Optimization and Validation of CO2 Laser-Machining Parameters for Wood–Plastic Composites (WPCs)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Equipment

2.2. Experimental Design

2.3. Response Measures and Data Collection

- Cutting Depth: The depth of the laser cut into the material, measured in millimetres (mm). If the laser fully cut through the 18 mm panel, the depth was recorded as 18 mm (full penetration). For cuts that did not fully penetrate, the depth of the kerf was measured by examining the cut cross-section. A thin feeler gauge (0.5 mm thickness) and a calliper were used initially to probe and measure depths, and for more precise measurement the samples were later cross-sectioned and examined under an optical microscope with a measurement reticle. The maximum depth of the kerf from the top surface was recorded to the nearest 0.5 mm. Figure 4 illustrates a representative WPC sample machined at a feed rate of 2000 mm/min, using a 1500 W CO2 laser and an assist-gas pressure of 1 bar.

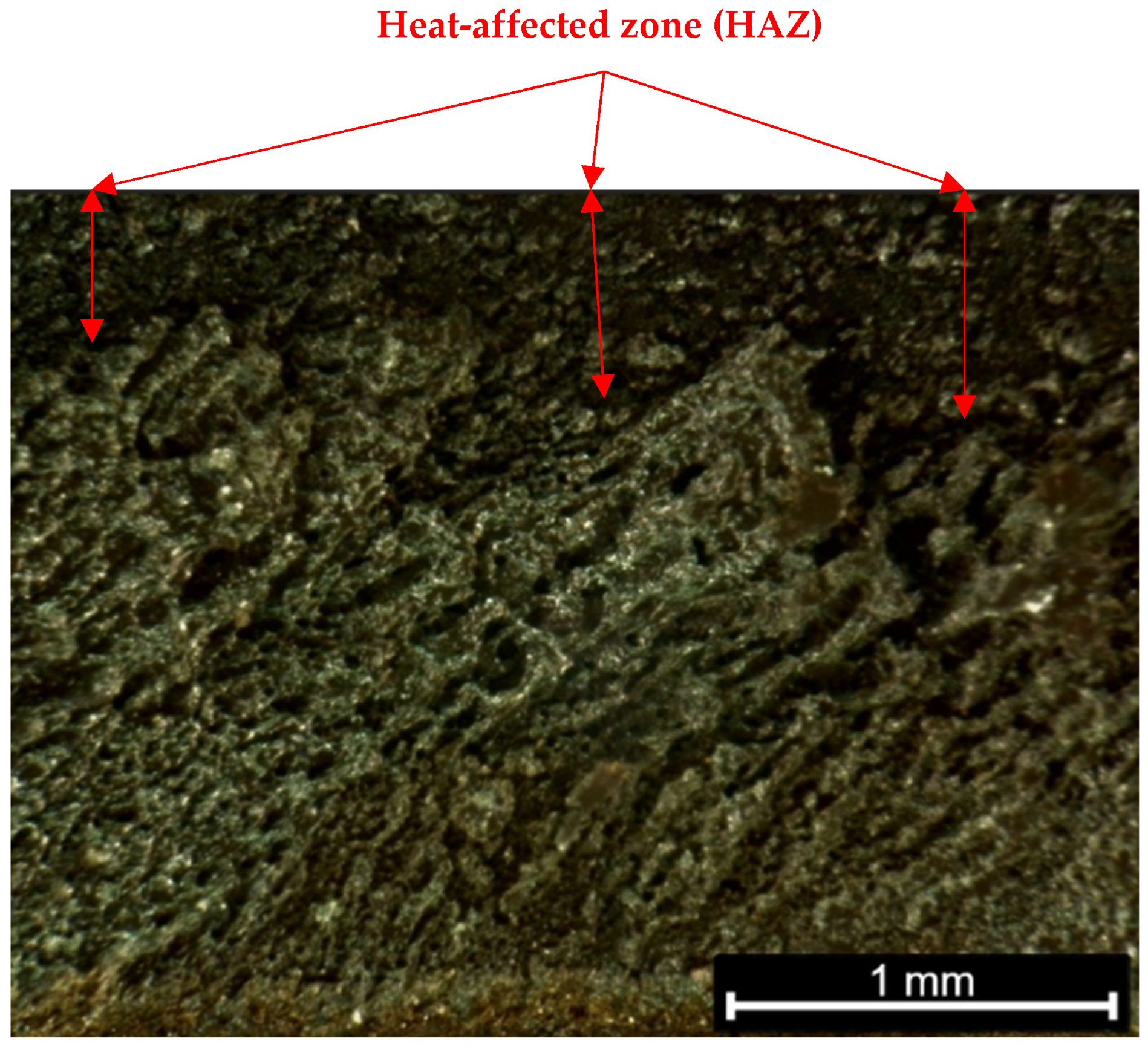

- Heat-Affected Zone (HAZ) Width: The width of the thermally affected region adjacent to the cut, measured in millimetres. This was determined by visual inspection of the cut cross-sections and surface (see Figure 5), looking for the darkened or charred band along the cut edges. The HAZ width was measured on the top surface of the cut using a calibrated optical microscope (at 5× magnification) with an in-built scale. Two measurements were taken on each side of the kerf (if present) for each cut, and the average HAZ width on either side was recorded. In cases of full penetration, HAZ was measured at both the top and bottom cut edges. For consistency, the reported HAZ width refers to the top surface HAZ (which was typically larger than the bottom due to the focus position and gravity-assisted debris removal).

