Effect of Build Orientation on Surface Finish and Hydrodynamic Stability of Inkjet 3D-Printed Microfluidic Channels

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

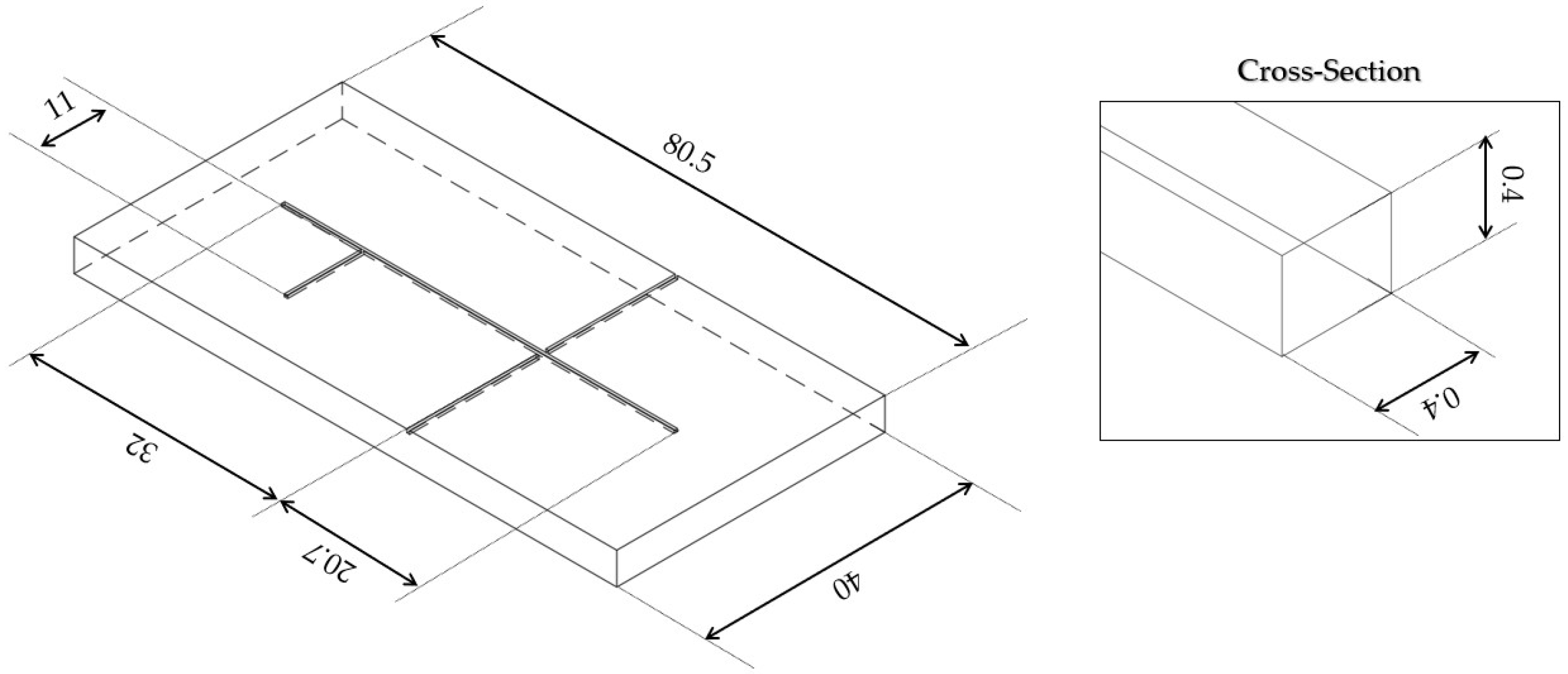

2.2. MoF Device: Design, Working Principle, and Manufacturing Protocol

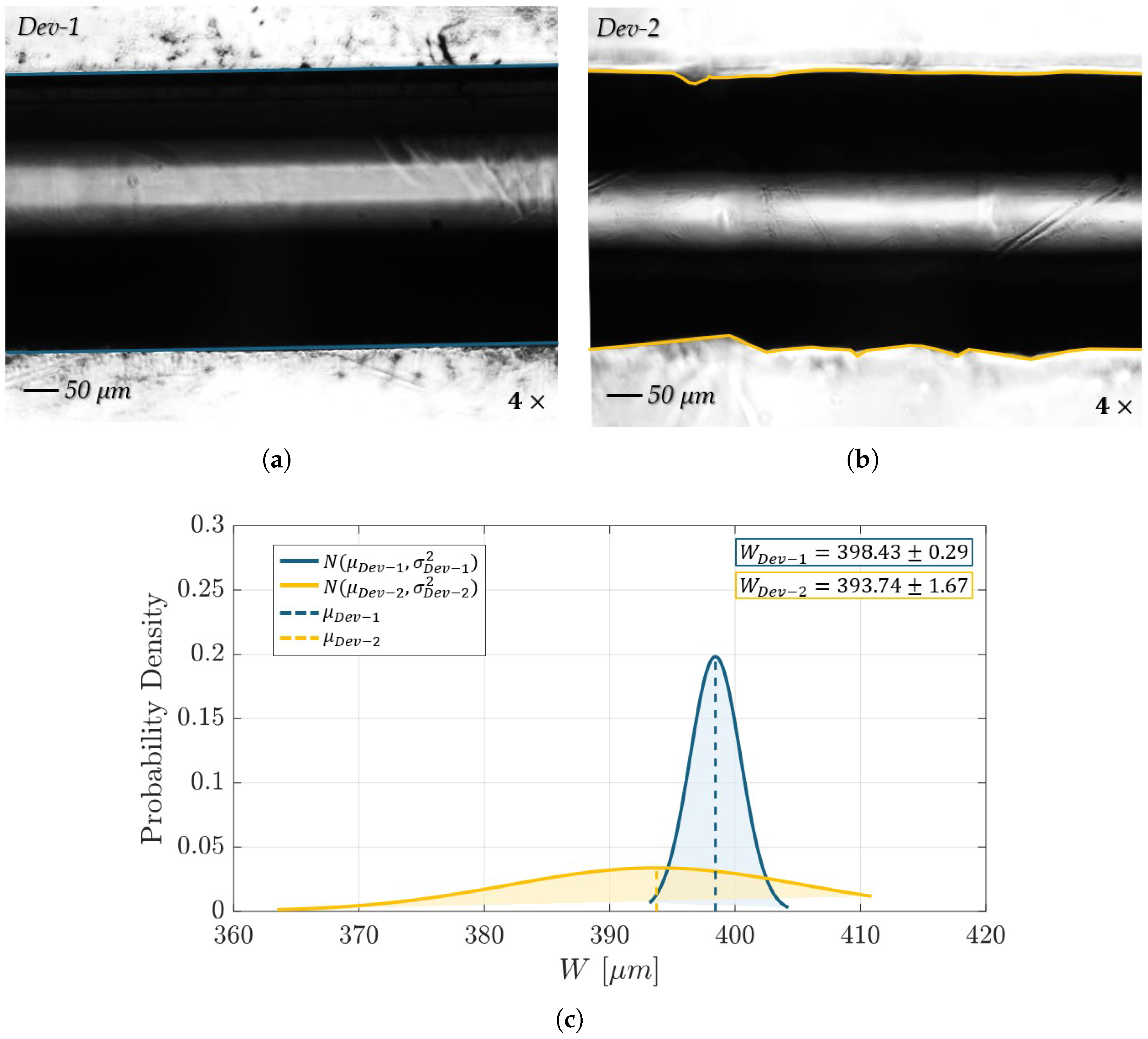

2.3. Quality Control of Consistency of MoF Device’s Surface Finish

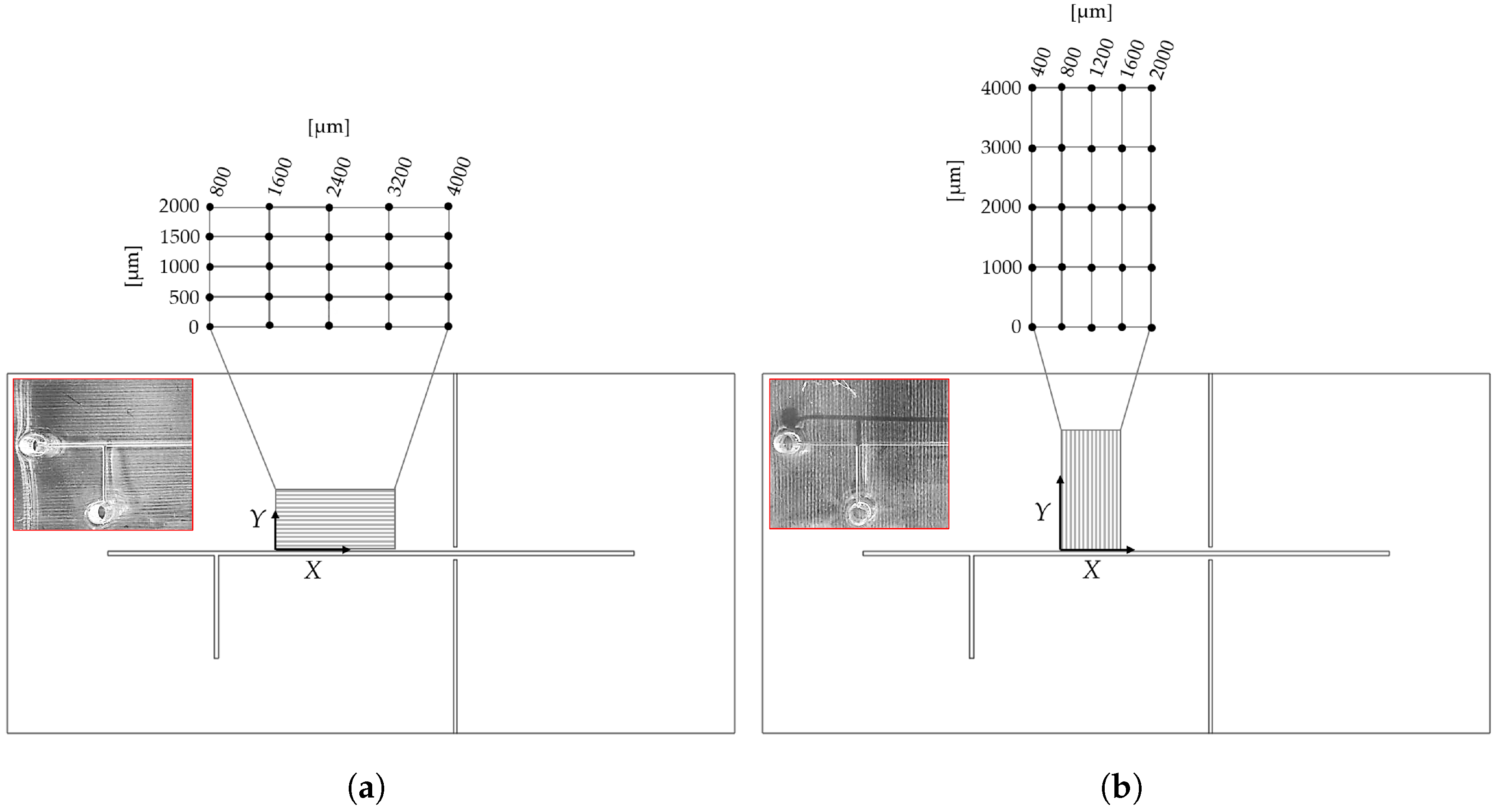

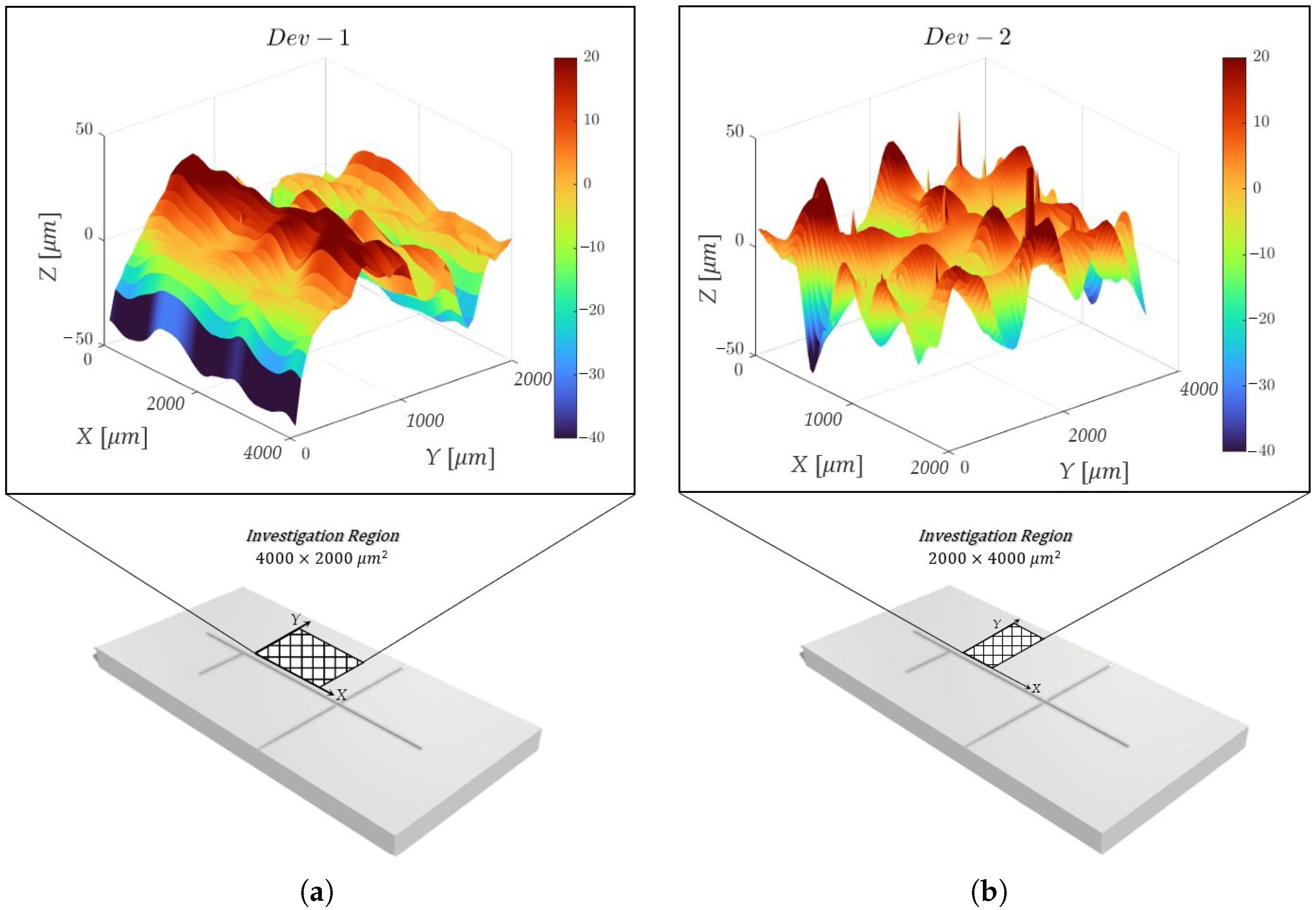

- Step 2. Observation collection. For each 3D-printed mol, the primary profile was acquired by using a KLA Tencor®P-7 Stylus Profiler (Gambetti, Milan, Italy) at a scan speed of 200 µm/s, an X resolution of 4 µm, and a Y resolution of 50.5 µm. For each mold a surface of 2000 × 4000 µ, oriented as represented in Figure 4a,b for Dev-1 and Dev-2, respectively, was mapped.

- Step 3. ANOVA study. For each 3D-printed mold, the surface consistency was examined as follows: a replicated general factorial design was studied by means of a third-order model (p-value < 0.0001), which was the most significant from the sequential model’s sum of squares (Type I) test, with the aim of finding a suitable approximation for the true functional relationship between the primary profile and the set of independent variables. In detail, the investigated factors (independent variables) for the experimental design are reported below:

- -

- Coordinates (factor A)—numerical factor varied among five different levels () corresponding to µm for Dev-1 and µm for Dev-2.

- -

- Coordinates (factor B)—numerical factor varied among five different levels () corresponding to µm for Dev-1 and µm for Dev-2.

The number of replications was fixed at , for a total number of experimental runs. The investigated response (dependent variable) for the experimental plan was the height (expressed in [µm]) related to the acquired primary profile. Once the observations for the latter response were collected, a further analysis of variance (ANOVA) was performed to examine the statistical significance of each investigated factor together with their potential interaction. The experimental plans are reported in Table 1 and Table 2 for Dev-1 and Dev-2, respectively. It was necessary to consider two different experimental plans for the two devices, since the used profilometer was characterized by two diverse resolutions along X and Y.

