CRITIC–EDAS Approach for Evaluating Mechanical Properties of Flax/Vetiver/MFF Hybrid Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Mahogany Fruit Fillers (MFFs)

2.2.1. FTIR Analysis of Untreated and Treated Mahogany Fruit Fillers (MFFs)

2.2.2. XRD Analysis of Untreated and Treated Mahogany Fruit Fillers (MFFs)

2.2.3. Particle Size Analysis of Treated Mahogany Fruit Fillers (MFFs)

2.3. Preparation of Vetiver Grass and Flax Fiber

2.4. Design of Experiments

2.5. Fabrication of the Flax/Vetiver/MFF-Based Composites

2.6. Testing of FVM Composites

2.7. CRITIC Technique

2.8. EDAS Method

3. Results and Discussions

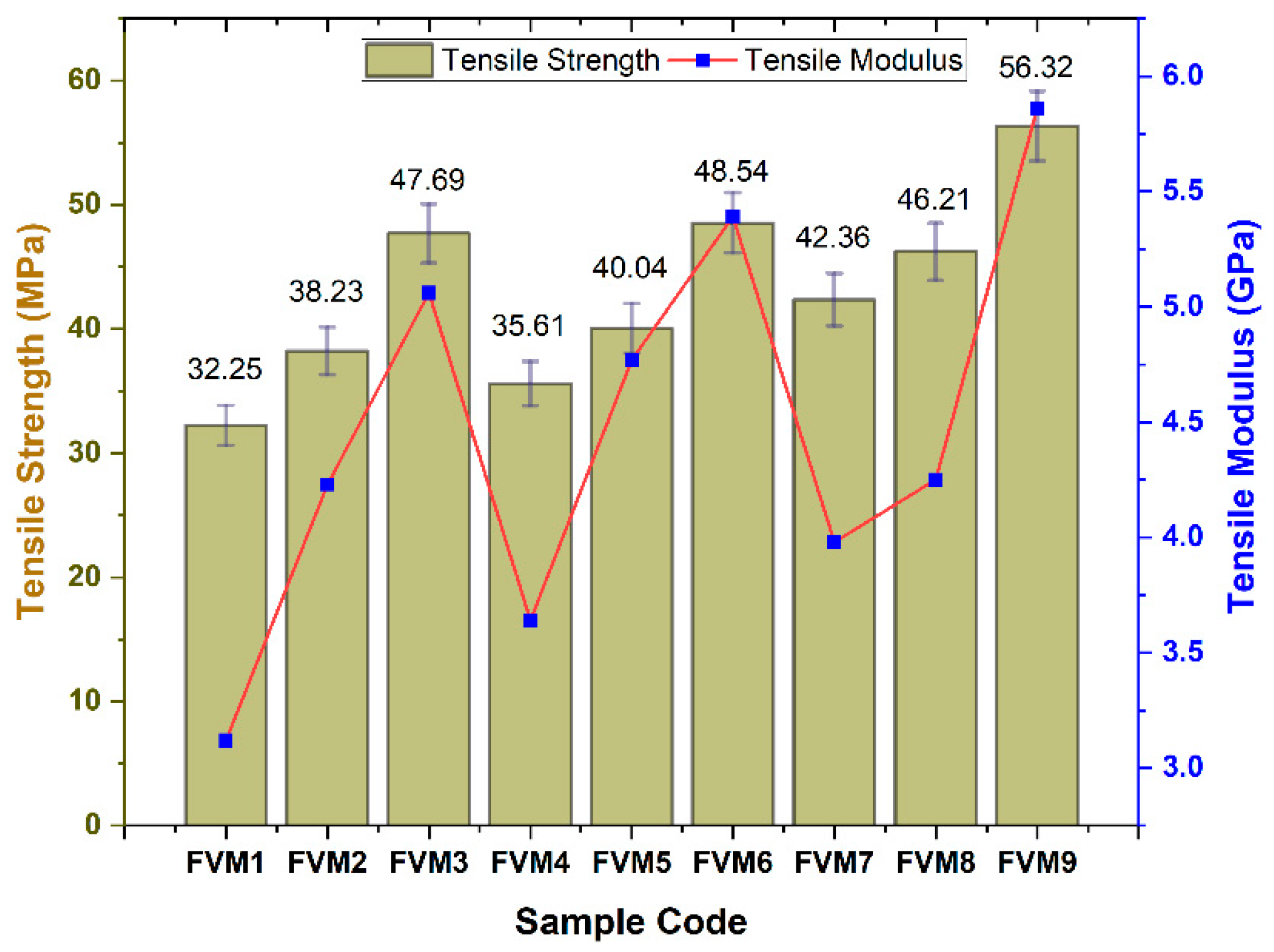

