Preparation of Tung Oil Microcapsules Coated with Chitosan–Arabic Gum and Its Effect on the Properties of UV Coating

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Tung Oil Microcapsules Coated with Chitosan–Arabic Gum

2.3. Preparation of UV Topcoat Film-Containing Microcapsules

2.4. Test and Characterization

2.4.1. Microcapsule Sample Characterization

2.4.2. UV Topcoat Performance Tests

3. Results and Discussion

3.1. Microcapsules Testing

3.1.1. Yield and Coverage Rate Test

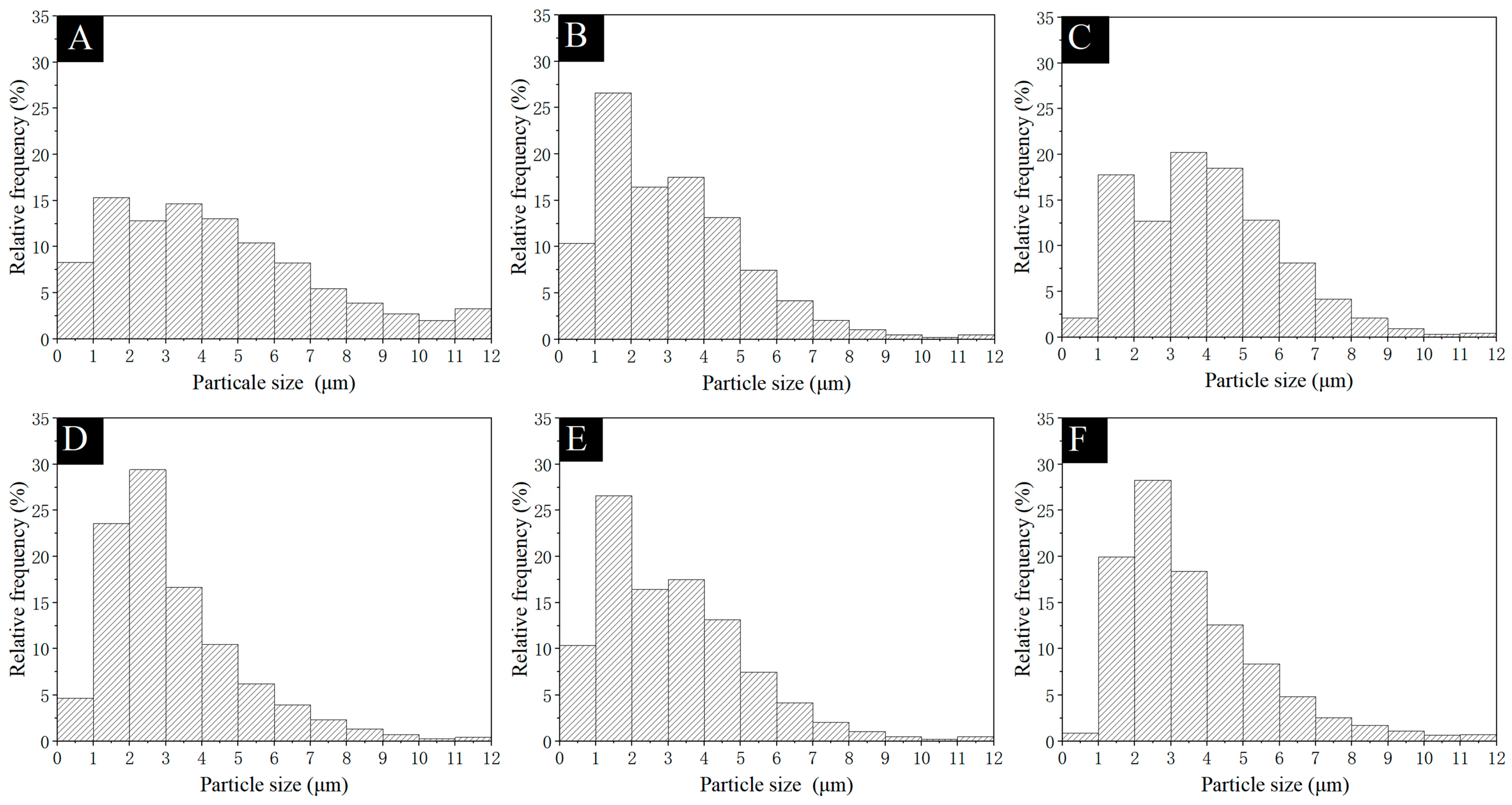

3.1.2. Morphology Testing of Microcapsules

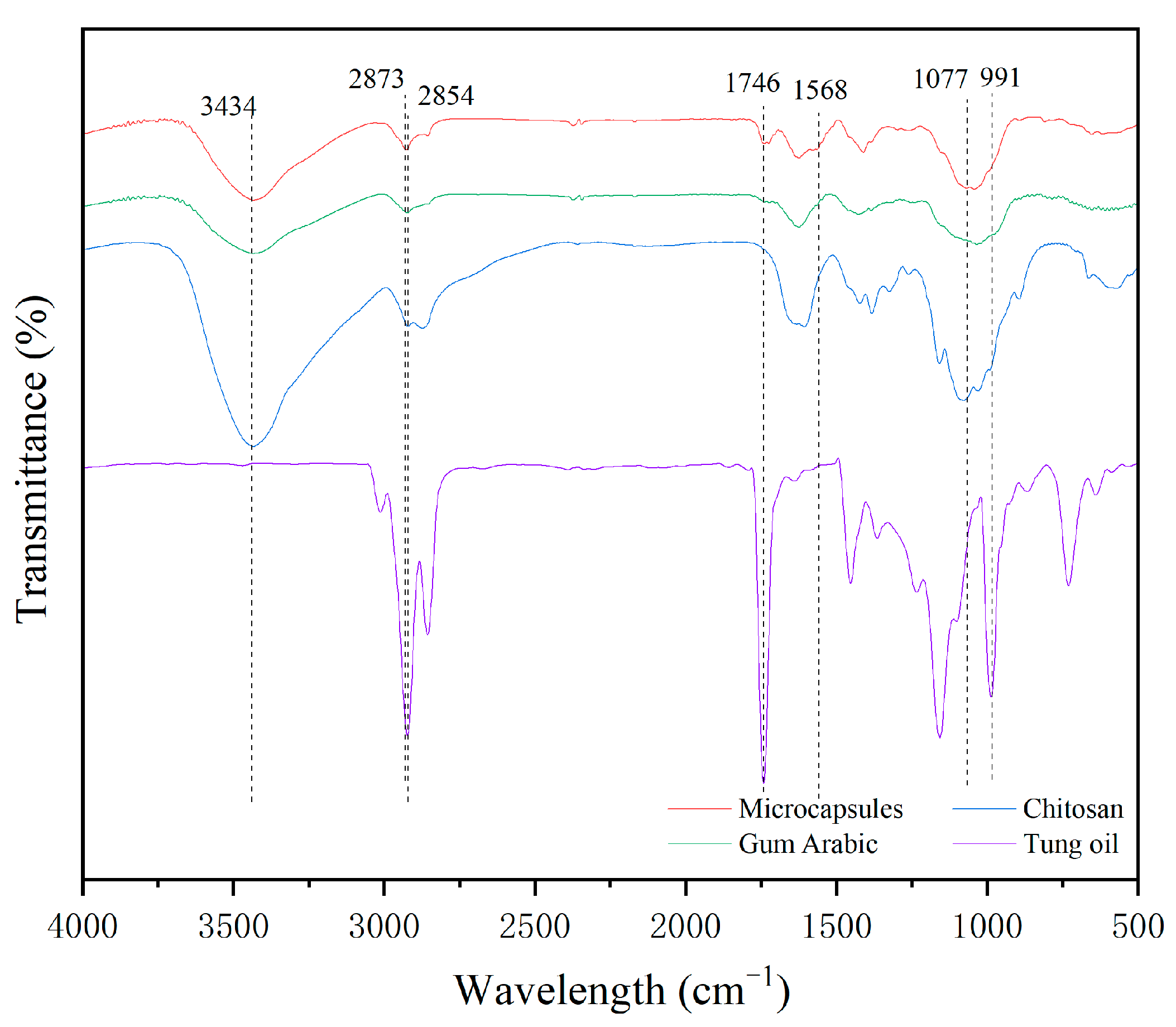

3.1.3. Microcapsule Chemical Composition Testing

3.2. UV Topcoat Testing

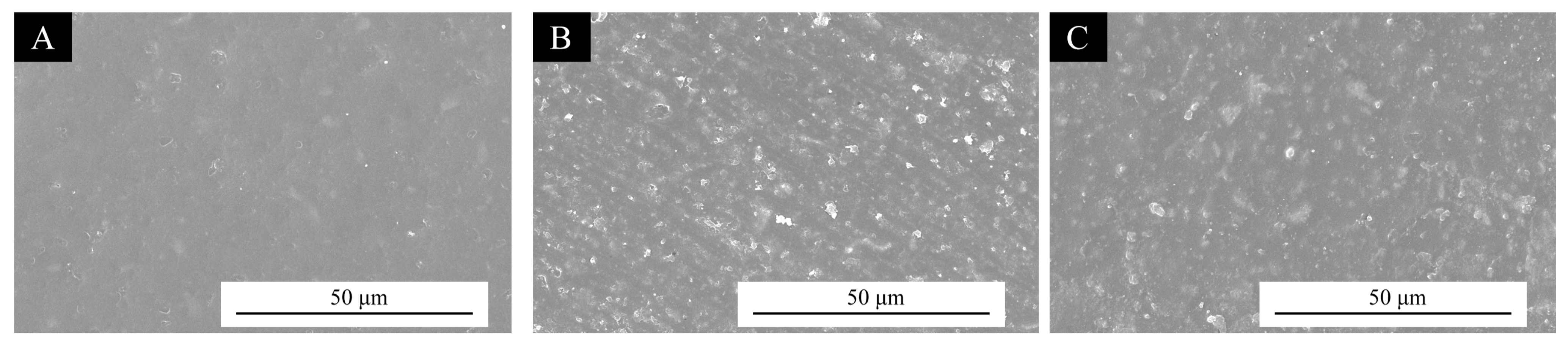

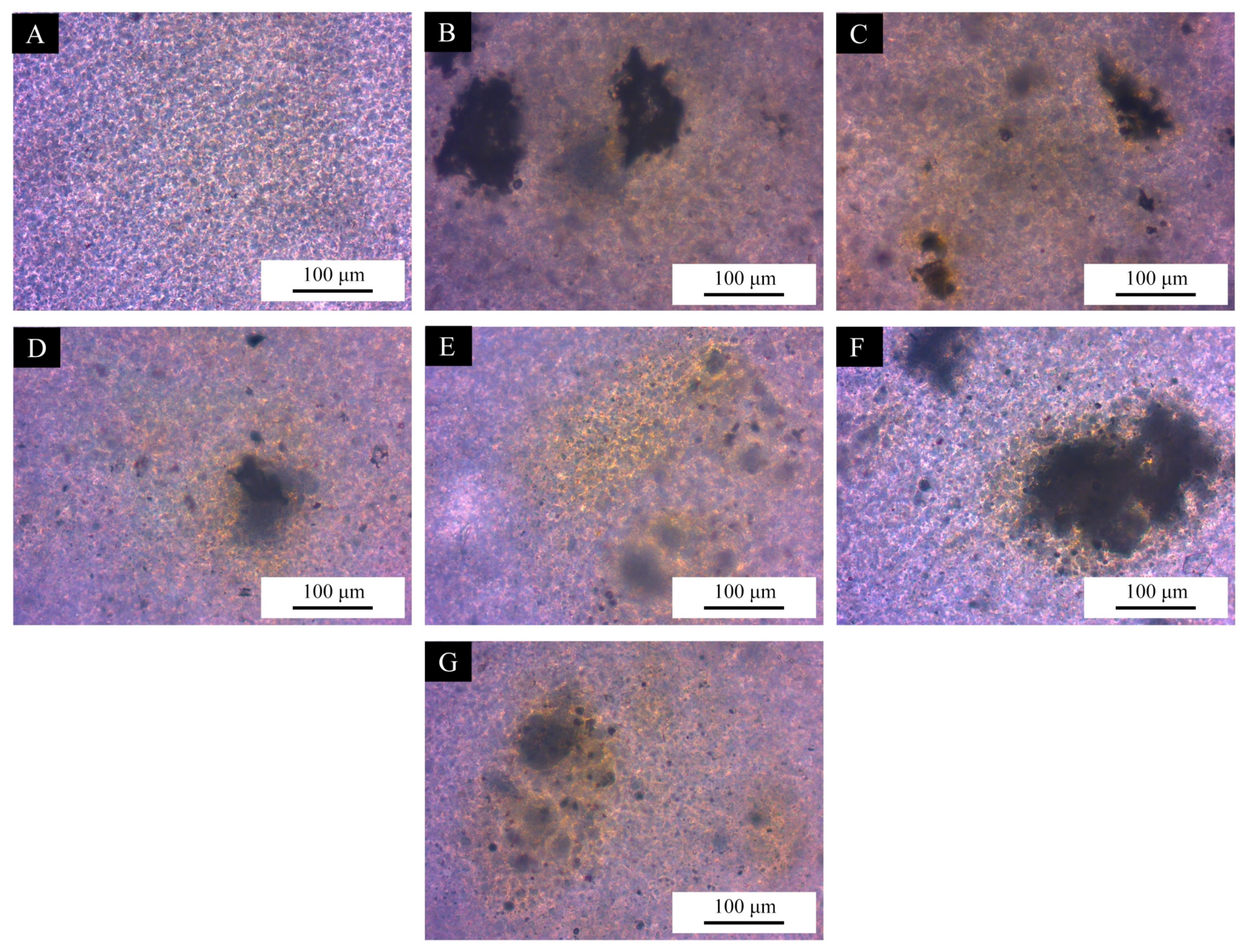

3.2.1. Surface Morphology of UV Topcoat

3.2.2. Chemical Composition Testing of UV Topcoat

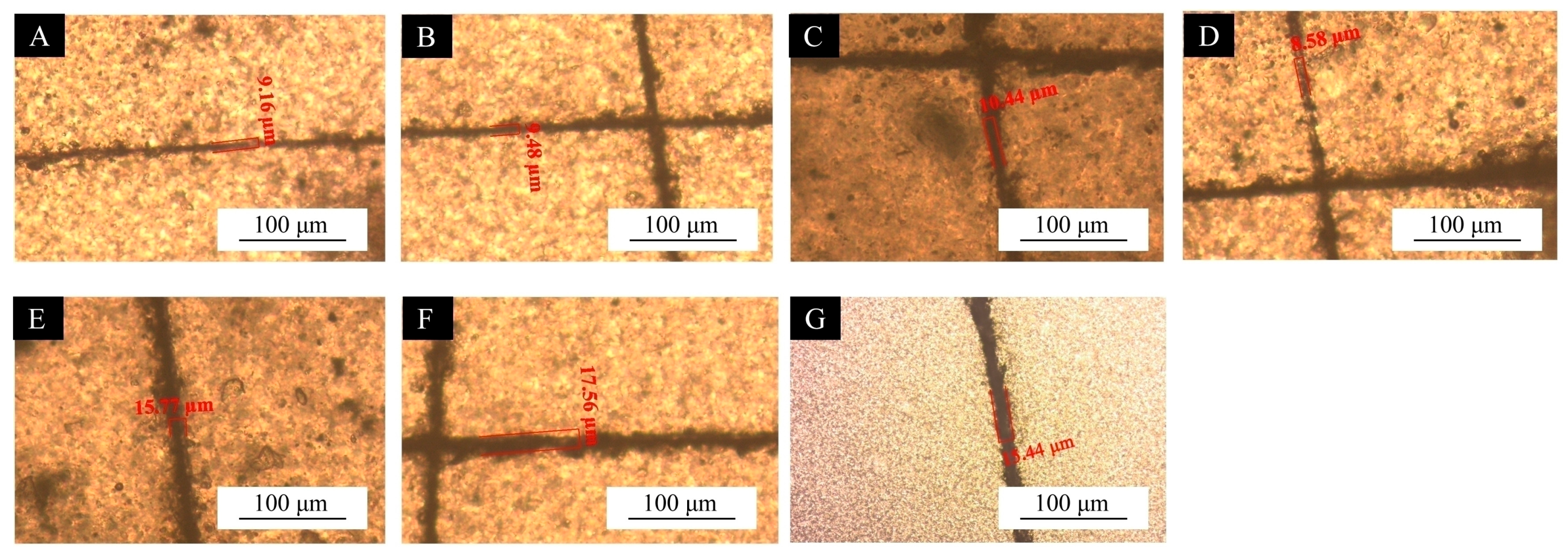

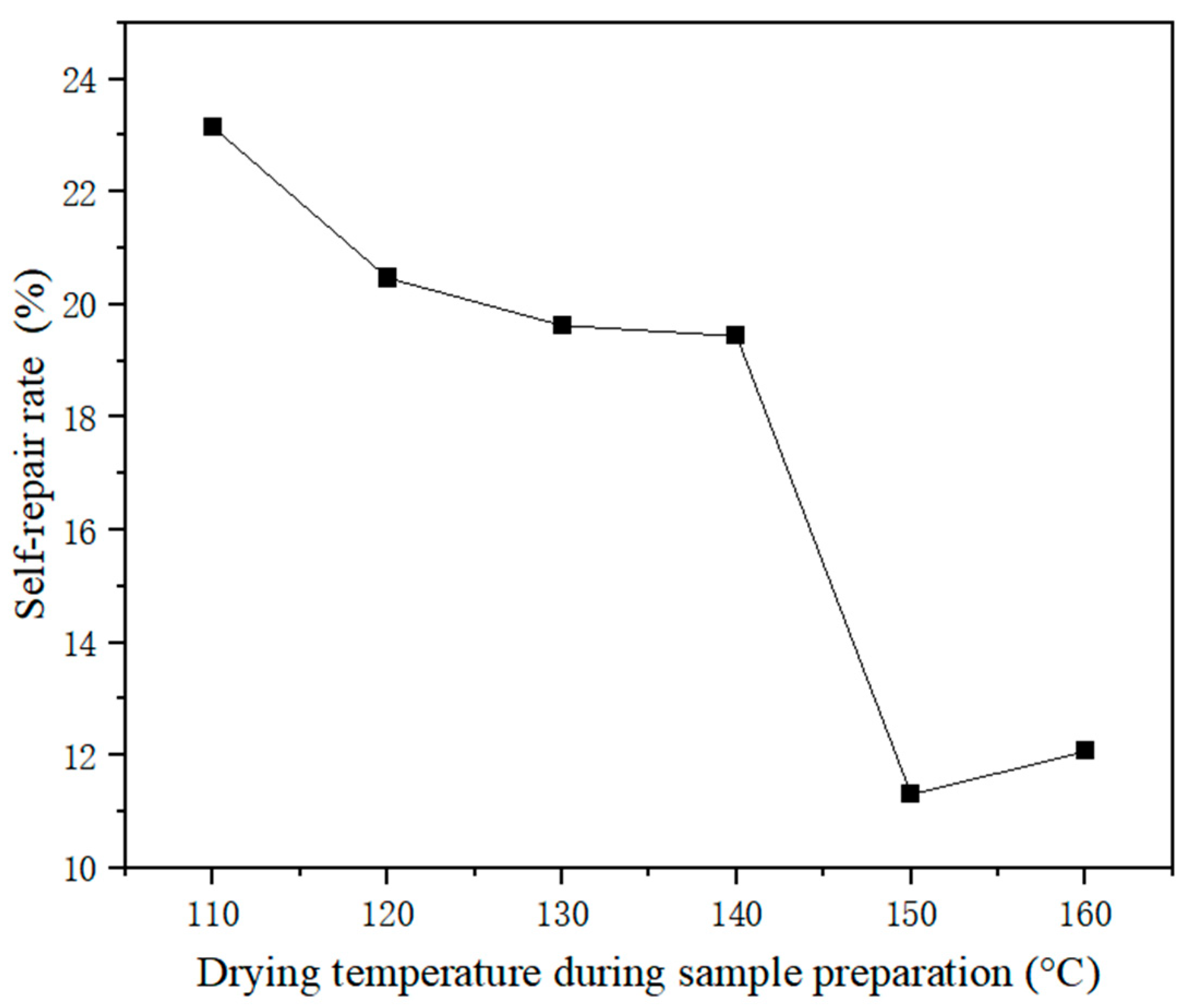

3.2.3. Self-Repairing Performance Test of UV Topcoat