2.4. Morphological Analysis: Optical Microscopy

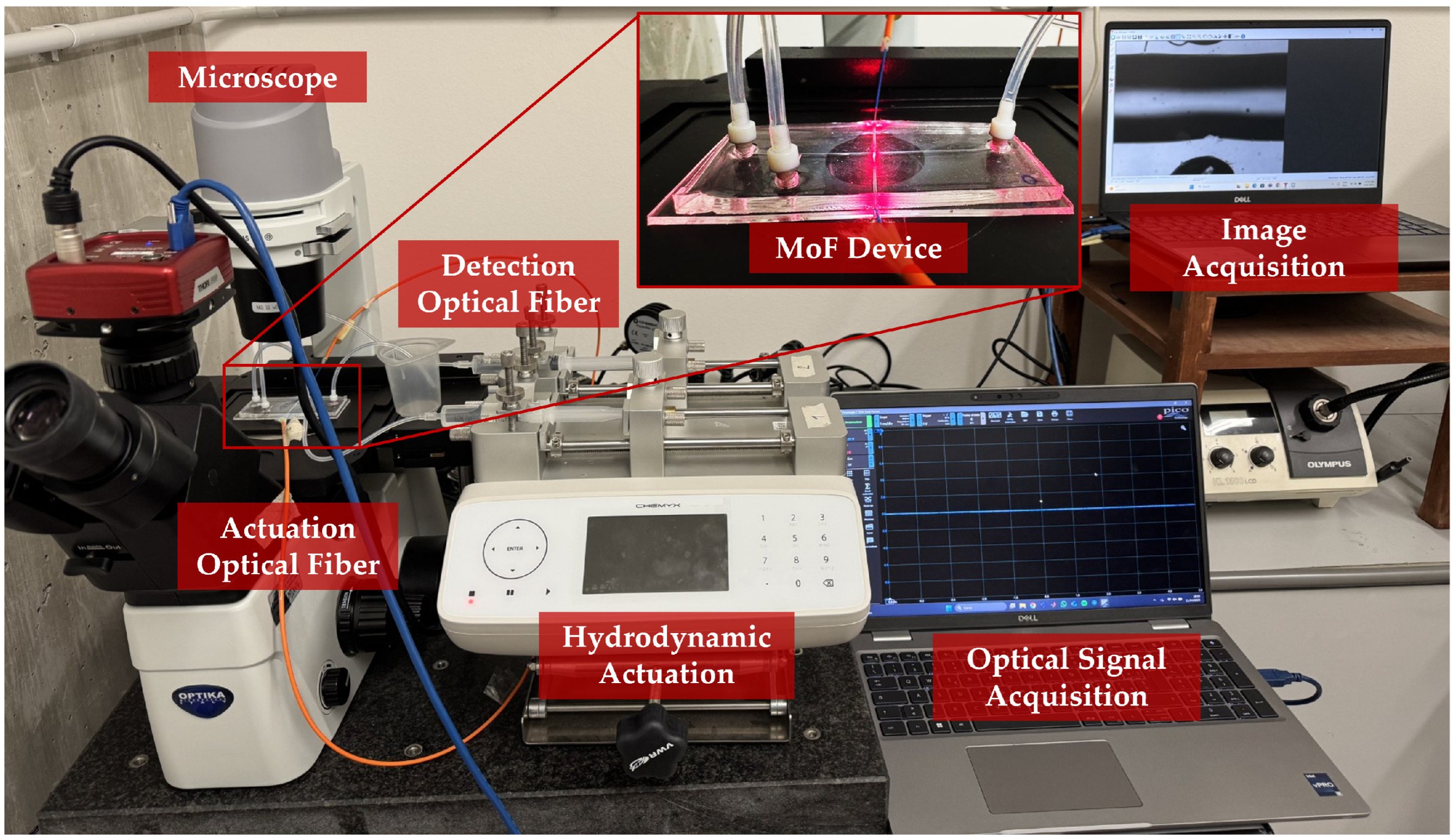

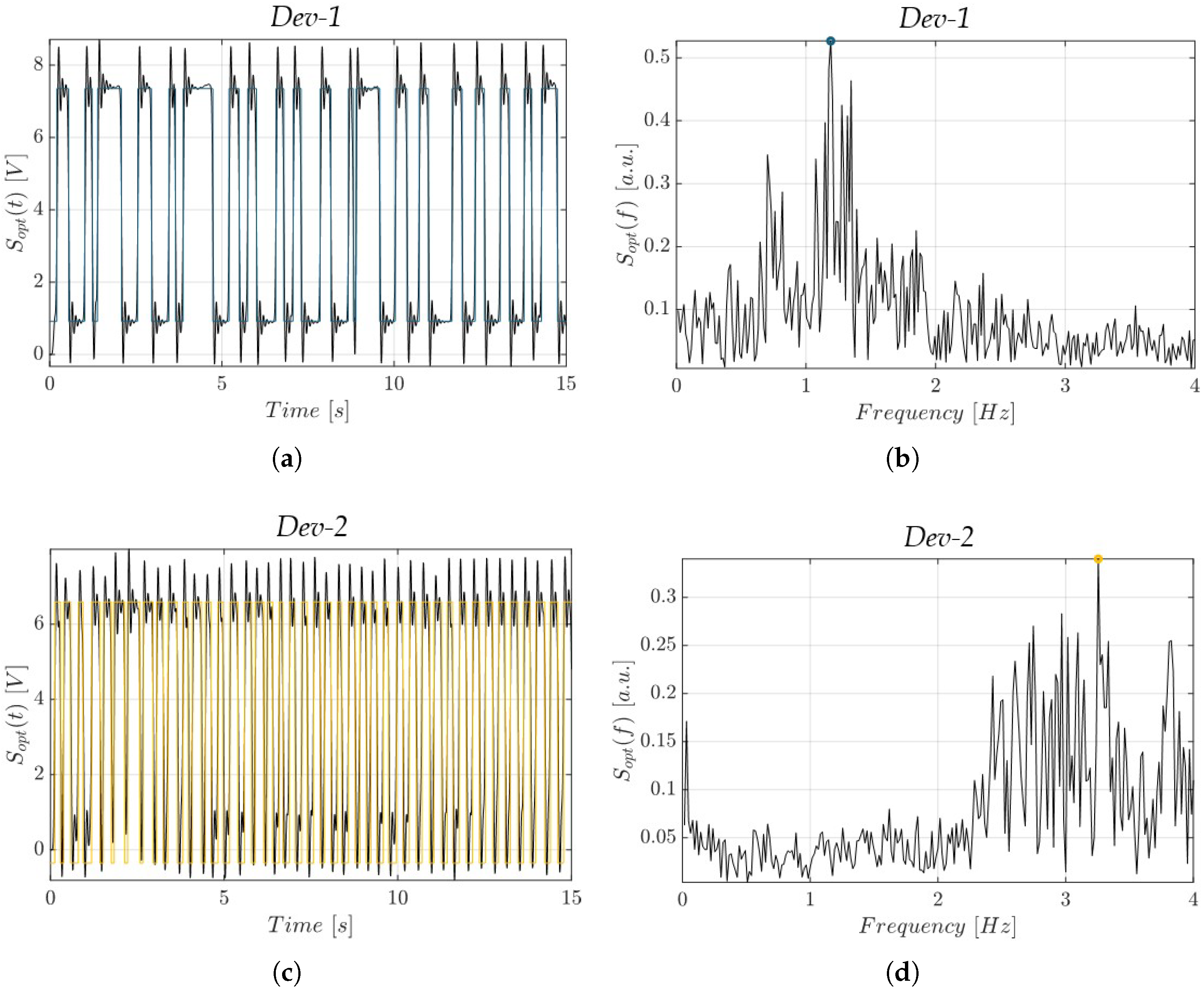

2.5. Impact of Build Orientation on Slug Flow’s Hydrodynamic Stability: Experimental Setup and Campaign

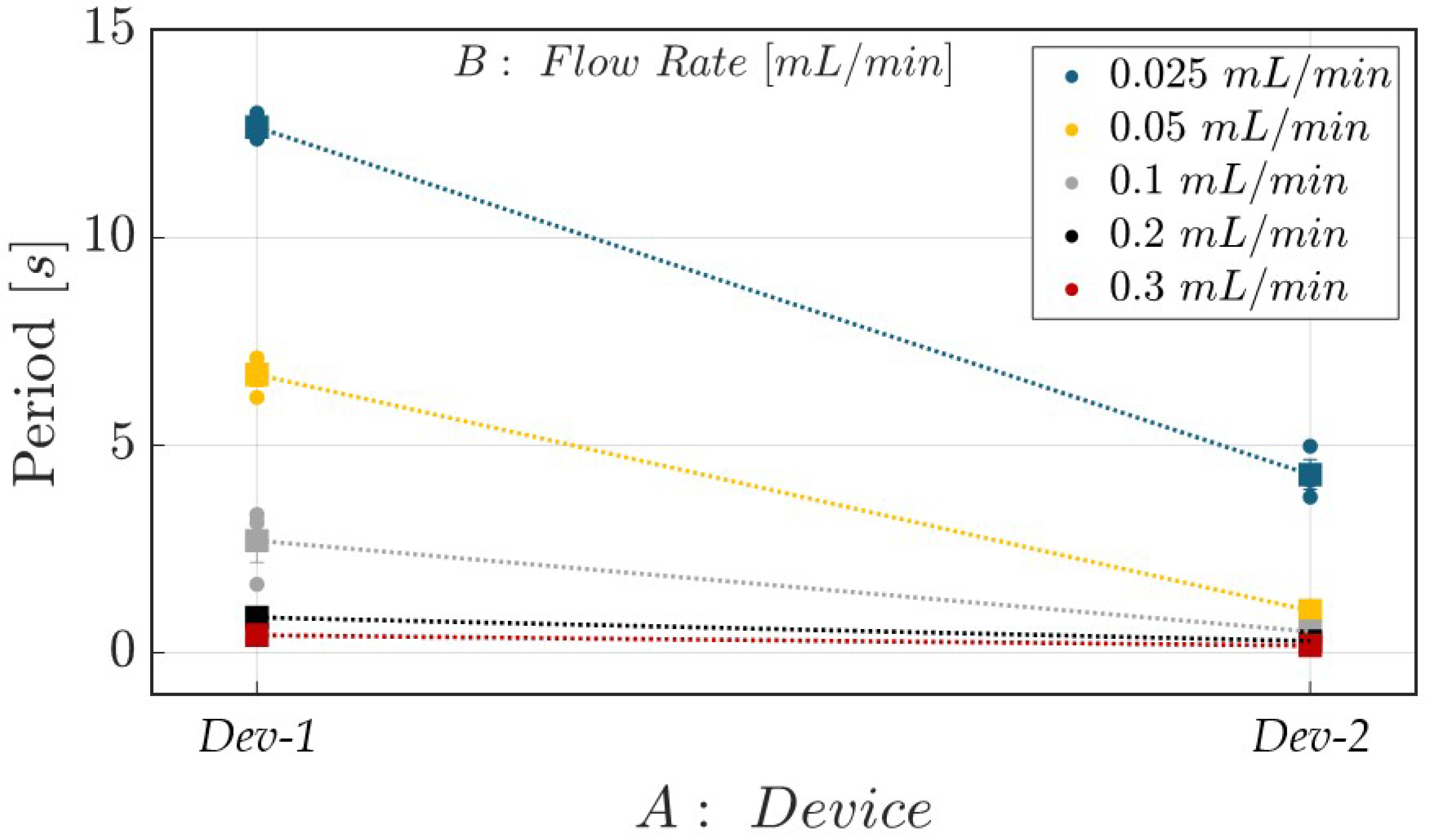

- Device (factor A)—categorical factor varied among two levels (), which were {Dev-1, Dev-2};

- Flow rate (factor B)—quantitative factor varied among five levels (), which were mL/min.

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Alshahrani, H.A. Review of 4D printing materials and reinforced composites: Behaviors, applications and challenges. J. Sci. Adv. Mater. Devices 2021, 6, 167–185. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2010. [Google Scholar]

- Jadhav, A.; Jadhav, V.S. A review on 3D printing: An additive manufacturing technology. Mater. Today Proc. 2022, 62, 2094–2099. [Google Scholar] [CrossRef]

- Zhou, L.; Miller, J.; Vezza, J.; Mayster, M.; Raffay, M.; Justice, Q.; Al Tamimi, Z.; Hansotte, G.; Sunkara, L.D.; Bernat, J. Additive manufacturing: A comprehensive review. Sensors 2024, 24, 2668. [Google Scholar] [CrossRef]

- ASTM International F2792-12a; Standard Terminology for Additive Manufacturing Technologies. ASTM International: West Conshohocken, PA, USA, 2012.

- Razavykia, A.; Brusa, E.; Delprete, C.; Yavari, R. An overview of additive manufacturing technologies—A review to technical synthesis in numerical study of selective laser melting. Materials 2020, 13, 3895. [Google Scholar] [CrossRef]

