Sustainable Polymer Composites for Thermal Insulation in Automotive Applications: A Systematic Literature Review

Abstract

1. Introduction

2. Research Questions Regarding Insulation Materials

- The role of insulation in components and its influence on the strength and performance of systems.

- Identifying suitable materials for insulation, considering both technical performance and sustainability.

- Approaches through which insulation materials can be optimized to provide superior performance while reducing costs and ecological impact.

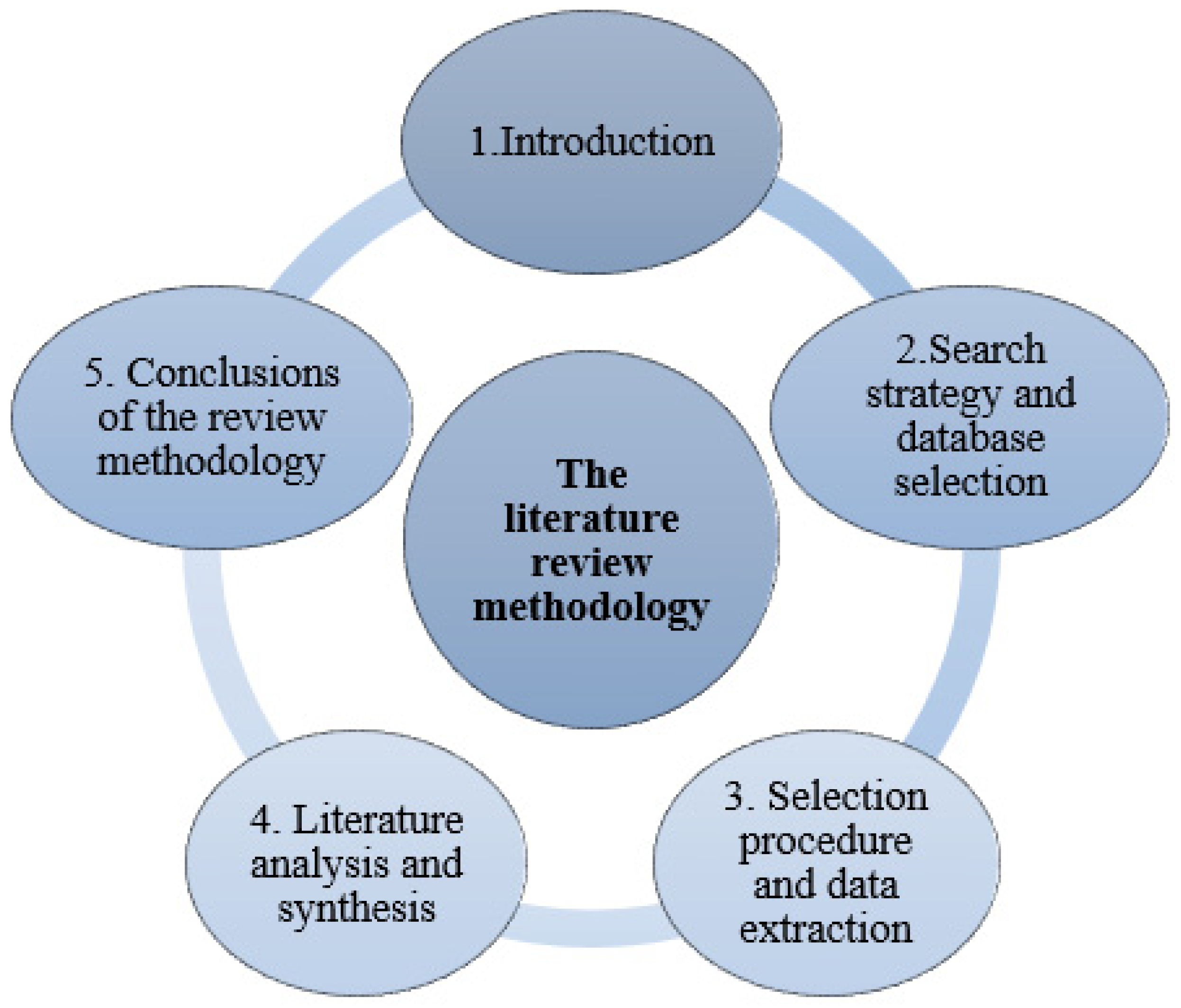

3. Literature Review Methodology

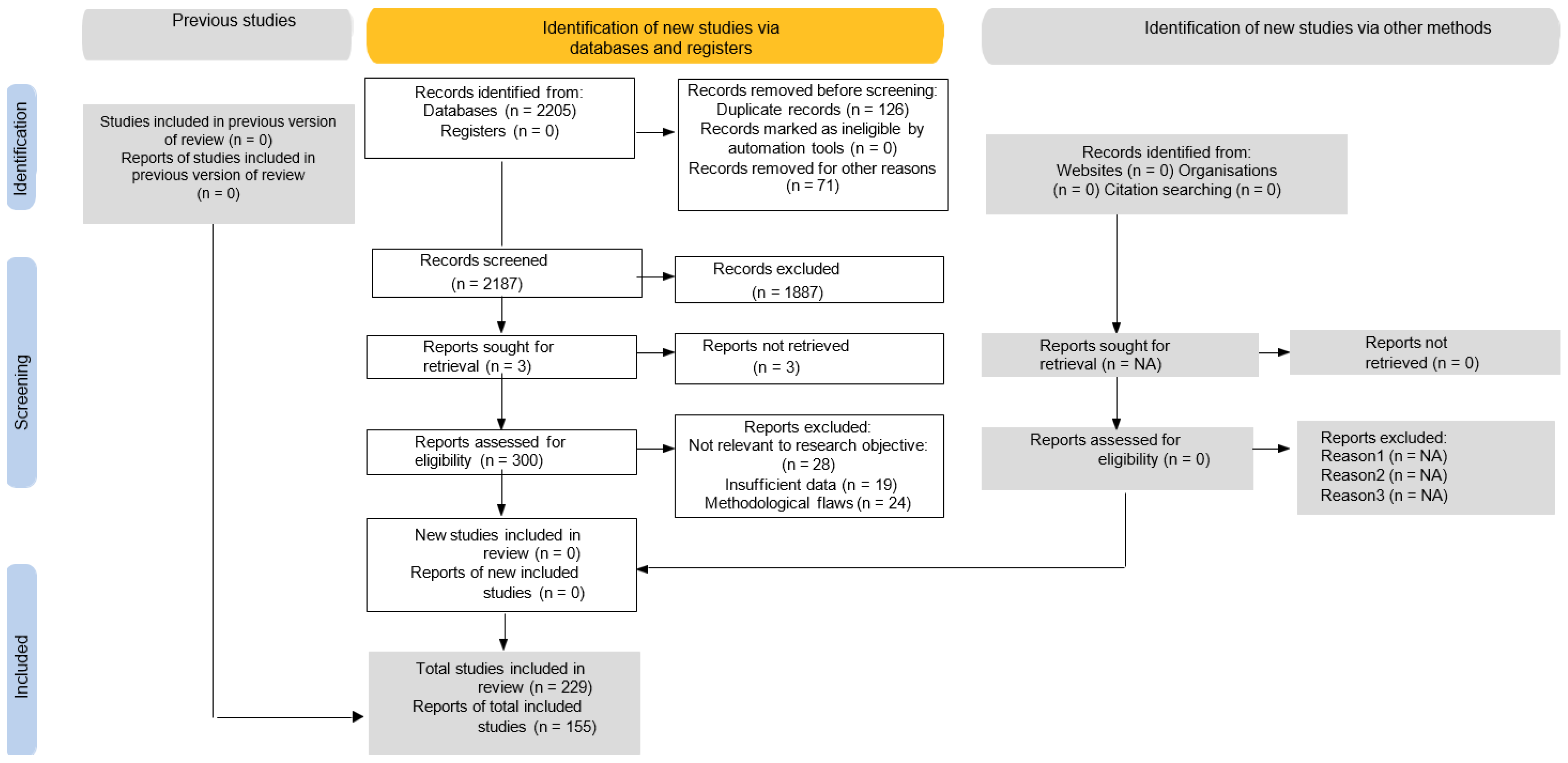

3.1. Search Strategy and Selection Criteria

- MDPI

- ScienceDirect (Elsevier)

