From Waste to Function: Compatibilized r-PET/r-HDPE Blends for Pellet Extrusion 3D Printing

Abstract

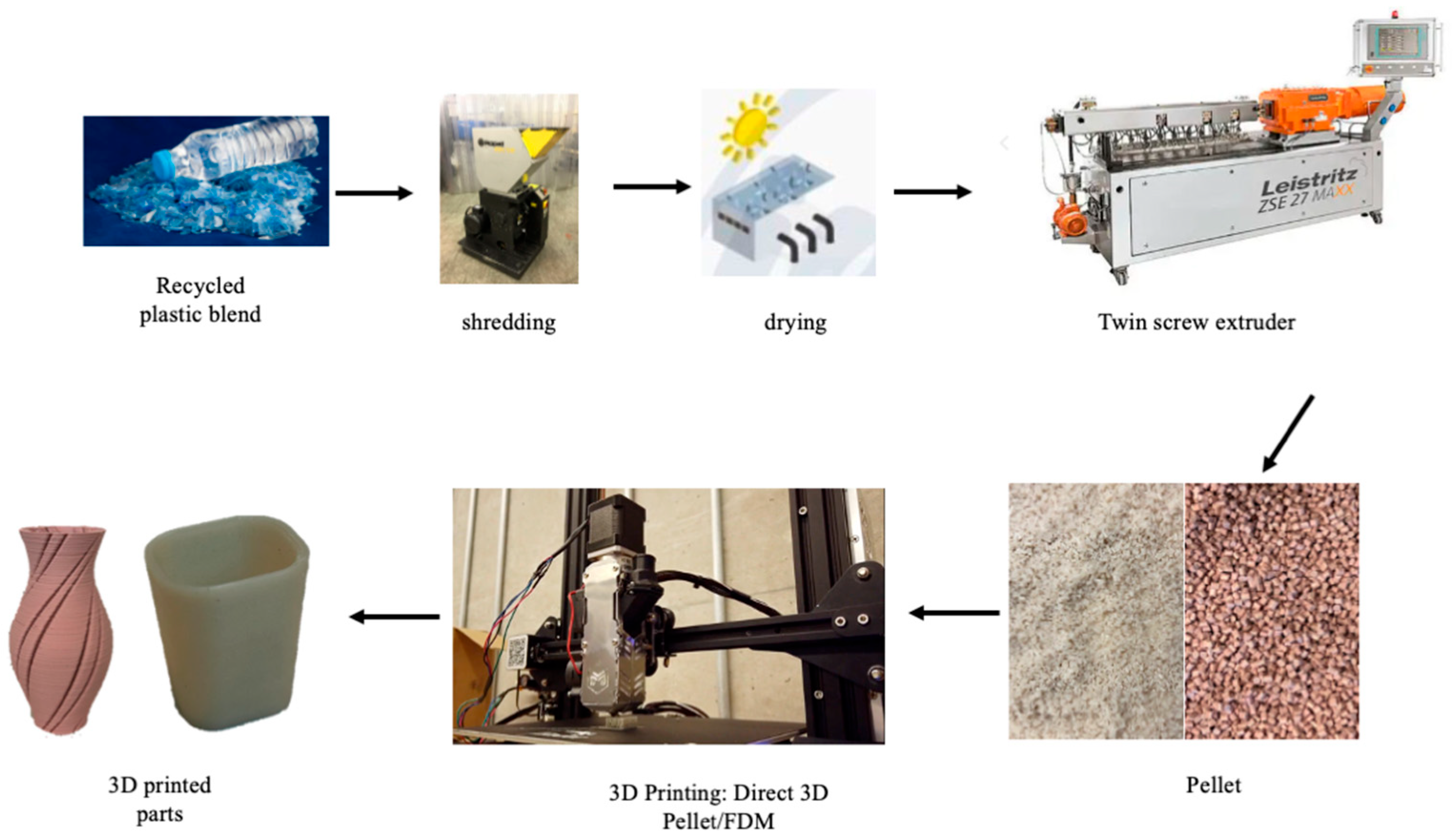

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Polymer Blending with Twin-Screw Extruder