3.2.4. Mechanical Testing of UV Topcoat

3.2.5. Optical Testing of UV Topcoat

3.2.6. Cold Liquid Resistance Testing of UV Topcoat

3.2.7. Aging Testing of UV Topcoat

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Yu, J.H.; Jiang, M.H.; Li, J.Y. Effect of selective enhancement on the bending performance of fused deposition methods 3D-printed PLA models. BioResources 2024, 19, 2660–2669. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, Z.Y. Optical properties and lampshade design applications of PLA 3D printing materials. BioResources 2023, 18, 1545–1553. [Google Scholar] [CrossRef]

- Zhou, J.C.; Xu, W. A fast method to prepare highly isotropic and optically adjustable transparent wood-based composites based on interface optimization. Ind. Crops Prod. 2024, 218, 118898. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.Y.; Ding, K.Q.; Jiang, M.H. Immersion polishing post-treatment of PLA 3D printed formed parts on its surface and mechanical performance. BioResources 2023, 18, 7995–8006. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.Y.; Zhu, Y. Reverse design and additive manufacturing of furniture protective foot covers. Bioresources 2024, 19, 4670–4678. [Google Scholar] [CrossRef]

- Zhang, N.; Xu, W.; Tan, Y. Multi-attribute hierarchical clustering for product family division of customized wooden doors. BioResources 2023, 18, 7889–7904. [Google Scholar] [CrossRef]

- Gu, Y.T.; Zhang, J.L. Tensile properties of natural and synthetic rattan strips used as furniture woven materials. Forests 2020, 11, 1299. [Google Scholar] [CrossRef]

- Hu, W.G.; Yu, R.Z. Mechanical and acoustic characteristics of four wood species subjected to bending load. Maderas Cienc. Tecnol. 2023, 25, 39. [Google Scholar] [CrossRef]

- Xue, J.X.; Xu, W.; Zhou, J.C.; Mao, W.G.; Wu, S.S. Effects of high-temperature heat treatment modification by impregnation on physical and mechanical properties of poplar. Materials 2022, 15, 7334. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.Y.; Liu, X.; Wu, S.S.; Xu, W. The influence of different impregnation factors on mechanical properties of silica sol-modified Populus tomentosa. Wood Fiber Sci. 2024, 56, 65–71. [Google Scholar]

- Hu, W.G.; Liu, Y.; Konukcu, A.C. Study on withdrawal load resistance of screw in wood-based materials: Experimental and numerical. Wood Mater. Sci. Eng. 2023, 18, 334–343. [Google Scholar] [CrossRef]

- Hu, W.G.; Luo, M.Y.; Hao, M.M.; Tang, B.; Wan, C. Study on the effects of selected factors on the diagonal tensile strength of oblique corner furniture joints constructed by wood dowel. Forests 2023, 14, 1149. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, W.G.; Kasal, A.; Erdil, Y.Z. The state of the art of biomechanics applied in ergonomic furniture design. Appl. Sci. 2023, 13, 12120. [Google Scholar] [CrossRef]

- Hu, W.G.; Luo, M.Y.; Yu, R.Z.; Zhao, Y. Effects of the selected factors on cyclic load performance of T-shaped mortise-and-tenon furniture joints. Wood Mater. Sci. Eng. 2024, 18, 1–10. [Google Scholar] [CrossRef]