- Scopus

- Web of Science

- Wiley

- SpringerLink

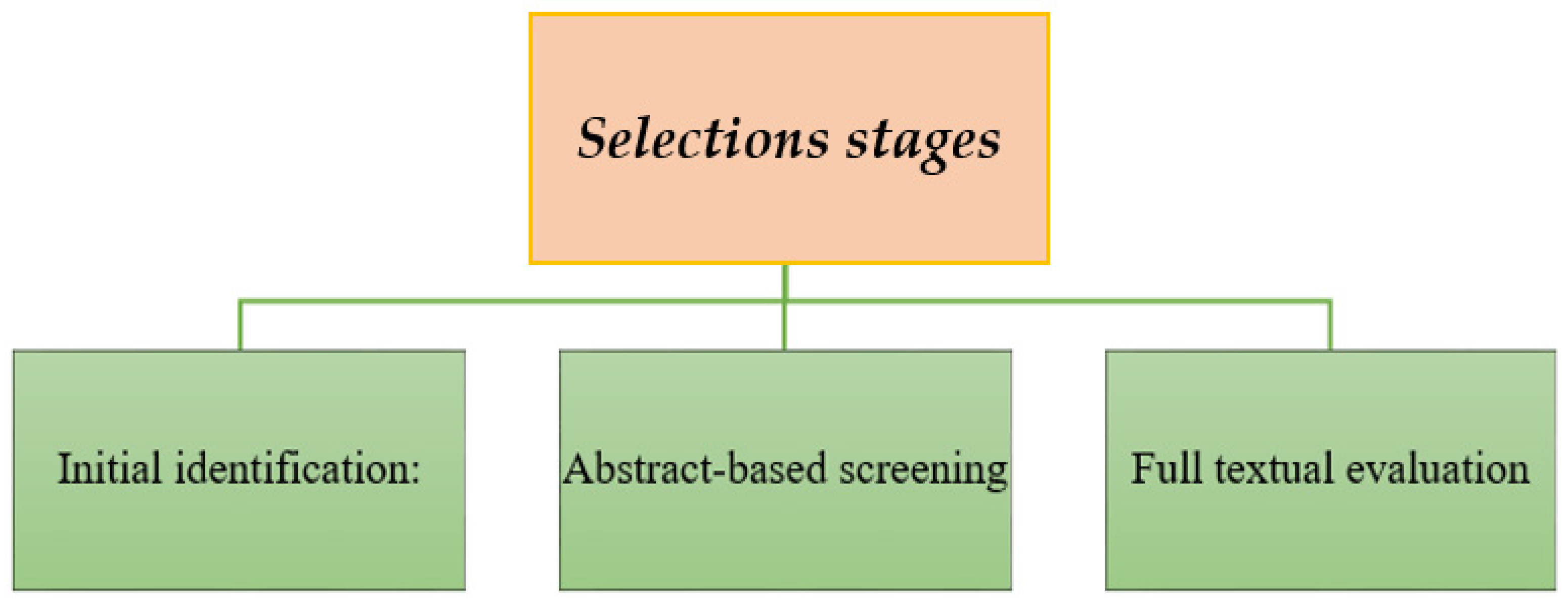

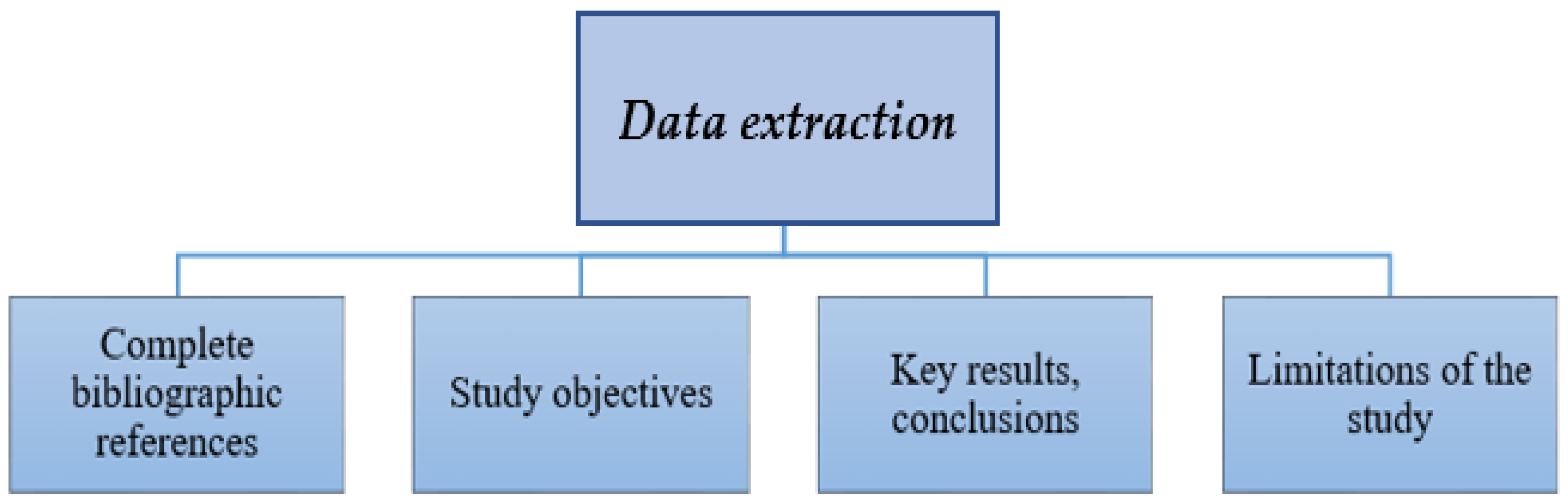

- Initial identification—Extensive searches were conducted in the mentioned databases using the established keywords and filters. In this stage, a significant number of articles were collected, which were later reviewed based on their titles and abstracts.

- Screening based on abstract—Each article was evaluated for relevance based on the abstract. Studies that did not directly address the impact of environmental factors, microstructural changes, or aspects related to degradation identification were excluded.

- Full-text evaluation—The articles selected in the screening phase were read in full to verify whether they met the necessary criteria.

3.2. Review Protocol

- Thematic classification—The sources were grouped according to the main topics identified: properties of polymer materials, optimization methods for component insulation, recyclability, and sustainability.

- Identification of research gaps—The focus was on highlighting issues that were insufficiently analyzed, which led to the formulation of directions for future research.

- Time period—The search for articles was limited to those published in the last 10–15 years, with some exceptions for basic sources to obtain updated information. This approach may exclude fundamentally older studies, which, although valuable, may not reflect the most recent technological evolution.

- Language—The focus was on articles in English (and occasionally Romanian), which may have led to the exclusion of some helpful works published in other languages.

- Databases—Although key recognized databases were accessed, there is a possibility of omitting studies from lesser-known sources.

