Abstract

This study presents the results of optimizing FDM 3D printing parameters (layer height deposited in one pass—Lh and filling density—Id) to enhance the mechanical performance of three-point bending specimens made from PETG and recycled PETG (rPETG). The objectives of the study are to investigate the influence of variable parameters (Lh and Id) on the three-point bending behavior of additively manufactured specimens by thermoplastic extrusion of PETG and rPETG. It is also aims to optimize the manufacturing parameters to maximize mechanical performance, but also to evaluate the potential of using rPETG in mechanical engineering applications. The materials analyzed in this study are PETG and recycled PETG (rPETG), in the context of promoting the concept of circular economy. Using the QIDI Q1 Pro 3D printer, and the variable parameters of FDM, Lh = (0.10; 0.15; 0.20) mm and Id = (50; 75; 100)%, 90 three-point bending specimens (45 from PETG and 45 from rPETG) were additively manufactured. To determine the mechanical strength characteristics under three-point bending stress, all 90 additively manufactured specimens were tested in three-point bending using a Barrus White 20 kN universal testing machine. The maximum bending stress is influenced by the two considered variable parameters of FDM (Lh and Id), the parameter with the greater impact being Id. Comparing the results of the maximum bending stresses of the additively manufactured specimens made of PETG and rPETG using the optimal parameters, it was found that the maximum bending stresses are higher in the case of the rPETG specimens, which highlights the potential of using recycled plastics in mechanical engineering applications.

1. Introduction

Given the current economic context, the climate crisis and resource depletion, the transition to a circular economy has become a major global priority [1,2,3,4,5,6,7]. The manufacturing industry is forced to find opportunities to reduce production costs, reduce waste and make production processes more flexible [8,9,10,11,12]. Additive manufacturing technologies, especially fused deposition modeling (FDM), offer significant advantages over conventional manufacturing technologies (formative and subtractive) in terms of material efficiency, the ability to create complex geometries and sustainability. In contrast to subtractive processes which generate significant material losses leading to low material utilization indexes or to formative processes, additive manufacturing technologies stand out due to the principle of functionality, which is based on the successive addition of material layer. The proposed approach of additive manufacturing technologies minimizes the amount of waste resulting from the production process [13,14,15,16,17,18,19,20,21,22,23,24,25]. FDM is one of the most popular additive manufacturing technologies due to its accessibility, and is also a technology that can easily adopt the use of recycled plastics [26,27,28,29,30,31,32,33,34,35,36]. One of the main challenges in adopting recycled plastics is the use of a large amount of recycled material without affecting mechanical performance. PETG (polyethylene terephthalate glycol) is a thermoplastic material widely used for various applications such as packaging, medical and pharmaceutical device manufacturing, 3D printing, industrial and engineering applications [11,14,25]. Printing parameters significantly influence the mechanical properties and manufacturing costs of parts [10,11,26,28]. Optimization of parameters is essential in the context of efficient use of resources, and is highlighted in the following specialized works. In the paper [37], the influence of FDM parameters (filling density, number of wall perimeters, layer height deposited in one pass) on the mechanical characteristics of parts manufactured by thermoplastic extrusion of PLA is studied. The results of the study show that by increasing the filling density and the number of wall perimeters and by decreasing the layer height deposited in one pass, increases in the rigidity of the parts are obtained. In the paper [38], the authors investigate the influence of filling density and printing speed on the breaking strength of tensile specimens additively manufactured from PLA. Artificial neural networks (ANN) trained on experimental data were used to predict the mechanical behavior of tensile specimens. The conclusions of the study show that increasing the filling density results in an increase in the tensile strength of the specimens, and increasing the printing speed from 5 mm/s to 35 mm/s resulted in a decrease in the tensile strength. The research presented in the paper [39] analyzes the influence of the filling pattern and filling density on the mechanical properties of PLA/Cu composites 3D printed by FDM. The results of the study show that the highest results of the tensile strength were recorded for the parts manufactured with a filling density of 90% and the linear filling pattern. In the paper [40], the authors present the results of the study on the optimization of FDM parameters to maximize the flexural strength. For the study, ABS three-point bending test specimens were additively fabricated according to ASTM D790 using the following FDM parameters: layer height, Lh = (0.10; 0.20; 0.30) mm; extrusion temperature, Et = (220; 230; 240) °C; and printing speed, Ps = (30; 50; 70) mm/s. The study conclusions show that the highest flexural strength (56.65 MPa) was obtained for the additively fabricated specimen using the following parameters: Lh = 0.10 mm; Et = 230 °C; and Ps = 30 mm/s. Before using recycled materials in practical applications, it is necessary to carry out a rigorous evaluation of the behavior under specific mechanical stresses such as tensile, compression, three-point bending, and resilience. In the paper [41], the study on the tensile behavior of specimens manufactured by FDM from rPETG is presented; the research results show that the tensile strength of specimens manufactured from recycled material is higher by up to 31.59% compared to the tensile strength of specimens manufactured from virgin PETG. In the paper [42], the study on the optimization of FDM parameters for the manufacture of compression specimens from rPETG is presented; the conclusions of the study show that the compressive strengths of specimens manufactured from rPETG are higher by 11.39–25.91% compared to the compressive strengths of specimens manufactured from virgin PETG. In [43], the authors present a study on the valorization of HDPE waste and industrial glass fibers by integrating additive manufacturing technologies into applications through plastic extrusion. The results of the study show that the composite mixture formed by HDPE waste and glass fibers offers good mechanical characteristics; this material mix can be used for the manufacture of functional parts.