- Cut-Edge Profile Quality: A qualitative rating of the cut-edge geometry and integrity, focusing on kerf width and edge straightness/taper. After each cut, the cut face (profile) of the sample was inspected. Cuts that fully penetrated produced a detached piece, allowing direct observation of the cut edge; partial cuts were examined by cutting the sample to expose the kerf. The cut profile quality was scored on a subjective scale (1 to 5) based on smoothness and consistency of the kerf: a higher score indicated a straighter, smoother kerf with minimal taper or irregularities, whereas a lower score indicated irregular or tapered kerf profiles (e.g., top and bottom kerf misalignment or non-uniform width). Two independent observers scored each cut, and the average was taken as the cutting profile score.

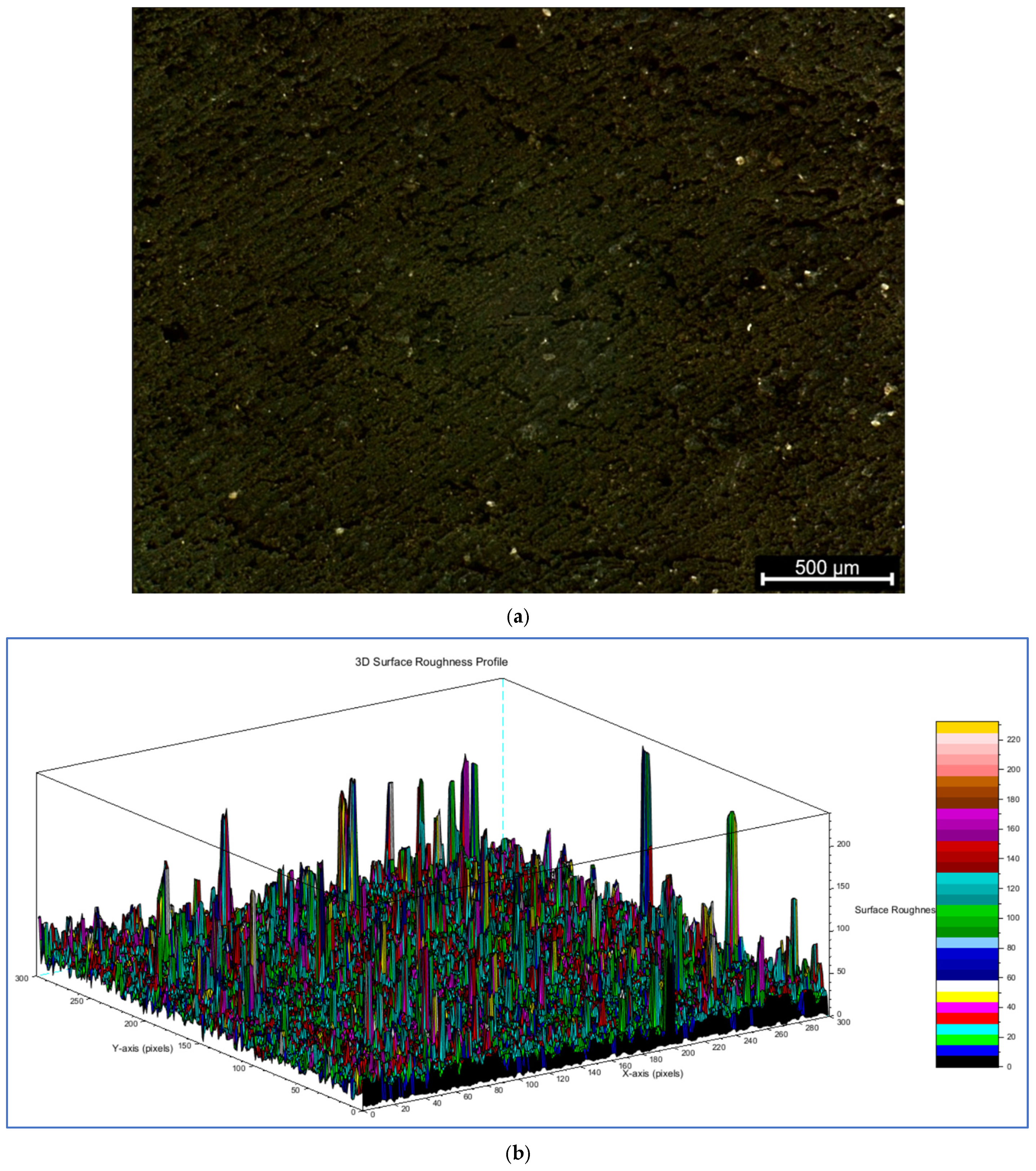

- Surface Finish Quality: A qualitative assessment of the cut surface (the side walls of the kerf) in terms of roughness and charring. This was also rated on a 1 to 5 scale, where a higher score corresponds to a smoother, cleaner cut surface with little residue or char, and a lower score corresponds to a rough or heavily charred surface. Photomicrographs of the cut surfaces were taken using a digital microscope for documentation. Additionally, for cuts that did not go through, the bottom of the kerf was inspected to see if there was residual material or incomplete cutting. The surface quality rating emphasizes visual smoothness and absence of adhered debris. Figure 6 illustrates the evaluation of three sides.

2.4. Statistical Analysis and Optimization Procedure

- Multivariate Analysis of Variance (MANOVA): A two-way MANOVA was first performed considering the two factors (feed rate and gas pressure) and the four response variables collectively. This multivariate approach tests whether there are overall differences in the vector of responses due to the factors. It is particularly appropriate here since the responses (depth, HAZ, profile, surface quality) are interrelated aspects of cut quality. The MANOVA results (Wilks’ Lambda, Pillai’s Trace, etc.) were used to confirm whether feed rate and gas pressure have a statistically significant impact on the combined outcomes, and whether there is a significant interaction between these factors.

- Analysis of Variance (ANOVA): Following a significant MANOVA, separate two-way ANOVAs were conducted for each response variable. This allowed identification of which factors significantly affect each individual metric. The ANOVAs included the main effects of feed rate and gas pressure and their interaction. Post hoc tests (Tukey’s HSD) were used to compare differences between specific levels (e.g., between 1000 vs. 2000 mm/min, or 1 bar vs. 3 bar) for responses where the factor effect was significant.