- Niemelä, M.; Shi, A.; Shirowzhan, S.; Sepasgozar, S.; Liu, C. 3D printing architectural freeform elements: Challenges and opportunities in manufacturing for industry 4.0. In Proceedings of the 36th International Symposium on Automation and Robotics in Construction (ISARC), Banff, AB, Canada, 21–24 May 2019; pp. 1298–1304. [Google Scholar]

- Su, J.W.; Gao, W.; Trinh, K.; Kenderes, S.M.; Pulatsu, E.T.; Zhang, C.; Whittington, A.; Lin, M.; Lin, J. 4D printing of polyurethane paint-based composites. Int. J. Smart Nano Mater. 2019, 10, 237–2448. [Google Scholar] [CrossRef]

- Gujba, A.K.; Medraj, M. Power ultrasonic additive manufacturing: Process parameters, microstructure, and mechanical properties. Adv. Mater. Sci. Eng. 2020, 2020, 1064870. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Sieber, I.; Moser, D.; Gengenbach, U. Design-for-manufacture of high-resolution 3D printed rotation optics. In Proceedings of the Optical Fabrication and Testing, Washington, DC, USA, 10–12 June 2019; Optica Publishing Group: Washington, DC, USA, 2019; p. JW3A–2. [Google Scholar]

- Park, Y.G.; Yun, I.; Chung, W.G.; Park, W.; Lee, D.H.; Park, J.U. High-resolution 3D printing for electronics. Adv. Sci. 2022, 9, 2104623. [Google Scholar] [CrossRef]

- Silva, M.R.; Pereira, A.M.; Sampaio, Á.M.; Pontes, A.J. Assessment of the dimensional and geometric precision of micro-details produced by material jetting. Materials 2021, 14, 1989. [Google Scholar] [CrossRef]