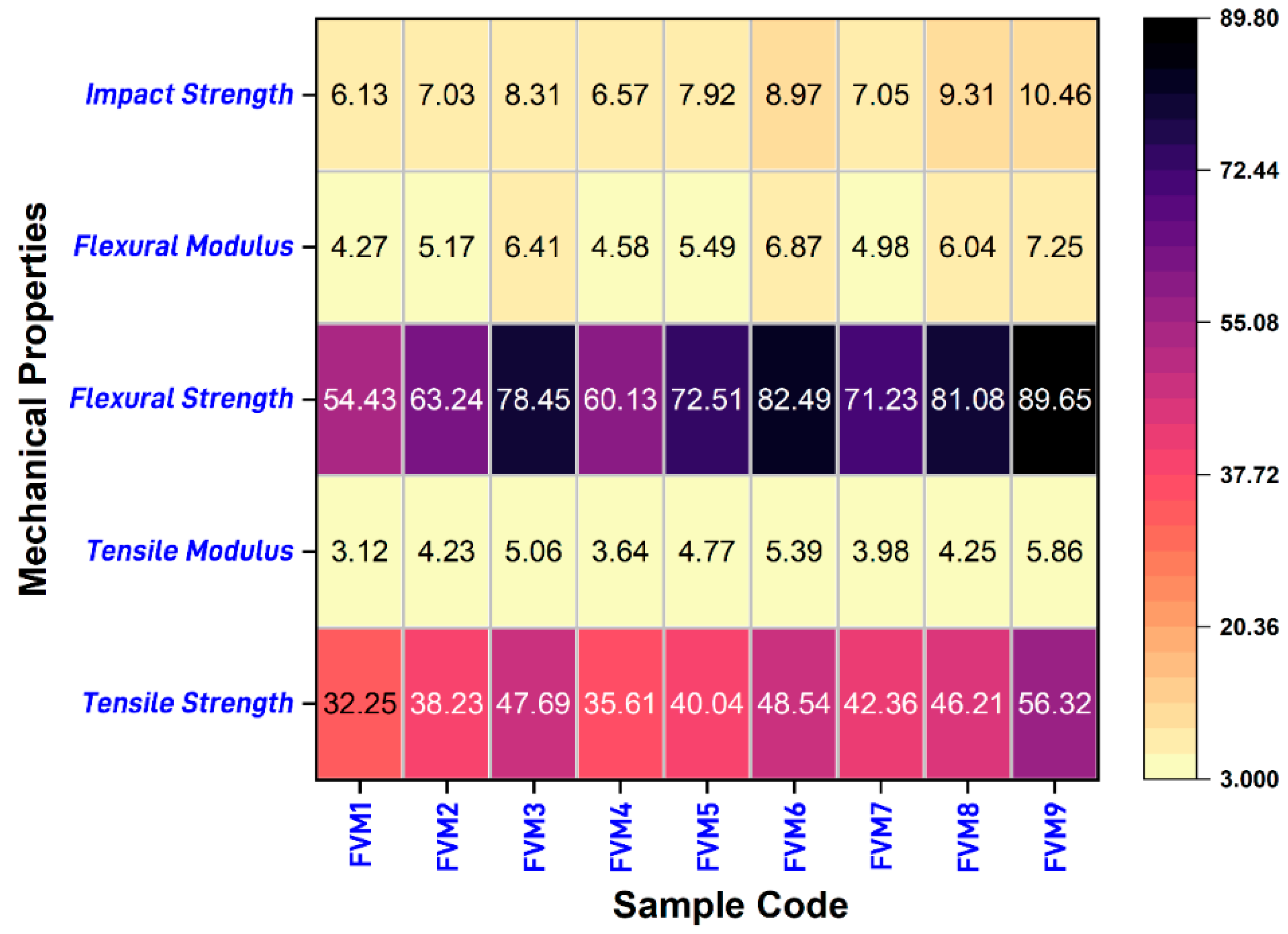

3.1. Tensile Properties of Flax/Vetiver/MFF (FVM) Hybrid Composite

3.2. Flexural Properties of Flax/Vetiver/MFF (FVM) Hybrid Composite

3.3. Impact Properties of Flax/Vetiver/MFF (FVM) Hybrid Composites

3.4. Overall Properties of Mechanical Properties

3.5. Comparison with the Similar Work

4. CRITIC—EDAS Optimization

4.1. Optimality Criterion for Selecting FVM Hybrid Composite Composition

4.2. Sensitivity Analysis

4.3. Limitations and Future Scope of the Present Study

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CRITIC | Criteria Importance Through Inter-Criteria Correlation |