The article [44] provides an analysis of the progress of using recycled PET in applications of additive manufacturing technologies through plastic extrusion. PET waste is mostly derived from packaging that requires rigorous processing consisting of washing, drying, grinding and extruding the material into filament. The technical challenges identified are represented by residual moisture, thermal degradation, but also by low viscosity. The solutions identified to mitigate the technical problems are represented by compatibilization with other polymers, the addition of stabilizers and the optimization of process parameters. The study presented in [45] investigates the potential of composites obtained from industrial waste polypropylene with glass fibers, which are first processed by 3D printing, and subsequently recycled and reprocessed by injection molding in order to obtain new components. The results of the study demonstrate the viability of reusing composite waste using a hybrid method (3D printing and injection molding). The results of the study presented in [46] demonstrate the viability of using composites made of PETG with short carbon fibers and which are subjected to heat treatment, which have excellent applicability for the production of functional parts due to their high mechanical performance.

This work is part of a larger research study that examines the influence of variable FDM parameters (Lh and Id) on the mechanical behavior of additively manufactured parts made of PETG and rPETG. In previous research, the authors studied other types of mechanical tests, such as tensile and compression tests [41,42].

In this paper, the influence of variable FDM parameters (Lh—layer height deposited in one pass and Id—filling density) on the mechanical performance of PETG and rPETG specimens in three-point bending is studied. Using statistical analysis and optimization methods, the optimal parameters for the manufacture of three-point bending specimens were identified. This paper serves as a basis for further research on the integration of recycled materials in the field of additive manufacturing technologies through plastic extrusion; at the same time, this paper brings value to the specialized literature, filling existing gaps.

2. Materials and Methods

2.1. Manufacturing of Specimens for Three-Point Bending Test

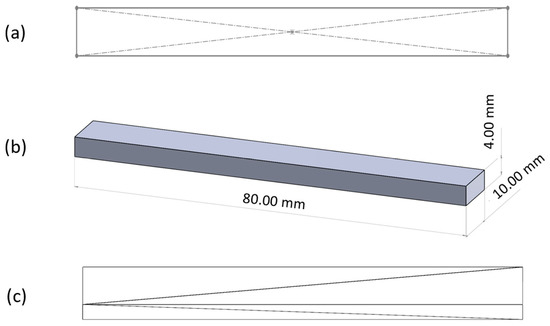

The 2D sketch (Figure 1a) and subsequently the 3D model (Figure 1b) of the three-point bending specimen, according to the ISO 178:2019 standard, was created using the Solidworks 2023 CAD software [47]. The 3D model corresponding to the three-point bending specimen (Figure 1c) was converted from SLD format to STL format using the same CAD software.

Figure 1.

Three-point bending test specimen in Solidworks 2023: (a) 2D sketch; (b) 3D model; (c) STL model.

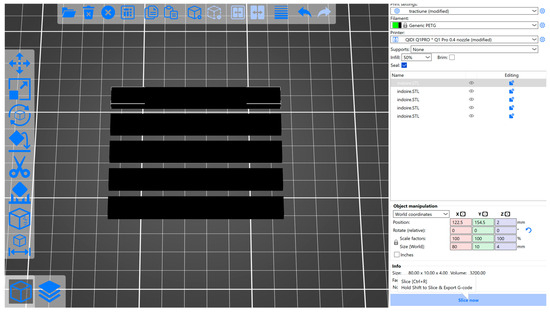

The STL file corresponding to the specimen for the three-point bending test was processed in the QIDISlicer software version 1.2.1, (see Figure 2), where the process parameters were set according to Table 1 and the work instructions in G-Code format were generated.

Figure 2.

Specimens for three-point bending test in QIDISlicer [48].

Table 1.

FDM printing parameters used to manufacture flexural samples from PETG and rPETG.

