Development of Silylated Lignin-Based Intumescent Flame Retardants for Biodegradable Plastics

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

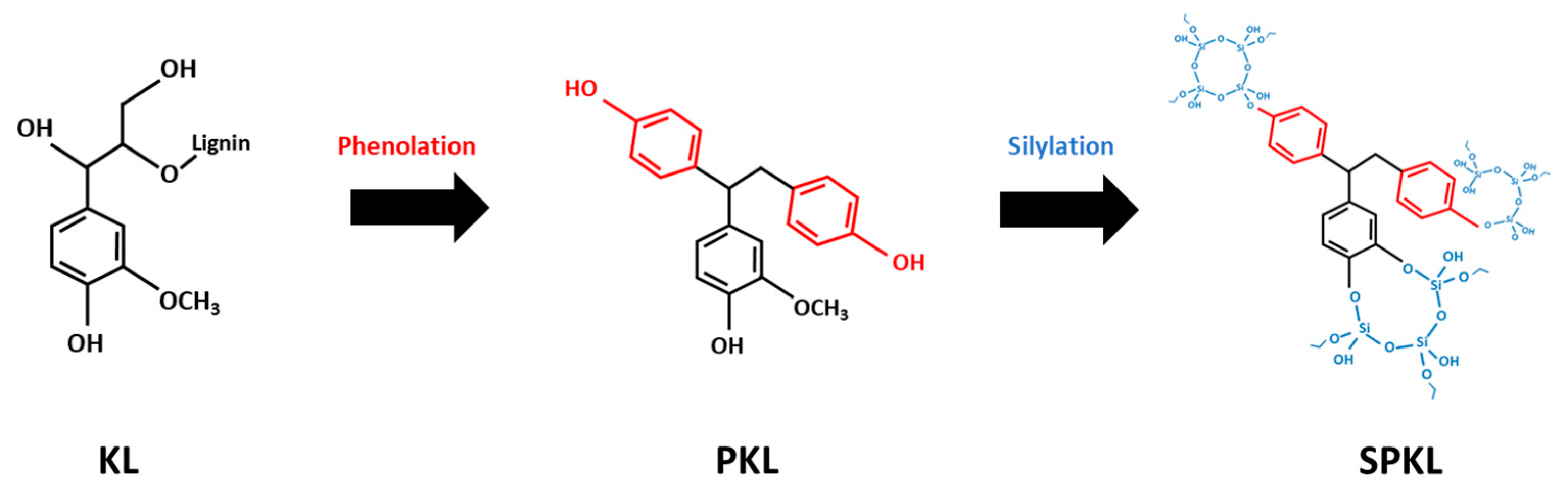

2.2. Phenolation of Kraft Lignin (PKL)

2.3. Silylation of Phenolated Kraft Lignin (SPKL)

2.4. Preparation of PLA, APP, and Modified KL Composites with Intumescent Flame Retardancy

2.5. Characterization of Modified Lignin and Composites

3. Results and Discussion

