The Advances in Polymer-Based Electrothermal Composites: A Review

Abstract

1. Introduction

2. Theoretical Basis

3. Research Progress of Polymer-Based Electrothermal Composites

3.1. Graphene Electrothermal Material

3.1.1. Flexible Graphene/Polymer Bilayer Film Heater

3.1.2. Graphene/Polymer Electrothermal Composites

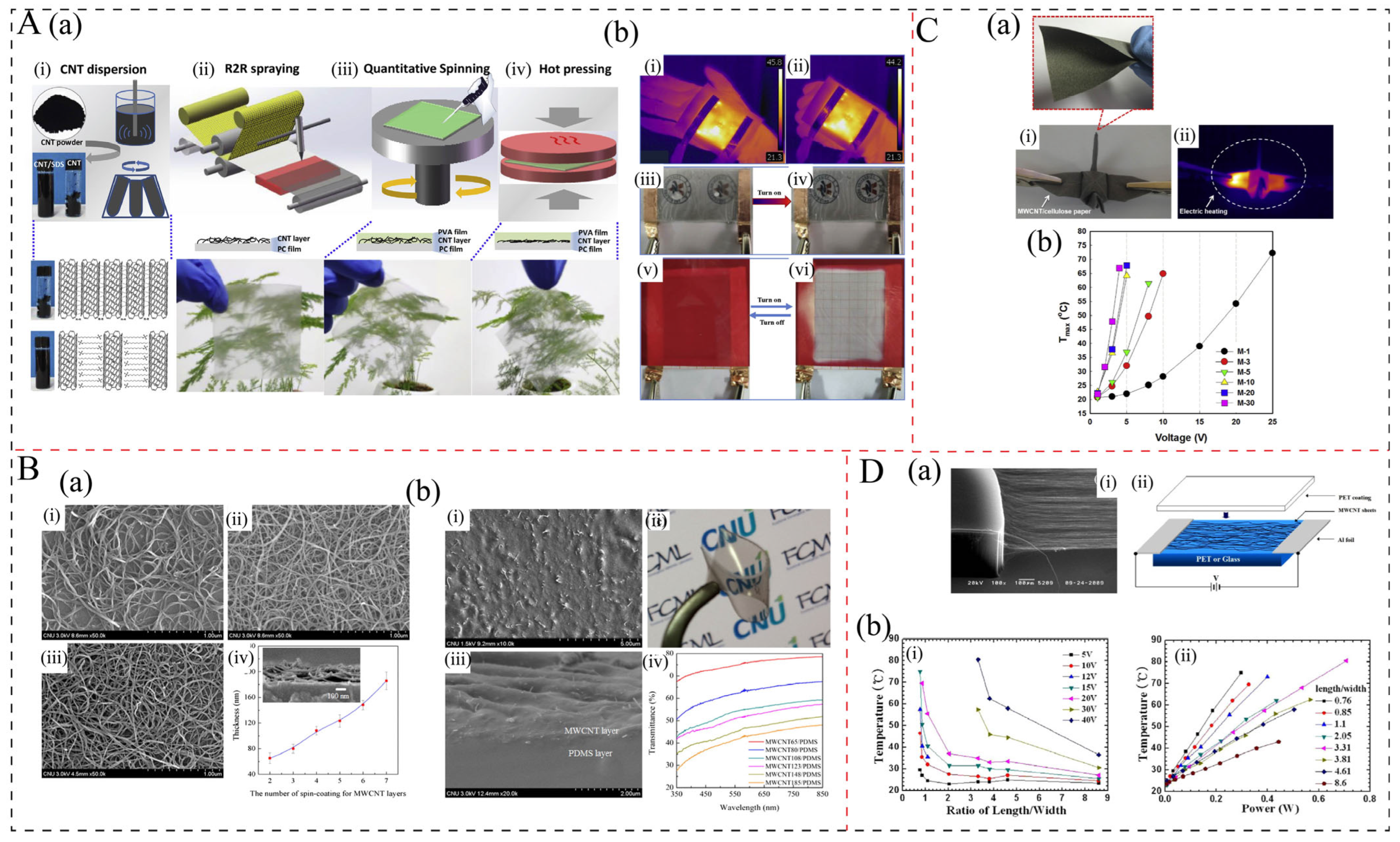

3.2. Carbon Nanotube Electrothermal Composites

3.2.1. Flexible CNT/Polymer Bilayer Film Heater

3.2.2. CNT/Polymer Electrothermal Composites

3.2.3. Aligned CNT/Polymer Bilayer Film Heater

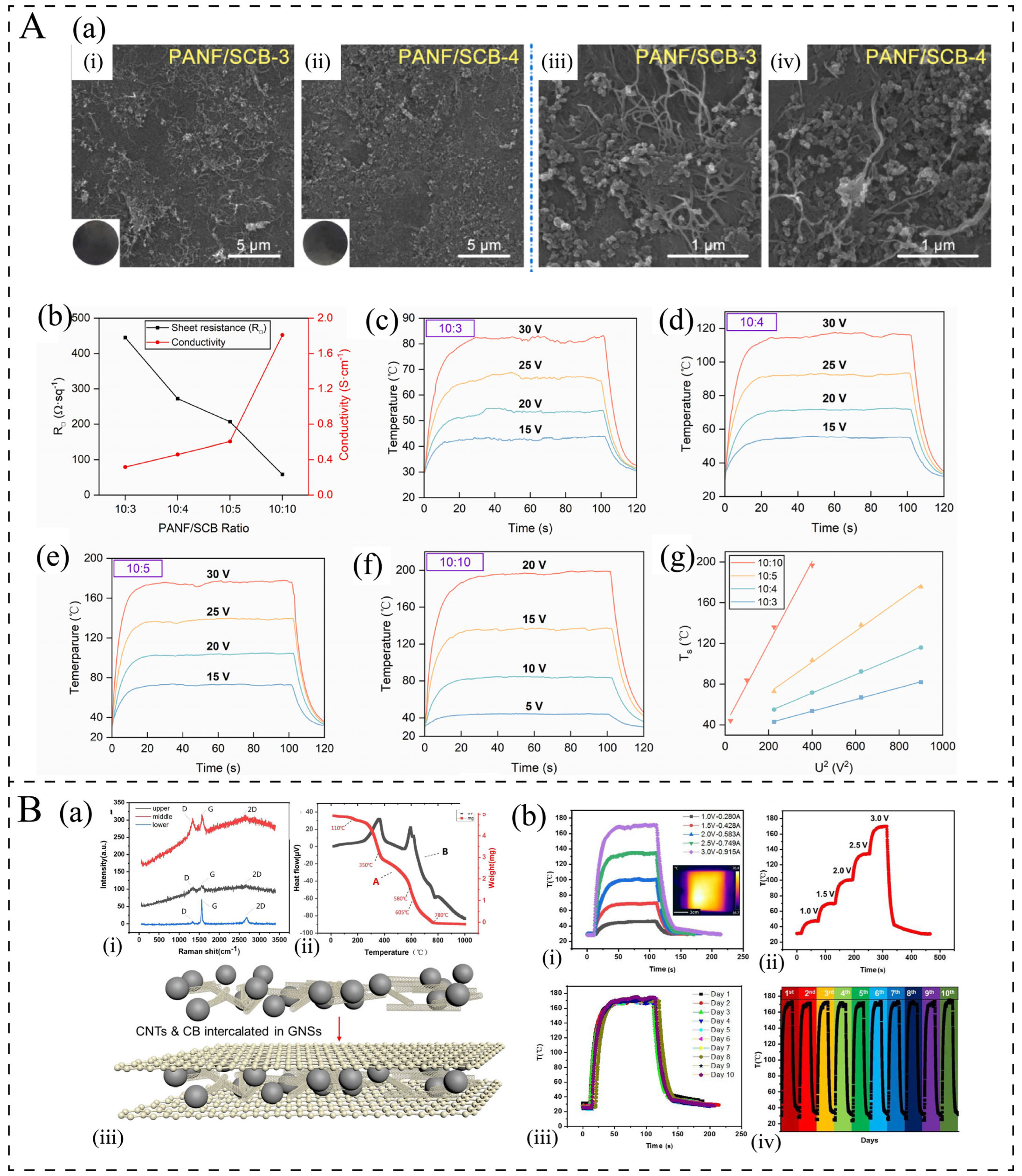

3.3. Carbon Black Electrothermal Composites

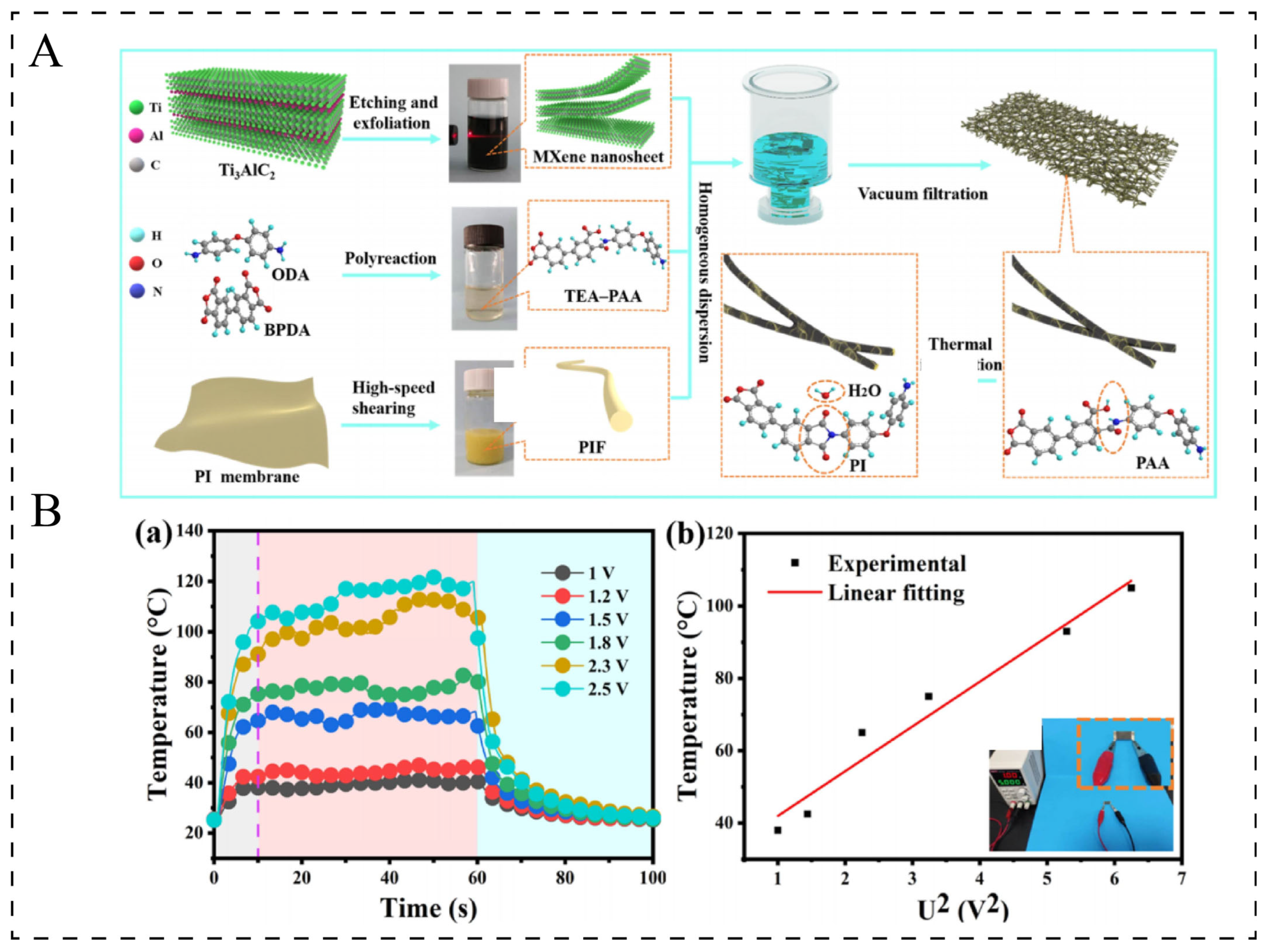

3.4. Mxene Electrothermal Composites