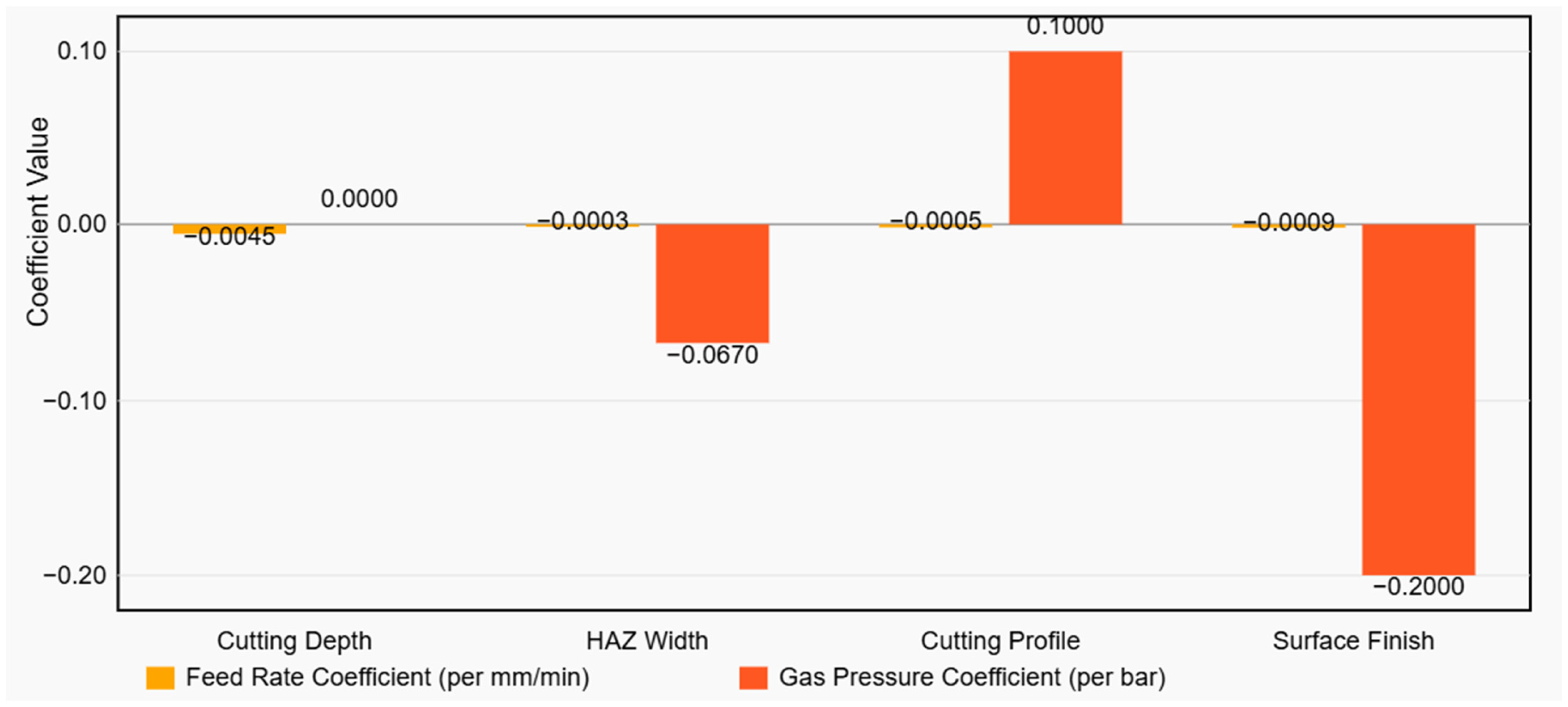

- Regression Modelling: To enable prediction and optimization, multiple linear regression models were developed for each response. The models are expressed in the form shown in Equation (1):

- Optimization Strategy: Using the regression models, an optimization analysis was performed to identify favourable combinations of feed rate and gas pressure for different objectives. Rather than a single “global” optimum, it was sought to determine parameter trade-offs that would optimize specific goals:

- Maximum Cutting Depth: Find conditions that maximize depth of cut (important for through-cutting thick WPC).

- Minimum HAZ/Best Quality: Find conditions that minimize HAZ and maximize surface/profile quality (important for achieving clean, precise cuts).

- Balanced Performance: Identify a middle-ground setting that provides a reasonable compromise between depth and cut quality, for cases where both penetration and quality are needed. These optimization targets were informed by the regression trends. Because the objectives conflict (e.g., deeper cuts require slower speed, but slower speed worsens HAZ), the optimal parameters differ depending on the priority. Therefore, a multi-objective optimization approach was implicitly taken by examining the regression surfaces and selecting points that best satisfy each objective. Formal multi-objective algorithms were not applied; instead, engineering judgement and model predictions were used to pinpoint recommended settings (which conveniently corresponded to or near the tested factor levels).

- Validation Trials: After determining the recommended parameter settings from the model (for each objective scenario), additional laser-cutting trials were conducted at those settings to validate the model predictions. These validation trials involved cutting new WPC samples using the optimal feed rate and gas pressure combinations, then measuring the same responses (depth, HAZ, etc.) to see if the outcomes match the predicted improvements. By comparing the validation results with model-predicted values and with the original experimental data, it can confirm whether the optimization truly yields better performance and ensure the results are reproducible.

3. Results

3.1. Experimental Results: Effects of Feed Rate and Gas Pressure

3.2. Regression Models for Predictive Optimization

3.3. Optimization of Laser Parameters and Validation Trials

