Circular Shear Printing of Spiral-Oriented CF-PP Components for Enhanced Mechanical Performance and Warp Mitigation

Abstract

1. Introduction

2. Experiment

2.1. Materials

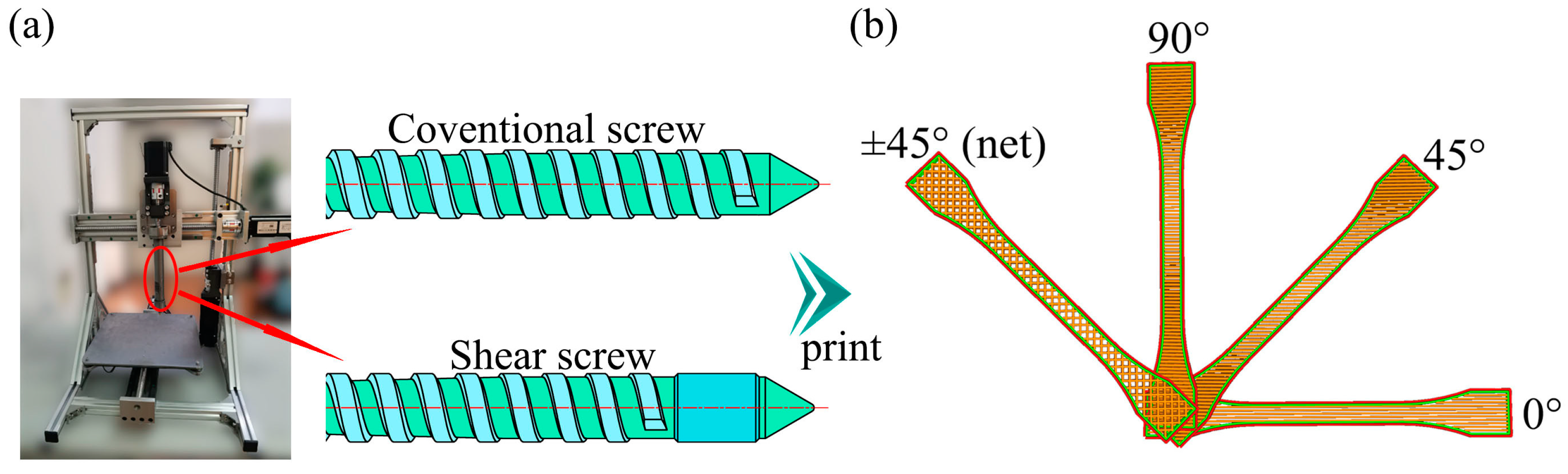

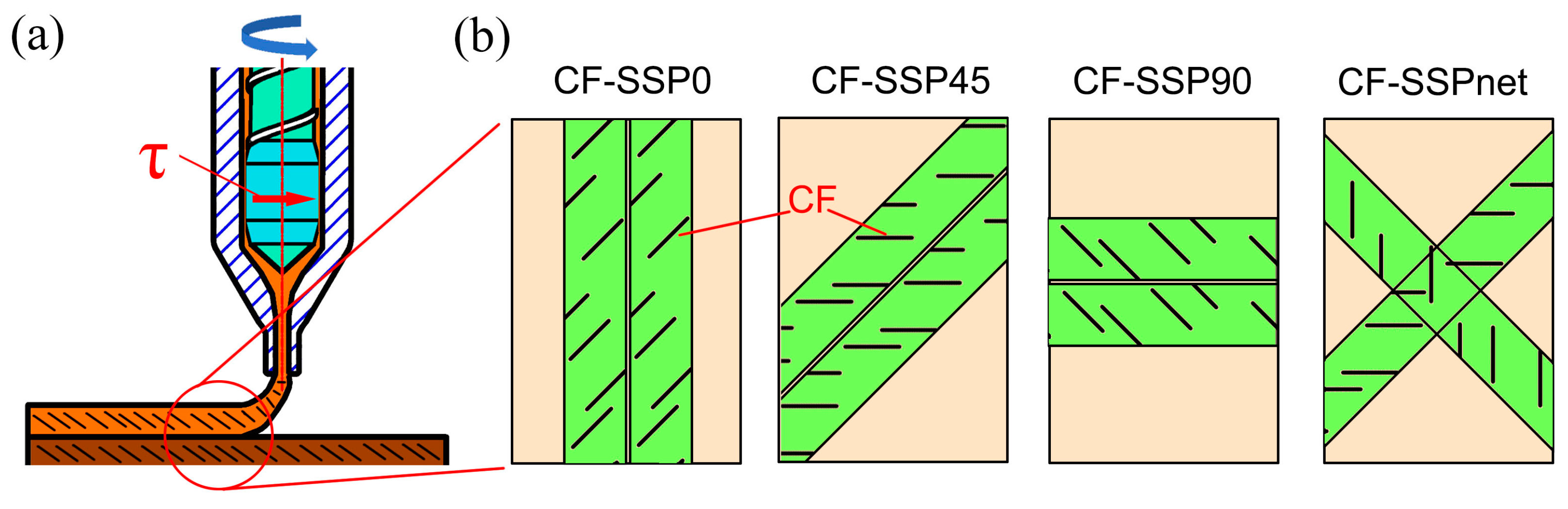

2.2. Sample Preparation

2.3. Mechanical Properties

2.4. Crystal Structure

2.5. Morphology

3. Results and Discussion

3.1. Crystal Structure

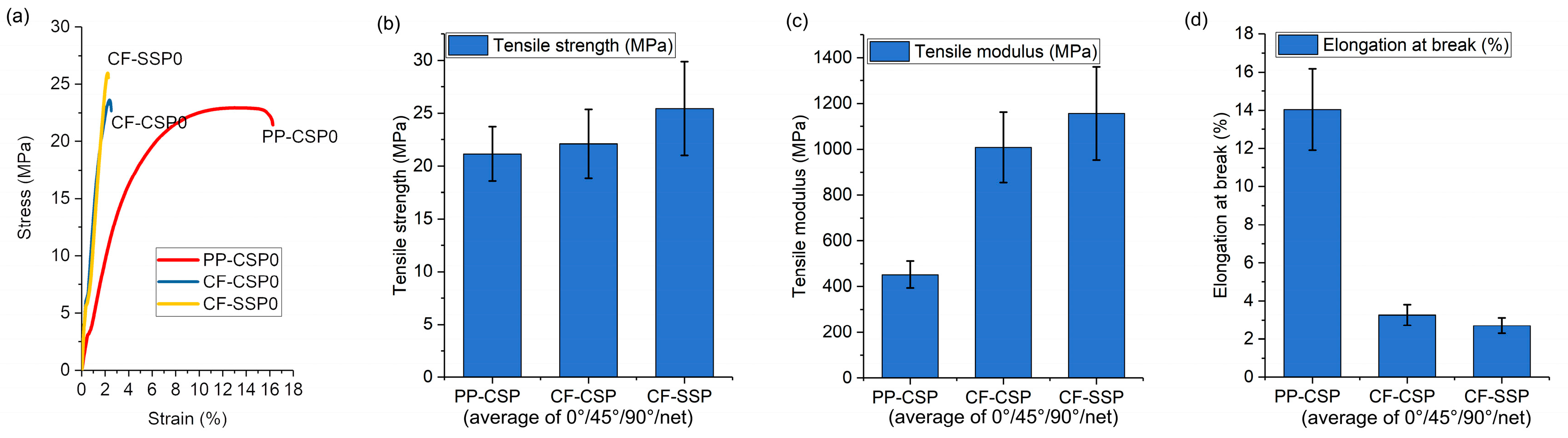

3.2. Effects of High Shear and CF Addition on Mechanical Properties

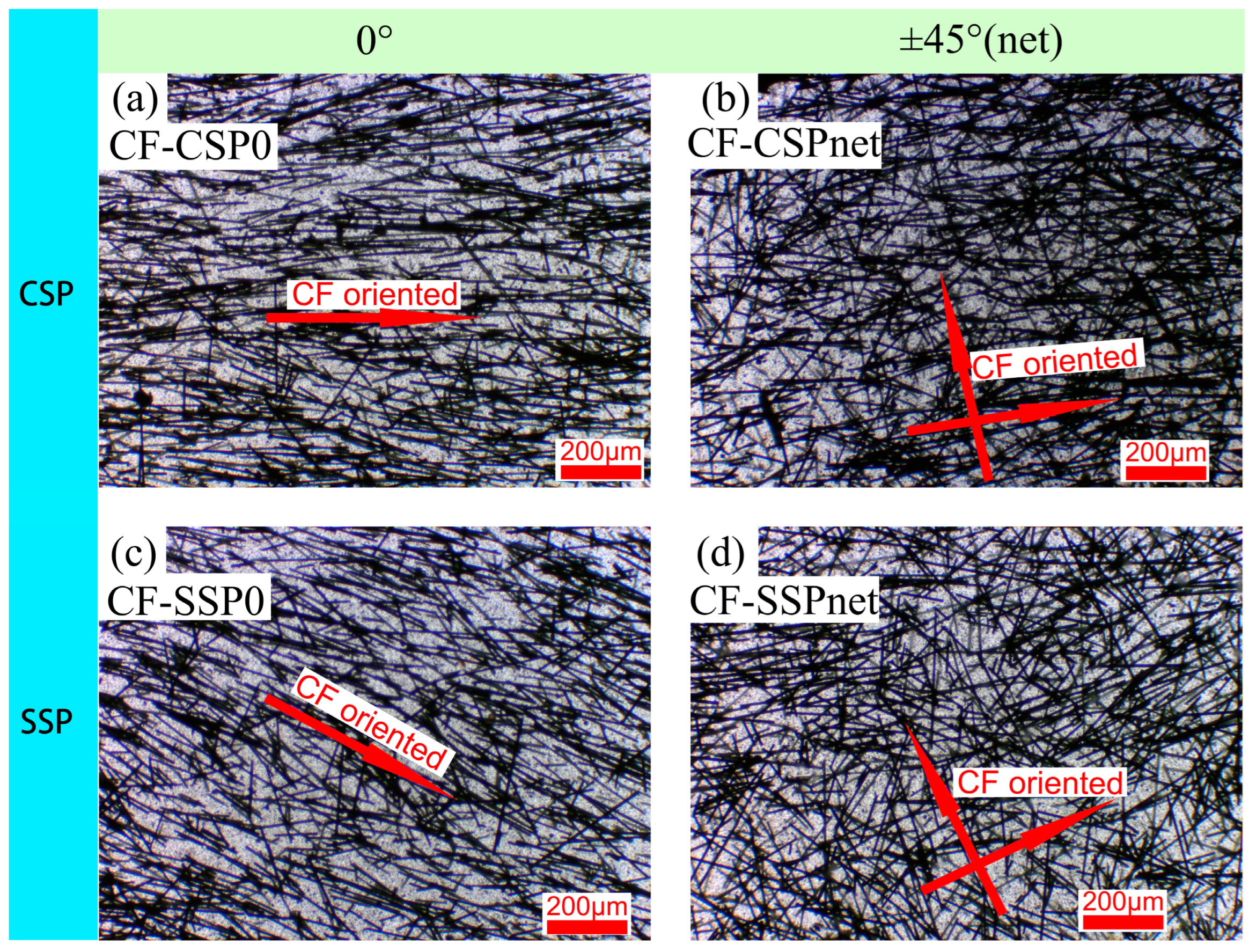