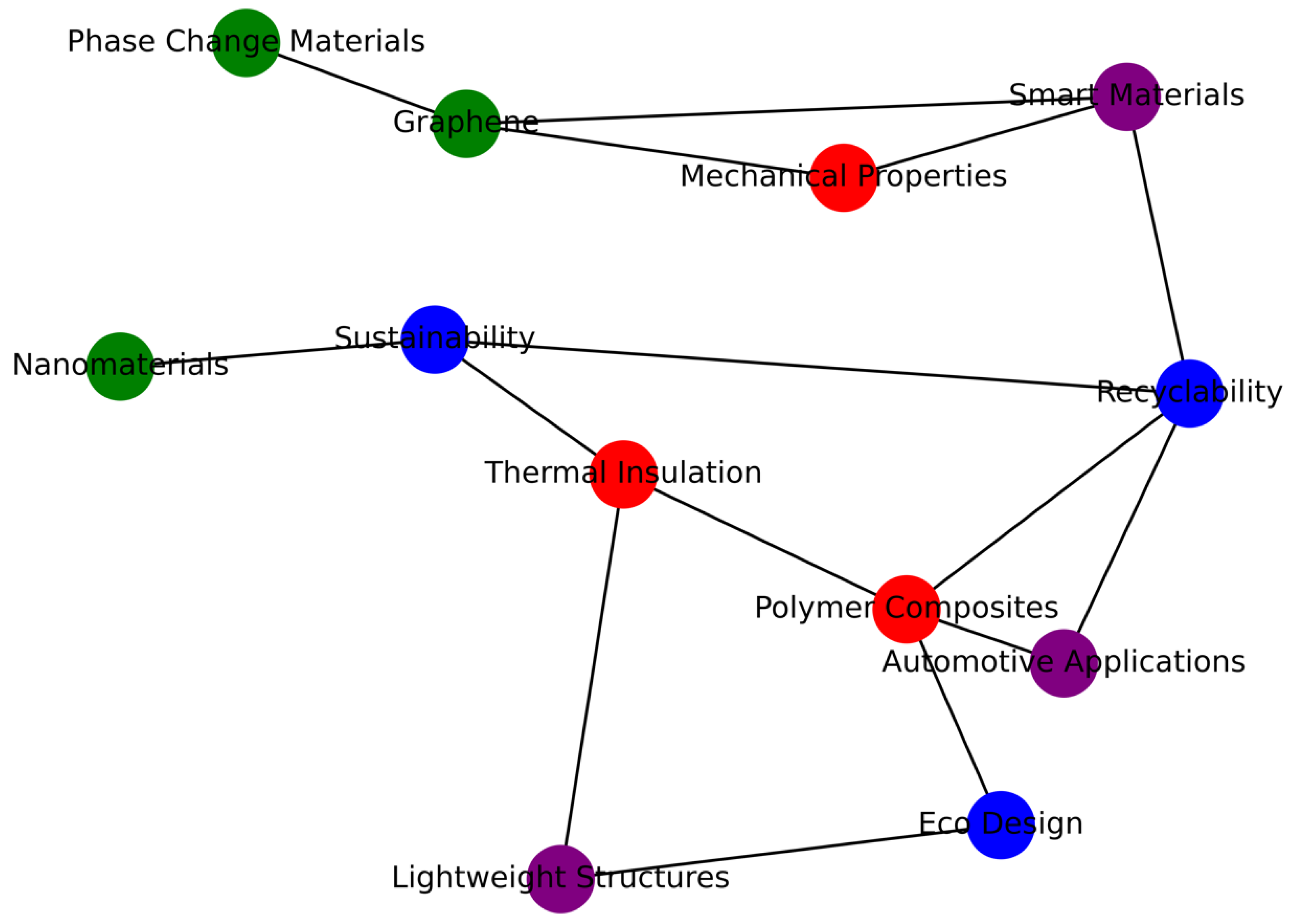

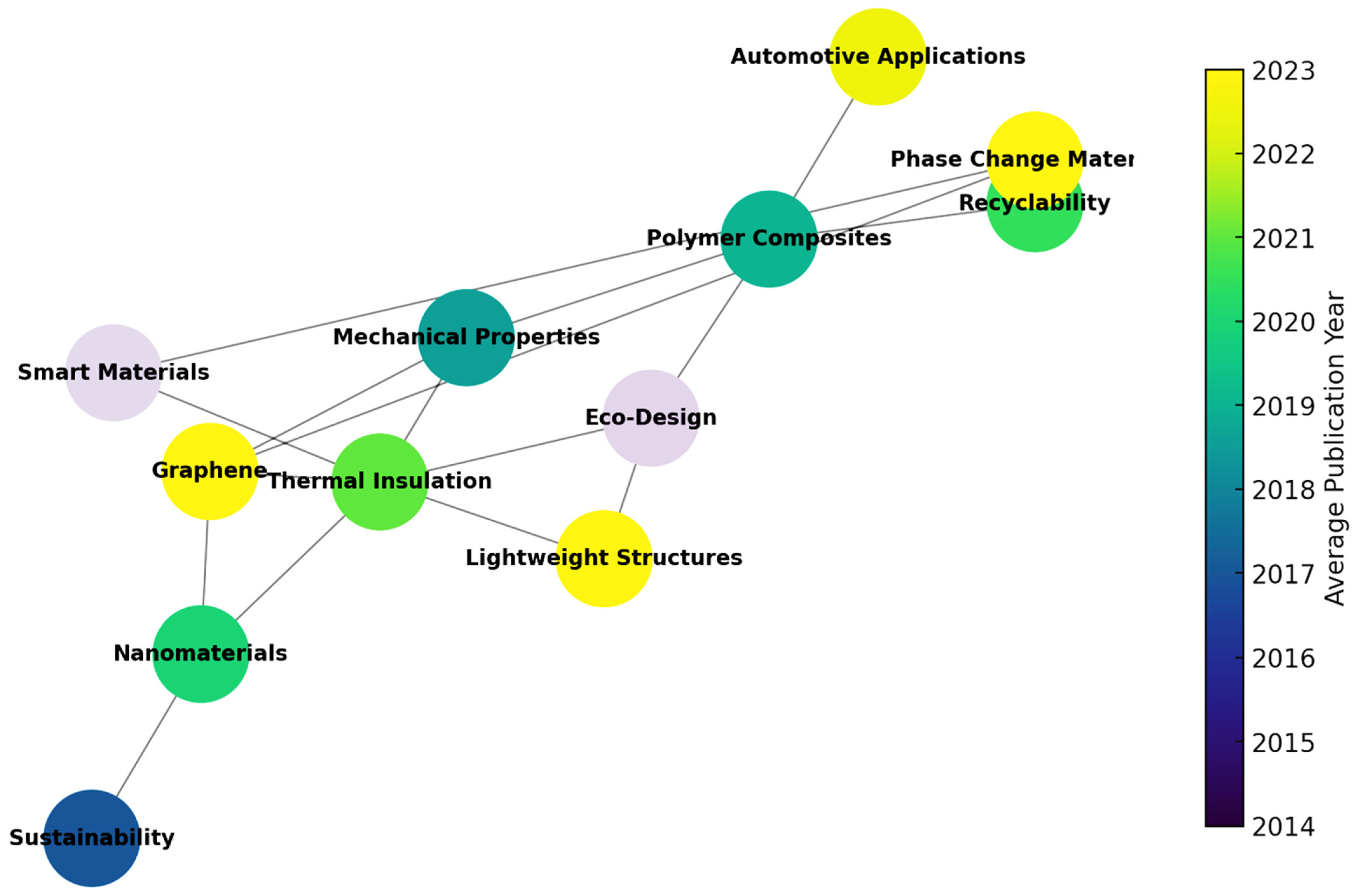

3.3. Bibliometric Analysis and Keyword Mapping

- The red cluster centers around the terms “polymer composites”, “thermal insulation”, and “mechanical properties”, reflecting a core research focus on material performance and characterization.

- The blue cluster includes keywords such as “recyclability”, “eco-design”, and “sustainability”, indicating a growing interest in environmentally responsible material development.

- The green cluster highlights terms like “nanomaterials”, “phase-change materials (PCM)”, and “graphene”, associated with advanced functionalization strategies for enhancing insulation behavior.

4. Evaluation of Questions Q1, Q2, and Q3 Regarding the Insulation of Components with Polymeric Resins

- Thermal protection and energy loss reduction—Thermal insulation is a key element in protecting industrial components, helping maintain an optimal operating temperature and preventing energy losses. In industries like energy and chemicals, where controlled temperature is crucial for manufacturing processes, thermal insulation can significantly reduce operational costs by minimizing heat loss. Researchers [29] investigated the total energy consumption of a single-screw extruder, identifying optimization methods. The study “Monitoring and Modelling of the Energy Consumption in Polymer Extrusion” involved measuring energy consumption under different processing conditions and modeling it based on process variables. Results showed that the equipment’s energy demand is strongly influenced by machine, material, and process parameters. The proposed models demonstrated excellent agreement with experimental measurements and proved useful for optimizing energy efficiency in the process.

- Protection against corrosion and wear—Metal corrosion, caused by exposure to humidity, chemicals, and extreme temperatures, can significantly shorten the lifespan of industrial components. Adequate insulation can effectively mitigate this phenomenon by safeguarding sensitive materials and lowering both maintenance and replacement costs [25]. It was observed that the use of epoxy resins as an insulating material on metal surfaces can reduce oxidation by over 60%, improving mechanical strength and reducing maintenance frequency. Additionally, research by [28] highlighted that using composites based on epoxy resins and lignin (a complex organic polymer) can provide long-term protection against metal corrosion, due to their chemical stability and mechanical strength. Therefore, by implementing optimal insulation solutions, industrial equipment can endure longer in aggressive environmental conditions, contributing to maintaining its performance and reducing operational costs.

- Prevention of short circuits and fire protection—The insulation of electrical and electronic components is especially important for preventing short circuits and fires in industrial installations. Insulating materials not only protect electrical equipment from negative external factors but also prevent the risks of overheating. According to a report by [26] in the paper “Plastics: Materials and Processing (3rd Edition),” the use of flame-retardant polyurethanes in electrical component insulation can reduce the fire risk by 35% compared to conventional materials. These materials are essential for operational safety and for protecting industrial equipment and personnel.

- Product durability and lifetime extension—The long-term properties of polymers and their degradation processes are not opposing aspects. In fact, they are intrinsically connected through the balance between durability and degradation capacity [30]. Researchers [31] conducted a detailed analysis of the synthesis and degradation mechanisms of biodegradable polymers in natural environments, focusing on polymers such as PLA (polylactic acid), starch-based polymers, and vegetable fibers. They studied the interaction between abiotic and enzymatic factors in degradation processes, as well as the effects of chemical and physical changes on the stability and performance of these polymers.

- Type of insulation required (thermal, electrical, etc.).

- Operating temperature and thermal resistance.

- Mechanical properties—shock resistance, flexibility.

