Investigation of Diffusion Induced Fiber–Matrix Interface Damages in Adhesively Bonded Polymer Composites

Abstract

1. Introduction

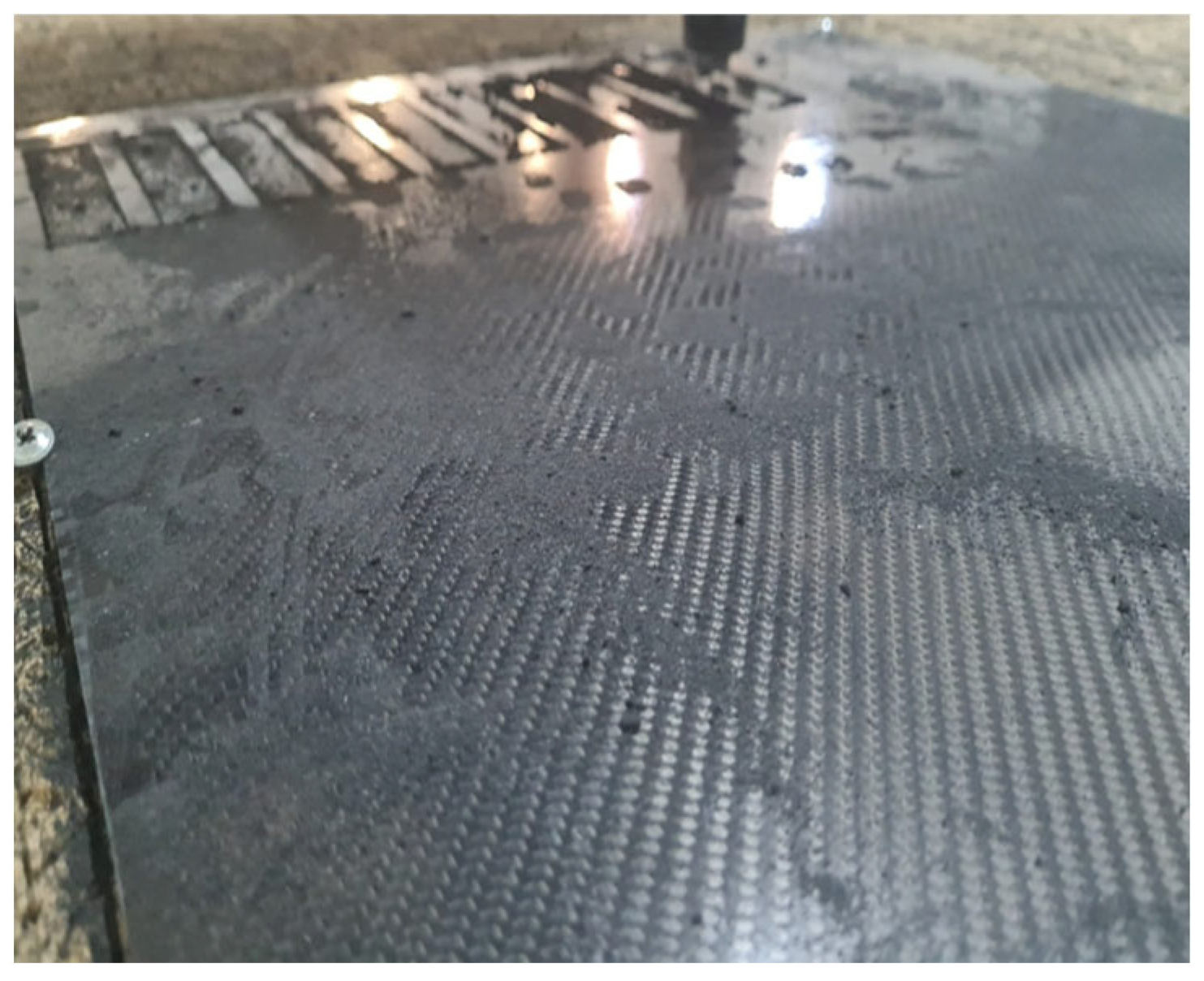

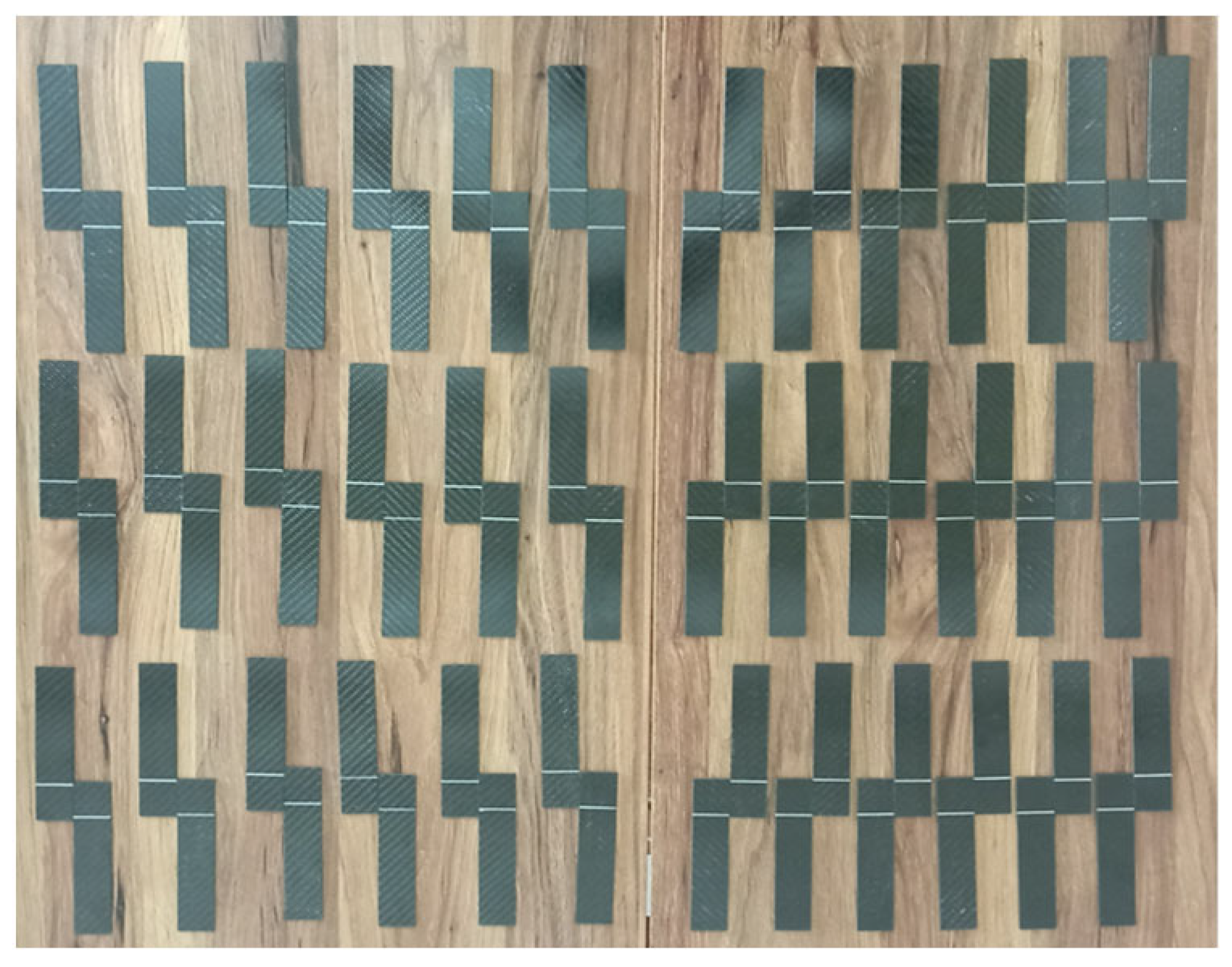