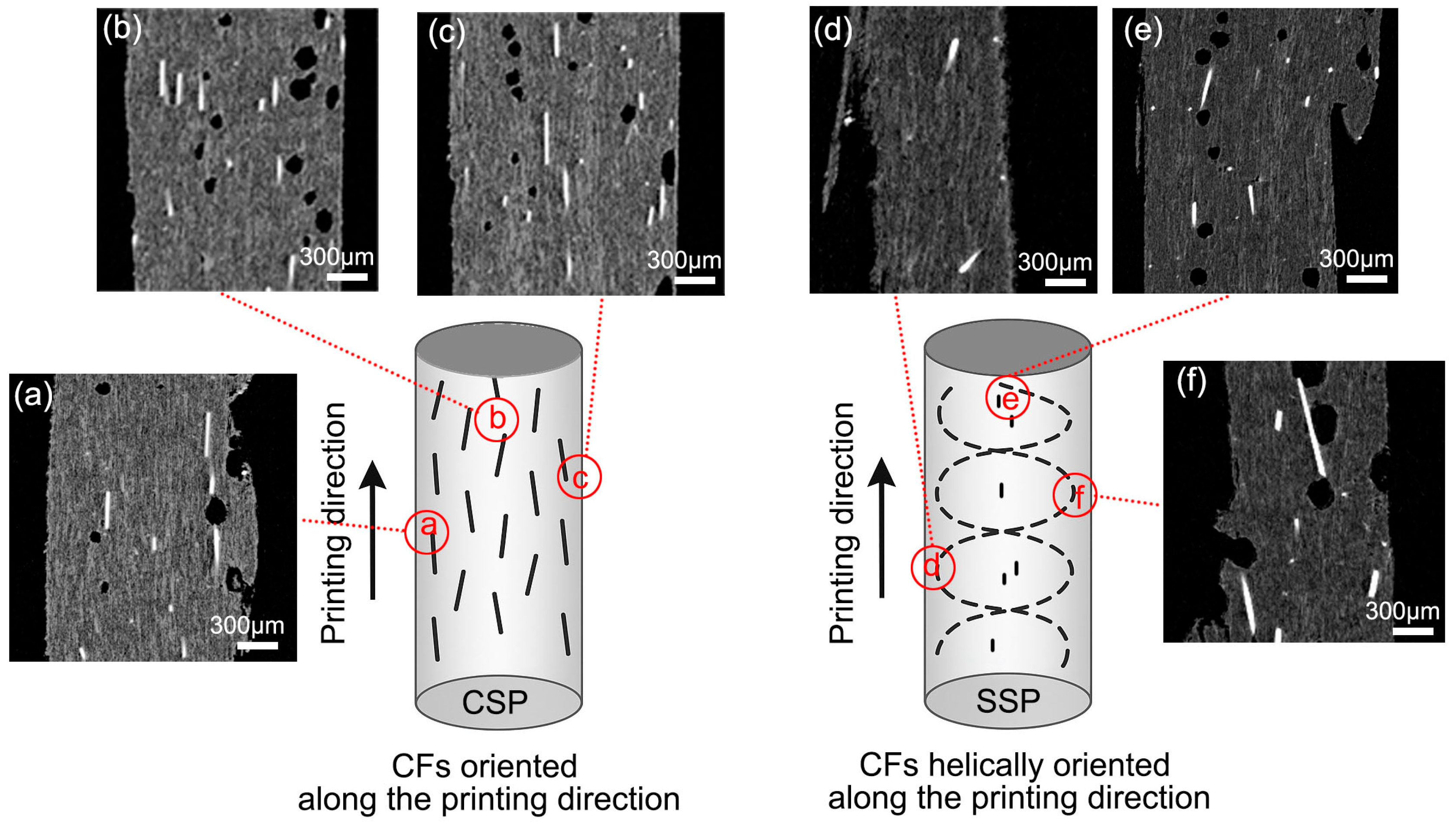

3.3. Effects of CF Orientation on Mechanical Properties

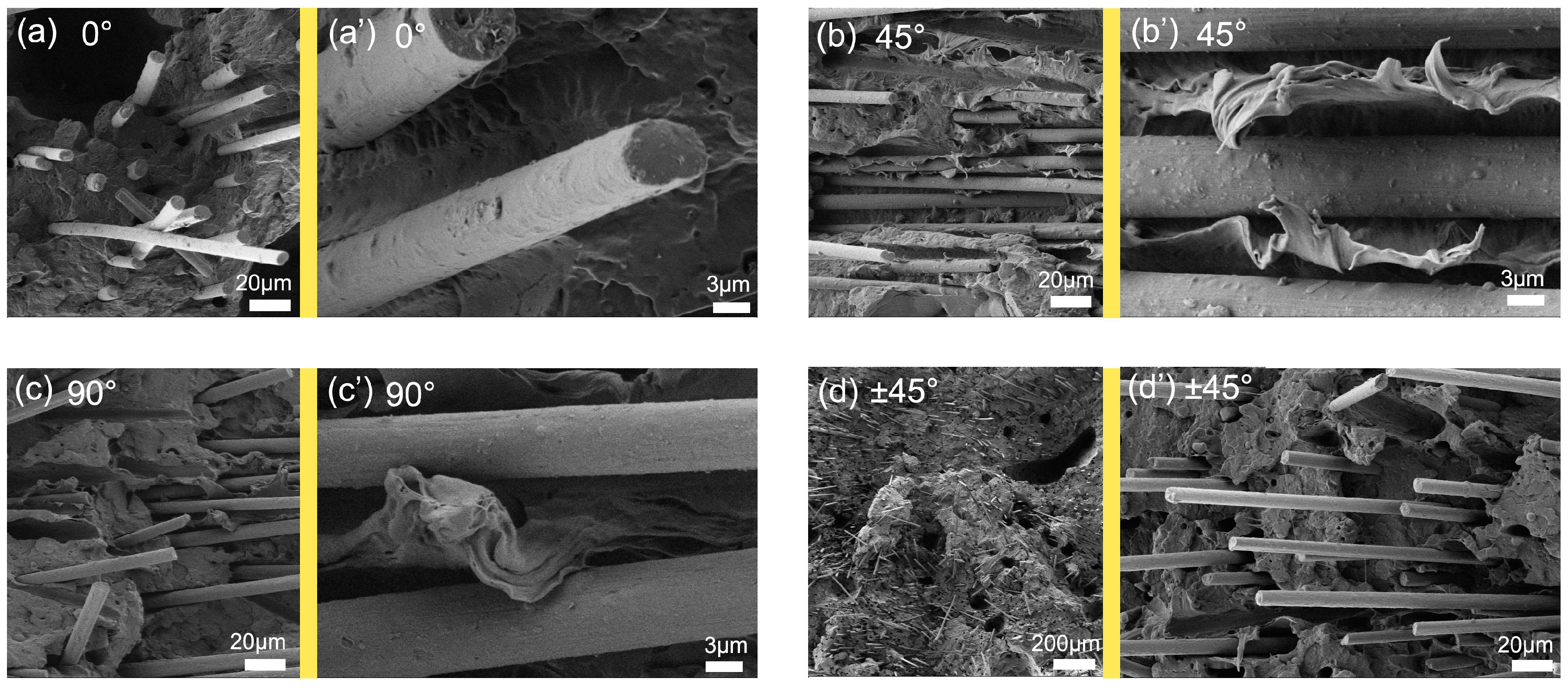

3.4. Effects of CF Orientation on Fracture Surface

3.5. Reduction in Warpage by CF Helical Orientation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Jiang, Y.; Wu, J.; Leng, J.; Cardon, L.; Zhang, J. Reinforced and toughened PP/PS composites prepared by Fused Filament Fabrication (FFF) with in-situ microfibril and shish-kebab structure. Polymer 2020, 186, 121971. [Google Scholar] [CrossRef]