- Maximum Penetration: If the goal is to ensure full cut-through of the 18 mm thick WPC, a slow feed rate should be used, since depth is maximized at the lowest feed. Experimental results indicate that 1000 mm/min was sufficient to achieve full depth in one pass at 1500 W. In terms of gas pressure, the depth does not depend on it, so one might choose a lower gas setting if depth is the sole concern. However, to avoid excessive charring when going slow, at least a moderate gas flow is beneficial. It is recommended to apply the p1000 mm/min with 1–2 bar assist gas. Based on these experiments, 1000 mm/min at 1 bar achieved 18 mm depth (full cut) with heavy char, whereas 1000 mm/min at 3 bar achieved 18 mm depth with somewhat less char. Thus, using some gas (even though it does not improve depth) will help maintain edge quality in the slow-feed scenario.

- Minimum HAZ/Best Quality: If the priority is to minimize thermal damage and produce the cleanest possible cut (even if depth is sacrificed), a fast feed rate and high gas pressure are optimal. It is recommended that 3000 mm/min with 3 bar assist gas for this objective (see Figure 13). At 3000 mm/min, the HAZ was minimal (~0.3–0.5 mm) and the cut edges were very clean, especially with maximum gas flow expelling debris. The trade-off is that this setting will not fully penetrate an 18 mm panel (only ~9 mm deep in one pass). However, for applications such as surface grooving, engraving, or if multiple passes are acceptable, this setting yields the highest quality cut surfaces. Notably, this combination essentially halves the HAZ width compared to the worst-case scenario and yields nearly char-free edges.

- Balanced Cutting (Depth and Quality): For many practical situations, a compromise is desired, i.e., achieving sufficient penetration while also maintaining good edge quality. The model and experiments suggest that an intermediate feed rate around 2000 mm/min with a moderate-to-high gas pressure (≈2 bar) strikes a good balance. Specifically, 2000 mm/min and 2 bar was found to be a balanced setting: in one pass it cut to ~15 mm depth (so almost through the panel, perhaps requiring a second pass or slight backside cutting to finish), and it produced moderate HAZ (~0.6 mm) with acceptable char that could be cleaned. At 2000 mm/min, using 3 bar further improved the surface (HAZ maybe down to 0.5 mm), so if the gas supply can be maximized, it is beneficial. Thus, it can generalize that the balanced recommendation as ≈2000 mm/min with ≥2 bar assist gas for cases where both penetration and quality are important.