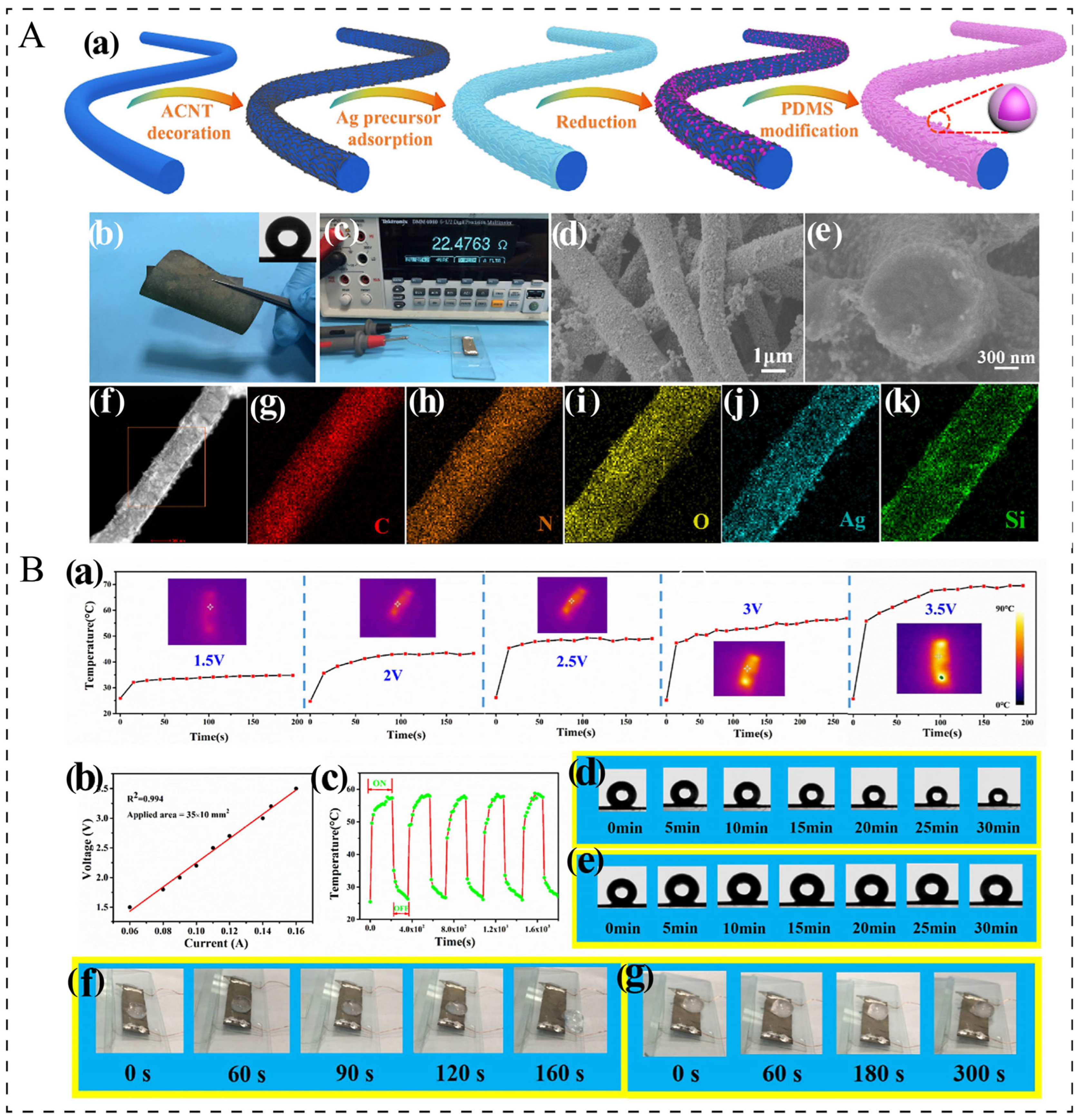

3.5. Metal Nanowire Electrothermal Composites

| Material | Method | ψ/ wt.% | Thickness/μm | ρ/Ω cm | V/V | Pd/ W/cm2 | r/(°C/s) | ΔT/°C | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| GNP film-PET | CVD + roll-to-roll | 100 | n.a. | 43 Ω/sq | 12 | 0.213 | 1.33 | 80 | [6] |

| GNP film-PET | Film transfer | 100 | n.a. | 159 Ω/sq | 30 | 0.113 | 13.7 | 139 | [36] |

| GNP/epoxy film | Solution mixing | 2 | 100 | 102–104 | 100 | 0.1 | 1.6 | 40 | [4] |

| 5 | 70 | 0.25 | 3.6 | 90 | |||||

| 10 | 30 | 0.5 | 4.2 | 106 | |||||

| Graphene Nanoribbon/epoxy | Solution mixing | 5 | 5000 | <1 | 40 | 0.5 | n.a. | 160 | [33] |

| GNP/epoxy coating | Solution mixing | 8 | 194 | 61–416 | 800 | 0.2 | 0.12 | 20 | [12] |