- Zhou, J.C.; Xu, W. Optimizing the Interface Compatibility of transparent wood for green phase-change thermal storage. Wood Sci. Technol. 2025, 59, 45. [Google Scholar] [CrossRef]

- Wu, S.S.; Zhou, L.C.; Xu, W. A convenient approach to manufacturing lightweight and high-sound-insulation plywood using furfuryl alcohol/multilayer graphene oxide as a shielding layer. Wood Mater. Sci. Eng. 2024, 19, 1226–1233. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Wang, J.X.; Xu, W. Study of selective modification effect of constructed structural color layers on European beech wood surfaces. Forests 2024, 15, 261. [Google Scholar] [CrossRef]

- Weng, M.Y.; Zhu, Y.T.; Mao, W.G.; Zhou, J.C.; Xu, W. Nano-Silica/Urea-Formaldehyde Resin-Modified Fast-Growing Lumber Performance Study. Forests 2023, 14, 1440. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Influence of the Bottom Color Modification and Material Color Modification Process on the Performance of Modified Poplar. Coatings 2021, 11, 660. [Google Scholar] [CrossRef]

- Liu, Q.Q.; Gao, D.; Xu, W. Effect of Polyurethane Non-Transparent Coating Process on Paint Film Performance Applied on Modified Poplar. Coatings 2022, 12, 39. [Google Scholar] [CrossRef]

- Liu, C.; Xu, W. Effect of Coating Process on Properties of Two-Component Waterborne Polyurethane Coatings for Wood. Coatings 2022, 12, 1857. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, M.Y.; Li, P.; Xu, B.; Zhang, Y.; Zuo, Y.F. Influence of coating technology on performance of coated wood surface. J. For. Eng. 2024, 9, 169–179. [Google Scholar] [CrossRef]

- Zhang, W.W.; Peng, X.X.; Li, K.; Zhang, H.; Ma, J.J.; Zhang, J.Y. Aminated modification of shellac resin and properties of its waterborne coatings. J. For. Eng. 2024, 9, 55–62. [Google Scholar] [CrossRef]

- Xu, R.; Wang, D.; Dou, L.H.; Cui, J.Q.; He, L.; Feng, F.Q.; Liu, F.F. Preparation and properties of self-healing polyurethane wood coatings with borate eater bonds. J. For. Eng. 2024, 9, 54–60. [Google Scholar] [CrossRef]

- Ma, L.; Xu, S.Y. Investigation on the restoration properties of wood oil microcapsules in wood coatings. Prog. Org. Coat. 2024, 197, 108853. [Google Scholar] [CrossRef]

- Kartsonakis, I.A.; Kontiza, A.; Kanellopoulou, I.A. Advanced micro/nanocapsules for self-healing coatings. Appl. Sci. 2024, 14, 8396. [Google Scholar] [CrossRef]

- Chang, Y.J.; Yan, X.X.; Wu, Z.H. Application and prospect of self-healing microcapsules in surface coating of wood. Colloid Interfac. Sci. 2023, 56, 100736. [Google Scholar] [CrossRef]

- Zhang, H.; Cheng, C.R.; Guo, M.L. Fabrication of diisocyanate microcapsules for self-healing anti-corrosion coatings via integrating electrospraying and interfacial polymerization. Colloid Surf. A Physicochem. Eng. Asp. 2024, 695, 134247. [Google Scholar] [CrossRef]

- Karampoor, M.R.; Bahrami, A.; Atapour, M. Towards an antibacterial self-healing coating based on linseed oil/ZnO nanoparticles repair agent, encapsulated in polyurea formaldehyde microcapsules. Micro Nano Lett. 2024, 19, e12195. [Google Scholar] [CrossRef]

- Xia, Y.X.; Yan, X.X. Preparation of UV topcoat microcapsules and their effect on the properties of UV topcoat paint film. Polymers 2024, 16, 1410. [Google Scholar] [CrossRef] [PubMed]

- Gu, C.Y.; Shao, J.Q.; Liu, X.L.; Wei, J.T.; Huang, G.Q.; Xiao, J.X. Spray drying the Pickering emulsions stabilized by chitosan/ovalbumin polyelectrolyte complexes for the production of oxidation stable tuna oil microcapsules. Int. J. Biol. Macromol. 2024, 273, 133139. [Google Scholar] [CrossRef] [PubMed]

- Lai, H.Z.; Liu, Y.; Huang, G.T.; Chen, Y.C.; Song, Y.G.; Ma, Y.Q.; Yue, P.F. Fabrication and antibacterial evaluation of peppermint oil-loaded composite microcapsules by chitosan-decorated silica nanoparticles stabilized Pickering emulsion templating. Int. J. Biol. Macromol. 2021, 183, 2314–2325. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.C.; Li, M.Y.; Zhang, D.Y.; Yu, Y.; Zhu, K.X.; Zang, X.D.; Liu, D.Y. Preparation and investigation of sustained-release nanocapsules containing cumin essential oil for their bacteriostatic properties. Food 2024, 13, 947. [Google Scholar] [CrossRef] [PubMed]

- Lobato-Guarnido, I.; Luzón, G.; Ríos, F.; Fernández-Serrano, M. Synthesis and characterization of environmentally friendly chitosan-Arabic gum nanoparticles for encapsulation of oregano essential oil in Pickering emulsion. Nanomaterials 2023, 13, 2651. [Google Scholar] [CrossRef] [PubMed]

- Qian, J.; Chen, Y.; Wang, Q.; Zhao, X.H.; Yang, H.Y.; Gong, F.; Guo, H. Preparation and antimicrobial activity of pectin-chitosan embedding nisin microcapsules. Eur. Polym. J. 2021, 157, 110676. [Google Scholar] [CrossRef]

- Butstraen, C.; Salaün, F. Preparation of microcapsules by complex coacervation of gum Arabic and chitosan. Carbohydr. Polym. 2014, 99, 608–616. [Google Scholar] [CrossRef] [PubMed]

- Baiocco, D.; Preece, J.A.; Zhang, Z.B. Microcapsules with a fungal chitosan-gum Arabic-maltodextrin shell to encapsulate health-beneficial peppermint oil. Food Hydrocoll. Health 2021, 1, 100016. [Google Scholar] [CrossRef]

