3.1. Properties of Soybean Oil

To evaluate the feasibility of using edible oil products as eco-friendly plasticizers in bicycle tire rubber compounds, the physicochemical properties of four non-petroleum-based vegetable oils, namely SBO, r-SBO, e-SBO, and ESBO, were first characterized. As shown in

Table 2, the viscosities of SBO, r-SBO, and e-SBO at 40 °C were comparable to that of CH450, indicating suitable flowability for rubber compounding. In contrast, ESBO exhibited a significantly higher viscosity (212.9 mm

2/s), suggesting lower flowability. This high viscosity is anticipated to enhance mechanical strength and elasticity in the rubber matrix [

13]. Specific gravity data showed that ESBO possessed the highest value (0.979), attributable to its high molecular polarity, while e-SBO had the lowest (0.933), implying varying degrees of lubrication potential [

14]. Initial boiling point, freezing point, and flash point analyses confirmed that all oils possess acceptable storage safety. Spectral analysis revealed distinctive epoxy functional group absorption peaks for ESBO, indicating successful chemical modification. UV–vis analysis further suggested a reduction in double bond content, lowering oxidative susceptibility. Overall, SBO emerges as the most suitable base replacement due to its stability and biodegradability, whereas r-SBO and e-SBO offer cost and sustainability advantages but pose challenges in consistency. ESBO holds potential for performance enhancement but faces processing and cost constraints.

At present, the evaluation of oil products based solely on their physicochemical properties does not allow for a complete prediction of their actual impact on rubber compound performance and finished product quality. Therefore, this study proposes a practical investigation by substituting petroleum-based processing oils with four types of vegetable oils (SBO, r-SBO, e-SBO, and ESBO). In the first phase, the systematic replacement of petroleum oil with SBO and ESBO at the 25 wt%, 50 wt%, 75 wt%, and 100 wt% levels is conducted to assess its effects on the processing behavior, mechanical strength, aging resistance, and durability of rubber compounds. Based on the resulting data, a comprehensive evaluation is then carried out to determine the suitability, limitations, and optimization strategies for each oil type in sustainable rubber formulation development. This approach addresses both material property gaps and practical performance, offering insights for future bio-based processing oil applications in green rubber technologies.

