Mechanical Characterization of Graphene-Enhanced Fiber Rope Composites for Strengthening-Oriented Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

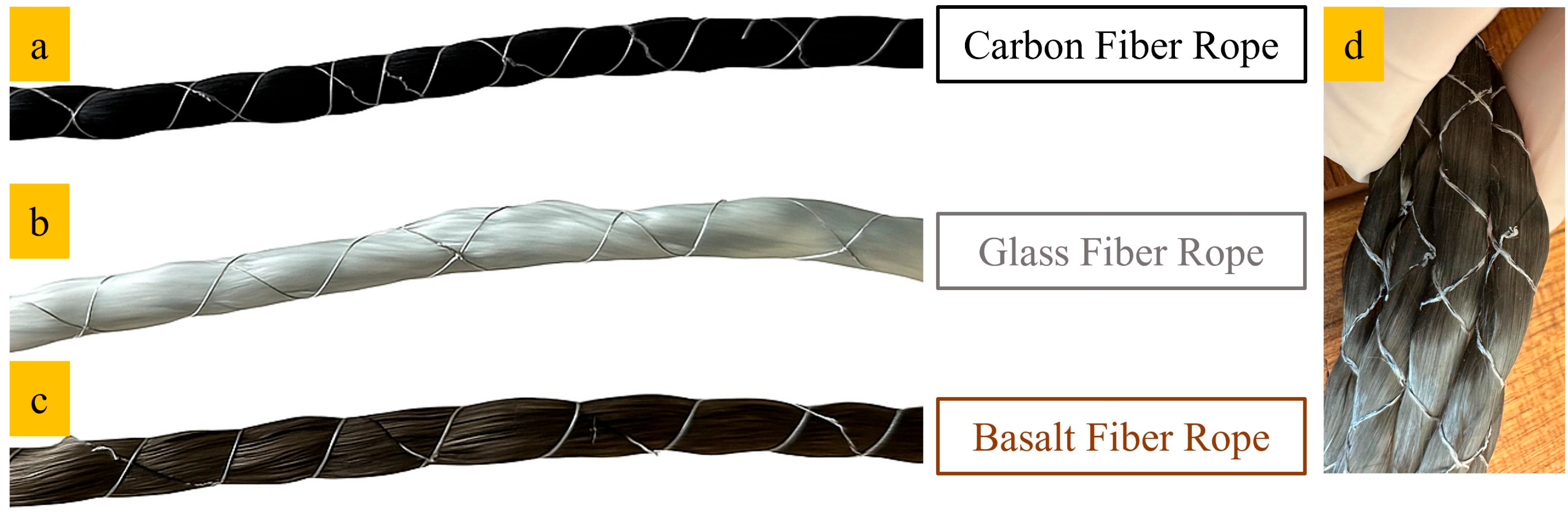

2.1.1. Fiber Ropes

2.1.2. Epoxy System

2.1.3. Graphene Nanoplatelets (GNPs)

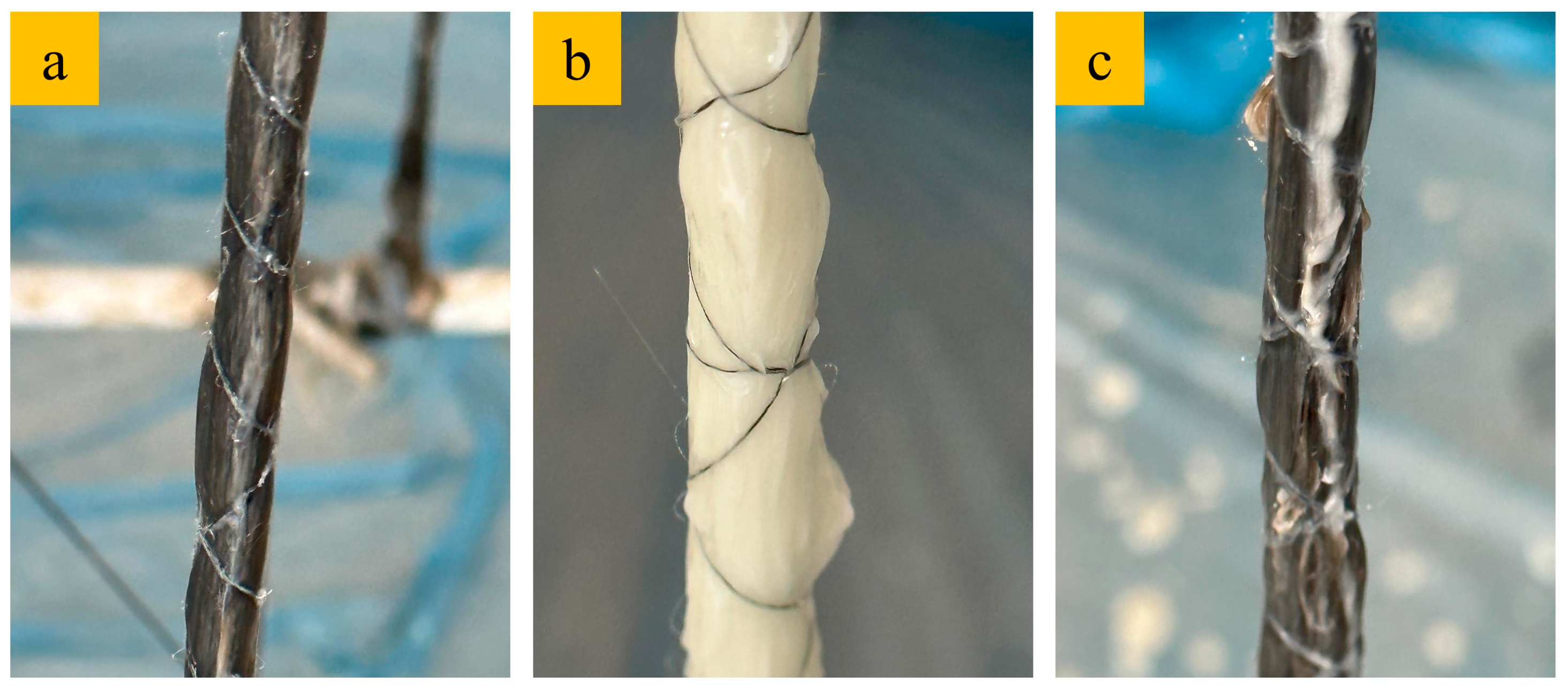

2.2. Manufacturing of the Composite Ropes

2.2.1. Manufacturing of Unmodified Fiber Rope Composites

2.2.2. Manufacturing of GNP-Modified Fiber Rope Composites

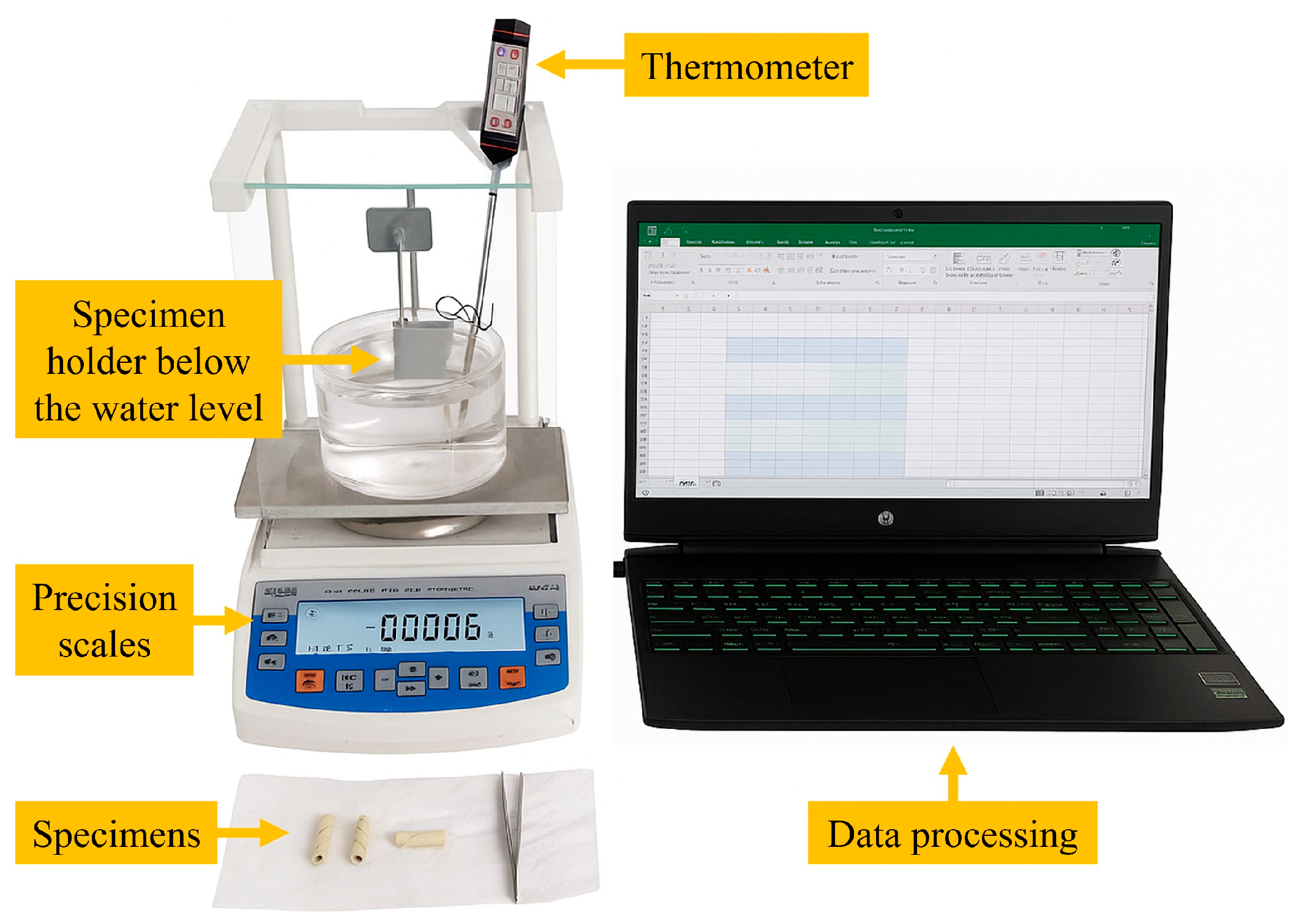

2.3. Density Measurements

2.4. Mechanical Tests

