Modeling Approach to Calculate the Orientation of Liquid Crystal Polymers in a Flow Channel Under Varying Boundary Conditions

Abstract

1. Introduction

2. Modeling

2.1. Basic Orientation Model

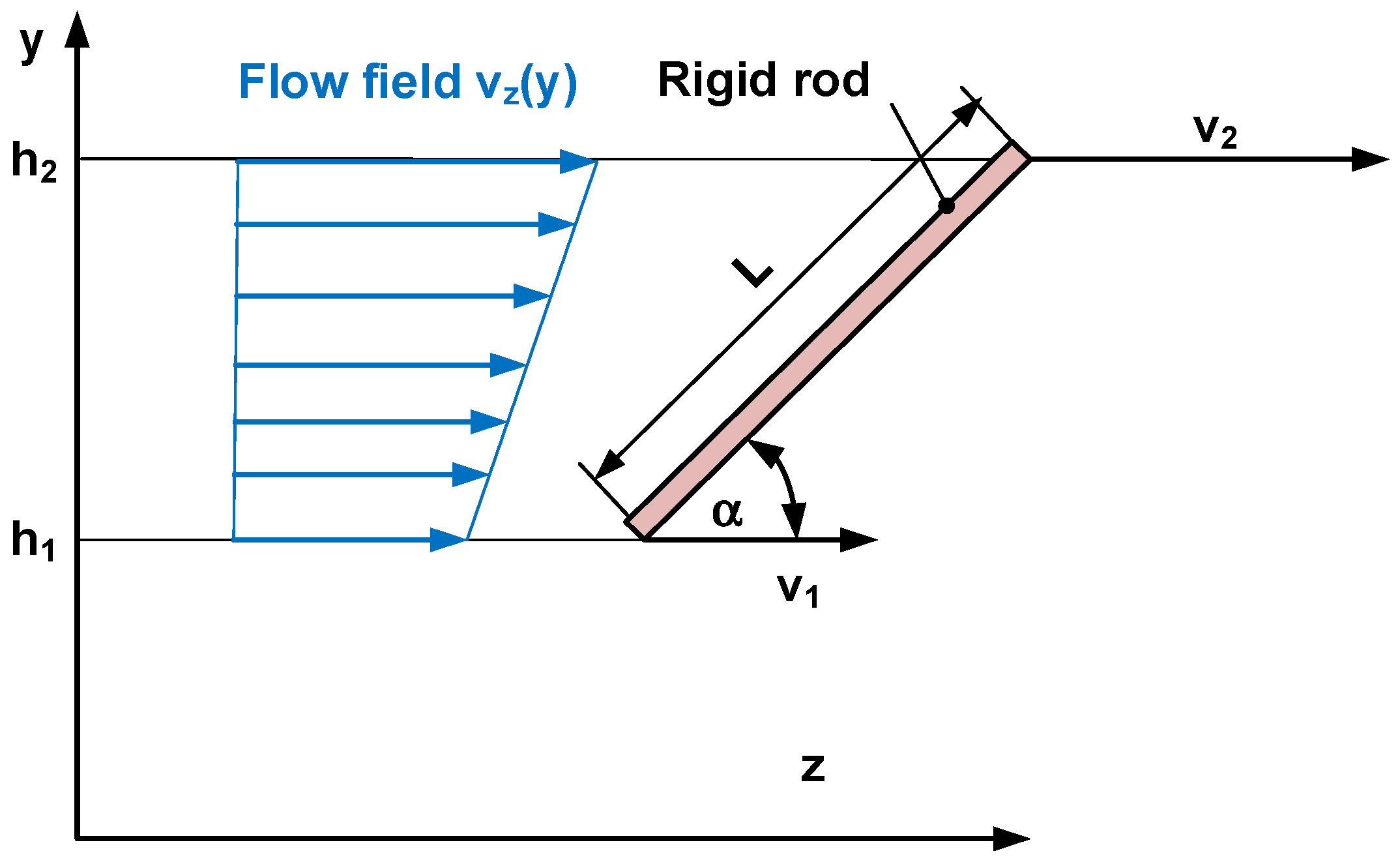

- The rigid rod has the length L and the orientation angle α in the flow. The dimensions of the rod are very small compared to the geometry of the flow channel. The positions of the top and the lower end of the rod are h2 and h1, respectively.