| 10 | 0.3 | 0.17 | 28 | ||||||

| 12 | 0.4 | 0.23 | 30 | ||||||

| MWCNT Films-PDMS | Spin-coating | 100 | 0.065 | 105–103 Ω/sq | 100 | 0.07 | n.a. | 40 | [41] |

| 0.123 | 90 | 0.56 | n.a. | 215 | |||||

| 0.183 | 60 | 0.42 | n.a. | 180 | |||||

| SWCNT films | Spray- coating | 100 | n.a. | 130–190 Ω/sq | 60 | n.a. | n.a. | 135 | [81] |

| MWCNTs/cellulose papers | Dip-coating | 1.5 | 157.3–170.1 | 0.9–50 | 25 | n.a. | 1 | 50 | [34] |

| 13.3 | 3 | n.a. | 1 | 45 | |||||

| MCNTs/cellulose film | Solution mixing | 10 | 300 | 0.05–0.7 | 2 | 0.1 | 1 | 30 | [19] |

| 30 | 0.3 | 3.33 | 100 | ||||||

| 50 | 1 | 4.86 | 146 | ||||||

| Aligned CNT unsupported films | CVD | 100 | n.a. | 10−2 | n.a. | 3.33 | 750 | 375 | [75] |

| Aligned CNT film-PET | CVD | 100 | 0.2 | 699 Ω/sq | 0.542 | 1.0 | 52 | [76] | |

| Aligned CNT film/GF/epoxy | CVD | n.a. | 24 | 20.9 Ω/sq | 16 | 0.49 | 2.6 | 140 | [78] |

| CB/PVDF | Solution mixing | 7 | n.a. | 100–104 | 36 | 0.075 | n.a. | 8 | [32] |

| 10 | 0.15 | n.a. | 15 | ||||||

| 7 | 60 | 0.3 | n.a. | 40 | |||||

| 10 | 0.55 | 0.4 | 60 | ||||||

| SCB/PANF | Solution mixing | 23 | 76–122 | 0.3~1.8 | 20 | n.a. | n.a. | 20 | [24] |

| 33 | n.a. | n.a. | 140 | ||||||

| 50 | n.a. | n.a. | 196 | ||||||

| PIF/MXene film | Solution mixing | 43.1 | 132 | 0.026 | 2.5 | n.a. | 10.5 | 105 | [20] |

| Alternating multilayered CNF@MXene films | Alternating vacuum filtration | 100 | 35 | 621–82 | 3 | n.a. | 5.8 | 58 | [93] |

| 6 | n.a. | 11.4 | 114 | ||||||

| CC@ZnO/AgNWs/PVA films | Layer-by-layer coating | n.a. | n.a. | n.a. | 2 | n.a. | 0.9 | 45 | [21] |

4. Factors Affecting Electric Heating Performance

4.1. Electrical Conductivity

| Polymer | Fillers | Method | pc | ρ/(S/cm) | Ref. |

|---|---|---|---|---|---|

| PMMA | rGO | Solution mixing | 0.25 vol.% | ~10−4 | [105] |

| P(MMA-co-BA) | GNP | Emulsion polymerization | 0.1 vol.% | 2.17 | [106] |

| PMMA | GNP | Solution mixing | 0.4 vol.% | ~10−3 | [107] |

| PS | GNP | Solution mixing | 0.33 vol.% | 0.0349 | [108] |

| CNT | 0.5 vol.% (1.08 wt.%) | ~10−3 | |||

| PS/PLA | GNP | 0.075 vol.% | ~10−3 | ||

| TPU | rGO | Solution mixing | <0.3 | n.a. | [101] |

| In situ polymerization | 0.3–0.5 | ||||

| Melt blending | 1–1.5 | ||||

| Epoxy | GNP | Solution mixing | 0.5–1 vol.% | 10−4 | [109] |

| Epoxy | CNT | Solution mixing | 0.5–1 vol.% | [110] | |

| PP | CNT | Melt blending | 7.5 wt.% | ~10−8 | [111] |

| rGO | 5 wt.% | ~10−6 | |||

| CB | 7.5 wt.% | ~10−7 | |||

| LLDPE | rGO | Melt blending | 0.5–0.9 vol.% | ~10−4 | [112] |

| HDPE | CNT | Powder dispersion and hot-pressing process | 0.15 vol.% (0.3 wt.%) | ~10−2 | [113] |