| EDAS | Evaluation based on Distance from Average Solution |

| FVM | Flax/Vetiver/Mahogany Fruit Filler (Hybrid Composite) |

| MFF | Mahogany Fruit Filler |

| FTIR | Fourier Transform Infrared Spectroscopy |

| XRD | X-Ray Diffraction |

| SEM | Scanning Electron Microscopy |

| MCDM | Multi-criteria decision-making |

| WASPAS | Weighted Aggregated Sum Product Assessment |

| COPRAS | Complex Proportional Assessment |

| TOPSIS | Technique for Order Preference by Similarity to Ideal Solution |

| VIKOR | VlseKriterijumska Optimizacija I Kompromisno Resenje |

| DoE | Design of Experiments |

| UTM | Universal Testing Machine |

| PDA | Positive Distance from Average |

| NDA | Negative Distance from Average |

| NSP | Normalized Sum of Positive Distance |

| NSN | Normalized Sum of Negative Distance |

| PLA | Polylactic Acid |

| MABAC | Multi-Attributive Border Approximation Area Comparison |

| CrI | Crystallinity Index |

| NaOH | Sodium Hydroxide |

| PVA | Polyvinyl Alcohol |

References

- Boopathi, S.; Sureskumar, M.; Jeyakumar, M.; Sanjeev Kumar, R.; Subbiah, R. Influences of Fabrication Parameters on Natural Fiber Reinforced Polymer Composite (NFRPC) Material: A Review. Mater. Sci. Forum 2022, 1075, 115–124. [Google Scholar] [CrossRef]

- Divya, D.; Devi, S.Y.; Indran, S.; Raja, S.; Sumesh, K.R. Extraction and Modification of Natural Plant Fibers—A Comprehensive Review. In Plant Fibers, their Composites, and Applications; Woodhead Publishing: Cambridge, UK, 2022; pp. 25–50. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Gokulkumar, S.; Navaneethakrishnan, P. Natural Fiber-Reinforced Biocomposites. In Encyclopedia of Materials: Plastics and Polymers; Elsevier: Amsterdam, The Netherlands, 2022; Volume 1–4, pp. 504–510. ISBN 978-0-12-823291-0. [Google Scholar]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural Fiber–Reinforced Composites: A Review on Material, Manufacturing, and Machinability. J. Thermoplast. Compos. Mater. 2019, 34, 238–284. [Google Scholar] [CrossRef]

- Atmakuri, A.; Palevicius, A.; Vilkauskas, A.; Janusas, G. Numerical and Experimental Analysis of Mechanical Properties of Natural-Fiber-Reinforced Hybrid Polymer Composites and the Effect on Matrix Material. Polymers 2022, 14, 2612. [Google Scholar] [CrossRef] [PubMed]

- Jawaid, M.; Siengchin, S. Hybrid Composites: A Versatile Materials for Future. Appl. Sci. Eng. Prog. 2019, 12, 223. [Google Scholar] [CrossRef]

- Mohapatra, D.K.; Deo, C.R.; Mishra, P.; Dash, P. Influence of Pistachio Shell Filler Addition and Interply Hybridization on Mechanical and Thermal Performances of Polyester Composites. J. Elastomers Plast. 2023, 56, 169–193. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Thyavihalli Girijappa, Y.G.; Rangappa, S.M.; Siengchin, S. Effect of Natural Filler Materials on Fiber Reinforced Hybrid Polymer Composites: An Overview. J. Nat. Fibers 2020, 19, 4132–4147. [Google Scholar] [CrossRef]

- Sahayaraj, A.F.; Muthukrishnan, M.; Ramesh, M.; Rajeshkumar, L. Effect of Hybridization on Properties of Tamarind (Tamarindus Indica L.) Seed Nano-Powder Incorporated Jute-Hemp Fibers Reinforced Epoxy Composites. Polym. Compos. 2021, 42, 6611–6620. [Google Scholar] [CrossRef]

- Giuliani, P.M.; Giannini, O.; Panciroli, R. Creep and Stress Relaxation of Unidirectional Flax Fiber Reinforced Laminates. Compos. Struct. 2023, 310, 116755. [Google Scholar] [CrossRef]

- Amroune, S.; Belaadi, A.; Bourchak, M.; Makhlouf, A.; Satha, H. Statistical and Experimental Analysis of the Mechanical Properties of Flax Fibers. J. Nat. Fibers 2020, 19, 1387–1401. [Google Scholar] [CrossRef]

- Rajesh, D.; Lenin, N.; Cep, R.; Anand, P.; Elangovan, M. Enhancement of Thermal Behaviour of Flax with a Ramie Fibre-Reinforced Polymer Composite. Polymers 2023, 15, 350. [Google Scholar] [CrossRef]