2.3. Pellet 3D Printing

2.4. Printer Configuration

3. Characterization

3.1. Rheology Test

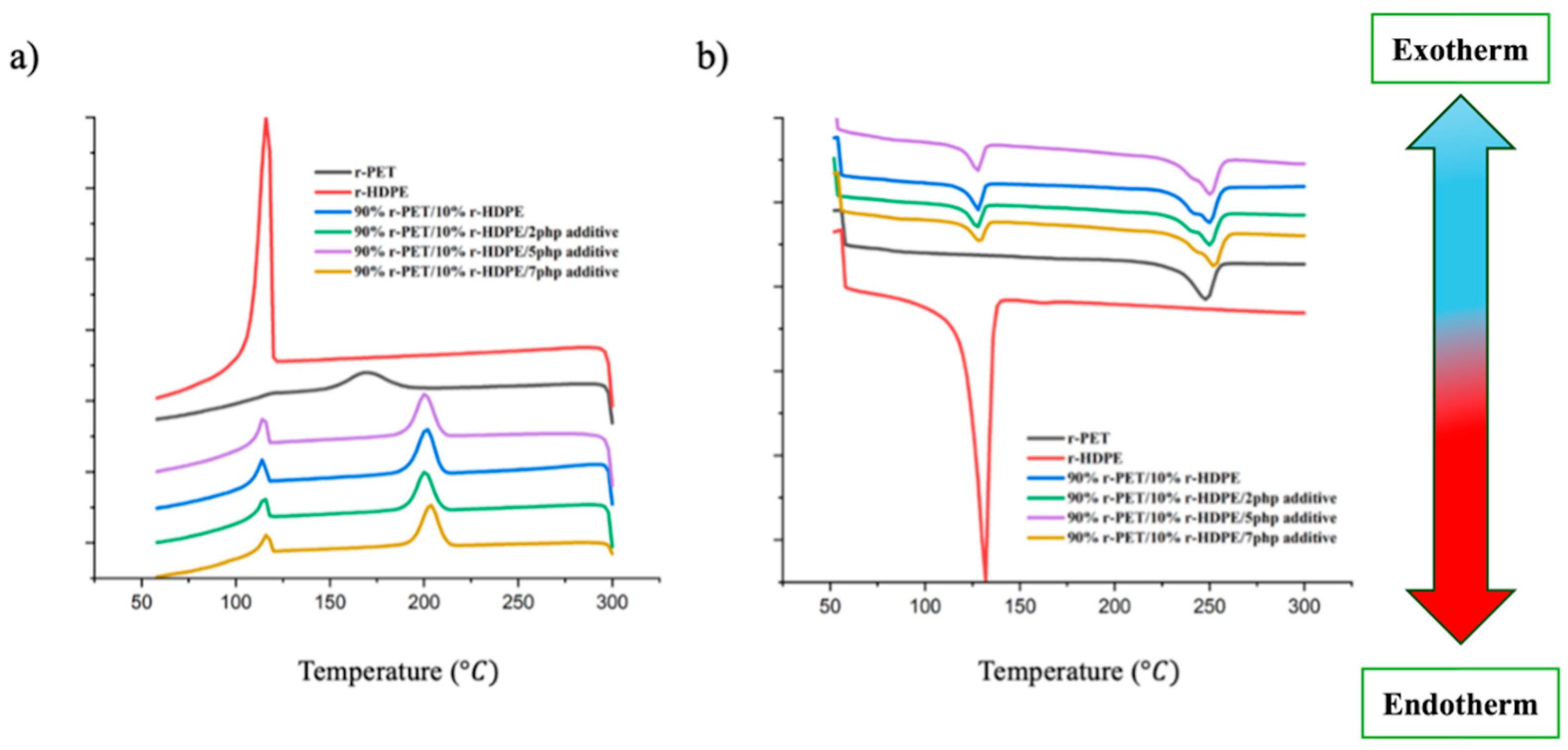

3.2. Thermal Characterization