| GNP | 0.953 vol.% | ~10−5 | |||

| PP | MWCNT | Melt blending | 0.22 wt.% | 10−3 | [114] |

| PP | S-MWCNT | Melt blending | >1 wt.% | n.a. | [115] |

| L-MWCNT | 0.1 wt.% | n.a. | |||

| Epoxy | CNT | Solution mixing | 0.0025 wt.% | 0.01 | [83] |

| CCB | 1 wt.% | 10−3 |

4.2. The Size of Heaters

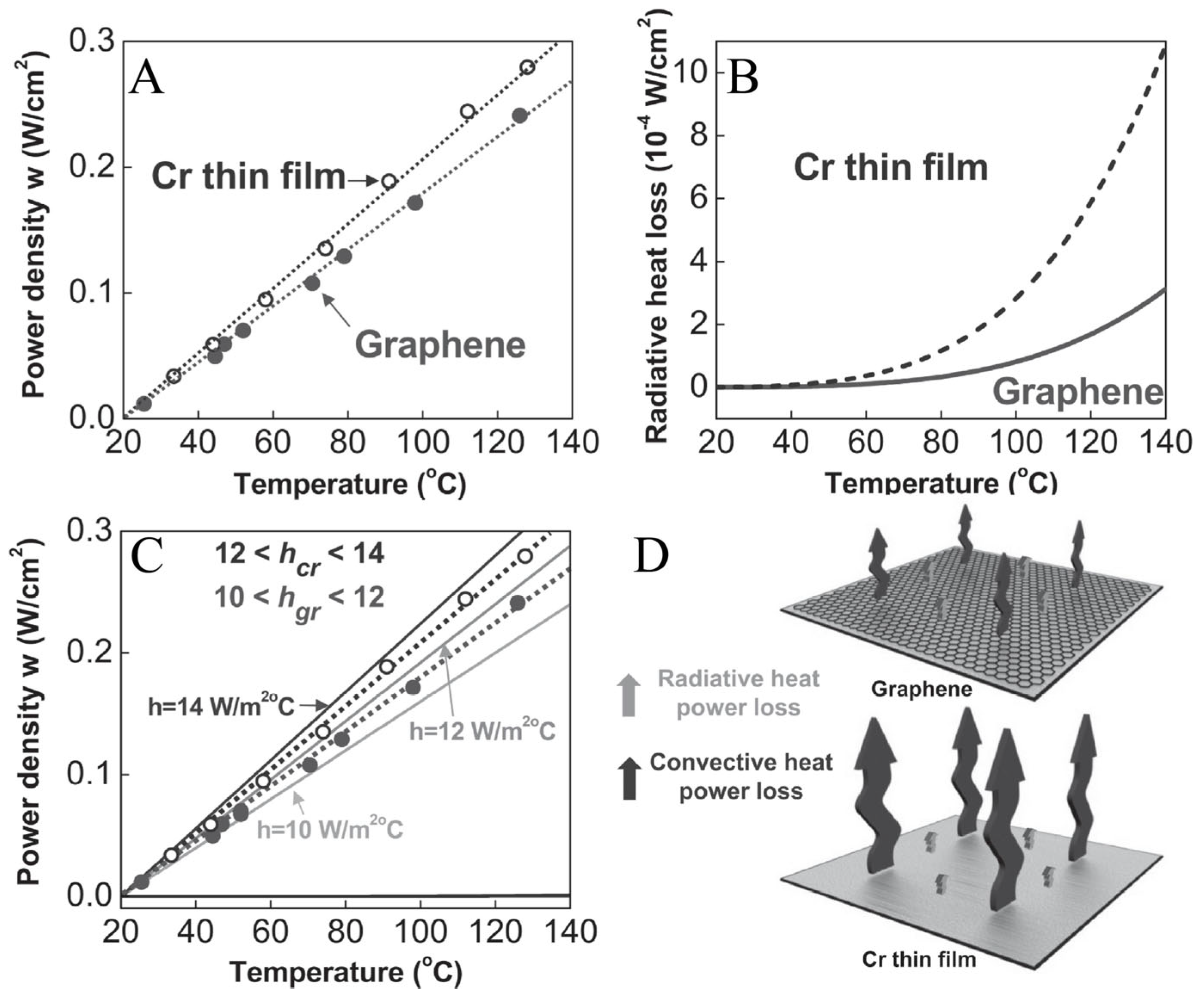

4.3. Heat Dissipation

5. The Application of Polymer-Based Electrothermal Composites

5.1. De-Icing/Anti-Icing

5.2. Multi-Functional Electrothermal Composites

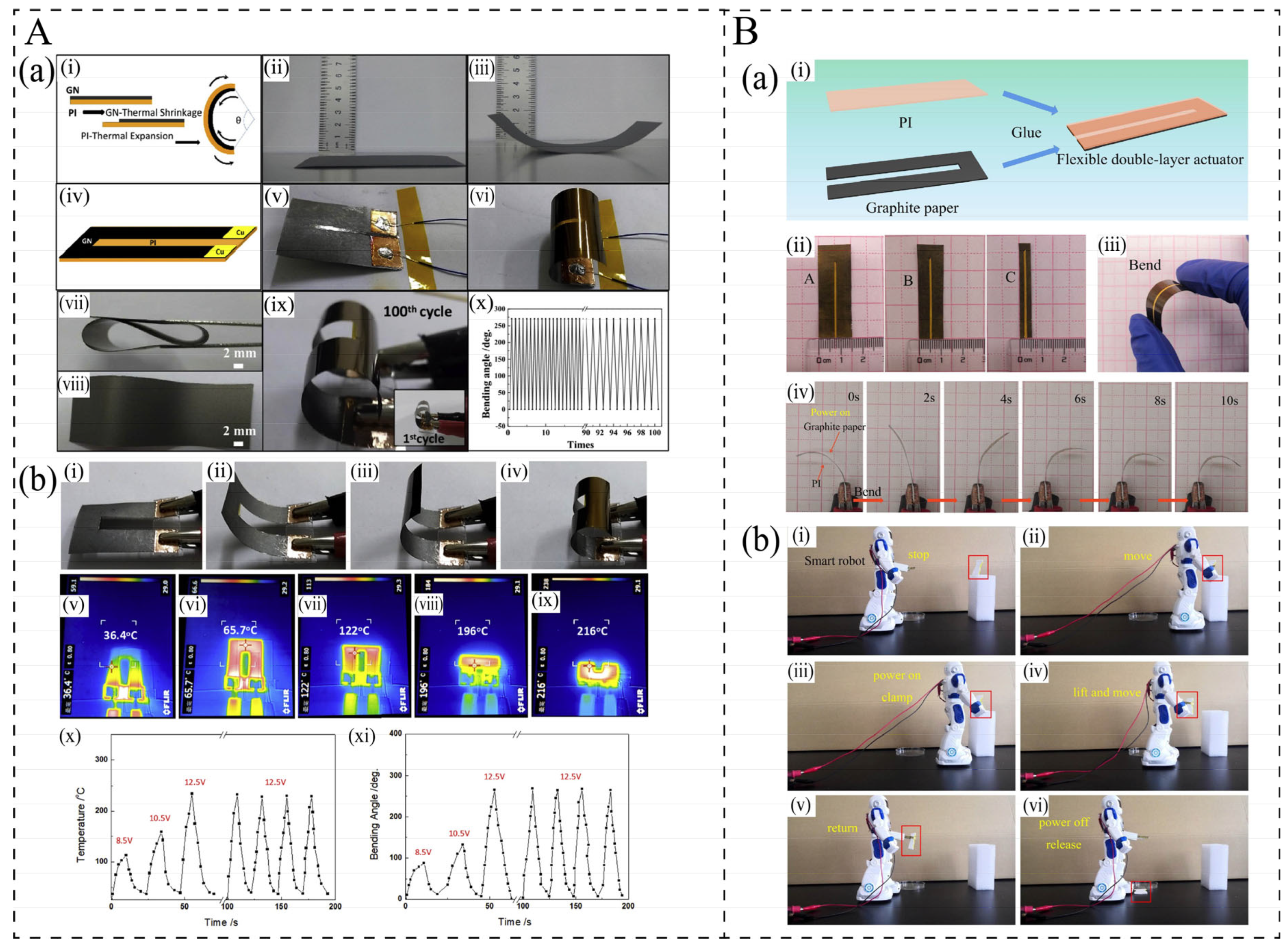

5.3. Electrothermal Actuators

6. Conclusions and Future Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chuang, D.D.L. Self-heating structural materials. Smart Mater. Struct. 2004, 13, 562. [Google Scholar] [CrossRef]

- Deng, H.; Lin, L.; Ji, M.; Zhang, S.; Yang, M. QF Progress on the morphological control of conductive network in conductive polymer composites and the use as electroactive multifunctional materials. Prog. Polym. Sci. 2014, 39, 627–655. [Google Scholar] [CrossRef]

- Sui, D.; Huang, Y.; Huang, L.; Liang, J.; Ma, Y.; Chen, Y. Flexible and transparent electrothermal film heaters based on graphene materials. Small 2011, 7, 3186–3192. [Google Scholar] [CrossRef]

- An, J.E.; Jeong, Y.G. Structure and electric heating performance of graphene/epoxy composite films. Eur. Polym. J. 2013, 49, 1322–1330. [Google Scholar] [CrossRef]

- Zeng, Z.; Jin, H.; Zhang, L.; Zhang, H.; Chen, Z.; Gao, F.; Zhang, Z. Low-voltage and high-performance electrothermal actuator based on multi-walled carbon nanotube/polymer composites. Carbon 2015, 84, 327–334. [Google Scholar] [CrossRef]

- Kang, J.; Kim, H.; Kim, K.S.; Lee, S.-K.; Bae, S.; Ahn, J.-H.; Kim, Y.-J.; Choi, J.-B.; Hong, B.H. High-performance graphene-based transparent flexible heaters. Nano Lett. 2011, 11, 5154–5158. [Google Scholar] [CrossRef]

- Bae, J.; Lim, S.; Han, G.H.; Jo, Y.W.; Doung, D.L.; Kim, E.S.; Chae, S.J.; Huy, T.Q.; Van Luan, N.; Lee, Y.H. Heat dissipation of transparent graphene defoggers. Adv. Funct. Mater. 2012, 22, 4819–4826. [Google Scholar] [CrossRef]

- Jung, D.; Kim, D.; Lee, K.H.; Overzet, L.J.; Lee, G.S. Transparent film heaters using multi-walled carbon nanotube sheets. Sens. Actuators A Phys. 2013, 199, 176–180. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, L.; Cabrera, E.D.; Pan, J.-J.; Yang, H.; Zhang, D.; Yang, Z.-G.; Yu, J.-F.; Castro, J.; Huang, H.-X.; et al. Carbide-bonded graphene coated zirconia for achieving rapid thermal cycling under low input voltage and power. Ceram. Int. 2019, 45, 24318–24323. [Google Scholar] [CrossRef]

- Sun, H.; Chen, D.; Ye, C.; Li, X.; Dai, D.; Yuan, Q.; Chee, K.W.; Zhao, P.; Jiang, N.; Lin, C.-T. Large-area self-assembled reduced graphene oxide/electrochemically exfoliated graphene hybrid films for transparent electrothermal heaters. Appl. Surf. Sci. 2018, 435, 809–814. [Google Scholar] [CrossRef]

- Karim, N.; Zhang, M.; Afroj, S.; Koncherry, V.; Potluri, P. SNK Graphene-based surface heater for de-icing applications. RSC Adv. 2018, 8, 16815–16823. [Google Scholar] [CrossRef]

- Redondo, O.; Prolongo, S.G.; Campo, M.; Sbarufatti, C.; Giglio, M. Anti-icing and de-icing coatings based Joule’s heating of graphene nanoplatelets. Compos. Sci. Technol. 2018, 164, 65–73. [Google Scholar] [CrossRef]

- Botura, G.; Sweet, D.; Flosdorf, D. Development and demonstration of low power electrothermal de-icing system. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005; p. 1460. [Google Scholar]

- Zhao, Z.; Chen, H.; Liu, X.; Liu, H.; Zhang, D. Development of high-efficient synthetic electric heating coating for anti-icing/de-icing. Surf. Coat. Technol. 2018, 349, 340–346. [Google Scholar] [CrossRef]

- Fan, Q.; Miao, J.; Tian, M.; Zhao, H.; Zhu, S.; Liu, X.; Ma, Y.; Qu, L. Low-voltage driven flexible double-layer electrothermal actuator for smart human-machine interactions. Sens. Actuators A Phys. 2020, 315, 112352. [Google Scholar] [CrossRef]

- Wang, Q.; Li, Y.-T.; Zhang, T.-Y.; Wang, D.-Y.; Tian, Y.; Yan, J.-C.; Tian, H.; Yang, Y.; Yang, F.; Ren, T.-L. Low-voltage, large-strain soft electrothermal actuators based on laser-reduced graphene oxide/Ag particle composites. Appl. Phys. Lett. 2018, 112, 133902. [Google Scholar] [CrossRef]

