Wrinkling Analysis and Process Optimization of the Hydroforming Processes of Uncured Fiber Metal Laminates for Aircraft Fairing Structures

Abstract

1. Introduction

2. Materials and Methods

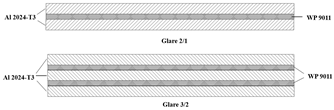

2.1. Materials

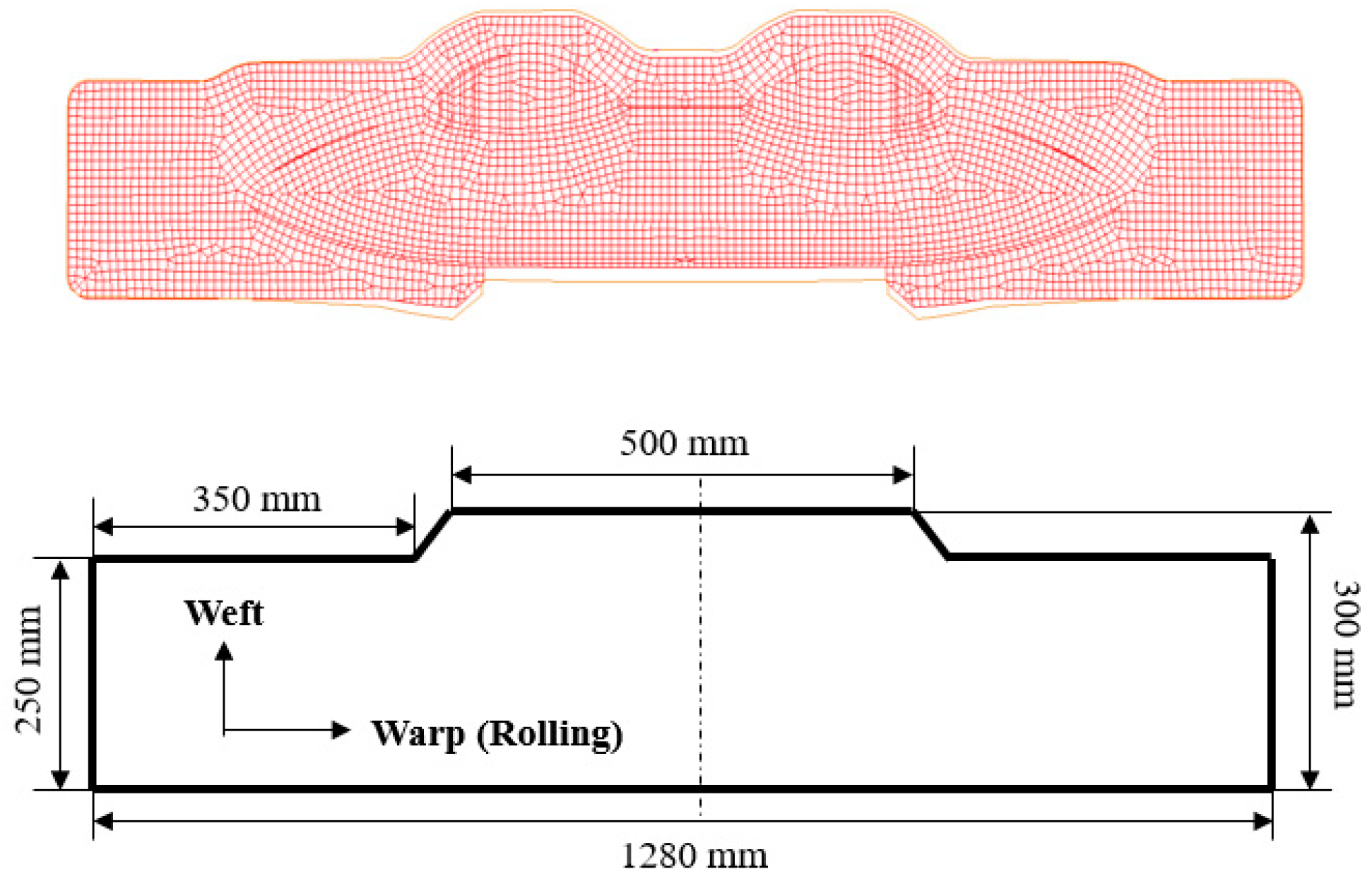

2.2. Structures

2.3. Hydroforming

