In this study, the use of CFD for aerodynamic analysis and FEM for structural analysis is essential for the integrated design of an AAA intended for high-altitude unmanned aerial operations in stratospheric environments. These methods enable the comprehensive analysis and optimization of both aerodynamic and structural characteristics, which are critical to achieving a light weight, strength, and efficiency in the overall design.

Both approaches are integrated into a unified workflow: CFD is used to determine the aerodynamic loads, which are subsequently applied in FEM simulations to evaluate structural integrity. This combined strategy ensures a balance between aerodynamic performance and structural reliability, which is particularly important for AAA, where mass (≤400 kg) and long-term durability are of paramount importance. CFD assists in selecting the optimal wing configuration, while FEM validates that the chosen materials and joints can withstand the expected loads—ensuring both lightness and robustness.

The application of CFD and FEM also eliminates the need for costly physical testing, which is especially valuable in AAA development where prototyping at 30 km altitude is impractical. These simulation-based methods support iterative design improvements and confirm that the KMU-3 CFRP structure—with a 0.1 mm wall thickness and truss segments up to 5 m in length—achieves the target mass and strength requirements while sustaining a cruise speed of 70 m/s with 13 kW of solar power input.

2.3.1. Aerodynamic Analysis Methodology (CFD)

CFD serves as a critical tool in the aerodynamic design of the AAA for high-altitude unmanned platforms operating at 30 km in the stratosphere. Under extreme atmospheric conditions—including a low air density (0.0184 kg/m3), ambient temperature of −46.5 °C, and exposure to radiation—CFD enables the accurate modeling of aerodynamic characteristics such as lift, drag, and stability to support optimal wing design.

In this study, CFD is employed to evaluate various wing configurations (e.g., delta, rhomboid, flying wing) to ensure efficient flight at a cruise speed of 70 m/s with minimal energy consumption. The core governing equations are the Navier–Stokes equations, which are solved numerically using finite difference or finite volume methods. CFD simulation identifies critical regions of aerodynamic stress, refines structural shapes, reduces drag, and enhances stability—all without the need for costly full-scale physical testing.

The aerodynamic simulations are conducted under the following standard atmospheric conditions at an altitude of 30 km:

- -

—air density;

- -

—temperature;

- -

—dynamic viscosity;

- -

—flight speed;

- -

—Mach number, where is the speed of sound; although subsonic, the proximity to Mach 0.3 necessitates compressibility considerations;

- -

—Reynolds number (based on wing chord length L = 5 m), computed as ; indicates transitional flow, making turbulence modeling critical;

- -

—wing area.