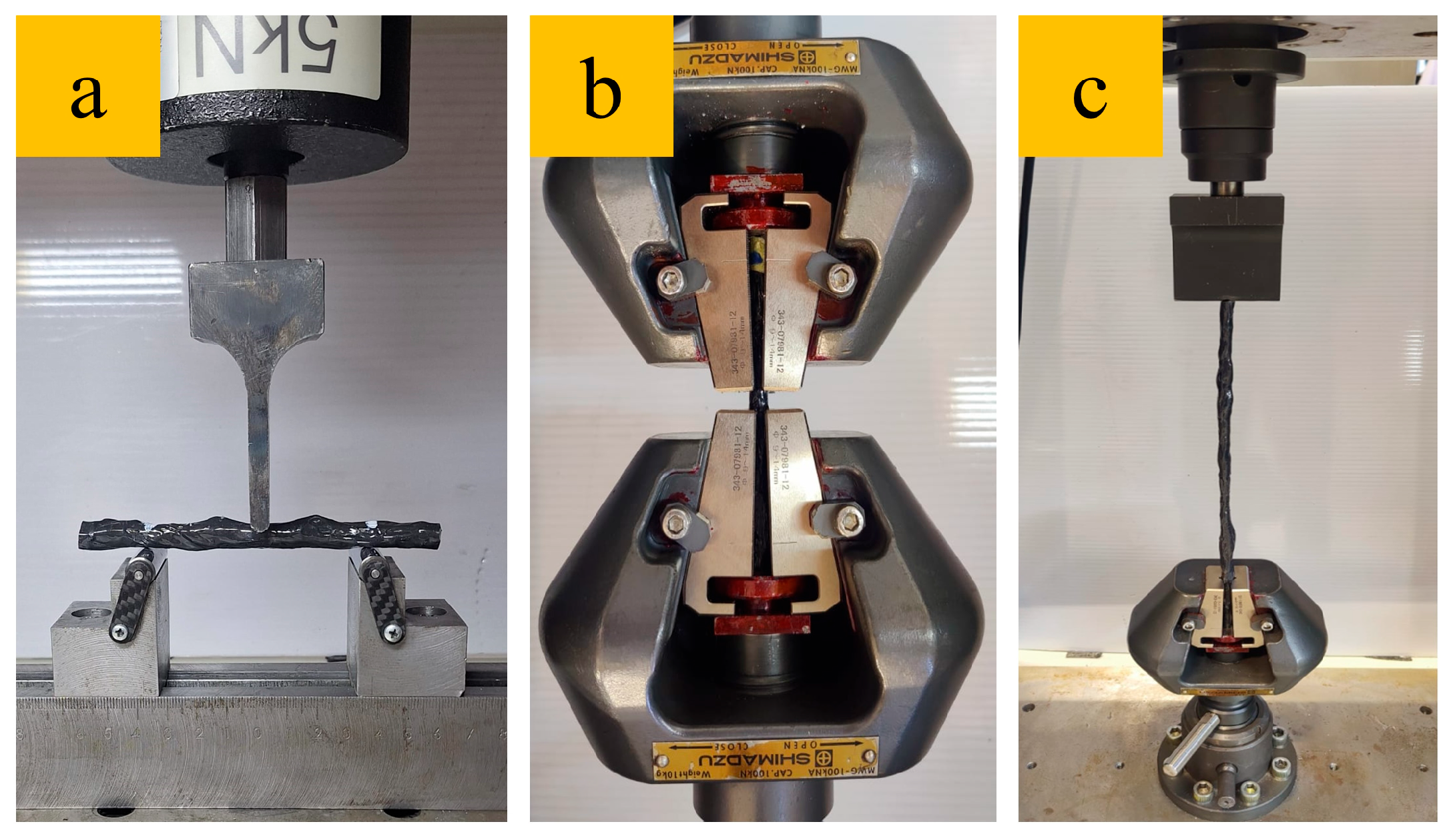

2.4.1. Flexural Test

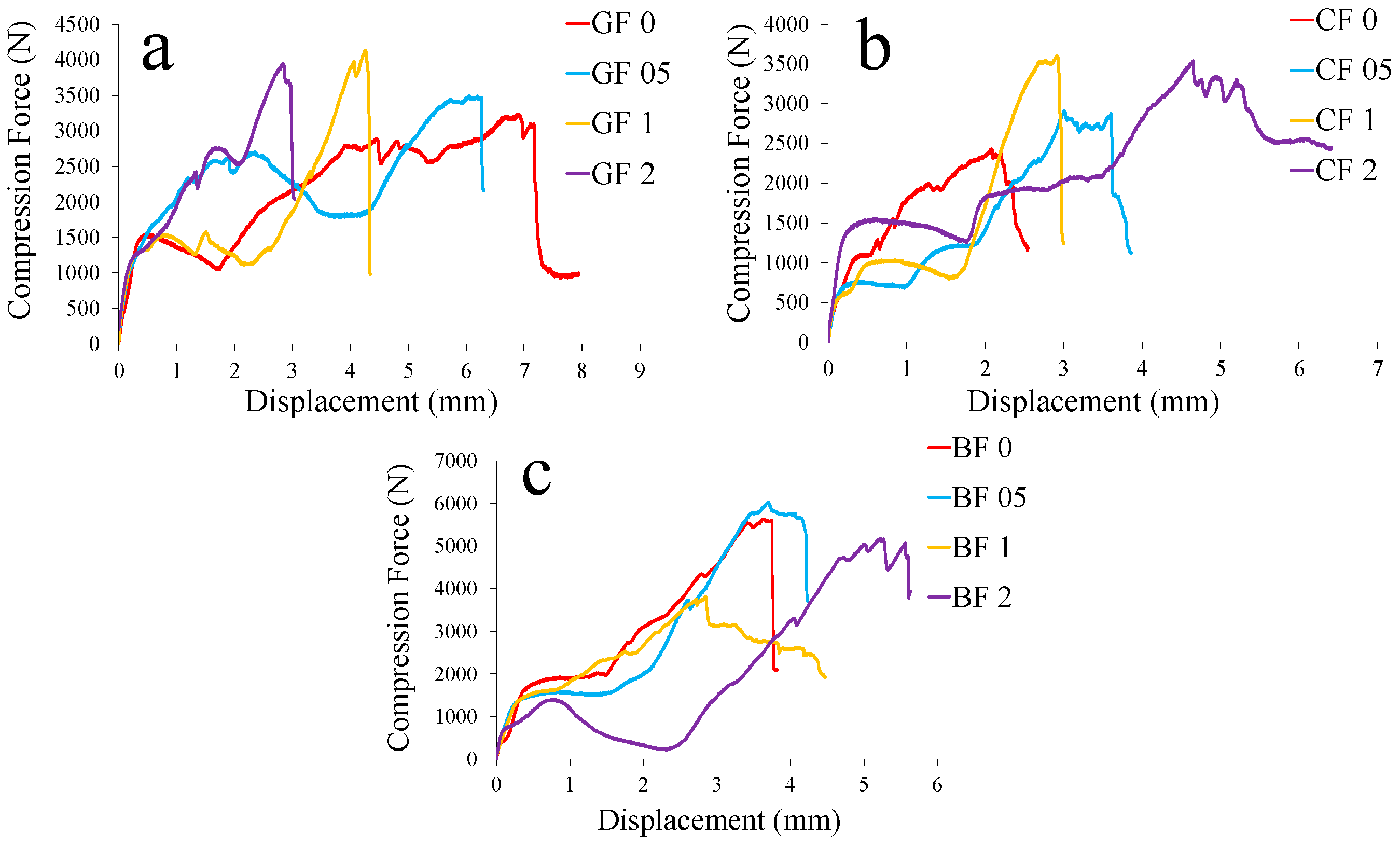

2.4.2. Compression Test

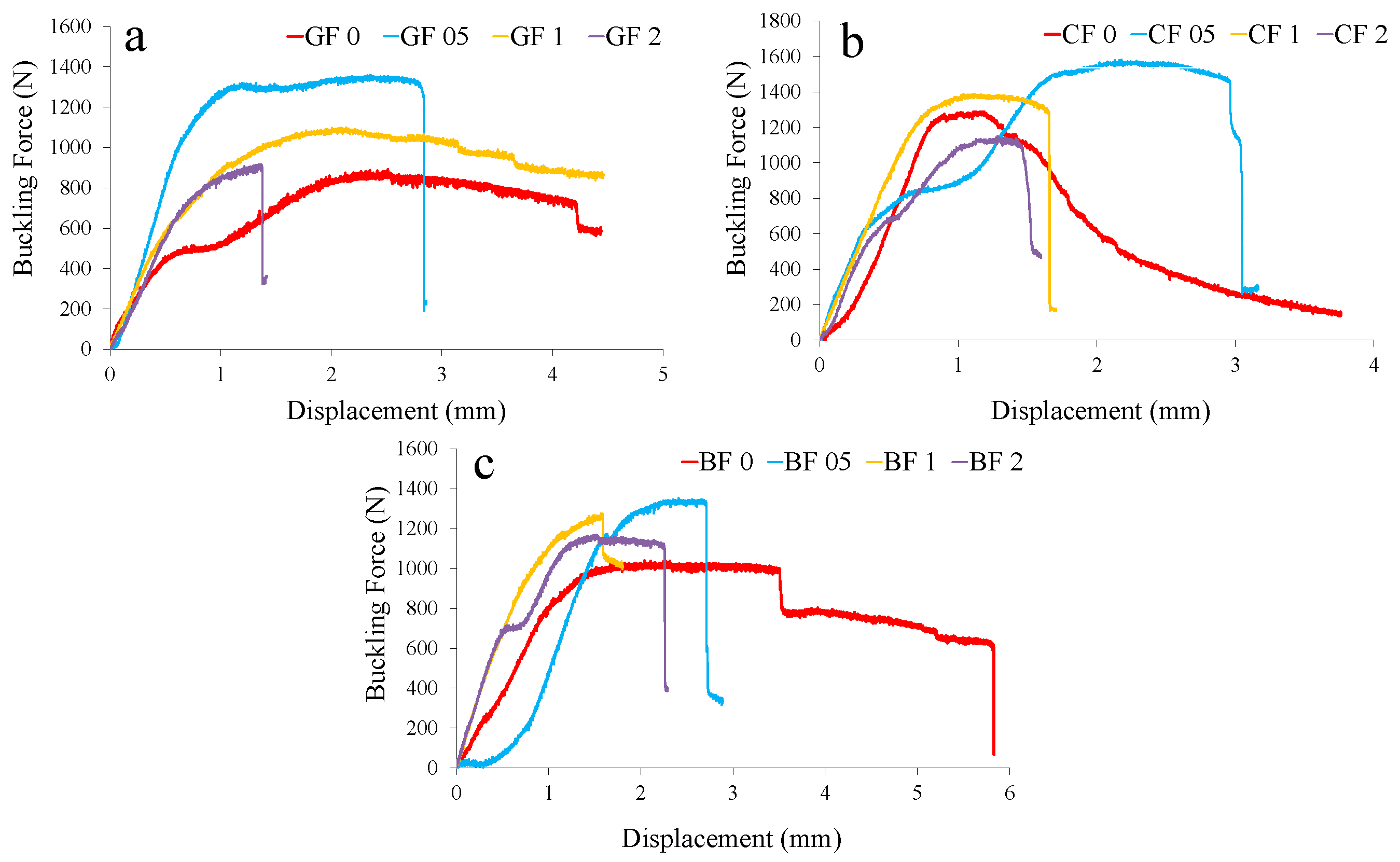

2.4.3. Buckling Test

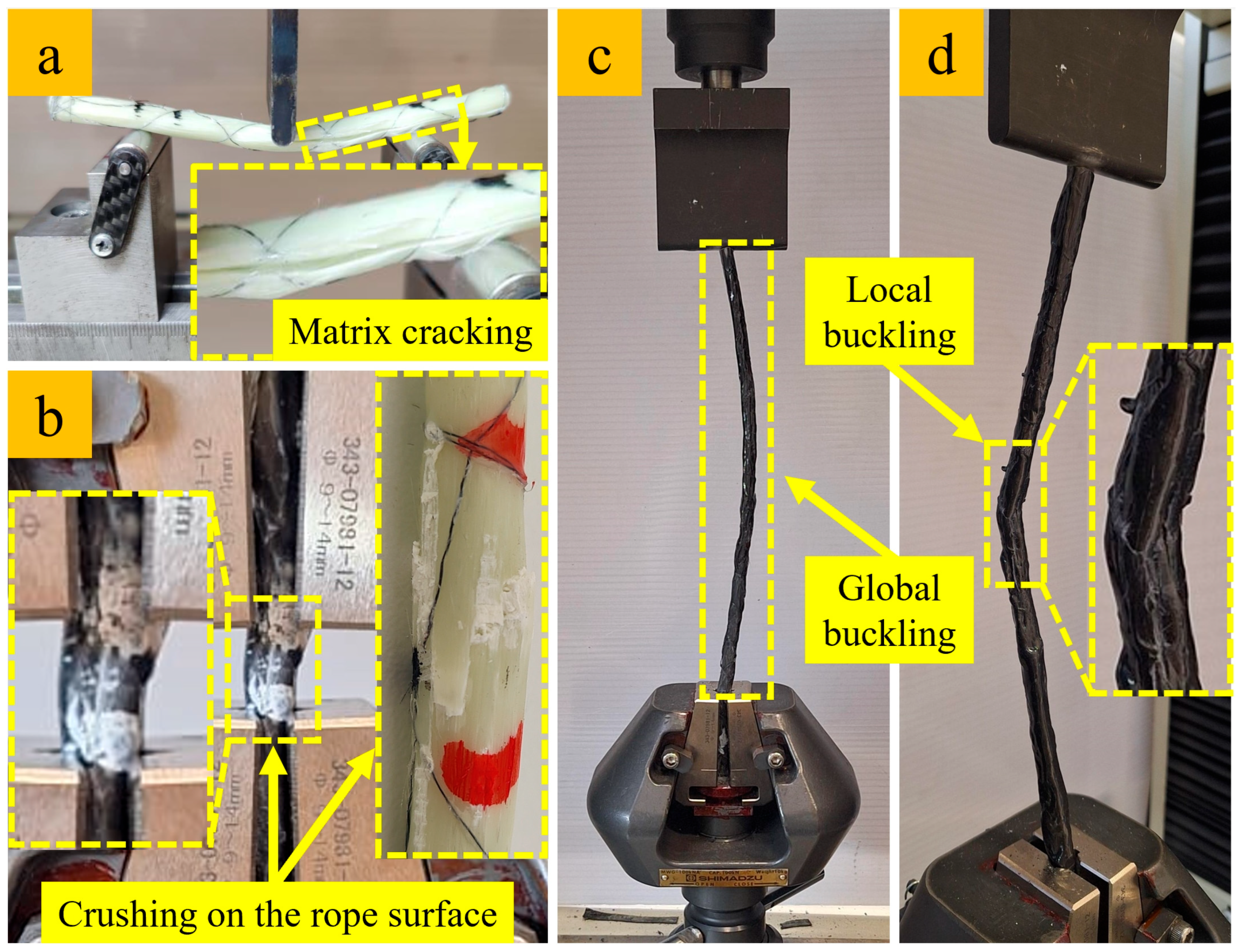

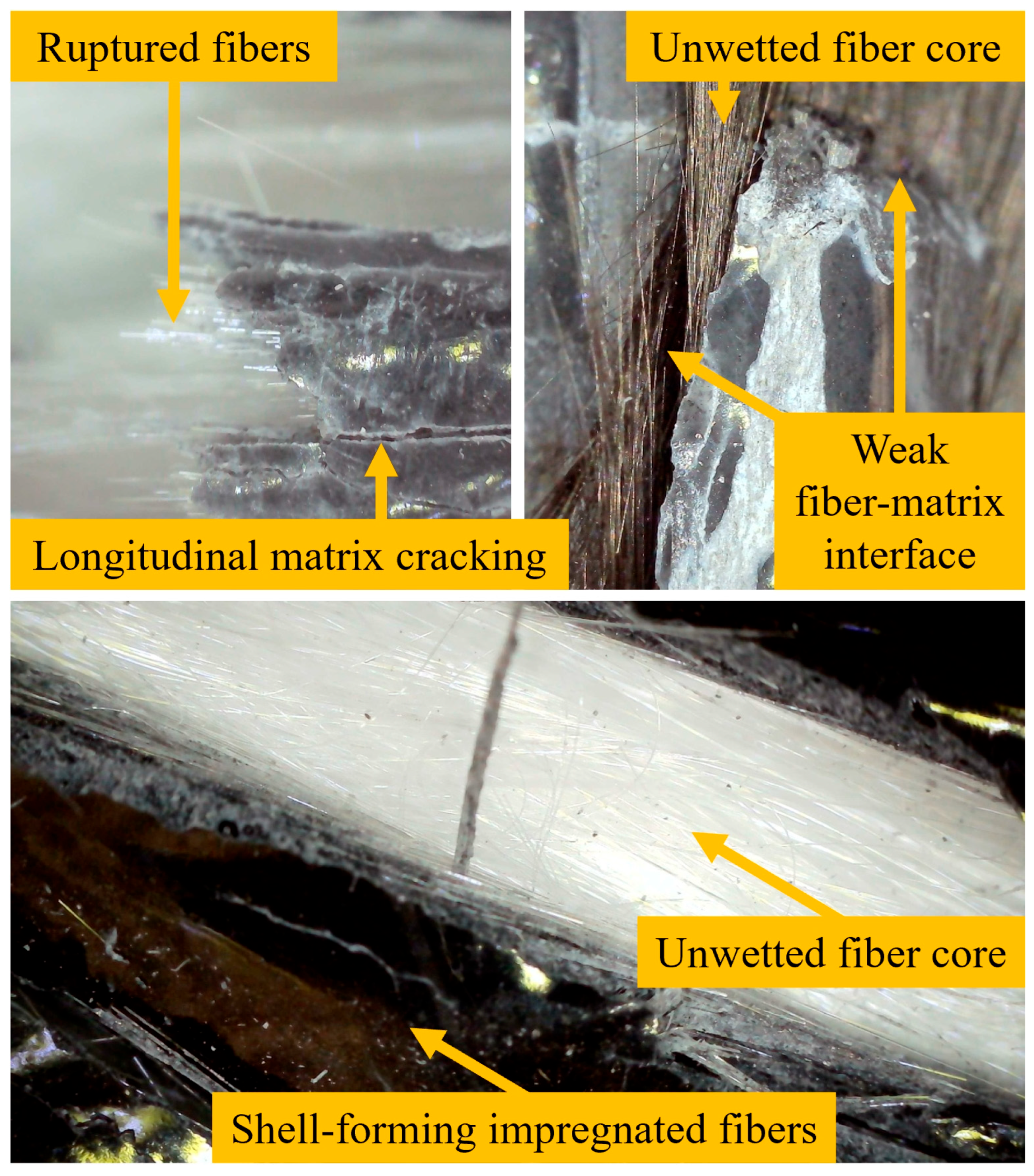

2.5. Fracture Analysis and Visual Inspection

3. Results

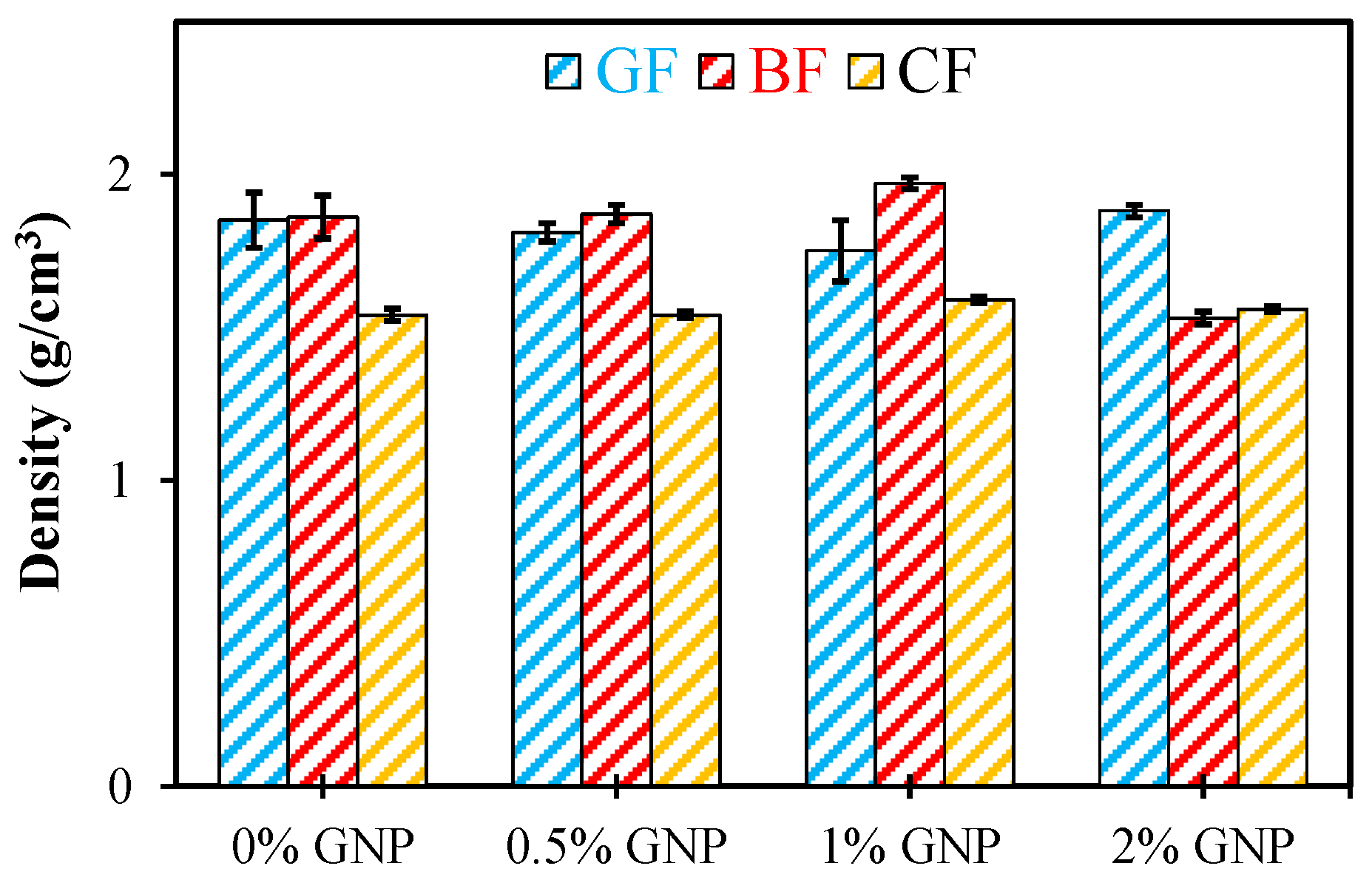

3.1. Density Results

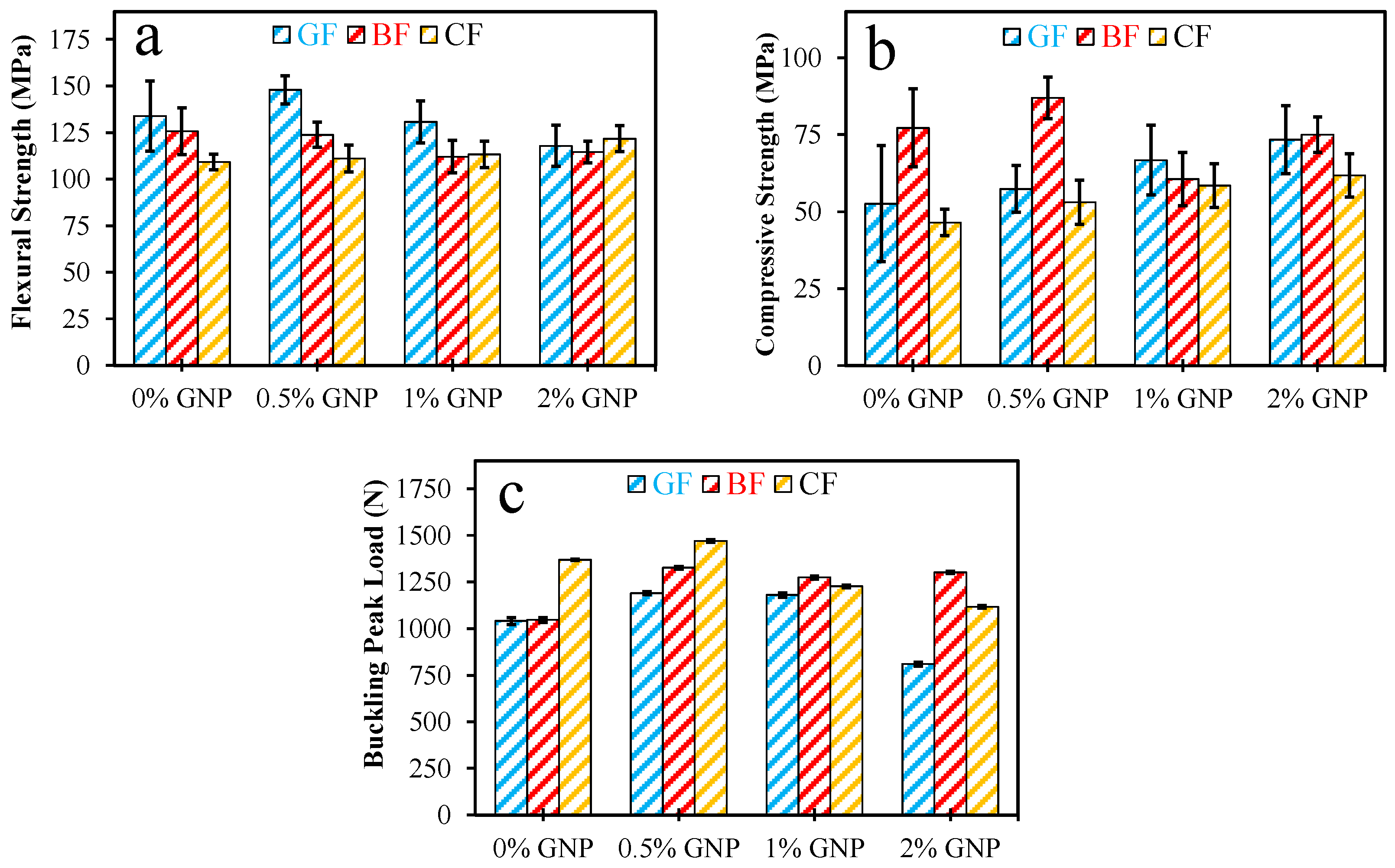

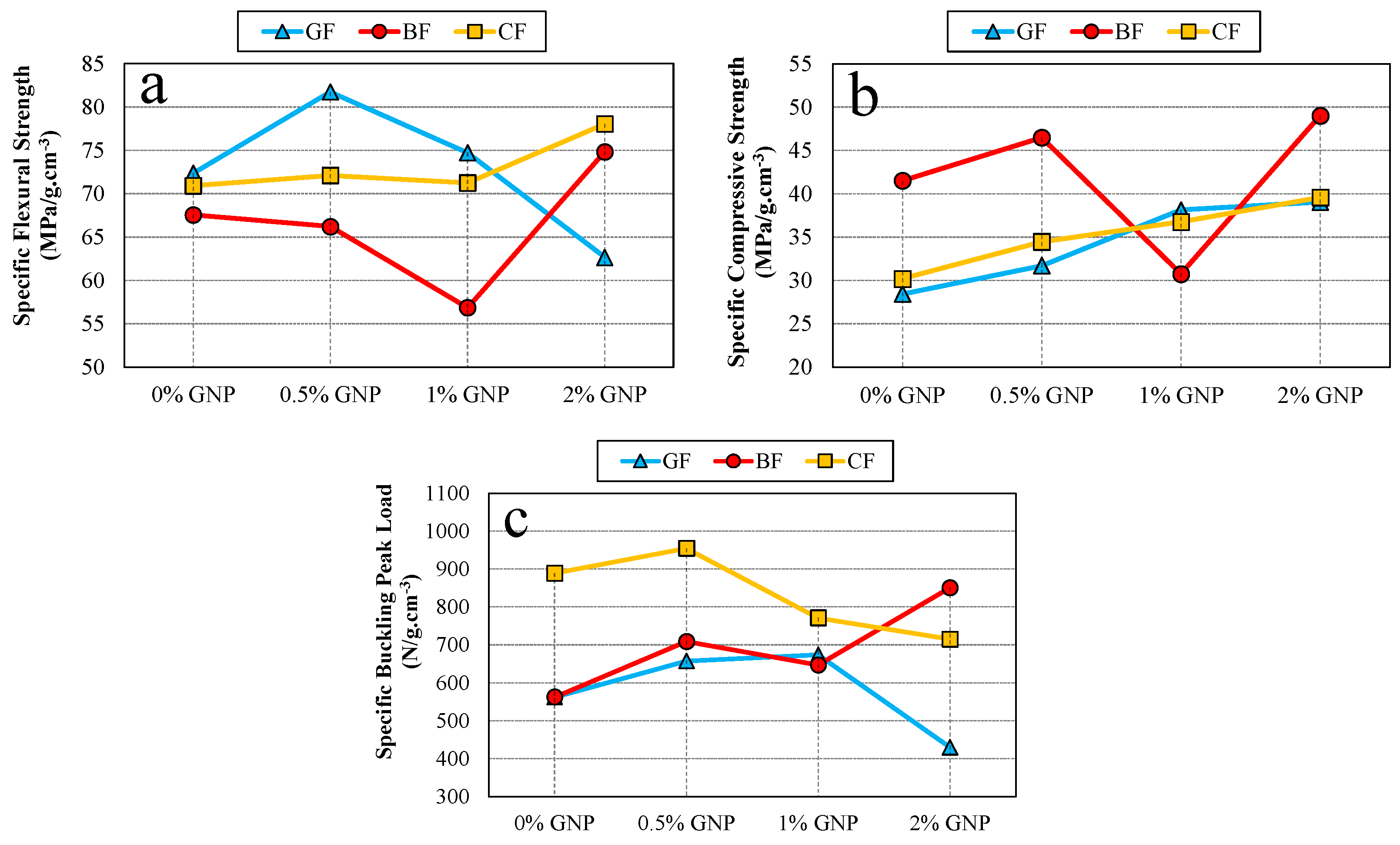

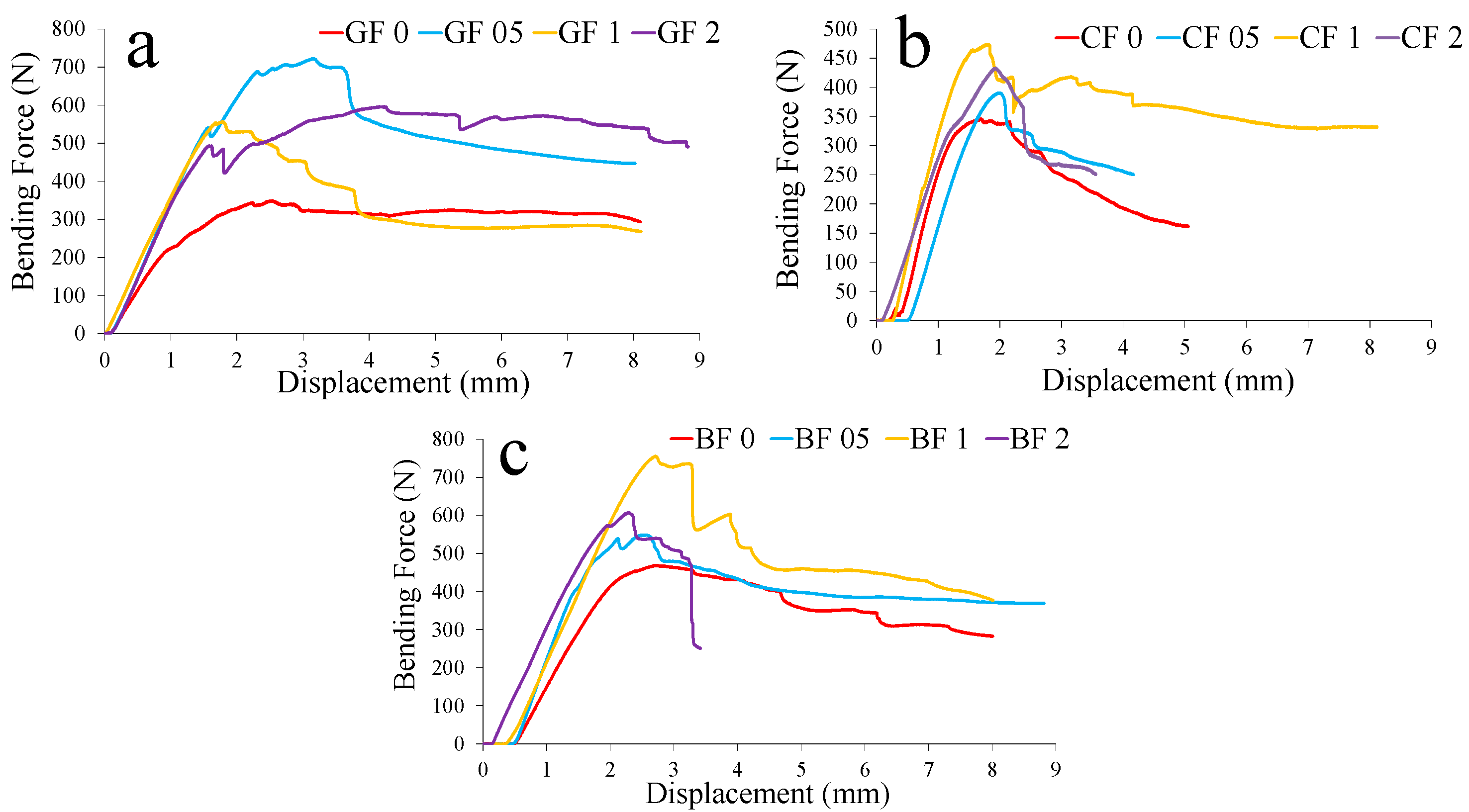

3.2. Mechanical Test Results

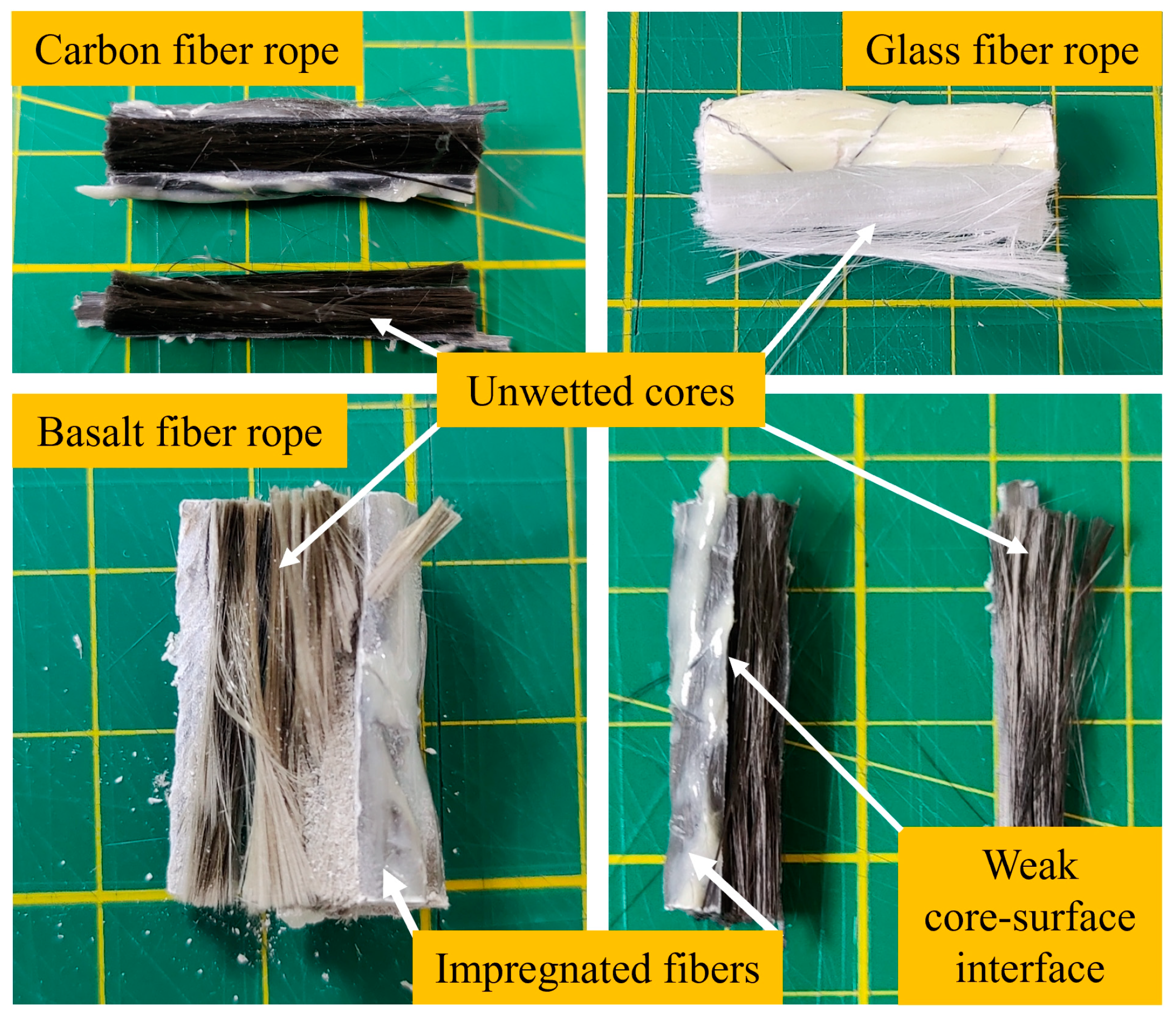