- Interactions between the rods are neglected.

- A laminar flow is assumed.

- A steady state and fully developed flow is assumed.

- Gravity and inertia forces are neglected.

- The flow takes place in a flow channel with a rectangular cross section with the die height H, which is much smaller than the die width W. In this case, the influence of the sidewalls can be neglected. Consequently, the problem can be simplified as a flow between two parallel plates with infinite lateral extension. The flow velocity field is one-dimensionally modeled in the yz-plane.

2.2. Wall Adherence in the Flow Channel (No Slip Condition)

2.3. Wall Slip in the Flow Channel

3. Results

3.1. Orientation Angle and Degree of Orientation

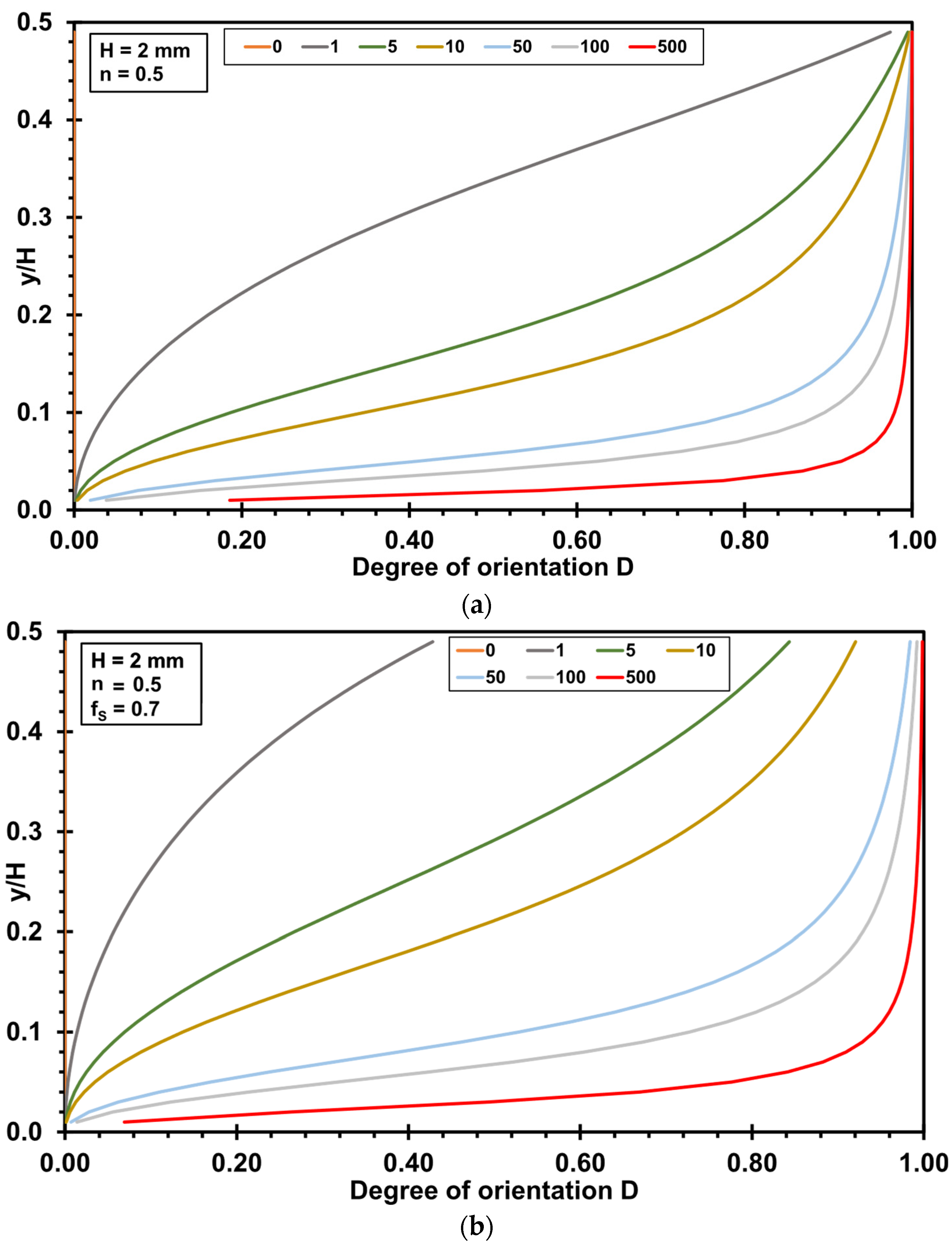

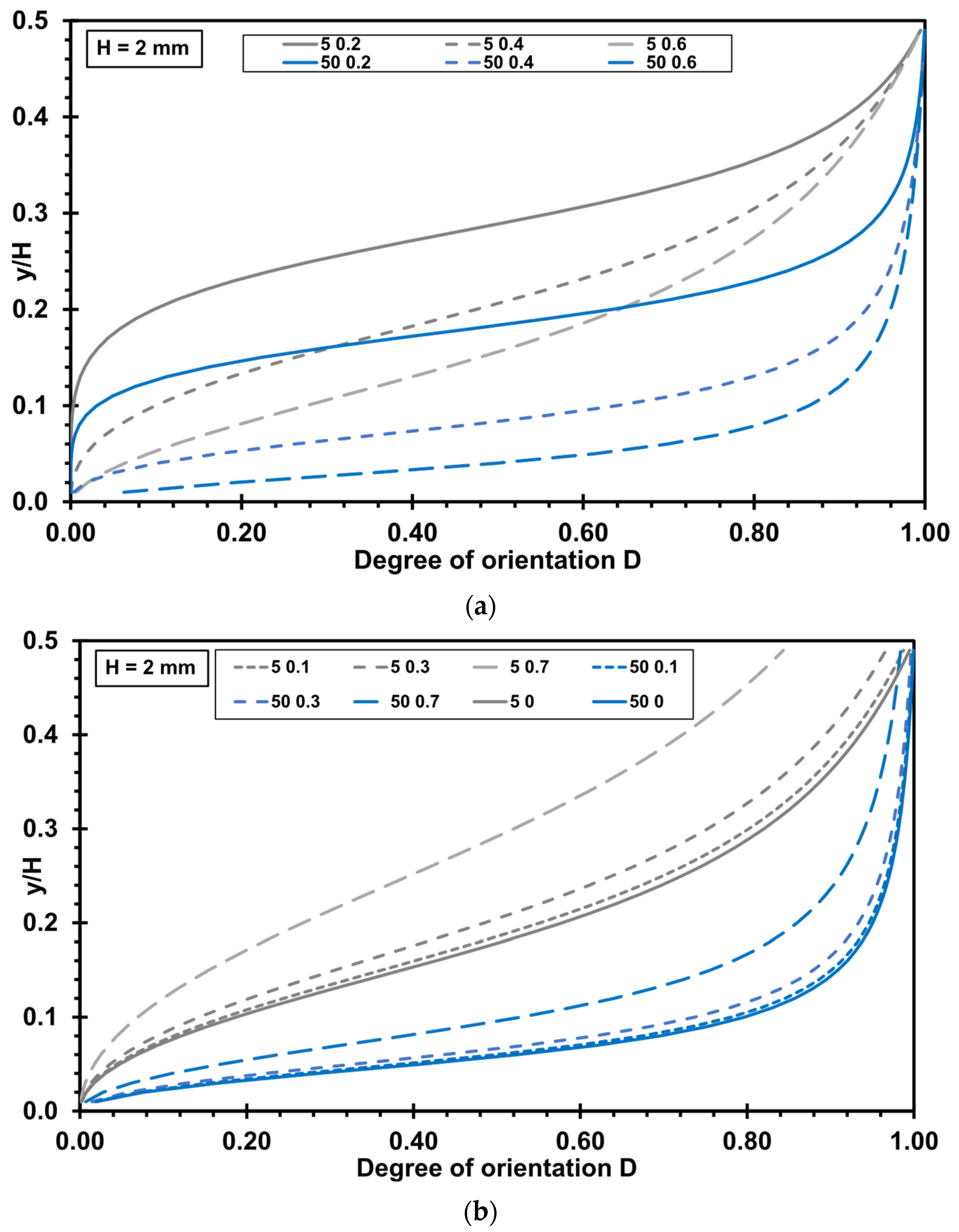

3.2. Influence of Rheological Parameters on the Degree of Orientation

3.3. Highly Oriented Boundary Layer

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| α | Orientation angle of the rigid rod |

| α0 | Initial orientation angle of the rigid rod |

| Shear rate | |

| φ | Rotation angle |

| Shear stress component in z-direction (yz-plane) | |

| D | Degree of orientation |

| D0 | Initial degree of orientation |

| Db | Critical orientation value at the beginning of the highly oriented boundary layer |