- Yu, Y.; Su, Z.; Chen, W.; Yang, Z.; Yang, K.; Meng, F.; Qiu, S.; Wu, X.; Yao, H.; Li, J.; et al. Electro-thermally driven biaxial bending artificial muscle based on oriented graphite nanoplate nanocomposite/polyimide complex structure. Compos. Part A Appl. Sci. 2022, 163, 107164. [Google Scholar] [CrossRef]

- Kim, B.S.; Kim, M.; Cho, Y.; Hamed, E.E.; Gillette, M.U.; Cha, H.; Miljkovic, N.; Aakalu, V.K.; Kang, K.; Son, K.-N.; et al. Electrothermal soft manipulator enabling safe transport and handling of thin cell/tissue sheets and bioelectronic devices. Sci. Adv. 2020, 6, 11. [Google Scholar] [CrossRef]

- Lu, H.; Xia, Z.; Mi, Q.; Zhang, J.; Zheng, X.; He, Z.; Wu, J.; Zhang, J. Cellulose-based conductive films with superior joule heating performance, electromagnetic shielding efficiency, and high stability by In situ welding to construct a segregated MWCNT conductive network. Ind. Eng. Chem. Res. 2022, 61, 1773–1785. [Google Scholar] [CrossRef]

- Sun, K.; Wang, F.; Yang, W.; Liu, H.; Pan, C.; Guo, Z.; Liu, C.; Shen, C. Flexible conductive polyimide fiber/MXene composite film for electromagnetic interference shielding and joule heating with excellent harsh environment tolerance. ACS Appl. Mater. Interfaces 2021, 13, 50368–50380. [Google Scholar] [CrossRef]

- Han, X.; Huang, Y.; Wang, J.; Zhang, G.; Li, T.; Liu, P. Flexible hierarchical ZnO/AgNWs/carbon cloth-based film for efficient microwave absorption, high thermal conductivity and strong electro-thermal effect. Compos. Part B-Eng. 2022, 229, 109458. [Google Scholar] [CrossRef]

- Peng, T.; Si, Y.; Qian, J.; Zhang, Z.; Yan, X.; Zhu, C.; Hong, X. Reduced graphene oxide/MnFe2O4 nanocomposite papers for fast electrical heating and microwave absorption. Appl. Surf. Sci. 2023, 613, 156001. [Google Scholar] [CrossRef]

- Berzina, A.; Klemenoks, I.; Tupureina, V.; Knite, M. Ethylene-octene copolymer and carbon black composite electro-thermal properties for self-regulating heating. IOP Conf. Ser. Mater. Sci. Eng. 2019, 500, 012012. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, C.; Yang, S.; He, R.; Guo, Y.; Guo, Z.-X.; Guo, B.; Tuo, X. Aramid-based electric heating films by incorporating carbon black. Mater. Today Commun. 2023, 34, 105105. [Google Scholar] [CrossRef]

- Ba, H.; Truong-Phuoc, L.; Romero, T.; Sutter, C.; Nhut, J.-M.; Schlatter, G.; Giambastiani, G.; Pham-Huu, C. Lightweight, few-layer graphene composites with improved electro-thermal properties as efficient heating devices for de-icing applications. Carbon 2021, 182, 655–668. [Google Scholar] [CrossRef]

- Jang, S.-H.; Park, Y.-L. Carbon nanotube-reinforced smart composites for sensing freezing temperature and deicing by self-heating. Nanomater. Nanotechnol. 2018, 8, 1–8. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Xiao, H. Self-deicing road system with a CNFP high-efficiency thermal source and MWCNT/cement-based high-thermal conductive composites. Cold Reg. Sci. Technol. 2013, 86, 22–35. [Google Scholar] [CrossRef]

- Luo, J.; Lu, H.; Zhang, Q.; Yao, Y.; Chen, M.; Li, Q. Flexible carbon nanotube/polyurethane electrothermal films. Carbon 2016, 110, 343–349. [Google Scholar] [CrossRef]

- Gwon, S.; Kim, H.; Shin, M. Self-heating characteristics of electrically conductive cement composites with carbon black and carbon fiber. Cem. Concr. Compos. 2023, 137, 104942. [Google Scholar] [CrossRef]

- Wang, B.; Jia, P.; Zhang, Y.; He, R.; Song, L.; Hu, Y. Multifunctional composite polyvinyl alcohol films prepared with economic conductive carbon black and MXene microcapsuled APP. Mater. Today Phys. 2023, 30, 100928. [Google Scholar] [CrossRef]

- Cao, Y.; Farha, F.I.; Ge, D.; Liu, X.; Liu, W.; Li, G.; Zhang, T.; Xu, F. Highly effective E-heating performance of nickel coated carbon fiber and its composites for de-icing application. Compos. Struct. 2019, 229, 111397. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, J.; Wang, X. The ultra-flexible films of super conductive carbon black/poly(vinylidene fluoride) as electrothermal materials. Mater. Res. Express 2019, 6, 116402. [Google Scholar] [CrossRef]

- Raji, A.R.; Varadhachary, T.; Nan, K.; Wang, T.; Lin, J.; Ji, Y.; Genorio, B.; Zhu, Y.; Kittrell, C.; Tour, J.M. Composites of graphene nanoribbon stacks and epoxy for joule heating and deicing of surfaces. ACS Appl. Mater. Interfaces 2016, 8, 3551–3556. [Google Scholar] [CrossRef]

- Lee, T.-W.; Lee, S.-E.; Jeong, Y.G. Carbon nanotube/cellulose papers with high performance in electric heating and electromagnetic interference shielding. Compos. Sci. Technol. 2016, 131, 77–87. [Google Scholar] [CrossRef]

- Xie, X.-M.; Su, J.-F.; Guo, Y.-D.; Wang, L.-Q. Evaluation of a cleaner de-icing production of bituminous material blending with graphene by electrothermal energy conversion. J. Clean. Prod. 2020, 274, 122947. [Google Scholar] [CrossRef]

- Li, C.; Xu, Y.-T.; Zhao, B.; Jiang, L.; Chen, S.-G.; Xu, J.-B.; Fu, X.-Z.; Sun, R.; Wong, C.-P. Flexible graphene electrothermal films made from electrochemically exfoliated graphite. J. Mater. Sci. 2015, 51, 1043–1051. [Google Scholar] [CrossRef]

- Enríquez, E.; Fernández, J.F.; Frutos, J.D.; Rubia, M.A.D.L. Tailoring of the electrical properties of carbon black-silica coatings for de-icing applications. Ceram. Int. 2015, 41, 2735–2743. [Google Scholar] [CrossRef]

- Wu, B.; Cui, X.; Jiang, H.; Wu, N.; Peng, C.; Hu, Z.; Liang, X.; Yan, Y.; Huang, J.; Li, D. A superhydrophobic coating harvesting mechanical robustness, passive anti-icing and active de-icing performances. J. Colloid Interface Sci. 2021, 590, 301–310. [Google Scholar] [CrossRef]

- Tang, P.; Zhang, R.; Shi, R.; Bin, Y. Synergetic effects of carbon nanotubes and carbon fibers on electrical and self-heating properties of high-density polyethylene composites. J. Mater. Sci. 2014, 50, 1565–1574. [Google Scholar] [CrossRef]

- Song, Y.; Zheng, Q. Self-heating and conduction of an acetylene carbon black filled high-density polyethylene composite at the electric-thermal equilibrium state. J. Polym. Sci. Polym. Phys. 2005, 43, 2484–2492. [Google Scholar] [CrossRef]

- Yan, J.; Jeong, Y.G. Highly elastic and transparent multiwalled carbon nanotube/polydimethylsiloxane bilayer films as electric heating materials. Mater. Des. 2015, 86, 72–79. [Google Scholar] [CrossRef]

- Zhou, B.; Han, X.; Li, L.; Feng, Y.; Fang, T.; Zheng, G.; Wang, B.; Dai, K.; Liu, C.; Shen, C. Ultrathin, flexible transparent Joule heater with fast response time based on single-walled carbon nanotubes/poly(vinyl alcohol) film. Compos. Sci. Technol. 2019, 183, 107796. [Google Scholar] [CrossRef]

- Loeblein, M.; Bolker, A.; Tsang, S.H.; Atar, N.; Uzan-Saguy, C.; Verker, R.; Gouzman, I.; Grossman, E.; Teo, E.H.T. 3D graphene-infused polyimide with enhanced electrothermal performance for long-term flexible space applications. Small 2015, 11, 6425–6434. [Google Scholar] [CrossRef]