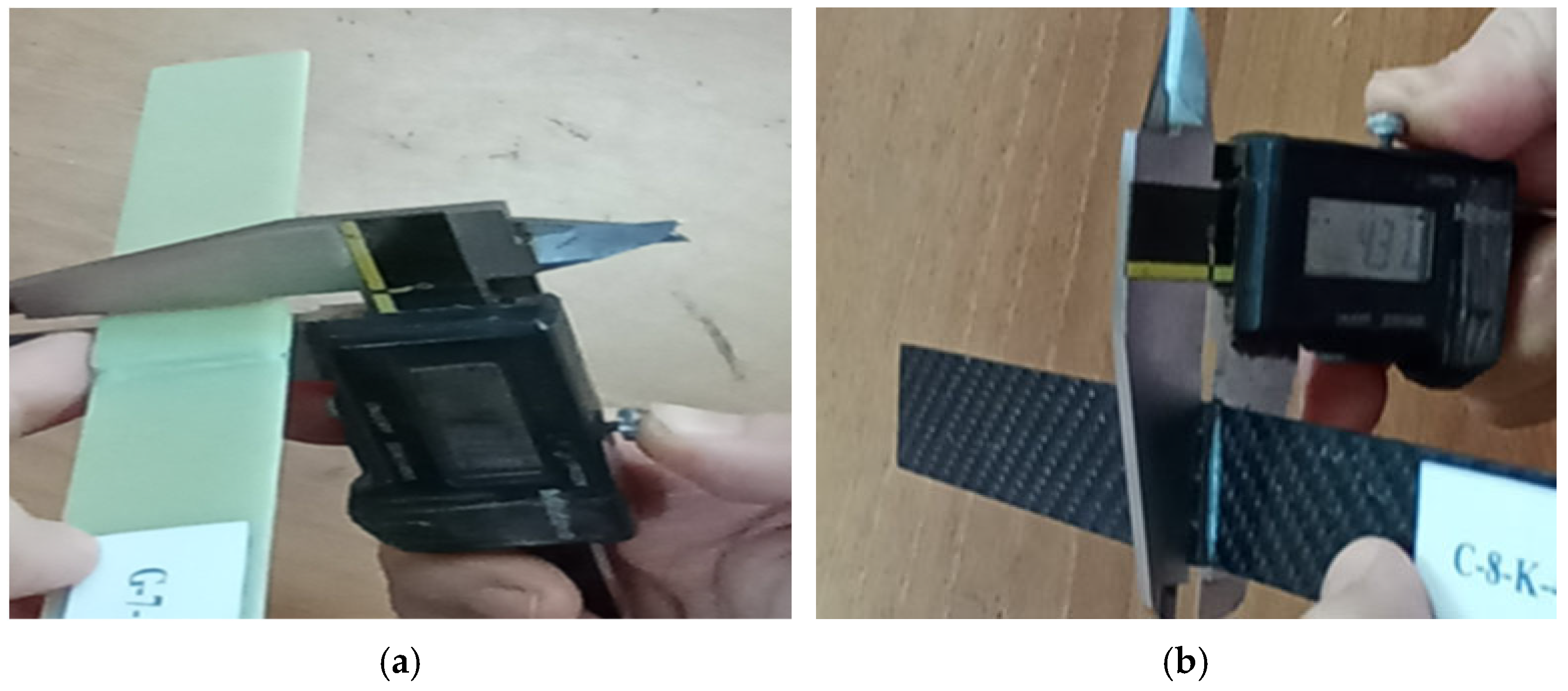

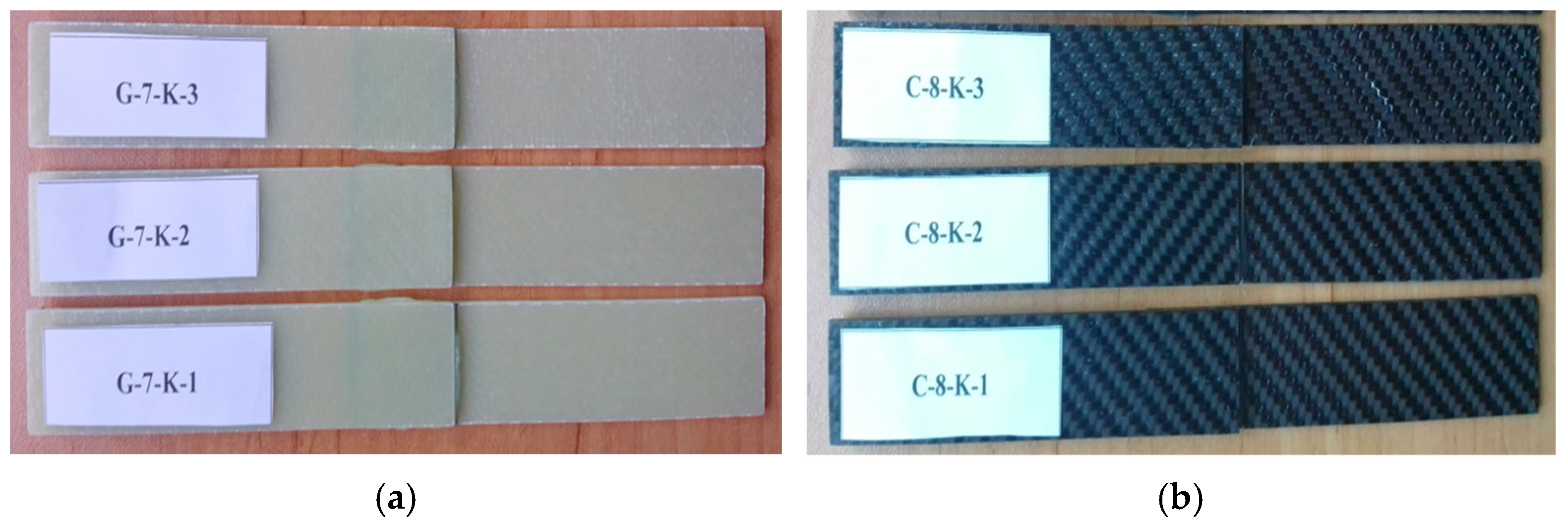

2. Materials and Methods

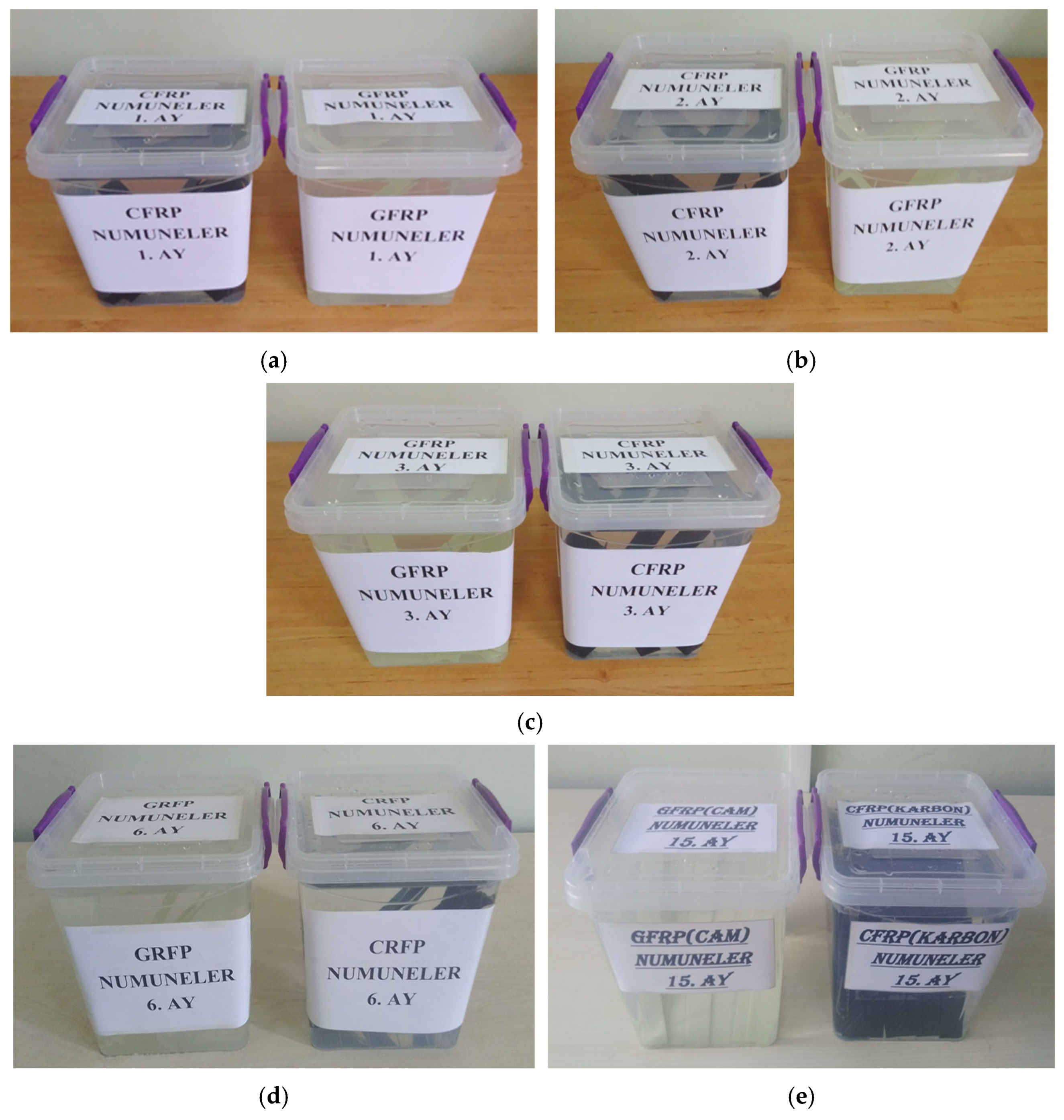

2.1. Moisture Retention Performance of GFRP and CFRP Composites in Seawater Exposure