3.3. Visual Fracture Observations

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aydın, M.R.; Acar, V.; Çakır, F.; Gündoğdu, Ö. Effect of Manufacturing Parameters on Low-Velocity Impact Behavior of Aramid, Carbon and Glass Fiber Reinforced Polymer Composites Using Taguchi Experimental Design. Appl. Compos. Materials 2025, 32, 849–877. [Google Scholar] [CrossRef]

- Foster, G.P. Advantages of Fiber Rope Over Wire Rope. J. Ind. Text. 2002, 32, 67–75. [Google Scholar] [CrossRef]

- Monni, F.; Quagliarini, E.; Lenci, S.; Clementi, F. Dry Masonry Strengthening Thotugh Basalt Fiber Ropes:Experimental Results Versus Out-Of-Plane Actions. Key Eng. Mater. 2015, 624, 584–594. [Google Scholar] [CrossRef]

- Monni, F.; Quagliarini, E.; Lenci, S. Pre-Tensioned Basalt Fibers Ropes Stitching for Masonry Strengthening against Vertical Bending: A First Experimental Insight. Key Eng. Mater. 2017, 747, 119–127. [Google Scholar] [CrossRef]

- TRousakis, C.; Panagiotakis, G.D.; Archontaki, E.E.; Kostopoulos, A.K. Prismatic RC columns externally confined with FRP sheets and pretensioned basalt fiber ropes under cyclic axial load. Compos. Part B 2019, 163, 96–106. [Google Scholar] [CrossRef]