2.4. Numerical Simulations

3. Results and Discussion

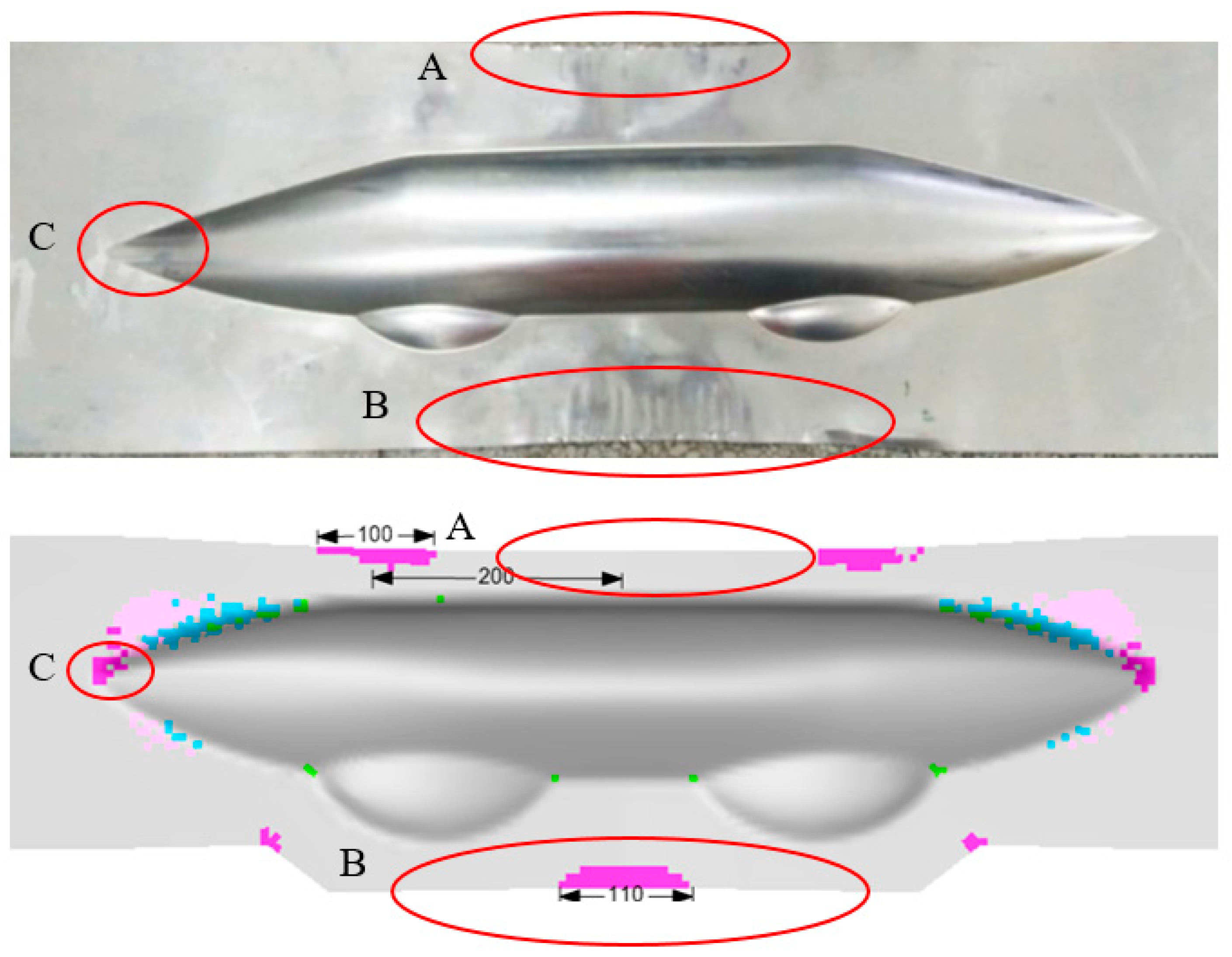

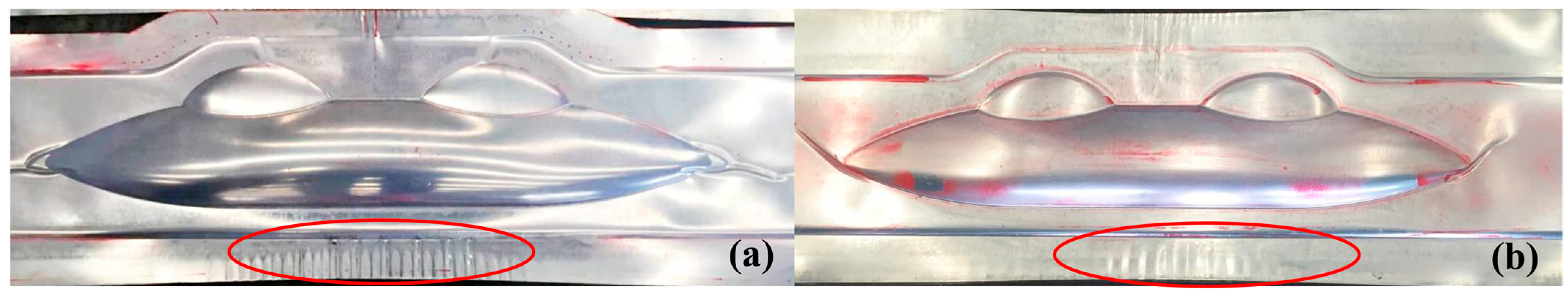

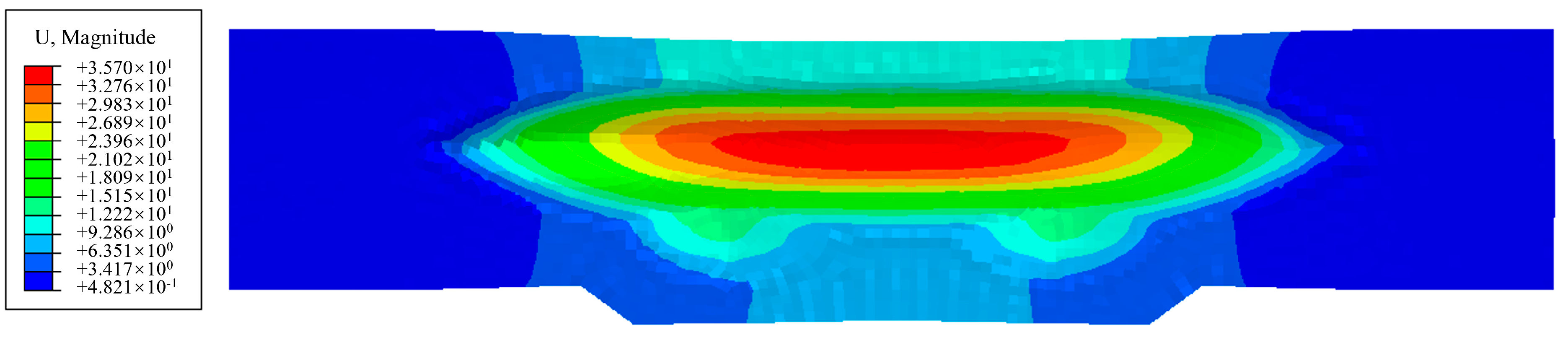

3.1. Part Wrinkling Analysis

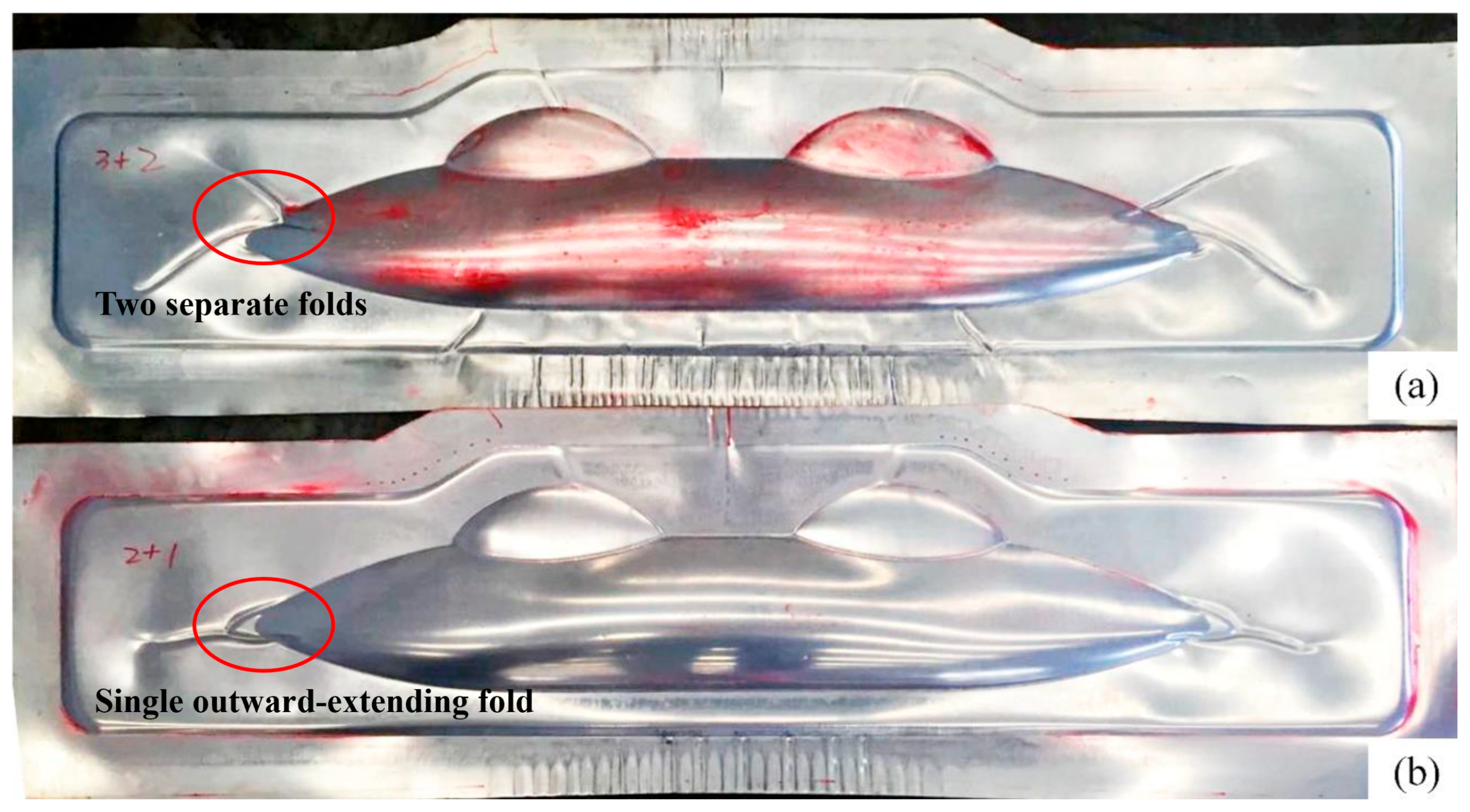

3.2. Process Parameter Optimization

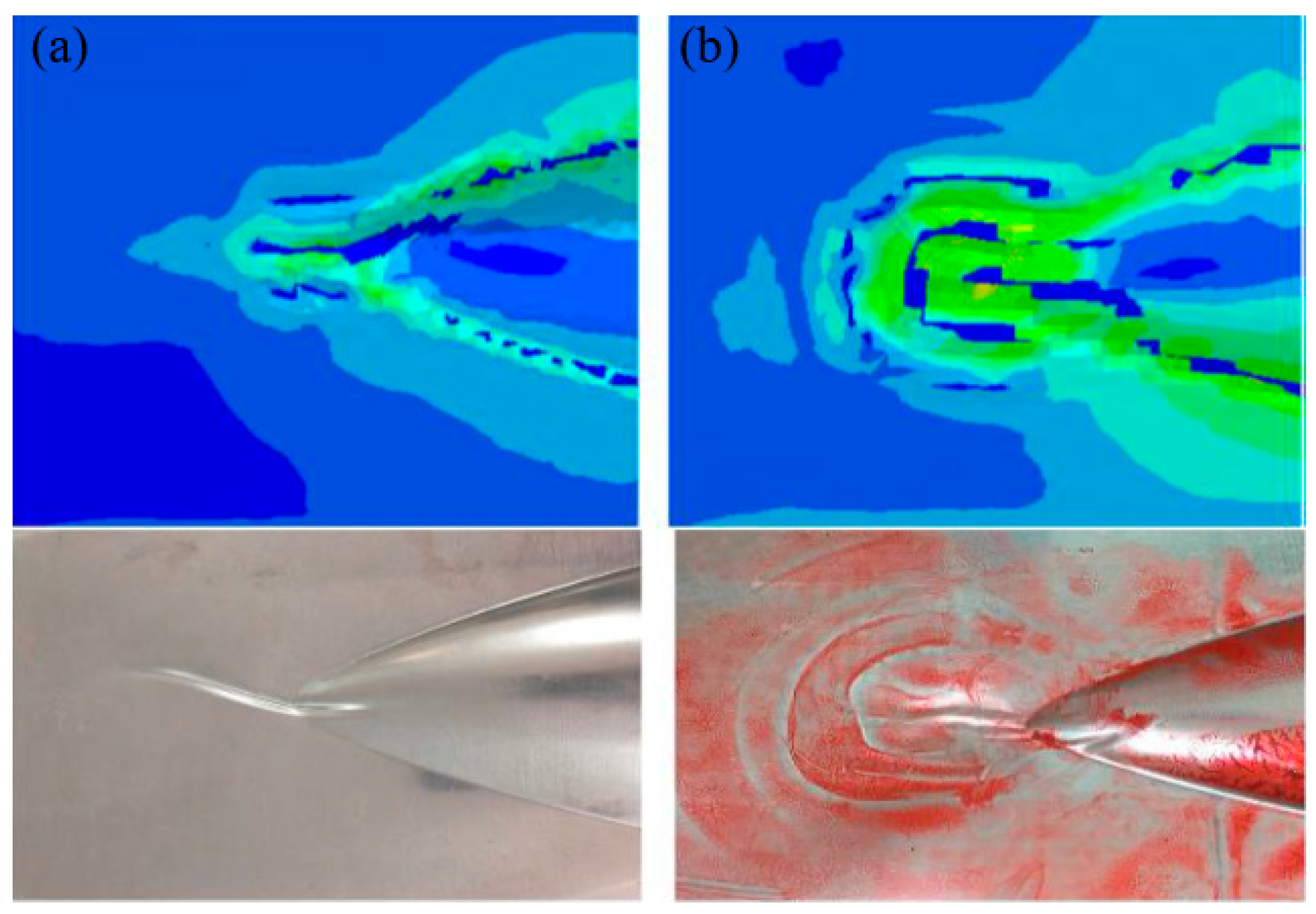