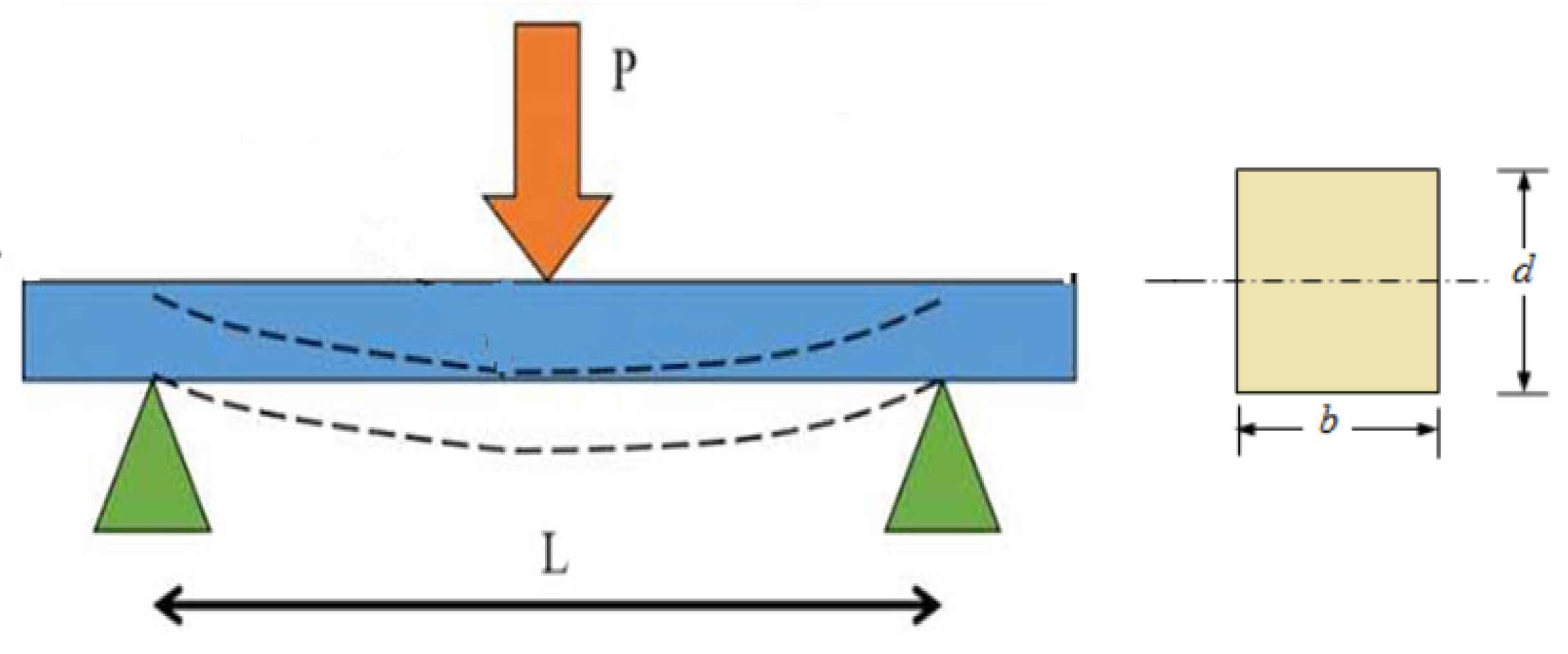

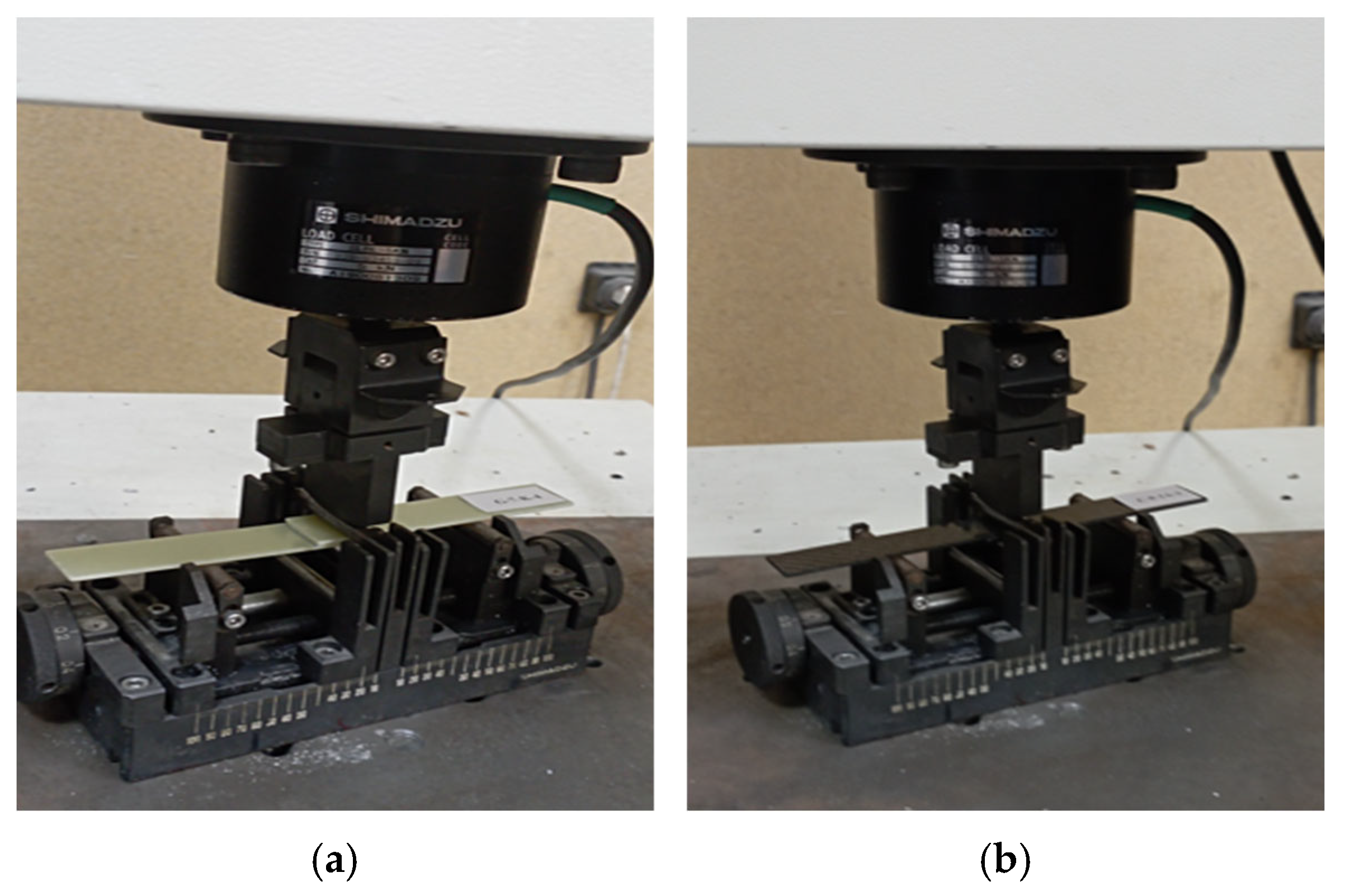

2.2. Three Point Bending Test

3. Results

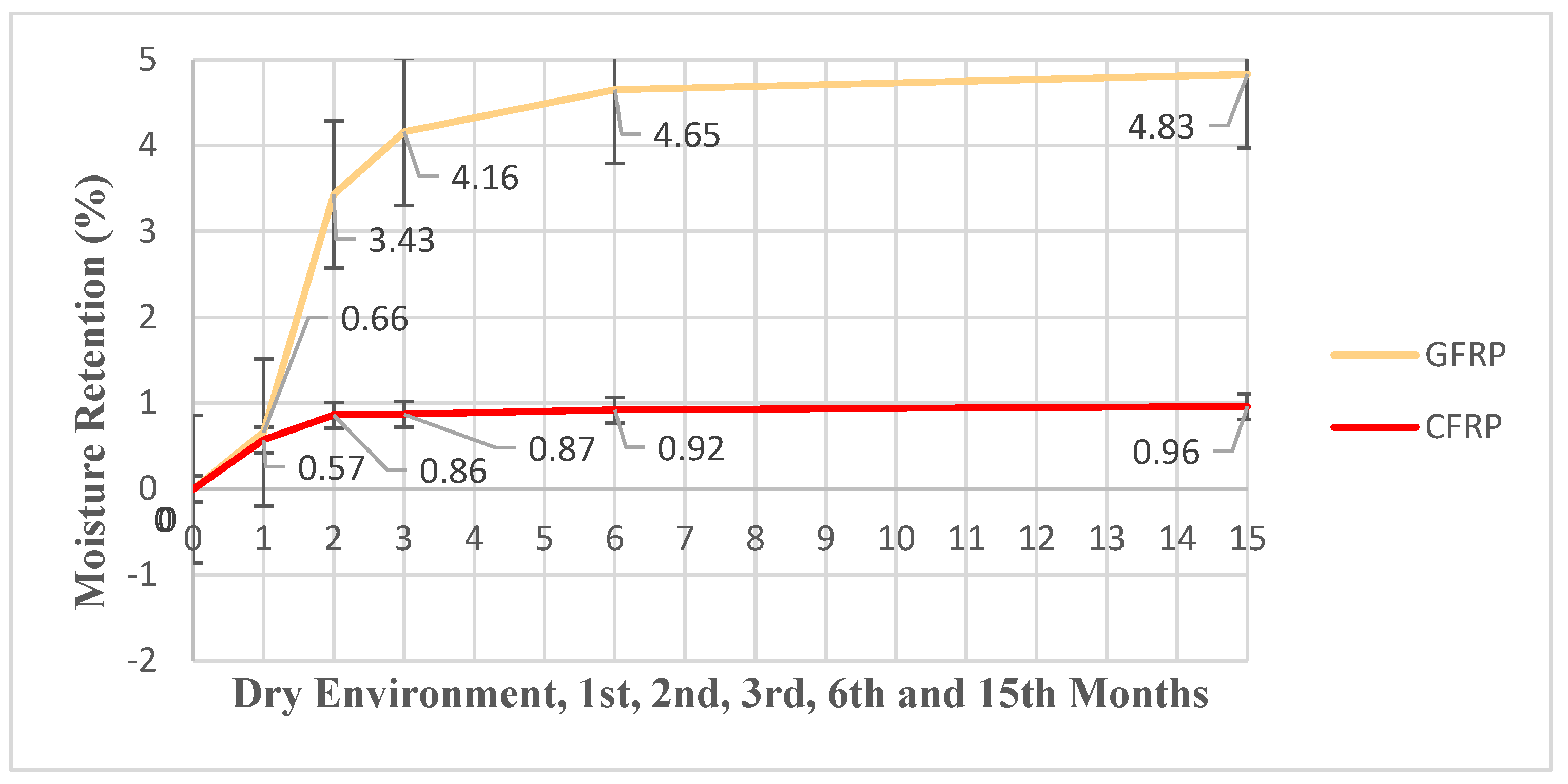

3.1. Moisture Diffusion in Composite Materials

- Calculation of Diffusion Coefficient (D):

- Theoretical Mass Change (M):

- The rate of moisture diffusion in composite materials (D),

- The moisture uptake behavior over time (M),

- The effect of material geometry on this process.