- Phong, N.H.; Matsumoto, A.; Shimomura, T.; Sekijima, K. Seismic Retrofitting of Reinforced Concrete Columns with Continuous Fiber Rope. Proc. Jpn. Concr. Inst. 2006, 28, 1171–1176. [Google Scholar]

- Pan, J.; Wang, X.; Dong, H. Strengthening of Precast RC Frame to Mitigate Progressive Collapse by Externally Anchored Carbon Fiber Ropes. Polymers 2021, 13, 1306. [Google Scholar] [CrossRef]

- Ali, M. Seismic performance of coconut-fiber-reinforced-concrete columns with different reinforcement configurations of coconut-fiber ropes. Constr. Build. Mater. 2017, 70, 226–230. [Google Scholar] [CrossRef]

- Ali, M.; Chouw, N. Experimental investigations on coconut-fiber rope tensile strength and pullout from coconut fiber reinforced concrete. Constr. Build. Mater. 2013, 41, 681–690. [Google Scholar] [CrossRef]

- Abdulla, K.F.; Cunningham, L.S.; Gillie, M. Out-of-plane strengthening of adobe masonry using hemp fiber ropes: An experimental investigation. Eng. Struct. 2021, 245, 112931. [Google Scholar] [CrossRef]

- Hussain, Q.; Ruangrassamee, A.; Joyklad, P.; Wijeyewickrema, A.C. Shear Enhancement of RC Beams Using Low-Cost Natural Fiber Rope Reinforced Polymer Composites. Buildings 2022, 12, 602. [Google Scholar] [CrossRef]

- Alraie, A.; Spadea, S.; Matsagar, V. Enhanced sustainability through strengthening of existing structures with natural fiber ropes. Procedia Struct. Integr. 2024, 64, 1943–1950. [Google Scholar] [CrossRef]

- Quagliarini, E.; Monni, F.; Lenci, S.; Bondioli, F. Tensile characterization of basalt fiber rods and ropes: A first contribution. Constr. Build. Mater. 2012, 34, 372–380. [Google Scholar] [CrossRef]