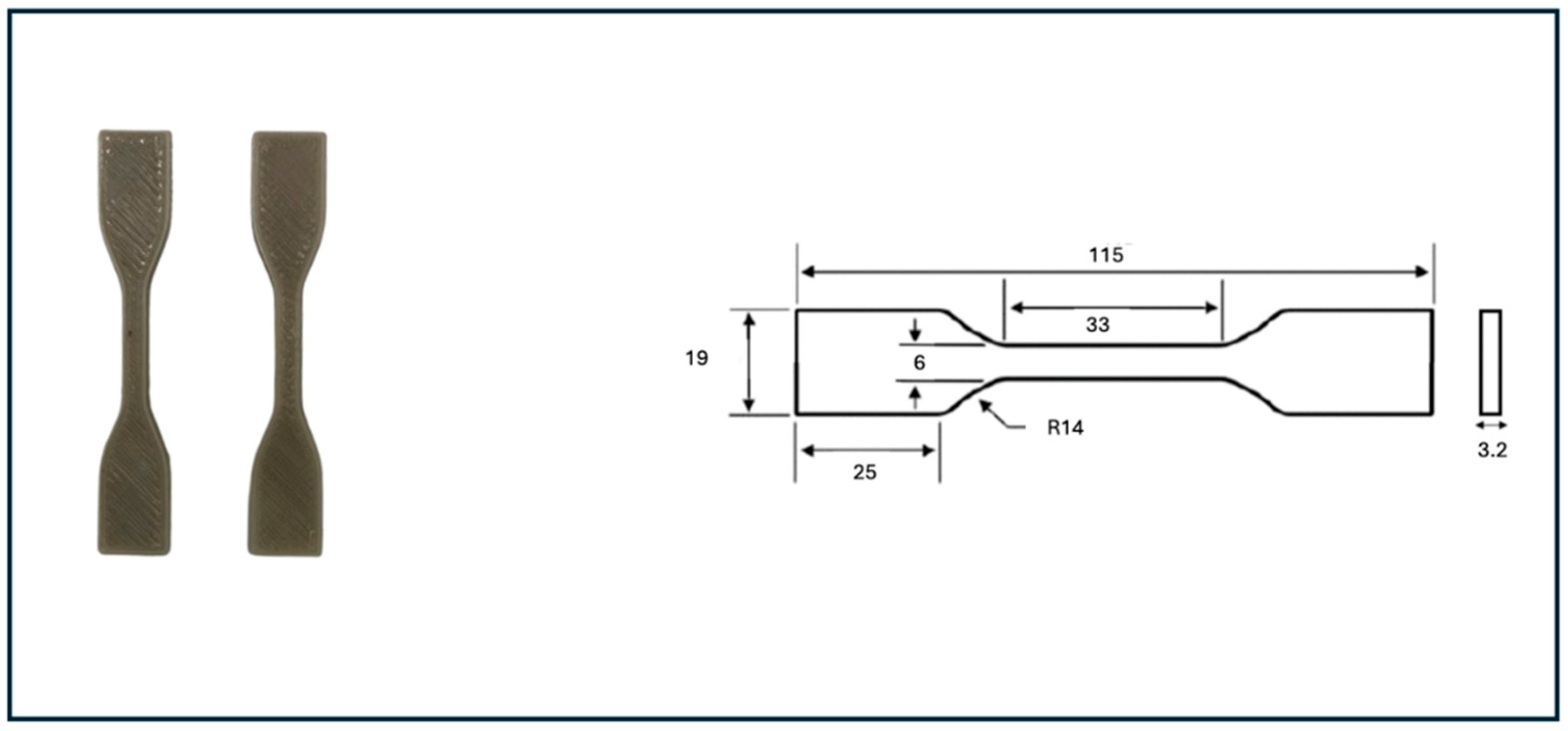

3.3. Mechanical Test

3.4. SEM Analysis

4. Results and Discussion

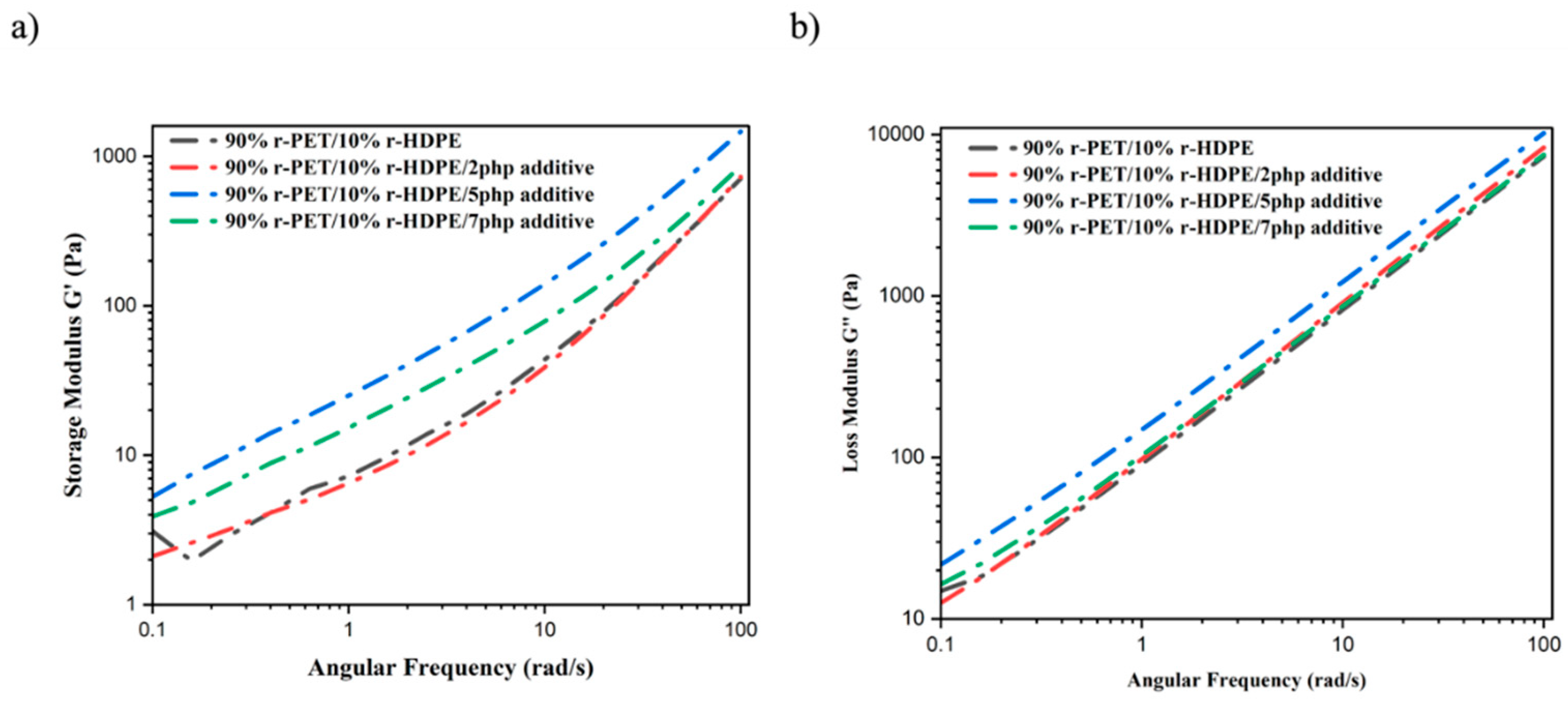

4.1. Rheology Test