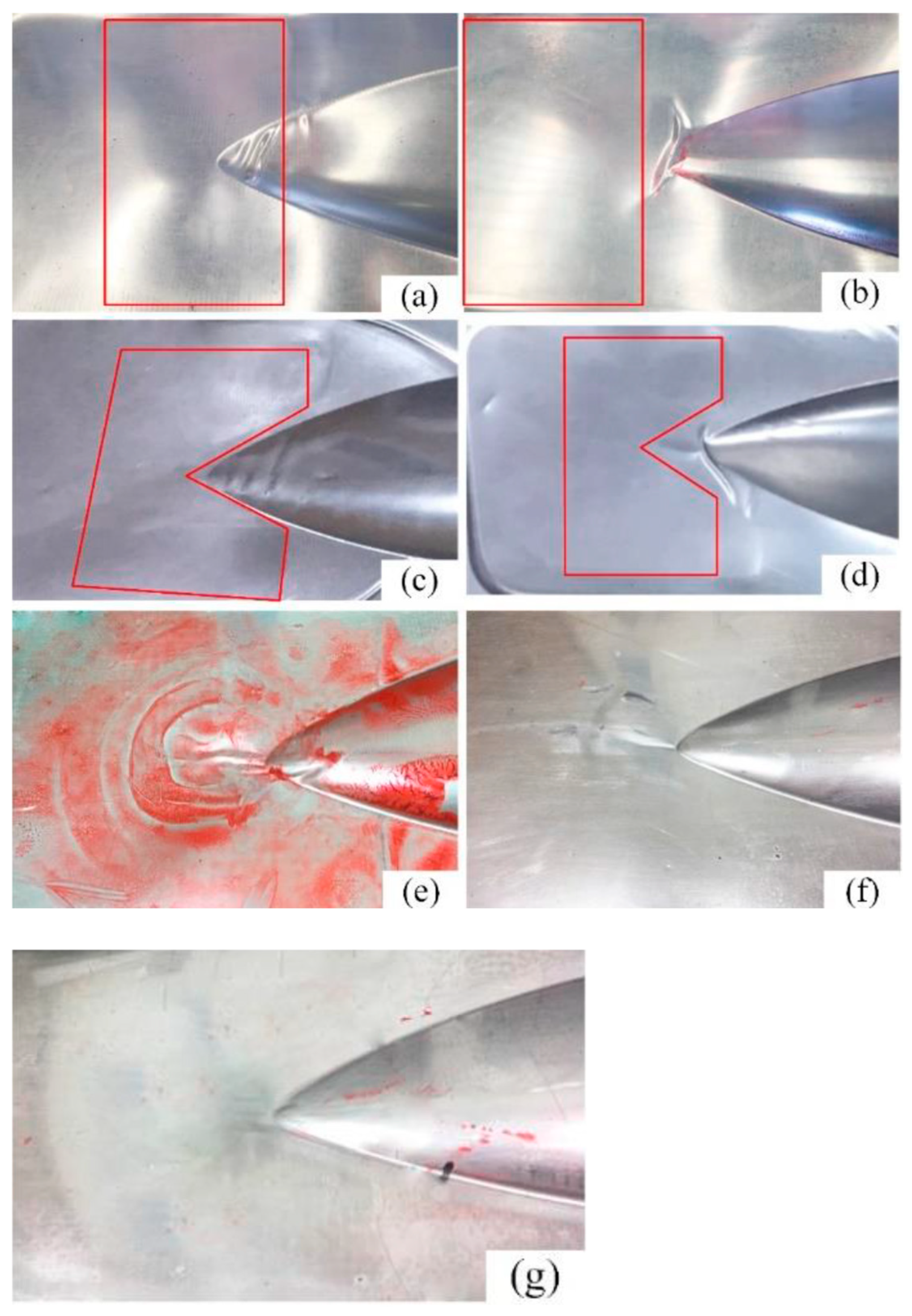

3.3. Local Support Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Asundi, A.; Choi, A.Y.N. Fiber metal laminates: An advanced material for future aircraft. J. Mater. Process Technol. 1997, 63, 384–394. [Google Scholar] [CrossRef]

- Sinmazçelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Kavitha, K.; Vijayan, R.; Sathishkumar, T. Fibre-metal laminates: A review of reinforcement and formability characteristics. Mater. Today Proc. 2020, 22, 601–605. [Google Scholar] [CrossRef]

- Ersoy, N.; Potter, K.; Wisnom, M.R.; Clegg, M.J. An experimental method to study the frictional processes during composites manufacturing. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1536–1544. [Google Scholar] [CrossRef]

- Fetfatsidis, K.A.; Jauffrès, D.; Sherwood, J.A.; Chen, J. Characterization of the tool/fabric and fabric/fabric friction for woven-fabric composites during the thermostamping process. Int. J. Mater. Form. 2013, 6, 209–221. [Google Scholar] [CrossRef]

- Khan, M.A.; Reynolds, N.; Williams, G.; Kendall, K.N. Processing of thermoset prepregs for high-volume applications and their numerical analysis using superimposed finite elements. Compos. Struct. 2015, 131, 917–926. [Google Scholar] [CrossRef]