- Cutuli, E.; Sanalitro, D.; Stella, G.; Saitta, L.; Bucolo, M. A 3D-Printed Micro-Optofluidic Chamber for Fluid Characterization and Microparticle Velocity Detection. Micromachines 2023, 14, 2115. [Google Scholar] [CrossRef]

- Stella, G.; Barcellona, M.; Saitta, L.; Tosto, C.; Cicala, G.; Gulino, A.; Bucolo, M.; Fragalà, M.E. 3D printing manufacturing of polydimethyl-siloxane/zinc oxide micro-optofluidic device for two-phase flows control. Polymers 2022, 14, 2113. [Google Scholar] [CrossRef] [PubMed]

- Stella, G.; Saitta, L.; Moscato, S.; Cicala, G.; Bucolo, M. 3D-Printed Micro-Optofluidic Slug Flow Detector. IEEE Sens. J. 2024, 24, 18813–18826. [Google Scholar] [CrossRef]

- Go, J.; Schiffres, S.N.; Stevens, A.G.; Hart, A.J. Rate limits of additive manufacturing by fused filament fabrication and guidelines for high-throughput system design. Addit. Manuf. 2017, 16, 1–11. [Google Scholar] [CrossRef]

- Chand, R.; Sharma, V.S.; Trehan, R.; Gupta, M.K.; Sarikaya, M. Investigating the dimensional accuracy and surface roughness for 3D printed parts using a multi-jet printer. J. Mater. Eng. Perform. 2023, 32, 1145–1159. [Google Scholar] [CrossRef]

- Shoji, A.; Tasaki, R.; Terashima, K. High-speed additive manufacturing process using variable motion trajectory. In Proceedings of the 2018 IEEE Conference on Control Technology and Applications (CCTA), Copenhagen, Denmark, 21–24 August 2018; IEEE: New York, NY, USA, 2018; pp. 483–488. [Google Scholar]

- Phan, T.; Masood, S. An analysis of textured features fabricated by FDM rapid prototyping process. Int. J. Theory Appl. 2010, 6, 13–22. [Google Scholar]

- Aslani, K.E.; Vakouftsi, F.; Kechagias, J.D.; Mastorakis, N.E. Surface roughness optimization of poly-jet 3D printing using Grey Taguchi method. In Proceedings of the 2019 International Conference on Control, Artificial Intelligence, Robotics & Optimization (ICCAIRO), Athens, Greece, 8–10 December 2019; IEEE: New York, NY, USA, 2019; pp. 213–218. [Google Scholar]

- Kumar, K.; Kumar, G.S. An experimental and theoretical investigation of surface roughness of poly-jet printed parts: This paper explains how local surface orientation affects surface roughness in a poly-jet process. Virtual Phys. Prototyp. 2015, 10, 23–34. [Google Scholar] [CrossRef]

- Kamble, P.; Mittal, Y.; Gote, G.; Patil, M.; Karunakaran, K. A mathematical surface roughness model for objects made by material jetting. Prog. Addit. Manuf. 2024, 9, 2213–2224. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Maropoulos, S. An investigation of sloped surface roughness of direct poly-jet 3D printing. In Proceedings of the International Conference on Industrial Engineering—INDE, Novocherkassk, Russia, 22–23 October 2015; pp. 150–153. [Google Scholar]

- Cazón, A.; Morer, P.; Matey, L. PolyJet technology for product prototyping: Tensile strength and surface roughness properties. Proc. Inst. Mech. Eng. Part J. Eng. Manuf. 2014, 228, 1664–1675. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vaxevanidis, N.; Kechagias, J. Surface roughness investigation of poly-jet 3D printing. Mathematics 2020, 8, 1758. [Google Scholar] [CrossRef]

- Xiao, J.; Pan, F.; Xia, H.; Zou, S.; Zhang, H.; George, O.A.; Zhou, F.; Huang, Y. Computational study of single droplet deposition on randomly rough surfaces: Surface morphological effect on droplet impact dynamics. Ind. Eng. Chem. Res. 2018, 57, 7664–7675. [Google Scholar] [CrossRef]

- Saitta, L.; Celano, G.; Tosto, C.; Arcadio, F.; Zeni, L.; Sergi, C.; Cennamo, N.; Cicala, G. The effect of surface roughness on the performance of 3D printed surface plasmon resonance sensors for refractive index measurements. Int. J. Adv. Manuf. Technol. 2024, 132, 5503–5519. [Google Scholar] [CrossRef]

- Gal-Or, E.; Gershoni, Y.; Scotti, G.; Nilsson, S.M.; Saarinen, J.; Jokinen, V.; Strachan, C.J.; af Gennäs, G.B.; Yli-Kauhaluoma, J.; Kotiaho, T. Chemical analysis using 3D printed glass microfluidics. Anal. Methods 2019, 11, 1802–1810. [Google Scholar] [CrossRef]

- Cutuli, E.; Stella, G.; Guarino, F.; Bucolo, M. Automatic label-free image-based system for cell viability monitoring on-a-chip. Biomed. Signal Process. Control. 2025, 106, 107768. [Google Scholar] [CrossRef]

- Ayuso, J.M.; Virumbrales-Muñoz, M.; Lang, J.M.; Beebe, D.J. A role for microfluidic systems in precision medicine. Nat. Commun. 2022, 13, 3086. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.M.; Lv, S.; Zhang, W.; Cui, Y. Microfluidic point-of-care (POC) devices in early diagnosis: A review of opportunities and challenges. Sensors 2022, 22, 1620. [Google Scholar] [CrossRef]

- Bordbar, A.; Taassob, A.; Zarnaghsh, A.; Kamali, R. Slug flow in microchannels: Numerical simulation and applications. J. Ind. Eng. Chem. 2018, 62, 26–39. [Google Scholar] [CrossRef]

- Lei, L.; Zhao, Y.; Chen, W.; Li, H.; Wang, X.; Zhang, J. Experimental studies of droplet formation process and length for liquid–liquid two-phase flows in a microchannel. Energies 2021, 14, 1341. [Google Scholar] [CrossRef]

- Maurice, A.; Theisen, J.; Gabriel, J.C.P. Microfluidic lab-on-chip advances for liquid–liquid extraction process studies. Curr. Opin. Colloid Interface Sci. 2020, 46, 20–35. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Q.; Yue, J.; Yao, C.; Chen, G. Effect of mixing on mass transfer characterization in continuous slugs and dispersed droplets in biphasic slug flow microreactors. Chem. Eng. J. 2021, 406, 126885. [Google Scholar] [CrossRef]