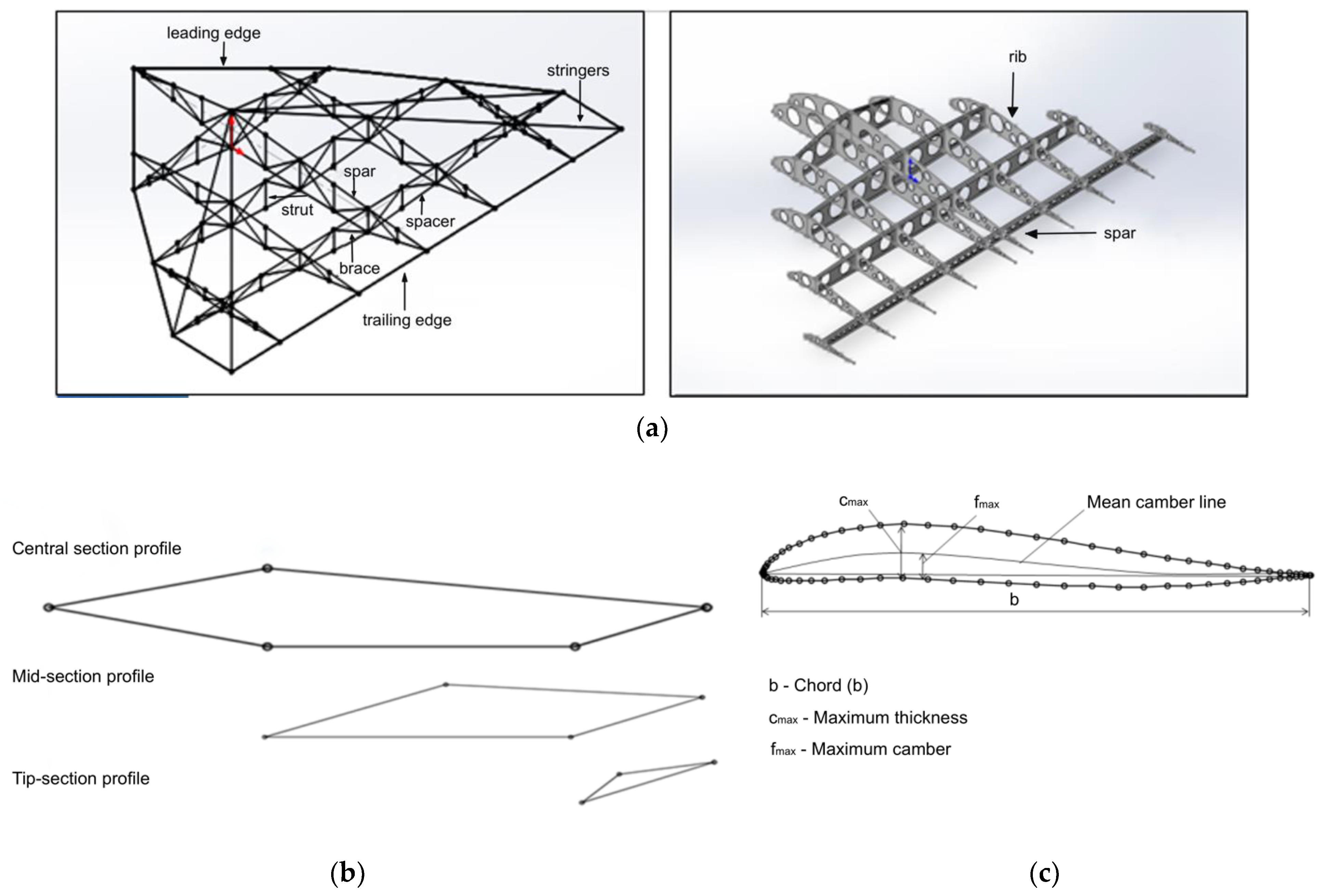

To determine the optimal aerodynamic configuration for the AAA, several wing designs—including wedge-shaped, delta-wing, and flying wing with internal truss structure—were modeled. For each design, 3D CAD models were developed, and the flow behavior was simulated using the ANSYS Fluent R1 (22.1) software package.

Figure 6 shows an example of a three-dimensional model of the AAA, illustrating its overall geometry and the possible placement of the truss elements.

A structured hexahedral mesh is employed to ensure high accuracy in the boundary layer region. Inflation layers with are used to resolve the near-wall flow accurately. The mesh is refined in regions with high gradient concentrations, such as the leading and trailing edges. A mesh convergence study is performed to verify that the simulation results are independent of the grid resolution.

In general, the solution of the flow problem around an aircraft involves the numerical solution of the Navier–Stokes Equation (4) under specified initial and boundary conditions [

35].

In the absence of body forces and assuming

= const, Equation (1) can be written as follows:

The boundary and initial conditions include no-slip or slip conditions for the velocity vector at solid boundaries, pressure values specified at domain boundaries, and flow velocity conditions normal or at an angle to the boundary. In addition, a combination of these conditions can be applied, such as specified pressure and velocity values at the boundary.

The lift force (Y) depends on the circulation of velocity (Γ) and is given by Joukowski’s theorem for a wing section of length L (along the span) in a plane-parallel flow of an ideal incompressible fluid, shown as follows in Equation (5):

where r—the density of the fluid and u—the free stream velocity.

