The Effect of Poly (Methyl Methacrylate) Content on Chemical, Thermomechanical, Mechanical, and Fatigue Life Characteristics of Ternary PC/ABS/PMMA Blends

Abstract

1. Introduction

2. Materials and Methods

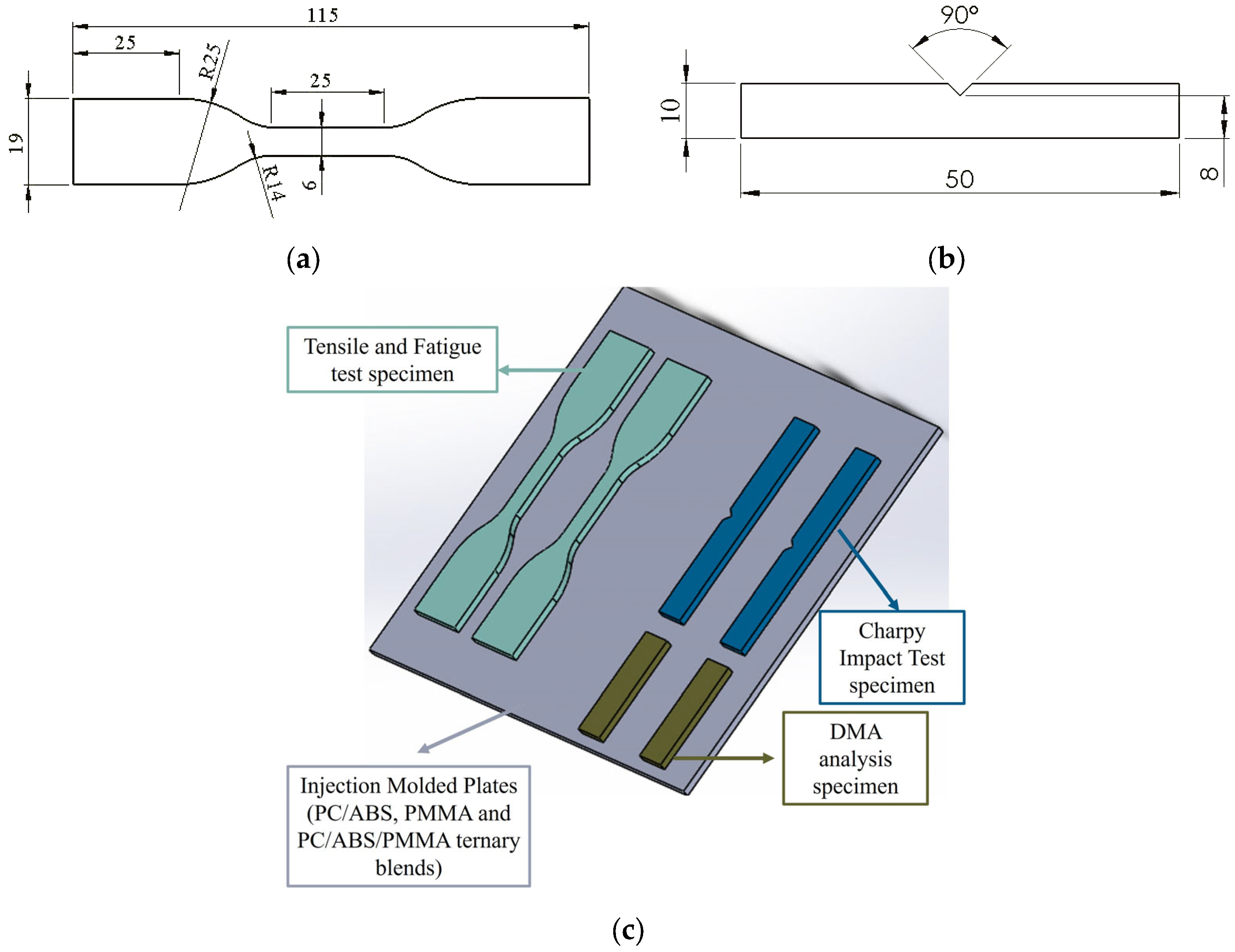

2.1. Materials and the Production of Specimens

2.2. Analyses and Testing Procedures

3. Results

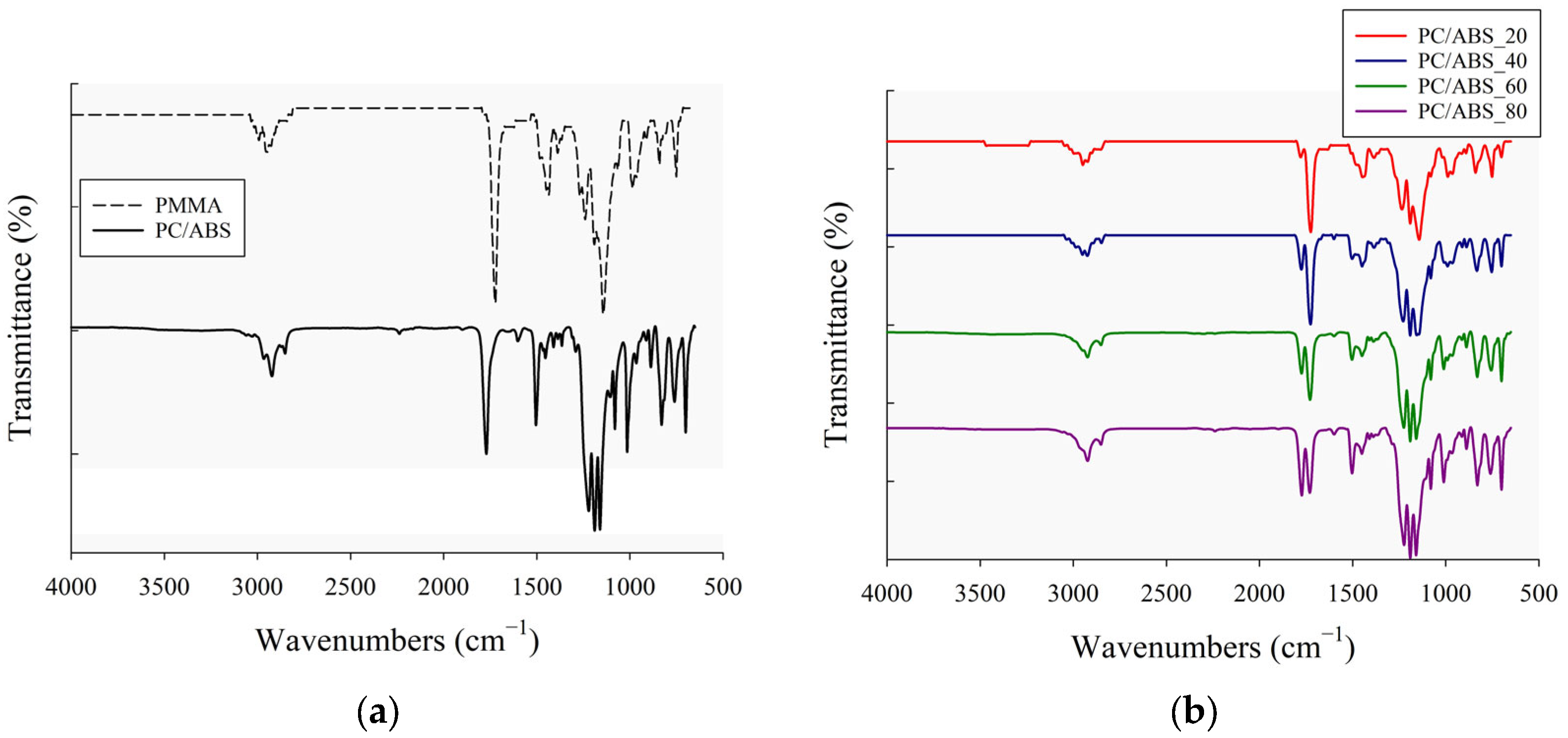

3.1. Chemical Properties

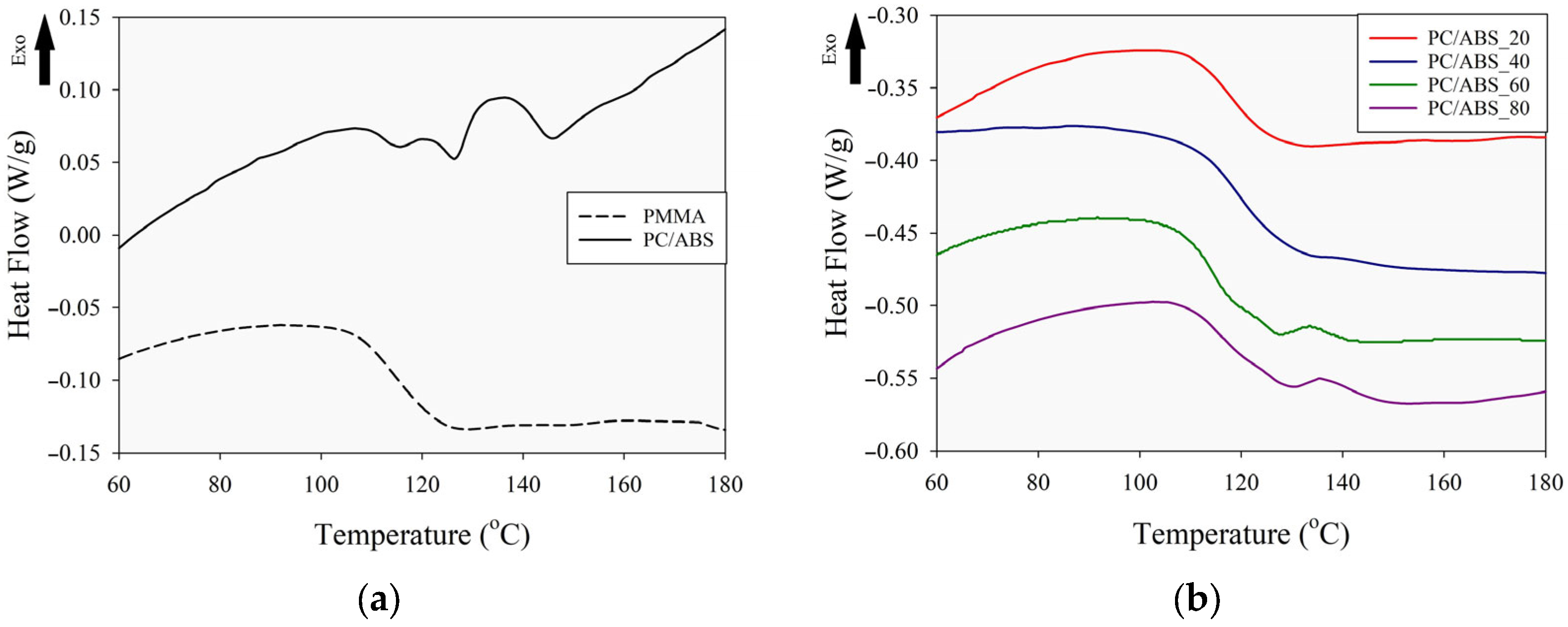

3.2. Thermal Properties

3.3. Thermomechanical Properties

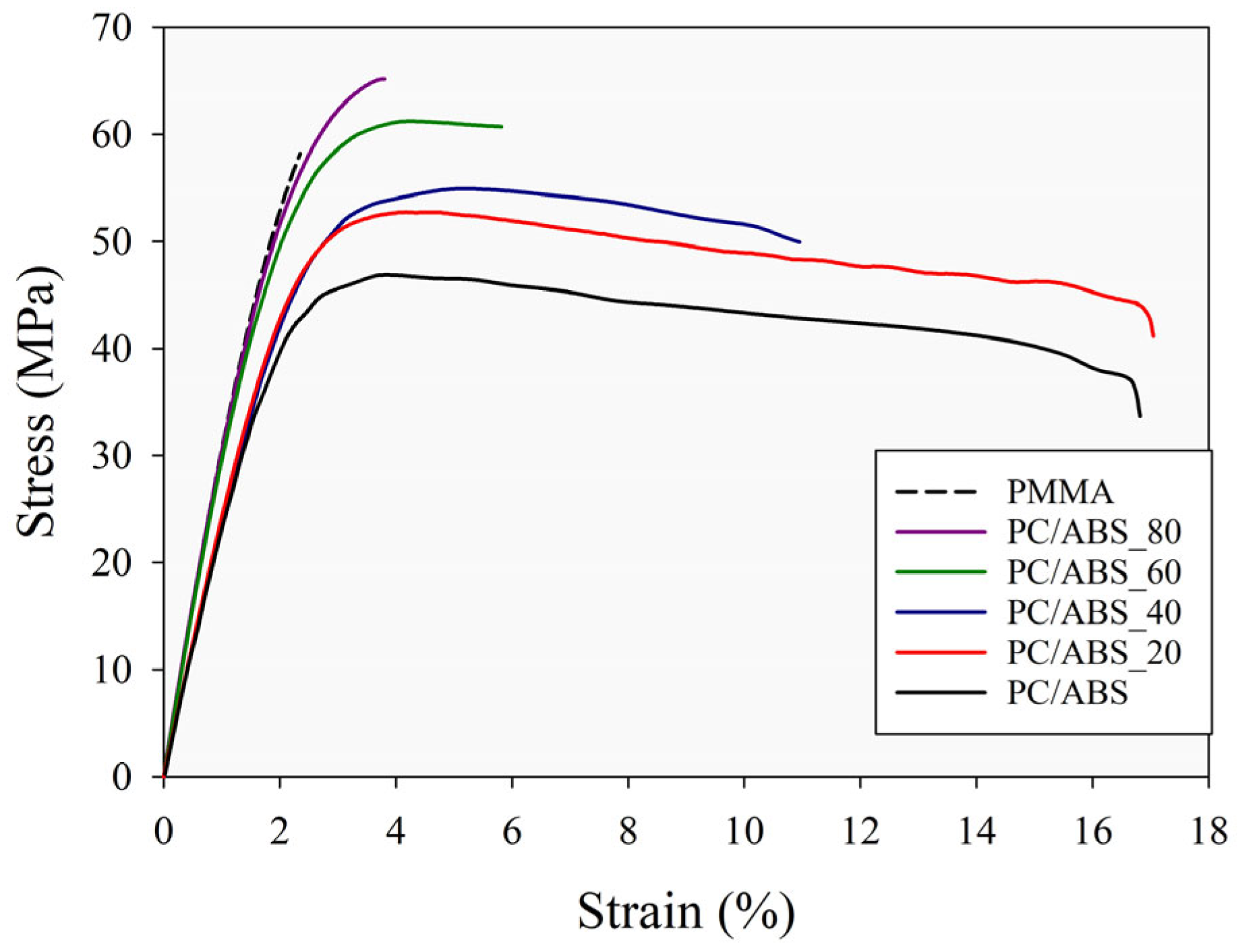

3.4. Mechanical Properties

3.5. Fatigue Life Behavior

4. Discussion

5. Conclusions

- Analysis of the FTIR chemical behavior showed that the PC/ABS/PMMA ternary blend samples contained characteristic absorption peaks belonging to the three components