| fs | Fraction of slip flow |

| H | Die height |

| h1 | Position of the lower end of the rod |

| h2 | Position of the top end of the rod |

| K | Consistency (power law model) |

| n | Power law index |

| l | Length of the die |

| L | Length of the rigid rod |

| LCP | Liquid crystal polymers |

| PE | Polyethylene |

| p | Pressure |

| ∆p | Pressure loss |

| v1 | Velocity of the lower end of the rod |

| v2 | Velocity of the top end of the rod |

| ∆vz | Velocity difference between the top and the lower end of the rod |

| vm | Velocity of the center of the rod |

| vt | Tangential velocity of the ends of the rod |

| vz | Flow velocity in the slit die |

| vs | Slip velocity at the die surface |

| Q | Volume flow rate |

| Qv | Volume flow rate due to shear flow |

| Qs | Volume flow rate due to slip flow |

| W | Die width |

| x | Coordinate direction, indifferent direction |

| y | Coordinate direction, shear direction |

| z | Coordinate direction, direction of the flow |

| zb | Position of the border of the highly oriented boundary layer |

References

- Geiger, K. Verformungsinduzierte Selbstorganisation Steifer Makromoleküle in Thermotropen Flüssigkristallinen Polymerschmelzen. Habilitation Thesis, University Stuttgart, Stuttgart, Germany, 2013. [Google Scholar]