3.2. Characterization of Staining Rubbers with Soybean-Derived Alternatives

According to

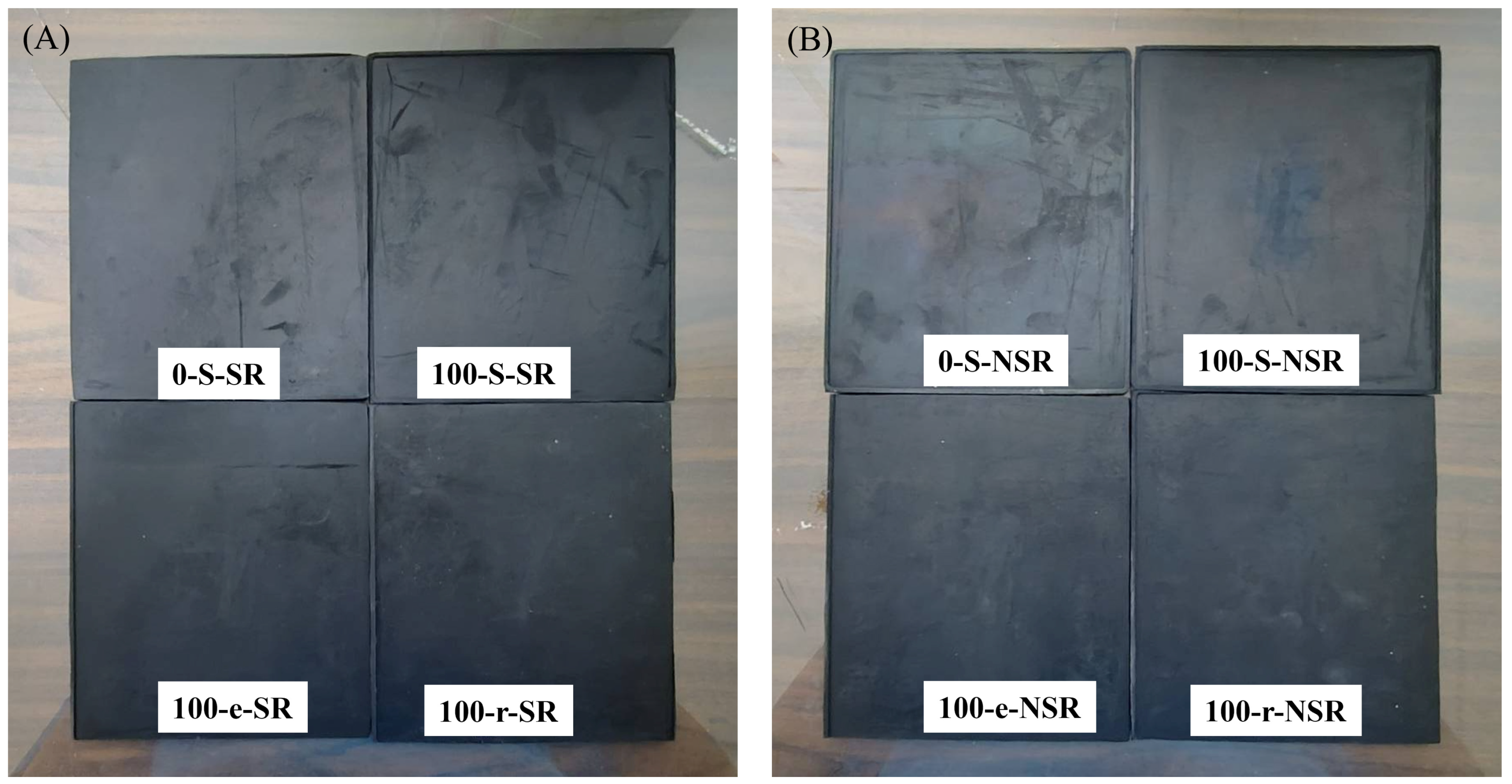

Table 1, staining rubber (SR) formulations were modified by substituting petroleum-based oil with SBO and ESBO at varying proportions. As illustrated in

Figure 2, there were no visually discernible differences in the surface color, texture, or integrity of the rubber specimens across all formulations. This indicates that the type and ratio of bio-based oil used had minimal impact on the macroscopic appearance of the final rubber products. This result suggests that, despite variations in viscosity and polarity between SBO and ESBO, these factors do not significantly influence the rubber’s esthetic or surface morphology under the tested processing conditions. This finding supports the practical feasibility of incorporating bio-based oils in rubber compounding without compromising visual uniformity, a key factor for end-use applications in consumer-facing products [

15,

16].