- Chemical compatibility—resistance to aggressive substances.

- Cost and availability.

- Durability and resistance to aging.

- Weight—important for mobile/aerospace applications.

- Sustainability—ecological impact, recyclability.

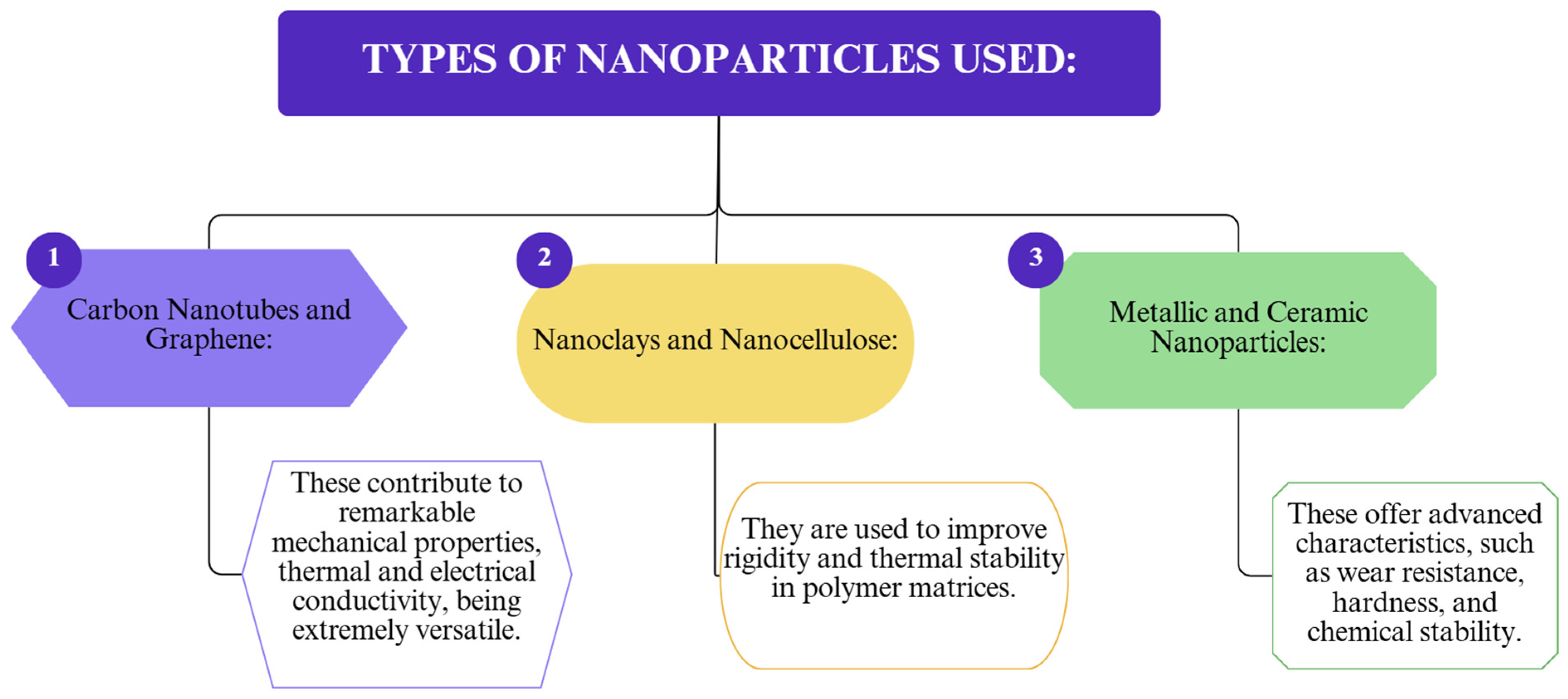

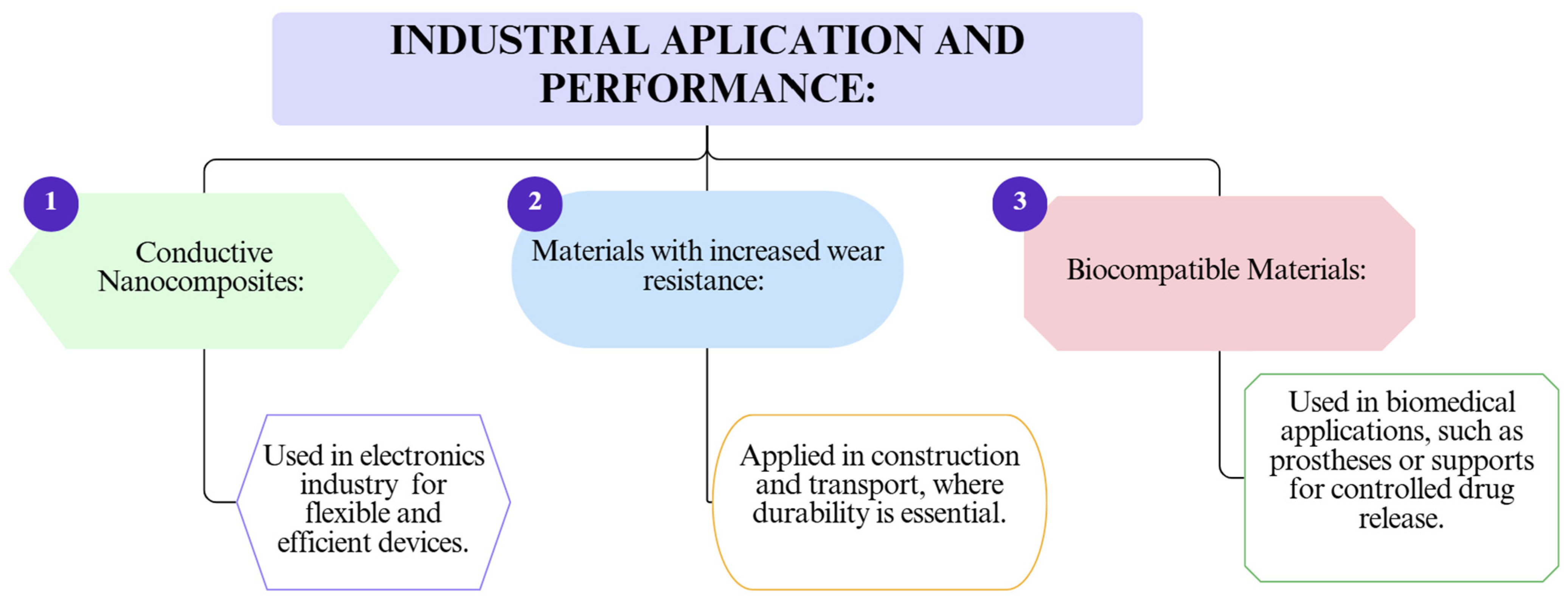

- Nanomaterials for improving thermal and mechanical performance

- Recyclable and biodegradable materials to reduce the carbon footprint

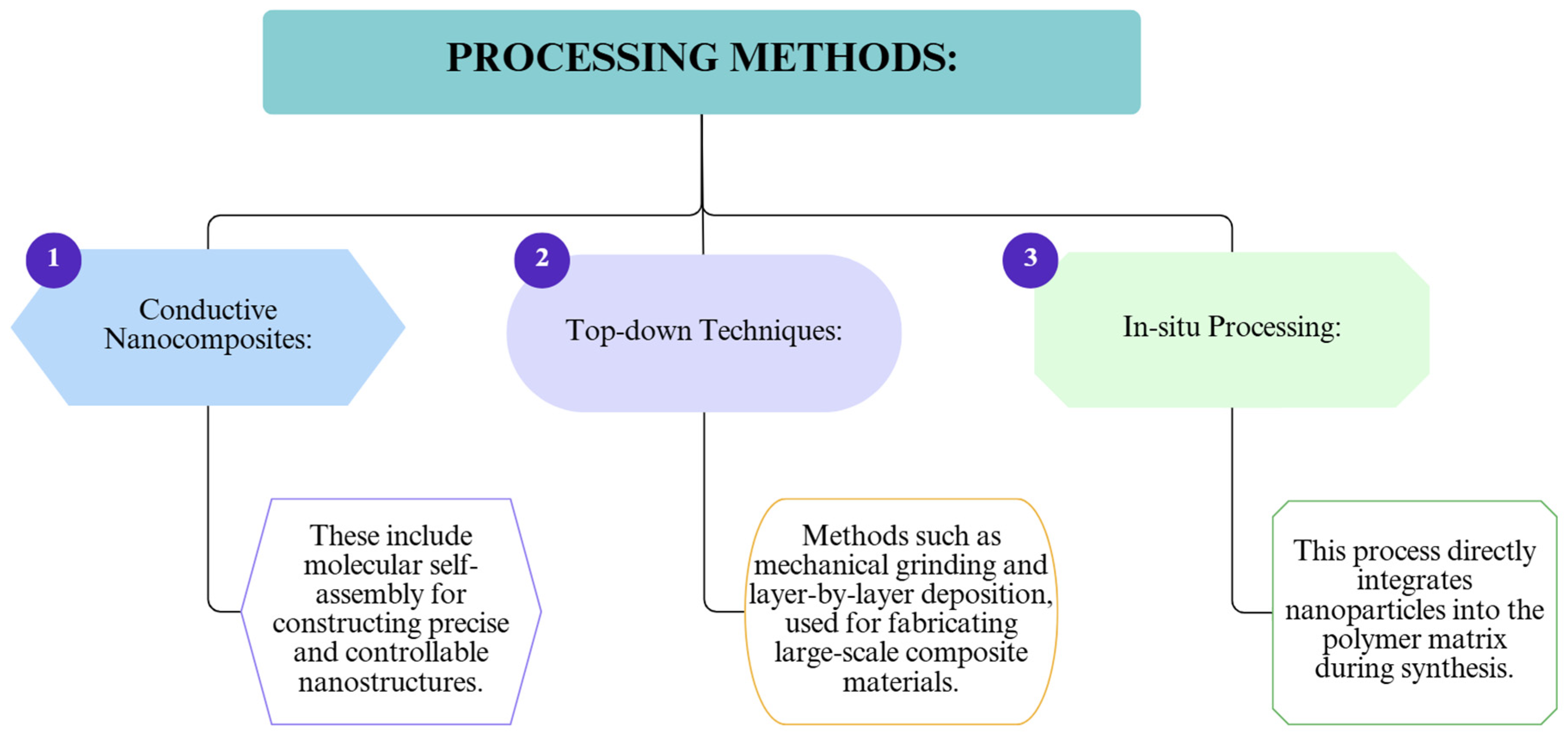

- Advanced manufacturing technologies: 3D printing and controlled polymerization

- Self-healing techniques for extending insulation lifespan

- Reversible covalent bonds: Materials can heal by re-establishing chemical bonds.

- Dynamic physical bonds: Molecular interactions that enable healing without compromising mechanical properties.

- Microcapsules and channels: Systems that release healing agents in damaged areas.

- Diels–Alder reaction—This type of reaction allows the reversible reformation of covalent bonds, enabling repeatable self-healing capabilities.

- Metallic bonds—These provide a combination of good mechanical properties and healing ability.

- Hydrogen and ionic bonds—These non-covalent interactions allow healing at low temperatures and under mild conditions.

- Disulfide bonds—These are used to create self-healing materials in oxidative environments.

- Nanostructuring of materials for enhanced performance

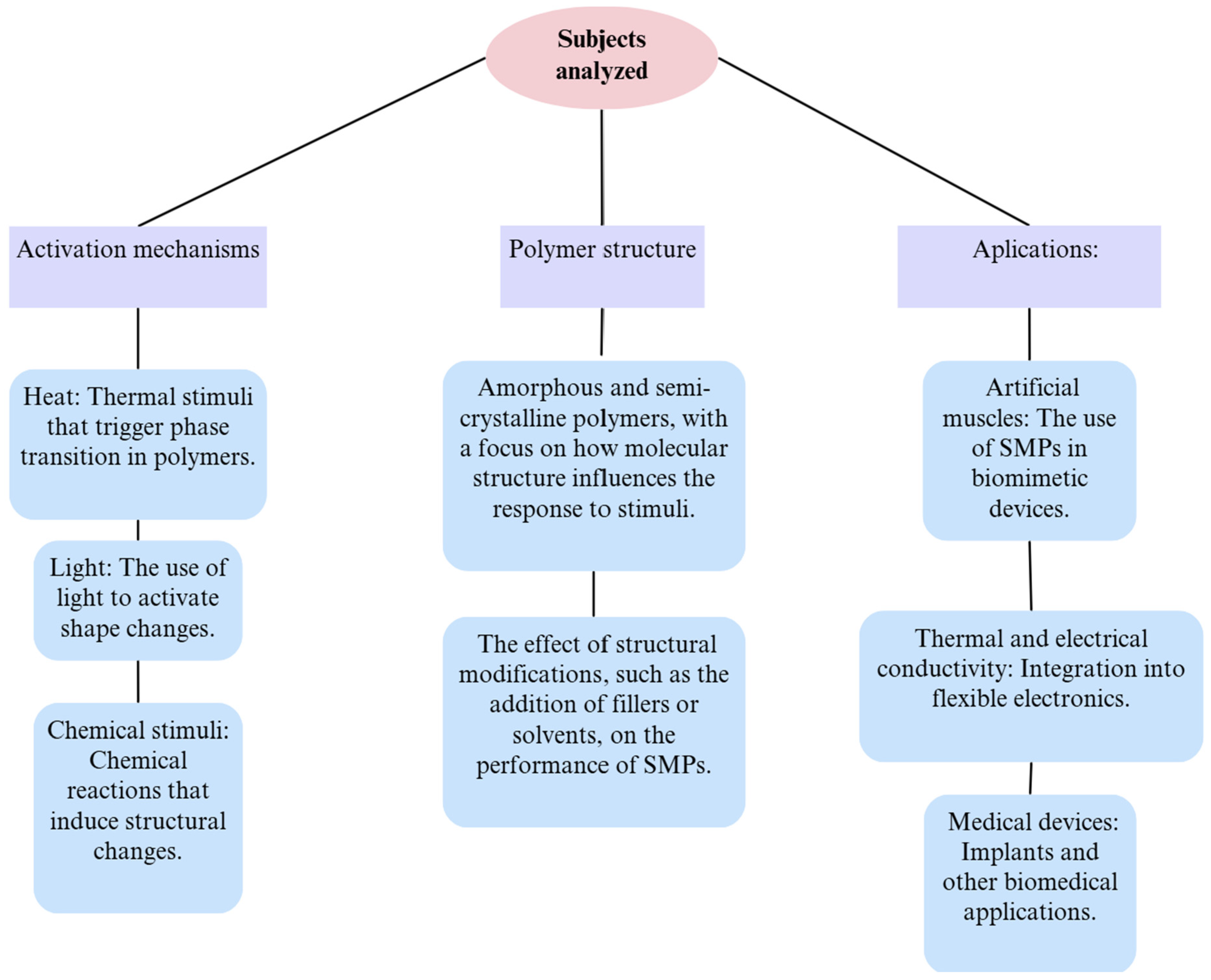

- Development of smart polymers

- Exploration of bioinspired materials

- Synthesis methods:

- -

- Molecular self-assembly into ordered structures.

- -

- Use of electrospinning to produce aligned nanofibers.

- Material characterization:

- -

- Structural and functional analyses to evaluate porosity and conductivity.

- Battery performance:

- -

- Testing of electrodes made from nanofibers in lithium-metal batteries.

- Advanced computer simulations