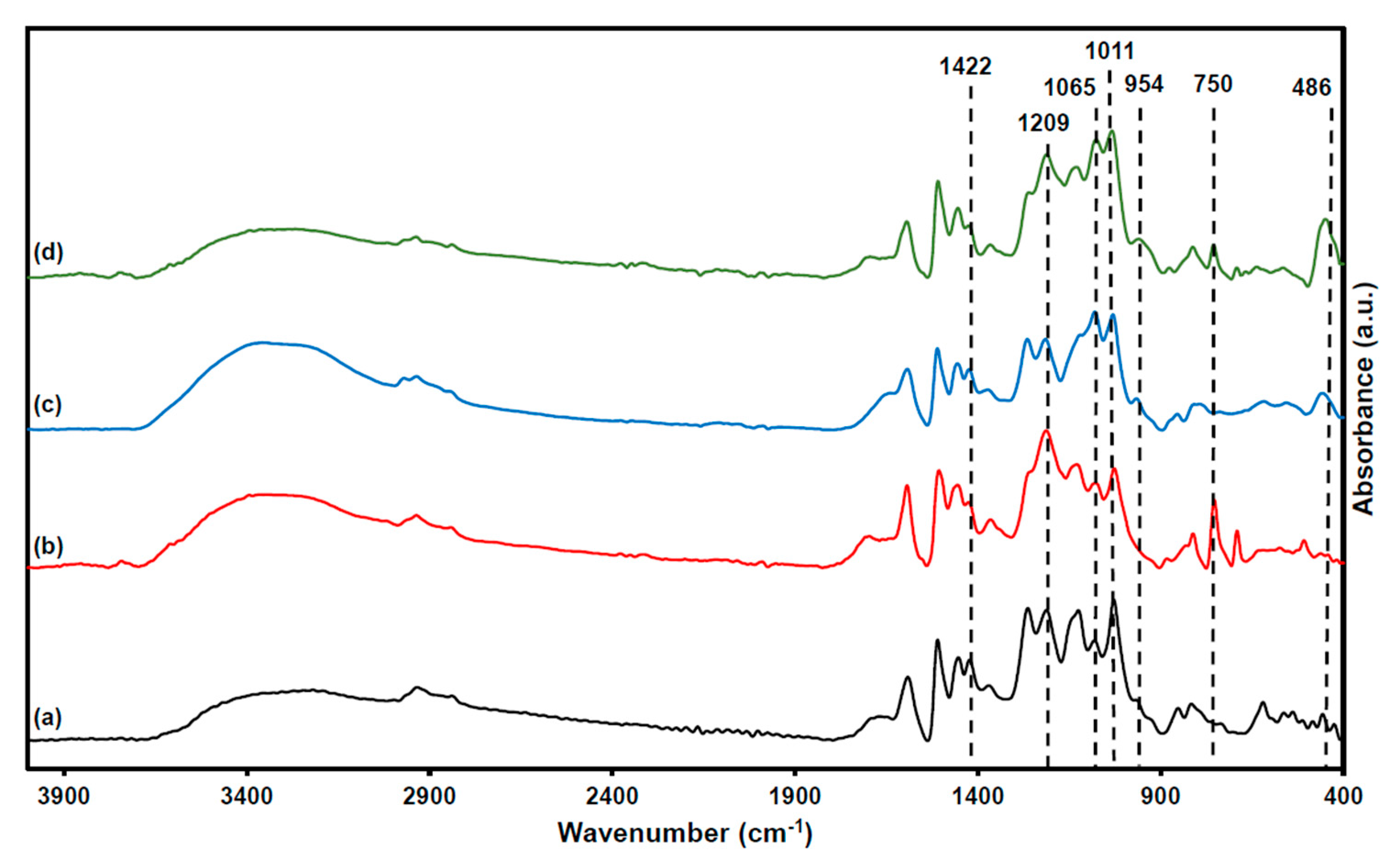

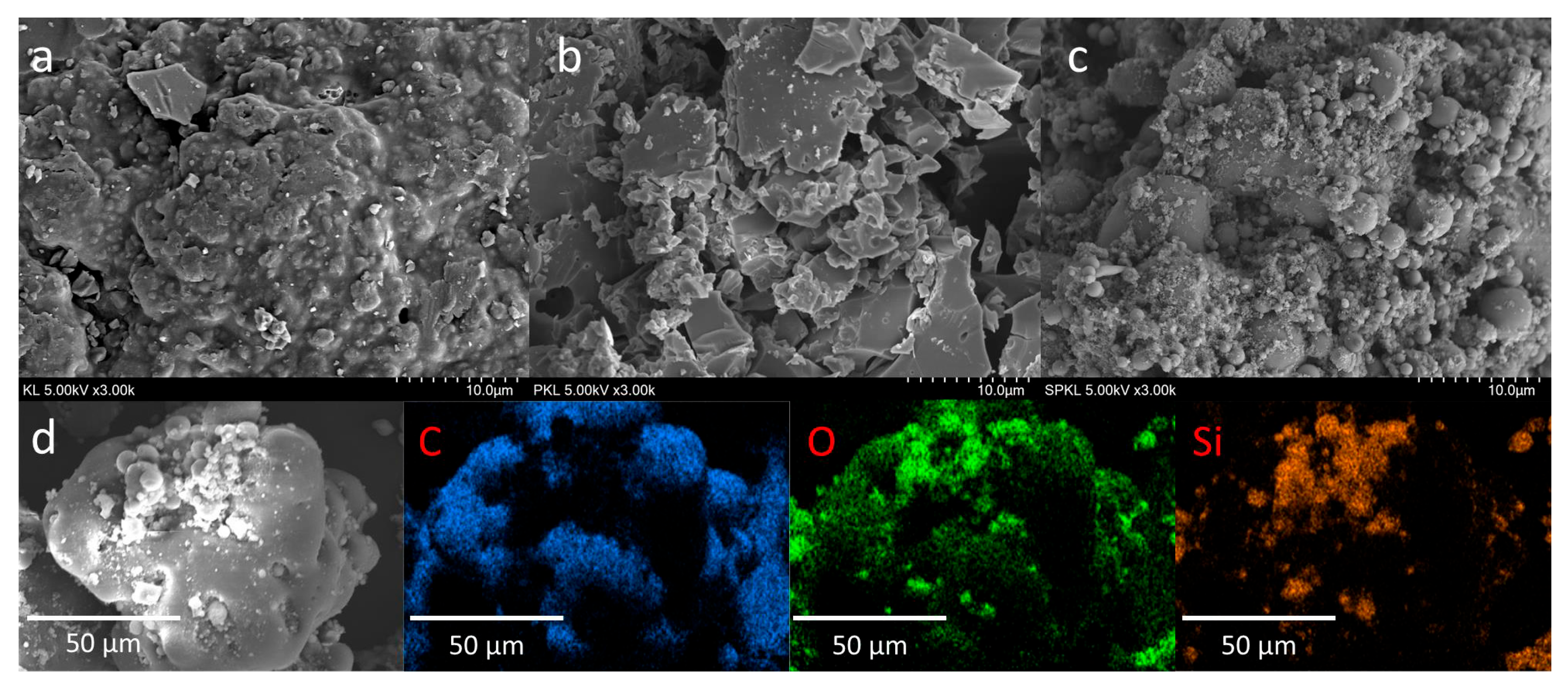

3.1. Chemical Characterization of Modified KL

3.2. Evaluation of Flame Retardancy of PLA Composites

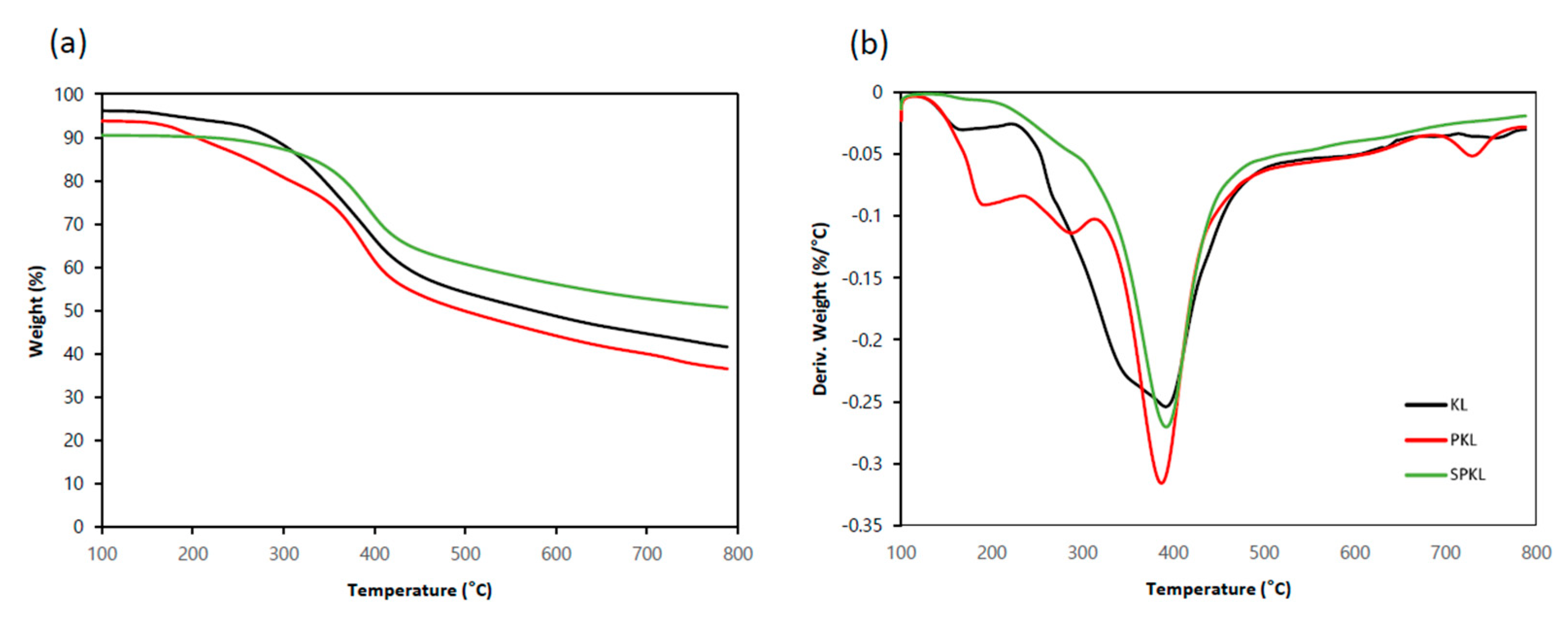

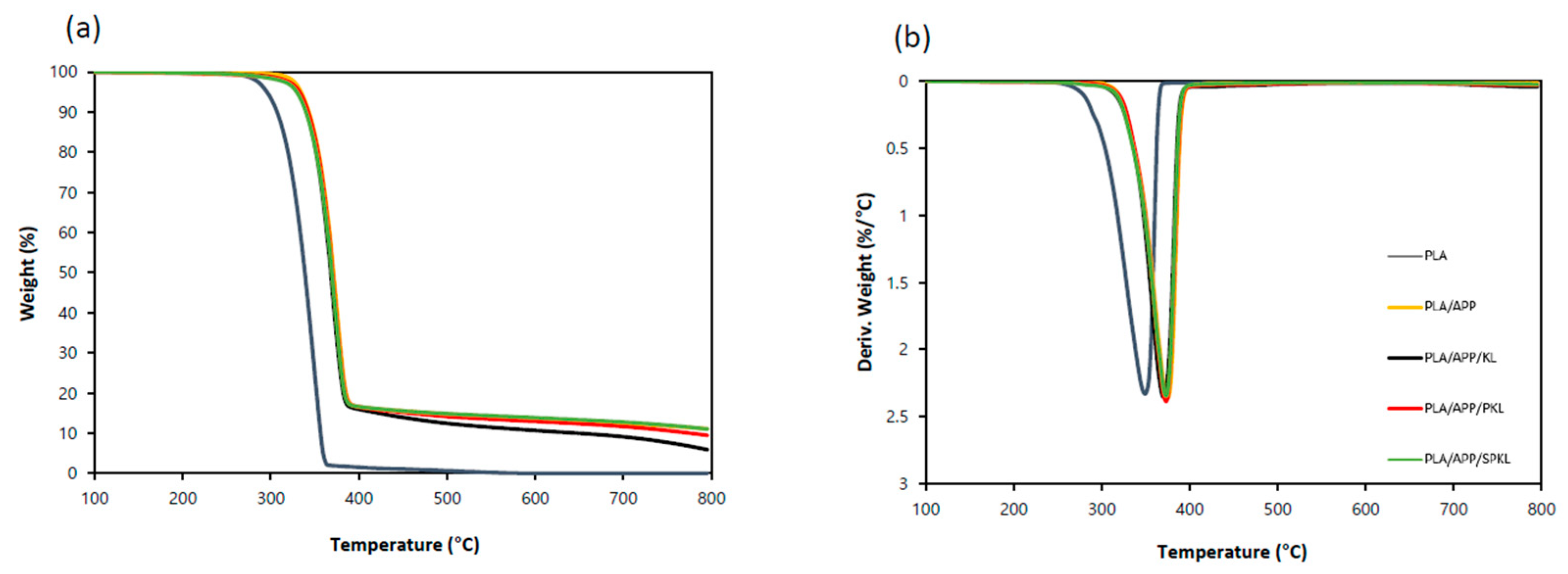

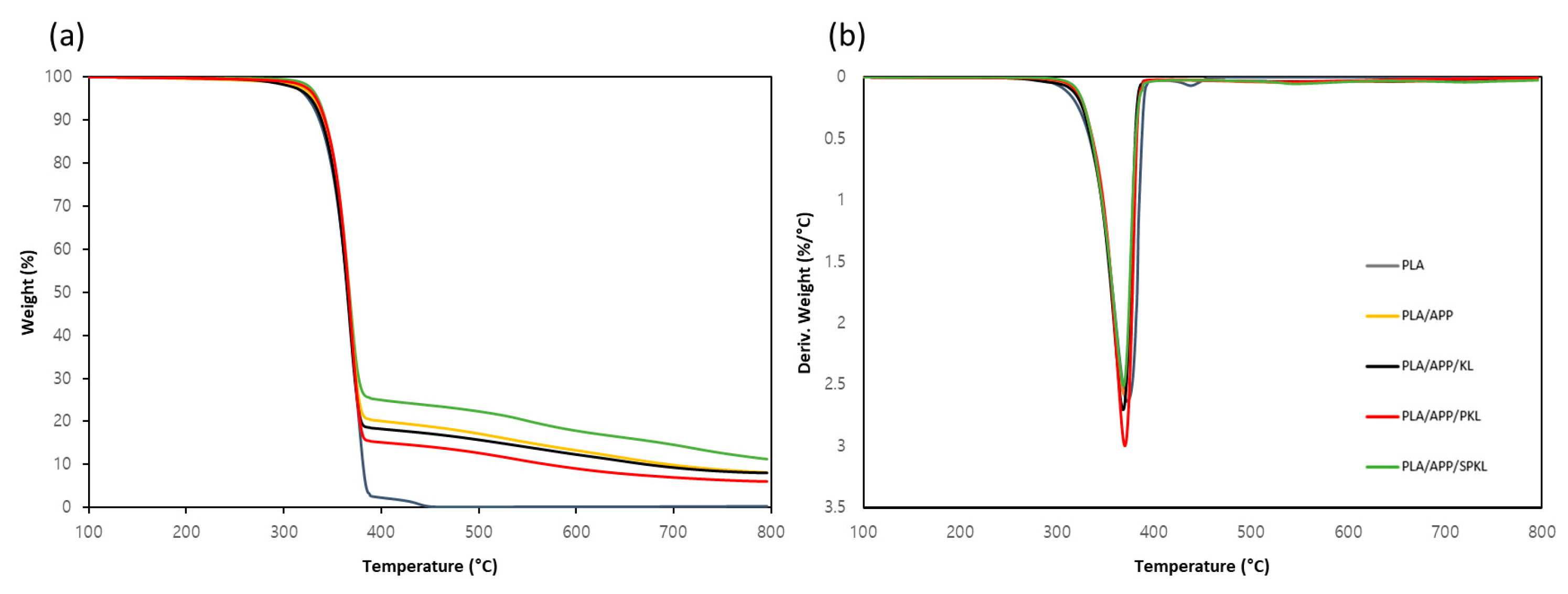

3.3. Thermal Stability of Lignin and PLA Composites

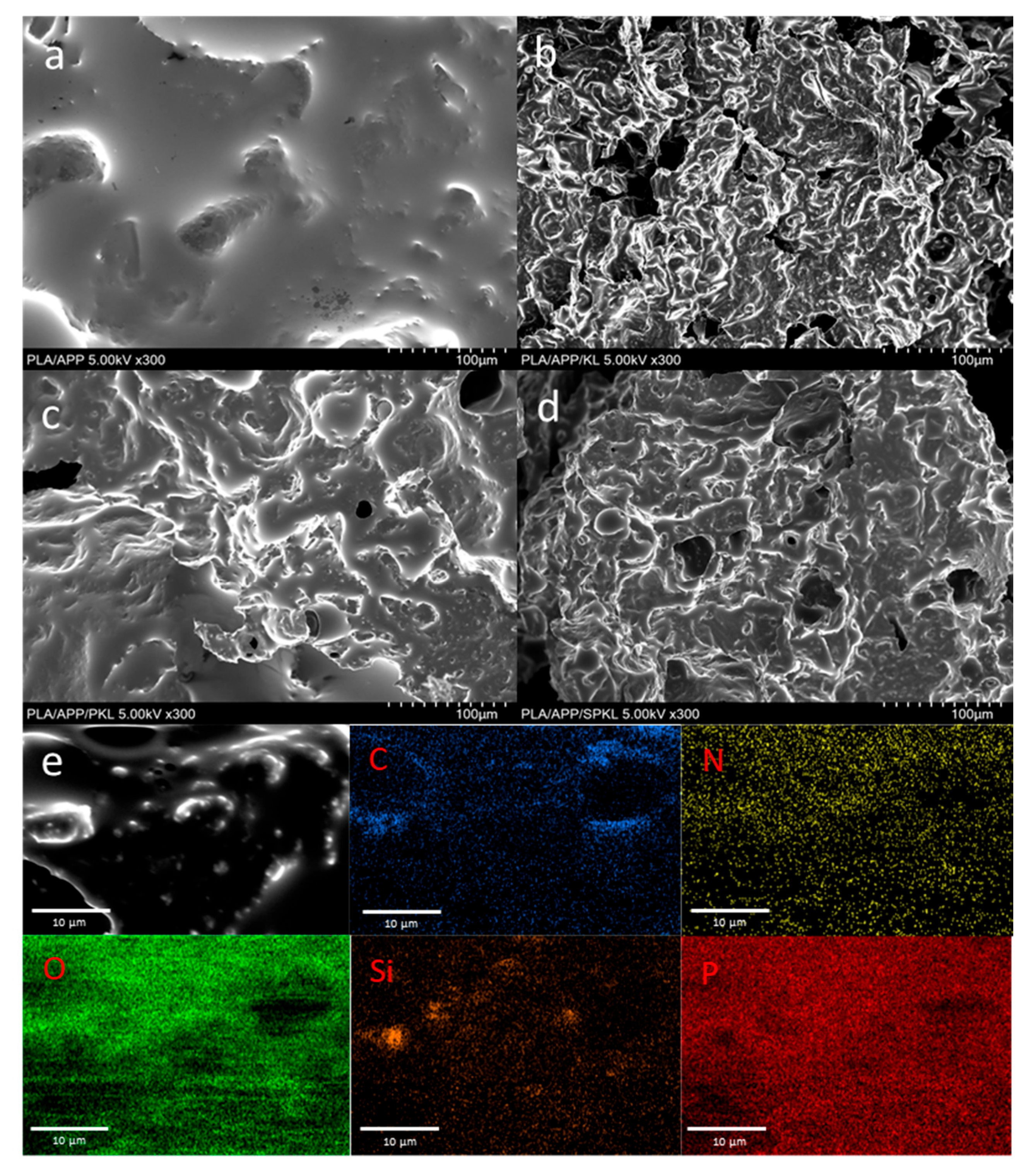

3.4. Analysis of Residual Char

