Natural Fiber-Reinforced Foamed Rubber Composites: A Sustainable Approach to Achieving Lightweight and Structural Stability in Sole Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Modified Natural Fibers

2.3. Preparation of Pure NR and Composites

2.4. Characterization

3. Results and Discussion

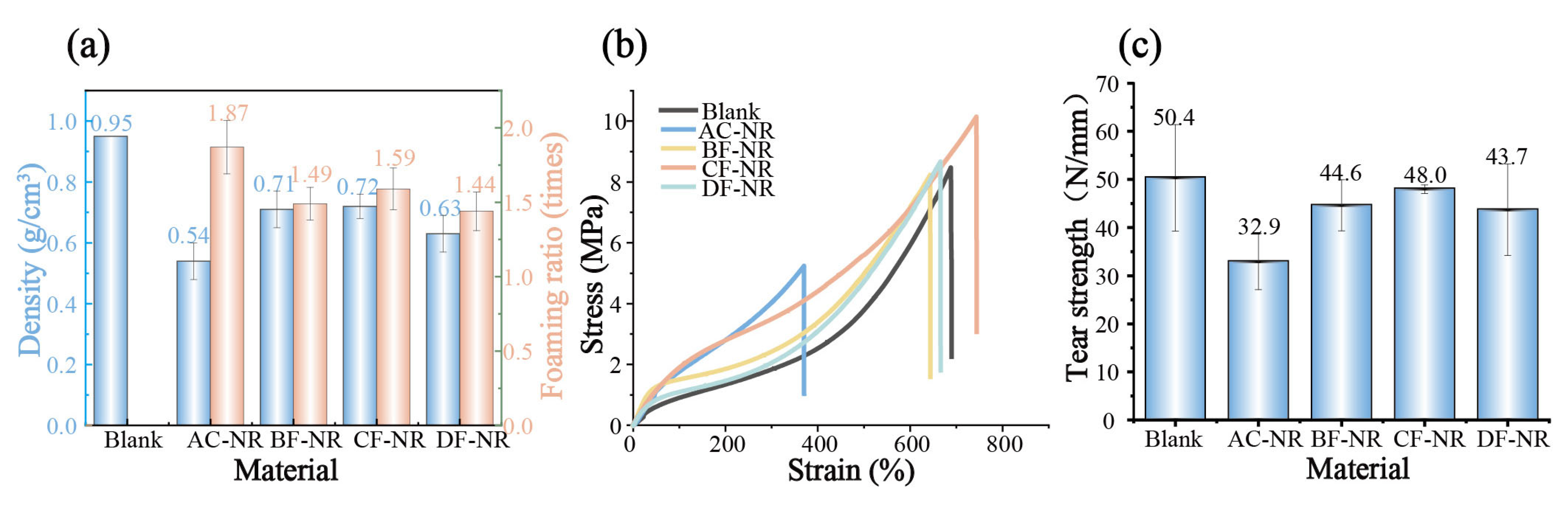

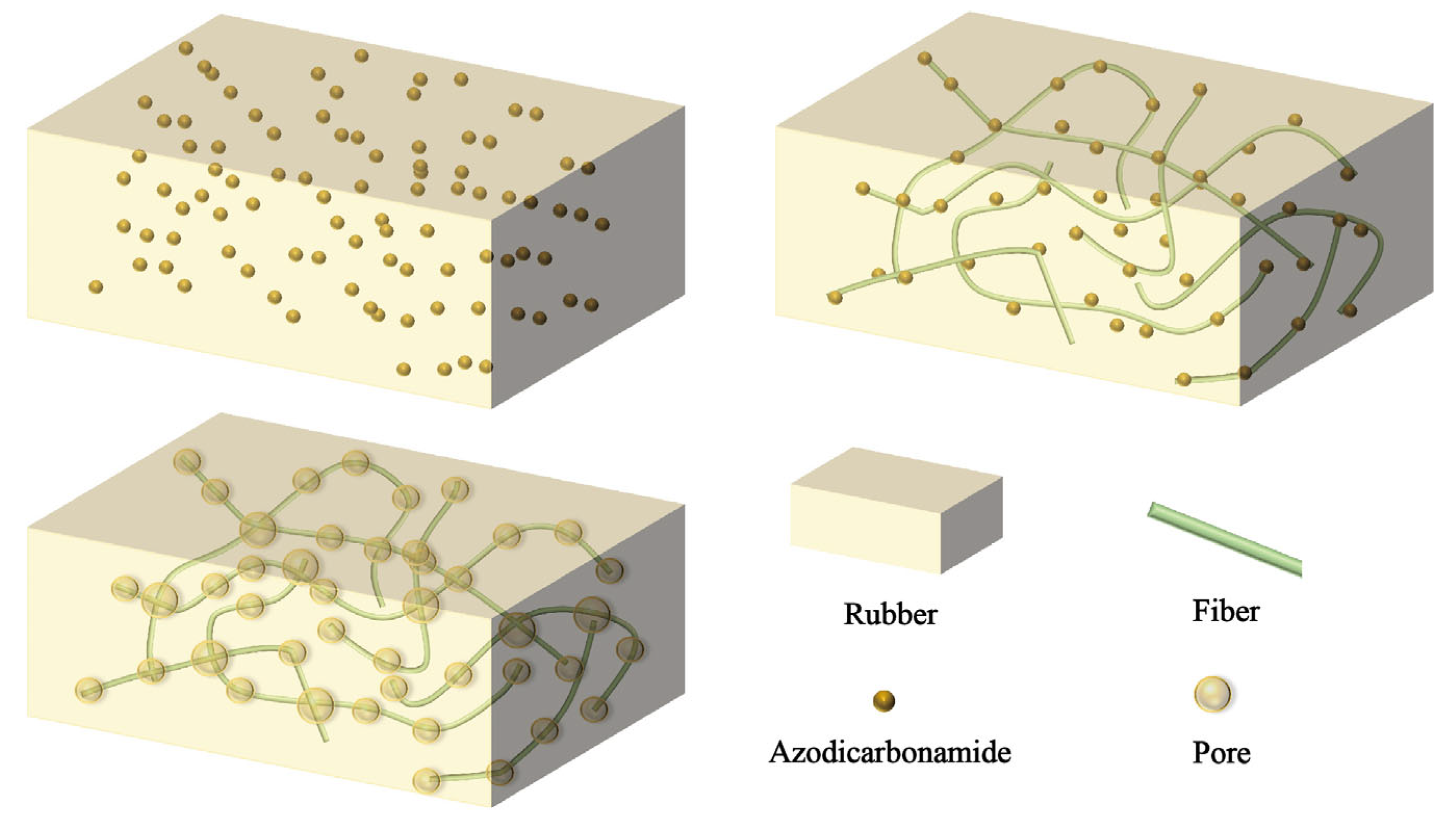

3.1. Effect of Natural Fiber Addition on the Mechanical Properties of Composites

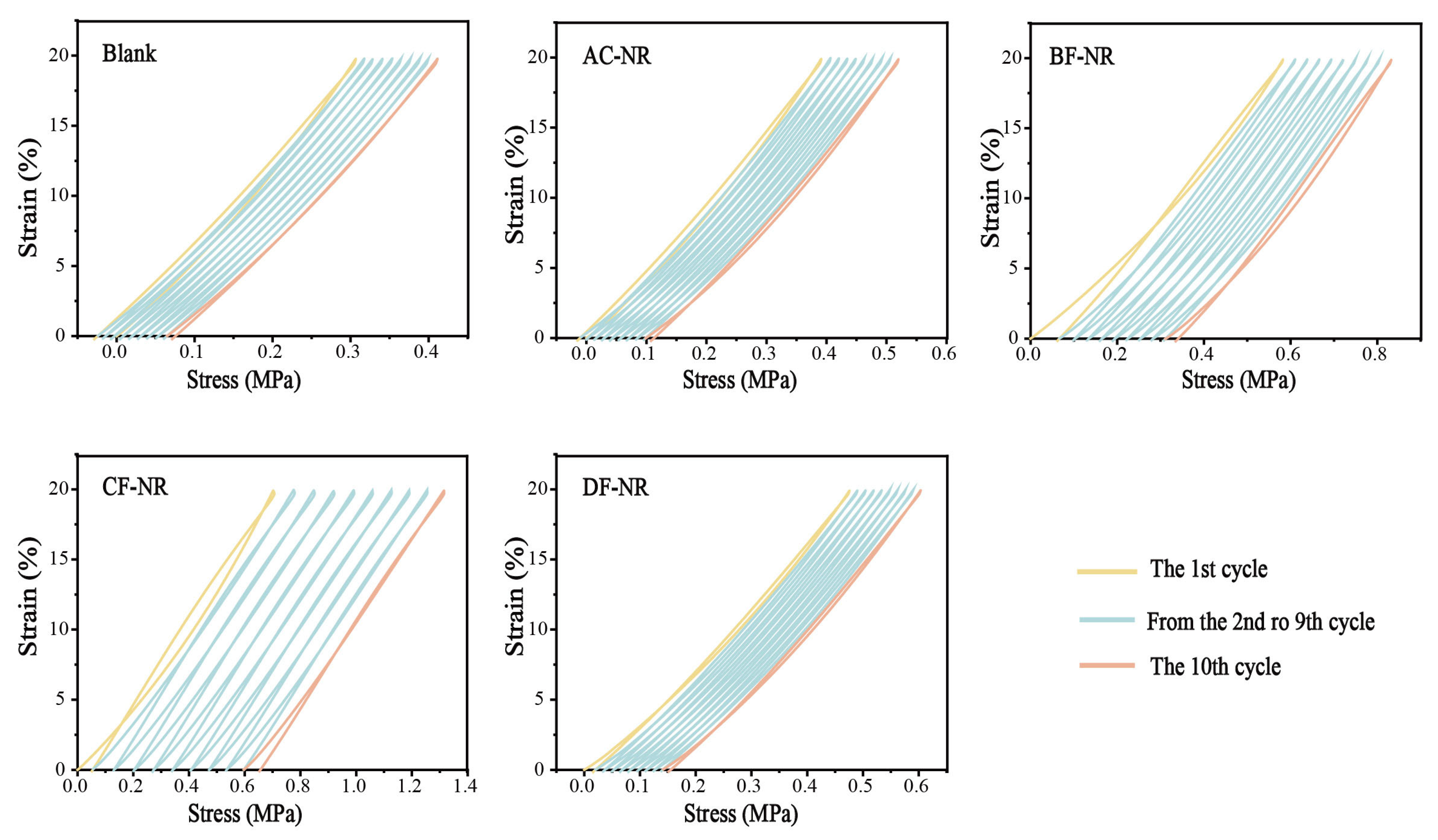

3.2. Effect of Fibers on the Structural Stability of Composites

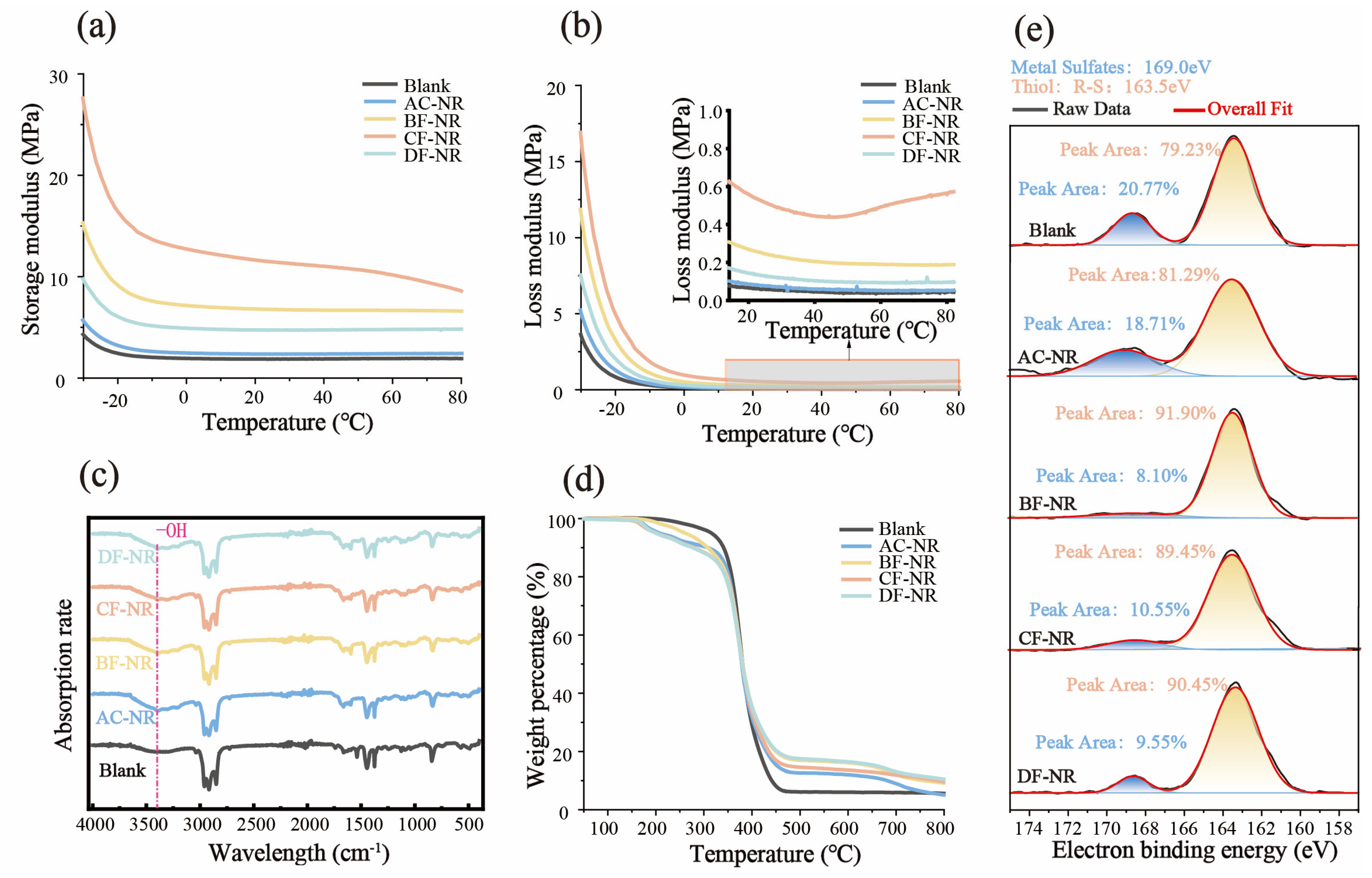

3.3. Mechanism of Natural Fiber Enhancement of Structural Stability of Composites

3.4. Other Properties of Pure NR and Composites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| NR | Natural Rubber |