5. Critical Discussion and Comparison of the Literature

- Material systems—Epoxy resins, widely studied for their mechanical strength and chemical stability, exhibit excellent adhesion and thermal resistance. Despite their advantageous properties, these materials exhibit poor recyclability and increased brittleness under thermal cycling, which restricts their applicability in demanding automotive conditions [6,22]. In contrast, polyurethane-based composites offer better flexibility and ease of processing, making them suitable for vibration-prone components, but they degrade under UV exposure and may emit toxic byproducts during thermal aging [33]. Silicone materials provide superior thermal stability and elasticity, yet their lower adhesion to substrates and high cost restrict their broader adoption [32].

- Processing methods—Traditional thermosetting approaches allow for high-performance curing but complicate end-of-life recycling. Additive manufacturing (e.g., DLP 3D printing) enables custom geometries and embedded functionality (such as smart sensors or self-healing layers), but scalability remains limited [47,48]. Nanostructuring, via incorporation of fillers such as graphene or CNTs, enhances performance across metrics but suffers from challenges in uniform dispersion, increased cost, and industrial reproducibility [40].

- Application contexts—Materials for passive components (e.g., housings, insulation panels) prioritize long-term thermal resistance and cost-efficiency, favoring polyester or fiberglass composites. In contrast, applications involving thermal shock or electromagnetic interference (e.g., battery enclosures or control units) benefit from hybrid aerogels or phase-change smart polymers that combine insulation, mechanical strength, and thermal management [51,59]. Automotive lightweighting requirements further complicate selection, as denser composites may offer better performance but at the expense of fuel efficiency.