3.5. Mechanical Properties of PLA Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, L.; Wang, Y.Z. A review on flame retardant technology in China. Part I: Development of flame retardants. Polym. Adv. Technol. 2010, 21, 1–26. [Google Scholar] [CrossRef]

- Liu, L.; Yao, M.; Zhang, H.; Zhang, Y.; Feng, J.; Fang, Z.; Song, P. Aqueous self-assembly of bio-based flame retardants for fire-retardant, smoke-suppressive, and toughened polylactic acid. ACS Sustain. Chem. Eng. 2022, 10, 16313–16323. [Google Scholar] [CrossRef]

- Zhu, T.; Guo, J.; Fei, B.; Feng, Z.; Gu, X.; Li, H.; Sun, J.; Zhang, S. Preparation of methacrylic acid modified microcrystalline cellulose and their applications in polylactic acid: Flame retardancy, mechanical properties, thermal stability and crystallization behavior. Cellulose 2020, 27, 2309–2323. [Google Scholar] [CrossRef]

- Chen, C.; Gu, X.; Jin, X.; Sun, J.; Zhang, S. The effect of chitosan on the flammability and thermal stability of polylactic acid/ammonium polyphosphate biocomposites. Carbohydr. Polym. 2017, 157, 1586–1593. [Google Scholar] [CrossRef] [PubMed]

- Yiga, V.A.; Lubwama, M.; Pagel, S.; Benz, J.; Olupot, P.W.; Bonten, C. Flame retardancy and thermal stability of agricultural residue fiber-reinforced polylactic acid: A Review. Polym. Compos. 2021, 42, 15–44. [Google Scholar] [CrossRef]