| AC | Azodicarbonamide |

| BF | Bamboo Fibers |

| CF | Collagen Fibers |

| DF | Rice Husk Fibers Derived from Distiller’s Grains |

| TMTD | Tetramethylthiuram Disulfide |

| DMA | Dynamic Mechanical Analyzer |

| FT-IR | Fourier Transform Infrared Spectroscopy |

| XPS | X-ray Photoelectron Spectroscopy |

| SEM | Scanning Electron Microscopy |

| FESEM | Field Emission Scanning Electron Microscope |

| TGA | Thermogravimetric Analyzer |

| PU | Polyurethane |

| EVA | Ethylene-Vinyl Acetate |

| MIP | Mercury Intrusion Porosimeter |

References

- Bai, X.; Huo, H. Research progress on the function of sports shoes based on sports biomechanic. J. Leather Sci. Eng. 2023, 33, 73–78. [Google Scholar] [CrossRef]

- Muhammad, A.; Rahman, M.R.; Hamdan, S.S.K. Recent developments in bamboo fiber-based composites: A review. Polym. Bull. 2019, 76, 2655–2682. [Google Scholar] [CrossRef]

- Al-Azzawi, A.A. Viscoelastic behavior of glass fiber reinforced rubber-modified epoxy. Curved Layer Struct. 2022, 9, 390–395. [Google Scholar] [CrossRef]

- Vahidifar, A.; Esmizadeh, E.; Rodrigue, D.; Khonakdar, H.A.; Wagenknecht, U. Towards novel super-elastic foams based on isoperene rubber: Preparation and characterization. Polym. Adv. Technol. 2020, 31, 1508–1518. [Google Scholar] [CrossRef]

- Xue, C.; Gao, H.; Hu, Y.; Hu, G. Experimental test and curve fitting of creep recovery characteristics of modified graphene oxide natural rubber and its relationship with temperature. Polym. Test. 2020, 87, 106509. [Google Scholar] [CrossRef]

- Stochioiu, C.; Hadăr, A.; Piezel, B. Mechanical response of epoxy resin—Flax fiber composites subjected to repeated loading and creep recovery tests. Polymers 2023, 15, 766. [Google Scholar] [CrossRef]

- Saiz-Arroyo, C.; Rodríguez-Pérez, M.Á.; Velasco, J.I.; Saja, J.A.d. Influence of foaming process on the structure–properties relationship of foamed LDPE/silica nanocomposites. Compos. Part B 2013, 48, 40–50. [Google Scholar] [CrossRef]

- Xu, W.; Wu, X.; Wen, Q.; Li, S.; Song, Y.; Shi, B. Effects of collagen fiber addition on the combustion and thermal stability of natural rubber. J. Leather Sci. Eng. 2020, 2, 27. [Google Scholar] [CrossRef]

- Sethulekshmi, A.S.; Saritha, A.; Joseph, K. A comprehensive review on the recent advancements in natural rubber nanocomposites. Int. J. Biol. Macromol. 2022, 194, 819–842. [Google Scholar] [CrossRef]