- At 1000 mm/min, 1 bar (maximum depth setting), the validation cut fully penetrated the 18 mm WPC as expected. The measured HAZ in the validation cut was about 1.1 mm, and the edges were heavily charred, consistent with earlier trials at this condition. This confirms that the slow speed ensures full cutting, but quality is poor. A second validation cut at 1000 mm/min, 3 bar showed again full penetration, and this time the HAZ was ~0.8 mm—demonstrating that upping the gas pressure at slow feed does help reduce HAZ (roughly 25–30% reduction in this case), although it cannot fully eliminate char due to the long exposure time.

- At 3000 mm/min, 3 bar (high-quality setting), the validation cut did not fully pierce the material (depth was measured ~9 mm, matching the prior result). Crucially, the cut edges from the top down to that depth were extremely clean: the HAZ measured only ~0.3 mm on the top surface, and the cut surface had almost no visible charring. The bottom of the kerf (where the laser beam energy attenuated) showed that the cut was terminating gradually, but even there the material was slightly charred only at the very tip. These observations match the prediction that this setting yields superb surface quality at the expense of depth. If a through-cut were attempted at this speed, multiple passes would be required; however, each pass would produce minimal additional HAZ since most charring occurs in the first pass and subsequent passes remove previously charred material (this was not explicitly tested, but is a known phenomenon in multi-pass laser cutting of thick sections).

- At 2000 mm/min, 2 bar (balanced setting), the validation cut achieved approximately 14–15 mm depth out of 18 mm (around 80% penetration). The HAZ was measured around 0.6 mm, and moderate char was present but significantly less than in the 1000 mm/min case. The top edge was reasonably clean with only a thin soot line, and the surface finish inside the kerf was fairly smooth (some striations from the cutting path were evident). These results align well with the compromise nature of this setting: one pass nearly cuts through, and the quality is decent. Interestingly, when a second pass on the same cut was attempted (at 2000 mm/min, 2 bar), the beam easily cut through the remaining thickness and the combined HAZ did not grow much beyond ~0.7 mm, indicating that the second pass did not overheat the material significantly. This suggests that for industrial practice, one could use an intermediate speed with multiple passes to both achieve full depth and still maintain a relatively small HAZ.

4. Discussion

4.1. Dominance of Feed Rate

4.2. Role of Assist-Gas Pressure

4.3. Parameter Interactions and Multi-Response Trade-Offs

4.4. Validation of Model Predictions

4.5. Comparison with Other Materials

4.6. Limitations and Future Work

4.7. Practical Application Guidelines for Industrial Use (Decking, Grooving, Panel Shaping)

4.8. Future Parameter Priorities for CO2 Cutting of Thick WPCs

- Laser power and power density (spot size/focus position): Raising power (or tightening the spot) increases energy per unit length at a given feed, which should recover depth at higher speeds while maintaining short thermal dwell; defocus and mid-thickness focal shifts can be tuned for symmetric kerf and reduced top-edge char. This extends our fixed-power findings and the preliminary rationale already noted in the paper.

- Pulsed operation/modulation (frequency, duty cycle, peak power): Pulsed CO2 (or modulated CW) can deliver high peak power with inter-pulse cooling, a known route to narrower HAZ in organic/polymer systems; systematic sweeps of frequency–duty cycle would quantify HAZ/depth trade-offs relative to our CW baseline.

- Multi-pass strategy (number of passes, inter-pass cooling): Our validation already showed a second pass at 2000 mm min−1 completed penetration with little HAZ growth; formalizing pass count and cool-time could enable ‘quality-first’ cutting (fast feed + high gas) while achieving full depth.

- Assist-gas composition, flow rate, and nozzle design: Beyond pressure, inert gases (N2, He) and higher mass flow should further suppress oxidation and improve plume evacuation in combustible WPCs; nozzle diameter/stand-off will modulate shear on the melt plume and kerf cleanliness.

- Dynamic focus and path control (lead-ins, corner dwell compensation): Active refocusing across thickness, plus motion strategies that limit local dwell at corners or starts/stops, should cut HAZ ‘hot spots’ while preserving edge geometry.

- Beam polarization and incidence angle: Although second-order for isotropic WPCs, linear vs. circular polarization and slight off-normal incidence may influence absorption and ejection asymmetry along fibre orientations; this is worth exploring for parts with directional lay or textured skins.