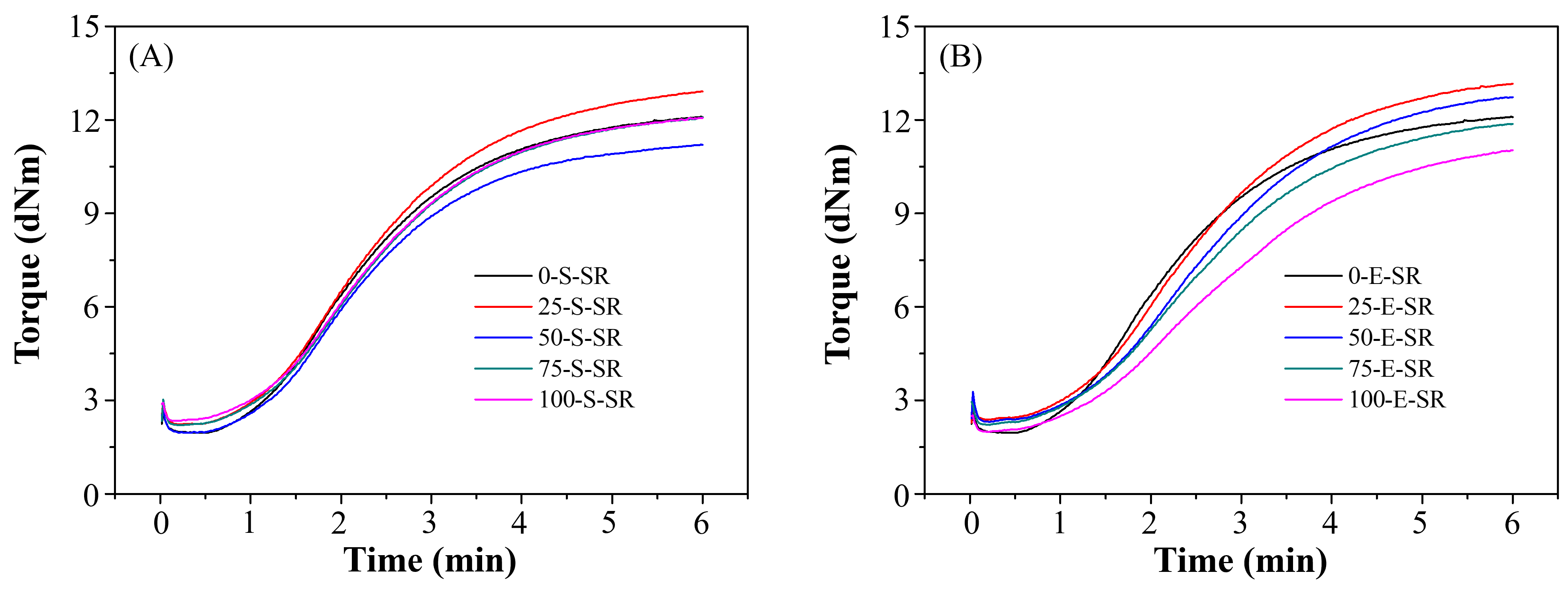

To evaluate processability, rubber compounds incorporating various levels of SBO and ESBO were analyzed using Mooney viscosity (MV) and rheographs (

Figure 3), including TS1 (scorch time) and TC90 (optimum cure time). As shown in

Table 3, MV and rheological responses showed limited variation across different SBO replacement levels (X = 25, 50, 75, 100). However, compounds in the X-E-SR group (using ESBO) exhibited consistently higher MV values, attributed to the significantly higher viscosity of ESBO, which hinders flow and mixing efficiency [

17]. TS1 values remained relatively stable across all oil ratios, indicating a similar onset of vulcanization. In contrast, TC90 increased with higher ESBO content, suggesting prolonged cure time. This is likely due to the difficulty in dispersing ESBO uniformly in the rubber matrix, which delays crosslinking [

18]. Overall, ESBO’s high viscosity negatively impacts both fluidity and curing efficiency, while SBO maintains favorable processing characteristics.

The interaction between processing oils and rubber compounds is fundamental to both processing behavior and the final performance of vulcanizates. SBO, a triglyceride-based bio-oil rich in unsaturated fatty acids, exhibits a solubility parameter of approximately 16.2–16.7 MPa1/2. This value closely matches that of common diene rubbers such as natural rubber, polybutadiene rubber, and styrene–butadiene rubber, indicating favorable miscibility and internal plasticization behavior. As a result, the addition of SBO facilitates polymer chain mobility, lowers Mooney viscosity, and improves the dispersion of fillers during compounding.

However, the high degree of unsaturation in SBO introduces challenges during vulcanization. The double bonds in the fatty acid chains are reactive and may compete with the rubber matrix for the vulcanizing agent (e.g., sulfur), potentially leading to a reduction in crosslink density. This effect was reflected in our results, where SBO-plasticized compounds exhibited a slightly reduced 300% modulus and hardness compared to those using conventional aromatic oil, although tensile strength and elongation at break remained acceptable. This trade-off highlights the dual role of virgin SBO as both a plasticizer and a reactive species within the curing system.

These findings are consistent with previous studies reporting that while virgin vegetable oils enhance processing characteristics and offer environmental advantages, their high reactivity can influence vulcanization kinetics and mechanical properties if not properly balanced with the formulation strategy. Future work may explore oil modification or synergistic use with co-additives to optimize performance further.

Table 4 presents the influence of various oil replacement ratios on the physical properties of SR. Hardness and specific gravity values remained within acceptable ranges, showing minimal variation across formulations. However, noticeable differences were observed in tensile and tear strengths. In the X-E-SR group, tensile strength was lower than that in the X-S-SR group, likely due to the higher viscosity of ESBO impeding uniform raw material dispersion, which negatively affected crosslinking efficiency and mechanical integrity [

18]. Additionally, the inherent formulation characteristics of SR, compared with non-staining rubber (NSR), may contribute to significant variation in tear strength, with SR consistently exhibiting higher tear resistance. This enhanced tear strength is advantageous for applications requiring extended durability and resistance to mechanical wear, such as tire treads and industrial rubber components [

19].

After exposing the X-Y-SR samples (X = 25, 50, 75, 100; Y = S, E) to an ozone-rich environment (50 ppm) for 12 h, surface cracking was examined to evaluate ozone resistance. The results, summarized in

Table 5, show no significant difference in ozone-induced degradation among samples using CH450, SBO, or ESBO as processing oils. This indicates that replacing CH450 with vegetable-derived oils does not compromise the rubber’s ozone resistance. Interestingly, the 100-E-SR formulation exhibited marginally enhanced ozone resistance. This improvement is likely due to the reduced content of carbon–carbon double bonds (C = C) in ESBO, resulting from the epoxidation process. As C = C bonds are primary targets for ozone attack, their reduction decreases the vulnerability of the rubber matrix to oxidative cleavage [

20]. Consequently, ESBO contributes to enhanced oxidative stability and reduced surface cracking under ozone exposure, supporting its viability as a sustainable alternative to petroleum-based plasticizers in rubber formulations.