The circulation (Γ) has the dimension [u × l], and it can be shown that the lift force can be expressed as follows:

where S is the characteristic reference area of the body (wing planform area, given by L × b, where b is the chord length of the airfoil) and

is the dimensionless lift coefficient, which generally depends on aerothermodynamic conditions, including the shape of the body, its orientation in the flow, and the Reynolds (Re) and Mach (M) numbers.

In addition to the lift force, the airfoil also experiences a drag force, which can be expressed as follows:

The drag coefficient and the drag force X primarily consist of the following four main components:

- -

, wave , w)—Wave drag, which appears at Mach numbers close to the critical Mach number (M ≈ 0.8).

- -

, friction (, tr)—Friction drag, caused by air resistance against the aircraft surface.

- -

, pressure (, vorticity drag)—Also referred to as vortex drag, resulting from pressure differences around the body.

- -

, induced (, i)—Induced drag, occurring due to flow deflection, including wing-tip vortices and pressure differences between the upper and lower surfaces of the wing.

From Equations (6) and (7), the following dependency can be derived in Equation (8):

where

ε—the aerodynamic efficiency.

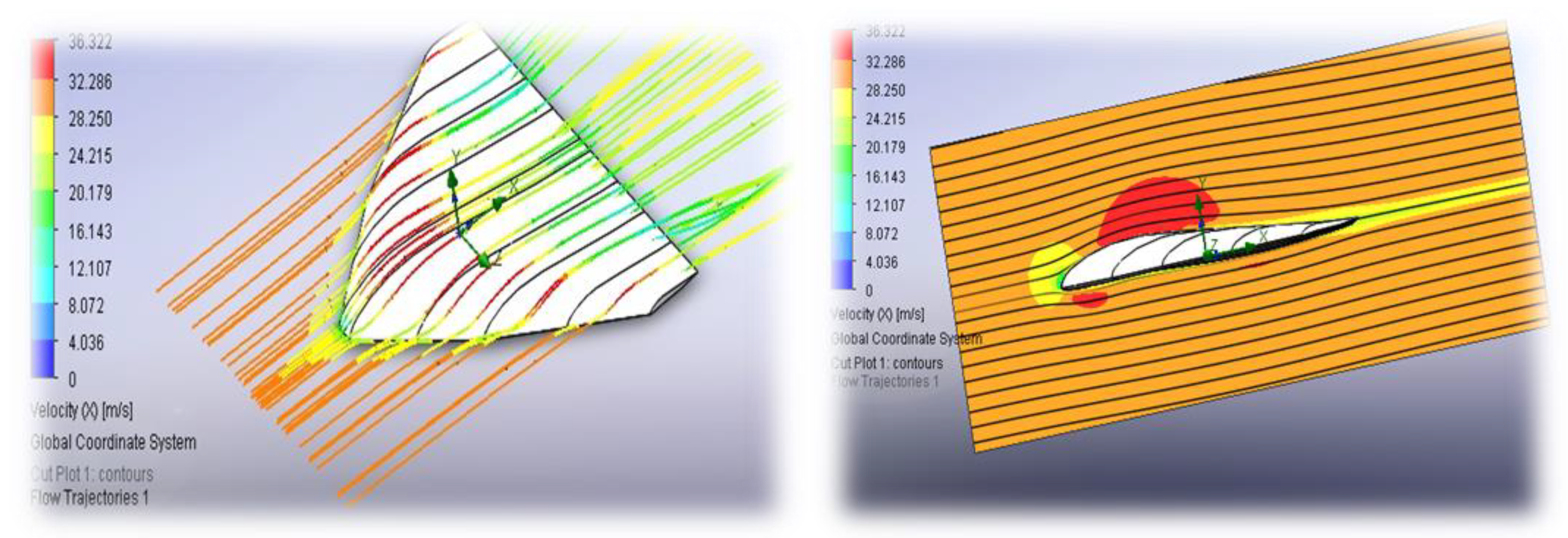

The results of the numerical simulation of flow velocities around the apparatus are shown in

Figure 7. Numerical simulations were performed using the following boundary conditions: a free-stream flow was applied at the far-field boundary with a velocity of 70 m/s, temperature of 226.65 K, and static pressure of 1197 Pa. A no-slip and adiabatic wall condition was imposed on the wing surface. To optimize computational efficiency, geometric symmetry was utilized by modeling only half of the configuration.