- Leng, D.; Xu, K.; Qin, L.; Ma, Y.; Liu, G. A hyper-elastic creep approach and characterization analysis for rubber vibration systems. Polymers 2019, 11, 988. [Google Scholar] [CrossRef]

- Lopez-Gonzalez, E.; Salmazo, L.O.; Lopez-Gil, A.; Rodriguez-Perez, M.A. Study of the effect of different electron irradiation doses on the decomposition temperature of azodicarbonamide. Polym. Eng. Sci. 2018, 59, 791–798. [Google Scholar] [CrossRef]

- Rostami-Tapeh-Esmaeil, E.; Vahidifar, A.; Esmizadeh, E.; Rodrigue, D. Chemistry, processing, properties, and applications of rubber foams. Polymers 2021, 13, 1565. [Google Scholar] [CrossRef]

- Alcalá, N.; Castrillón, M.; Viejo, I.; Izquierdo, S.; Gracia, L.A. Rubber material-model characterization for coupled thermo-mechanical vulcanization foaming processes. Polymers 2022, 14, 1101. [Google Scholar] [CrossRef]

- Jin, F.L.; Zhao, M.; Park, M.; Park, S.J. Recent trends of foaming in polymer processing: A review. Polymers 2019, 11, 953. [Google Scholar] [CrossRef]

- Jayamani, E.; Loong, T.G.; Bakri, M.K.B. Comparative study of Fourier transform infrared spectroscopy (FTIR) analysis of natural fibres treated with chemical, physical and biological methods. Polym. Bull. 2020, 77, 1605–1629. [Google Scholar] [CrossRef]

- Richely, E.; Bourmaud, A.; Placet, V.; Guessasma, S.; Beaugrand, J. A critical review of the ultrastructure, mechanics and modelling of flax fibres and their defects. Prog. Mater. Sci. 2022, 124, 100851. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Gopi, J.A.; Radoor, S.; Dominic, C.D.M.; Krishnasamy, S.; Deshmukh, K.; Hameed, N.; Salim, N.V.; Sienkiewicz, N. Turning waste plant fibers into advanced plant fiber reinforced polymer composites: A comprehensive review. Compos. Part C Open Access 2023, 10, 100333. [Google Scholar] [CrossRef]

- Rajendran, S.; Palani, G.; Trilaksana, H.; Marimuthu, U.; Kannan, G.; Yang, Y.L.; Shanmugam, V. Advancements in natural fibre based polymeric composites: A comprehensive review on mechanical-thermal performance and sustainability aspects. Elsevier B.V. 2025, 44, 01345. [Google Scholar] [CrossRef]

- Fancey, K.S. A mechanical model for creep, recovery and stress relaxation in polymeric materials. J. Mater. Sci. 2005, 40, 4827–4831. [Google Scholar] [CrossRef]

- Sukcharoen, K.; Noraphaiphipaksa, N.; Hasap, A.; Kanchanomai, C. Experimental and numerical evaluations of localized stress relaxation for vulcanized rubber. Polymers 2022, 14, 873. [Google Scholar] [CrossRef]

- Rajendran, S.; Palani, G.; Arunprasath, K.; Shanmugam, V.; Marimuthu, U.; Veerasimman, A. Eco-friendly sugarcane biochar filler for enhanced mechanical properties in S-glass/polyester hybrid composites. Cardiovasc. Eng. Technol. 2024, 20, 100759. [Google Scholar] [CrossRef]

- Hernández, M.; Bernal, M.d.M.; Verdejo, R.; Ezquerra, T.A.; López-Manchado, M.A. Overall performance of natural rubber/graphene nanocomposites. Compos. Sci. Technol. 2012, 73, 40–46. [Google Scholar] [CrossRef]

- Nasir, M.; Hashim, R.; Sulaiman, O.; Gupta, A.; Khan, T.A.; Jawaid, M.; Asim, M. Natural fiber improvement by laccase; optimization, characterization and application in medium density fiberboard. J. Nat. Fibers 2016, 14, 379–389. [Google Scholar] [CrossRef]

- Lauer, M.K.; Estrada-Mendoza, T.A.; McMillen, C.D.; Chumanov, G.; Tennyson, A.G.; Smith, R.C. Durable cellulose-sulfur composites derived from agricultural and petrochemical waste. Adv. Sustain. Syst. 2019, 3, 1900062. [Google Scholar] [CrossRef]

- Lei, C.; Xu, W.; Shi, B.; Zeng, Y. Enhancement of mechanical and thermal insulation properties of polyvinyl chloride foam using leather shavings. J. Am. Leather Chem. Assoc. 2024, 119, 268–278. [Google Scholar]