- Elabbadi, A.; Erni, P. Gum Arabic/Chitosan Coacervate System. EP 3657961A1, 3 June 2020. [Google Scholar]

- Wang, J.P.; Wang, J.K.; Zhou, Q.; Li, Z.; Han, Y.S.; Song, Y.; Yang, S.; Song, X.K.; Qi, T.; Möhwald, H.; et al. Adaptive polymeric coatings with self-reporting and self-healing dual functions from porous core-shell nanostructures. Macromol. Mater. Eng. 2018, 303, 1700616. [Google Scholar] [CrossRef]

- Zhang, Z.T.; Ye, D.Y.; Li, Y.H.; Hu, F.; Yang, Y.; Liao, Y.W. Enhancing weatherability and mechanical properties of tung oil wood finishes through natural rubber modification via the Diels-Alder reaction. Int. J. Biol. Macromol. 2024, 272, 132602. [Google Scholar] [CrossRef] [PubMed]

- Samadzadeh, M.; Boura, S.H.; Peikari, M.; Ashrafi, A.; Kasiriha, M. Tung oil: An autonomous repairing agent for self-healing epoxy coatings. Prog. Org. Coat. 2011, 70, 383–387. [Google Scholar] [CrossRef]

- Chang, Y.J.; Wu, Z.H.; Liu, E.W. Fabrication of chitosan-encapsulated microcapsules containing wood wax oil for antibacterial self-healing wood coatings. Ind. Crop. Prod. 2024, 222, 119438. [Google Scholar] [CrossRef]

- GB/T 4893.6-2013; Physical and Chemical Performance Tests of the Paint Film on the Surface of Furniture—Part 6: Method for Determining Gloss. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- GB/T 4893.1-2021; Methods for Measuring the Colour of Paint Films—Part I: Cold Liquid Resistance Measurement Method. Standardization Administration of the People’s Republic of China: Beijing, China, 2021.

- GB/T 1766-2008; Paints and Varnishes—Rating Schemes of Degradation of Coats. Standardization Administration of the People’s Republic of China: Beijing, China, 2008.

- Beirao-da-Costa, S.; Duarte, C.; Bourbon, A.I.; Pinheiro, A.C.; Januário, M.I.N.; Vicente, A.A.; Beirao-da-Costa, M.L.; Delgadillo, I. Inulin potential for encapsulation and controlled delivery of Oregano essential oil. Food Hydrocoll. 2013, 33, 199–206. [Google Scholar] [CrossRef]

- Yan, X.X.; Tao, Y.; Chang, Y.J. Effect of Shellac Waterborne Coating Microcapsules on the Optical, Mechanical and Self-Healing Properties of Waterborne Primer on Tilia European L. Wood. Coat. 2021, 11, 785. [Google Scholar] [CrossRef]

- Peng, W.W.; Yan, X.X. Preparation of Tung Oil Microcapsule and Its Effect on Wood Surface Coating. Polymers 2022, 14, 1536. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhou, L.M.; Shehzad, H.; Farooqi, Z.H.; Sharif, A.; Ahmed, E.; Habiba, U.; Qaisar, F.; Noor, E.-F.; Begum, R.; et al. Innovative free radical induced synthesis of WO3– doped diethyl malonate grafted chitosan encapsulated with phosphorylated alginate matrix for UO22+ adsorption: Parameters optimisation through response surface methodology. Sep. Purif. Technol. 2024, 353, 128455. [Google Scholar] [CrossRef]

- Baiocco, D.; Preece, J.A.; Zhang, Z.B. Encapsulation of hexylsalicylate in an animal-free chitosan-gum Arabic shell by complex coacervation. Colloid Surf. A 2021, 625, 126861. [Google Scholar] [CrossRef]

- Shukla, A.; Syaifie, P.H.; Rochman, N.T.; Syaifullah, S.J.; Jauhar, M.M.; Mardliyati, E. A recent study of natural hydrogels: Improving mechanical properties for biomedical applications. Biomed. Mater. 2025, 20, 022010. [Google Scholar] [CrossRef] [PubMed]

| Materials | Molecular Formula | CAS | Producer |

|---|---|---|---|

| Chitosan | (C6H11NO4)n | 9012-76-4 | China National Pharmaceutical Group Chemical Reagent Co., Ltd., Shanghai, China |

| Arabic gum | C12H36 | 9000-01-5 | Tianjin Zhonglian Chemical Reagent Co., Ltd., Tianjin, China |

| Acetic acid | C2H4O2 | 64-19-7 | China National Pharmaceutical Group Chemical Reagent Co., Ltd., Shanghai, China |

| Tung oil | C65H100O14 | - | Shanghai Shenmeng Home Furnishings Co., Ltd., Shanghai, China |

| Tannic acid | C76H52O46 | 1401-55-4 | Tianjin Zhonglian Chemical Reagent Co., Ltd., Tianjin, China |

| Equipment | Model | Manufacturer |

|---|---|---|

| Heat collecting magnetic stirrer | DF-101Z | Shanghai Yixin Scientific Instrument Co., Ltd., Shanghai, China |

| Ultrasonic emulsifier disperser | BILONG-500 | Shanghai Bilon Instrument Co., Ltd., Shanghai, China |

| Spray dryer | JA-PWGZ100 | Shenyang Jingao Instrument Technology Co., Ltd., Shenyang, China |

| Circulating water vacuum pump | SHZ-D | Shanghai Simite Instrument Equipment Co., Ltd., Shanghai, China |

| UV curing machine | 620# | Huzhou Tongxu Machinery Equipment Co., Ltd., Huzhou, China |

| Roughness tester | J8-4C | Shanghai Taiming Optical Instrument Co., Ltd., Shanghai, China |

| Gloss meter | HG268 | Shenzhen 3nh Technology Co., Ltd., Shenzhen, China |

| Universal mechanics testing machine | AGS-X | Shimazu Manufacturing Co., Ltd., Kyoto, Japan |

| Ultraviolet spectrophotometer | U-3900 | Hitachi Instruments (Suzhou) Co., Ltd., Suzhou, China |