constituting the structure. Also, it was determined that the peak intensity of the IR spectrum varied according to the PMMA composition ratio in the structure.

- The viscoelastic properties of the PMMA, PC/ABS, and PC/ABS/PMMA ternary blends were investigated using DMA analysis. This analysis indicates that the addition of PMMA to PC/ABS structures increased both the storage and loss modulus with increasing PMMA content. The peak value of the loss factor also increased with the increasing PMMA ratio in the ternary blends. Furthermore, the DMA results showed that blends with higher PMMA content exhibited a larger area under the loss modulus curve, reflecting greater structural energy absorption, while lower PMMA content resulted in a smaller area under the curve. This situation is an indicator of the improved energy absorption capability of the structure.

- For the PC/ABS specimen, mechanical properties such as the elastic modulus, yield strength, and ultimate tensile strength were found to be quite low compared to PMMA, while the elongation at break was significantly higher. Also, ternary blend specimens with the addition of PMMA to the structure have a higher elastic modulus, yield strength, and ultimate tensile strength with respect to the PC/ABS specimen. It is observed that with an increasing PMMA ratio in the structure, the elastic modulus, yield strength, and tensile strength values increase, while elongation-at-break values decrease. In the PC/ABS/PMMA ternary blend samples, it is observed that the impact strength decreases significantly with the increasing PMMA content in the structure.