- Arpitha, G.R.; Verma, A.; Sanjay, M.R.; Gorbatyuk, S.; Khan, A.; Sobahi, T.R.; Asiri, A.M.; Siengchin, S. Bio-Composite Film from Corn Starch Based Vetiver Cellulose. J. Nat. Fibers 2022, 19, 14634–14644. [Google Scholar] [CrossRef]

- Zaman, H. The Influence of Process Parameters on Tensile Features of Vetiver Fiber Reinforced Polymer Matrix Composites. Malays. J. Compos. Sci. Manuf. 2024, 15, 13–24. [Google Scholar] [CrossRef]

- Alipour, A.; Jayaraman, K. Performance of Flax/Epoxy Composites Made from Fabrics of Different Structures. Fibers 2024, 12, 34. [Google Scholar] [CrossRef]

- Hadj-Djilani, A.; Toubal, L.; Bougherara, H.; Zitoune, R. Investigating the Influence of High-Void Content on the Impact and Post-Impact Properties of Flax/Epoxy Composite Laminates with Different Stacking Configurations. Compos. Struct. 2024, 330, 117832. [Google Scholar] [CrossRef]

- Graupner, N.; Hohe, J.; Schober, M.; Rohrmüller, B.; Weber, D.; Bruns, L.; Bruns, A.; Müssig, J. A Competitive Study of the Static and Fatigue Performance of Flax, Glass, and Flax/Glass Hybrid Composites on the Structural Example of a Light Railway Axle Tie. Front. Mater. 2022, 9, 837289. [Google Scholar] [CrossRef]

- Calabrese, L.; Badagliacco, D.; Sanfilippo, C.; Fiore, V. Flax–Glass Fiber Reinforced Hybrid Composites Exposed to a Salt-Fog/Dry Cycle: A Simplified Approach to Predict Their Performance Recovery. Polymers 2023, 15, 2542. [Google Scholar] [CrossRef] [PubMed]

- Krishnakumari, A.; Devaraju, A.; Saravanan, M. Evaluation of Mechanical Properties of Hybrid Rootfiber Reinforced Polymer Composites. Mater. Today Proc. 2018, 5, 14560–14566. [Google Scholar] [CrossRef]

- Vinay, H.B.; Govindaraju, H.K.; Banakar, P. Experimental Study on Mechanical Properties of Polymer Based Hybrid Composite. Mater. Today Proc. 2017, 4, 10904–10912. [Google Scholar] [CrossRef]

- Janyakunmongkol, K.; Nhuapeng, W.; Thamjaree, W. Effect of Alkaline Treatment on Mechanical Properties of Composites between Vetiver Fibers and Epoxy Resin. J. Mech. Behav. Mater. 2024, 33, 20220310. [Google Scholar] [CrossRef]

- Benjamin, U. Tensile Behaviour of Oil Bean Pod Shell and Mahogany Sawdust Reinforced Epoxy Resin Composite. Int. J. Sci. Technol. Soc. 2019, 7, 1–7. [Google Scholar] [CrossRef]

- Jaroenta, J.; Siangsawad, R.; Onkate, R.; Jearjiratikul, V.; Thongpin, C. Study of Rubber Composites between Natural Rubber and Mahogany Shell Powder (MHSP) and Potential for Pavement Block. IOP Conf. Ser. Mater. Sci. Eng. 2020, 773, 012044. [Google Scholar] [CrossRef]

- Edafiadhe, E.O.; Nyorere, O.; Hilary, U. Compressive Behaviours of Oil Bean Shell and Wood Particulates/Epoxy Composite Board. Arch. Curr. Res. Int. 2019, 16, 1–8. [Google Scholar] [CrossRef]

- Frank, N.; Alfred, E. Flexural Properties of Wood Sawdust and Oil Bean Pod Shell Filled Composite. Int. J. Res. Granthaalayah 2018, 6, 337–344. [Google Scholar] [CrossRef]

- Asrofi, M.; Setyobudi, R.; Ilyas, R.A.; Sanyang, M.L.; Adegbenjo, A.O.; Idris, I.; Thiagamani, S.M.K.; Dominic, C.D.M.; Knight, V.F.; Norrrahim, M.N.F.; et al. Influence of Ultrasonication Time on the Various Properties of Alkaline-Treated Mango Seed Waste Filler Reinforced PVA Biocomposite. Rev. Adv. Mater. Sci. 2023, 62, 20230137. [Google Scholar] [CrossRef]

