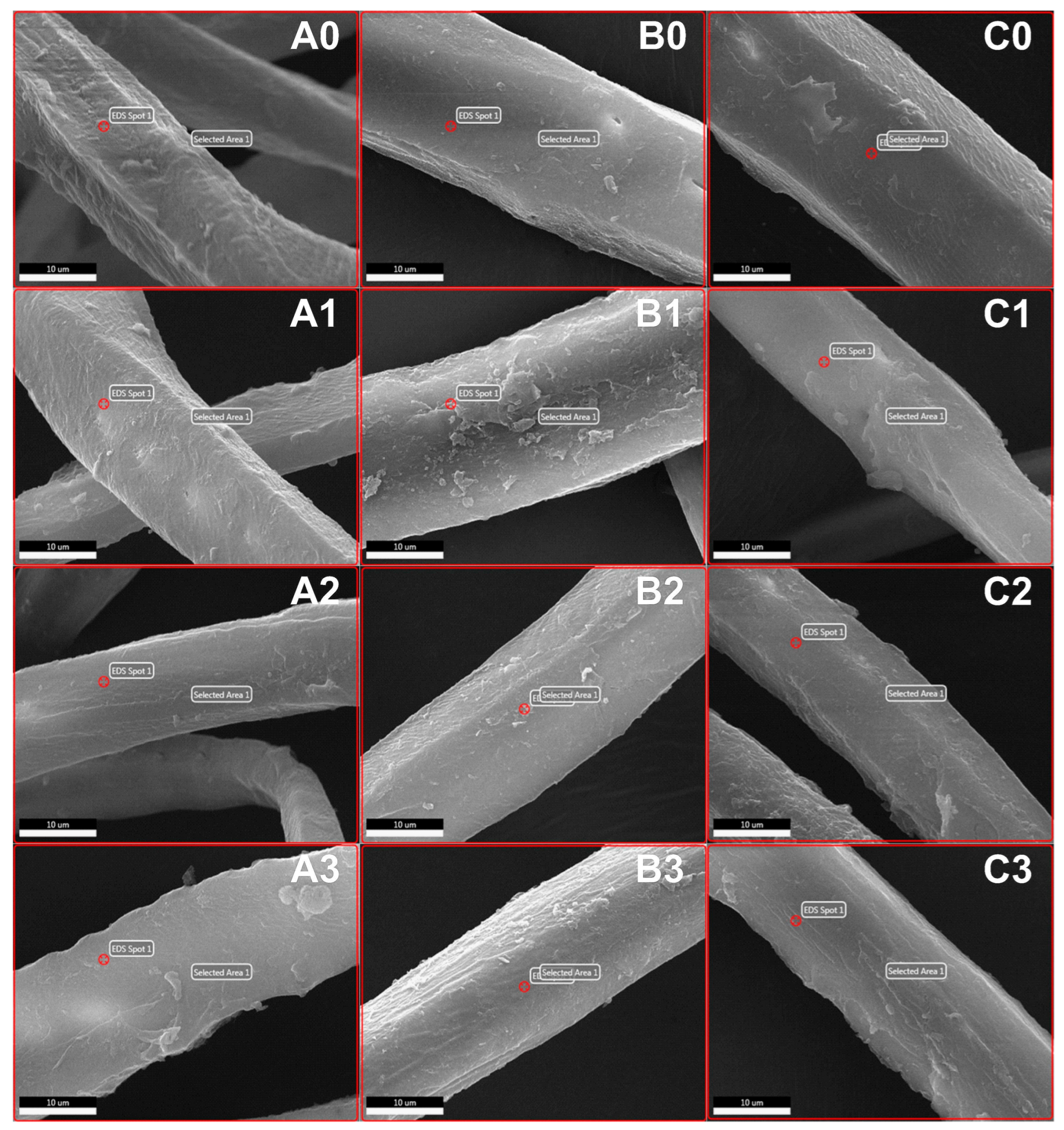

3.1.4. Morphological and Surface Analysis

3.2. Epoxy Composites Characterization

4. Conclusions

- -

- ZnCl2 concentrations of 20% and 30% were effective in removing UF resin and resulted in a significant decrease in the nitrogen content of the recovered fibers. This situation was supported by FT-IR and SEM-EDS analyses.