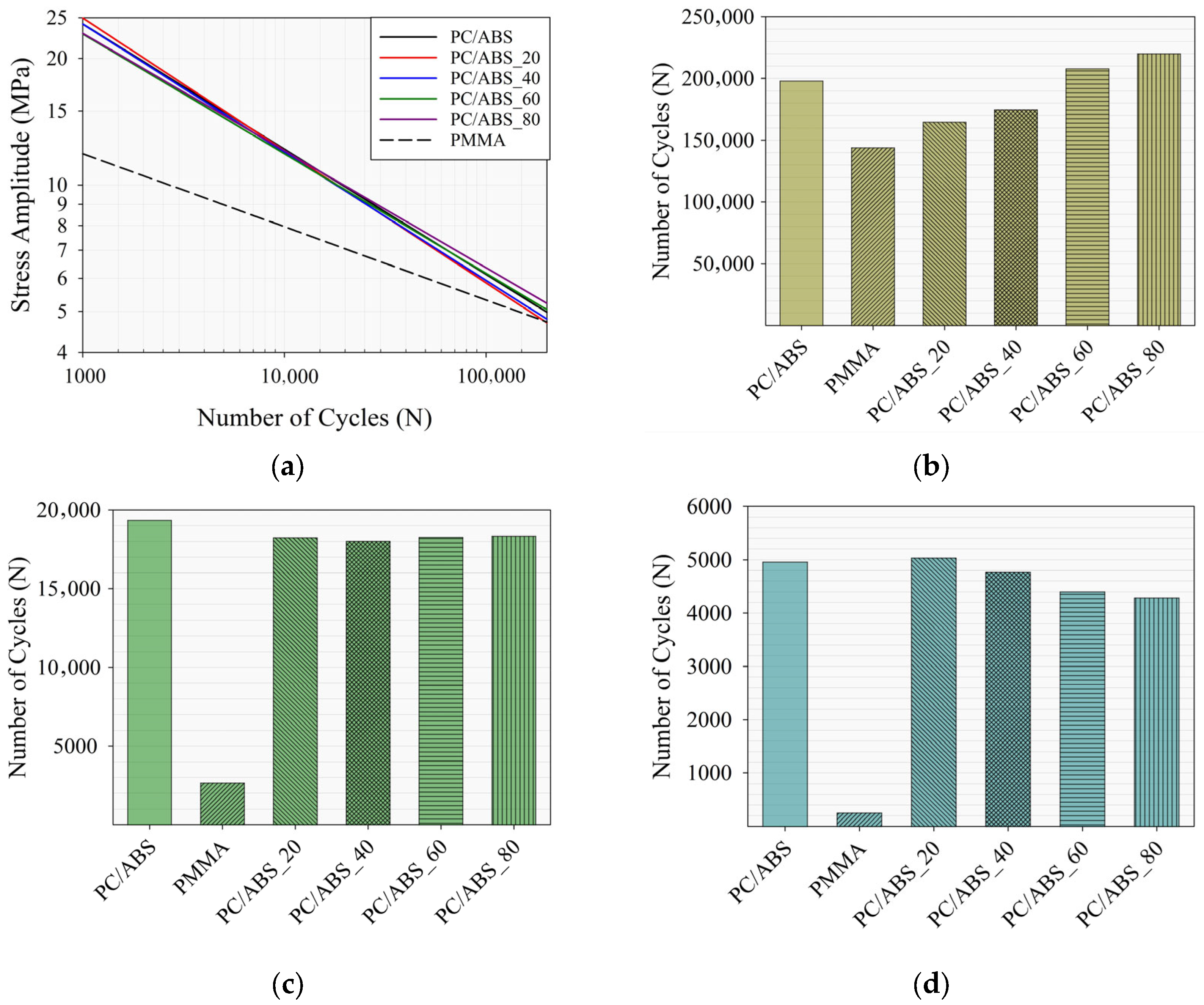

- The experimental results from the fatigue tests demonstrate improvements in the life cycle performance of the PC/ABS/PMMA ternary blends at low and high stress amplitudes depending on the PMMA content. A 20% and 40% addition of PMMA to PC/ABS leads to an increase in fatigue strength and the absolute fatigue strength exponent, obtaining a high number of cycles at high stress amplitudes. Also, with higher PMMA content (60% and 80%), the life cycle performances improved at low stress amplitudes, resulting from the decrease in the absolute value of the fatigue strength exponents.

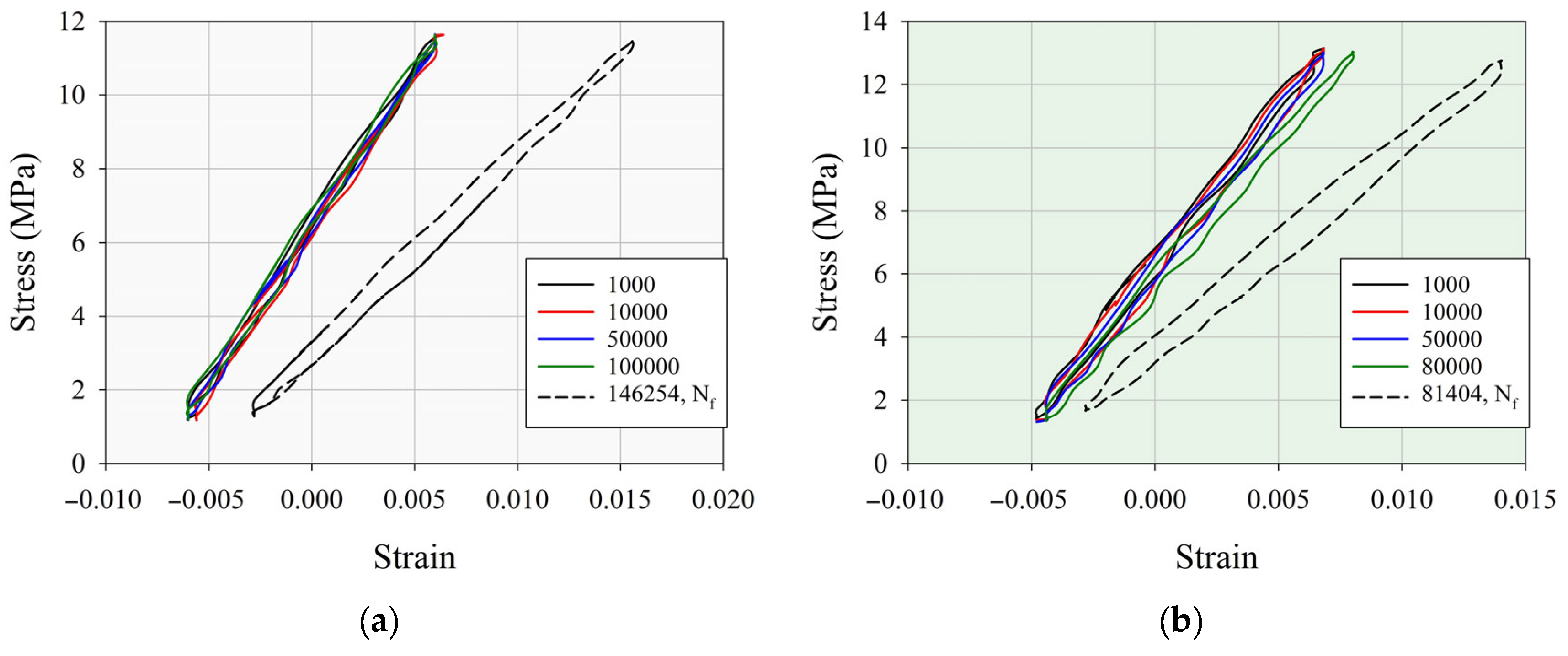

- The hysteresis energy values at different cycles increased with increasing PMMA content in the PC/ABS matrix, and the slope of the stress–strain hysteresis loops (dynamic modulus of elasticity) significantly improved with PMMA addition to the PC/ABS matrix. It was determined that the dynamic elastic modulus improved by approximately 12% to 58% with the addition of PMMA. Similarly, hysteresis energy values improved by approximately 26% to 117% due to the effect of PMMA.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Utracki, L.A.; Wilkie, C.A. Polymer Blends Handbook; Springer: Berlin/Heidelberg, Germany, 2014; ISBN 9789400760646. [Google Scholar]

- Bouzouita, A.; Samuel, C.; Notta-Cuvier, D.; Odent, J.; Lauro, F.; Dubois, P.; Raquez, J.M. Design of Highly Tough Poly(l -Lactide)-Based Ternary Blends for Automotive Applications. J. Appl. Polym. Sci. 2016, 133, 1–9. [Google Scholar] [CrossRef]