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| BN | Boron Nitride |

| CNFs | Cellulose Nanofibers |

| CO2 | Carbon Dioxide |

| CNT | Carbon Nanotubes |

| DLP | Digital Light Processing |

| HCP | Hexagonal Close-Packing |

| HOI | Inorganic Oxide Heterostructures |

| HTL | Hole Transport Layer |

| OMeTAD | O-methyl-2,2′,7,7′-tetramethyl-spiro[fluorene-9,9′-xanthene]-2,2′-diol |

| PCM | Phase-Change Materials |

| PEEK | PolyEtherEtherKetone |

| PHA | Polyhydroxyalkanoate |

| PLA | Polylactic Acid |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| RAFT | Reversible Addition–Fragmentation Chain Transfer |

| SMPs | Shape-Memory Polymers |

| SPACIER | Smart Polymer Artificial Chemical Intelligence Engine for Research |

| VNPB | N,N’-Bis(naphthalen-1-yl)-N,N’-bis(phenyl)-benzidine |

| W/m·K | Watts per meter-kelvin |

References

- Khan, F.; Hossain, N.; Mim, J.J.; Rahman, S.M.M.; Iqbal, M.J.; Billah, M.; Chowdhury, M.A. Advances of Composite Materials in Automobile Applications—A Review. J. Eng. Res. 2025, 13, 1001–1023. [Google Scholar] [CrossRef]

- Ellis, B. (Ed.) Chemistry and Technology of Epoxy Resins; Springer: Dordrecht, The Netherlands, 1993; ISBN 978-94-011-2932-9. [Google Scholar] [CrossRef]

- Yan, B.; Zhang, Z.; Li, Y.; Cui, H.; Zhang, C.; He, J. Research and Application Progress of Resin-Based Composite Materials in the Electrical Insulation Field. Materials 2023, 16, 6394. [Google Scholar] [CrossRef] [PubMed]

- Marin, N.M. Green Chemistry Applications Using Complexing Materials for Water Treatment. Polymers 2025, 17, 1467. [Google Scholar] [CrossRef] [PubMed]

- Umoren, S.A.; Solomon, M.M.; Saji, V.S. Chapter 18—Resin based polymers. In Polymeric Materials in Corrosion Inhibition; Umoren, S.A., Solomon, M.M., Saji, V.S., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 419–441. [Google Scholar] [CrossRef]

- Verma, C.; Olasunkanmi, L.O.; Akpan, E.D.; Quraishi, M.A.; Dagdag, O.; El Gouri, M.; Sherif, E.-M.; Ebenso, E.E. Epoxy Resins as Anticorrosive Polymeric Materials: A Review. React. Funct. Polym. 2020, 156, 104741. [Google Scholar] [CrossRef]

- Tabacu, S.; Hadar, A.; Marinescu, D.; Marin, D.; Dinu, G.; Ionescu, D. Structural performances of thermoplastic manufactured parts. Mater. Plast. 2008, 45, 113–118. [Google Scholar]

- Callister, W.D., Jr. Materials Science and Engineering: An Introduction, 10th ed.; Wiley: Hoboken, NJ, USA, 2018; ISBN 9781119405436. [Google Scholar]

- Ren, L.; Guo, H.; Kang, L.; Niu, H.; Lv, R.; Bai, S.-L. Lightweight, Electrical Insulating, and High Thermally Conductive All-Polymer Composites with Reinforced Interfaces. Compos. Sci. Technol. 2023, 240, 110080. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M. Epoxy Resin Based Hybrid Polymer Composites. In Hybrid Polymer Composite Materials; Thakur, V.K., Thakur, M.K., Pappu, A., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 57–82. ISBN 9780081007877. [Google Scholar] [CrossRef]

- Chen, X.M.; Ellis, B. Coatings and Other Applications of Epoxy Resins. In Chemistry and Technology of Epoxy Resins; Ellis, B., Ed.; Springer: Dordrecht, The Netherlands, 1993; pp. 303–325. [Google Scholar] [CrossRef]

- Aziz, T.; Haq, F.; Farid, A.; Cheng, L.; Chuah, L.F.; Bokhari, A.; Mubashir, M.; Tang, D.Y.Y.; Show, P.L. The epoxy resin system: Function and role of curing agents. Carbon Lett. 2024, 34, 477–494. [Google Scholar] [CrossRef]

- Li, J.; Aung, H.H.; Du, B. Curing Regime-Modulating Insulation Performance of Anhydride-Cured Epoxy Resin: A Review. Molecules 2023, 28, 547. [Google Scholar] [CrossRef]

- Li, Q.; Ahmed, I.; Phan Minh Ngoc, P.; Ta Phuong Hoa, T.; Tran Vinh Dieu, T.; Sultan Irshad, M.; Xuan Nang, H.; Dao, V.-D. Contemporary Advances in Polymer Applications for Sporting Goods: Fundamentals, Properties, and Applications. RSC Adv. 2024, 14, 37445–37469. [Google Scholar] [CrossRef]

- Hadăr, A.; Baciu, F.; Voicu, A.-D.; Vlăsceanu, D.; Tudose, D.-I.; Adetu, C. Mechanical Characteristics Evaluation of a Single Ply and Multi-Ply Carbon Fiber-Reinforced Plastic Subjected to Tensile and Bending Loads. Polymers 2022, 14, 3213. [Google Scholar] [CrossRef]

- Ciprioti, S.V.; Raimondo, M.; Vertuccio, L.; Calabrese, E.; Aliberti, F.; Guadagno, L. Multi-technique characterization and thermal degradation study of epoxy modified resins designed for multifunctional applications. J. Therm. Anal. Calorim. 2024, 149, 11041–11055. [Google Scholar] [CrossRef]

- Zhu, H.-Y.; Zhu, Y.-J.; Bao, D.; Pei, L.-C.; Xu, F.; Wang, Z.; Wang, H.-Y. Research on Improving the Thermal Conductivity of Epoxy Resin with Flexible Assisted Rigid Groups. Chin. J. Polym. Sci. 2024, 42, 1845–1854. [Google Scholar] [CrossRef]

- El-Aouni, N.; Berradi, M.; Eddaoukhi, A.; Rissouli, L.; Berradi, O.; Yacoubi, A.; Rafik, M.; El Bachiri, A. Synthesis of New Epoxy Polymers and Their Comparative Viscosimetric, Rheological, and Thermal Characterization. Interactions 2024, 246, 11. [Google Scholar] [CrossRef]

- Iulia, P.G.; Dragomir, C.M.B.; Păduraru, I. Importance of the Basic Reactions in the Manufacture of Synthetic Resins. Acta Tech. Napoc. Ser.–Appl. Math. Mech. Eng. 2022, 65, 1161–1168. [Google Scholar]

- Iliescu, N.; Atanasiu, C.; Hadar, A. The Simulation of the Mechanical Behaviour of Engineering Structures on Models Made of Plastic Materials with Special Properties. Mater. Plast. 2005, 42, 72–76. [Google Scholar]

- Lazăr, S.; Dobrotă, D.; Breaz, R.-E.; Racz, S.-G. Eco-Design of Polymer Matrix Composite Parts: A Review. Polymers 2023, 15, 3634. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, Y.; Wang, G.; Gao, C.; Yu, J.; Zhang, X.; Wu, Y. Alcohol degradation of anhydride-cured epoxy resin insulations and the properties of recycled materials. Polym. Degrad. Stab. 2025, 232, 111134. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, C.; Liu, P.; Huang, D.; Li, P. Recycling of ammonia-cured epoxy resin by oxidative degradation of nitric acid assisted by swelling agent. Eur. Polym. J. 2023, 186, 111823. [Google Scholar] [CrossRef]

- Domininghaus, H. Plastics for Engineers: Materials, Properties, Applications; Oxford University Press: New York, NY, USA, 1993; ISBN 9783446157231. [Google Scholar]

- Mark, H.F. Encyclopedia of Polymer Science and Technology, 4th ed.; Wiley: Hoboken, NJ, USA, 2014; ISBN 978-1-118-63389-2. [Google Scholar]

- Strong, A.B. Plastics: Materials and Processing, 3rd ed.; Pearson Education: Hoboken, NJ, USA, 2005; ISBN 978-0-13-114558-0. [Google Scholar]

- Mesa, J.A.; Gonzalez-Quiroga, A.; Aguiar, M.F.; Jugend, D. Linking product design and durability: A review and research agenda. Heliyon 2022, 8, e10734. [Google Scholar] [CrossRef]

- Komartin, R.S.; Balanuca, B.; Necolau, M.I.; Cojocaru, A.; Stan, R. Composite Materials from Renewable Resources as Sustainable Corrosion Protection Coatings. Polymers 2021, 13, 3792. [Google Scholar] [CrossRef]

- Abeykoon, C.; Kelly, A.L.; Vera-Sorroche, J.; Brown, E.C.; Coates, P.D. Monitoring and Modelling of the Energy Consumption in Polymer Extrusion. In Proceedings of the 2014 European Control Conference (ECC), Strasbourg, France, 25–27 June 2014; pp. 1030–1035. [Google Scholar]

- Badia, J.D.; Gil-Castell, O.; Ribes-Greus, A. Long-term properties and end-of-life of polymers from renewable resources. Polym. Degrad. Stab. 2017, 137, 35–57. [Google Scholar] [CrossRef]

- Yao, X.; Yang, X.; Lu, Y.; Qiu, Y.; Zeng, Q. Review of the Synthesis and Degradation Mechanisms of Some Biodegradable Polymers in Natural Environments. Polymers 2025, 17, 66. [Google Scholar] [CrossRef]

- Rosca, A. Plastics and Polymeric Materials; WordPress: San Francisco, CA, USA, 2015; Available online: https://andreirosca147.wordpress.com/2015/12/13/masele-plastice-si-materialele-polimerice (accessed on 11 April 2025).