| Scanning electron microscope (SEM) | QUANTA-200 | FEI Company, Hillsboro, OR, USA |

| Infrared spectrometer | VERTEX 80V | Germany BRUKER Co., Ltd., Karlsruhe, Germany |

| UV yellowing resistance test chamber | WJ-UV-150 | Hangzhou Wujia machine Co., Ltd., Hangzhou, China |

| Levels | Factor A Core–Wall Mass Ratio | Factor B pH | Factor C The Ratio of Two Wall Materials | Factor D The Temperature During Spray Drying (°C) |

|---|---|---|---|---|

| 1 | 0.5:1.0 | 3.0 | 1.0:4.0 | 150 |

| 2 | 0.8:1.0 | 3.5 | 1.0:5.0 | 170 |

| 3 | 1.0:1.0 | 4.0 | 1.0:6.0 | 190 |

| Sample (#) | Factor A Core–Wall Mass Ratio | Factor B pH | Factor C The Ratio of Two Wall Materials | Factor D The Temperature During Spray Drying (°C) |

|---|---|---|---|---|

| 1 | 0.5:1.0 | 3.0 | 1.0:4.0 | 150 |

| 2 | 0.5:1.0 | 3.5 | 1.0:5.0 | 170 |

| 3 | 0.5:1.0 | 4.0 | 1.0:6.0 | 190 |

| 4 | 0.8:1.0 | 3.0 | 1.0:5.0 | 190 |

| 5 | 0.8:1.0 | 3.5 | 1.0:6.0 | 150 |

| 6 | 0.8:1.0 | 4.0 | 1.0:4.0 | 170 |

| 7 | 1.0:1.0 | 3.0 | 1.0:6.0 | 170 |

| 8 | 1.0:1.0 | 3.5 | 1.0:4.0 | 190 |

| 9 | 1.0:1.0 | 4.0 | 1.0:5.0 | 150 |

| Text | Sample (#) | Arabic Gum (g) | Deionized Water (mL) | Chitosan (mL) | 1% Acetic Acid (g) | Tung Oil (g) | Tannic Acid (g) | Deionized Water (mL) |

|---|---|---|---|---|---|---|---|---|

| Orthogonal experiments | 1 | 3.200 | 76.800 | 0.800 | 79.200 | 2.000 | 0.020 | 9.980 |

| 2 | 4.000 | 76.000 | 0.800 | 79.200 | 2.400 | 0.020 | 9.980 | |

| 3 | 4.800 | 75.200 | 0.800 | 79.200 | 2.800 | 0.020 | 9.980 | |

| 4 | 4.000 | 76.000 | 0.800 | 79.200 | 3.840 | 0.020 | 9.980 | |

| 5 | 4.800 | 75.200 | 0.800 | 79.200 | 4.480 | 0.020 | 9.980 | |

| 6 | 3.200 | 76.800 | 0.800 | 79.200 | 3.200 | 0.020 | 9.980 | |

| 7 | 4.800 | 75.200 | 0.800 | 79.200 | 5.600 | 0.020 | 9.980 | |

| 8 | 3.200 | 76.800 | 0.800 | 79.200 | 4.000 | 0.020 | 9.980 | |

| 9 | 4.000 | 76.000 | 0.800 | 79.200 | 4.800 | 0.020 | 9.980 | |

| Single-factor experiment | 10 | 3.200 | 76.800 | 0.800 | 79.200 | 2.000 | 0.020 | 9.980 |

| 11 | 3.200 | 76.800 | 0.800 | 79.200 | 2.000 | 0.020 | 9.980 | |

| 12 | 3.200 | 76.800 | 0.800 | 79.200 | 2.000 | 0.020 | 9.980 | |

| 13 | 3.200 | 76.800 | 0.800 | 79.200 | 2.000 | 0.020 | 9.980 | |

| 14 | 3.200 | 76.800 | 0.800 | 79.200 | 2.000 | 0.020 | 9.980 | |

| 15 | 3.200 | 76.800 | 0.800 | 79.200 | 2.000 | 0.020 | 9.980 |

| Sample (#) | Factor A Core–Wall Mass Ratio | Factor B pH | Factor C The Ratio of Two Wall Materials | Factor D The Temperature During Spray Drying | C (%) |

|---|---|---|---|---|---|

| 1 | 0.5:1.0 | 3.0 | 1.0:4.0 | 150 | 54.00 |

| 2 | 0.5:1.0 | 3.5 | 1.0:5.0 | 170 | 36.00 |

| 3 | 0.5:1.0 | 4.0 | 1.0:6.0 | 190 | 20.00 |

| 4 | 0.8:1.0 | 3.0 | 1.0:5.0 | 190 | 22.00 |

| 5 | 0.8:1.0 | 3.5 | 1.0:6.0 | 150 | 42.00 |

| 6 | 0.8:1.0 | 4.0 | 1.0:4.0 | 170 | 24.00 |

| 7 | 1.0:1.0 | 3.0 | 1.0:6.0 | 170 | 36.00 |

| 8 | 1.0:1.0 | 3.5 | 1.0:4.0 | 190 | 35.00 |

| 9 | 1.0:1.0 | 4.0 | 1.0:5.0 | 150 | 38.00 |

| K1 | 110.00 | 112.00 | 113.00 | 134.00 | |

| K2 | 88.00 | 113.00 | 96.00 | 96.00 | |

| K3 | 109.00 | 82.00 | 98.00 | 77.00 | |

| k1 | 36.67 | 37.33 | 37.67 | 44.67 | |

| k2 | 29.33 | 37.67 | 32.00 | 32.00 | |

| k3 | 36.33 | 27.33 | 32.67 | 25.67 | |

| R | 7.33 | 10.33 | 5.67 | 19.00 | |

| Order of influencing factors | D > B > A > C | ||||

| Optimal level | A1 | B2 | C1 | D1 | |

| Recommended preparation process | A1B2C1D1 | ||||

| Sample (#) | Factor A Core–Wall Mass Ratio | Factor B pH | Factor C The Ratio of Two Wall Materials | Factor D The Temperature During Spray Drying | Y (%) |