- Shi, X.; Liao, F.; Ju, Y.; Dai, X.; Cao, Y.; Li, J.; Wang, X. Improving the flame retardance and melt dripping of poly (lactic acid) with a novel polymeric flame retardant of high thermal stability. Fire Mater. 2017, 41, 362–374. [Google Scholar] [CrossRef]

- Wang, F.; Wu, N.; Wang, M.; Deng, S.; Jia, H. Synthesis of phenylphosphorylated microcrystal cellulose biobased flame retardants and its flame-retardant modification on PLA biomaterials. Polym. Degrad. Stab. 2024, 227, 110843. [Google Scholar] [CrossRef]

- Shi, X.; Peng, X.; Zhu, J.; Lin, G.; Kuang, T. Synthesis of DOPO-HQ-functionalized graphene oxide as a novel and efficient flame retardant and its application on polylactic acid: Thermal property, flame retardancy, and mechanical performance. J. Colloid Interface Sci. 2018, 524, 267–278. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Wang, X.; Fei, B.; Li, H.; Gu, X.; Sun, J.; Zhang, S. Preparation of phytic acid-based green intumescent flame retardant and its application in PLA nonwovens. Polym. Adv. Technol. 2021, 32, 3039–3049. [Google Scholar] [CrossRef]

- Ma, X.; Wu, N.; Liu, P.; Cui, H. Fabrication of highly efficient phenylphosphorylated chitosan bio-based flame retardants for flammable PLA biomaterial. Carbohydr. Polym. 2022, 287, 119317. [Google Scholar] [CrossRef]

- Yang, H.; Yu, B.; Xu, X.; Bourbigot, S.; Wang, H.; Song, P. Lignin-derived bio-based flame retardants toward high-performance sustainable polymeric materials. Green Chem. 2020, 22, 2129–2161. [Google Scholar] [CrossRef]

- Meng, H.; Wen, M.; Shi, J.; Liang, Y.; Jian, H. Biomass flame retardants with application of cellulose, lignin, and hemicellulose from wood resources and their flame retardant technologies in related materials: A review. Sustain. Chem. Pharm. 2024, 42, 101816. [Google Scholar] [CrossRef]

- Jiang, X.; Liu, J.; Du, X.; Hu, Z.; Chang, H.-m.; Jameel, H. Phenolation to improve lignin reactivity toward thermosets application. ACS Sustain. Chem. Eng. 2018, 6, 5504–5512. [Google Scholar] [CrossRef]

- Thébault, M.; Kutuzova, L.; Jury, S.; Eicher, I.; Zikulnig-Rusch, E.; Kandelbauer, A. Effect of phenolation, lignin-type and degree of substitution on the properties of lignin-modified phenol-formaldehyde impregnation resins: Molecular weight distribution, wetting behavior, rheological properties and thermal curing profiles. J. Renew. Mater. 2020, 8, 603–630. [Google Scholar]

- Song, Y.; Zong, X.; Wang, N.; Yan, N.; Shan, X.; Li, J. Preparation of γ-Divinyl-3-Aminopropyltriethoxysilane modified lignin and its application in flame retardant poly (lactic acid). Materials 2018, 11, 1505. [Google Scholar] [CrossRef] [PubMed]

- Reti, C.; Casetta, M.; Duquesne, S.; Bourbigot, S.; Delobel, R. Flammability properties of intumescent PLA including starch and lignin. Polym. Adv. Technol. 2008, 19, 628–635. [Google Scholar] [CrossRef]

- Liang, D.; Zhu, X.; Dai, P.; Lu, X.; Guo, H.; Que, H.; Wang, D.; He, T.; Xu, C.; Robin, H.M. Preparation of a novel lignin-based flame retardant for epoxy resin. Mater. Chem. Phys. 2021, 259, 124101. [Google Scholar] [CrossRef]

- Carretier, V.; Delcroix, J.; Pucci, M.F.; Rublon, P.; Lopez-Cuesta, J.-M. Influence of sepiolite and lignin as potential synergists on flame retardant systems in polylactide (PLA) and polyurethane elastomer (PUE). Materials 2020, 13, 2450. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Yang, J.; Hu, Y. Preparation of lignin–silica hybrids and its application in intumescent flame-retardant poly (lactic acid) system. High Perform. Polym. 2012, 24, 738–746. [Google Scholar] [CrossRef]

- Peil, S.; Mouhoubi, R.; Streekstra, R.; Ridard, H.; Veith, L.; Ali, W.; Mayer-Gall, T.; Duvigneau, J.; Wurm, F.R. Encapsulation of ammonium polyphosphate in lignin nanocontainers enhances dispersion and flame retardancy in polylactic acid foams. ACS Appl. Polym. Mater. 2024, 6, 6096–6107. [Google Scholar] [CrossRef]

- Ou, J.; Li, S.; Li, W.; Liu, C.; Ren, J.; Yue, F. Revealing the structural influence on lignin phenolation and its nanoparticle fabrication with tunable sizes. ACS Sustain. Chem. Eng. 2022, 10, 14845–14854. [Google Scholar] [CrossRef]

- Liu, W.; Yi, S.; Liu, Z.; Mo, Q.; Xian, X.; Ma, L.; Li, Y. Sol-gel silica modified recovered lignin particles and its application as blend with HDPE. Ind. Crops Prod. 2022, 189, 115842. [Google Scholar] [CrossRef]

- ASTM D3801-20a; Standard Test Method for Measuring the Comparative Burning Characteristics of Solid Plastics in a Vertical Position. ASTM Internationnal: West Conshohocken, PA, USA, 2020.