5. Conclusions

- Feed Rate versus Gas Pressure: Feed rate is the primary determinant of cutting depth in WPC laser cutting, with slower feed rates (e.g., 1000 mm/min) enabling full penetration of thick (18 mm) composites, whereas higher feed rates (3000 mm/min) result in shallower cuts. However, faster feed rates greatly improve cut quality, yielding narrower heat-affected zones and cleaner cut edges by reducing the thermal dwell time. Assist-gas pressure does not affect depth but plays a crucial role in minimizing thermal damage, i.e., higher pressures (3 bar) consistently reduced HAZ width and char, and improved edge and surface smoothness by cooling the cut zone and expelling debris.

- Interaction Effects: There is a trade-off interplay between feed rate and gas pressure for quality outcomes. High gas pressure is most beneficial under slow feed (high thermal load) conditions, whereas at fast feed the cut is already relatively clean. Both factors together significantly influence the overall cut quality, as confirmed by MANOVA. This means that optimal laser cutting of WPCs requires a balanced consideration of speed and gas flow to meet specific goals.

- Statistical Models: Linear regression models for each response (depth, HAZ, edge profile, surface finish) showed excellent predictive capability (R2 ≥ 0.96). These models quantitatively captured the trends: feed rate had a strong negative effect on depth and HAZ, and a mild effect on quality metrics, while gas pressure had a negligible effect on depth but a significant effect on reducing HAZ and improving quality. The models provide a practical tool for forecasting cut outcomes under different parameter settings and form the basis for optimization.

- Optimal Parameter Guidelines: Depending on the cutting objective, different parameter settings are optimal: (a) For maximum depth (single-pass through cutting of thick WPC), a slow feed (~1000 mm/min) with low-to-moderate gas pressure is recommended (ensuring full cut at the expense of more char, which can be mitigated by some gas flow). (b) For the highest quality (minimal HAZ and char), a fast feed (3000 mm/min) with high gas pressure (3 bar) is optimal, accepting that multiple passes or reduced depth per pass may be required. (c) For a balanced outcome that reasonably achieves both penetration and quality, an intermediate feed (~2000 mm/min) with at least 2 bar gas strikes a good compromise. These recommendations were validated experimentally and can serve as a reference for process planning.

- Validation and Practical Implications: The validation trials confirmed that the optimized settings perform as predicted, lending confidence to the use of these parameters in real applications. By implementing the recommended parameters, manufacturers can significantly improve cut quality (reducing HAZ by up to ~50% and eliminating most charring) without sacrificing necessary throughput or depth. This optimization enables the laser cutting of WPCs to be more feasible for industrial use, providing precision cutting with minimal thermal damage. The outcomes contribute to improved efficiency (less need for post-cut processing) and better product quality in WPC fabrication. Furthermore, the experimental and modelling approach demonstrated here can be extended to other material systems or additional parameters (like laser power or different assist gases) to further enhance laser-machining processes. The findings underscore the innovative contribution of this study in confirming the interactive effects of feed rate and gas pressure during CO2 laser cutting of thick WPCs. Through a multi-objective optimization framework, the research successfully balances penetration depth, surface integrity, and thermal damage. This dual focus on interaction analysis and parameter trade-offs provides a new direction for achieving quality-focused, energy-efficient laser machining of composite materials.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HAZ | Heat-affected zone |

| MANOVA | Multivariate analysis of variance |

| ANOVA | Analysis of variance |

| WPC | Wood–plastic composite |

References

- Klyosov, A.A. Wood–Plastic Composites; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Ashori, A. Wood–plastic composites as promising green-composites for automotive industries! Bioresour. Technol. 2008, 99, 4661–4667. [Google Scholar] [CrossRef] [PubMed]

- Najafi, S.K. Use of recycled plastics in wood plastic composites—A review. Waste Manag. 2013, 33, 1898–1905. [Google Scholar] [CrossRef] [PubMed]

- Kubovský, I.; Krišťák, Ľ.; Suja, J.; Gajtanska, M.; Igaz, R.; Ružiak, I.; Réh, R. Optimization of Parameters for the Cutting of Wood-Based Materials by a CO2 Laser. Appl. Sci. 2020, 10, 8113. [Google Scholar] [CrossRef]

- Tamrin, K.F.; Zakariyah, S.S.; Sheikh, N.A. Multi-criteria optimization in CO2 laser ablation of multimode polymer waveguides. Opt. Lasers Eng. 2015, 75, 48–56. [Google Scholar] [CrossRef]

- Sobri, M.S.; Ahmad Sobri, S.; Norizan, M.N.; Hermawan, A.; Mohamad Amini, M.H.; Mohamed, M.; Wan Ismail, W.O.A.S.; Mohamed Sultan, A.A. The Influence of Laser Cutting Parameters on the Heat-Affected Zone in Fast-Growing Malaysian Wood Species. J. Manuf. Mater. Process. 2025, 9, 54. [Google Scholar] [CrossRef]

- Ahmad Sobri, S.; Heinemann, R.; Whitehead, D. Development of laser drilling strategy for thick carbon fibre reinforced polymer composites (CFRP). Polymers 2020, 12, 2674. [Google Scholar] [CrossRef]