- Głowińska, E.; Parcheta, P.; Datta, J. Rheology of liquid crystalline polymers. In Rheology of Polymer Blends and Nanocomposites: Theory, Modelling and Applications; Sabu, T., Sarathchandran, C., Chandran, N., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 205–224. [Google Scholar]

- Lyu, X.; Xiao, A.; Shi, D.; Li, Y.; Shen, Z.; Chen, E.-Q.; Chen, S.; Zheng, X.-H.; Fan, Q.-F.; Zhou, Q.F. Liquid crystalline polymers: Discovery, development, and the future. Polymer 2020, 202, 122740. [Google Scholar] [CrossRef]

- Guardià, J.; Reina, J.A.; Giamberini, M.; Montané, X. An Up-to-Date Overview of Liquid Crystals and Liquid Crystal Polymers for Different Applications: A Review. Polymers 2024, 16, 2293. [Google Scholar] [CrossRef] [PubMed]

- Ide, Y.; Ophir, Z. Orientation development in thermotropic liquid crystal polymers. Polym. Eng. Sci. 1983, 23, 261–265. [Google Scholar] [CrossRef]

- Song, B.S.; Lee, J.Y.; Jang, S.H.; Hahm, W.-G. Fiber Formation and Structural Development of HBA/HNA Thermotropic Liquid Crystalline Polymer in High-Speed Melt Spinning. Polymers 2021, 13, 1134. [Google Scholar] [CrossRef] [PubMed]

- Thapar, H.; Bevis, M. The micromorphology of an injection moulded thermotropic liquid crystal polymer. J. Mater. Sci. Lett. 1983, 2, 733–736. [Google Scholar] [CrossRef]