4.2. Differential Scanning Calorimetry

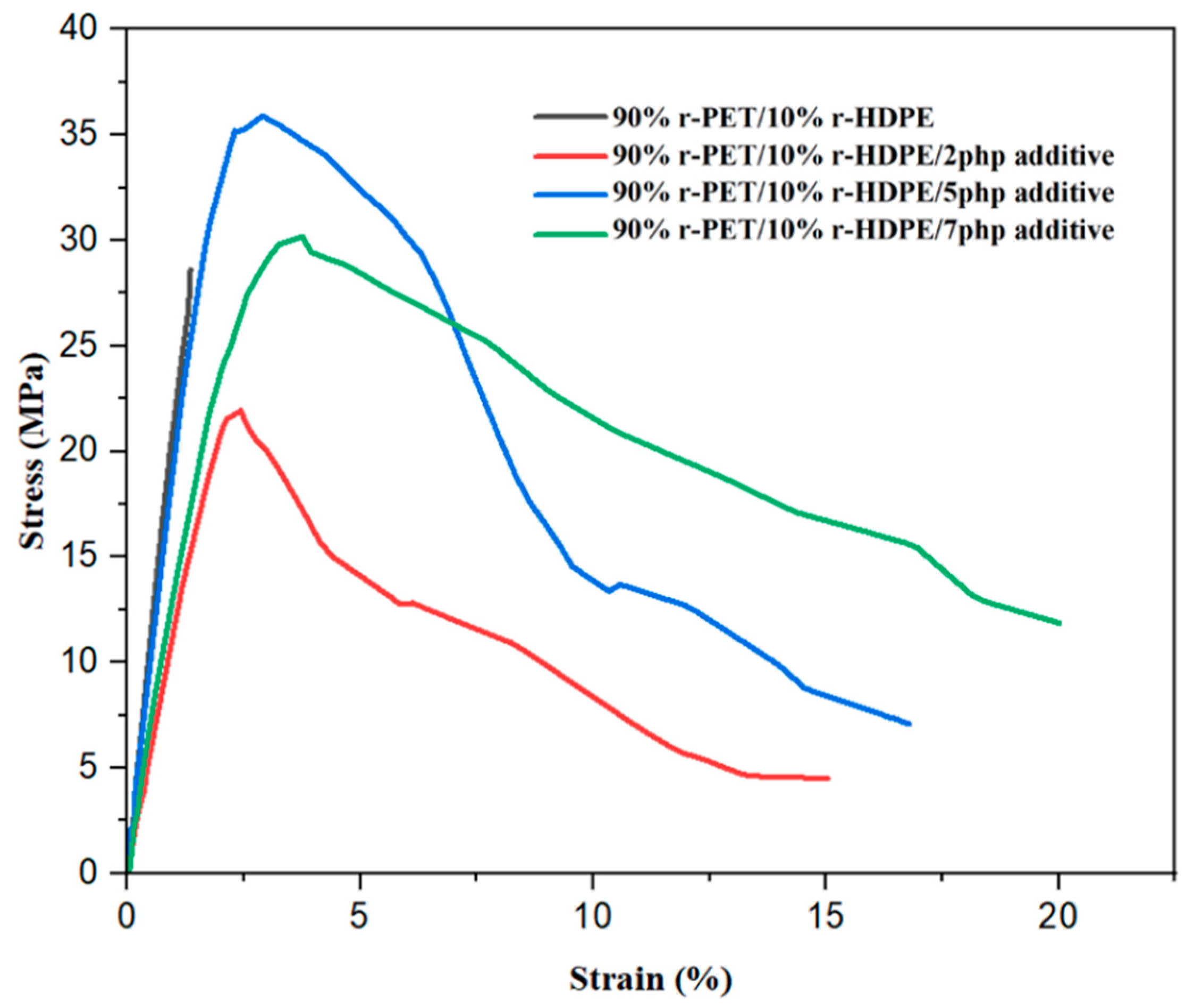

4.3. Mechanical Properties

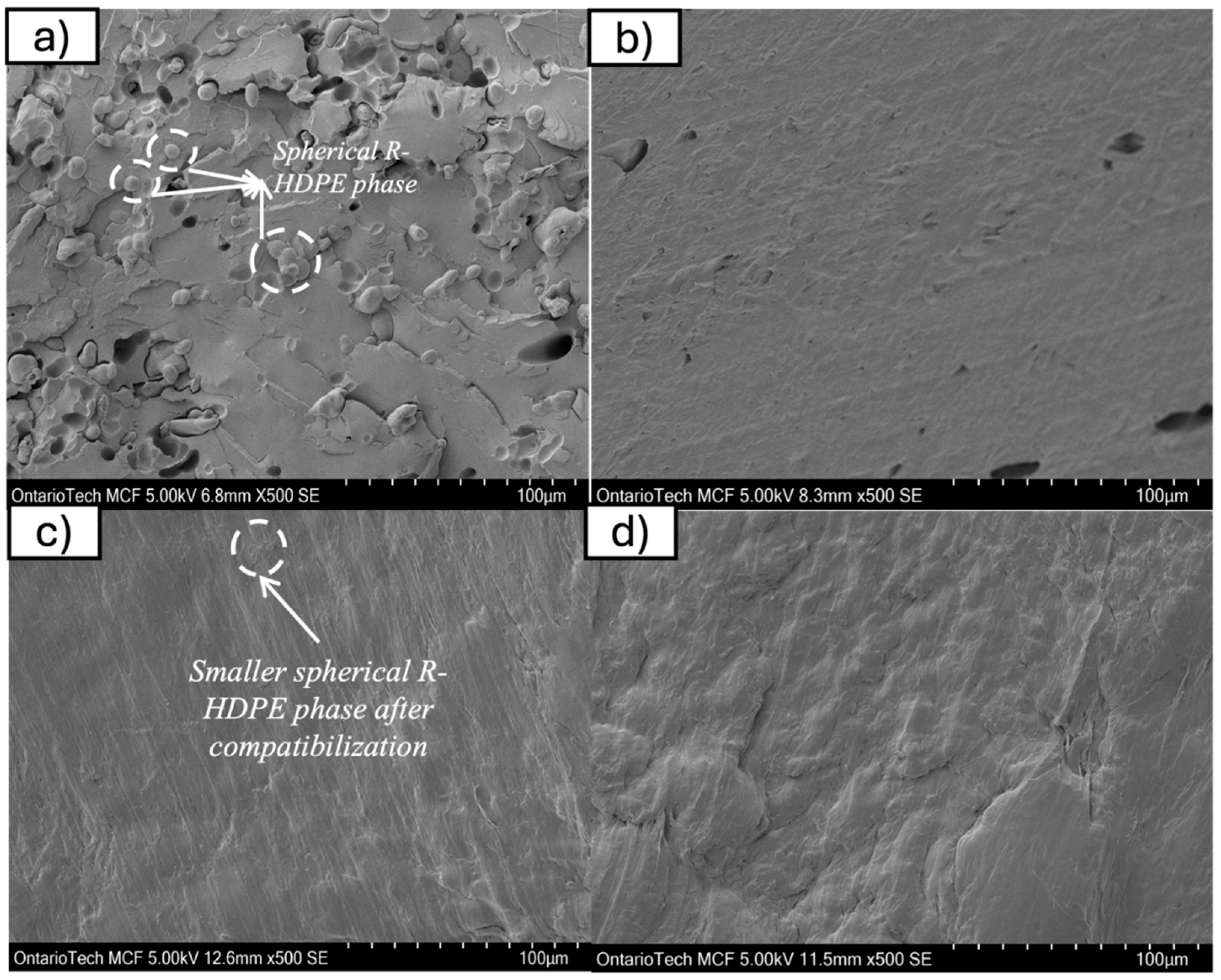

4.4. Scanning Electron Microscopy Analysis

5. Conclusions

5.1. Rheological Analysis

- The addition of compatibilizer up to 5 php significantly increased complex viscosity, storage modulus (G′), and loss modulus (G″), enhancing elasticity and interfacial adhesion.

- Excess compatibilizer (>5 php) led to a decrease in viscosity and modulus due to phase plasticization and interfacial saturation.