- Toh, H.W.; Toong, D.W.Y.; Ng, J.C.K.; Ow, V.; Lu, S.; Tan, L.P.; Wong, P.E.H.; Venkatraman, S.; Huang, Y.; Ang, H.Y. Polymer Blends and Polymer Composites for Cardiovascular Implants. Eur. Polym. J. 2021, 146, 110249. [Google Scholar] [CrossRef]

- Abderrafai, Y.; Diouf-Lewis, A.; Sosa-Rey, F.; Farahani, R.D.; Piccirelli, N.; Lévesque, M.; Therriault, D. Additive Manufacturing and Characterization of High Temperature Thermoplastic Blends for Potential Aerospace Applications. Compos. Sci. Technol. 2023, 231, 109839. [Google Scholar] [CrossRef]

- Mofokeng, T.G.; Ojijo, V.; Ray, S.S. The Influence of Blend Ratio on the Morphology, Mechanical, Thermal, and Rheological Properties of PP/LDPE Blends. Macromol. Mater. Eng. 2016, 301, 1191–1201. [Google Scholar] [CrossRef]

- Yang, X.; Feng, J. Improving Mechanical Performance of Immiscible Polypropylene/Poly(Methyl Methacrylate) Blends by Adding Calcium Carbonate Nanoparticles with Bifunctions of Compatibilization and β-Nucleation. Compos. Part. A Appl. Sci. Manuf. 2025, 190, 108640. [Google Scholar] [CrossRef]

- Robeson, L. Historical Perspective of Advances in the Science and Technology of Polymer Blends. Polymers 2014, 6, 1251–1265. [Google Scholar] [CrossRef]

- Dehghani, S.; Salehiyan, R.; Pholharn, D.; Srithep, Y. Mechanical and Thermal Properties of Polylactic Acid Blended with Recycled Polymethyl Methacrylate. Polym. Eng. Sci. 2025, 65, 2119–2132. [Google Scholar] [CrossRef]

- Seo, J.S.; Jeon, H.T.; Han, T.H. Rheological Investigation of Relaxation Behavior of Polycarbonate/Acrylonitrile-Butadiene-Styrene Blends. Polymers 2020, 12, 1916. [Google Scholar] [CrossRef]

- Wong, A.C.-Y. Polycarbonate Effects on Selected Mechanical Properties of Polycarbonate/Acrylonitrile-Butadiene-Styrene (PC/ABS) Binary Blending Systems. Polym. Plast. Technol. Eng. 2003, 42, 171–180. [Google Scholar] [CrossRef]

- Ezzeddine, R.; Elfehri, K.; Marcos-Fernández, Á.; Samet, B. Optimization of Physical and Mechanical Properties of PC/ABS/PMMA Blends by Mixture Design Approach. Polym. Int. 2024, 73, 1030–1040. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Mohanty, A.K.; Misra, M. Development of Hybrid Composites Reinforced with Biocarbon/Carbon Fiber System. The Comparative Study for PC, ABS and PC/ABS Based Materials. Compos. B Eng. 2020, 200, 108319. [Google Scholar] [CrossRef]

- Mostaani, F.; Khosravi, S.; Jalilian, M. Enhancing Mechanical Properties of PC/ABS Compound through Compatibilizers and Investigation of Morphology and Flammability of the Improved Compound: A Comprehensive Study. Mater. Perform. Charact. 2024, 13, 72–83. [Google Scholar] [CrossRef]

- Yu, X.; Xu, Z.; Lu, Y.; Yang, L.; Sun, S.; Du, M.; Zuo, M.; Zheng, Q. Effects of Selective Distribution of Poly(Methyl Methacrylate)-Grafted Graphene Oxide on the Phase Behavior and Conductivity of Poly(Methyl Methacrylate)/Poly(Vinyl Acetate) Blends. Compos. Part. A Appl. Sci. Manuf. 2025, 188, 108563. [Google Scholar] [CrossRef]

- Li, J.; Feng, Y.; Yang, J.; Li, Z.; Zhao, Z. Heat-Resistant Behavior of PLA/PMMA Transparent Blends Induced by Nucleating Agents. Applied Sciences 2025, 15, 6738. [Google Scholar] [CrossRef]

- Kang, Y.; Zou, Y.; Di, X.; Yang, J.; Sun, J.; Li, H.; Gu, X.; Zhang, S. To Improve the Flame Retardancy, Mechanical Properties, and Water Resistance of PC/ABS Alloy by a Polydimethylsiloxane. Polym. Degrad. Stab. 2025, 238, 111347. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Zhang, Y.; Peng, Z.; Zhang, Y.; Zhou, W. Effects of ABS-g-MAH on Mechanical Properties and Compatibility of ABS/PC Alloy. J. Appl. Polym. Sci. 2001, 81, 831–836. [Google Scholar] [CrossRef]

- Debbah, I.; Krache, R.; Aranburu, N.; Fernández, M.; Etxeberria, A. Effect of SEBS-g-MAH Addition on the Mechanical, Rheological, and Morphological Properties of Polycarbonate/Acrylonitrile–Butadiene–Styrene Blends. J. Elastomers Plast. 2018, 50, 611–633. [Google Scholar] [CrossRef]

- Tjong, S.C.; Meng, Y.Z. Effect of Reactive Compatibilizers on the Mechanical Properties of Polycarbonate/Poly(Acrylonitrile-Butadiene-Styrene) Blends. Eur. Polym. J. 2000, 36, 123–129. [Google Scholar] [CrossRef]

- Ramesh, V.; Biswal, M.; Mohanty, S.; Nayak, S.K. Compatibilization Effect of EVA-g-MAH on Mechanical, Morphological and Rheological Properties of Recycled PC/ABS Blend. Mater. Express 2014, 4, 499–507. [Google Scholar] [CrossRef]

- Joynal Abedin, F.N.; Fizal, A.N.S.; Alkarkhi, A.F.M.; Khalil, N.A.; Ahmad Yahaya, A.N.; Hossain, M.S.; Safie, S.I.; Ismail, N.A.; Zulkifli, M. Synergistic Reinforcement with SEBS-g-MAH for Enhanced Thermal Stability and Processability in GO/RGO-Filled PC/ABS Composites. Polymers 2024, 16, 2554. [Google Scholar] [CrossRef]

- Verma, N.; S, A.; Banerjee, S.S. Development of Material Extrusion 3D Printable ABS/PC Polymer Blends: Influence of Styrene–Isoprene–Styrene Copolymer on Printability and Mechanical Properties. Polym. Plast. Technol. Mater. 2023, 62, 419–432. [Google Scholar] [CrossRef]