- Kastner, J.; Salaberger, D.; Zitzenbacher, G.; Stadlbauer, W.; Freytag, R. Determination of Diameter, Length and Three-dimensional Distribution of Fibres in Short Glass-fibre Reinforced Injection Moulded Parts by μ-X-ray Computed Tomography. In Proceedings of the 24th Annual Meeting of the Polymer Processing Society, Salerno, Italy, 15–19 June 2008; p. 8. [Google Scholar]

- Kastner, J.; Schlotthauer, E.; Angermaier, D.; Zitzenbacher, G.; Stadlbauer, W.; Freytag, R. Quantitative Messung von Faserlängen und-verteilung in faserverstärkten Kunststoffteilen mittels µ-Röntgen-Computertomographie. In Proceedings of the DGZfP (Deutsche Gesellschaft für Zerstörungsfreie Prüfung) Yearly Conference 2007, Fuerth, Germany, 14–16 May 2007; pp. 345–352. [Google Scholar]

- Kenig, S. Shear-Induced orientation in liquid crystalline polymers. Polym. Eng. Sci. 1989, 29, 1136–1141. [Google Scholar] [CrossRef]

- Williams, G.E. Thermotropic liquid crystal polymers. In Special Polymers for Electronics and Optoelectronics, 1st ed.; Chilton, J.A., Goosey, M., Eds.; Springer Science & Business Media: Dordrecht, The Netherlands, 1995; pp. 256–283. [Google Scholar]

- Dealy, J.M.; Wissbrun, K.F. Melt Rheology and Its Role in Plastics Processing: Theory and Applications; Springer Science & Business Media: Dordrecht, The Netherlands, 2012. [Google Scholar]

- Jigounov, A. Structure, Thermal and Physical Properties of Liquid Crystalline Polymers. Ph.D. Thesis, Charles University Prague, Prague, Czech Republic, 2007. [Google Scholar]

- Wang, Y.; Wu, D. Extrusion, fiber formation, and characterization of thermotropic liquid crystalline copolyesters. J. Appl. Polym. Sci. 1997, 66, 1389–1397. [Google Scholar] [CrossRef]

- Seo, K.S. Rheology and processing of thermotropic liquid crystalline polymers. In Thermotropic Liquid Crystal Polymers: Thin-Film Polymerization, Characterization, Blends and Applications; Chung, T.-S., Ed.; Technomic Publishing: Lancaster, UK, 2001; pp. 219–256. [Google Scholar]

- Kneidinger, C.; Selinger, A.; Zitzenbacher, G. Characterization of the rheological behavior of thermotropic liquid crystal polymers related to extrusion processes. AIP Conf. Proc. 2023, 2607, 020004-1–020004-6. [Google Scholar] [CrossRef]

- Hull, J.B.; Jones, A.R. Processing of liquid crystal polymers and blends. In Rheology and Processing of Liquid Crystal Polymers; Acierno, D., Collyer, A.A., Eds.; Springer Science & Business Media: Dordrecht, The Netherlands, 1996; pp. 218–250. [Google Scholar]

- Jüttner, G. Fließinduzierte Orientierungen in Spritzgegossenen LCP-Teilen. Ph.D. Thesis, Technical University of Chemnitz, Chemnitz, Germany, 2004. [Google Scholar]

- Taut, M. Flüssigkristalline Polymere (LCP)—Mit speziellen Eigenschaften in wachsende Anwendungsgebiete. Kunststoffe 2014, 10, 104–106. [Google Scholar]

- Lusignea, R.W. Orientation of LCP blown film with rotating dies. Polym. Eng. Sci. 1999, 39, 2326–2334. [Google Scholar] [CrossRef]

- Yang, Z.; Zeng, J.; Yang, Z.; Tong, Y.; Lai, Y.; Cao, X. Rotational blow molding of thermotropic liquid crystal polymers and resulting orientational structure and mechanical properties. Polymer 2022, 255, 125144. [Google Scholar] [CrossRef]