5.2. Thermal Characterization

- The results of the differential scanning calorimetry (DSC) analysis showed that the compatibilizer increased the melting temperature (Tm) of r-PET, improving crystallinity and phase miscibility.

- The crystallization temperature (Tc) of r-PET increased with compatibilizer addition, leading to improved nucleation efficiency and faster solidification.

- Thermogravimetric analysis (TGA) demonstrated enhanced thermal stability with compatibilizer addition, shifting the decomposition temperature of the blend from 370 °C to approximately 400 °C.

5.3. Mechanical Properties

- The unmodified r-PET/r-HDPE blend exhibited poor mechanical properties due to weak interfacial adhesion (28 MPa UTS and 3% elongation at break).

- The addition of 2 php compatibilizer increased elongation at break to 15% but reduced tensile strength, suggesting limited compatibility improvements.

- At 5 php compatibilizer, the blend exhibited the best mechanical performance, with 35 MPa UTS and 17% elongation at break, demonstrating improved stress transfer and interfacial bonding.

- The 7 php compatibilizer blend exhibited phase plasticization effects, resulting in a UTS reduction to 30 MPa but increased elongation at break to 22.5%, suggesting a shift in balance between stiffness and ductility.

5.4. Morphological Analysis (SEM)

- Unmodified r-PET/r-HDPE blends exhibited phase separation with distinct HDPE domains, indicating poor compatibility.

- Compatibilizer addition resulted in finer dispersion of HDPE within the PET matrix, reducing interfacial defects and improving blend homogeneity.

- At 5 php, the morphology transitioned to a more uniform structure with enhanced adhesion, while 7 php led to self-aggregation effects.

5.5. 3D Printability & Process Optimization

- Direct pellet extrusion printing was optimized to improve flow consistency and eliminate nozzle clogging.

- A calibrated extrusion multiplier (4.5) was found to provide the best balance between flow rate and layer adhesion.

- Optimized nozzle temperature (300 °C) ensured stable extrusion, preventing incomplete melting and phase separation.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tabary, S.A.A.B.; Fayazfar, H.R. Circular economy solutions for plastic waste: Improving rheological properties of recycled polyethylene terephthalate (r-PET) for direct 3D printing. Prog. Addit. Manuf. 2024, 10, 2795–2804. [Google Scholar] [CrossRef]

- Plastic Waste and Pollution Reduction—Canada.ca. Available online: https://www.canada.ca/en/environment-climate-change/services/managing-reducing-waste/reduce-plastic-waste.html (accessed on 1 March 2025).

- Schwarz, A.E.; Ligthart, T.N.; Godoi Bizarro, D.; De Wild, P.; Vreugdenhil, B.; van Harmelen, T. Plastic recycling in a circular economy; determining environmental performance through an LCA matrix model approach. Waste Manag. 2021, 121, 331–342. [Google Scholar] [CrossRef] [PubMed]

- Collias, D.I.; James, M.I.; Layman, J.M. Introduction—Circular Economy of Polymers and Recycling Technologies. In ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2021; pp. 1–21. [Google Scholar] [CrossRef]

- Zhao, X.; Boruah, B.; Chin, K.F.; Đokić, M.; Modak, J.M.; Soo, H.S. Upcycling to Sustainably Reuse Plastics. Adv. Mater. 2022, 34, 2100843. [Google Scholar] [CrossRef]

- Carrete, I.A.; Quiñonez, P.A.; Bermudez, D.; Roberson, D.A. Incorporating Textile-Derived Cellulose Fibers for the Strengthening of Recycled Polyethylene Terephthalate for 3D Printing Feedstock Materials. J. Polym. Environ. 2021, 29, 662–671. [Google Scholar] [CrossRef]

- Geyer, R.; Kuczenski, B.; Zink, T.; Henderson, A. Common Misconceptions about Recycling. J. Ind. Ecol. 2016, 20, 1010–1017. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2024, 3, e1700782. [Google Scholar] [CrossRef]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Fries, E.; Dekiff, J.H.; Willmeyer, J.; Nuelle, M.-T.; Ebert, M.; Remy, D. Identification of polymer types and additives in marine microplastic particles using pyrolysis-GC/MS and scanning electron microscopy. Environ. Sci. Process Impacts 2013, 15, 1949–1956. [Google Scholar] [CrossRef]