Second-order upwind schemes were used for the convective terms, while central dif-ferencing was applied for the diffusive terms. A density-based solver suitable for compressible flow was employed. Solution convergence was monitored through residuals falling below 10–5 and the stabilization of lift, drag, and moment coefficients.

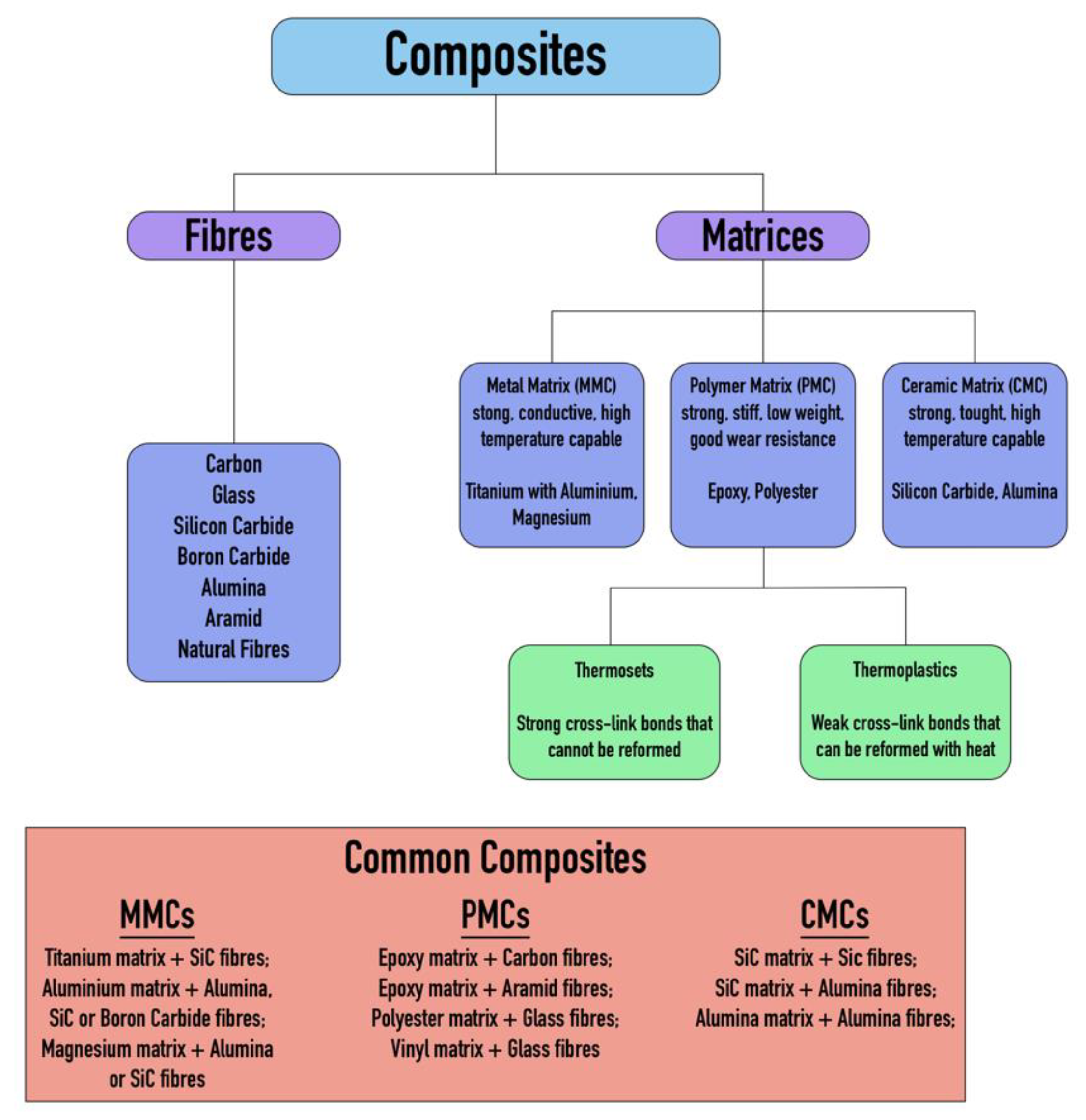

Steady-state simulations were conducted for angles of attack ranging from 0° to 15° in 2° increments to generate lift and drag polars. For each wing configuration, lift, drag, and moment coefficients were computed. Pressure and velocity distributions were analyzed, along with flow visualization via streamlines and vortex structures. In particular, for delta-wing configurations, vortex-induced lift becomes significant at high angles of attack, highlighting the importance of an integrated approach to material selection and the need for further research on hybrid composite materials.

As a visual representation of the numerical simulation results,

Figure 8 shows an example of the study of static and dynamic loads and overloads applied to the aircraft.

Figure 8 shows the following:

- -

The pressure distribution on the surface of the airframe and the main truss elements (

Figure 8a).

- -

The variation in local stresses in the structure under static loading (

Figure 8b).

- -

The potential overloads occurring during maneuvers or wind gusts (

Figure 8c).

The CFD analysis aims to ensure that the generated lift force matches the vehicle’s weight (3920 N for 400 kg). The calculations show that achieving this balance at a cruise velocity and wing area requires a lift coefficient of approximately .

This is derived from the following lift Equation (9):

Substituting known values as follows:

However, using a slightly higher would yield a lift force of approximately 4508 N, indicating a margin of excess lift or the possibility of adjusting the angle of attack for optimized cruise performance. This highlights the importance of an integrated design approach to enhance the aerodynamic efficiency of aerospace systems through careful material and geometry selection.

The expected results for the delta-wing configuration are as follows:

- -

(parasitic drag);

- -

;

- -

(due to vortex-induced lift).