- Vertuccio, L.; De Santis, F.; Pantani, R.; Lafdi, K.; Guadagno, L. Effective de-icing skin using graphene-based flexible heater. Compos. Part B-Eng. 2019, 162, 600–610. [Google Scholar] [CrossRef]

- Wang, Y.; Li, K.; Li, X.; Cui, H.; Liu, G.; Xu, H.; Wu, X.; Yao, W.; Zhong, B. Electro-thermally driven flexible robot arms based on stacking-controlled graphite nanocomposites. Carbon 2019, 152, 873–881. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, N.; Zhang, Y.; Zheng, N.; Li, H.; Jiao, Y.; Cheng, J.; Wang, Y.; Zhang, X.; Chen, Y.; et al. Conformal in-ear bioelectronics for visual and auditory brain-computer interfaces. Nat. Commun. 2023, 14, 4213. [Google Scholar] [CrossRef]

- Yang, G.; Li, L.; Lee, W.B.; Ng, M.C.; Chan, C.Y. Investigation of the heating behavior of carbide-bonded graphene coated silicon wafer used for hot embossing. Appl. Surf. Sci. 2018, 435, 130–140. [Google Scholar] [CrossRef]

- Guo, Q.; Guinea, F.; Deng, B.; Sarpkaya, I.; Li, C.; Chen, C.; Ling, X.; Kong, J.; Xia, F. Electrothermal control of graphene plasmon-phonon polaritons. Adv. Mater. 2017, 29, 1700566. [Google Scholar] [CrossRef]

- Liu, P.; Liu, L.; Jiang, K.; Fan, S. Carbon-nanotube-film microheater on a polyethylene terephthalate substrate and its application in thermochromic displays. Small 2011, 7, 732–736. [Google Scholar] [CrossRef]

- Li, Y.-H.; Shen, F.; Ke, L.-L. Multi-physics electrical contact analysis considering the electrical resistance and Joule heating. Int. J. Solids Struct. 2022, 256, 111975. [Google Scholar] [CrossRef]

- Costa, P.M.; Gautam, U.K.; Bando, Y.; Golberg, D. Direct imaging of Joule heating dynamics and temperature profiling inside a carbon nanotube interconnect. Nat. Commun. 2011, 2, 421. [Google Scholar] [CrossRef]

- Song, T.-B.; Chen, Y.; Chung, C.-H.; Yang, Y.M.; Bob, B.; Duan, H.-S.; Li, G.; Tu, K.-N.; Huang, Y.; Yang, Y. Nanoscale joule heating and electromigration enhanced ripening of silver nanowire contacts. ACS Nano 2014, 8, 2804–2811. [Google Scholar] [CrossRef]

- Liu, T.J.C. Thermo-electro-structural coupled analyses of crack arrest by Joule heating. Theor. Appl. Fract. Mech. 2008, 49, 171–184. [Google Scholar] [CrossRef]

- Jiang, J.W.; Wang, J.S. Joule heating and thermoelectric properties in short single-walled carbon nanotubes: Electron-phonon interaction effect. J. Appl. Phys. 2011, 110, 124319. [Google Scholar] [CrossRef]

- Grosse, K.L.; Bae, M.H.; Lian, F.; Pop, E.; King, W.P. Nanoscale joule heating, peltier cooling and current crowding at graphene-metal contacts. Nat. Nanotechnol. 2011, 6, 287–290. [Google Scholar] [CrossRef]

- Rutherglen, C.; Burke, P. Nanoelectromagnetics: Circuit and electromagnetic properties of carbon nanotubes. Small 2009, 5, 884–906. [Google Scholar] [CrossRef]

- Arao, Y.; Mizuno, Y.; Araki, K.; Kubouchi, M. Mass production of high-aspect-ratio few-layer-graphene by high-speed laminar flow. Carbon 2016, 102, 330–338. [Google Scholar] [CrossRef]

- Cao, Y.; Fatemi, V.; Fang, S.; Watanabe, K.; Taniguchi, T.; Kaxiras, E.; Jarillo-Herrero, P. Unconventional superconductivity in magic-angle graphene superlattices. Nature 2018, 556, 43–50. [Google Scholar] [CrossRef]

- Bolotin, K.I. Electronic transport in graphene: Towards high mobility. In Graphene; Woodhead Publishing: Cambridge, UK, 2014; pp. 199–227. [Google Scholar]

- Long, M.-Q.; Tang, L.; Wang, D.; Wang, L.; Shuai, Z. Theoretical predictions of size-dependent carrier mobility and polarity in graphene. J. Am. Chem. Soc. 2009, 131, 17728–17729. [Google Scholar] [CrossRef]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef]

- Wang, X.; Li, X.; Zhang, L.; Yoon, Y.; Weber, P.K.; Wang, H.; Guo, J.; Dai, H. N-doping of graphene through electrothermal reactions with ammonia. Science 2010, 324, 761–771. [Google Scholar] [CrossRef]

- Kim, Y.J.; Lee, H.S.; Noh, J.-S. Transient behaviors of ZnO thin films on a transparent, flexible polyethylene terephthalate substrate. Thin Solid Films 2016, 603, 160–164. [Google Scholar] [CrossRef]

- Feng, C.-P.; Wan, S.-S.; Wu, W.-C.; Bai, L.; Bao, R.-Y.; Liu, Z.-Y.; Yang, M.-B.; Chen, J.; Yang, W. Electrically insulating, layer structured SiR/GNPs/BN thermal management materials with enhanced thermal conductivity and breakdown voltage. Compos. Sci. Technol. 2018, 167, 456–462. [Google Scholar] [CrossRef]

- Feng, Y.; Zhou, F.; Dai, Y.; Xu, Z.; Deng, Q.; Peng, C. High dielectric and breakdown performances achieved in PVDF/graphene@MXene nanocomposites based on quantum confinement strategy. Ceram. Int. 2020, 46, 17992–18001. [Google Scholar] [CrossRef]

- Wu, X.; Liao, Y.; Yao, L.; Zha, Y.; Li, R.; Wang, Y.; Zhao, D.; Mo, S.; Huang, W. A non-percolative rGO/XLPE composite with high electrothermal performance at high voltage and effective de/anti-icing for transmission-lines. Compos. Sci. Technol. 2022, 230, 109772. [Google Scholar] [CrossRef]

- Kim, J.-I.; Kang, P.H.; Nho, Y.C. Positive temperature coefficient behavior of polymer composites having a high melting temperature. J. Appl. Polym. Sci. 2004, 92, 394–401. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Bilotti, E. Polymer nanocomposites for temperature sensing and self-regulating heating devices. In Polymer Nanocomposite Materials: Applications in Integrated Electronic Devices; Wiley: Hoboken, NJ, USA, 2021; pp. 247–266. [Google Scholar]

- Zhou, B.; Li, Y.; Zheng, G.; Dai, K.; Liu, C.; Ma, Y.; Zhang, J.; Wang, N.; Shen, C.; Guo, Z. Continuously fabricated transparent conductive polycarbonate/carbon nanotube nanocomposite films for switchable thermochromic applications. J. Mater. Chem. C 2018, 6, 8360–8371. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, H.R.; Saito, T.; Nishi, Y. Ultra-thin and high-response transparent and flexible heater based on carbon nanotube film. Appl. Phys. Lett. 2017, 110, 153301. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Liang, Z.; Yang, J.; Sun, J. Controllable p and n doping of single-walled carbon nanotubes by encapsulation of organic molecules and fullerene: Atheoretical investigation. Appl. Phys. Lett. 2005, 86, 223113. [Google Scholar] [CrossRef]

- Baughman, R.H.; Zakhidov, A.A.; Heer, D.H.W. Carbon nanotubes—The route toward applications. Science 2002, 297, 787–792. [Google Scholar] [CrossRef]

- Walters, D.A.; Ericson, L.M.; Casavant, M.J.; Liu, J.; Colbert, D.T.; Smith, K.A.; Smalley, R.E. Elastic strain of freely suspended single-wall carbon nanotube ropes. Appl. Phys. Lett. 1999, 74, 3803–3805. [Google Scholar] [CrossRef]

- Janas, D.; Koziol, K.K. Rapid electrothermal response of high-temperature carbon nanotube film heaters. Carbon 2013, 59, 457–463. [Google Scholar] [CrossRef]

- Jang, H.-S.; Jeon, S.K.; Nahm, S.H. The manufacture of a transparent film heater by spinning multi-walled carbon nanotubes. Carbon 2011, 49, 111–116. [Google Scholar] [CrossRef]