The G-Code files were transferred to the QIDI Q1 Pro 3D printer (WenZhou, China), where 90 three-point bending specimens (45 made of PETG and 45 made of rPETG) were additively manufactured by thermoplastic extrusion. To manufacture the parts, 1.75 mm diameter filament made of PETG and rPETG with 100% recycled material from the Everfil brand (Białystok, Poland) was used, (see Figure 3).

Figure 3.

Three-dimensional printer—QIDI Q1 Pro, used to manufacture three-point bending specimens from PETG and rPETG.

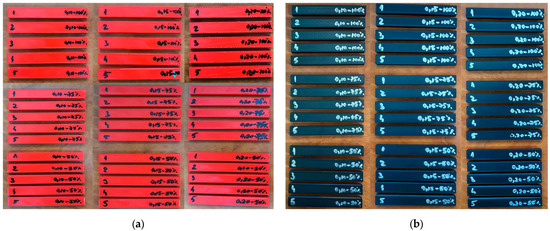

Figure 4 shows the 90 three-point bending test specimens manufactured on the QIDI Q1 Pro 3D printer.

Figure 4.

Three-point bend test specimens manufactured on the QIDI Q1 Pro printer: (a) PETG; (b) rPETG.

2.2. Three-Point Bending Test of Additively Manufactured PETG and rPETG Specimens

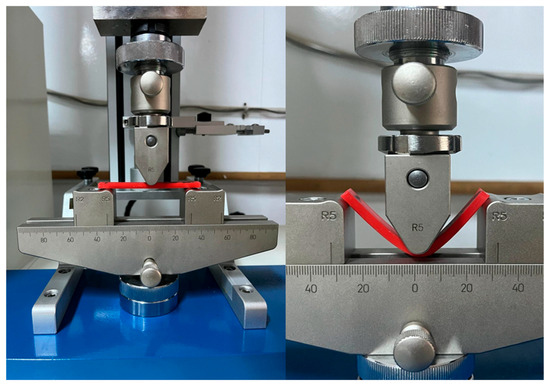

All 90 specimens (45 PETG and 45 rPETG) were tested in three-point bending on the Barrus White 20 kN universal testing machine (Budapest, Hungary), according to ISO 178:2019 standard, using a speed of 5 mm/min, (see Figure 5) [47].

Figure 5.

Three-point bending test on the Barrus White 20 kN universal testing machine.

Figure 6 shows the 90 specimens after the three-point bending test on the Barrus White 20 kN universal testing machine.

Figure 6.

Specimens manufactured on the QIDI Q1 Pro printer after three-point bending test: (a) PETG; (b) rPETG.

3. Results and Discussion

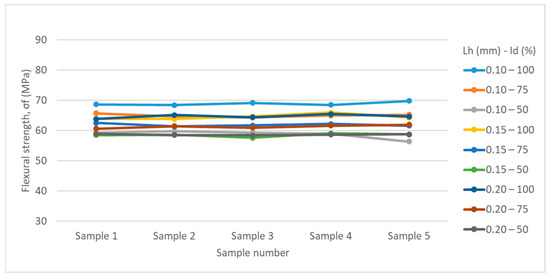

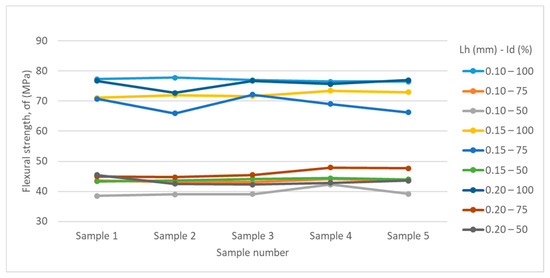

Table 2 and Table 3 and Figure 7 and Figure 8 summarize the results obtained from the experimental determinations of three-point bending of PETG and rPETG specimens on the Barrus White 20 kN universal testing machine.

Table 2.

Results of three-point bending tests of specimens made of PETG.

Table 3.

Results of three-point bending tests of specimens manufactured from rPETG.

Figure 7.

Graphical representation of the three-point flexural strengths of specimens made of PETG.

Figure 8.

Graphical representation of the three-point flexural strengths of specimens manufactured from rPETG.

Analyzing the data in Table 2 and Figure 7, we observe that the maximum flexural strength (69.78 MPa) was obtained for specimen 5 from the set manufactured with parameters Lh = 0.10 mm and Id = 100%, and the minimum flexural strength (56.37 MPa) was obtained for specimen 5 from the set manufactured with Lh = 0.10 mm and Id = 50%. Analyzing the average values of the flexural strengths, we observe that the maximum value (68.87 MPa) was obtained for the specimens manufactured with Lh = 0.10 mm and Id = 100%, and the minimum value of the flexural strengths (58.49) was obtained for the specimens manufactured with Lh = 0.15 mm and Id = 50%.