3.2. Three Point Bending Test Results

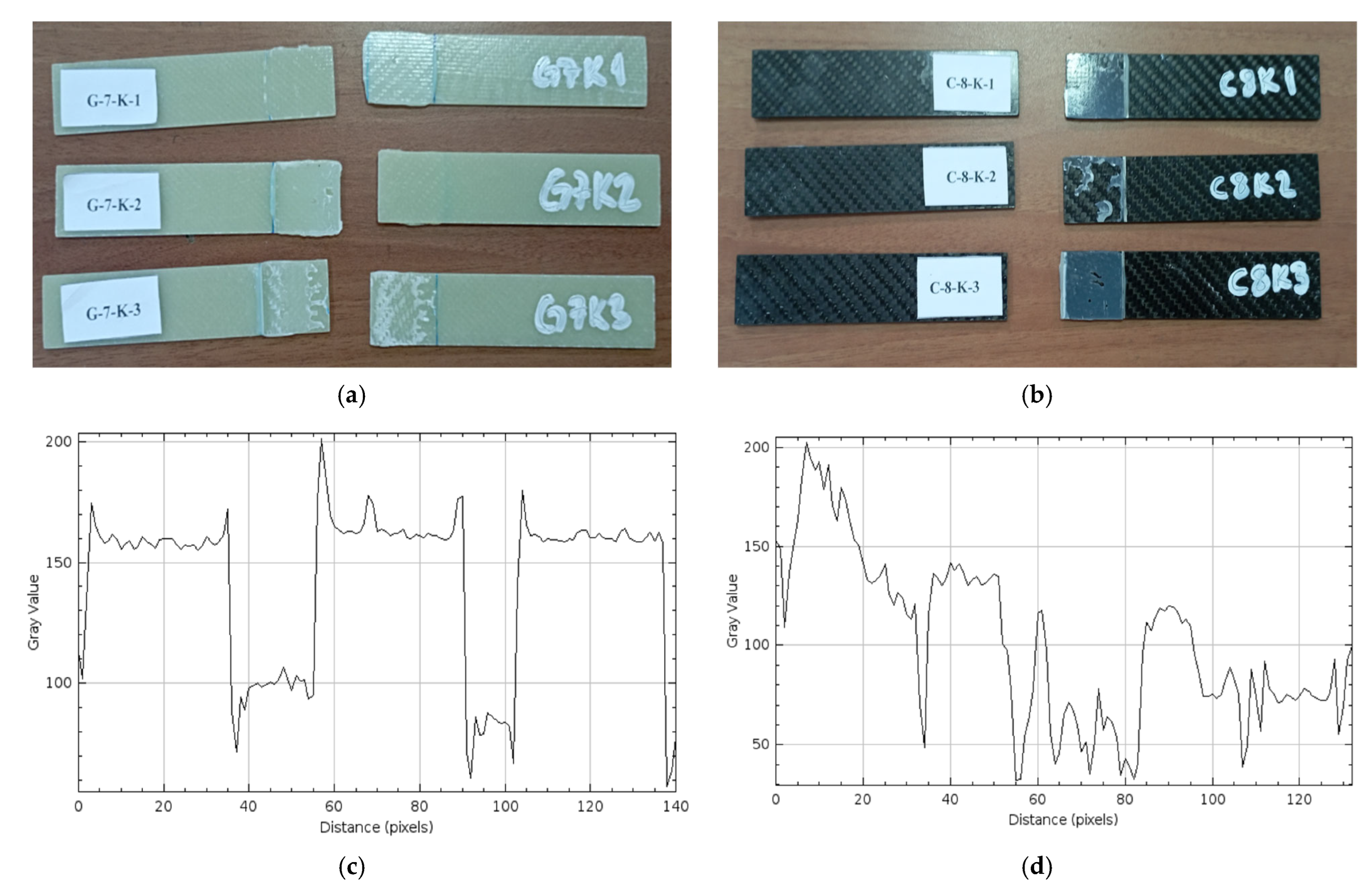

- Dry Environment Samples (G-7-K and C-8-K)

- Samples Soaked in Sea Water for 1 Month (720 h) (G-7-1A and C-8-1A)

- Samples Soaked in Sea Water for 2 Months (1440 h) (G-7-2A and C-8-2A)

- Samples soaked in sea water for 3 months (2160 h) (G-7-3A and C-8-3A)