- Lusiani, R.; Saefuloh, I.; Listijorini, E.; Sumarna, A.E.; Fawaid, M.; Meliana, Y. Particleboard Characterization Using Sawdust from Sengon Wood, Mahogany Wood, Bayur Wood, and Rice Husk Ash as Composite Fillers. IOP Conf. Ser. Mater. Sci. Eng. 2020, 909, 012028. [Google Scholar] [CrossRef]

- Rocha, A.L.F.; Feitosa, B.d.A.; Carolino, A.d.S.; Nunes, R.Z.d.A.; Macalia, C.M.A.; da Silva, K.A.; Dias, C.O.; de Souza, S.M.; Campelo, P.H.; Bezerra, J.d.A.; et al. Extraction and Modification of Cellulose Microfibers Derived from Biomass of the Amazon Ochroma pyramidale Fruit. Micro 2023, 3, 653–670. [Google Scholar] [CrossRef]

- Mahesh, V. Mechanical Characterization of Novel Parthenium hysterophorus and Jute Reinforced Polymer Matrix Composites for Light Weight Medium Load Applications and Application of MADM-VIKOR Approach. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2024, 238, 7123–7133. [Google Scholar] [CrossRef]

- Mahesh, V.; Mahesh, V.; Harursampath, D. Physio-Mechanical Characterization of Jute/Kevlar Hybrid Composites Coupled with MADM Approach for Selection of Composites. J. Nat. Fibers 2022, 19, 11105–11113. [Google Scholar] [CrossRef]

- Singh, T.; Pattnaik, P.; Shekhawat, D.; Ranakoti, L.; Lendvai, L. Waste Marble Dust-Filled Sustainable Polymer Composite Selection Using a Multi-Criteria Decision-Making Technique. Arab. J. Chem. 2023, 16, 104695. [Google Scholar] [CrossRef]

- Singh, T.; Pattnaik, P.; Aherwar, A.; Ranakoti, L.; Dogossy, G.; Lendvai, L. Optimal Design of Wood/Rice Husk-Waste-Filled PLA Biocomposites Using Integrated CRITIC–MABAC-Based Decision-Making Algorithm. Polymers 2022, 14, 2603. [Google Scholar] [CrossRef]

- Kavimani, V.; Paramasivam, B.; Sasikumar, R.; Venkatesh, S. A CRITIC Integrated WASPAS Approach for Selection of Natural and Synthetic Fibers Embedded Hybrid Polymer Composite Configuration. Multiscale Multidiscip. Model. Exp. Des. 2024, 7, 1721–1736. [Google Scholar] [CrossRef]

- Saha, A.; Kulkarni, N.D.; Kumari, P. Development of Bambusa tulda-Reinforced Different Biopolymer Matrix Green Composites and MCDM-Based Sustainable Material Selection for Automobile Applications. Environ. Dev. Sustain. 2025, 27, 10655–10691. [Google Scholar] [CrossRef]

- Chandrika, S.; Kumar, T.R.H.; Mahesh, V. Physio-Mechanical Characterization of Kenaf/Saw Dust Reinforced Polymer Matrix Composite and Selection of Optimal Configuration Using MADM-VIKOR Approach. Int. J. Interact. Des. Manuf. 2022, 18, 6359–6369. [Google Scholar] [CrossRef]

- Mahajan, A.; Binaz, V.; Singh, I.; Arora, N. Selection of Natural Fiber for Sustainable Composites Using Hybrid Multi Criteria Decision Making Techniques. Compos. Part C Open Access 2022, 7, 100224. [Google Scholar] [CrossRef]

- Mahesh, V.; Mahesh, V. Harnessing of Waste Rubber Crumb and Development of Sustainable Hybrid Composite Using Kenaf (Hibiscus cannabinus) for Structural Applications. J. Nat. Fibers 2023, 20, 45–55. [Google Scholar] [CrossRef]

- Mahesh, V.; Mahesh, V.; Nagaraj, S.M.; Subhashaya, P.; Shambu Singh, G.S.T. Physio-Mechanical and Thermal Characterization of Jute/Rubber Crumb Hybrid Composites and Selection of Optimal Configuration Using the MADM Approach. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 7942–7952. [Google Scholar] [CrossRef]

- Sriariyanun, M.; Koppiahraj, K.; Baranitharan, P.; Venkatesh, S.; Rajeshkumar, K.; Kavimani, V. Manufacturing and Mechanical Characterization of Alkali-Treated Borassus Fruit Natural Fiber with Cellulose Acetate Synthetic Fiber Reinforced Polymer Composite: Selection of Optimum Configuration Using CRITIC-Integrated EDAS Soft Computing Techniques. J. Mater. Cycles Waste Manag. 2025, 27, 880–897. [Google Scholar] [CrossRef]