- Das, A.; Mahanwar, P. A Brief Discussion on Advances in Polyurethane Applications. Adv. Ind. Eng. Polym. Res. 2020, 3, 93–101. [Google Scholar] [CrossRef]

- Sikkema, R.; Baker, K.; Zhitomirsky, I. Electrophoretic deposition of polymers and proteins for biomedical applications. Adv. Colloid Interface Sci. 2020, 284, 102272. [Google Scholar] [CrossRef] [PubMed]

- Acharya, A. Metal Oxide Glass Fibers. In Metal Oxide Glass Nanocomposites; Bhattacharya, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; Chapter 16; pp. 273–278. [Google Scholar] [CrossRef]

- Morampudi, P.; Namala, K.K.; Gajjela, Y.K.; Barath, M.; Prudhvi, G. Review on Glass Fiber Reinforced Polymer Composites. Mater. Today Proc. 2021, 43, 314–319. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Azdast, T.; Lee, P.C.; Park, C.B. A review of the state-of-the-art on thermal insulation performance of polymeric foams. Therm. Sci. Eng. Prog. 2023, 41, 101808. [Google Scholar] [CrossRef]

- Baek, K.; Park, H.; Shin, H.; Yang, S.; Cho, M. Multiscale Modeling to Evaluate Combined Effect of Covalent Grafting and Clustering of Silica Nanoparticles on Mechanical Behaviors of Polyimide Matrix Composites. Compos. Sci. Technol. 2021, 206, 108673. [Google Scholar] [CrossRef]

- Zafar, M.; Mehmood, S. Graphene-Based Polymer Nanocomposites for Energy Applications: Recent Advances and Future Prospects. Results Phys. 2024, 60, 107655. [Google Scholar] [CrossRef]

- Li, A.; Zhang, C.; Zhang, Y.-F. Thermal Conductivity of Graphene-Polymer Composites: Mechanisms, Properties, and Applications. Polymers 2017, 9, 437. [Google Scholar] [CrossRef]

- Ioniță, M.C. ZymoChem, $21 Million Investment for Durable and Sustainable Polymers; Green Start Up: Singapore, 2024; Available online: https://green.start-up.ro/ro/zymochem-investitie-de-21-mil-pentru-polimeri-durabili-si-sustenabili/?form=MG0AV3 (accessed on 15 April 2025).

- Lupescu, D.C. Biodegradable Polymers with Multiple Applications; Market Watch: New York, NY, USA, 2009; Available online: https://www.marketwatch.ro/articol/4890/Polimeri_biodegradabili_cu_aplicatii_multiple/?form=MG0AV3 (accessed on 18 April 2025).

- V Song, W.; Tang, Y.; Moon, B.Y.; Liao, Q.; Xu, H.; Hou, Q.; Zhang, H.; Yu, D.-G.; Liao, Y.; Kim, I. Green Synthesis of Hypercrosslinked Polymers for CO2 Capture and Conversion: Recent Advances, Opportunities, and Challenges. Green Chem. 2024, 26, 2476–2504. [Google Scholar] [CrossRef]

- Lakatos, Á. Thermal Insulation Capability of Nanostructured Insulations and Their Combination as Hybrid Insulation Systems. Case Stud. Therm. Eng. 2023, 41, 102630. [Google Scholar] [CrossRef]

- Amran, M.; Abdelgader, H.S.; Onaizi, A.M.; Fediuk, R.; Ozbakkaloglu, T.; Rashid, R.S.M.; Murali, G. 3D-Printable Alkali-Activated Concretes for Building Applications: A Critical Review. Constr. Build. Mater. 2022, 319, 126126. [Google Scholar] [CrossRef]

- Müller, T.; Scholz, S.; Ehrhardt, M.; Ruíz Trujillo, S.; Cogollo de Cádiz, M.; Díaz Lantada, A.; Guttmann, M. Hybridizing 3D printing and electroplating for the controlled forming of metal structures within fused deposition modelled contours. Int. J. Adv. Manuf. Technol. 2025, 136, 4369–4381. [Google Scholar] [CrossRef]

- Zhao, B.; Li, J.; Yang, C.; Pan, X.; Zhang, Z.; Zhu, J. Rapid and high-resolution 3D printing via photoacid generator induced cationic RAFT polymerization. Sci. China Chem. 2025, 68, 2010–2016. [Google Scholar] [CrossRef]

- Nam, J.; Kim, M. Advances in materials and technologies for digital light processing 3D printing. Nano Converg. 2024, 11, 45. [Google Scholar] [CrossRef]

- Zhou, X.; Li, Y.; Chen, J.; Huang, S.; Wang, Y.; Li, W. Enzyme Stability in Polymer Hydrogel–Enzyme Hybrid Nanocarrier Containing Phosphorylcholine Group. RSC Adv. 2024, 14, 12345–12356. [Google Scholar] [CrossRef]

- Al Zoubi, W.; Kamil, M.P.; Fatimah, S.; Nashrah, N.; Ko, Y.G. Recent advances in hybrid organic-inorganic materials with spatial architecture for state-of-the-art applications. Prog. Mater. Sci. 2020, 112, 100663. [Google Scholar] [CrossRef]

- Niu, Z.; Qu, F.; Chen, F.; Ma, X.; Chen, B.; Wang, L.; Xu, M.; Wang, S.; Jin, L.; Zhang, C.; et al. Multifunctional Integrated Organic–Inorganic-Metal Hybrid Aerogel for Excellent Thermal Insulation and Electromagnetic Shielding Performance. Nano-Micro Lett. 2024, 16, 200. [Google Scholar] [CrossRef] [PubMed]

- Ritzen, L.; Montano, V.; Garcia, S.J. 3D Printing of a Self-Healing Thermoplastic Polyurethane through FDM: From Polymer Slab to Mechanical Assessment. Polymers 2021, 13, 305. [Google Scholar] [CrossRef] [PubMed]

- Jadoun, S. Synthesis, Mechanism, and Applications of Self-healing Materials. Biomed. Mater. Devices 2024, 2, 225–240. [Google Scholar] [CrossRef]

- Song, T.; Jiang, B.; Li, Y. Self-healing Materials: A Review of Recent Developments. ES Mater. Manuf. 2021, 14, 1–19. [Google Scholar] [CrossRef]

- Peponi, A.; Puglia, D.; Torre, L.; Valentini, L.; Kenny, J.M. Processing of Nanostructured Polymers and Advanced Polymeric Based Nanocomposites. Mater. Sci. Eng. R Rep. 2014, 85, 1–46. [Google Scholar] [CrossRef]

- Piticescu, D.I. Obtaining Nanostructured Surfaces: A Value Chain for the Use of Advanced Materials in Multisectoral Applications; Market Watch: New York, NY, USA, 2012; Available online: https://www.marketwatch.ro/articol/11529/Obtinerea_suprafetelor_nanostructurate_un_lant_valoric_pentru_utilizarea_materialelor_avansate_in_aplicatii_multisectoriale/pagina/2 (accessed on 20 April 2025).

- Parás-Hernández, F.U.; Fabián-Mijangos, A.; Cardona-Castro, M.A.; Alvarez-Quintana, J. Enhanced Performance Nanostructured Thermoelectric Converter for Self-Powering Health Sensors. Nano Energy 2020, 74, 104854. [Google Scholar] [CrossRef]

- Jingcheng, L.; Reddy, V.S.; Jayathilaka, W.A.D.M.; Chinnappan, A.; Ramakrishna, S.; Ghosh, R. Intelligent Polymers, Fibers and Applications. Polymers 2021, 13, 1427. [Google Scholar] [CrossRef] [PubMed]

- Chandran, S.; JebaSingh, V.K. Polymer Phase Change Materials: Innovations, Applications, and Future Directions. J. Polym. Res. Appl. Chem. (JoRACHV) 2024, 11, 1–7. Available online: https://journals.stmjournals.com/jorachv/article=2024/view=177151/ (accessed on 21 April 2025).