- -

- Time is more important than solution concentration in terms of dimensional changes. Long processing times (60 min) resulted in deterioration in fiber morphology and excessive particle size refinement, which negatively affected the compressive strength of epoxy composites.

- -

- Composites produced with fibers added to epoxy at a 1% rate showed increased compressive strength. Fibers obtained by 20 min and 40 min hydrothermal hydrolysis can be used to improve the compressive strength of epoxy composites.

- -

- When all measured values were evaluated together, it was determined that the optimal application parameters was 20 min of treatment at 30% ZnCl2 concentration.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MDF | Middle Density Fiberboard |

| UF | Urea—Formaldehyde |

| ZnCl2 | Zinc chloride |

| FT-IR | Fourier transform infrared spectroscopy |

| SEM | Scanning Electron Microscope |

| EDS | Energy dispersive spectrometry |

| DSC | Differential scanning calorimetry |

| C | Carbon |

| N | Nitrogen |

| H | Hydrogen |

| O | Oxygen |

| A0 | Recycled fiber hydrothermally treated for 20 min with pure water |

| A1 | Recycled fiber hydrothermally treated for 20 min with 10% ZnCl2 |

| A2 | Recycled fiber hydrothermally treated for 20 min with 20% ZnCl2 |

| A3 | Recycled fiber hydrothermally treated for 20 min with 30% ZnCl2 |

| B0 | Recycled fiber hydrothermally treated for 40 min with pure water |

| B1 | Recycled fiber hydrothermally treated for 40 min with 10% ZnCl2 |

| B2 | Recycled fiber hydrothermally treated for 40 min with 20% ZnCl2 |

| B3 | Recycled fiber hydrothermally treated for 40 min with 30% ZnCl2 |

| C0 | Recycled fiber hydrothermally treated for 60 min with pure water |

| C1 | Recycled fiber hydrothermally treated for 60 min with 10% ZnCl2 |

| C2 | Recycled fiber hydrothermally treated for 60 min with 20% ZnCl2 |

| C3 | Recycled fiber hydrothermally treated for 60 min with 30% ZnCl2 |

References

- Zeng, Q.; Lu, Q.; Zhou, Y.; Chen, N.; Rao, J.; Fan, M. Circular development of recycled natural fibers from medium density fiberboard wastes. J. Clean. Prod. 2018, 202, 456–464. [Google Scholar] [CrossRef]

- Moezzipour, B.; Ahmadi, M.; Abdolkhani, A.; Doosthoseini, K. Chemical changes of wood fibers after hydrothermal recycling of MDF wastes. J. Indian Acad. Wood Sci. 2017, 14, 133–138. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G. Physical and Mechanical Properties of High-Density Fiberboard Bonded with Bio-Based Adhesives. Forests 2023, 14, 84. [Google Scholar] [CrossRef]

- Dunky, M. Urea–formaldehyde (UF) adhesive resins for wood. Int. J. Adhes. Adhes. 1998, 18, 95–107. [Google Scholar] [CrossRef]

- Lykidis, C.; Grigoriou, A. Hydrothermal recycling of waste and performance of the recycled wooden particleboards. Waste Manag. 2008, 28, 57–63. [Google Scholar] [CrossRef]

- Nuryawan, A.; Risnasari, I.; Pohan, A.P.; Husna, A.U.; Nasution, T.I.; Banurea, R.; Hartini, K.S. Properties of fibreboard (FBs) and recycle fibreboard (rFBs) and analysis of their wastage after recycling. IOP Conf. Ser. Mater. Sci. Eng. 2020, 935, 12060. [Google Scholar] [CrossRef]