Reducing the filling density (Id) from 100% to 75% led to a decrease in flexural strengths of 4.96–5.71%, and by reducing the filling density from 75% to 50%, the flexural strengths decreased by 4.57–9.53%.

Analyzing the data presented in Table 3 and Figure 8, we observe that the maximum flexural strength (77.01 MPa) was obtained for specimen 2 from the set manufactured with parameters Lh = 0.10 mm and Id = 100%, and the minimum flexural strength (38.48 MPa) was obtained for specimen 1 from the set manufactured with Lh = 0.10 mm and Id = 50%. Analyzing the average values of the flexural strengths, we observe that the maximum value (77.01 MPa) was obtained for the specimens manufactured with Lh = 0.10 mm and Id = 100%, and the minimum value of the flexural strengths (39.59) was obtained for the specimens manufactured with Lh = 0.10 mm and Id = 50%.

Reducing the filling density (Id) from 100% to 75% led to a decrease in flexural strengths by 10.61–39.79%, and by reducing the filling density from 75% to 50%, the flexural strengths decreased by 8.98–36.27%.

Analyzing Figure 8, we observe that the flexural strengths of rPETG specimens are considerably affected by the reduction in filling density.

Figure 9 shows a comparison of the average values of the three-point flexural strength for specimens manufactured by thermoplastic extrusion of PETG and rPETG.

Figure 9.

Average values of flexural strengths of PETG and rPETG specimens.

Analyzing Figure 9, we observe that the variable printing parameters (Lh and Id) and the material (PETG and rPETG) significantly influence the flexural strengths of the samples additively manufactured on the QIDI Q1 Pro 3D printer.

The flexural strength results obtained for the samples manufactured from rPETG with Id = 100% are higher by 10.58–10.72% compared to the flexural strengths results corresponding to the samples manufactured from PETG using the same parameters.

The flexural strengths values obtained for the samples manufactured from rPETG with Id = 75% are higher up to 6.02% compared to the flexural strengths results of the samples manufactured from PETG using the same parameters.

The flexural strengths of the specimens made of rPETG with Id = 50% are lower by 25.32–32.32% compared to the flexural strengths of the specimens made of PETG using the same parameters.

The average of all values of the flexural strengths of the specimens made of PETG with Lh = (0.10; 0.15; 0.20) mm and Id = (50; 75; 100)% is higher by 9.19% compared to the average flexural strengths of the specimens made of rPETG.

The superior performance of the samples manufactured from rPETG with Id = 100% is the result of improved adhesion of the overlapping layers, but also of increased crystallinity.

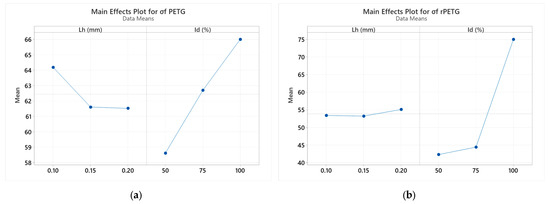

To evaluate the influence of the FDM process parameters, namely layer height (Lh) and infill density (Id) on the three-point flexural strengths of additively manufactured PETG and rPETG specimens, an ANOVA (Analysis of Variance) analysis was performed using Minitab 19 software [49]. The results obtained from this statistical analysis are presented in Figure 10. The p-value plays a crucial role in determining the statistical significance of the influence of factors on an analyzed characteristic. For PETG, the corresponding p-values for Lh and Id are 0.987 and 0.0051, respectively. In the case of rPETG, the obtained p-values for Lh and Id are 0.591 and 0.0001, respectively.

Figure 10.

Effect diagrams of factors influencing flexural strength: (a) PETG; (b) rPETG.

The graphs presented in Figure 10 show how the variable parameters of thermoplastic extrusion (Lh and Id) influence the mechanical performance of PETG and rPETG specimens in three-point bending. Interpreting the data in Figure 10a, we find that the filling density (Id) is the parameter that significantly influences the bending resistance of PETG additively manufactured specimens. At the same time, a decrease in bending resistance is observed due to the increase in the height of the deposited layer at a transition from 0.10 to 0.15 and 0.20 mm, respectively. Analyzing Figure 10b, we observe the major impact of the filling density on the bending resistance.

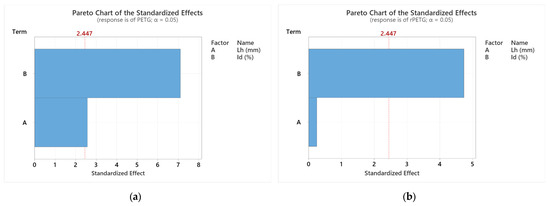

Figure 11 presents Pareto graphs regarding the influence of variable thermoplastic extrusion parameters on the flexural strengths of specimens made of PETG and rPETG.