- Barněkhov, V.G.; McMillin, C.W.; Huber, H.A. Factors influencing laser cutting of wood. For. Prod. J. 1986, 36, 55–58. [Google Scholar]

- Domadi, M.K.; Ismail, M.I.S.; Yusoff, M.Z.M.; Pisal, M.H.M. Evaluation of cutting parameters on heat affected zone in wood plastic composites by pulsed fiber laser. J. Kejuruter. 2024, 36, 837–846. [Google Scholar] [CrossRef]

- Eltawahni, H.A.; Olabi, A.G.; Benyounis, K.Y. Investigating the CO2 laser cutting parameters of MDF wood composite material. Opt. Laser Technol. 2011, 43, 648–659. [Google Scholar] [CrossRef]

- Tamrin, K.F.; Moghadasi, K.; Sheikh, N.A. Experimental and numerical investigation on multi-pass laser cutting of natural fibre composite. Int. J. Adv. Manuf. Technol. 2020, 107, 1483–1504. [Google Scholar] [CrossRef]

- Masoud, F.; Sapuan, S.M.; Ariffin, M.K.A.M.; Nukman, Y.; Bayraktar, E. Experimental analysis of heat-affected zone (HAZ) in laser cutting of sugar palm fiber reinforced unsaturated polyester composites. Polymers 2021, 13, 706. [Google Scholar] [CrossRef]

- Nugroho, G.; Winarbawa, H. Investigation of Agel leaf fiber/unsaturated polyester composite cutting parameters using CO2 laser. In Proceedings of the 4th International Conference on Science and Technology (ICST 2018), Yogyakarta, Indonesia, 7–8 August 2018; IEEE: New York, NY, USA; pp. 2–6. [Google Scholar] [CrossRef]

- Singh, Y.; Singh, J.; Sharma, S.; Aggarwal, V.; Pruncu, C.I. Multi-objective optimization of kerf-taper and surface-roughness quality characteristics for cutting-operation on coir and carbon fibre reinforced epoxy hybrid polymeric composites during CO2-pulsed laser-cutting using RSM. Lasers Manuf. Mater. Process. 2021, 8, 157–182. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, C.; Xue, B.; Miao, Q.; Liu, J. Processing technology and experimental analysis of gas-assisted laser cut micro thin wood. BioResources 2020, 15, 5366–5378. [Google Scholar] [CrossRef]

- Jani, S.P.; Kumar, A.S.; Khan, M.A.; Kumar, M.U. Machinability of hybrid natural fiber composite with and without filler as reinforcement. Mater. Manuf. Process. 2016, 31, 1393–1399. [Google Scholar] [CrossRef]

- Koay, S.C.; Subramanian, V.; Chan, M.Y.; Pang, M.M.; Tsai, K.Y.; Cheah, K.H. Preparation and characterization of wood plastic composite made up of durian husk fiber and recycled polystyrene foam. MATEC Web Conf. 2018, 152, 02019. [Google Scholar] [CrossRef]

- Shahani, S.; Gao, Z.; Qaisrani, M.A.; Ahmed, N.; Yaakob, H.; Khoshnaw, F.; Sher, F. Preparation and characterization of sustainable wood plastic composites extracted from municipal solid waste. Polymers 2021, 13, 3670. [Google Scholar] [CrossRef]

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive manufacturing of natural fiber reinforced polymer composites: Processing and prospects. Compos. Part B Eng. 2019, 174, 106956. [Google Scholar] [CrossRef]

- Zuraik, M.A.; Sobri, S.A.; Abdullah, N.; Hermawan, A.; Mohamed, M.; Shuaib, N.A. Preliminary Investigation of Delamination Factor for Drilling Wood Plastic Composites (WPC). IOP Conf. Ser. Earth Environ. Sci. 2020, 596, 012013. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Akhtar, S.S.; Keles, O.; Boran, K. Laser cutting of triangular geometry into 2024 aluminum alloy: Influence of triangle size on thermal stress field. J. Mech. Sci. Technol. 2015, 29, 3239–3248. [Google Scholar] [CrossRef]

- Hernandez-Castaneda, J.C.; Sezer, H.K.; Li, L. Single and dual gas jet effect in Ytterbium-doped fibre laser cutting of dry pine wood. Int. J. Adv. Manuf. Technol. 2011, 56, 539–552. [Google Scholar] [CrossRef]

- Der, O. Multi-Output Prediction and Optimization of CO2 Laser Cutting Quality in FFF-Printed ASA Thermoplastics Using Machine Learning Approaches. Polymers 2025, 17, 1910. [Google Scholar] [CrossRef]