- Savov, V.; Antov, P.; Panchev, C.; Lubis, M.A.; Lee, S.H.; Taghiyari, H.R.; Todorova, M.; Petrin, S. Effect of Hydrolysis Regime on the Properties of Fibers Obtained from Recycling Medium-Density Fiberboards. Fibers 2023, 11, 64. [Google Scholar] [CrossRef]

- Savov, V.; Antov, P.; Panchev, C.; Lubis, M.A.; Taghiyari, H.R.; Lee, S.H.; Krišťák, Ľ.; Todorova, M. The Impact of Hydrolysis Regime on the Physical and Mechanical Characteristics of Medium-Density Fiberboards Manufactured from Recycled Wood Fibers. Fibers 2023, 11, 103. [Google Scholar] [CrossRef]

- Olgun, Ç. Hidrotermal hidroliz yönteminde amonyum klorür kullanımının lif levhaların geri dönüşümüne etkisi TT-The effect of ammonium chloride usage on the recycling of fiberboards in the hydrothermal hydrolysis method. Turkish J. For. 2025, 26, 175–181. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Hidayat, W.; Zaini, L.H.; Park, B.D. Effects of Hydrolysis on the Removal of Cured Urea-Formaldehyde Adhesive in Waste Medium-Density Fiberboard. J. Sylva Lestari 2020, 8, 1–9. [Google Scholar] [CrossRef]

- Nuryawan, A.; Park, B.-D. Quantification of hydrolytic degradation of cured urea-formaldehyde resin adhesives using confocal laser scanning microscopy. Int. J. Adhes. Adhes. 2017, 74, 1–5. [Google Scholar] [CrossRef]

- Besserer, A.; Troilo, S.; Girods, P.; Rogaume, Y.; Brosse, N. Cascading Recycling of Wood Waste: A Review. Polymers 2021, 13, 1752. [Google Scholar] [CrossRef]

- Moezzipour, B.; Abdolkhani, A.; Doost-hoseini, K.; Ahmad Ramazani, S.A.; Tarmian, A. Practical properties and formaldehyde emission of medium density fiberboards (MDFs) recycled by electrical method. Eur. J. Wood Wood Prod. 2018, 76, 1287–1294. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Hong, M.-K.; Park, B.-D. Hydrolytic Removal of Cured Urea–Formaldehyde Resins in Medium-Density Fiberboard for Recycling. J. Wood Chem. Technol. 2018, 38, 1–14. [Google Scholar] [CrossRef]

- Bütün Buschalsky, F.Y.; Mai, C. Repeated thermo-hydrolytic disintegration of medium density fibreboards (MDF) for the production of new MDF. Eur. J. Wood Wood Prod. 2021, 79, 1451–1459. [Google Scholar] [CrossRef]

- Hagel, S.; Joy, J.; Cicala, G.; Saake, B. Recycling of Waste MDF by Steam Refining: Evaluation of Fiber and Paper Strength Properties. Waste Biomass Valorization 2021, 12, 5701–5713. [Google Scholar] [CrossRef]

- Troilo, S.; Besserer, A.; Rose, C.; Saker, S.; Soufflet, L.; Brosse, N. Urea-Formaldehyde Resin Removal in Medium-Density Fiberboards by Steam Explosion: Developing Nondestructive Analytical Tools. ACS Sustain. Chem. Eng. 2023, 11, 3603–3610. [Google Scholar] [CrossRef]

- Zimmer, A.; Angie Lunelli Bachmann, S. Challenges for recycling medium-density fiberboard (MDF). Results Eng. 2023, 19, 101277. [Google Scholar] [CrossRef]