- Pasco, C.; Kendall, K. Characterisation of the thermosetprepreg compression molding process. In Proceedings of the ACCE SPE 2016, Detroit, MI, USA, 7–9 September 2016. [Google Scholar]

- Sinke, J. Manufacturing of GLARE Parts and Structures. Appl. Compos. Mater. 2003, 10, 293–305. [Google Scholar] [CrossRef]

- Sinke, J. Feasibility of tailoring of press formed thermoplastic composite parts. AIP Conf. Proc. 2018, 1960, 020030. [Google Scholar] [CrossRef]

- Nardi, D.; Abouhamzeh, M.; Leonard, R.; Sinke, J. Investigation of kink induced defect in aluminium sheets for Glare manufacturing. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105531. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, W.J.; Choi, H.S. A comparative study on the properties of GLARE laminates cured by autoclave and autoclave consolidation followed by oven postcuring. Int. J. Adv. Manuf. Technol. 2010, 49, 605–613. [Google Scholar] [CrossRef]

- Liu, C.; Du, D.; Li, H.; Hu, Y.; Xu, Y.; Tian, J.; Tao, G.; Tao, J. Interlaminar failure behavior of GLARE laminates under short-beam three-point-bending load. Compos. Part B Eng. 2016, 97, 361–367. [Google Scholar] [CrossRef]

- Zafar, R.; Lang, L.; Zhang, R.J. Experimental and numerical evaluation of multilayer sheet forming process parameters for light weight structures using innovative methodology. Int. J. Mater. Form. 2016, 9, 35–47. [Google Scholar] [CrossRef]

- Zhang, R.; Lang, L.; Zafar, R. FEM-based strain analysis study for multilayer sheet forming process. Front. Mech. Eng. 2015, 10, 373–379. [Google Scholar] [CrossRef]

- Liu, S.; Lang, L.; Guan, S. An Investigation into the Formability and Processes of GLARE Materials Using Hydro-Bulging Test. Int. J. Precis. Eng. Manuf. 2019, 20, 121–128. [Google Scholar] [CrossRef]

- Liu, S.; Sinke, J.; Dransfeld, C. An inter-ply friction model for thermoset based fibre metal laminate in a hot-pressing process. Compos. Part B Eng. 2021, 227, 109400. [Google Scholar] [CrossRef]

- Liu, S.; Sinke, J.; Dransfeld, C. A modified bias-extension test method for the characterisation of intra-ply shear deformability of hybrid metal-composite laminates. Compos. Struct. 2023, 314, 116964. [Google Scholar] [CrossRef]

- Liu, S.; Sinke, J.; Dransfeld, C. Experimental characterisation of cure-dependent spring-back behaviour of metal composite laminates in a hot-pressing process. Appl. Compos. Mater. 2025, 32, 173–198. [Google Scholar] [CrossRef]

- Liu, S.; Lang, L.; Sherkatghanad, E.; Wang, Y. Investigation into the Fiber Orientation Effect on the Formability of GLARE Materials in the Stamp Forming Process. Appl. Compos. Mater. 2018, 25, 255–267. [Google Scholar] [CrossRef]

- Liu, S.; Lang, L.; Guan, S. Investigation into Composites Property Effect on the Forming Limits of Multi-Layer Hybrid Sheets Using Hydroforming Technology. Appl. Compos. Mater. 2019, 26, 205–217. [Google Scholar] [CrossRef]

- Abedrabbo, N.; Zampaloni, M.A.; Pourboghrat, F. Wrinkling control in aluminum sheet hydroforming. Int. J. Mech. Sci. 2005, 47, 333–358. [Google Scholar] [CrossRef]

- Lang, L.; Danckert, J.; Nielsen, K. Multi-layer sheet hydroforming: Experimental and numerical investigation into the very thin layer in the middle. J. Mater. Process. Technol. 2005, 170, 524–535. [Google Scholar] [CrossRef]

- Heggemann, T.; Homberg, W. Deep drawing of fiber metal laminates for automotive lightweight structures. Compos. Struct. 2019, 216, 53–57. [Google Scholar] [CrossRef]

- Çinar, K.; Ersoy, N. Effect of fiber wrinkling to the spring-in behaviour of L-shaped composite materials. Compos. Part A Appl. Sci. Manuf. 2015, 69, 105–114. [Google Scholar] [CrossRef]