- Guo, J.; Dai, R.; Chen, H.; Liang, Y.; Shan, Z. Research on the composite and functional characteristics of leather fiber mixed with nitrile rubber. J. Leather Sci. Eng. 2021, 3, 10. [Google Scholar] [CrossRef]

- Cho, N.; Chen, H.; Boyle, J.T.; Xuan, F. Enhanced fatigue damage under cyclic thermo-mechanical loading at high temperature by structural creep recovery mechanism. Int. J. Fatigue 2018, 113, 149–159. [Google Scholar] [CrossRef]

- Nuinu, P.; Sirisinha, C.; Suchiva, K.; Daniel, P.; Phinyocheep, P. Improvement of mechanical and dynamic properties of high silica filled epoxide functionalized natural rubber. J. Mater. Res. Technol. 2023, 24, 2155–2168. [Google Scholar] [CrossRef]

- Pu, Y.; Shi, C.; Yang, H.; Yang, J.; Wang, D.; Peng, F.; Shi, Z. Directionally arranged flexible bamboo/rubber materials with high cushion performance. Int. J. Biol. Macromol. 2025, 287, 138562. [Google Scholar] [CrossRef]

- Li, X.; Lei, C.; Wan, J.; Xu, W.; Zhou, J.; Shi, B. A novel complex coupling agent for enhancing the compatibility between collagen fiber and natural rubber: A utilization strategy for leather wastes. Int. J. Biol. Macromol. 2024, 265, 130942. [Google Scholar] [CrossRef]

- ISO 2781:2018; Rubber, vulcanized or thermoplastic—Determination of density. ISO: Geneva, Switzerland, 2018.

- ISO 37:2017; Rubber, vulcanized or thermoplastic—Determination of tensile stress-strain properties. ISO: Geneva, Switzerland, 2017.

- ISO 34-1:2022; Rubber, vulcanized or thermoplastic—Determination of tear strength—Part 1: Trouser, angle and crescent test pieces. ISO: Geneva, Switzerland, 2022.

- ISO 8295:1995; Plastics—Film and sheeting - Determination of the coefficients of friction. ISO: Geneva, Switzerland, 1995.

- Kawahara, S.; Nishioka, H.; Yamano, M.; Yamamoto, Y. Synthetic rubber with the tensile strength of natural rubber. ACS Appl. Polym. Mater. 2022, 4, 2323–2328. [Google Scholar] [CrossRef]

- Serrano-Martinez, V.M.; Perez-Aguilar, H.; Carbonell-Blasco, M.P.; Llobell-Andres, C.; Aran-Ais, F.; Garcia-Garcia, A.; Orgiles-Calpena, E. Exploring the mechanical and thermal impact of natural fillers on thermoplastic polyurethane and styrene-butadiene rubber footwear sole materials. Polymers 2024, 16, 3201. [Google Scholar] [CrossRef]

- Palanisamy, S.; Mayandi, K.; Palaniappan, M.; Alavudeen, A.; Rajini, N.; Camargo, F.V.d.; Santulli, C. Mechanical properties of phormium tenax reinforced natural rubber composites. Fibers 2021, 9, 11. [Google Scholar] [CrossRef]

- Brito-Oliveira, T.C.; Moraes, I.C.; Pinho, S.C.; Campanella, O.H. Modeling creep/recovery behavior of cold-set gels using different approaches. Food Hydrocoll. 2022, 123, 107183. [Google Scholar] [CrossRef]

- Zink, T.; Kehrer, L.; Hirschberg, V.; Wilhelm, M.; Böhlke, T. Nonlinear schapery viscoelastic material model for thermoplastic polymers. J. Appl. Polym. Sci. 2021, 139, 52028. [Google Scholar] [CrossRef]

- Chenrayan, V.; Shahapurkar, K.; Kanaginahal, G.M.; Tirth, V.; Alghtani, A.H.; Algahtani, A.; Althoey, F.; Soudagar, M.E.M.; Manivannan, C.; Murthy, H.C.A. Evaluation of dynamic mechanical analysis of crump rubber epoxy composites: Experimental and empirical perspective. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 145. [Google Scholar] [CrossRef]

- Li, W.; Zhang, H.; Yu, C.; Li, T.; Zhang, X.; Xiong, C.; Wang, T. Efficient and spectrally stable blue light-emitting diodes based on diphenylguanidine bromide passivated mixed-halide perovskites. ACS Appl. Electron. Mater. 2021, 3, 4912–4918. [Google Scholar] [CrossRef]