Table 5 presents the AKRON abrasion results for X-Y-SR formulations (X = 25, 50, 75, 100; Y = S, E), which were used to assess the wear resistance of the rubber compounds. The data indicate that the wear loss values of the X-S-SR group were comparable to those of the control group using CH450 petroleum-based processing oil (0-S-SR). This suggests that substituting CH450 with SBO does not significantly impair the wear resistance of the rubber. Conversely, the ESBO-containing samples did not exhibit the anticipated improvement in wear resistance. A plausible explanation for this outcome is the high viscosity of ESBO, which may hinder its uniform dispersion during compounding [

18]. This insufficient dispersion could lead to uneven filler distribution and suboptimal crosslinking, resulting in a less compact rubber matrix. Such microstructural looseness may, in turn, reduce the compound’s resistance to mechanical abrasion. These findings highlight the importance of balancing oil viscosity and compatibility to achieve optimal reinforcement in rubber formulations.

N: No cracks.

A: A few cracks (less than 20).

B: Many cracks (assuming that the number of cracks can be determined).

C: An infinite number of cracks (when unable to calculate the number of cracks).

E: The edge of the test piece.

e: Cracks on the edge of the test piece.

Those that cannot be seen with the naked eye but can be seen with a 10x magnifying glass.

Cracks that can be seen with the naked eye.

Crack growth, size less than 1 mm.

Crack growth, size more than 1 mm and less than 3 mm.

Cracks that grow larger than 3 mm or may cause fracture.

The physical properties of the X-Y-SR samples (X = 25, 50, 75, 100; Y = S, E) were evaluated before and after thermal aging at 100 °C for 72 h to assess the aging durability of each experimental group (as summarized in

Table 6). In general, key mechanical properties, such as tensile strength and elongation at break, declined to varying extents across all X-Y-SR groups following aging. Notably, within the same processing oil system, the 100-Y-SR (Y = S, E) formulations exhibited comparatively lower degradation rates, suggesting enhanced thermal aging stability. This improved performance may be attributed to the homogeneous oil composition at full replacement, which promotes consistent dispersion and compatibility within the rubber matrix. In contrast, formulations with mixed replacement ratios (X = 25, 50, 75) may suffer from inconsistencies in oil polarity, viscosity, or reactivity, potentially leading to non-uniform dispersion and irregular crosslinking during processing. These microstructural inconsistencies could compromise network integrity and contribute to the more pronounced deterioration in mechanical properties observed after aging.

3.3. Characterization of Non-Staining Rubbers with Soybean-Derived Alternatives

To evaluate the visual effect of vegetable oil substitution in NSR, samples were prepared using different replacement ratios (X = 0, 25, 50, 75, 100) and oil types (S and E), coded as X-Y-NSR. As shown in

Figure 4, the appearance of the rubber samples across all formulations exhibited no significant visual differences compared to the CH450-based control. This suggests that substituting CH450 with either SBO or ESBO, even at full replacement levels, does not adversely affect the surface uniformity or overall visual characteristics of NSR compounds. This observation aligns with the findings for SR, indicating the good compatibility of bio-based oils with both rubber types.