- Prodromou, A.; Chen, J. On the relationship between shear angle and wrinkling of textile composite preforms. Compos. Part A Appl. Sci. Manuf. 1997, 28, 491–503. [Google Scholar] [CrossRef]

- Hancock, S.; Potter, K. The use of kinematic drape modelling to inform the hand lay-up of complex composite components using woven reinforcements. Compos. Part A Appl. Sci. Manuf. 2006, 37, 413–422. [Google Scholar] [CrossRef]

- ASTM E8; ASTM E8/E8M Standard Test Methods for Tension Testing of Metallic Materials. ASTM: West Conshohocken, PA, USA, 2010.

- ASTM D3039; ASTM D-3039 Standard Test Methods for Tension Testing of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 1995.

- Package, S. ETA/DYNAFORM Application Manual; Engineering Technology Associates, Inc.: Troy, MI, USA, 2009. [Google Scholar]

- Zhu, J. Investigation of the Low Velocity Impact on Advanced Hybrid Laminates: Improving the Impact Resistance of CFRP Laminates by Embedding Metal Constituents. Master Thesis, Delft University of Technology, Delft, The Netherlands, 2018. [Google Scholar]

| Type | Materials | Lay-Ups | Total Thickness/mm | |

|---|---|---|---|---|

| 1 | Aluminum alloy | Single Layer | 0.3 | |

| 2 | Aluminum alloy + glass fiber prepreg | Glare 2/1 | 0.8 |  |

| 3 | Aluminum alloy + glass fiber prepreg | Glare 3/2 | 1.3 |

| Material Type | Blank Holder Force () | Cavity Pressure () |

|---|---|---|

| Al 2024-T3-0.3 | 1500 1700 | 20 22 |

| Glare 2/1-0.3 | 2000 2200 | 25 28 |

| Glare 3/2-0.3 | 2500 | 30 |

| Definition | Value |

|---|---|

| Density (kg/m3) | |

| Initial penalty stiffness (MPa/m) | |

| Damage initiation strength (MPa) | |

| Fracture toughness (N/m) | |

| Mixed-mode fit parameter |

| Group | Local Support Material | Maximum Wrinkle Length (mm) | Control Effect |

|---|---|---|---|

| 0 | No | 22.8 | Severe wrinkles |

| a | 10 mm square steel plate | 14.2 | Severe wrinkles |

| b | 10 mm square steel plate | 16.5 | Severe wrinkles |

| c | 10 mm conformal steel plate | 9.7 | Slight wrinkles |

| d | 10 mm conformal steel plate | 12.4 | Severe wrinkles |

| e | 5 mm conformal polyurethane rubber with 5 mm local steel plate | 8.8 | Slight wrinkles |

| f | 5 mm conformal polyurethane rubber with 5 mm local polyurethane rubber | 6.5 | Slight wrinkles |

| g | 1 mm conformal steel plate with 9 mm local polyurethane rubber | 0.3 | No wrinkles |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Liu, S. Wrinkling Analysis and Process Optimization of the Hydroforming Processes of Uncured Fiber Metal Laminates for Aircraft Fairing Structures. Polymers 2025, 17, 2267. https://doi.org/10.3390/polym17162267

Chen Y, Liu S. Wrinkling Analysis and Process Optimization of the Hydroforming Processes of Uncured Fiber Metal Laminates for Aircraft Fairing Structures. Polymers. 2025; 17(16):2267. https://doi.org/10.3390/polym17162267

Chicago/Turabian StyleChen, Yunlong, and Shichen Liu. 2025. "Wrinkling Analysis and Process Optimization of the Hydroforming Processes of Uncured Fiber Metal Laminates for Aircraft Fairing Structures" Polymers 17, no. 16: 2267. https://doi.org/10.3390/polym17162267

APA StyleChen, Y., & Liu, S. (2025). Wrinkling Analysis and Process Optimization of the Hydroforming Processes of Uncured Fiber Metal Laminates for Aircraft Fairing Structures. Polymers, 17(16), 2267. https://doi.org/10.3390/polym17162267