- ASTM D2863-19; Standard Test Method for Measuring the Minimum Oxygen Concentration to Support Candle-Like Combustion of Plastics (Oxygen Index). ASTM: West Conshohocken, PA, USA, 2023.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- Liu, L.-Y.; Chiang, W.-S.; Chang, H.-m.; Yeh, T.-F. Phenolation to improve hardwood kraft lignin for wood adhesive application. Polymers 2024, 16, 1923. [Google Scholar] [CrossRef] [PubMed]

- Ahadyani, N.; Abdollahi, M. Phenolation, amination and cross-linking of lignin: Synthesis and characterization of functionalized lignin. Polym. Bull. 2024, 81, 8643–8661. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Nowacka, M.; Milczarek, G.; Jesionowski, T. Physicochemical and electrokinetic properties of silica/lignin biocomposites. Carbohydr. Polym. 2013, 94, 345–355. [Google Scholar] [CrossRef] [PubMed]

- Guo, Y.; Hu, L.; Bo, C.; Shang, Q.; Feng, G.; Jia, P.; Zhang, B.; Zhou, Y. Mechanical property of lignin-modified phenolic foam enhanced by nano-SiO 2 via a novel method. Chem. Pap. 2018, 72, 763–767. [Google Scholar] [CrossRef]

- Shweta, K.; Jha, H. Rice husk extracted lignin–TEOS biocomposites: Effects of acetylation and silane surface treatments for application in nickel removal. Biotechnol. Rep. 2015, 7, 95–106. [Google Scholar] [CrossRef] [PubMed]

- Jesionowski, T.; Klapiszewski, Ł.; Milczarek, G. Structural and electrochemical properties of multifunctional silica/lignin materials. Mater. Chem. Phys. 2014, 147, 1049–1057. [Google Scholar] [CrossRef]

- Palakurthy, S.; Houben, L.; Elbaum, M.; Elbaum, R. Silica Biomineralization with Lignin Involves Si–O–C Bonds That Stabilize Radicals. Biomacromolecules 2024, 25, 3409–3419. [Google Scholar] [CrossRef]

- Carneiro, A.A.B.; Patekar, S.; Goyal, M.; de Almeida, S.; Dayarathne, N.K.; De Campos, S.B.; Bally, J.; Hassanpour, M.; Zhang, Z. Lignin-enabled silica hybrid nanoparticles from rice husk for improved biopesticide delivery and cotton bollworm control. Int. J. Biol. Macromol. 2025, 309, 142589. [Google Scholar] [CrossRef]

- Alongi, J.; Carosio, F.; Malucelli, G. Influence of ammonium polyphosphate-/poly (acrylic acid)-based layer by layer architectures on the char formation in cotton, polyester and their blends. Polym. Degrad. Stab. 2012, 97, 1644–1653. [Google Scholar] [CrossRef]

- Li, H.; Hou, L.; Liu, Y.; Yao, Z.; Liang, L.; Tian, D.; Liu, C.; Xue, J.; Zhan, L.; Liu, Y. Balanced thermal insulation, flame-retardant and mechanical properties of PU foam constructed via cost-effective EG/APP/SA ternary synergistic modification. Polymers 2024, 16, 330. [Google Scholar] [CrossRef] [PubMed]

- Liang, X.; Hu, Q.; Wang, X.; Li, L.; Dong, Y.; Sun, C.; Hu, C.; Gu, X. Thermal kinetics of a lignin-based flame retardant. Polymers 2020, 12, 2123. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Q.; Gao, T.; Qiao, C.; Yao, J.; Zhang, C. Phenolation of lignin for polycatecholamines to remove Cr (VI). J. Water Process Eng. 2022, 50, 103334. [Google Scholar] [CrossRef]

- Rahman, M.M.; Jahan, E.; Jahan, M.S.; Liton, M.A.K. Phenolation of potassium hydroxide lignin and its effect on copolymerization with acrylic acid. Biomass Convers. Biorefinery 2024, 14, 30515–30523. [Google Scholar] [CrossRef]

- Li, X.; Xu, Y.; An, X.-y.; Gong, L.; Wang, R.; Liu, Z.-m. Eco-friendly and efficient flame retardant rigid polyurethane foam reinforced with lignin and silica aerogel. Int. J. Biol. Macromol. 2025, 304 Pt 2, 140947. [Google Scholar] [CrossRef]

- Wang, S.; Li, Y.; Xiang, H.; Zhou, Z.; Chang, T.; Zhu, M. Low cost carbon fibers from bio-renewable lignin/poly (lactic acid)(PLA) blends. Compos. Sci. Technol. 2015, 119, 20–25. [Google Scholar] [CrossRef]