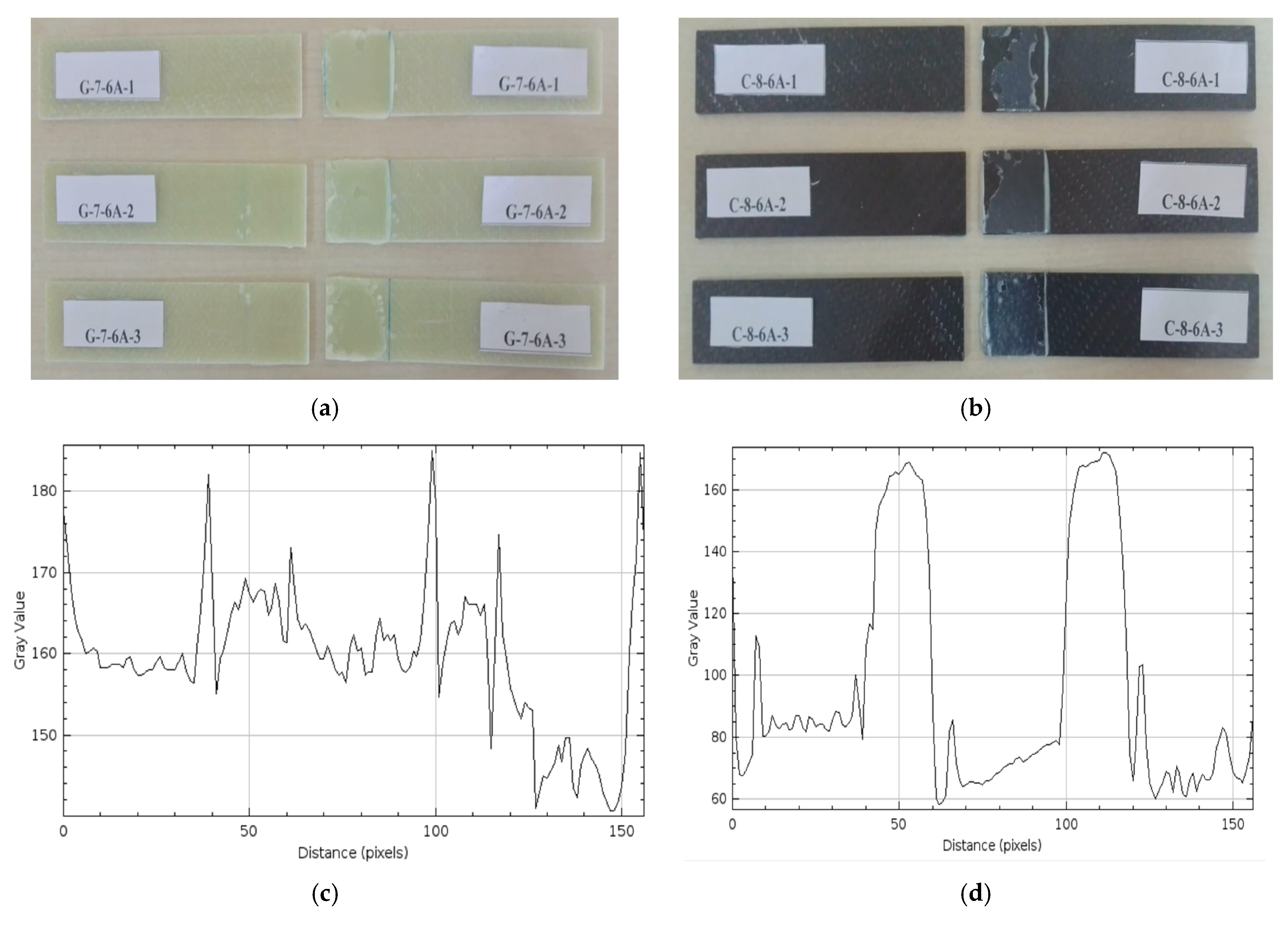

- Samples Soaked in Sea Water for 6 months (4320 h) (G-7-6A and C-8-6A)

- Samples Soaked in Sea Water for 15 months (10,800 h) (G-7-15A and C-8-15A)

3.3. Damage Analysis of GFRP and CFRP Composites Subjected to Bending Tests with SEM

4. Discussion

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Phiri, R.; Rangappa, S.M.; Siengchin, S.; Oladijo, O.P.; Ozbakkaloglu, T. Advances in lightweight composite structures and manufacturing technologies: A comprehensive review. Heliyon 2024, 10, e39661. [Google Scholar] [CrossRef] [PubMed]

- Chawla, K.K. Composite Materials: Science and Engineering; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Huang, S.; Fu, Q.; Yan, L.; Kasal, B. Characterization of interfacial properties between fibre and polymer matrix in composite materials–A critical review. J. Mater. Res. Technol. 2021, 13, 1441–1484. [Google Scholar] [CrossRef]

- Katsiropoulos, C.V.; Chamos, A.N.; Tserpes, K.I.; Pantelakis, S.G. Fracture toughness and shear behavior of composite bonded joints based on a novel aerospace adhesive. Compos. Part B Eng. 2012, 43, 240–248. [Google Scholar] [CrossRef]

- Davies, P.; Rajapakse, Y.D.; Verdu, J. (Eds.) Durability of Composites in a Marine Environment; Springer International Publishing: Cham, Switzerland, 2018; Volume 245. [Google Scholar]

- Yildirim, B.; Ertekin, K.; Demirci, S.; Gultekin, S. Boosting optical performance of polymer embedded phosphors using iodine-free and iodine-decorated sol-gel synthesized α-Fe2O3. Opt. Mater. 2019, 95, 109238. [Google Scholar] [CrossRef]

- Mertgenç Yoldaş, D.; Yoldaş, M.F. Investigation of Diffusion of Different Composite Materials on the Damage Caused by Axial Impact Adhesive Joints. J. Compos. Sci. 2025, 9, 188. [Google Scholar] [CrossRef]

- Shen, C.H.; Springer, G.S. Moisture absorption and desorption of composite materials. J. Compos. Mater. 1976, 10, 2–20. [Google Scholar] [CrossRef]

- Roy, S.; Xu, W.X.; Park, S.J.; Liechti, K.M. Anomalous moisture diffusion in viscoelastic polymers: Modeling and testing. J. Appl. Mech. 2000, 67, 391–396. [Google Scholar] [CrossRef]

- Camino, G.; Luda, M.P.; Polishchuk, A.Y.; Revellino, M.; Blancon, R.; Merle, G.; Martinez-Vega, J.J. Kinetic aspects of water sorption in polyester-resin/glass-fibre composites. Compos. Sci. Technol. 1997, 57, 1469–1482. [Google Scholar] [CrossRef]

- Öner, G.; Önal, H.Y.; Pekbey, Y. Karbon nanotüp katkılı camlifi-epoksi kompozitlerin termal ve eğilme özelliklerinin araştırılması. Dicle Üniversitesi Mühendislik Fakültesi Mühendislik Derg. 2017, 8, 805–816. [Google Scholar]

- Oner, G.; Unal, H.Y.; Pekbey, Y.E.L.İ.Z. Mechanical performance of hybrid carbon/fiberglass composite laminates reinforced with nanoclay. Acta Phys. Pol. A 2018, 134, 164–167. [Google Scholar] [CrossRef]

- Mansouri, L.; Djebbar, A.; Khatir, S.; Wahab, M.A. Effect of hygrothermal aging in distilled and saline water on the mechanical behaviour of mixed short fibre/woven composites. Compos. Struct. 2019, 207, 816–825. [Google Scholar] [CrossRef]

- Vizentin, G.; Vukelic, G. Marine environment induced failure of FRP composites used in maritime transport. Eng. Fail. Anal. 2022, 137, 106258. [Google Scholar] [CrossRef]

- Mourad, A.H.I.; Abdel-Magid, B.M.; El-Maaddawy, T.; Grami, M.E. Effect of seawater and warm environment on glass/epoxy and glass/polyurethane composites. Appl. Compos. Mater. 2010, 17, 557–573. [Google Scholar] [CrossRef]

- Yalçınkaya, S.; Mertgenç Yoldaş, D.; Yoldaş, M.F. Experimental Investigation of the Effect of Seawater on Glass and Carbon Fiber Composites via Mechanical Characterization. J. Compos. Sci. 2025, 9, 107. [Google Scholar] [CrossRef]

- Vaishakh, K.V.; Parambil, N.K.; Srivastava, V. Hygroscopic damage of fiber–matrix interface in unidirectional composites: A computational approach. Int. J. Mech. Sci. 2024, 279, 109460. [Google Scholar] [CrossRef]

- Zhang, W.; Zou, J.; Liu, M.; Han, Z.; Xiong, Y.; Liang, B.; Hu, N.; Zhang, W. Investigating the role of fibre-matrix interfacial degradation on the ageing process of carbon fibre-reinforced polymer under hydrothermal conditions. Compos. Sci. Technol. 2025, 259, 110922. [Google Scholar] [CrossRef]

- da Silva, G.D.A.; d’Almeida, J.R.; Cardoso, D.C.; Vieira, P.S.; Lopes, B.J.; da Silva, A.H.D.F.; Perrut, V.A. Development of an extrapolation method to predict the flexural properties of glass-fiber/epoxy composites subject to hygrothermal aging. Compos. Struct. 2025, 360, 119038. [Google Scholar] [CrossRef]

- Rodríguez-Dopico, F.J.; Álvarez García, A.; Tarrío-Saavedra, J. Characterization of Epoxy Adhesive for Marine Applications. Oceans 2024, 5, 906–922. [Google Scholar] [CrossRef]

- Atakok, G.; Mertgenc Yoldas, D. Comparison of GFRP (Glass Fiber-Reinforced Polymer) and CFRP (Carbon Fiber-Reinforced Polymer) Composite Adhesive-Bonded Single-Lap Joints Used in Marine Environments. Sustainability 2024, 16, 11105. [Google Scholar] [CrossRef]

- ASTMD5868-01; Standard Test Method for Lap Shear Adhesion for Fiber Reinforced Plastic (FRP) Bonding. ASTM International: West Conshohocken, PA, USA, 2023.