- Gürsoy, S.; Ayrilmis, N. Effect of Lignin Modification of Recycled and Fresh Wood Fibers on Physical, Mechanical, and Thermal Properties of Fiberboard. Forests 2023, 14, 2007. [Google Scholar] [CrossRef]

- Olgun, Ç.; Ateş, S.; Uzer, E. Effects of Medium Density Fiberboards (MDF) Recycling Methods on Fiber Dimensions and Some Reconstructed Board Properties. Drv. Ind. 2023, 74, 61–69. [Google Scholar] [CrossRef]

- Savov, V.; Antov, P.; Dudeva, V.; Panchev, C. Properties of Medium-Density Fiberboards with Different Contents of Recycled Fibers and Urea–Formaldehyde Resin. Fibers 2025, 13, 40. [Google Scholar] [CrossRef]

- Hu, Z.; Musikavanhu, B.; Li, J.; Li, J.; He, Z. ZnCl2 pretreatment of bamboo chips to produce chemi-thermomechanical pulp: Saving refining energy and improving pulp properties. BioResources 2018, 13, 5164–5178. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T.; Hassan, A. Recent advances in epoxy resin, natural fiber-reinforced epoxy composites and their applications. J. Reinf. Plast. Compos. 2015, 35, 447–470. [Google Scholar] [CrossRef]

- Patra, A.; Bisoyi, D.K.; Manda, P.K.; Singh, A.K. Electrical and Mechanical Properties of the Potassium Permanganate Treated Short Sisal Fiber Reinforced Epoxy Composite in Correlation to the Macromolecular Structure of the Reinforced Fiber. J. Appl. Polym. Sci. 2013, 128, 1011–1019. [Google Scholar] [CrossRef]

- Fidan, I.; Imeri, A.; Gupta, A.; Hasanov, S.; Nasirov, A.; Elliott, A.; Alifui-Segbaya, F.; Nanami, N. The Trends and Challenges of Fiber Reinforced Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2019, 102, 1801–1818. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, K.; Sahoo, P.; Bhowmik, S. Study of Mechanical Properties of Wood Dust Reinforced Epoxy Composite. Procedia Mater. Sci. 2014, 6, 551–556. [Google Scholar] [CrossRef]

- B H, M.P.; Gowda, S.; S, R.; T K, N.; Kandagal, Z.B.; M, P.P.; P, D.P.; Sharma, P.; Anne, G. Effect of Teak Wood Dust as Filler Material on Mechanical Properties of Abaca-Pineapple-Epoxy Hybrid Composite. J. Nat. Fibers 2024, 21, 2434603. [Google Scholar] [CrossRef]

- Fayzulla, B.J. Effect of Medium-Density Fiberboard Sawdust Content on the Dynamic and Mechanical Properties of Epoxy-Based Composite. J. Mech. Behav. Mater. 2025, 34, 20250060. [Google Scholar] [CrossRef]

- Sienkiewicz, A.; Czub, P. Modification of Epoxy Compositions by the Application of Various Fillers of Natural Origin. Materials 2023, 16, 3149. [Google Scholar] [CrossRef]

- Malakar, C.; Dutta, H.; Bhowmik, S.; Ravivarman, R.; Roy Choudhury, M. Influence of Powdered Bamboo Filler Content on the Tensile Strength and Fatigue Life of Epoxy Composites. Mater. Res. Express 2025, 12, 075305. [Google Scholar] [CrossRef]

- Peltola, H.; Pääkkönen, E.; Jetsu, P.; Heinemann, S. Wood Based PLA and PP Composites: Effect of Fibre Type and Matrix Polymer on Fibre Morphology, Dispersion and Composite Properties. Compos. Part A Appl. Sci. Manuf. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Das, R.; Dash, C.; Bisoyi, D.K. Effect of Loading of Kapok Fiber with Epoxy on Mechanical and Electrical Properties of Its Composites. Polym. Sci. Ser. A 2024, 66, 103–112. [Google Scholar] [CrossRef]

- ASTM D 695-15; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- EN ISO 11357-1; Plastics—Differential Scanning Calorimetry (DSC)—Part 1: General principles. European Committee for Standardization: Brussels, Belgium, 2023.