- Awd Allah, M.M.; Abd El-baky, M.A.; Alshahrani, H.; Sebaey, T.A.; Hegazy, D.A. Multi Attribute Decision Making through COPRAS on Tensile Properties of Hybrid Fiber Metal Laminate Sandwich Structures for Aerospace and Automotive Industries. J. Compos. Mater. 2023, 57, 3757–3773. [Google Scholar] [CrossRef]

- Gokulkumar, S.; Thyla, P.R.; ArunRamnath, R.; Karthi, N. Acoustical Analysis and Drilling Process Optimization of Camellia Sinensis/Ananas Comosus/GFRP/Epoxy Composites by TOPSIS for Indoor Applications. J. Nat. Fibers 2020, 18, 2284–2301. [Google Scholar] [CrossRef]

- Alagarsamy, M.; Pitchipoo, P.; Kumar, S. An Investigation of Sound Absorption Characteristics of Cocos nucifera Fiber Composite Using Taguchi Design. Polym. Bull. 2024, 81, 9287–9304. [Google Scholar] [CrossRef]

- Benini, K.C.C.d.C.; Voorwald, H.J.C.; Cioffi, M.O.H.; Rezende, M.C.; Arantes, V. Preparation of Nanocellulose from Imperata brasiliensis Grass Using Taguchi Method. Carbohydr. Polym. 2018, 192, 337–346. [Google Scholar] [CrossRef]

- Murugan, A.; Selvaraj, S.; Sivanantham, G.; Ponnambalam, A. Taguchi Fuzzy Multi-Response Optimization of Process Parameters in Compression Molding of Natural Hybrid Composite. Iran. Polym. J. 2023, 32, 811–828. [Google Scholar] [CrossRef]

- Muhammad, F.; Jalal, S. Optimization of Stirrer Parameters by Taguchi Method for a Better Ceramic Particle Stirring Performance in the Production of Aluminum Alloy Matrix Composite. Cogent Eng. 2023, 10, 2154005. [Google Scholar] [CrossRef]

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM D256; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2010.

- Arivendan, A.; Keerthiveettil Ramakrishnan, S.; Chen, X.; Zhang, Y.F.; Gao, W.; Syamani, F.A.; Thangiah, W.J.J.; Siva, I.; Prabhu, S.R.B. Effect of Moringa Filler Powder in Eichhornia crassipes Fibre-Reinforced Polymer Composites: Advancement in Mechanical Properties and Environmental Sustainability. Polym. Bull. 2024, 81, 16121–16135. [Google Scholar] [CrossRef]

- Barczewski, M.; Mysiukiewicz, O.; Kloziński, A. Complex Modification Effect of Linseed Cake as an Agricultural Waste Filler Used in High Density Polyethylene Composites. Iran. Polym. J. 2018, 27, 677–688. [Google Scholar] [CrossRef]

- Sathesh Babu, M.; Ramamoorthi, R. Development of Lightweight Hybrid Polymeric Composites Reinforced with Cellulose Microfillers Derived from Linseed Oil Cake. Polym. Compos. 2024, 45, 3272–3283. [Google Scholar] [CrossRef]

- Raja, T.; Yuvarajan, D.; Sundaram, V. Impact of Bran Filler Amount on Flax Fiber Reinforced Epoxy Composite-Mechanical and Thermal Properties for Secondary Structural Applications. Int. J. Mech. Eng. 2024, 11, 16–23. [Google Scholar] [CrossRef]

- Arul, S.J.; Jani, S.P.; Adhikary, P.; Lenin, A.H. Effect of Chemical Treatments of Fibre Surface on Mechanical Properties and Wear Rate of Beerakaya (Luffa acutangula) Reinforced Epoxy Polymer Composites. Polym. Bull. 2025, 82, 885–904. [Google Scholar] [CrossRef]

- Rahman, G.M.S.; Mamun, M.A.A.; Aftab, H.; Khan, M.A. Influence of CaCO3 Filler on Physico-Mechanical Properties of Jute Fabric Reinforced Polyester Composites. Eur. J. Adv. Eng. Technol. 2020, 7, 18–25. [Google Scholar]

- Xu, C.; Soudagar, M.E.M.; Kumar Singh, P.; Nasir Bashir, M.; Sang Lee, J.; Rezaul Karim, M.; Seikh, A.H. Effect of Wheat Bran Filler Particulates Nettle Fiber Reinforced Epoxy Matrix Composite—A Novel Material for Thermal Insulation Application. Therm. Sci. Eng. Prog. 2024, 55, 102917. [Google Scholar] [CrossRef]