The rhomboid wing design may yield a lower but offers reduced drag at lower angles of attack. An analysis of the lift-to-drag ratio (L/D) is used to identify the most aerodynamically efficient configuration.

A three-level grid independence study was performed (

Table 4). The coarse mesh contained 1.23 × 10

6 hexahedral cells with a first layer height of 0.030 mm; the medium mesh 3.82 × 10

6 cells at 0.015 mm; and the fine mesh 5.57 × 10

6 cells at 0.010 mm. Twenty inflation layers with a growth rate of 1.15 produced y

+ ≤ 1 over 90% of the wing surface and y

+ < 3 elsewhere. The lift and drag coefficients differ by less than 2.5% between the medium and fine grids; consequently the 3.82 M-cell mesh was adopted for production runs. The steady-state pressure field exported from ANSYS Fluent was mapped into ANSYS Mechanical via the External Data interface. Perturbing this pressure field by ±3% changed the peak von Mises stress by only 1.6%, well inside the ultimate safety factor of 2.0.

The computational results suggest that unconventional configurations, when operated at optimal angles of attack, offer high aerodynamic efficiency. Additionally, the structural mass is reduced through the use of lightweight CFRP tubing, which is particularly advantageous for high-altitude operations. Similar findings were reported by NASA laboratories, emphasizing the benefits of lightweight composite load-bearing systems.

The CFD results are validated through comparisons with analytical models (e.g., Zhukovsky’s lift theorem) and data from analogous HAPS designs. Due to the lack of empirical data under stratospheric conditions, this study relies on well-established correlations and findings from prior research, such as analyses of high-altitude airships.

The simulation results confirm that CFRP is the only material capable of meeting the stringent strength-to-weight requirements without additional corrosion protection, even under harsh environmental conditions. CFD thus plays a critical role in the design of AAAs, enabling aerodynamic optimization [

46] for sustained flight at 30 km altitude. The simulations verify that a wing with

≈ 0.435–0.5 produces sufficient lift (≈3920 N) to balance vehicle weight while minimizing drag. When coupled with FEM analysis, the KMU-3 truss structure is confirmed to withstand mechanical loads with adequate safety margins while keeping the total mass below 400 kg.