- Hsu, T.C.; Lichkus, A.M.; Harrison, I.R. Liquid crystal polymer/polyethylene blends for thin film applications. Polym. Eng. Sci. 1993, 33, 860–863. [Google Scholar] [CrossRef]

- Chinsirikul, W.; Hsu, T.C.; Harrison, I.R. Liquid crystalline polymer (LCP) reinforced polyethylene blend blown film: Effects of counter-rotating die on fiber orientation and film properties. Polym. Eng. Sci. 1996, 36, 2708–2717. [Google Scholar] [CrossRef]

- Ji, Y.; Bai, Y.; Liu, X.; Jia, K. Progress of liquid crystal polyester (LCP) for 5G application. Adv. Ind. Eng. Polym. Res. 2020, 3, 160–174. [Google Scholar] [CrossRef]

- Houriet, C.; Claassen, E.; Mascolo, C.; Jöhri, H.; Brieva, A.; Szmolka, S.; Vincent-Bonnieu, S.; Suliga, A.; Heeb, R.; Gantenbein, S.; et al. 3D Printing of Liquid Crystal Polymers for Space Applications. Adv. Mater. Technol. 2025, 10, 2400571. [Google Scholar] [CrossRef]

- Gantenbein, S.; Masania, K.; Woigk, W.; Sesseg, J.P.; Tervoort, T.A.; Studart, A.R. Three-dimensional printing of hierarchical liquid-crystal-polymer structures. Nature 2018, 561, 226–230. [Google Scholar] [CrossRef] [PubMed]

- Johann, K.S.; Böhm, F.; Kapernaum, N.; Giesselmann, F.; Bonten, C. Orientation of liquid crystalline polymers after filament extrusion and after passing through a 3D printer nozzle. ACS Appl. Polym. Mater. 2024, 6, 10006–10018. [Google Scholar] [CrossRef]

- Michaeli, W. Extrusion Dies for Plastics and Rubber: Design and Engineering Computations, 3rd ed.; Hanser Publishers: Munich, Germany, 2003; pp. 55–69. [Google Scholar]

- Zitzenbacher, G.; Selinger, A.; Kneidinger, C. Evaluation of Mesogen-Orientation in Extruded Liquid Crystal Polymer Films Using Grey Scale Analysis. In Proceedings of the Polymer Processing Society, PPS-2024, Ferrol, Galicia, Spain, 30 September–3 October 2024. [Google Scholar]

- Hsiung, C.M.; Tian, J.; Cakmak, M. Detailed Investigations of Structural Layering Phenomena in Injection Molded Thermotropic LCP: Part I: Characterization by Image Analysis Technique. Int. Polym. Process. 1993, 8, 164–177. [Google Scholar] [CrossRef]

- Blundell, D.J.; Chivers, R.A.; Curson, A.D.; Love, J.C.; MacDonald, W.A. The relationship of chain linearity of aromatic liquid-crystal polyesters to molecular orientation and stiffness of mouldings. Polymer 1998, 29, 1459–1467. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zitzenbacher, G. Modeling Approach to Calculate the Orientation of Liquid Crystal Polymers in a Flow Channel Under Varying Boundary Conditions. Polymers 2025, 17, 2209. https://doi.org/10.3390/polym17162209

Zitzenbacher G. Modeling Approach to Calculate the Orientation of Liquid Crystal Polymers in a Flow Channel Under Varying Boundary Conditions. Polymers. 2025; 17(16):2209. https://doi.org/10.3390/polym17162209

Chicago/Turabian StyleZitzenbacher, Gernot. 2025. "Modeling Approach to Calculate the Orientation of Liquid Crystal Polymers in a Flow Channel Under Varying Boundary Conditions" Polymers 17, no. 16: 2209. https://doi.org/10.3390/polym17162209

APA StyleZitzenbacher, G. (2025). Modeling Approach to Calculate the Orientation of Liquid Crystal Polymers in a Flow Channel Under Varying Boundary Conditions. Polymers, 17(16), 2209. https://doi.org/10.3390/polym17162209