Figure 11.

Pareto charts regarding the influence of variable parameters A = Lh and B = Id on flexural strengths: (a) PETG; (b) rPETG.

Analyzing Figure 11a, we observe that both parameters (A = Lh and B = Id) influence the flexural strengths of PETG specimens, the factor B = Id having a 63.85% greater influence than the factor with A = Lh. Evaluating the graph in Figure 11b, we observe the decisive influence of the factor B = Id on the flexural strengths of specimens manufactured from rPETG. The influence of the factor A = Lh is insignificant, being 94.79% lower than the influence of the factor B = Id.

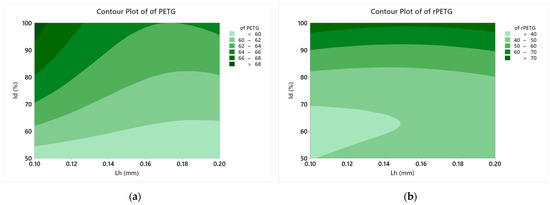

Figure 12 presents the contour plots regarding the influence of the parameters Lh and Id on the three-point flexural strengths.

Figure 12.

Contour plots corresponding to the influence of Lh and Id on the flexural strengths: (a) PETG; (b) rPETG.

Analyzing Figure 12, we observe how Lh and Id influence the flexural strengths of specimens manufactured from PETG and rPETG. The graph in Figure 12a shows the strong influence of Id and the moderate influence of Lh; by increasing the filling density (Id), higher values of flexural strengths are obtained. The graph shown in Figure 12b shows that Id is the critical factor for the flexural strength of specimens manufactured additively from rPETG. By increasing the filling density, a clear increase in flexural strengths is obtained.

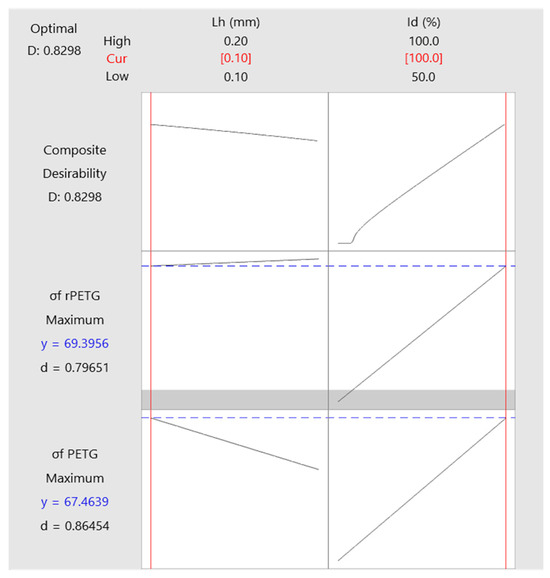

Figure 13 shows the optimization plots of the variable manufacturing parameters (Lh—deposited layer height and Id—filling density) for specimens made of PETG and rPETG, in order to maximize the three-point coving resistance. The optimization results show that for both materials, the optimal configuration for maximizing the three-point flexural strength is Lh = 0.10 mm and Id = 100%.

Figure 13.

Manufacturing parameter optimization plots for PETG and rPETG three-point bending specimens.

Using Minitab and the variable parameters of thermoplastic extrusion in Table 1, regression equations were obtained with which the three-point bending strength can be predicted for each type of material studied.

4. Conclusions

This paper presents the results of research on optimizing FDM parameters for the manufacture of PETG and recycled PETG bending specimens in the context of the transition to a circular economy. For the study, 45 three-point bending specimens of PETG and 45 three-point bending specimens of rPETG were manufactured on the QIDI Q1 Pro 3D printer, which were subsequently tested on the Barrus White 20 kN universal testing machine.

- Optimal parameters for maximum flexural strength:

- Lh = 0.10 mm and Id = 100%.

Key findings:

- rPETG outperforms PETG under optimal conditions, showing 10.72% higher bending resistance.

- The average bending resistances of the 45 PETG specimens are 9.19% higher compared to the average bending resistances of rPETG specimens.

Statistical validation:

The results obtained in this study highlight the potential of using recycled materials in mechanical engineering applications for the manufacture of functional parts that are subject to moderate loads. The use of recycled materials helps to reduce the negative impact on the environment caused by the amount of plastic waste. Another benefit of using recycled materials in applications of additive manufacturing technologies through plastic extrusion is the reduction in production costs, the costs of recycled materials being lower compared to those of virgin materials.