- Dai, R.; Zuo, Y.; Xu, L.; Li, S. Effect of Compatibilizers on Impact Strength in Polycarbonate-Rich Blends With Acrylonitrile–Butadiene–Styrene. Adv. Polym. Technol. 2025, 2025, 3241235. [Google Scholar] [CrossRef]

- Hong, J.H.; Song, K.H.; Lee, H.G.; Han, M.S.; Kim, Y.H.; Kim, W.N. Morphological, Mechanical and Rheological Properties of Poly(Acrylonitrile-Butadienestyrene)/Polycarbonate/Poly(ε-Caprolactone) Ternary Blends. Macromol. Res. 2007, 15, 520–526. [Google Scholar] [CrossRef]

- Rybnicek, J.; Lach, R.; Lapcikova, M.; Steidl, J.; Krulis, Z.; Grellmann, W.; Slouf, M. Increasing Recyclability of PC, ABS and PMMA: Morphology and Fracture Behavior of Binary and Ternary Blends. J. Appl. Polym. Sci. 2008, 109, 3210–3223. [Google Scholar] [CrossRef]

- Kuram, E.; Ozcelik, B.; Yilmaz, F.; Timur, G.; Sahin, Z.M. The Effect of Recycling Number on the Mechanical, Chemical, Thermal, and Rheological Properties of PBT/PC/ABS Ternary Blends: With and without Glass-fiber. Polym. Compos. 2014, 35, 2074–2084. [Google Scholar] [CrossRef]

- Kuram, E.; Ozcelik, B.; Yilmaz, F. The Effects of Recycling Process on Thermal, Chemical, Rheological, and Mechanical Properties of PC/ABS Binary and PA6/PC/ABS Ternary Blends. J. Elastomers Plast. 2016, 48, 164–181. [Google Scholar] [CrossRef]

- Cheng, T.W.; Keskkula, H.; Paul, D.R. Property and Morphology Relationships for Ternary Blends of Polycarbonate, Brittle Polymers and an Impact Modifier. Polymer 1992, 33, 1606–1619. [Google Scholar] [CrossRef]

- Yang, K.; Lee, S.; Oh, J. Effects of Viscosity Ratio and Compatibilizers on the Morphology and Mechanical Properties of Polycarbonate/Acrylonitrile-butadiene-styrene Blends. Polym. Eng. Sci. 1999, 39, 1667–1677. [Google Scholar] [CrossRef]

- Pogorelčnik, B.; Pulko, I.; Wilhelm, T.; Žigon, M. Influence of Phosphorous-based Flame Retardants on the Mechanical and Thermal Properties of Recycled PC/ABS Copolymer Blends. J. Appl. Polym. Sci. 2020, 137, 48377. [Google Scholar] [CrossRef]

- Jin, D.W.; Shon, K.H.; Jeong, H.M.; Kim, B.K. Compatibility Enhancement of ABS/Polycarbonate Blends. J. Appl. Polym. Sci. 1998, 69, 533–542. [Google Scholar] [CrossRef]

- Gaitho, F.M.; Tsige, M.; Mola, G.T.; Pellicane, G. Surface Segregation of Cyclic Chains in Binary Melts of Thin Polymer Films: The Influence of Constituent Concentration. Polymers 2018, 10, 324. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Bertilsson, H. Recycling of ABS and ABS/PC Blends. J. Appl. Polym. Sci. 1999, 74, 510–515. [Google Scholar] [CrossRef]

- Moussaif, N.; Jérôme, R. Compatibilization of Immiscible Polymer Blends (PC/PVDF) by the Addition of a Third Polymer (PMMA): Analysis of Phase Morphology and Mechanical Properties. Polymer 1999, 40, 3919–3932. [Google Scholar] [CrossRef]

- Bubmann, T.; Seidel, A.; Ruckdäschel, H.; Altstädt, V. Transparent PC/PMMA Blends with Enhanced Mechanical Properties via Reactive Compounding of Functionalized Polymers. Polymers 2021, 14, 73. [Google Scholar] [CrossRef]

- Bärwinkel, S.; Seidel, A.; Hobeika, S.; Hufen, R.; Mörl, M.; Altstädt, V. Morphology Formation in PC/ABS Blends during Thermal Processing and the Effect of the Viscosity Ratio of Blend Partners. Materials 2016, 9, 659. [Google Scholar] [CrossRef]

- Ge, B.; Liu, Z.; Zheng, Y.; Zhu, S.; Ma, M.; Chen, S.; Shi, Y.; He, H.; Zhu, Y.; Wang, X. Highly Enhanced the Toughness and Fatigue Resistance of PC/ABS Blends by Constructing a Double-Comb Compatibilizer. Polymer 2025, 323, 128170. [Google Scholar] [CrossRef]

- Rybnicek, J.; Lach, R.; Grellmann, W.; Lapcikova, M. Ternary PC/ABS/PMMA Blends-Morphology and Mechanical Properunder Quasi-Static Loading Conditions. Polimery 2012, 57, 85–94. [Google Scholar] [CrossRef]

- ISO 1133-1:2012-03; Determination of the Melt Mass-Flow Rate (MFR) and Melt Volume-Flow Rate (MVR) of Thermo-Plastics: Part 1: Standad Method (ISO 1133-1:2011). Beuth Verlag: Berlin, Germany, 2012.

- ISO 527; Plastics—Determination of Tensile Properties. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 179-1:2023; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. ISO: Geneva, Switzerland, 2023.

- ASTM D5023-23; Standard Test Method for Plastics: Dynamic Mechanical Properties: In Flexure (Three-Point Bending). ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D7791-12; Standard Test Method for Uniaxial Fatigue Properties of Plastics, D20.10. ASTM International: West Conshohocken, PA, USA, 2015.