This approach reduces the reliance on costly physical testing and establishes a solid foundation for the development of reliable and efficient HAPS platforms for extended-duration stratospheric missions.

According to the computational experiment, a non-traditional configuration with an optimal angle of attack provides high aerodynamic performance indicators. Additionally, the structural mass is reduced due to the use of carbon fiber tubes, which is particularly significant for high-altitude flights. Similar results were obtained in NASA laboratories, where the advantage of lightweight composite load-bearing systems was emphasized.

As demonstrated above, the only material capable of meeting the stringent requirements for mass and strength under such conditions is CFRP. Based on such studies, specific requirements for the properties of composites (elastic modulus, compressive strength limits, impact toughness, etc.) are formulated, which were taken into account in the design of the AAA.

2.3.2. Calculation of Strength Characteristics (FEM)

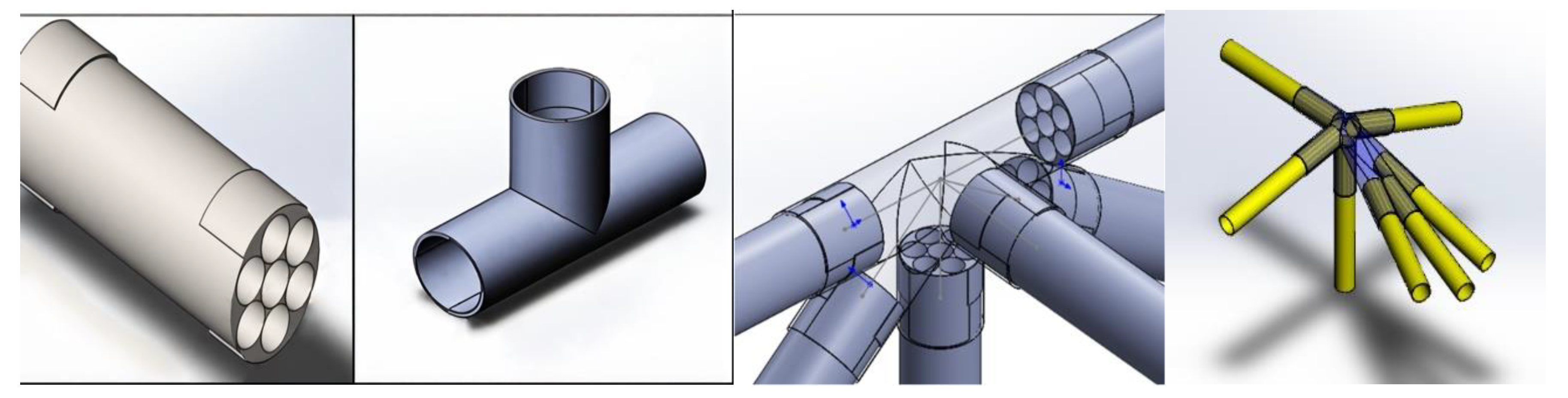

This section examines the finite element method (FEM) used to analyze the structural strength characteristics of composite materials. A finite element model has been developed in ANSYS Mechanical to determine the stress–strain state of tubular elements and their connection zones (fitting-based thermal bonding). This method allows the simulation of the stress and deformation distribution in composite materials, taking into account the complex loading conditions of the KMU-3 carbon fiber composite, as well as the adhesive in the joints.

The objective is to determine the minimum required wing area (approximately 200 m2) and mass (no more than 400 kg) to meet operational requirements, including powering engines and on-board systems using solar energy, maintaining a reasonable battery reserve (up to 40% of total mass), achieving a cruise speed of 70 m/s, and ensuring a propulsion power of 13 kW with 95% efficiency.