- Quagliarini, E.; Monni, F.; Bondioli, F.; Lenci, S. Basalt fiber ropesandrods:Durabilitytestsfortheiruseinbuilding engineering. J. Build. Eng. 2016, 5, 142–150. [Google Scholar] [CrossRef]

- Liang, J.; Wu, C.; Ping, H.; Wang, M.; Tang, W. Surface Pretreatment and Fabrication Technology of Braided Carbon Fiber Rope Aluminum Matrix Composite. Metals 2020, 10, 1212. [Google Scholar] [CrossRef]

- Sry, V.; Jung, D.Y.; Mizutani, Y.; Endo, G.; Todoroki, A. Effect of preload treatment on elastic modulus of braided synthetic fiber rope for static loading. J. Text. Inst. 2021, 112, 286–292. [Google Scholar] [CrossRef]

- Bain, C.; Davies, P.; Bles, G.; Marco, Y.; Barnet, J. Influence of bedding-in on the tensile performance of HMPE fiber ropes. Ocean. Eng. 2020, 203, 107144. [Google Scholar] [CrossRef]

- Durmuş-Sayar, A.; Tansan, M.; Çinko-Çoban, T.; Serttan, D.; Dizman, B.; Yildiz, M.; Ünal, S. Incorporation of Graphene Nanoplatelets into Fiber-Reinforced Polymer Composites in the Presence of Highly Branched Waterborne Polyurethanes. Polymers 2024, 16, 828. [Google Scholar] [CrossRef] [PubMed]

- Acar, V.; Erden, S.; Sarıkanat, M.; Seki, Y.; Akbulut, H.; Seydibeyoğlu, M.Ö. Graphene oxide modified carbon fiber prepregs: A mechanical comparison of the effects of oxidation methods. Express Polym. Lett. 2020, 14, 1106–1115. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.Z.; Koratkar, N. Enhanced Mechanical Properties of Nanocomposites at Low Graphene Content. Acsnano 2009, 3, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Zaman, I.; Phan, T.T.; Kuan, H.C.; Meng, Q.; La, L.T.B.; Luong, L.; Youssf, O.; Ma, J. Epoxy/graphene platelets nanocomposites with two levels of interface strength. Polymer 2011, 52, 1603–1611. [Google Scholar] [CrossRef]

- Çakir, F.; Uysal, H. Experimental modal analysis of brick masonry arches strengthened prepreg composites. J. Cult. Herit. 2015, 16, 284–292. [Google Scholar] [CrossRef]

- Çakir, F.; Uysal, H.; Acar, V. Experimental modal analysis of masonry arches strengthened with graphene nanoplatelets reinforced prepreg composites. Measurement 2016, 90, 233–241. [Google Scholar] [CrossRef]

- Acar, V.; Çakir, F.; Uysal, H.; Seydibeyoğlu, M.Ö.; Akbulut, H.; Mosalam, K.M. Strengthening of concrete beams by monolayer prepreg composites with and without graphene reinforcement. Constr. Build. Mater. 2017, 151, 866–880. [Google Scholar] [CrossRef]

- Cakir, F.; Acar, V.; Zulfikar, A.C.; Tutar, A.I. A novel strengthening process for masonry tower-type structures with irregular geometry using carbon fiber composite ropes. Bull. Earthq. Eng. 2025. [Google Scholar] [CrossRef]

- Technical Datasheet. Teknobond 330 Epoxy Based Adhesive and Lamination Resin, Tekno Construction Chemicals. Available online: https://www.teknoyapi.com.tr/en/products/construction-reinforcement-products/teknobond-330-epoxy-based-adhesive-and-lamination-resin (accessed on 20 August 2025).

- Chen, L.; Zhao, Y.; Li, M.; Li, L.; Hou, L.; Hou, H. Reinforced AZ91D magnesium alloy with thixomolding process facilitated dispersion of graphene nanoplatelets and enhanced interfacial interactions. Mater. Sci. Eng. A 2021, 804, 140793. [Google Scholar] [CrossRef]

- ASTM D792-13; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2013.

| 0% GNP | 0.5% GNP | 1% GNP | 2% GNP | |

|---|---|---|---|---|

| GF | 1.85 ± 0.09 | 1.81 ± 0.03 | 1.81 ± 0.02 | 1.88 ± 0.02 |

| BF | 1.86 ± 0.07 | 1.87 ± 0.03 | 1.97 ± 0.02 | 1.53 ± 0.02 |

| CF | 1.54 ± 0.02 | 1.54 ± 0.01 | 1.59 ± 0.01 | 1.56 ± 0.01 |

| Flexural Strength (MPa) | Compressive Strength (MPa) | Buckling Peak Load (N) | |

|---|---|---|---|

| GF Rope Comp. | 133.88 ± 18.84 | 52.60 ± 4.49 | 1040.63 ± 161.04 |

| GF Rope Comp. −0.5% GNP | 147.97 ± 7.59 | 57.38 ± 2.64 | 1190.53 ± 162.85 |

| GF Rope Comp. −1% GNP | 130.77 ± 11.28 | 66.70 ± 6.60 | 1179.79 ± 124.13 |

| GF Rope Comp. −2% GNP | 117.80 ± 11.07 | 73.38 ± 2.79 | 808.59 ± 82.58 |

| Flexural Strength (MPa) | Compressive Strength (MPa) | Buckling Peak Load (N) | |

|---|---|---|---|

| BF Rope Comp. | 125.66 ± 12.60 | 77.21 ± 5.05 | 1046.23 ± 45.27 |

| BF Rope Comp. −0.5% GNP | 123.81 ± 6.73 | 86.93 ± 7.27 | 1325.57 ± 60.33 |

| BF Rope Comp. −1% GNP | 112.02 ± 8.67 | 60.56 ± 10.98 | 1274.48 ± 99.76 |

| BF Rope Comp. −2% GNP | 114.54 ± 5.77 | 74.99 ± 7.48 | 1302.09 ± 186.98 |

| Flexural Strength (MPa) | Compressive Strength (MPa) | Buckling Peak Load (N) | |

|---|---|---|---|

| CF Rope Comp. | 109.22 ± 4.32 | 46.50 ± 4.35 | 1369.54 ± 155.44 |

| CF Rope Comp. −0.5% GNP | 111.06 ± 7.16 | 53.08 ± 1.94 | 1470.32 ± 127.45 |

| CF Rope Comp. −1% GNP | 113.30 ± 7.09 | 58.45 ± 7.53 | 1226.57 ± 160.16 |

| CF Rope Comp. −2% GNP | 121.77 ± 7.05 | 61.73 ± 2.12 | 1115.63 ± 48.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haberdar, A.E.; Acar, V.; Cakir, F. Mechanical Characterization of Graphene-Enhanced Fiber Rope Composites for Strengthening-Oriented Applications. Polymers 2025, 17, 2304. https://doi.org/10.3390/polym17172304

Haberdar AE, Acar V, Cakir F. Mechanical Characterization of Graphene-Enhanced Fiber Rope Composites for Strengthening-Oriented Applications. Polymers. 2025; 17(17):2304. https://doi.org/10.3390/polym17172304

Chicago/Turabian StyleHaberdar, Ahmet E., Volkan Acar, and Ferit Cakir. 2025. "Mechanical Characterization of Graphene-Enhanced Fiber Rope Composites for Strengthening-Oriented Applications" Polymers 17, no. 17: 2304. https://doi.org/10.3390/polym17172304

APA StyleHaberdar, A. E., Acar, V., & Cakir, F. (2025). Mechanical Characterization of Graphene-Enhanced Fiber Rope Composites for Strengthening-Oriented Applications. Polymers, 17(17), 2304. https://doi.org/10.3390/polym17172304