- Yang, S.; Liu, Z.; Pan, Y.; Guan, J.; Yang, P.; Asel, M. A Review of Research Progress on the Performance of Intelligent Polymer Gel. Molecules 2023, 28, 4246. [Google Scholar] [CrossRef]

- Tao, P.; Shang, W.; Song, C.; Shen, Q.; Zhang, F.; Luo, Z.; Yi, N.; Zhang, D.; Deng, T. Bioinspired Engineering of Thermal Materials. Adv. Mater. 2015, 27, 428–463. [Google Scholar] [CrossRef] [PubMed]

- Wan, X.; Xia, X.; Chen, Y.; Lin, D.; Zhou, Y.; Xiong, R. Bioinspired thermal conductive cellulose nanofibers/boron nitride coating enabled by co-exfoliation and interfacial engineering. Polymers 2024, 16, 805. [Google Scholar] [CrossRef]

- Dayyoub, T.; Maksimkin, A.V.; Filippova, O.V.; Tcherdyntsev, V.V.; Telyshev, D.V. Shape Memory Polymers as Smart Materials: A Review. Polymers 2022, 14, 3511. [Google Scholar] [CrossRef]

- Nanjo, S.; Arifin; Maeda, H.; Hayashi, Y.; Hatakeyama-Sato, K.; Himeno, R.; Hayakawa, T.; Yoshida, R. SPACIER: On-demand polymer design with fully automated all-atom classical molecular dynamics integrated into machine learning pipelines. npj Comput. Mater. 2025, 11, 16. [Google Scholar] [CrossRef]

| Material | Key Properties | Advantages | Disadvantages |

|---|---|---|---|

| Epoxy resins | High mechanical strength, chemical stability, good adhesion | Excellent durability, high chemical resistance, versatile applications | High cost, may require additives or structural fillers to meet advanced thermal conditions |

| Polyurethane | Flexible, good thermal and acoustic insulation, moisture resistance | Easy to apply, high efficiency, water resistant | UV-sensitive, may release toxic substances over time |

| Polyesters | Moderate mechanical strength, decent thermal stability | Low cost, easy processing, multiple industrial uses | Brittle compared to other resins, sensitive to humidity |

| Silicones | High elasticity, resistance to extreme temperatures, hydrophobic | Long lifespan, weather resistant, highly flexible | High cost, limited adhesion to certain substrates |

| Acrylic resins | Good UV resistance, chemical stability, transparent | Yellowing resistant, lightweight, versatile in applications | Lower mechanical strength compared to epoxies or polyurethanes |

| Ref. No. | Aim of the Study | Material/System Studied | Key Findings | Application Area | Source |

|---|---|---|---|---|---|

| [1] | Review of composite materials in automotive applications | Various automotive composites | Summarizes benefits of composites in reducing weight and improving efficiency | Automotive | Khan et al. (2024) |

| [3] | Study on resin-based composite materials in insulation | Resin-based composites | Highlights advantages of electrical insulation and durability | Electrical/Automotive | Yan et al. (2023) |

| [5] | Overview of resin-based polymers | Epoxy resins | Demonstrates anti-corrosion properties and versatility | Coatings/Automotive | Umoren et al. (2022) |

| [6] | Review on epoxy resins as anticorrosive materials | Epoxy resins | Effective in protecting metals in harsh environments | Corrosion Protection | Verma et al. (2020) |

| [9] | Development of high thermally conductive polymer composites | All-polymer composites | Enhanced thermal conductivity for insulation | Thermal Management/Automotive | Ren et al. (2023) |

| [13] | Evaluation of insulation performance of anhydride-cured epoxy resin | Epoxy resin | Improved thermal insulation through curing regime control | Automotive/Electrical | Li et al. (2023) |

| [15] | Mechanical evaluation of carbon fiber-reinforced plastic | Carbon fiber-reinforced plastic | Analyzes tensile and bending loads | Automotive/Aerospace | Haldar et al. (2022) |

| [16] | Thermal degradation of epoxy-modified resins | Epoxy-modified resins | High temperature tolerance and multifunctional properties | Multifunctional Applications | Ciprioti et al. (2024) |

| [17] | Improving thermal conductivity in epoxy resin | Epoxy resin with rigid groups | Increased thermal conductivity for thermal shock conditions | Electronics/Automotive | Zhu et al. (2024) |

| [18] | Synthesis of new epoxy polymers | Epoxy polymers | Viscosimetric and rheological improvements | Thermal/Mechanical Insulation | El-Aouni et al. (2024) |

| [21] | Eco-design of polymer matrix composite parts | Eco-composites | Guidelines for sustainable material selection | Automotive/Green Design | Lazăr et al. (2023) |

| [22] | Recycling of anhydride-cured epoxy resin | Recycled epoxy resin | Describes degradation and reuse methods | Sustainable Manufacturing | Zhang et al. (2025) |

| [23] | Oxidative degradation for ammonia-cured epoxy recycling | Epoxy resin | Use of nitric acid to enable material recovery | Circular Economy | Zhang et al. (2023) |

| Material | Property and Application |

|---|---|

| Epoxy resins | These have a strong adhesion capability to various substrates, especially metal surfaces, with low shrinkage—unlike most thermosetting polymer-based adhesives, which are associated with low-resistance polymers [6]. Obtained through a chemical condensation reaction of ethylene oxides (epoxides) with polyphenols, diols, or amines, they are used as strong adhesives for various materials (concrete, metal, glass, wood, etc.), in industrial flooring, concrete element repair, and protective coatings [32]. |

| Polyurethanes | Obtained through a chemical condensation reaction between diisocyanates and alcohols, they are used as flexible foams for upholstery and rigid ones for thermal and acoustic insulation [32]. They combine the hardness and rigidity of metals and plastics with the flexibility of rubbers. This preferable point of material properties and characteristics has made polyurethane the material of choice for many applications, even over metals and plastics [33]. |

| Polyetheretherketone (PEEK) | It is a thermoplastic polyaromatic polymer that exhibits high thermal and chemical stability. It is also a high-performance semicrystalline polymer produced using stepwise polymerization through double alkylation of bisphenol salts [34]. |

| Silicones | They are obtained through the polycondensation of siliceous acids with certain organic substances; used as liquid silicones and as lubricants, as well as in the production of fairly durable paints; silicone rubber is used for sealing gaskets that work in variable climates [32]. |

| Materials: fiberglass composites | Fiberglass is a material made up of multiple extremely fine glass fibers, and it has mechanical properties comparable to other fibers such as polymers and carbon fiber [35]. Recently, more research has been conducted on fiberglass-reinforced composites due to their excellent mechanical properties [36]. |

| Polymer System | Thermal Resistance | Recyclability | Processing Ease | Typical Application | Key Limitation |

|---|---|---|---|---|---|

| Epoxy Resins | High | Low | Moderate | Battery enclosures | Brittle, non-recyclable |

| Polyurethanes | Moderate | Moderate | High | Interior insulation | UV degradation, toxicity |

| Silicones | Very High | Low | Low | Seals, electronics | High cost, weak adhesion |

| Bio-based Hybrids | Moderate–High | High | Developing | Sustainable insulation panels | Limited industrial testing |

| Fiberglass Composites | Moderate | Low | High | Housings, body panels | Brittle under vibration |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dobrotă, D.; Sava, G.-A.; Bărbușiu, A.-M.; Dobrescu, G.T. Sustainable Polymer Composites for Thermal Insulation in Automotive Applications: A Systematic Literature Review. Polymers 2025, 17, 2200. https://doi.org/10.3390/polym17162200

Dobrotă D, Sava G-A, Bărbușiu A-M, Dobrescu GT. Sustainable Polymer Composites for Thermal Insulation in Automotive Applications: A Systematic Literature Review. Polymers. 2025; 17(16):2200. https://doi.org/10.3390/polym17162200

Chicago/Turabian StyleDobrotă, Dan, Gabriela-Andreea Sava, Andreea-Mihaela Bărbușiu, and Gabriel Tiberiu Dobrescu. 2025. "Sustainable Polymer Composites for Thermal Insulation in Automotive Applications: A Systematic Literature Review" Polymers 17, no. 16: 2200. https://doi.org/10.3390/polym17162200

APA StyleDobrotă, D., Sava, G.-A., Bărbușiu, A.-M., & Dobrescu, G. T. (2025). Sustainable Polymer Composites for Thermal Insulation in Automotive Applications: A Systematic Literature Review. Polymers, 17(16), 2200. https://doi.org/10.3390/polym17162200