- Wan, H.; Wang, X.-M.; Shen, J. Recycling Wood Composite Panels: Characterizing Recycled Materials. BioResources 2014, 9, 7554–7565. [Google Scholar] [CrossRef]

- Potadar, O.V.; Kadam, G.S. Preparation and Testing of Composites using Waste Groundnut Shells and Coir Fibres. Procedia Manuf. 2018, 20, 91–96. [Google Scholar] [CrossRef]

- Chauhan, S.S.; Maurya, N.K.; Dwivedi, S.P. Effect of Particle Size and Weight Percent of Different Wood Dust on the Tensile Strength of Glass Fiber Epoxy/Saw Dust Composite Using RSM. Mater. Today Proc. 2021, 47, 3936–3942. [Google Scholar] [CrossRef]

- Aizat, G.A.; Paiman, B.; Lee, S.H.; Zaidon, A. Physico-Mechanical Properties and Formaldehyde Emission of Rubberwood Particleboard Made with UF Resin Admixed with Ammonium and Aluminium-Based Hardeners. Pertanika J. Sci. Technol. 2019, 27, 473–488. [Google Scholar]

- Lubis, M.A.R.; Park, B.-D. Analysis of the hydrolysates from cured and uncured urea-formaldehyde (UF) resins with two F/U mole ratios. Holzforschung 2018, 72, 759–768. [Google Scholar] [CrossRef]

- Hagel, S.; Saake, B. Fractionation of Waste MDF by Steam Refining. Molecules 2020, 25, 2165. [Google Scholar] [CrossRef] [PubMed]

- Fu, Q.; Wang, X.; Cloutier, A.; Roussière, F. Chemical characteristics of thermo-hydrolytically recycled particles. BioResources 2020, 15, 3774–3786. [Google Scholar] [CrossRef]

- Rodríguez, G.E.; Garcia, R.; Cloutier, A. Recycling Particleboard by Acid Hydrolysis: Effects on the Physical, Thermal, and Chemical Characteristics of Recycled Wood Particles. Fibers 2025, 13, 90. [Google Scholar] [CrossRef]

- Kacem, M.A.; Guebailia, M.; Halimi, R.; Abdi, S.; Bodaghi, M. Epoxy Composites Reinforced by Alkaline–Acid Treated Yucca Fibers. Macromol. Mater. Eng. 2025, 70003. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Hong, M.-K.; Park, B.-D.; Lee, S.-M. Effects of recycled fiber content on the properties of medium density fiberboard. Eur. J. Wood Wood Prod. 2018, 76, 1515–1526. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Ozbakkaloglu, T. Lignocellulosic fiber reinforced composites: Progress, performance, properties, applications, and future perspectives. Polym. Compos. 2022, 43, 645–691. [Google Scholar] [CrossRef]

- Sajith, S.; Arumugam, V.; Dhakal, H.N. Comparison on mechanical properties of lignocellulosic flour epoxy composites prepared by using coconut shell, rice husk and teakwood as fillers. Polym. Test. 2017, 58, 60–69. [Google Scholar] [CrossRef]

- Hidalgo-Salazar, M.A.; Correa, J.P. Mechanical and thermal properties of biocomposites from nonwoven industrial Fique fiber mats with Epoxy Resin and Linear Low Density Polyethylene. Results Phys. 2018, 8, 461–467. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Pereira, A.C.; Monteiro, S.N.; da Costa Garcia Filho, F.; da Cruz Demosthenes, L.C. Thermal Behavior of Epoxy Composites Reinforced with Fique Fabric by DSC. In Green Materials Engineering; Ikhmayies, S., Li, J., Vieira, C.M.F., Margem (Deceased), J.I., de Oliveira Braga, F., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 101–106. [Google Scholar]