|---|---|---|---|---|---|

| 1 | 0.5:1.0 | 3.0 | 1.0:4.0 | 150 | 26.80 |

| 2 | 0.5:1.0 | 3.5 | 1.0:5.0 | 170 | 30.89 |

| 3 | 0.5:1.0 | 4.0 | 1.0:6.0 | 190 | 43.14 |

| 4 | 0.8:1.0 | 3.0 | 1.0:5.0 | 190 | 32.13 |

| 5 | 0.8:1.0 | 3.5 | 1.0:6.0 | 150 | 25.79 |

| 6 | 0.8:1.0 | 4.0 | 1.0:4.0 | 170 | 33.89 |

| 7 | 1.0:1.0 | 3.0 | 1.0:6.0 | 170 | 23.07 |

| 8 | 1.0:1.0 | 3.5 | 1.0:4.0 | 190 | 31.40 |

| 9 | 1.0:1.0 | 4.0 | 1.0:5.0 | 150 | 25.50 |

| K1 | 100.83 | 82.00 | 92.09 | 78.09 | |

| K2 | 91.81 | 88.08 | 88.52 | 87.85 | |

| K3 | 79.97 | 102.53 | 92.00 | 106.67 | |

| k1 | 33.61 | 27.33 | 30.70 | 26.03 | |

| k2 | 30.63 | 29.36 | 29.51 | 29.28 | |

| k3 | 26.67 | 34.18 | 30.67 | 35.56 | |

| R | 6.95 | 6.84 | 1.19 | 9.53 | |

| Order of influencing factors | D > A > B > C | ||||

| Optimal level | A1 | B3 | C1 | D3 | |

| Recommended preparation process | A1B3C1D3 | ||||

| Sample (#) | Factor D The Temperature During Spray Drying (°C) | Y (%) | C (%) |

|---|---|---|---|

| 10 | 110 | 29.65 | 28.75 |

| 11 | 120 | 29.79 | 33.25 |

| 12 | 130 | 32.85 | 33.20 |

| 13 | 140 | 31.25 | 32.40 |

| 14 | 150 | 30.05 | 31.25 |

| 15 | 160 | 28.86 | 25.75 |

| Microcapsules (#) | Temperature During Spray Drying (°C) | Scratch Width Before Repair (μm) | Scratch Width After Repair (μm) | Self-Repairing Rate (%) |

|---|---|---|---|---|

| 10 | 110 | 11.92 | 9.16 | 23.15 |

| 11 | 120 | 11.92 | 9.48 | 20.47 |

| 12 | 130 | 12.99 | 10.44 | 19.63 |

| 13 | 140 | 10.65 | 8.58 | 19.44 |

| 14 | 150 | 17.78 | 15.77 | 11.30 |

| 15 | 160 | 19.97 | 17.56 | 12.07 |

| Microcapsules (#) | Roughness (μm) | Breaking Elongation (%) |

|---|---|---|

| 0 | 0.31 | 4.43 |

| 10 | 0.84 | 10.42 |

| 11 | 0.79 | 5.04 |

| 12 | 0.81 | 4.28 |

| 13 | 0.87 | 7.43 |

| 14 | 0.85 | 7.30 |

| 15 | 0.82 | 5.10 |

| Microcapsules (#) | Transmittance (%) |

|---|---|

| 0 | 87.90 |

| 10 | 83.13 |

| 11 | 77.96 |

| 12 | 79.65 |

| 13 | 78.79 |

| 14 | 79.32 |

| 15 | 82.59 |

| Microcapsules (#) | Glossiness (GU) | Gloss Loss Rate (%) |

|---|---|---|

| 0 | 49.30 | - |

| 10 | 43.40 | 11.97 |

| 11 | 43.90 | 10.95 |

| 12 | 43.50 | 11.76 |

| 13 | 41.90 | 15.01 |

| 14 | 40.40 | 18.05 |

| 15 | 37.60 | 23.73 |

| Microcapsules (#) | Glossiness Before Testing (GU) | Glossiness After Testing (GU) | Cold Liquid Resistance Grade (Grade) |

|---|---|---|---|

| 0 | 49.30 | 43.70 | 1 |

| 10 | 43.40 | 34.70 | 2 |

| 11 | 43.90 | 38.80 | 2 |

| 12 | 43.50 | 26.00 | 2 |

| 13 | 41.90 | 26.50 | 2 |

| 14 | 40.40 | 23.60 | 2 |

| 15 | 37.60 | 22.30 | 2 |

| Microcapsules (#) | Before Aging Test | After Aging Test | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Glossiness (GU) | Gloss Loss Rate (%) | L | a | b | ΔE | Glossiness (GU) | Gloss Loss Rate (%) | L | a | b | ΔE | |

| 0 | 49.30 | - | 76.93 | −2.24 | 5.08 | - | 41.00 | - | 71.20 | −0.78 | 3.69 | - |

| 11 | 43.90 | 10.95 | 71.94 | −1.95 | 8.08 | 5.83 | 26.30 | 35.85 | 69.92 | 2.15 | 16.62 | 13.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, J.; Yan, X. Preparation of Tung Oil Microcapsules Coated with Chitosan–Arabic Gum and Its Effect on the Properties of UV Coating. Polymers 2025, 17, 1985. https://doi.org/10.3390/polym17141985

Deng J, Yan X. Preparation of Tung Oil Microcapsules Coated with Chitosan–Arabic Gum and Its Effect on the Properties of UV Coating. Polymers. 2025; 17(14):1985. https://doi.org/10.3390/polym17141985

Chicago/Turabian StyleDeng, Jinzhe, and Xiaoxing Yan. 2025. "Preparation of Tung Oil Microcapsules Coated with Chitosan–Arabic Gum and Its Effect on the Properties of UV Coating" Polymers 17, no. 14: 1985. https://doi.org/10.3390/polym17141985

APA StyleDeng, J., & Yan, X. (2025). Preparation of Tung Oil Microcapsules Coated with Chitosan–Arabic Gum and Its Effect on the Properties of UV Coating. Polymers, 17(14), 1985. https://doi.org/10.3390/polym17141985