Given the contrast between the results obtained in this study and the superior mechanical results obtained for rPETG in the works [41,42], the authors propose to study the internal structures of the parts, the effect of recycling on material adhesion, and the bonding between the layers in our future research.

The authors propose to extend this research by carrying out a technical–economic study based on maximizing the ratio between the use value (flexural strength) and the production cost. At the same time, the authors propose to extrapolate this study to other types of materials.

Author Contributions

Conceptualization, D.G.Z., M.M. and D.V.I.; methodology, D.G.Z., M.M. and D.V.I.; validation, D.G.Z., M.M. and D.V.I.; formal analysis, D.G.Z.; investigation, D.G.Z., M.M. and D.V.I.; resources, D.G.Z., M.M. and D.V.I.; writing—original draft preparation, D.V.I.; writing—review and editing, D.G.Z., M.M. and D.V.I.; visualization D.G.Z., M.M. and D.V.I.; supervision, D.G.Z. and M.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Nikolaou, I.E.; Jones, N.; Stefanakis, A. Circular Economy and Sustainability: The Past, the Present and the Future Directions. Circ. Econ. Sustain. 2021, 1, 1–20. [Google Scholar] [CrossRef]

- Arruda, E.H.; Melatto, R.A.P.B.; Levy, W.; Conti, D.d.M. Circular Economy: A Brief Literature Review (2015–2020). Sustain. Oper. Comput. 2021, 2, 79–86. [Google Scholar] [CrossRef]

- Provenzano, V.; Seminara, M. The Nexus Between Circular Economy and Sustainable Development Goals. In International Symposium: New Metropolitan Perspectives; Springer: Berlin/Heidelberg, Germany, 2024; pp. 72–82. ISBN 978-3-031-74671-0. [Google Scholar]

- Ghosh, A.; Bhola, P.; Sivarajah, U. Emerging Associates of the Circular Economy: Analysing Interactions and Trends by a Mixed Methods Systematic Review. Sustainability 2022, 14, 9998. [Google Scholar] [CrossRef]

- Mangău, A.; Vermeșan, H.; Pădurețu, S.; Hegyi, A. An Incursion into Actuality: Addressing the Precautionary Principle in the Context of the Circular Economy. Sustainability 2022, 14, 10090. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm. J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence from the European Union (EU). Ecol. Econ. 2018, 150, 264–272. [Google Scholar] [CrossRef]

- Liu, L.; Ramakrishna, S. (Eds.) An Introduction to Circular Economy; Springer: Singapore, 2021. [Google Scholar]

- Bolat, Ç.; Yıldırım, E. A Comparative Effort on the Influence of Liquid Treatment Media Type, Fiber Addition, and Deformation Load on the Wear Performance of Additively Manufactured Polyamide 6 and Acrylonitrile Butadiene Styrene Composites. Polymer Composites. Polym. Compos. 2025. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Nae, I.; Portoaca, A.I.; Ramadan, I. A Statistical Approach of the Flexural Strength of PLA and ABS 3D Printed Parts. Eng. Technol. Appl. Sci. Res. 2022, 12, 8248–8252. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Influence of FDM Parameters on the Compressive Behavior of PET-G Parts. Eng. Technol. Appl. Sci. Res. 2024, 14, 13592–13597. [Google Scholar] [CrossRef]

- Raja, S.; Rusho, M.; Karthikeyan, S.; Surakasi, R.; Anand, R.; Devarasu, N. Energy-Efficient FDM Printing of Sustainable Polymers: Optimization Strategies for Material and Process Performance. Appl. Chem. Eng. 2024, 7, 5537. [Google Scholar] [CrossRef]

- Agrawal, A.P.; Kumar, V.; Kumar, J.; Paramasivam, P.; Dhanasekaran, S.; Prasad, L. An Investigation of Combined Effect of Infill Pattern, Density, and Layer Thickness on Mechanical Properties of 3D Printed ABS by Fused Filament Fabrication. Heliyon 2023, 9, e16531. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Kleiner, C.; Tabigue, A.; Shah, V.; Sacks, G.; Shah, D.; DeStefano, V. PETG: Applications in Modern Medicine. Eng. Regen. 2024, 5, 45–55. [Google Scholar] [CrossRef]

- Rivera-López, F.; Pavón, M.M.L.; Correa, E.C.; Molina, M.H. Effects of Nozzle Temperature on Mechanical Properties of Polylactic Acid Specimens Fabricated by Fused Deposition Modeling. Polymers 2024, 16, 1867. [Google Scholar] [CrossRef]

- Chidara, A.; Cheng, K.; Gallear, D. Engineering Innovations for Polyvinyl Chloride (PVC) Recycling: A Systematic Review of Advances, Challenges, and Future Directions in Circular Economy Integration. Machines 2025, 13, 362. [Google Scholar] [CrossRef]