| Groups | Time (min) | Concentration (% w/w) |

|---|---|---|

| A0 | 20 | - |

| A1 | 20 | 10 |

| A2 | 20 | 20 |

| A3 | 20 | 30 |

| B0 | 40 | - |

| B1 | 40 | 10 |

| B2 | 40 | 20 |

| B3 | 40 | 30 |

| C0 | 60 | - |

| C1 | 60 | 10 |

| C2 | 60 | 20 |

| C3 | 60 | 30 |

| Groups | N (%) | C (%) | H (%) |

|---|---|---|---|

| A0 | 1.376 | 46.204 | 5.945 |

| A1 | 0.639 | 45.843 | 5.761 |

| A2 | 0.397 | 43.426 | 5.686 |

| A3 | 0.309 | 42.740 | 5.587 |

| B0 | 1.166 | 46.601 | 5.694 |

| B1 | 0.710 | 44.747 | 5.616 |

| B2 | 0.334 | 44.630 | 5.429 |

| B3 | 0.292 | 43.839 | 5.411 |

| C0 | 1.337 | 46.716 | 5.665 |

| C1 | 0.646 | 45.972 | 5.646 |

| C2 | 0.365 | 44.912 | 5.511 |

| C3 | 0.310 | 40.115 | 5.497 |

| N | C | O | ||||

|---|---|---|---|---|---|---|

| Groups | Weight% | Atomic% | Weight% | Atomic% | Weight% | Atomic% |

| A0 | 6.57 | 6.32 | 53.41 | 59.95 | 40.02 | 33.72 |

| A1 | 3.64 | 3.49 | 55.37 | 62.03 | 40.99 | 34.47 |

| A2 | 1.99 | 1.89 | 59.66 | 66.18 | 38.35 | 31.93 |

| A3 | 1.59 | 1.48 | 67.68 | 73.47 | 30.73 | 25.05 |

| B0 | 7.49 | 7.08 | 59.87 | 65.94 | 32.64 | 26.98 |

| B1 | 4.89 | 4.65 | 58.27 | 64.66 | 36.83 | 30.68 |

| B2 | 4.26 | 4.04 | 59.68 | 66.02 | 36.05 | 29.94 |

| B3 | 4.20 | 3.99 | 58.48 | 64.90 | 37.33 | 31.10 |

| C0 | 3.84 | 3.59 | 65.40 | 71.25 | 30.76 | 25.16 |

| C1 | 3.50 | 3.28 | 64.35 | 70.34 | 32.15 | 26.38 |

| C2 | 2.87 | 2.70 | 62.82 | 69.00 | 34.31 | 28.30 |

| C3 | 2.63 | 2.52 | 56.05 | 62.75 | 41.32 | 34.73 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olgun, Ç.; Çufa, K. Effect of ZnCl2 Treatment Parameters on the Thermo-Hydrolysis of Recycled MDF for Epoxy Composites. Polymers 2025, 17, 2493. https://doi.org/10.3390/polym17182493

Olgun Ç, Çufa K. Effect of ZnCl2 Treatment Parameters on the Thermo-Hydrolysis of Recycled MDF for Epoxy Composites. Polymers. 2025; 17(18):2493. https://doi.org/10.3390/polym17182493

Chicago/Turabian StyleOlgun, Çağrı, and Koray Çufa. 2025. "Effect of ZnCl2 Treatment Parameters on the Thermo-Hydrolysis of Recycled MDF for Epoxy Composites" Polymers 17, no. 18: 2493. https://doi.org/10.3390/polym17182493

APA StyleOlgun, Ç., & Çufa, K. (2025). Effect of ZnCl2 Treatment Parameters on the Thermo-Hydrolysis of Recycled MDF for Epoxy Composites. Polymers, 17(18), 2493. https://doi.org/10.3390/polym17182493