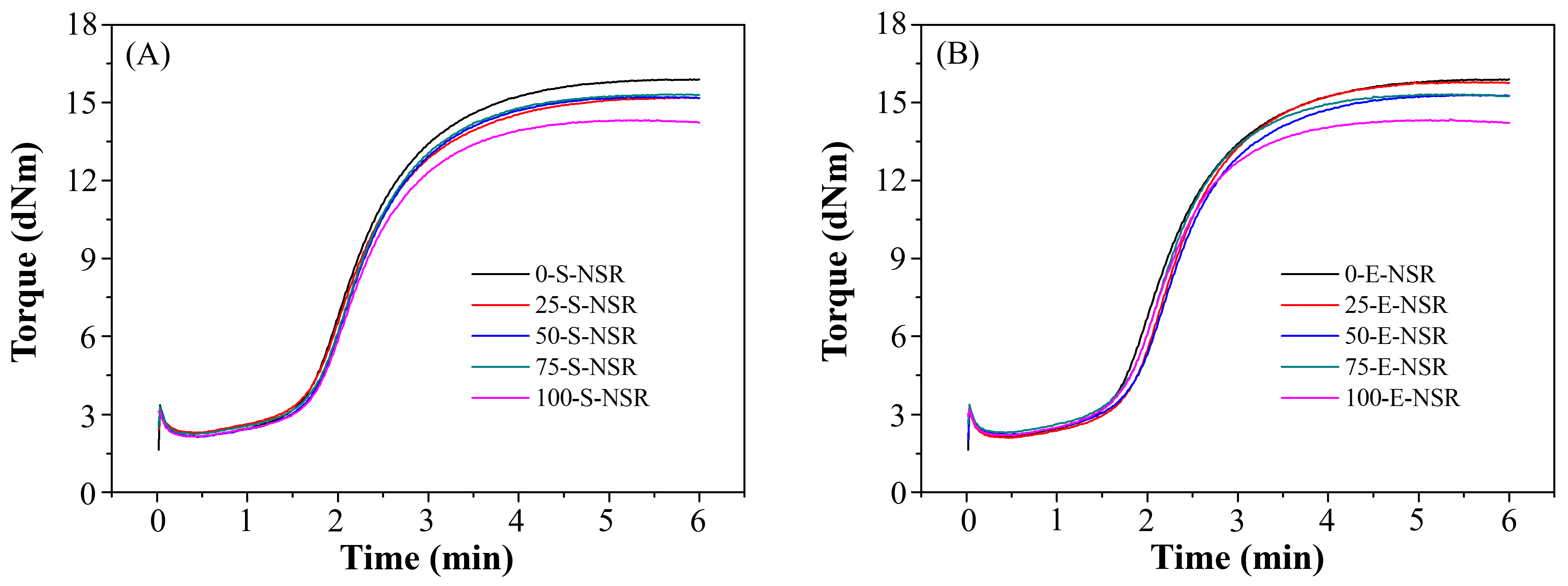

The processing properties of NSR compounds were evaluated by replacing CH450 naphthenic oil with SBO and ESBO in varying proportions. MV values and rheological parameters, including TS1 and TC90, were measured from rheographs (

Figure 5), and the results are summarized in

Table 7. Across all experimental groups (X-Y-NSR), MV values were slightly higher than the standard range (53–63). However, within each oil type group, variations in the replacement ratio had minimal impact on MV, suggesting that the oil substitution ratio does not significantly affect viscosity and that mixing stability remains acceptable. TS1 values remained within a reasonable range and exhibited no clear trend with changes in oil content, indicating comparable initial vulcanization reactivity for both SBO and ESBO. Notably, the TC90 values in the SBO group remained relatively stable across ratios, whereas the ESBO group showed a slight decrease in TC90 with an increasing replacement ratio, potentially reflecting enhanced cure kinetics due to the functional characteristics of ESBO.

The physical properties of the X-Y-NSR compounds are summarized in

Table 8. Replacing CH450 with vegetable oils revealed a mixed impact on material performance, with specific properties improving while others declined. Specifically, hardness and specific gravity remained relatively unchanged across all X-Y-NSR groups (X = 25, 50, 75, 100; Y = S, E), suggesting that the substitution had a limited effect on the density and mass of the rubber matrix. Within each oil type, changes in the replacement ratio did not lead to significant fluctuations in these physical parameters, indicating good formulation consistency. However, for all X-Y-NSR groups (Y = S, E), a reduction was observed in ductility-related mechanical properties, including tensile strength, elongation at break, and tear strength. These decreases suggest that while vegetable oil substitution is feasible, it may adversely affect the elasticity and toughness of NSR to some extent, warranting further optimization in formulation or processing conditions.

As presented in

Table 9, NSR compounds demonstrated excellent ozone resistance after substituting CH450 with varying proportions of SBO and ESBO. Across all replacement levels (25%, 50%, 75%, and 100%), the NSR samples exhibited no observable surface cracking after exposure to an accelerated aging environment of 50 ppm ozone for 12 h. These results suggest that incorporating vegetable oils, whether SBO or ESBO, does not compromise the ozone durability of the NSR formulation. The absence of degradation indicates that such bio-based oils are viable alternatives to petroleum-based processing oils in applications requiring ozone stability.

The AKRON wear test results for X-Y-NSR samples (X = 0, 25, 50, 75, 100; Y = S, E), presented in

Table 9, reveal a trend consistent with that observed in the SR formulations. Specifically, the X-Y-NSR groups (Y = E) exhibit comparatively higher wear loss. This suggests that when ESBO is used to replace CH450, even in NSR systems, its high intrinsic viscosity continues to hinder efficient dispersion during mixing. Poor dispersion likely leads to inhomogeneous filler distribution and suboptimal crosslinking, resulting in a looser rubber matrix and diminished abrasion resistance. In contrast, the wear loss in SBO-based NSR formulations remains close to that of the reference sample (X = 0), indicating more favorable processing characteristics and better overall wear performance.