- Li, J.; Leng, J.; Jiang, Y.; Zhang, J. Experimental characterization of 3D printed PP/h-BN thermally conductive composites with highly oriented h-BN and the effects of filler size. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106586. [Google Scholar] [CrossRef]

- Netto, J.M.J.; Idogava, H.T.; Santos, L.E.F.; Silveira, Z.D.C.; Romio, P.; Alves, J.L. Screw-assisted 3D printing with granulated materials: A systematic review. Int. J. Adv. Manuf. Technol. 2021, 115, 2711–2727. [Google Scholar] [CrossRef]

- Leng, J.; Wu, J.; Chen, N.; Xu, X.; Zhang, J. The development of a conical screw-based extrusion deposition system and its application in fused deposition modeling with thermoplastic polyurethane. Rapid Prototyp. J. 2020, 26, 409–417. [Google Scholar] [CrossRef]

- Reddy, B.; Reddy, N.; Ghosh, A. Fused deposition modelling using direct extrusion. Virtual Phys. Prototyp. 2007, 2, 51–60. [Google Scholar] [CrossRef]

- Bai, H.; Qin, W.; Jia, S.; Ren, L.; An, Y.; Bao, J. A new type of 3D printing molding equipment: Overall structural design and the numerical simulation for the flow field characteristics of its screw module. Int. J. Precis. Eng. Manuf. 2021, 22, 1639–1656. [Google Scholar] [CrossRef]

- Netto, J.M.J.; Sarout, A.I.; Santos, A.L.G.; de Almeida Lucas, A.; Chinelatto, M.A.; Alves, J.L.; Gaspar-Cunha, A.; Covas, J.A.; de Castro Silveira, Z. Design and validation of an innovative 3D printer containing a co-rotating twin screw extrusion unit. Addit. Manuf. 2022, 59, 103192. [Google Scholar]

- Zhang, P.; Wang, Z.; Li, J.; Li, X.; Cheng, L. From materials to devices using fused deposition modeling: A state-of-art review. Nanotechnol. Rev. 2020, 9, 1594–1609. [Google Scholar] [CrossRef]