- Islam, T.; Hossain, S.; Jalil, M.A.; Mujahid, S.M.Z.; Bhoumik, T.K.; Mahmud, R.U. Development of Reinforced Polyester Hybrid Composites Using Varied Ratios of Jack Tree and Jute Fibers with Eggshell Filler. Mech. Compos. Mater. 2024, 60, 817–830. [Google Scholar] [CrossRef]

- Ganesan, K.; Kailasanathan, C.; Sanjay, M.R.; Senthamaraikannan, P.; Saravanakumar, S.S. A New Assessment on Mechanical Properties of Jute Fiber Mat with Egg Shell Powder/Nanoclay-Reinforced Polyester Matrix Composites. J. Nat. Fibers 2020, 17, 482–490. [Google Scholar] [CrossRef]

- Haiter Lenin, A.; Arul, S.J.; Basavaraj, N.M.; Jani, S.P. Influence of Bio Fillers on the Characteristics of Luffa acutangula Fiber Reinforced Polymer Composites and Parametric Optimization Using Taguchi Technique. Sci. Rep. 2024, 14, 30730. [Google Scholar] [CrossRef]

- Sharma, P.; Pradhan, S.; Kishor Sharma, Y.; Sharan Dangayach, G.; Patnaik, A. Experimental Investigation on Physical and Mechanical Properties of Wheat Fiber Filled Epoxy Composites. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Kumar, N.; Walia, R.S.; Angra, S. An Interactive Study on Wear Behaviour and Mechanical Properties of Carbonized Eggshells Filler Loaded Glass-Jute Reinforced Polyester Hybrid Bio-Composites. Int. J. Interact. Des. Manuf. 2022, 16, 913–925. [Google Scholar] [CrossRef]

- Ashok Kumar, B.; Saminathan, R.; Tharwan, M.; Vigneshwaran, M.; Sekhar Babu, P.; Ram, S.; Manoj Kumar, P. Study on the Mechanical Properties of a Hybrid Polymer Composite Using Egg Shell Powder Based Bio-Filler. Mater. Today Proc. 2022, 69, 679–683. [Google Scholar] [CrossRef]

| Factors | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Ash (%) | Moisture Content (%) |

|---|---|---|---|---|---|

| Before 5% NaOH treatment | 37.4 | 18.2 | 23.5 | 6.8 | 11.1 |

| After 5% NaOH treatment | 52.5 | 10.3 | 13.1 | 4.3 | 7.6 |

| Factors | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Ash (%) | Moisture Content (%) |

|---|---|---|---|---|---|

| Vetiver Fibers | |||||

| Before 5% NaOH treatment | 32.3 | 39.8 | 11.2 | 4.3 | 12.4 |

| After 5% NaOH treatment | 48.7 | 22.5 | 6.8 | 2.5 | 8.3 |

| Flax Fibers | |||||

| Before 5% NaOH treatment | 62.6 | 16.1 | 3.4 | 3.9 | 9.3 |

| After 5% NaOH treatment | 73.7 | 9.5 | 2.3 | 1.5 | 6.2 |

| Factors | Flax Fiber (wt.%) | Vetiver Fiber (wt.%) | MFF (wt.%) |

|---|---|---|---|

| Flax fiber mat (wt.%) | 10 | 15 | 20 |

| Unidirectional vetiver fiber (wt.%) | 10 | 15 | 20 |

| Mahogany fruit filler (MFF) (wt.%) | 0 | 5 | 10 |

| Table Trial Run | Sample Code | Flax Fiber (wt.%) | Vetiver Fiber (wt.%) | MFF (wt.%) |

|---|---|---|---|---|

| 1 | FVM1 | 10 | 10 | 0 |

| 2 | FVM2 | 10 | 15 | 10 |

| 3 | FVM3 | 10 | 20 | 5 |

| 4 | FVM4 | 15 | 10 | 5 |

| 5 | FVM5 | 15 | 15 | 0 |

| 6 | FVM6 | 15 | 20 | 10 |

| 7 | FVM7 | 20 | 10 | 10 |

| 8 | FVM8 | 20 | 15 | 5 |

| 9 | FVM9 | 20 | 20 | 0 |

| Composite System | Filler wt.% | Matrix | Fibers | Fillers | Density (g/cm3) | References |

|---|---|---|---|---|---|---|

| Flax/Vetiver + Mahogany Fruit Filler (MFF) | 10 | Epoxy | Flax + Vetiver | MFF | 1.05–1.15 | Present Work |

| Flax + Wheat Bran | 6 | Epoxy | Flax | Wheat Bran | 1.25–1.30 | [52] |

| Luffa Fiber + Wood Dust | 20 | Phenol–formaldehyde | Luffa acutangula | Wood Dust | 1.10–1.30 | [53] |