- Saitta, L.; Celano, G.; Cicala, G.; Fragalà, M.E.; Stella, G.; Barcellona, M.; Tosto, C.; Bucolo, M. Projection micro-stereolithography versus master–slave approach to manufacture a micro-optofluidic device for slug flow detection. Int. J. Adv. Manuf. Technol. 2022, 120, 4443–4460. [Google Scholar] [CrossRef]

- Saitta, L.; Cutuli, E.; Celano, G.; Tosto, C.; Sanalitro, D.; Guarino, F.; Cicala, G.; Bucolo, M. Projection micro-stereolithography to manufacture a biocompatible micro-optofluidic device for cell concentration monitoring. Polymers 2023, 15, 4461. [Google Scholar] [CrossRef] [PubMed]

- Saitta, L.; Cutuli, E.; Celano, G.; Tosto, G.C.; Guarino, F.; Cicala, G.; Bucolo, M. Monolithic 3D Printed Micro-Optofluidic Device for Two-Phase Flow Monitoring and Bioapplications. In Proceedings of the 2024 IEEE International Conference And Exposition On Electric And Power Engineering (EPEi), Iaşi, Romania, 17–19 October 2024; IEEE: New York, NY, USA, 2024; pp. 642–647. [Google Scholar]

- Moscato, S.; Cutuli, E.; Camarda, M.; Bucolo, M. Experimental and Numerical Study of Slug-Flow Velocity Inside Microchannels Through In Situ Optical Monitoring. Micromachines 2025, 16, 586. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Xiang, X.; Wang, Z.; Zhu, C.; Ma, Y.; Fu, T. Uniformity and stability of droplet formation at T-junctions in symmetrical microchannels. Chem. Eng. J. 2024, 481, 148718. [Google Scholar] [CrossRef]

- Khan, W.; Chandra, A.; Kishor, K.; Sachan, S.; Alam, M.S. Slug formation mechanism for air–water system in T-junction microchannel: A numerical investigation. Chem. Pap. 2018, 72, 2921–2932. [Google Scholar] [CrossRef]

- Walczak, R.; Adamski, K. Inkjet 3D printing of microfluidic structures—on the selection of the printer towards printing your own microfluidic chips. J. Micromech. Microeng. 2015, 25, 085013. [Google Scholar] [CrossRef]

- Yan, C.; Jiang, P.; Jia, X.; Wang, X. 3D printing of bioinspired textured surfaces with superamphiphobicity. Nanoscale 2020, 12, 2924–2938. [Google Scholar] [CrossRef]

- Sikora, M.; Bohdal, T.; Tandecka, K.; Kacalak, W.; Mathia, T.G. The Effect of Channel Surface Roughness on Two–Phase Flow Patterns: A Review. Energies 2024, 17, 5483. [Google Scholar] [CrossRef]

- Chai, L.K.; Yeoh, C.V.; Ooi, E.H.; Foo, J.J. Lattice Boltzmann-based microchannel concentration mixing with surface roughness-mediated flow dynamics. Phys. Fluids 2025, 37. [Google Scholar] [CrossRef]

- Rabiei, N.; Hidrovo, C.H. Hydrodynamic characteristics of textured microchannel flow. J. Fluids Eng. 2023, 145, 051301. [Google Scholar] [CrossRef]

- Khoshkhoo, A.; Carrano, A.L.; Blersch, D.M. Effect of surface slope and build orientation on surface finish and dimensional accuracy in material jetting processes. Procedia Manuf. 2018, 26, 720–730. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, H.; Yao, K.; He, G.; Zhou, Z.; Sun, D. Surface roughness improvement of 3D printed microchannel. J. Micromech. Microeng. 2020, 30, 065003. [Google Scholar] [CrossRef]

- Lin, T.Y.; Do, T.; Kwon, P.; Lillehoj, P.B. 3D printed metal molds for hot embossing plastic microfluidic devices. Lab Chip 2017, 17, 241–247. [Google Scholar] [CrossRef] [PubMed]

- Parthiban, P.; Vijayan, S.; Doyle, P.S.; Hashimoto, M. Evaluation of 3D-printed molds for fabrication of non-planar microchannels. Biomicrofluidics 2021, 15. [Google Scholar] [CrossRef] [PubMed]

- Cairone, F.; Gagliano, S.; Bucolo, M. Experimental study on the slug flow in a serpentine microchannel. Exp. Therm. Fluid Sci. 2016, 76, 34–44. [Google Scholar] [CrossRef]

- Schembri, F.; Sapuppo, F.; Bucolo, M. Experimental classification of nonlinear dynamics in microfluidic bubbles’ flow. Nonlinear Dyn. 2012, 67, 2807–2819. [Google Scholar] [CrossRef]

- Ma, H.; Zhao, Q.; Yao, C.; Zhao, Y.; Chen, G. Effect of fluid viscosities on the liquid-liquid slug flow and pressure drop in a rectangular microreactor. Chem. Eng. Sci. 2021, 241, 116697. [Google Scholar] [CrossRef]

- Molla, S.; Eskin, D.; Mostowfi, F. Pressure drop of slug flow in microchannels with increasing void fraction: Experiment and modeling. Lab Chip 2011, 11, 1968–1978. [Google Scholar] [CrossRef]

- Desir, P.; Chen, T.Y.; Bracconi, M.; Saha, B.; Maestri, M.; Vlachos, D.G. Experiments and computations of microfluidic liquid–liquid flow patterns. React. Chem. Eng. 2020, 5, 39–50. [Google Scholar] [CrossRef]

| Factor | Symbol | Type | Unit | Levels | Level I | Level II | Level III | Level IV | Level V |

|---|---|---|---|---|---|---|---|---|---|

| Coordinates | A | Numerical | [µm] | 800 | 1600 | 2400 | 3200 | 4000 | |

| Coordinates | B | Numerical | [µm] | 0 | 500 | 1000 | 1500 | 2000 |

| Factor | Symbol | Type | Unit | Levels | Level I | Level II | Level III | Level IV | Level V |

|---|---|---|---|---|---|---|---|---|---|

| Coordinates | A | Numerical | [µm] | 400 | 800 | 1200 | 1600 | 2000 | |

| Coordinates | B | Numerical | [µm] | 0 | 1000 | 2000 | 3000 | 4000 |

| Factor | Symbol | Type | Unit | Levels | Level I | Level II | Level III | Level IV | Level V |