The wing is a thin-walled structure made of KMU-3 carbon fiber composite with a wall thickness of 0.1 mm. For simplicity, the wing shape is assumed to be rectangular with a span of 40 m and a chord of 5 m, giving an area of 200 m2. The internal structure is reinforced with a truss system of carbon fiber tubes. The total mass of the wing does not exceed 400 kg, of which up to 40% (160 kg) is accounted for by the solar panels and batteries, evenly distributed over the surface.

The material properties of KMU-3 are as follows:

- -

Density: 1450 kg/m3;

- -

Tensile strength along fibers: 1100 MPa;

- -

Young’s modulus along fibers: 180 GPa;

- -

Young’s modulus across fibers: 9 GPa;

- -

Shear modulus: 5.1 GPa.

Considering the operational requirements, the wing must provide sufficient power for the propulsion system, which operates at 13 kW with 95% efficiency, giving an effective power output of approximately 13.7 kW after losses. The solar panels, which cover a significant part of the 200 m2 wing area, generate energy during the day, while batteries (weighing up to 160 kg) maintain operation at night. The aircraft achieves a cruise speed of 70 m/s at an altitude of about 30 km, where the air density is extremely low (about 0.018 kg/m3).

The aerodynamic lift force is calculated to ensure stable flight at the specified speed. The lift formula is given by Equation (10) as follows:

where

- -

= 0.018 kg/m3—air density at an altitude of 30 km;

- -

V = 70 m/s—cruise speed;

- -

S = 200 m2—wing area;

- -

= 0.5—lift coefficient (a typical value for a wing).

The values are substituted as follows:

This force is evenly distributed across the wing and balances the weight of the structure (400 kg × 9.81 m/s2 ≈ 3924 N), confirming that a 200 m2 wing area is sufficient.

The weight load from the 400 kg mass, including 160 kg of batteries and solar panels, is also distributed across the wing. The total load consists of a combination of aerodynamic lift force and weight force.

The FEM simulations employ an orthotropic material model, with fiber orientation aligned at 0°/90° in the longerons to maximize axial strength, and ±45° in the diagonal members to ensure shear and torsional resistance. The matrix material used is epoxy resin 5-211B, which provides strong adhesion and enhanced radiation resistance.

Thermal effects are taken into account, with the elastic modulus increasing by approximately 5% at −60 °C and decreasing by about 10% at +80 °C. These variations highlight the importance of a comprehensive material selection strategy and suggest the potential of hybrid composites for improving the performance and reliability of aerospace systems under extreme conditions.

For structural analysis, a 3D wing model with a truss structure is created. The thin-walled sections are modeled as shell elements, while the truss system is represented by beam elements. The anisotropic properties of the KMU-3 carbon fiber composite are assigned according to its mechanical characteristics. Boundary conditions include fixing the wing at its attachment points to the fuselage. Loads are applied as distributed aerodynamic forces and weight loads.

Figure 9 shows the 3D models of the selected AAA elements during assembly. The calculation results confirmed that with the correct choice of wall thickness (approximately 0.1 mm) and material (KMU-3), the required strength margin is achieved while maintaining the mass and dimensional constraints within 400 kg.