- Yao, X.; Falzon, B.G.; Hawkins, S.C.; Tsantzalis, S. Aligned carbon nanotube webs embedded in a composite laminate: A route towards a highly tunable electro-thermal system. Carbon 2018, 129, 486–494. [Google Scholar] [CrossRef]

- Yao, X.; Hawkins, S.C.; Falzon, B.G. An advanced anti-icing/de-icing system utilizing highly aligned carbon nanotube webs. Carbon 2018, 136, 130–138. [Google Scholar] [CrossRef]

- Yu, L.; Shearer, C.; Shapter, J. Recent development of carbon nanotube transparent conductive films. Chem. Rev. 2016, 116, 13413–13453. [Google Scholar] [CrossRef]

- Yao, S.; Zhu, Y. Nanomaterial-enabled stretchable conductors: Strategies, materials and devices. Adv. Mater. 2015, 27, 1480–1511. [Google Scholar] [CrossRef]

- Duckjong, K.; Hyun-Chang, L.; Ju, Y.W.; Han, C.-S. Thermal behavior of transparent film heaters made of single-walled carbon nanotubes. J. Phys. Chem. C 2010, 114, 5817–5821. [Google Scholar] [CrossRef]

- Lau, P.H.; Takei, K.; Wang, C.; Ju, Y.; Kim, J.; Yu, Z.; Takahashi, T.; Cho, G.; Javey, A. Fully printed, high performance carbon nanotube thin-film transistors on flexible substrates. Nano Lett. 2013, 13, 3864–3869. [Google Scholar] [CrossRef]

- Zhao, D.; Qian, X.; Jin, L.; Yang, X.; Wang, S.; Shen, X.; Yao, S.; Rao, D.; Zhou, Y.; Xi, X. Separator modified by Ketjen black for enhanced electrochemical performance of lithium–sulfur batteries. RSC Adv. 2016, 6, 13680–13685. [Google Scholar] [CrossRef]

- Choi, H.J.; Kim, M.S.; Ahn, D.; Yeo, S.Y.; Lee, S. Electrical percolation threshold of carbon black in a polymer matrix and its application to antistatic fibre. Sci. Rep. 2019, 9, 6338. [Google Scholar] [CrossRef]

- Shen, L.; Ding, H.; Cao, Q.; Jia, W.; Wang, W.; Guo, Q. Fabrication of Ketjen black-high density polyethylene superhydrophobic conductive surfaces. Carbon 2012, 50, 4284–4290. [Google Scholar] [CrossRef]

- Yoo, Y.; Park, J.; Kim, M.S.; Kim, W. Development of 2.8 V Ketjen black supercapacitors with high rate capabilities for AC line filtering. J. Power Sources 2017, 360, 383–390. [Google Scholar] [CrossRef]

- Liao, Y.; Tian, Y.; Ma, X.; Zhao, M.; Qian, J.; Wang, X. Screen-printed high-performance flexible electrothermal films based on three-dimensional intercalation graphene nanosheets/MWCNT/carbon black composite. ACS Appl. Mater. Interfaces 2020, 12, 48077–48083. [Google Scholar] [CrossRef]

- Huang, H.; Guo, Z.; Yang, P.; Chen, P.; Wu, J. Electrical conductivity, oil absorption and electric heating of carbon black-modified carbon nanofibers. Chem. Res. Chin. Univ. 2021, 37, 541–548. [Google Scholar] [CrossRef]

- Iqbal, A.; Shahzad, F.; Hantanasirisakul, K.; Kim, M.-K.; Kwon, J.; Hong, J.; Kim, H.; Kim, D.; Gogotsi, Y.; Koo, C.M. Anomalous absorption of electromagnetic waves by 2D transition metal carbonitride Ti3CNTx (MXene). Science 2020, 369, 446–450. [Google Scholar] [CrossRef]

- Fan, Z.; Lu, L.; Sang, M.; Wu, J.; Wang, X.; Xu, F.; Gong, X.; Luo, T.; Leung, K.C.; Xuan, S. Wearable safeguarding leather composite with excellent sensing, thermal management, and electromagnetic interference shielding. Adv. Sci. 2023, 10, e2302412. [Google Scholar] [CrossRef]

- Gong, S.; Sheng, X.; Li, X.; Sheng, M.; Wu, H.; Lu, X.; Qu, J. A multifunctional flexible composite film with excellent multi-source driven thermal management, electromagnetic interference shielding, and fire safety performance, inspired by a “Brick-Mortar” sandwich structure. Adv. Funct. Mater. 2022, 32, 2200570. [Google Scholar] [CrossRef]

- Xie, Y.; Cheng, Y.; Ma, Y.; Wang, J.; Zou, J.; Wu, H.; Yue, Y.; Li, B.; Gao, Y.; Zhang, X.; et al. 3D MXene-based flexible network for high-performance pressure sensor with a wide temperature range. Adv. Sci. 2023, 10, e2205303. [Google Scholar] [CrossRef]

- Zhou, B.; Zhang, Z.; Li, Y.; Han, G.; Feng, Y.; Wang, B.; Zhang, D.; Ma, J.; Liu, C. Flexible, robust, and multifunctional electromagnetic interference shielding film with alternating cellulose nanofiber and MXene layers. ACS Appl. Mater. Interfaces 2020, 12, 4895–4905. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, P.; Soomro, R.A.; Zhu, Q.; Xu, B. Advances in the synthesis of 2D MXenes. Adv. Mater. 2021, 33, e2103148. [Google Scholar] [CrossRef]

- Lin, L.; Wang, L.; Li, B.; Luo, J.; Huang, X.; Gao, Q.; Xue, H.; Gao, J. Dual conductive network enabled superhydrophobic and high performance strain sensors with outstanding electro-thermal performance and extremely high gauge factors. Chem. Eng. J. 2020, 385, 123391. [Google Scholar] [CrossRef]

- Gupta, R.; Rao, K.D.; Kiruthika, S.; Kulkarni, G.U. Visibly transparent heaters. ACS Appl. Mater. Interfaces 2016, 8, 12559–12575. [Google Scholar] [CrossRef]

- Ambrosetti, G.; Johner, N.; Grimaldi, C.; Danani, A.; Ryser, P. Percolative properties of hard oblate ellipsoids of revolution with a soft shell. Phys. Rev. E 2008, 78, 061126. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. A review of the mechanical and thermal properties of graphene and its hybrid polymer nanocomposites for structural applications. J. Mater. Sci. 2018, 54, 5992–6026. [Google Scholar] [CrossRef]

- Kim, H.; Kobayashi, S.; AbdurRahim, M.A.; Zhang, M.J.; Khusainova, A.; Hillmyer, M.A.; Abdala, A.A.; Macosko, C.W. Graphene/polyethylene nanocomposites: Effect of polyethylene functionalization and blending methods. Polymer 2011, 52, 1837–1846. [Google Scholar] [CrossRef]

- Xu, H.; Gong, L.-X.; Wang, X.; Zhao, L.; Pei, Y.-B.; Wang, G.; Liu, Y.-J.; Wu, L.-B.; Jiang, J.-X.; Tang, L.-C. Influence of processing conditions on dispersion, electrical and mechanical properties of graphene-filled-silicone rubber composites. Compos. Part A-Appl. Sci. 2016, 91, 53–64. [Google Scholar] [CrossRef]

- Kim, H.; Miura, Y.; Macosko, C.W. Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity. Chem. Mater. 2010, 22, 3441–3450. [Google Scholar] [CrossRef]

- Du, J.H.; Bai, J.; Cheng, H.M. The present status and key problems of carbon nanotube based polymer composites. Express Polym. Lett. 2007, 1, 253–273. [Google Scholar] [CrossRef]

- Klason, C.; Kubát, J. Anomalous behavior of electrical conductivity and thermal noisein carbon black ontaining polymers at Tg and Tm. J. Appl. Polym. Sci. 1975, 19, 831–845. [Google Scholar] [CrossRef]

- Min, C.; Shen, X.; Shi, Z.; Chen, L.; Xu, Z. The Electrical properties and conducting mechanisms of carbon nanotube/polymer nanocomposites: A review. Polym.-Plast. Technol. Eng. 2010, 49, 1172–1181. [Google Scholar] [CrossRef]

- Zeng, X.; Yang, J.; Yuan, W. Preparation of a poly(methyl methacrylate)-reduced graphene oxide composite with enhanced properties by a solution blending method. Eur. Polym. J. 2012, 48, 1674–1682. [Google Scholar] [CrossRef]

- Noël, A.; Faucheu, J.; Rieu, M.; Viricelle, J.-P.; Elodie, B.-L. Tunable architecture for flexible and highly conductive graphene-polymer composites. Compos. Sci. Technol. 2014, 95, 82–88. [Google Scholar] [CrossRef]