- Mi, D.; Zhang, Y.; Bai, H.; Zhao, Z.; Jia, S. Effect of shear element and process in screw-based extrusion printer of polypropylene/carbon nanotubes composite. Polym. Compos. 2025. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, L.; Fang, Y.; Sun, W. Design, characterization, and 3D printing of cardiovascular stents with zero Poisson’s ratio in longitudinal deformation. Engineering 2021, 7, 979–990. [Google Scholar] [CrossRef]

- Little, H.A.; Tanikella, N.G.; Reich, M.J.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Towards distributed recycling with additive manufacturing of PET flake feedstocks. Materials 2020, 13, 4273. [Google Scholar] [CrossRef] [PubMed]

- Carneiro, O.S.; Silva, A.; Gomes, R. Fused deposition modeling with polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Jin, M.; Neuber, C.; Schmidt, H.-W. Tailoring polypropylene for extrusion-based additive manufacturing. Addit. Manuf. 2020, 33, 101101. [Google Scholar] [CrossRef]

- Austermann, J.; Kuscera, R.; Wipperfürth, J.; Hopmann, C.; Dahlmann, R. Influence of material modification and fillers on the dimensional stability and warpage of polypropylene in screw-extrusion-based large area additive manufacturing. Polym. Eng. Sci. 2023, 63, 1598–1612. [Google Scholar] [CrossRef]

- Wu, T.; Huan, X.; Jia, X.; Sui, G.; Wu, L.; Cai, Q.; Yang, X. 3D printing nanocomposites with enhanced mechanical property and excellent electromagnetic wave absorption capability via the introduction of ZIF-derivative modified carbon fibers. Compos. Part B Eng. 2022, 233, 109658. [Google Scholar] [CrossRef]

- Rahim, T.N.A.T.; Abdullah, A.M.; Akil, H.M. Recent developments in fused deposition modeling-based 3D printing of polymers and their composites. Polym. Rev. 2019, 59, 589–624. [Google Scholar] [CrossRef]

- Omgba, A.D.B.; Zhang, L.; Martoïa, F.; Boller, E.; Pelletreau, S.; Dimanche, M.; Joffre, T.; Dumont, P.J. Towards in situ and real time characterization of flow-induced phenomena during material extrusion of polymer composites using 3D X-ray microtomography. Addit. Manuf. 2025, 100, 104683. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S.; Huang, C.; Shi, Z.; Ma, Y.; Yao, P. Preparation of short CF/GF reinforced PEEK composite filaments and their comprehensive properties evaluation for FDM-3D printing. Compos. Part B Eng. 2020, 198, 108175. [Google Scholar] [CrossRef]

- Raney, J.R.; Compton, B.G.; Mueller, J.; Ober, T.J.; Shea, K.; Lewis, J.A. Rotational 3D printing of damage-tolerant composites with programmable mechanics. Proc. Natl. Acad. Sci. USA 2018, 115, 1198–1203. [Google Scholar] [CrossRef]

- Tseng, J.-W.; Liu, C.-Y.; Yen, Y.-K.; Belkner, J.; Bremicker, T.; Liu, B.H.; Sun, T.-J.; Wang, A.-B. Screw extrusion-based additive manufacturing of PEEK. Mater. Des. 2018, 140, 209–221. [Google Scholar] [CrossRef]

- Yu, N.; Sun, X.; Wang, Z.; Zhang, D.; Li, J. Effects of auxiliary heat on warpage and mechanical properties in carbon fiber/ABS composite manufactured by fused deposition modeling. Mater. Des. 2020, 195, 108978. [Google Scholar] [CrossRef]

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- Du, H.; Zhang, Y.; Liu, H.; Liu, K.; Zhang, J. Influence of phase morphology and crystalline structure on the toughness of rubber-toughened isotatic polypropylene blends. Polymer 2014, 55, 5001–5012. [Google Scholar] [CrossRef]

- Pantani, R.; Coccorullo, I.; Volpe, V.; Titomanlio, G. Shear-induced nucleation and growth in isotactic polypropylene. Macromolecules 2010, 43, 9030–9038. [Google Scholar] [CrossRef]

- Yu, K.; Zhang, J.; Liu, G.; Yao, J.; Liu, H.; Chen, C. Inverse effects of cooling rates on the interfacial shear strength of carbon Fiber/PEEK composites with and without presence of transcrystal layers. Polymer 2024, 302, 127067. [Google Scholar] [CrossRef]