- Park, S.Y.; Kim, J.-Y.; Youn, H.J.; Choi, J.W. Utilization of lignin fractions in UV resistant lignin-PLA biocomposites via lignin-lactide grafting. Int. J. Biol. Macromol. 2019, 138, 1029–1034. [Google Scholar] [CrossRef] [PubMed]

- Kumar, A.; Tumu, V.R.; Chowdhury, S.R.; SVS, R.R. A green physical approach to compatibilize a bio-based poly (lactic acid)/lignin blend for better mechanical, thermal and degradation properties. Int. J. Biol. Macromol. 2019, 121, 588–600. [Google Scholar] [CrossRef]

- Ou, J.; Hu, S.; Yao, L.; Chen, Y.; Qi, H.; Yue, F. Simultaneous strengthening and toughening lignin/cellulose nanofibril composite films: Effects from flexible hydrogen bonds. Chem. Eng. J. 2023, 453, 139770. [Google Scholar] [CrossRef]

- Falireas, P.G.; Gracia-Vitoria, J.; Hensen, A.; Vanbroekhoven, K.; Vendamme, R. Incorporating phenolated lignin into polyurethane materials: Impact on mechanical, thermal, and adhesion performance. Ind. Eng. Chem. Res. 2024, 63, 3921–3935. [Google Scholar] [CrossRef]

- Klapiszewski, Ł.; Bula, K.; Sobczak, M.; Jesionowski, T. Influence of Processing Conditions on the Thermal Stability and Mechanical Properties of PP/Silica-Lignin Composites. Int. J. Polym. Sci. 2016, 2016, 1627258. [Google Scholar] [CrossRef]

| Sample | PLA | APP | KL | PKL | SPKL |

|---|---|---|---|---|---|

| PLA | 100 | 0 | 0 | 0 | 0 |

| PLA/APP | 80 | 20 | 0 | 0 | 0 |

| PLA/APP/KL | 80 | 14 | 6 | 0 | 0 |

| PLA/APP/PKL | 80 | 14 | 0 | 6 | 0 |

| PLA/APP/SPKL | 80 | 14 | 0 | 0 | 6 |

| Sample | PLA | PLA/APP | PLA/APP/KL | PLA/APP/PKL | PLA/APP/SPKL |

|---|---|---|---|---|---|

| Rating | NR | V-2 | V-2 | V-1 | V-0 |

| Dripping * | Yes/Yes | Yes/Yes | No/Yes | No/Yes | No/No |

| Ignition of the cotton | Yes | Yes | Yes | No | No |

| Sample | Tonset (°C) | Tmax (°C) | Residue at 800 °C (wt%) |

|---|---|---|---|

| KL | 286.05 | 391.86 | 41.59 |

| PKL | 299.40 | 387.12 | 36.54 |

| SPKL | 332.47 | 392.40 | 50.75 |

| Sample | T5 (°C) | T50 (°C) | Tmax (°C) | Residue at 800 °C (wt%) |

|---|---|---|---|---|

| PLA | 295.65 | 338.70 | 349.28 | 0.58 |

| PLA/APP | 334.53 | 371.00 | 375.25 | 11.40 |

| PLA/APP/KL | 330.12 | 367.98 | 370.64 | 6.21 |

| PLA/APP/PKL | 332.70 | 370.04 | 373.40 | 9.85 |

| PLA/APP/SPKL | 329.46 | 369.26 | 373.40 | 11.37 |

| Sample | T5 (°C) | T50 (°C) | Tmax (°C) | Residue at 800 °C (wt%) |

|---|---|---|---|---|

| PLA | 325.15 | 365.57 | 372.22 | 0.29 |

| PLA/APP | 331.24 | 366.16 | 368.63 | 8.14 |

| PLA/APP/KL | 327.73 | 365.09 | 367.97 | 8.03 |

| PLA/APP/PKL | 333.34 | 366.57 | 369.84 | 6.04 |

| PLA/APP/SPKL | 335.10 | 367.32 | 367.99 | 11.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoo, H.; Jo, J.; Kim, S.J.; Koo, B. Development of Silylated Lignin-Based Intumescent Flame Retardants for Biodegradable Plastics. Polymers 2025, 17, 1727. https://doi.org/10.3390/polym17131727

Yoo H, Jo J, Kim SJ, Koo B. Development of Silylated Lignin-Based Intumescent Flame Retardants for Biodegradable Plastics. Polymers. 2025; 17(13):1727. https://doi.org/10.3390/polym17131727

Chicago/Turabian StyleYoo, Heesu, Jaemin Jo, Sung Jin Kim, and Bonwook Koo. 2025. "Development of Silylated Lignin-Based Intumescent Flame Retardants for Biodegradable Plastics" Polymers 17, no. 13: 1727. https://doi.org/10.3390/polym17131727

APA StyleYoo, H., Jo, J., Kim, S. J., & Koo, B. (2025). Development of Silylated Lignin-Based Intumescent Flame Retardants for Biodegradable Plastics. Polymers, 17(13), 1727. https://doi.org/10.3390/polym17131727