- Mutlay, İ.; Tudoran, L.B. Percolation behavior of electrically conductive graphene nanoplatelets/polymer nanocomposites: Theory and experiment. Fuller. Nanotub. Carbon Nanostruct. 2014, 22, 413–433. [Google Scholar] [CrossRef]

- Qi, X.Y.; Yan, D.; Jiang, Z.; Cao, Y.-K.; Yu, Z.-Z.; Yavari, F.; Koratkar, N. Enhanced electrical conductivity in polystyrene nanocomposites at ultra-low graphene content. ACS Appl. Mater. Interfaces 2011, 3, 3130–3133. [Google Scholar] [CrossRef]

- Monti, M.; Rallini, M.; Puglia, D.; Peponi, L.; Torre, L.; Kenny, J.M. Morphology and electrical properties of graphene–epoxy nanocomposites obtained by different solvent assisted processing methods. Compos. Part-A Appl. Sci. 2013, 46, 166–172. [Google Scholar] [CrossRef]

- Allaoui, A.; Bai, S.; Cheng, H.M.; Bai, J.B. Mechanical and electrical properties of a MWNTepoxy composite. Compos. Sci. Technol. 2002, 62, 1993–1998. [Google Scholar] [CrossRef]

- Hofmann, D.; Wartig, K.A.; Thomann, R.; Dittrich, B.; Schartel, B.; Mülhaupt, R. Functionalized graphene and carbon materials as additives for melt-extruded flame retardant polypropylene. Macromol. Mater. Eng. 2013, 298, 1322–1334. [Google Scholar] [CrossRef]

- Vasileiou, A.A.; Kontopoulou, M.; Docoslis, A. A noncovalent compatibilization approach to improve the filler dispersion and properties of polyethylene/graphene composites. ACS Appl. Mater. Interfaces 2014, 6, 1916–1925. [Google Scholar] [CrossRef]

- Du, J.; Zhao, L.; Zeng, Y.; Zhang, L.; Li, F.; Liu, P.; Liu, C. Comparison of electrical properties between multi-walled carbon nanotube and graphene nanosheet/high density polyethylene composites with a segregated network structure. Carbon 2011, 49, 1094–1100. [Google Scholar] [CrossRef]

- Tjong, S.C.; Liang, G.D.; Bao, S.P. Electrical behavior of polypropylene/multiwalled carbon nanotube nanocomposites with low percolation threshold. Scr. Mater. 2007, 57, 461–464. [Google Scholar] [CrossRef]

- Li, Z.-I.; Lou, C.-W.; Pan, Y.-J.; Hsieh, C.-T.; Huang, C.-L.; Huang, C.-H.; Chen, Y.-S.; Lin, J.H. The effects of MWCNT length on the mechanical, crystallization and electromagnetic interference shielding effectiveness of PP/MWCNT composites. J. Polym. Res. 2017, 24, 32. [Google Scholar] [CrossRef]

- Kang, T.J.; Kim, T.; Seo, S.M.; Park, Y.J.; Kim, Y.H. Thickness-dependent thermal resistance of a transparent glass heater with a single-walled carbon nanotube coating. Carbon 2011, 49, 1087–1093. [Google Scholar] [CrossRef]

- Guo, Z.-Y.; Li, Z.-X. Size effect on single-phase channel flow and heat transfer at microscale. Int. J. Heat Fluid Flow 2003, 24, 284–298. [Google Scholar] [CrossRef]

- Radziemska, E.W.A.; Lewandowski, W.M. The effect of plate size on the natural convective heat transfer intensity of horizontal surfaces. Heat Transf. Eng. 2005, 26, 50–53. [Google Scholar] [CrossRef]

- Avilés, F.; Oliva, A.I.; Aznárez, J.A. Dynamical thermal model for thin metallic film–substrate system with resistive heating. Appl. Surf. Sci. 2003, 206, 336–344. [Google Scholar] [CrossRef]

- Keshtkar, M.; Mehdipour, N.; Eslami, H. Thermal Conductivity of Polyamide-6,6/Carbon Nanotube Composites: Effects of Tube Diameter and Polymer Linkage Between Tubes. Polymers 2019, 11, 1465. [Google Scholar] [CrossRef]

- Zheng, B.; Wang, H.; Wu, X.; Yang, K.; Yu, Y.; Cui, H.; Gao, F.; Qian, K.; Yao, H.; Li, J.; et al. Flexible nanocomposite electrothermal films based on carbon nanotubes and waterborne polyurethane with high reliability, stretchability and low-temperature performance for wind turbine blade deicing. Compos. Part-A Appl Sci. 2022, 158, 106979. [Google Scholar] [CrossRef]

- Zhou, B.; Li, Z.; Li, Y.; Liu, X.; Ma, J.; Feng, Y.; Zhang, D.; He, C.; Liu, C.; Shen, C. Flexible hydrophobic 2D Ti3C2Tx-based transparent conductive film with multifunctional self-cleaning, electromagnetic interference shielding and joule heating capacities. Compos. Sci. Technol. 2021, 201, 108534. [Google Scholar] [CrossRef]

- Jia, Y.; Sun, R.; Pan, Y.; Wang, X.; Zhai, Z.; Min, Z.; Zheng, G.; Liu, C.; Shen, C.; Liu, X. Flexible and thin multifunctional waterborne polyurethane/Ag film for high-efficiency electromagnetic interference shielding, electro-thermal and strain sensing performances. Compos. Part-B Eng. 2021, 210, 108668. [Google Scholar] [CrossRef]

- Chen, G.; Yang, Z.; Wang, W.; Bi, L.; Chen, L.; Peng, Y.; Ye, C. Electrothermal actuators with ultrafast response speed and large deformation. Adv. Intell. Syst. 2020, 2, 2000036. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Tabassian, R.; Oh, S.; Nam, S.; Mahato, M.; Thangasamy, P.; Rajabi-Abhari, A.; Hwang, W.-J.; Taseer, A.K.; Oh, I.-K. Stimuli-responsive MXene-based actuators. Adv. Funct. Mater. 2020, 30, 1909504. [Google Scholar] [CrossRef]

- Sachyani, E.; Layani, M.; Tibi, G.; Avidan, T.; Degani, A.; Magdassi, S. Enhanced movement of CNT-based actuators by a three-layered structure with controlled resistivity. Sens. Actuators B Chem. 2017, 252, 1071–1077. [Google Scholar] [CrossRef]

| Composite Samples | Filler Content (wt.%) | τ (s) | h (W/°C) | Ref |

| Graphene/epoxy | 2 | 5.67 ± 1.06 | 0.0017 ± 0.0005 | [4] |

| 3 | 3.01 ± 0.76 | 0.0020 ± 0.0007 | ||

| 5 | 3.36 ± 0.67 | 0.0024 ± 0.0007 | ||

| 7 | 2.93 ± 0.31 | 0.0022 ± 0.0005 | ||

| 10 | 2.92 ± 0.20 | 0.0026 ± 0.0002 | ||

| Cr/glass | 100 (glass substrate) | 105 | 13.1 W/(m2·°C) | [7] |

| Graphene/glass | 100 (glass substrate) | 73 | 11.3 W/(m2·°C) | |

| Graphene | 100 | — | 0.00124 W/(m2·°C) | |

| MWCNT/cellulose papers | 1.5 | 6.1 ± 2.6 | 4.1 ± 1.1 | [34] |

| 5 | 4.3 ± 2.2 | 5.6 ± 0.4 | ||

| 10.1 | 3.3 ± 0.5 | 7.2 ± 0.5 | ||

| 13.3 | 2.5 ± 0.5 | 7.9 ± 0.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Yin, T.; Liu, W.; Wan, L.; Liao, Y. The Advances in Polymer-Based Electrothermal Composites: A Review. Polymers 2025, 17, 2047. https://doi.org/10.3390/polym17152047

Wu X, Yin T, Liu W, Wan L, Liao Y. The Advances in Polymer-Based Electrothermal Composites: A Review. Polymers. 2025; 17(15):2047. https://doi.org/10.3390/polym17152047

Chicago/Turabian StyleWu, Xiaoli, Ting Yin, Wenyan Liu, Libo Wan, and Yijun Liao. 2025. "The Advances in Polymer-Based Electrothermal Composites: A Review" Polymers 17, no. 15: 2047. https://doi.org/10.3390/polym17152047

APA StyleWu, X., Yin, T., Liu, W., Wan, L., & Liao, Y. (2025). The Advances in Polymer-Based Electrothermal Composites: A Review. Polymers, 17(15), 2047. https://doi.org/10.3390/polym17152047