- Wie, J.; Kim, J. Thermal Conductivity Enhancement Derived from Poly(Methyl Methacrylate)-Grafted Carbon Nanotubes in Poly(Methyl Methacrylate)/Polystyrene Blends. Polymers 2019, 11, 1347. [Google Scholar] [CrossRef]

- Lin, C.K.; Xie, J.W.; Tsai, P.J.; Wang, H.Y.; Lu, Z.W.; Lin, T.Y.; Kuo, C.Y. The Effects of Different Blending Methods on the Thermal, Mechanical, and Optical Properties of PMMA/SiO2 Composites. J. Compos. Sci. 2024, 8, 369. [Google Scholar] [CrossRef]

- Ramesh, S.; Leen, K.H.; Kumutha, K.; Arof, A.K. FTIR Studies of PVC/PMMA Blend Based Polymer Electrolytes. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2007, 66, 1237–1242. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Joseph, G.; Sidhardhan, S.K.; Jose, S.; Hameed, N. Miscibility, UV Resistance, Thermal Degradation, and Mechanical Properties of PMMA/SAN Blends and Their Composites with MWCNTs. J. Appl. Polym. Sci. 2016, 43628, 1–11. [Google Scholar] [CrossRef]

- Dechet, M.A.; Bonilla, J.S.G.; Lanzl, L.; Drummer, D.; Bück, A.; Schmidt, J.; Peukert, W. Spherical Polybutylene Terephthalate (PBT)-Polycarbonate (PC) Blend Particles by Mechanical Alloying and Thermal Rounding. Polymers 2018, 10, 1373. [Google Scholar] [CrossRef] [PubMed]

- Bulanda, K.; Oleksy, M.; Oliwa, R.; Budzik, G.; Przeszłowski, Ł.; Fal, J.; Jesionowski, T. Polymer Composites Based on Polycarbonate (PC) Applied to Additive Manufacturing Using Melted and Extruded Manufacturing (MEM) Technology. Polymers 2021, 13, 2455. [Google Scholar] [CrossRef]

- Liu, G.; Liao, Y.; Ma, X. Thermal Behavior of Vehicle Plastic Blends Contained Acrylonitrile-Butadiene-Styrene (ABS) in Pyrolysis Using TG-FTIR. Waste Manag. 2017, 61, 315–326. [Google Scholar] [CrossRef]

- de León, A.S.; Domínguez-Calvo, A.; Molina, S.I. Materials with Enhanced Adhesive Properties Based on Acrylonitrile-Butadiene-Styrene (ABS)/Thermoplastic Polyurethane (TPU) Blends for Fused Filament Fabrication (FFF). Mater. Des. 2019, 182, 108044. [Google Scholar] [CrossRef]

- Li, J.; Chen, F.; Yang, L.; Jiang, L.; Dan, Y. FTIR Analysis on Aging Characteristics of ABS/PC Blend under UV-Irradiation in Air. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2017, 184, 361–367. [Google Scholar] [CrossRef]

- Desrousseaux, C.; Cueff, R.; Aumeran, C.; Garrait, G.; Mailhot-Jensen, B.; Traoré, O.; Sautou, V. Fabrication of Acrylonitrile-Butadiene-Styrene Nanostructures with Anodic Alumina Oxide Templates, Characterization and Biofilm Development Test for Staphylococcus Epidermidis. PLoS ONE 2015, 10, e0135632. [Google Scholar] [CrossRef]

- Kumaraswamy, G.N.; Ranganathaiah, C.; Urs, M.V.D.; Ravikumar, H.B. Miscibility and Phase Separation in SAN/PMMA Blends Investigated by Positron Lifetime Measurements. Eur. Polym. J. 2006, 42, 2655–2666. [Google Scholar] [CrossRef]

- Zin, M.H.; Abdan, K.; Norizan, M.N. The Effect of Different Fiber Loading on Flexural and Thermal Properties of Banana/Pineapple Leaf (PALF)/Glass Hybrid Composite. In Structural Health Monitoring of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–17. [Google Scholar]

- Ma, J. The Influence of Processing Conditions on the Mechanical Properties of Poly(Acrylonitrile-Butadiene-Styrene)/ Poly(Methyl Methacrylate) (ABS/PMMA) Blends. J. Macromol. Sci. Part. B Phys. 2023, 62, 153–171. [Google Scholar] [CrossRef]

- Reinaldo, J.S.; Pereira, L.M.; Silva, E.S.; Macedo, T.C.P.; Damasceno, I.Z.; Ito, E.N. Thermal, Mechanical and Morphological Properties of Multicomponent Blends Based on Acrylic and Styrenic Polymers. Polym. Test. 2020, 82, 106265. [Google Scholar] [CrossRef]

- Panin, S.V.; Bogdanov, A.A.; Eremin, A.V.; Buslovich, D.G.; Alexenko, V.O. Estimating Low-and High-Cyclic Fatigue of Polyimide-CF-PTFE Composite through Variation of Mechanical Hysteresis Loops. Materials 2022, 15, 4656. [Google Scholar] [CrossRef] [PubMed]

- Islam, M.Z.; Amiri, A.; Ulven, C.A. Fatigue Behavior Comparison of Inter-Ply and Intra-Ply Hybrid Flax-Carbon Fiber Reinforced Polymer Matrix Composites. J. Compos. Sci. 2021, 5, 184. [Google Scholar] [CrossRef]

- Hülsbusch, D.; Kohl, A.; Striemann, P.; Niedermeier, M.; Strauch, J.; Walther, F. Development of an Energy-Based Approach for Optimized Frequency Selection for Fatigue Testing on Polymers—Exemplified on Polyamide 6. Polym. Test. 2020, 81, 106260. [Google Scholar] [CrossRef]

- Panin, S.V.; Bogdanov, A.A.; Aleksenko, V.O.; Bochkareva, S.A.; Lyubutin, P.S.; Panov, I.L.; Tian, D. Digital Image Correlation Analysis of Fatigue Degradation of Layered Polymer Composites (Polyetheretherketone/Polyetherimide, PEEK/PEI) with Carbon-Fiber Fabric Prepreg. Phys. Mesomech. 2024, 27, 541–555. [Google Scholar] [CrossRef]

- Kuleyin, H.; Gümrük, R.; Çalişkan, S. The Effect of ABS Fraction on the Fatigue Behavior of PMMA/ABS Polymer Blends. Mater. Today Commun. 2022, 33, 104139. [Google Scholar] [CrossRef]

- Kuleyin, H.; Gümrük, R.; Çalışkan, S. Fatigue Behavior of Polymethyl Methacrylate/Acrylonitrile Butadiene Styrene Blends Including Blend Composition, Stress Ratio, Frequency, and Holding Pressure Effects. Int. J. Fatigue 2024, 187, 108483. [Google Scholar] [CrossRef]