- Bogoeva-Gaceva, G.; Janevski, A.; Mader, E. Nucleation activity of glass fibers towards iPP evaluated by DSC and polarizing light microscopy. Polymer 2001, 42, 4409–4416. [Google Scholar] [CrossRef]

- Tadmor, Z.; Gogos, C.G. Principles of Polymer Processing; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Han, R.; Yang, Q.; Wang, Z.; Cao, D.; Li, G.; Zheng, L.; Peng, B.; Gao, X.; Chen, G. 3D printing-enabled self-assembling β-nucleating agent alignment: Structural evolution and mechanical performances. Polymer 2022, 246, 124736. [Google Scholar] [CrossRef]

- Yan, J.; Demirci, E.; Ganesan, A.; Gleadall, A. Extrusion width critically affects fibre orientation in short fibre reinforced material extrusion additive manufacturing. Addit. Manuf. 2022, 49, 102496. [Google Scholar] [CrossRef]

- Rauwendaal, C. Polymer Extrusion; Carl Hanser Verlag GmbH Co KG: Munich, Germany, 2014. [Google Scholar]

- Yu, N.; Zhang, Q.; Wang, Z.; Zhang, D.; Li, J. Effects of a rotary shear field on the interlayer bond and mechanical properties of carbon-fiber-reinforced plastic composites fabricated using fused deposition modeling. J. Manuf. Process. 2022, 83, 172–179. [Google Scholar] [CrossRef]

- Feraboli, P.; Peitso, E.; Cleveland, T.; Stickler, P.B. Modulus measurement for prepreg-based discontinuous carbon fiber/epoxy systems. J. Compos. Mater. 2009, 43, 1947–1965. [Google Scholar] [CrossRef]

- Yavas, D.; Zhang, Z.; Liu, Q.; Wu, D. Fracture behavior of 3D printed carbon fiber-reinforced polymer composites. Compos. Sci. Technol. 2021, 208, 108741. [Google Scholar] [CrossRef]

- Winter, K.; Wilfert, J.; Häupler, B.; Erlmann, J.; Altstädt, V.J.M.M. Engineering, Large scale 3D printing: Influence of fillers on warp deformation and on mechanical properties of printed polypropylene components. Macromol. Mater. Eng. 2022, 307, 2100528. [Google Scholar] [CrossRef]

| Sample | Printer | PP | CF | Printing Angle |

|---|---|---|---|---|

| PP-CSP0/45/90/net | Conventional screw printer | 100% | 0 | 0/45/90/net |

| CF-CSP0/45/90/net | Conventional screw printer | 85% | 15% | 0/45/90/net |

| CF-SSP0/45/90/net | Shear screw printer | 85% | 15% | 0/45/90/net |

| Sample | Tm onset (℃) | Tm (℃) | Tc onset (℃) | Tc (℃) | Xc |

|---|---|---|---|---|---|

| PP-CSP0 | 154.2 | 167.2 | 117.1 | 112.4 | 39.6% |

| CF-CSP0 | 156.7 | 166.2 | 124.9 | 124.9 | 65.2% |

| CF-SSP0 | 156.4 | 167.1 | 126.5 | 121.4 | 67.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mi, D.; Yang, T.; Jiang, J.; Bai, H.; Jia, S. Circular Shear Printing of Spiral-Oriented CF-PP Components for Enhanced Mechanical Performance and Warp Mitigation. Polymers 2025, 17, 1739. https://doi.org/10.3390/polym17131739

Mi D, Yang T, Jiang J, Bai H, Jia S. Circular Shear Printing of Spiral-Oriented CF-PP Components for Enhanced Mechanical Performance and Warp Mitigation. Polymers. 2025; 17(13):1739. https://doi.org/10.3390/polym17131739

Chicago/Turabian StyleMi, Dashan, Tao Yang, Jinghua Jiang, Haiqing Bai, and Shikui Jia. 2025. "Circular Shear Printing of Spiral-Oriented CF-PP Components for Enhanced Mechanical Performance and Warp Mitigation" Polymers 17, no. 13: 1739. https://doi.org/10.3390/polym17131739

APA StyleMi, D., Yang, T., Jiang, J., Bai, H., & Jia, S. (2025). Circular Shear Printing of Spiral-Oriented CF-PP Components for Enhanced Mechanical Performance and Warp Mitigation. Polymers, 17(13), 1739. https://doi.org/10.3390/polym17131739