- Yu, W.; Sun, L.; Li, M.; Li, M.; Lei, W.; Wei, C. FDM 3D Printing and Properties of PBS/PLA Blends. Polymers 2023, 15, 4305. [Google Scholar] [CrossRef]

- Li, M.; Lei, W.; Yu, W. FDM 3D Printing and Properties of WF/PBAT/PLA Composites. Molecules 2024, 29, 5087. [Google Scholar] [CrossRef]

- Yalçın, M.M. Flexural Behavior of 3D-Printed Carbon Fiber-Reinforced Nylon Lattice Beams. Polymers 2024, 16, 2991. [Google Scholar] [CrossRef]

- Raja, S.; Jayalakshmi, M.; Rusho, M.A.; Selvaraj, V.K.; Subramanian, J.; Yishak, S.; Kumar, T.A. Fused Deposition Modeling Process Parameter Optimization on the Development of Graphene Enhanced Polyethylene Terephthalate Glycol. Sci. Rep. 2024, 14, 30744. [Google Scholar] [CrossRef]

- Suteja, T.J. Optimization of Infill Density, Layer Height, and Shell Thickness to Achieve Maximum Bending Strength and Minimum Printing Time of PLA 3D Printed Part. J. Polimesin 2023, 21, 1–5. [Google Scholar] [CrossRef]

- Jatti, V.; Sapre, M.; Jatti, A.; Khedkar, N.; Jatti, V. Mechanical Properties of 3D-Printed Components Using Fused Deposition Modeling: Optimization Using the Desirability Approach and Machine Learning Regressor. Appl. Syst. Innov. 2022, 5, 112. [Google Scholar] [CrossRef]

- Al-Tamimi, A.A.; Pandžić, A.; Kadrić, E. Investigation and Prediction of Tensile, Flexural, and Compressive Properties of Tough PLA Material Using Definitive Screening Design. Polymers 2023, 15, 4169. [Google Scholar] [CrossRef] [PubMed]

- Smirnov, A.; Nikitin, N.; Peretyagin, P.; Khmyrov, R.; Kuznetsova, E.; Solis Pinargote, N.W. Experimental and Statistical Modeling for Effect of Nozzle Diameter, Filling Pattern, and Layer Height of FDM-Printed Ceramic–Polymer Green Body on Biaxial Flexural Strength of Sintered Alumina Ceramic. J. Compos. Sci. 2023, 7, 381. [Google Scholar] [CrossRef]

- Sv, L.S.; Karthick, A.; Dinesh, C. Evaluation of Mechanical Properties of 3D Printed PETG and Polyamide (6) Polymers. Chem. Phys. Impact 2024, 8, 100491. [Google Scholar] [CrossRef]

- Kumaresan, R.; Kadirgama, K.; Samykano, M.; Harun, W.S.W.; Thirugnanasambandam, A.; Aslfattahi, N.; Samylingam, L.; Kok, C.K.; Ghazali, F.M. Optimization of Inter-Layer Printing Parameters for Enhanced Mechanical Performance of PETG in Fused Deposition Modeling (FDM). Results Eng. 2025, 25, 104564. [Google Scholar] [CrossRef]

- Pyka, D.; Słowiński, J.J.; Kurzawa, A.; Roszak, M.; Stachowicz, M.; Kazimierczak, M.; Stępczak, M.; Grygier, D. Research on Basic Properties of Polymers for Fused Deposition Modelling Technology. Appl. Sci. 2024, 14, 11151. [Google Scholar] [CrossRef]

- Vălean, C.; Marșavina, L.; Mărghitaș, M.; Linul, E.; Razavi, N.; Berto, F. Effect of Manufacturing Parameters on Tensile Properties of FDM Printed Specimens. Procedia Struct. Integr. 2020, 26, 313–320. [Google Scholar] [CrossRef]

- Tsai, H.-H.; Wu, S.-J.; Wu, Y.-D.; Hong, W.-Z. Feasibility Study on the Fused Filaments of Injection-Molding-Grade Poly(Ethylene Terephthalate) for 3D Printing. Polymers 2022, 14, 2276. [Google Scholar] [CrossRef]

- Lopes, L.; Penazzato, L.; Reis, D.C.; Almeida, M.; Oliveira, D.V.; Lourenço, P.B. A Holistic Modular Solution for Energy and Seismic Renovation of Buildings Based on 3D-Printed Thermoplastic Materials. Sustainability 2024, 16, 2166. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Printability and Tensile Performance of 3D Printed Polyethylene Terephthalate Glycol Using Fused Deposition Modelling. Polymers 2019, 11, 1220. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Grammatikos, S.A.; Porfyrakis, E.; Maniadi, A.; Mountakis, N. Sustainable Additive Manufacturing: Mechanical Response of Polyethylene Terephthalate Glycol over Multiple Recycling Processes. Materials 2021, 14, 1162. [Google Scholar] [CrossRef]