The results of the heat aging test conducted at 100 °C for 72 h indicate that the physical properties of the X-Y-NSR formulations declined only slightly after aging (as summarized in

Table 10). There were minimal variations between the replacement ratios within the same oil type, suggesting stable thermal performance. The 100-S-NSR formulation demonstrated a strong retention of mechanical properties, likely due to effective oil dispersion and consistent crosslinking during processing. These findings suggest that NSR formulations, particularly those with the complete substitution of SBO, exhibit good resistance to thermal aging and are suitable for applications that require heat stability.

3.4. Effects on Processing Behavior and Mechanical Properties Using e-SBO and r-SBO

To promote environmental sustainability and enhance resource recycling, this study investigates the feasibility of replacing CH450 naphthenic oil with r-SBO and e-SBO. The formulation codes for the oil-replaced rubber compounds are provided in

Table 1. As shown in

Figure 6, regardless of the rubber type (SR or NSR), the appearance of samples made with 100% r-SBO and 100% e-SBO shows no significant difference compared to those prepared with CH450. This indicates that the substitution does not negatively affect the visual quality of the final rubber products.

Table 11 displays the processing performance of 100-Y-SR and 100-Y-NSR (where Y = e, r). The measured MV values for 100-e-SR and 100-r-SR were 38.18 and 37.41, respectively, significantly below the standard processing range (SR: 56–66; NSR: 53–63). This notable reduction in MV values can likely be attributed to changes in the chemical composition and oxidation levels of e-SBO or r-SBO. Specifically, oxidation or degradation during storage or prior use may have led to lower-molecular-weight components or increased polarity. These factors can lead to strong plasticizer behavior in the rubber matrix, altering the compound’s viscosity and causing the rubber to become excessively soft during processing. The rheological parameters, including TS1 and TC90, were measured from the rheographs (

Figure 7).

The results of the physical property tests for the use of 100-Y-SR and 100-Y-NSR (where Y = e, r) show that the fundamental characteristics of these substitute oils are similar to those of SBO. As a result, the differences in mechanical performance are minimal. Parameters such as hardness, tensile strength, elongation at break, M300, and tear strength do not significantly differ from those observed in the 100-S-SR and 100-S-NSR groups, as summarized in

Table 12.

Based on the data presented in

Table 13, both 100% e-SBO and 100% r-SBO rubber compounds (SR, NSR) show ozone and abrasion resistance similar to that of the reference group using CH450. In the ozone resistance test, the NSR formulations containing 100% e-SBO or r-SBO exhibited no surface cracking, performing comparably to the X-S-NSR (where X = 0, 100) group. Additionally, the AKRON wear test results indicate that the wear losses of 100-e-SR and 100-r-SR are consistent with those of the formulations based on 100-S-SR. This suggests that substituting CH450 with 100% e-SBO or r-SBO does not negatively affect wear resistance. These findings highlight the potential for using waste-based SBO as sustainable processing oil alternatives without compromising key performance attributes.

As shown in

Table 14, after thermal aging at 100 °C for 72 h, the physical properties of rubber compounds made with 100% e-SBO (100-e-SR) and 100% r-SBO (100-r-SR) showed a significant decline, particularly in tensile strength, elongation, and modulus. This decline suggests that oxidative degradation and increased acidification in expired and recycled SBO may disrupt the rubber matrix and impair the stability of the crosslinks, leading to reduced resistance to thermal aging. In contrast, the physical properties of the NSR formulations using the same oils remained relatively stable after aging. This stability indicates that the NSR system has a greater tolerance to variations in oil quality, likely due to enhanced structural integrity and improved filler–matrix interaction. These factors help maintain crosslink density and mechanical performance under thermal stress.

3.5. Evaluation Performance of Tire Fabricated with 100-S-SR

The test results indicate that 100% SBO outperformed other oil types in terms of processability, the retention of physical properties, and resistance to thermal aging. These benefits position SBO as a promising eco-friendly alternative to conventional mineral oils used in rubber compounding. As a result, 100% SBO was chosen as the preferred sustainable processing oil for tire formulations. Additionally, the large-scale production of NSR compounds using 100% SBO demonstrated consistent processing behavior and mechanical performance, remaining within the acceptable specification ranges required for commercial applications. It is noteworthy that the vulcanization time applied in the preparation of laboratory test sheets differs from that used in actual tire manufacturing. This discrepancy arises from the fundamental differences in material structure and processing configuration. In the small-scale laboratory tests, vulcanization was conducted on rubber-only specimens, enabling a focused evaluation of the compound’s curing behavior. In contrast, the tire vulcanization process involves complex, multi-layered assemblies incorporating not only rubber but also reinforcing materials such as steel belts and textile plies. These additional components significantly affect heat conduction and the overall curing dynamics. Consequently, the industrial vulcanization process requires an extended curing time and temperature adjustments to accommodate the thicker tread rubber and ensure consistent crosslinking throughout the tire structure. Given that this study originates from an industry–academia collaborative project targeting practical application, the vulcanization conditions for tire production were optimized accordingly to reflect real-world manufacturing constraints and performance criteria.