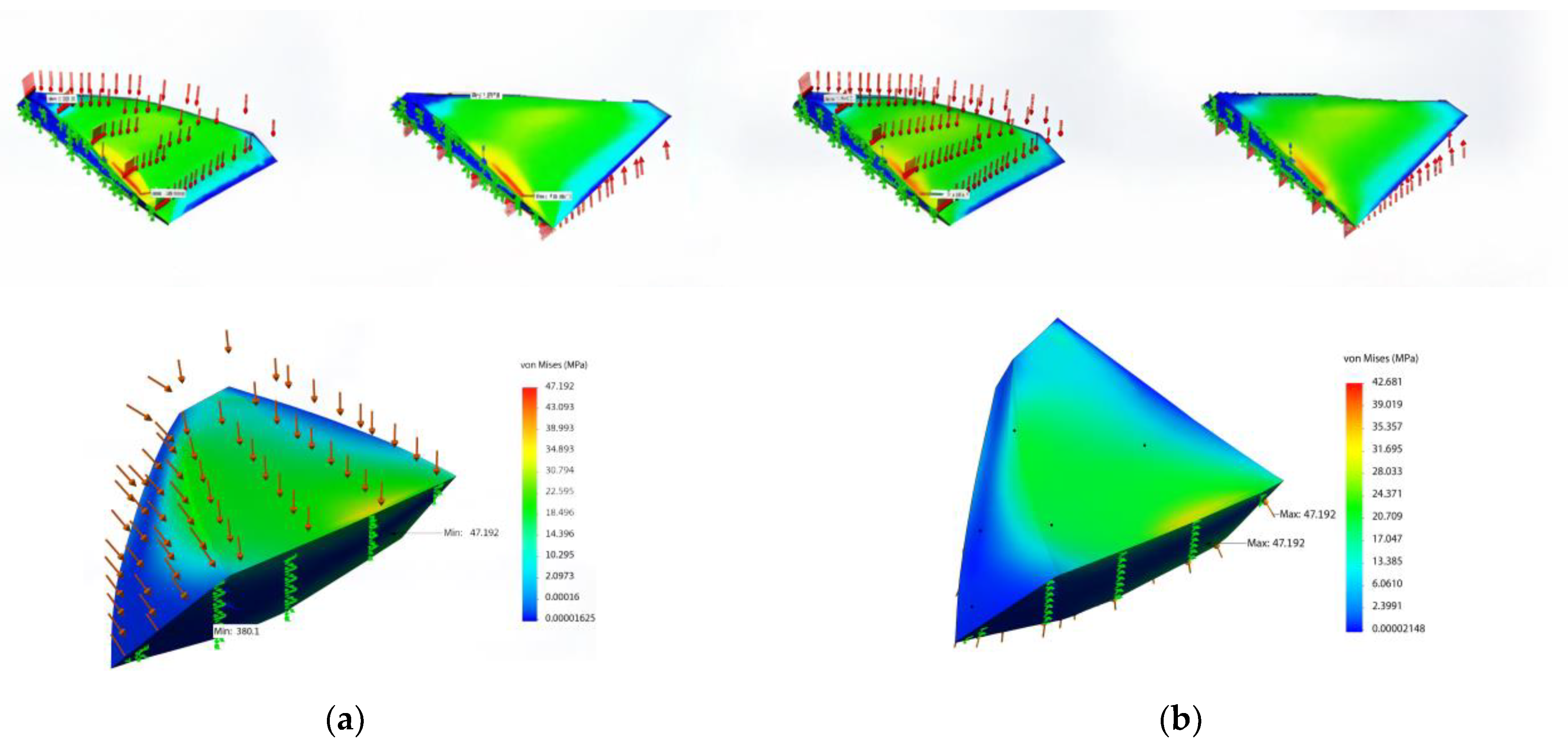

During the FEM analysis (

Figure 10), the stress and deformation distribution was determined for the blade in both the traditional and unconventional configurations (delta and rhombic profiles). In addition, the behavior of a tubular element with one end fixed was analyzed (

Figure 11). The red and yellow zones indicate areas of maximum stress, while the blue zones correspond to areas of minimum stress. The maximum stress was found to be 37.23 MPa and the minimum stress was 9.9 MPa.

Following the FEM analysis in ANSYS Mechanical, the following characteristics were obtained:

- -

The maximum stress in the structure is about 50 MPa, which is significantly lower than the tensile strength of the carbon fiber composite (1100 MPa).

- -

The maximum wing deflection is about 0.5 m, which is acceptable for a 40 m wingspan.

- -

The total structural mass is less than 400 kg, including a battery reserve of up to 160 kg.

The finite element analysis confirms that a 200 m

2 wing with a total mass of no more than 400 kg made of KMU-3 carbon fiber composite meets the operational requirements. It can withstand aerodynamic loads at a cruise speed of 70 m/s, power the propulsion system (13 kW) from solar energy [

41], and maintain a reasonable battery reserve (up to 40% of total mass). The structure has sufficient strength and stability for flights at altitudes of up to 30 km.