| Jute Fabric + Eggshell | 10 | Polyester | Jute fabric | Eggshell | 1.20–1.30 | [54] |

| Flax Fiber + Bran Filler | Variable | Epoxy | Flax | Bran | 1.25 | [55] |

| Hybrid Jute + Jack Tree + Eggshell | 10 | Polyester | Jute + Jack tree | Eggshell | 1.25–1.35 | [56] |

| Jute Fiber + Eggshell + Nanoclay | 3–12 | Epoxy | Jute fiber | Nanoclay/Eggshell | 1.25–1.30 | [57] |

| Luffa + Coir + Wood Dust | 10 | Phenolic | Luffa, Coir | Wood Dust | 1.1–1.3 | [58] |

| Wheat Fiber + Bran Filler | 10 | Epoxy | Wheat fiber | Bran | 1.20–1.30 | [59] |

| Glass–Jute Hybrid + Eggshell Ash | 10 | Polyester | Glass + Jute | Eggshell Ash | 1.5–1.6 | [60] |

| Jute + Eggshell | 12 | Epoxy | Jute | Eggshell | 1.45 | [61] |

| Tensile Strength (MPa) | Flexural Strength (MPa) | Impact Strength (kJ/m2) | CCj | OWj | |

|---|---|---|---|---|---|

| Tensile (MPa) | 1 | 0.9735 | 0.944578 | 0.5926 | 0.3195 |

| Flexural (MPa) | 0.9735 | 1 | 0.9623 | 0.6356 | 0.3426 |

| Impact (kJ/m2) | 0.9445 | 0.9623 | 1 | 0.6265 | 0.3377 |

| Criterion | Average Solution (Δj) |

|---|---|

| Tensile Strength (MPa) | 38.364 |

| Flexural Strength (MPa) | 65.352 |

| Impact Strength (kJ/m2) | 7.192 |

| Sample Code | NSPi (Normalized PDA) | NSNi (Normalized NDA) | Øi (Appraisal Score) | Rank |

|---|---|---|---|---|

| FVM1 | 0 | 0 | 0 | 9 |

| FVM2 | 0 | 0.5897 | 0.2949 | 7 |

| FVM3 | 0.6232 | 1 | 0.8116 | 4 |

| FVM4 | 0 | 0.3967 | 0.1983 | 8 |

| FVM5 | 0.1489 | 1 | 0.5744 | 5 |

| FVM6 | 0.6877 | 1 | 0.8438 | 2 |

| FVM7 | 0.1921 | 0.8127 | 0.5024 | 6 |

| FVM8 | 0.6345 | 1 | 0.8173 | 3 |

| FVM9 | 1 | 1 | 1 | 1 |

| Ri | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| FVM1 | FVM2 | FVM3 | FVM4 | FVM5 | FVM6 | FVM7 | FVM8 | FVM9 | |

| Actual Condition | 0 | 0.254 | 0.632 | 0.143 | 0.450 | 0.727 | 0.392 | 0.713 | 1 |

| S1 | 0 | 0.255 | 0.634 | 0.144 | 0.447 | 0.727 | 0.396 | 0.709 | 1 |

| S2 | 0 | 0.254 | 0.632 | 0.143 | 0.447 | 0.725 | 0.391 | 0.711 | 1 |

| Ranking | FVM9 > FVM 6 > FVM 8 > FVM 3 > FVM 5 > FVM 7 > FVM 2 > FVM 4 > FVM 1 | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navin, M.; Ramakrishnan, T.; Balaji, D.; Bhuvaneswari, V. CRITIC–EDAS Approach for Evaluating Mechanical Properties of Flax/Vetiver/MFF Hybrid Composites. Polymers 2025, 17, 1790. https://doi.org/10.3390/polym17131790

Navin M, Ramakrishnan T, Balaji D, Bhuvaneswari V. CRITIC–EDAS Approach for Evaluating Mechanical Properties of Flax/Vetiver/MFF Hybrid Composites. Polymers. 2025; 17(13):1790. https://doi.org/10.3390/polym17131790

Chicago/Turabian StyleNavin, M., Thirumalaisamy Ramakrishnan, Devarajan Balaji, and Venkateswaran Bhuvaneswari. 2025. "CRITIC–EDAS Approach for Evaluating Mechanical Properties of Flax/Vetiver/MFF Hybrid Composites" Polymers 17, no. 13: 1790. https://doi.org/10.3390/polym17131790

APA StyleNavin, M., Ramakrishnan, T., Balaji, D., & Bhuvaneswari, V. (2025). CRITIC–EDAS Approach for Evaluating Mechanical Properties of Flax/Vetiver/MFF Hybrid Composites. Polymers, 17(13), 1790. https://doi.org/10.3390/polym17131790