- Croccolo, D.; De Agostinis, M.; Fini, S.; Olmi, G. Influence of the engagement ratio on the shear strength of an epoxy adhesive by push-out tests on pin-and-collar joints: Part I: Campaign at room temperature. Int. J. Adhes. Adhes. 2016, 67, 69–75. [Google Scholar] [CrossRef]

- Callister, W.D., Jr.; Rethwisch, D.G. Materials Science and Engineering: An Introduction; John Wiley & Sons: New York, NY, USA, 2020. [Google Scholar]

- ASTMD790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Crank, J. The Mathematics of Diffusion, 2nd ed.; Oxford University Press: New York, NY, USA, 1975. [Google Scholar]

- Weitsman, Y. Stress assisted diffusion in elastic and viscoelastic materials. J. Mech. Phys. Solids 1987, 35, 73–93. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.A.; Richardson, M.O. Effect of water absorption on the mechanical properties of hemp fibre reinforced unsaturated polyester composites. Compos. Sci. Technol. 2007, 67, 1674–1683. [Google Scholar] [CrossRef]

- Selzer, R.; Friedrich, K. Mechanical properties and failure behaviour of carbon fibre-reinforced polymer composites under the influence of moisture. Compos. Part A Appl. Sci. Manuf. 1997, 28, 595–604. [Google Scholar] [CrossRef]

- Fick, A.V. On liquid diffusion. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1855, 10, 30–39. [Google Scholar] [CrossRef]

- Kathavate, V.S.; Amudha, K.; Adithya, L.; Pandurangan, A.; Ramesh, N.R.; Gopakumar, K. Mechanical behavior of composite materials for marine applications–an experimental and computational approach. J. Mech. Behav. Mater. 2018, 27, 20180003. [Google Scholar] [CrossRef]

- Mayya, H.B.; Pai, D.; Kini, V.M.; NH, P. Effect of marine environmental conditions on physical and mechanical properties of fiber-reinforced composites—A review. J. Inst. Eng. Ser. C 2021, 102, 843–849. [Google Scholar] [CrossRef]

- Siriruk, A.; Penumadu, D. Effect of sea water on polymeric marine composites. In Durability of Composites in a Marine Environment; Springer: Dordrecht, The Netherlands, 2013; pp. 129–142. [Google Scholar]

- Bradley, W.L.; Grant, T.S. The effect of the moisture absorption on the interfacial strength of polymeric matrix composites. J. Mater. Sci. 1995, 30, 5537–5542. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mahmood, H.; Pegoretti, A. Recent advances in fiber/matrix interphase engineering for polymer composites. Prog. Mater. Sci. 2015, 73, 1–43. [Google Scholar] [CrossRef]

- Hassanpour, B.; Karbhari, V.M. Characteristics and Models of Moisture Uptake in Fiber-Reinforced Composites: A Topical Review. Polymers 2024, 16, 2265. [Google Scholar] [CrossRef]

- Song, M.G.; Kweon, J.H.; Choi, J.H.; Byun, J.H.; Song, M.H.; Shin, S.J.; Lee, T.J. Effect of manufacturing methods on the shear strength of composite single-lap bonded joints. Compos. Struct. 2010, 92, 2194–2202. [Google Scholar] [CrossRef]

- Osa-Uwagboe, N.; Silberschmidt, V.V.; Demirci, E. Review on mechanical performance of Fibre-Reinforced Plastics in Marine environments. Appl. Compos. Mater. 2024, 31, 1991–2018. [Google Scholar] [CrossRef]

- Guo, F.; Al-Saadi, S.; Singh Raman, R.K.; Zhao, X. Durability of fibre reinforced polymers in exposure to dual environment of seawater sea sand concrete and seawater. Materials 2022, 15, 4967. [Google Scholar] [CrossRef] [PubMed]

- Vaidya, A.; Pathak, K. Mechanical stability of dental materials. In Applications of Nanocomposite Materials in Dentistry; Woodhead Publishing: Cambridge, UK, 2019; pp. 285–305. [Google Scholar]

- Aceti, P.; Carminati, L.; Bettini, P.; Sala, G. Hygrothermal ageing of composite structures. Part 1: Technical review. Compos. Struct. 2023, 319, 117076. [Google Scholar] [CrossRef]

- Ray, B.C. Effects of changing environment and loading speed on mechanical behavior of FRP composites. J. Reinf. Plast. Compos. 2006, 25, 1227–1240. [Google Scholar] [CrossRef]

| Property | GFRP (Glass Fiber Reinforced Polymer) | CFRP (Carbon Fiber Reinforced Polymer) |

|---|---|---|

| Number of Layers | 7 layers (due to volume and density ratio) | 8 layers (due to volume and density ratio) |

| Orientation | 0/90 | 0/90 |

| Weave Type | Twill | Twill |

| Areal Density (g/m2) | 390 | 245 |

| Fiber Type | 390 g glass fiber weft yarn | 3K carbon fiber weft yarn |

| Prepreg Production | Drum-type prepreg machine | Drum-type prepreg machine |

| Resin System | F-RES 21 epoxy + F-Hard 22 hardener | F-RES 21 epoxy + F-Hard 22 hardener |

| Laminate Thickness | 2 mm | 2 mm |

| Manufacturer | Fibermak Engineering Company (Izmir, Türkiye) | Fibermak Engineering Company (Izmir, Türkiye) |

| Property | Specification |

|---|---|

| Mixing Ratio (by weight) | RES 21 Resin: 100 F-Hard 22 Hardener: 21 |

| Mixture Viscosity (at 25 °C) | 500–800 mPa·s |

| Prepreg Curing | 120 °C for 60 min |

| Property | Value (MPa) |

|---|---|

| Tensile Strength | 80 |

| Tensile Modulus | 3300 |

| Flexural Strength | 125 |

| Flexural Modulus | 3200 |

| Fiber Type | G (GFRP) | C (CFRP) |

| Number of Layers | 7 (7 floors) | 8 (8 floors) |

| Environment | Dry (K), Monthly residence times in sea water (1A, 2A, 3A, 6A, 15A) | Dry (K), Monthly residence times in sea water (1A, 2A, 3A, 6A, 15A) |

| Sample No | 1, 2, 3 | 1, 2, 3 |

| Dry Sample Code | Dry Weight (g) | Store Time | Soaked in Sea Water Sample Code | Wet Weight (g) | Moisture Retention Rate (%) |