- Sepahi, M.T.; Abusalma, H.; Jovanovic, V.; Eisazadeh, H. Mechanical Properties of 3D-Printed Parts Made of Polyethylene Terephthalate Glycol. J. Mater. Eng. Perform. 2021, 30, 6851–6861. [Google Scholar] [CrossRef]

- Benyathiar, P.; Kumar, P.; Carpenter, G.; Brace, J.; Mishra, D.K. Polyethylene Terephthalate (PET) Bottle-to-Bottle Recycling for the Beverage Industry: A Review. Polymers 2022, 14, 2366. [Google Scholar] [CrossRef] [PubMed]

- Hassan, M.H.; Omar, A.M.; Daskalakis, E.; Hou, Y.; Huang, B.; Strashnov, I.; Grieve, B.D.; Bártolo, P. The Potential of Polyethylene Terephthalate Glycol as Biomaterial for Bone Tissue Engineering. Polymers 2020, 12, 3045. [Google Scholar] [CrossRef] [PubMed]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Technical–Economic Study on Optimizing FDM Parameters to Manufacture Pieces Using Recycled PETG and ASA Materials in the Context of the Circular Economy Transition. Polymers 2025, 17, 122. [Google Scholar] [CrossRef]

- Ghaffar, A.; Riaz, M.T.; Rehman, A.; Al Mahmud, M.M.S. An Optimized 3D Printer by Enhancing Material Properties and Surface Finish of PLA Through Modifications. J. Eng. 2024, 2024, 9198329. [Google Scholar] [CrossRef]

- Mazlan, M.A.; Anas, M.A.; Nor Izmin, N.A.; Abdullah, A.H. Effects of Infill Density, Wall Perimeter and Layer Height in Fabricating 3D Printing Products. Materials 2023, 16, 695. [Google Scholar] [CrossRef]

- Hamoud, M.; Elshalakany, A.B.; Gamil, M.; Mohamed, H. Investigating the Influence of 3D Printing Parameters on the Mechanical Characteristics of FDM Fabricated (PLA/Cu) Composite Material. Int. J. Adv. Manuf. Technol. 2024, 134, 3769–3785. [Google Scholar] [CrossRef]

- Dev, S.; Srivastava, R. Optimization of Fused Deposition Modeling (FDM) Process Parameters for Flexural Strength. Mater. Today Proc. 2021, 44, 3012–3016. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study on the Tensile Behavior of Specimens Manufactured by FDM from Recycled PETG in the Context of the Circular Economy Transition. Eng. Technol. Appl. Sci. Res. 2024, 14, 18681–18687. [Google Scholar] [CrossRef]

- Zisopol, D.G.; Minescu, M.; Iacob, D.V. A Study of the Optimization of FDM Parameters for the Manufacture of Compression Specimens from Recycled PETG in the Context of the Transition to the Circular Economy. Eng. Technol. Appl. Sci. Res. 2024, 14, 18774–18779. [Google Scholar] [CrossRef]

- Ghabezi, P.; Sam-Daliri, O.; Flanagan, T.; Walls, M.; Harrison, N.M. Mechanical and Microstructural Analysis of Glass Fibre-Reinforced High Density Polyethylene Thermoplastic Waste Composites Manufactured by Material Extrusion 3D Printing Technology. Compos. Part A Appl. Sci. Manuf. 2025, 194, 108930. [Google Scholar] [CrossRef]

- Toth, L.; Slezák, E.; Bocz, K.; Ronkay, F. Progress in 3D Printing of Recycled PET. Mater. Today Sustain. 2024, 26, 100757. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Flanagan, T.; Modi, V.; Finnegan, W.; Harrison, N.; Ghabezi, P. Composite Upcycling: An Experimental Study on Mechanical Behaviour of Injection Moulded Parts Prepared from Recycled Material Extrusion Printed Parts, Previously Prepared Using Glass Fibre Polypropylene Composite Industry Waste. J. Clean. Prod. 2025, 499, 145280. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Soleyman, E.; Bashi, M.; Aberoumand, M.; Soltanmohammadi, K.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. 4D Printing and Annealing of PETG Composites Reinforced with Short Carbon Fibers. Phys. Scr. 2024, 99, 055957. [Google Scholar] [CrossRef]

- ISO 178:2019; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2019.

- Available online: https://qidi3d.com/pages/software-firmware (accessed on 4 January 2025).

- Available online: https://www.minitab.com/en-us/ (accessed on 15 February 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).