|---|---|---|---|---|---|---|---|---|---|

| Device | A | Categorical | [mL/min] | Dev-1 | Dev-2 | [-] | [-] | [-] | |

| Flow Rate | B | Categorical | [-] |

| Printing Method | 3D Printer | Material | Roughness [µm] | Measurement Method | Reference |

|---|---|---|---|---|---|

| Inkjet | Projet3510 HD | Visijet M3 Crystal | 6.81–34.63 | (1) | [49] |

| BJP | X1-Lab 3D printer | Stainless Steel (SS) 420 | 3.65–6.61 | (1) | [50] |

| FDM | QiDi Tech 1 | Polylactic acid (PLA) | 16.7 (2.6) | (2) | [51] |

| SLS | EOS Formiga | Polyamide (PA) | 3.3 (0.3) | (2) | [51] |

| PJ | Objet30 Prime | VeroClear | 2.3 (0.4) | (2) | [51] |

| SL | Structo OrthoForm | Proprietary | 1.4 (0.4) | (2) | [51] |

| PJ | Objet260 Connex1 | VeroClear | 0.9–1.2 | (2) | [28] |

| PJ | Eden250 | VeroClear | 0.5–2 | (2) | [24] |

| PJ | Eden350 | VeroClear | 2.8–17.6 | (3) | [22] |

| PJ | Objet260 Connex1 | VeroWhitePlus | 6.7–7.3 | (1) | This work |

| PJ | Objet260 Connex1 | VeroWhitePlus | 0.7–2.1 | (2) | This work |

| PJ | Objet260 Connex1 | VeroWhitePlus | 0.2–19.9 | (3) | This work |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 24,197.01 | 9 | 2688.56 | 38.85 | <0.0001 | significant |

| A—Coordinates | 113.78 | 1 | 113.78 | 1.64 | 0.2025 | |

| B—Coordinates | 6933.43 | 1 | 6933.43 | 100.18 | <0.0001 | significant |

| 26.78 | 1 | 26.78 | 0.39 | 0.5352 | ||

| 17.75 | 1 | 17.75 | 0.26 | 0.6136 | ||

| 135.12 | 1 | 135.12 | 1.95 | 0.1652 | ||

| 81.73 | 1 | 81.73 | 1.18 | 0.2796 | ||

| 42.89 | 1 | 42.89 | 0.62 | 0.4328 | ||

| 54.76 | 1 | 54.76 | 0.79 | 0.3757 | ||

| 17,050.10 | 1 | 17,050.10 | 246.36 | <0.0001 | significant | |

| Residual | 7543.82 | 109 | 69.21 | |||

| Lack of Fit | 2171.39 | 15 | 144.76 | 2.53 | 0.0034 | significant |

| Pure Error | 5372.44 | 94 | 57.15 | |||

| Cor Total | 31,740.84 | 118 | ||||

| Std. Dev. | 8.32 | 0.7623 | ||||

| Mean | −0.22 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Model | 11,166.12 | 9 | 1240.68 | 15.46 | <0.0001 | significant |

| A—Coordinates | 328.69 | 1 | 328.69 | 4.10 | 0.0454 | significant |

| B—Coordinates | 25.80 | 1 | 25.80 | 0.32 | 0.5718 | |

| 9.49 | 1 | 9.49 | 0.12 | 0.7315 | ||

| 265.74 | 1 | 265.74 | 3.31 | 0.0715 | ||

| 3086.83 | 1 | 3086.83 | 38.47 | <0.0001 | ||

| 1349.06 | 1 | 1349.06 | 16.81 | <0.0001 | ||

| 4598.28 | 1 | 4598.28 | 57.31 | <0.0001 | ||

| 40.55 | 1 | 40.55 | 0.51 | 0.4786 | ||

| 449.78 | 1 | 449.78 | 5.61 | 0.0196 | ||

| Residual | 8825.91 | 110 | 80.24 | |||

| Lack of Fit | 7635.34 | 14 | 545.38 | 43.98 | <0.0001 | significant |

| Pure Error | 1190.57 | 96 | 12.40 | |||

| Cor Total | 19,992.57 | 119 | ||||

| Std. Dev. | 8.96 | 0.5585 | ||||

| Mean | 1.18 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | |

|---|---|---|---|---|---|---|

| Block | 0.19 | 2 | 0.093 | |||

| Model | 437.19 | 9 | 48.58 | 290.35 | <0.0001 | significant |

| A Device | 87.47 | 1 | 87.47 | 522.79 | <0.0001 | significant |

| B-Flow Rate | 275.59 | 4 | 68.90 | 411.80 | <0.0001 | significant |

| AB | 74.13 | 4 | 18.53 | 110.77 | <0.0001 | significant |

| Residual | 3.01 | 18 | 0.17 | |||

| Cor Total | 440.39 | 29 | ||||

| Std. Dev | 0.41 | 0.9932 | ||||

| Mean | 2.96 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cutuli, E.; Saitta, L.; Tuccitto, N.; Cicala, G.; Bucolo, M. Effect of Build Orientation on Surface Finish and Hydrodynamic Stability of Inkjet 3D-Printed Microfluidic Channels. Polymers 2025, 17, 1864. https://doi.org/10.3390/polym17131864

Cutuli E, Saitta L, Tuccitto N, Cicala G, Bucolo M. Effect of Build Orientation on Surface Finish and Hydrodynamic Stability of Inkjet 3D-Printed Microfluidic Channels. Polymers. 2025; 17(13):1864. https://doi.org/10.3390/polym17131864

Chicago/Turabian StyleCutuli, Emanuela, Lorena Saitta, Nunzio Tuccitto, Gianluca Cicala, and Maide Bucolo. 2025. "Effect of Build Orientation on Surface Finish and Hydrodynamic Stability of Inkjet 3D-Printed Microfluidic Channels" Polymers 17, no. 13: 1864. https://doi.org/10.3390/polym17131864

APA StyleCutuli, E., Saitta, L., Tuccitto, N., Cicala, G., & Bucolo, M. (2025). Effect of Build Orientation on Surface Finish and Hydrodynamic Stability of Inkjet 3D-Printed Microfluidic Channels. Polymers, 17(13), 1864. https://doi.org/10.3390/polym17131864