- Zhang, W.; Lin, L.; Guo, J.; Wu, M.; Park, S.; Yao, H.; Paek, S.H.; Diao, G.; Piao, Y. Design strategy for vulcanization accelerator of diphenylguanidine/cyclodextrin inclusion complex for natural rbber latex foam with enhancing performance. Research 2022, 2022, 9814638. [Google Scholar] [CrossRef]

- Schindler, M.; Hawthorne, F.; Freund, M.; Burns, P. XPS spectra of uranyl minerals and synthetic uranyl compounds. II: The O 1s spectrum. Geochim. Cosmochim. Acta 2009, 73, 2488–2509. [Google Scholar] [CrossRef]

- Xu, H.; Shaoyu, J.; Jin, J.; Li, M.; Ji, L.; Zhuang, W.; Tang, C.; Chang, Z.; Ying, H.; Zhu, C. Fabrication of PBAT/lignin composite foam materials with excellent foaming performance and mechanical properties via grafting esterification and twin-screw melting free radical polymerization. Collagen Leather 2024, 6, 32. [Google Scholar] [CrossRef]

- Knipe, S.; Mycroft, J.; Pratt, A.; Nesbitt, H.; Bancroff, G. X-ray photoelectron spectroscopic study of water adsorption on iron sulphide minerals. Geochim. Cosmochim. Acta 1995, 59, 1079–1090. [Google Scholar] [CrossRef]

- Wei, Y.; Wang, Y.; Zhang, X.; Wang, B.; Wang, Q.; Wu, N.; Zhang, Y.; Wu, H. Superhierarchical conductive framework implanted with nickel/graphitic carbon nanocages as sulfur/lithium metal dual-role hosts for Li-S batteries. ACS Appl. Mater. Interfaces 2020, 12, 35058–35070. [Google Scholar] [CrossRef]

- Zedler, Ł.; Colom, X.; Saeb, M.R.; Formela, K. Preparation and characterization of natural rubber composites highly filled with brewers’ spent grain/ground tire rubber hybrid reinforcement. Compos. Part B 2018, 145, 182–188. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, X.; Yu, W. High performance of bamboo-based fiber composites from long bamboo fiber bundles and phenolic resins. J. Appl. Polym. Sci. 2014, 131, 40371. [Google Scholar] [CrossRef]

- Liu, J.Z.; Recupido, F.; Lama, G.C.; Oliviero, M.; Verdolotti, L.; Lavorgna, M. Recent advances concerning polyurethane in leather applications: An overview of conventional and greener solutions. Collagen Leather 2023, 5, 8. [Google Scholar] [CrossRef]

- Kim, Y.; Hendrickson, R.; Mosier, N.S.; Ladisch, M.R.; Bals, B.; Balan, V.; Dale, B.E. Enzyme hydrolysis and ethanol fermentation of liquid hot water and AFEX pretreated distillers’ grains at high-solids loadings. Bioresour. Technol. 2008, 12, 0960–8524. [Google Scholar] [CrossRef]

- Jing, Q.; Liu, Q.; Li, N.; Dong, Z.; Silberschmidt, V.V. Effect of graphene-oxide enhancement on large-deflection bending performance of thermoplastic polyurethane elastomer. Compos. Part B 2016, 89, 1–8. [Google Scholar] [CrossRef]

- Whba, R.; Su’ait, M.S.; Whba, F.; Sahinbay, S.; Altin, S.; Ahmad, A. Intrinsic challenges and strategic approaches for enhancing the potential of natural rubber and its derivatives: A review. Int. J. Biol. Macromol. 2024, 276, 133796. [Google Scholar] [CrossRef]

- Luo, R.K.; Zhou, X.; Tang, J. Numerical prediction and experiment on rubber creep and stress relaxation using time-dependent hyperelastic approach. Polym. Test. 2016, 52, 246–253. [Google Scholar] [CrossRef]

- Sandström, R. Basic analytical modeling of creep strain curves. Materials 2023, 16, 3542. [Google Scholar] [CrossRef]

- Kamarian, S.; Song, J.I. Review of literature on eco-friendly sandwich structures made of non-wood cellulose fibers. J. Sandw. Struct. Mater. 2022, 24, 1653–1705. [Google Scholar] [CrossRef]

- Luo, S.; Tian, J.; Liu, Z.; Lu, Q.; Zhong, K.; Yang, X. Rapid determination of styrene-butadiene-styrene (SBS) content in modified asphalt based on Fourier transform infrared (FTIR) spectrometer and linear regression analysis. Measurement 2020, 151, 107204. [Google Scholar] [CrossRef]