- Shariati, M.; Hatami, H.; Yarahmadi, H.; Eipakchi, H.R. An Experimental Study on the Ratcheting and Fatigue Behavior of Polyacetal under Uniaxial Cyclic Loading. Mater. Des. 2012, 34, 302–312. [Google Scholar] [CrossRef]

| Granules | Properties | |||

|---|---|---|---|---|

| Density (kg/m3) | Melt Flow Rate (g/10 min) (ISO 1133) [39] | Tensile Strength at Break (MPa) (ISO 527) [40] | Charpy Impact Strength (kJ/m2) (ISO 179/1) [41] | |

| PC | 1200 | 20 | 70 | 65 |

| ABS | 1060 | 4.0 | 50 | 14 |

| PMMA | 1190 | 4.2 | 78 | 1.4 |

| Wavenumber (cm−1) | Functional Group | Originate |

|---|---|---|

| ~2990 | C–H strength | PMMA and ABS |

| ~2950–2850 | C–H strength | PC and ABS |

| ~2238 | C≡N strength | ABS (acrylonitrile) |

| ~1720 | C=O strength | PMMA and PC (carbonyl) |

| ~1600–1500 | C=C aromatic | PC and ABS |

| ~1450–1380 | C–H bending | All components |

| ~1260–1140 | C–O strength | PMMA and PC |

| ~752–700 | Aromatic C–H bending | PC |

| Specimens | Tg,1 (°C) | Tg,2 (°C) | Tg,3 (°C) |

|---|---|---|---|

| PMMA | 114 | - | - |

| PC/ABS | 113 | 126 | 147 |

| PC/ABS_20 | 117 | - | - |

| PC/ABS_40 | 118 | - | 141 |

| PC/ABS_60 | 115.6 | - | 143.7 |

| PC/ABS_80 | 116.5 | 125 | 145 |

| Specimens | Storage Modulus (MPa) | Loss Modulus (MPa) | Loss Factors |

|---|---|---|---|

| PMMA | 3309 | 328 | 0.0991 |

| PC/ABS | 2245 | 84 | 0.0376 |

| PC/ABS_20 | 2340 | 127.5 | 0.0531 |

| PC/ABS_40 | 2490 | 161.7 | 0.0651 |

| PC/ABS_60 | 2760 | 203 | 0.0742 |

| PC/ABS_80 | 3280 | 268.3 | 0.0819 |

| Specimens | Mechanical Properties | ||||

|---|---|---|---|---|---|

| Elastic Modulus (MPa) | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation to Break (%) | Impact Strength (J/m2) | |

| PMMA | 3314.7 ± 61.7 | 44.7 ± 0.49 | 54.5 ± 3.33 | 2.05 ± 0.28 | 3.8 ± 0.12 |

| PC/ABS | 2363 ± 50.6 | 33.3 ± 1.49 | 46.4 ± 1.28 | 16.47 ± 0.36 | 82.4 ± 1.3 |

| PC/ABS_20 | 2383.7 ± 65.2 | 36.1 ± 1.53 | 52.2 ± 0.45 | 17.56 ± 0.36 | 33.4 ± 0.75 |

| PC/ABS_40 | 2491.7 ± 41.6 | 37.5 ± 1.52 | 54.1 ± 1.58 | 10.35 ± 0.85 | 23.8 ± 0.64 |

| PC/ABS_60 | 3068 ± 77.1 | 39.6 ± 0.66 | 61.8 ± 0.21 | 5.57 ± 0.97 | 18.4 ± 0.6 |

| PC/ABS_80 | 3231 ± 75.7 | 42.4 ± 1.69 | 65.2 ± 2.1 | 3.79 ± 0.09 | 7.2 ± 0.41 |

| Specimens | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PMMA | PC/ABS | PC/ABS_20 | PC/ABS_40 | PC/ABS_60 | PC/ABS_80 | ||||||

| Stress Amplitudes | Number of Cycles | Stress Amplitudes | Number of Cycles | Stress Amplitudes | Number of Cycles | Stress Amplitudes | Number of Cycles | Stress Amplitudes | Number of Cycles | Stress Amplitudes | Number of Cycles |

| 10.8 | 3137 ± 726 | 12.8 | 7980 ± 725 | 14.3 | 5639 ± 375 | 15.2 | 4596 ± 627 | 13.8 | 5142 ± 508 | 16.2 | 3189 ± 352 |

| 8.2 | 16,837 ± 3538 | 9.8 | 20,871 ± 1052 | 10.9 | 13,813 ± 1691 | 11.6 | 11,277 ± 3275 | 10.6 | 19,886 ± 1134 | 12.4 | 9314 ± 493 |

| 6.9 | 48,004 ± 15,551 | 6.8 | 75,569 ± 5242 | 7.6 | 52,037 ± 3597 | 8.0 | 33,931 ± 2624 | 7.3 | 50,167 ± 10,962 | 8.6 | 30,406 ± 3520 |

| 5.7 | 126,304 ± 7365 | 5.3 | 151,605 ± 6107 | 5.9 | 85,254 ± 3568 | 6.2 | 87,337 ± 3095 | 5.7 | 125,692 ± 17,785 | 6.7 | 80,821 ± 7860 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuleyin, H.; Gümrük, R. The Effect of Poly (Methyl Methacrylate) Content on Chemical, Thermomechanical, Mechanical, and Fatigue Life Characteristics of Ternary PC/ABS/PMMA Blends. Polymers 2025, 17, 1905. https://doi.org/10.3390/polym17141905

Kuleyin H, Gümrük R. The Effect of Poly (Methyl Methacrylate) Content on Chemical, Thermomechanical, Mechanical, and Fatigue Life Characteristics of Ternary PC/ABS/PMMA Blends. Polymers. 2025; 17(14):1905. https://doi.org/10.3390/polym17141905

Chicago/Turabian StyleKuleyin, Hamdi, and Recep Gümrük. 2025. "The Effect of Poly (Methyl Methacrylate) Content on Chemical, Thermomechanical, Mechanical, and Fatigue Life Characteristics of Ternary PC/ABS/PMMA Blends" Polymers 17, no. 14: 1905. https://doi.org/10.3390/polym17141905

APA StyleKuleyin, H., & Gümrük, R. (2025). The Effect of Poly (Methyl Methacrylate) Content on Chemical, Thermomechanical, Mechanical, and Fatigue Life Characteristics of Ternary PC/ABS/PMMA Blends. Polymers, 17(14), 1905. https://doi.org/10.3390/polym17141905