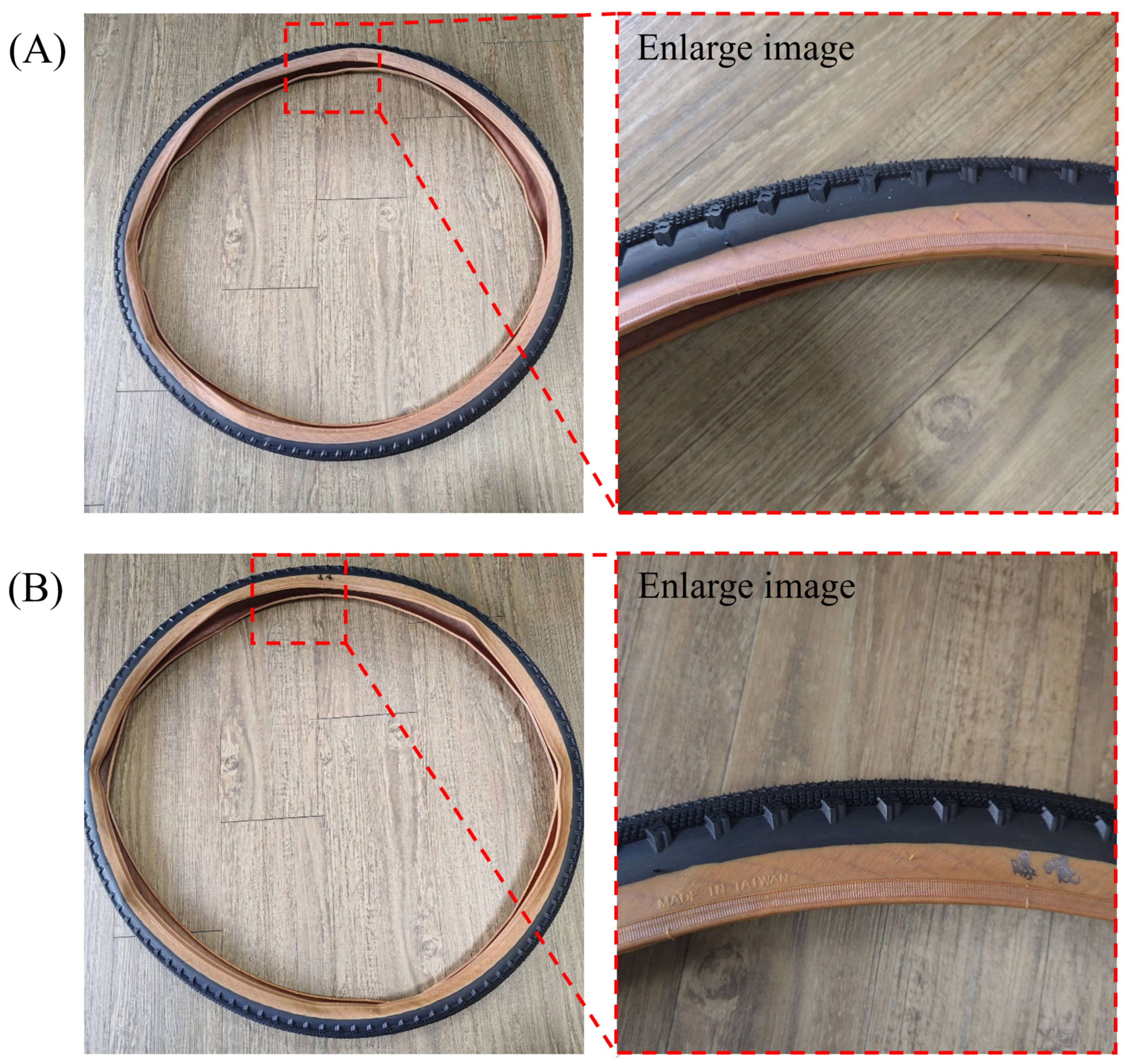

Figure 8A demonstrates that a tire manufactured with 100% SBO as the processing oil exhibits outstanding appearance quality and environmental stability. Remarkably, there were no visible defects, contamination, or phase separation among the rubber components. After seven days of direct sunlight exposure, the tire’s surface remained flawless, showing no signs of discoloration, exudation, or deposits, which underscores its exceptional weather resistance, as shown in