- Deka, R.; Sarmah, J.K.; Baruah, S.; Dutta, R.R. An okra polysaccharide (Abelmoschus esculentus) reinforced green hydrogel based on guar gum and poly-vinyl alcohol double network for controlled release of nanocurcumin. Int. J. Biol. Macromol. 2023, 234, 123618. [Google Scholar] [CrossRef]

| Sample | Rubber 1 | Fiber 1 | Stearic Acid 1 | Zinc Oxide 1 | Sulfur 1 | Accelerator 1 | AC 1 |

|---|---|---|---|---|---|---|---|

| Blank | 100 | 0 | 3 | 5 | 2 | 0.2 | 0 |

| AC-NR | 100 | 0 | 3 | 5 | 2 | 0.2 | 20 |

| BF-NR | 80 | 20 | 3 | 5 | 2 | 0.2 | 20 |

| CF-NR | 80 | 20 | 3 | 5 | 2 | 0.2 | 20 |

| DF-NR | 80 | 20 | 3 | 5 | 2 | 0.2 | 20 |

| Sample | /% | /% | /% | /% | /% | /% |

|---|---|---|---|---|---|---|

| Blank | 0.61 | 1.24 | 3.73 | 5.58 | 4.34 | 79.39 |

| AC-NR | 1.05 | 0.99 | 4.95 | 6.99 | 6.00 | 85.84 |

| BF-NR | 0.53 | 0.43 | 2.51 | 3.47 | 3.04 | 87.46 |

| CF-NR | 1.51 | 0.1 | 2.97 | 4.58 | 4.48 | 99.33 |

| DF-NR | 0.44 | 0.6 | 2.39 | 3.43 | 2.83 | 82.51 |

| Sample | EM/MPa | EK/MPa | /MPa | /s | τ/s |

|---|---|---|---|---|---|

| Blank | 0.38 | 8.58 | 1632.86 | 24,704.63 | 190.31 |

| AC-NR | 0.32 | 4.46 | 620.77 | 14,998.29 | 139.19 |

| BF-NR | 0.65 | 7.58 | 1426.75 | 25,950.58 | 188.23 |

| CF-NR | 0.52 | 3.18 | 322.88 | 26,157.90 | 101.53 |

| DF-NR | 0.65 | 8.61 | 1601.66 | 27,120.06 | 186.02 |

| Sample | /S | /% | /% | /% | ||

|---|---|---|---|---|---|---|

| Blank | 1597.86 | 0.14 | 0.85 | 0.95 | 3.78 | 4.63 |

| AC-NR | 3575.36 | 0.10 | 2.54 | 0.15 | 4.30 | 6.84 |

| BF-NR | 20,610.56 | 0.19 | 0.81 | 0.04 | 2.62 | 3.43 |

| CF-NR | 523.50 | 0.59 | 1.08 | 0.01 | 3.49 | 4.57 |

| DF-NR | 1592.80 | 0.27 | 0.47 | 0.43 | 2.53 | 3.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Y.; Chen, S.; Xie, J.; Xu, W.; Zeng, Y.; Shi, B. Natural Fiber-Reinforced Foamed Rubber Composites: A Sustainable Approach to Achieving Lightweight and Structural Stability in Sole Materials. Polymers 2025, 17, 2043. https://doi.org/10.3390/polym17152043

Jin Y, Chen S, Xie J, Xu W, Zeng Y, Shi B. Natural Fiber-Reinforced Foamed Rubber Composites: A Sustainable Approach to Achieving Lightweight and Structural Stability in Sole Materials. Polymers. 2025; 17(15):2043. https://doi.org/10.3390/polym17152043

Chicago/Turabian StyleJin, Yi, Shen Chen, Jinlan Xie, Weixing Xu, Yunhang Zeng, and Bi Shi. 2025. "Natural Fiber-Reinforced Foamed Rubber Composites: A Sustainable Approach to Achieving Lightweight and Structural Stability in Sole Materials" Polymers 17, no. 15: 2043. https://doi.org/10.3390/polym17152043

APA StyleJin, Y., Chen, S., Xie, J., Xu, W., Zeng, Y., & Shi, B. (2025). Natural Fiber-Reinforced Foamed Rubber Composites: A Sustainable Approach to Achieving Lightweight and Structural Stability in Sole Materials. Polymers, 17(15), 2043. https://doi.org/10.3390/polym17152043