- Sabri, H.; Mehrabi, O.; Khoran, M.; Moradi, M. Leveraging CO2 laser cutting for enhancing fused deposition modeling (FDM) 3D printed PETG parts through postprocessing. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 09544089241274037. [Google Scholar] [CrossRef]

| Material Property | Value | Source/Method |

|---|---|---|

| Wood fibre content | ~60 wt% | Supplier specification |

| HDPE matrix content | ~40 wt% (recycled) | Supplier specification |

| Coupling agent | None reported | Supplier specification |

| Fibre particle size | ~60–100 mesh (≈150–250 µm) | Supplier sieve data; visual check during prep |

| Thickness | 18 mm | As received; verified by calliper |

| Density | ~1.15 g cm−3 | Measured (ASTM D792 water-displacement) |

| Moisture content | <1% | Measured (oven-dry, pre-cut) |

| Flexural strength (typical) | ~20–25 MPa | Supplier technical datasheet |

| Surface hardness | ~2–3 Mohs | Supplier datasheet/handbook value |

| Thermal conductivity | 0.2–0.4 W m−1 K−1 | Literature range for HDPE-based WPCs |

| Water absorption | <1% | Supplier datasheet (low-porosity, closed-cell) |

| Appearance | Dark brown, matte, slight texture | Visual observation |

| Parameter | Level 1 | Level 2 | Level 3 | Description |

|---|---|---|---|---|

| Feed Rate (mm/min) | 1000 | 2000 | 3000 | Slow, medium, fast cutting speeds |

| Gas Pressure (bar) | 1 | 2 | 3 | Low, moderate, high assist-gas pressures |

| Run | Feed Rate (mm/min) | Gas Pressure (bar) | Cutting Depth Mean (mm) | Standard Deviation (mm) |

|---|---|---|---|---|

| 1 | 1000 | 1 | 18 | 0 |

| 2 | 1000 | 2 | 18 | 0 |

| 3 | 1000 | 3 | 18 | 0 |

| 4 | 2000 | 1 | 12.03 | 0.12 |

| 5 | 2000 | 2 | 12 | 0.15 |

| 6 | 2000 | 3 | 11.95 | 0.11 |

| 7 | 3000 | 1 | 9.10 | 0.09 |

| 8 | 3000 | 2 | 9.12 | 0.07 |

| 9 | 3000 | 3 | 9.08 | 0.10 |

| Cross-Sections | ||||

|---|---|---|---|---|

| Side A | Side B | Side C | ||

| Gas Pressure (Bar) | 1 |  |  |  |

| 2 |  |  |  | |

| 3 |  |  |  | |

| Response | Intercept | Feed Rate Coefficient * | Gas Pressure Coefficient | R2 ** |

|---|---|---|---|---|

| Cutting Depth (mm) | 22.00 | −0.0045 per mm/min | ~0.00 per bar | 0.964 |

| HAZ Width (mm) | 1.52 | −0.00028 per mm/min | −0.067 per bar | 0.991 |

| Cutting Profile (score) | 4.90 | −0.0005 per mm/min | +0.10 per bar | 1.000 |

| Surface Finish (score) | 6.13 | −0.0009 per mm/min | −0.20 per bar | 0.996 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad Sobri, S.; Chow, T.P.; Tatt, T.K.; Nordin, M.H.; Hermawan, A.; Mohamad Amini, M.H.; Norizan, M.N.; Shuaib, N.A.; Wan Ismail, W.O.A.S. Optimization and Validation of CO2 Laser-Machining Parameters for Wood–Plastic Composites (WPCs). Polymers 2025, 17, 2216. https://doi.org/10.3390/polym17162216

Ahmad Sobri S, Chow TP, Tatt TK, Nordin MH, Hermawan A, Mohamad Amini MH, Norizan MN, Shuaib NA, Wan Ismail WOAS. Optimization and Validation of CO2 Laser-Machining Parameters for Wood–Plastic Composites (WPCs). Polymers. 2025; 17(16):2216. https://doi.org/10.3390/polym17162216

Chicago/Turabian StyleAhmad Sobri, Sharizal, Teoh Ping Chow, Tan Koon Tatt, Mohd Hisham Nordin, Andi Hermawan, Mohd Hazim Mohamad Amini, Mohd Natashah Norizan, Norshah Afizi Shuaib, and Wan Omar Ali Saifuddin Wan Ismail. 2025. "Optimization and Validation of CO2 Laser-Machining Parameters for Wood–Plastic Composites (WPCs)" Polymers 17, no. 16: 2216. https://doi.org/10.3390/polym17162216

APA StyleAhmad Sobri, S., Chow, T. P., Tatt, T. K., Nordin, M. H., Hermawan, A., Mohamad Amini, M. H., Norizan, M. N., Shuaib, N. A., & Wan Ismail, W. O. A. S. (2025). Optimization and Validation of CO2 Laser-Machining Parameters for Wood–Plastic Composites (WPCs). Polymers, 17(16), 2216. https://doi.org/10.3390/polym17162216