Figure 8B. These compelling results indicate that SBO is compatible with the rubber matrix and effectively preserves the esthetic and structural integrity of the tire when faced with environmental challenges. This aligns seamlessly with prior research demonstrating that SBO-based rubbers enhance dispersion, elevate flexibility, and deliver impressive aging resistance in tire applications [

2,

3].

The burst test results highlight the remarkable performance of the outer tire created with the SBO-based rubber formulation. It endured a water pressure of 1000 kPa for 2 min without any sign of failure. There were no visible cracks, leaks, or deformations, which strongly attests to its outstanding structural integrity and internal pressure resilience. This impressive performance demonstrates that the rubber matrix and compounding strategy employed are practical and capable of maintaining dimensional stability and mechanical strength under extreme pressure conditions [

4,

5]. Such attributes meet the essential safety and durability standards for bicycle tires, reinforcing their reliability during high-pressure situations in real-world applications.

Table 15 demonstrates that tires made with 100% SBO as a processing oil provide exceptional durability in real-world conditions. After 5000 km of continuous driving at 40 km/h, no visible damage, such as cracks, delamination, or surface degradation, was observed. This impressive performance highlights the tires’ outstanding wear resistance, rubber cohesion, and oxidative stability, all critical factors in determining tire reliability. These results confirmed that SBO improves rubber flexibility and cold-weather traction and enhances overall compound performance while minimizing environmental impact. Thus, SBO is more than just an alternative; it is a vital component that meets the rigorous long-term performance standards for sustainable, high-durability tires [

2,

6].

As shown in

Figure 9, the innovative bicycle tire developed in this study was officially exhibited at the 2025 Taipei International Cycle Show (TAIPEI CYCLE 2025), one of the most prominent and influential exhibitions in Asia’s bicycle industry. During the exhibition, the product attracted significant attention from international media and industry stakeholders due to its eco-friendly materials, high-performance characteristics, and potential for carbon footprint reduction. Numerous buyers and companies inquired about future development plans and the possibility of procurement or licensing agreements. This public presentation not only validated the technical feasibility of the research outcomes but also demonstrated the product’s market readiness and strong potential for industrial application. The visibility and recognition at such a reputable platform underscore the value and impact of the developed green tire technology.

3.6. Comparative Analysis of Bio-Based and Petroleum-Based Processing Oils in Rubber Composites

The global shift toward sustainability has intensified efforts to replace petroleum-derived plasticizers with bio-based oils in rubber compounding. Our findings, consistent with previous reports [

4,

5,

6,

7,

8,

18], confirm that virgin SBO enhances compound processability and mechanical properties.

In the processing characteristics field, virgin SBO effectively lowers Mooney viscosity, facilitating better mixing and processing, aligned with the results from Xu et al. [

5] and Cataldo et al. [

8]. In contrast, ESBO increases viscosity and prolongs cure time due to its high kinematic viscosity [

18]. e-SBO and r-SBO exhibited even lower viscosities, resulting in overly soft compounds, likely due to degradation-induced molecular breakdown. For mechanical strength, SBO-plasticized compounds showed a >10% improvement in tensile strength, though with a slightly reduced 300% modulus and hardness compared to CH450. These results align with reports on unmodified bio-oils reducing crosslink density by competing with vulcanization agents [

5]. The poor dispersion of ESBO further diminished tensile performance. e-SBO and r-SBO mirrored the unaged performance of virgin SBO but showed post-aging declines in SR matrices while remaining stable in NSR systems. In the field of durability and aging resistance, the abrasion resistance of SBO matched that of CH450, while ESBO enhanced ozone resistance due to epoxide functionality but failed to improve wear resistance, likely due to dispersion issues. Virgin SBO and ESBO also enhanced thermal aging stability at full replacement [

18]. However, e-SBO and r-SBO showed significant degradation post-aging in SR systems, suggesting matrix-dependent tolerance to degradation products. For dynamic properties, while the loss factor was not directly measured, our green tire prototypes exhibited outstanding wear resistance, rubber cohesion, and oxidative stability in 5000 km road tests. These empirical observations align with Zhu et al. [

4] and Xu et al. [

5], who reported that improved chain mobility and filler dispersion from bio-oils reduce rolling resistance and enhance grip.