|---|---|---|---|---|---|

| G-7-K | 17.2374 | 1st Month (720 h) | G-7-1A | 17.3524 | 0.66 |

| G-7-K | 17.2374 | 2nd Month (1440 h) | G-7-2A | 17.8593 | 3.43 |

| G-7-K | 17.2374 | 3rd Month (2160 h) | G-7-3A | 17.9707 | 4.16 |

| G-7-K | 17.2374 | 6th Month (4320 h) | G-7-6A | 18.0389 | 4.65 |

| G-7-K | 17.2374 | 15th Month (10,800 h) | G-7-15A | 18.0699 | 4.83 |

| Dry Sample Code | Dry Weight (g) | Store Time | Soaked in Sea Water Sample Code | Wet Weight (g) | Moisture Retention Rate (%) |

|---|---|---|---|---|---|

| C-8-K | 14.7695 | 1st Month (720 h) | C-8-1A | 14.8808 | 0.57 |

| C-8-K | 14.7695 | 2nd Month (1440 h) | C-8-2A | 14.9247 | 0.86 |

| C-8-K | 14.7695 | 3rd Month (2160 h) | C-8-3A | 14.9252 | 0.87 |

| C-8-K | 14.7695 | 6th Month (4320 h) | C-8-6A | 14.9326 | 0.92 |

| C-8-K | 14.7695 | 15th Month (10,800 h) | C-8-15A | 14.9385 | 0.96 |

| Duration | Sample Type | Observed Damage Type | Damage Location |

|---|---|---|---|

| Dry environment | GFRP (G-7-K) | Adhesive bond line | Break in all samples |

| Dry environment | CFRP (C-8-K) | Adhesive bond line | Break in all samples |

| 1 Month (720 h) | GFRP (G-7-1A) | Adhesive bond line | No Rupture in all samples |

| 1 Month (720 h) | CFRP (C-8-1A) | Adhesive bond line | Sudden rupture (C-8-1A-1, C-8-1A-2) and Residual rupture (C-8-1A-3) |

| 2 Months (1440 h) | GFRP (G-7-2A) | Adhesive bond line | No rupture (G-7-2A-1), rupture (G-7-2A-2, G-7-2A-3) |

| 2 Months (1440 h) | CFRP (C-8-2A) | Adhesive bond line | Sudden rupture (C-8-2A-1) and Residual rupture (C-8-2A-2, C-8-2A-3) |

| 3 Months (2160 h) | GFRP (G-7-3A) | Adhesive bond line | Residual rupture in all samples |

| 3 Months (2160 h) | CFRP (C-8-3A) | Adhesive bond line | Sudden rupture (C-8-3A-1) and Residual rupture (C-8-3A-2, C-8-3A-3) |

| 6 Months (4320 h) | GFRP (G-7-6A) | Deformations in the adhesive bond line | Residual rupture in all samples |

| 6 Months (4320 h) | CFRP (C-8-6A) | Adhesive bond line | Residual rupture in all samples |

| 15 Months (10,800 h) | GFRP (G-7-15A) | Deformations in the adhesive bond line | Sudden rupture in all samples |

| 15 Months (10,800 h) | CFRP (C-8-15A) | Adhesive bond line | Residual rupture in all samples |

| Sample Code (GFRP) | E (GPa) | Evaluation |

|---|---|---|

| G-7-K | 5.39 | Dry environment (reference) |

| G-7-1A | 5.07 | % 5.94 |

| G-7-2A | 4.91 | % 8.90 |

| G-7-3A | 4.69 | % 12.98 |

| G-7-6A | 4.09 | % 24.11 |

| G-7-15A | 4.03 | % 25.23 |

| Sample Code (GFRP) | E (GPa) | Evaluation |

|---|---|---|

| C-8-K | 11.50 | Dry environment (reference) |

| C-8-1A | 11.36 | % 1.28 |

| C-8-2A | 11.11 | % 3.39 |

| C-8-3A | 11.07 | % 3.74 |

| C-8-6A | 10.44 | % 9.21 |

| C-8-15A | 10.22 | % 11.13 |

| Sample Code | Stress (MPa) | Strain (ε) | Observed Damage (SEM) |

|---|---|---|---|

| G-7-K | 63.0726 | Min: 0.0128 Max: 0.0129 | Damage onset, fiber fractures and breaks |

| G-7-1A | First: 72.2704 Min: 54.4886 Max: 80.0818 | First: 0.0163 Min: 0.0113 Max: 0.0347 | Fiber fractures, breaks, Irregularities and wears on matrix surface |

| G-7-2A | First: 75.8136 Min: 50.8163 Last: 75.6766 | First: 0.0156 Min: 0.0094 Last: 0.0154 | Fiber breakage, rupture, delamination |

| G-7-3A | 75.6723 | 0.0146 | Fiber breakage, rupture, fiber–matrix separation |

| G-7-6A | 58.4044 | 0.0160 | Matrix cracks, Separation at the fiber–matrix interface, delamination matrix plasticization (softening) |

| G-7-15A | First: 57.55439 Min: 50.4088 Last: 53.4619 | First: 0.0159 Min: 0.0129 Last: 0.0140 | Increased delamination, fiber removal and breakage, matrix dissolution, fiber–matrix separation advanced |

| Sample Code | Stress (MPa) | Strain (ε) | Observed Damage (SEM) |

|---|---|---|---|

| C-8-K | 146.5976 | 0.0131 | Initiation of damage: fiber fractures, no fiber–matrix separation |

| C-8-1A | First: 72.4395 Max: 83.6555 | First: 0.0065 Max: 0.0077 | Fiber breakage Slight irregularities and abrasions on the matrix surface |

| C-8-2A | 126.2889 | 0.0112 | Initial matrix cracks, interface separations Fiber breakage |

| C-8-3A | 69.1586 | 0.0107 | Gaps between fiber and matrix are evident, micropore formation is accelerated |

| C-8-6A | 109.3453 | 0.0160 | Fiber pull-outs, fiber breaks and ruptures |

| C-8-15A | 112.2266 | 0.0110 | Fiber breakage, porosity formation in internal areas and increase in micro voids |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mertgenç Yoldaş, D. Investigation of Diffusion Induced Fiber–Matrix Interface Damages in Adhesively Bonded Polymer Composites. Polymers 2025, 17, 1672. https://doi.org/10.3390/polym17121672

Mertgenç Yoldaş D. Investigation of Diffusion Induced Fiber–Matrix Interface Damages in Adhesively Bonded Polymer Composites. Polymers. 2025; 17(12):1672. https://doi.org/10.3390/polym17121672

Chicago/Turabian StyleMertgenç Yoldaş, Dudu. 2025. "Investigation of Diffusion Induced Fiber–Matrix Interface Damages in Adhesively Bonded Polymer Composites" Polymers 17, no. 12: 1672. https://doi.org/10.3390/polym17121672

APA StyleMertgenç Yoldaş, D. (2025). Investigation of Diffusion Induced Fiber–Matrix Interface Damages in Adhesively Bonded Polymer Composites. Polymers, 17(12), 1672. https://doi.org/10.3390/polym17121672