- Gonzalez, C.S.; Sanchez, F.A.C.; Boudaoud, H.; Nouvel, C.; Pearce, J.M. Multi-material distributed recycling via material extrusion: Recycled high density polyethylene and poly (ethylene terephthalate) mixture. Polym. Eng. Sci. 2024, 64, 1555–1570. [Google Scholar] [CrossRef]

- Adhikari, P. Sorting and Recycling Solid Plastic Waste: Challenges and Opportunities. Bachelor’s Thesis, Arcada University of Applied Sciences, Helsinki, Finland, 2021. [Google Scholar]

- da Silva, D.J.; Wiebeck, H. Current options for characterizing, sorting, and recycling polymeric waste, Progress in Rubber. Plast. Recycl. Technol. 2020, 36, 284–303. [Google Scholar]

- Al Rashid, A.; Koç, M. Additive manufacturing for sustainability and circular economy: Needs, challenges, and opportunities for 3D printing of recycled polymeric waste. Mater. Today Sustain. 2023, 24, 100529. [Google Scholar] [CrossRef]

- Ragab, A.; Elazhary, R.; Schmauder, S.; Ramzy, A. Plastic Waste Valorization for Fused Deposition Modeling Feedstock: A Case Study on Recycled Polyethylene Terephthalate/High-Density Polyethylene Sustainability. Sustainability 2023, 15, 13291. [Google Scholar] [CrossRef]

- Study of the Compatibilizer Effect on Blends Prepared From Waste Poly(ethylene-terephthalate) and High Density Polyethylene. Available online: www.hanser-elibrary.com (accessed on 2 May 2025).

- Kordjazi, S.; Kordjazi, Z.; Ebrahimi, N.G. The effect of different compatibilisers on the morphology and rheological properties of PP/PET polymer blends. Plast. Rubber Compos. 2022, 51, 250–258. [Google Scholar] [CrossRef]

- Perin, D.; Botta, L.; Rigotti, D.; Dorigato, A.; Fredi, G.; Pegoretti, A. Tuning the Compatibilizer Content and Healing Temperature in Thermally Mendable Polyamide 6/Cyclic Olefin Copolymer Blends. Polymers 2025, 17, 280. [Google Scholar] [CrossRef]

- Zhang, W.; Shen, J.; Guo, X.; Wang, K.; Jia, J.; Zhao, J.; Zhang, J. Comprehensive Investigation into the Impact of Degradation of Recycled Polyethylene and Recycled Polypropylene on the Thermo-Mechanical Characteristics and Thermal Stability of Blends. Molecules 2024, 29, 4499. [Google Scholar] [CrossRef]

- Cor, K.; Martin, V.D.; Christophe, P.; Robert, J. Strategies for Compatibilization of Polymer Blends. Prog. Polym. Sci. 1998, 23, 707–757. [Google Scholar]

- Pawlak, A.; Morawiec, J.; Gałęski, A. Compatibilization, processing and properties of post-consumer PET/polyolefin blends. Polimery 2002, 47, 491–499. [Google Scholar] [CrossRef]

- Ajitha, A.R.; Thomas, S. Introduction: Polymer blends, thermodynamics, miscibility, phase separation, and compatibilization. In Compatibilization of Polymer Blends; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–29. [Google Scholar]

- Eitouni, H.B.; Balsara, N.P. Thermodynamics of polymer blends. In Physical Properties of Polymers Handbook; Springer: New York, NY, USA, 2007; pp. 339–356. [Google Scholar]

- Jana, S.C.; Sau, M. Effects of viscosity ratio and composition on development of morphology in chaotic mixing of polymers. Polymer 2004, 45, 1665–1678. [Google Scholar] [CrossRef]

- Chen, S.C.; Zhang, L.H.; Zhang, G.; Zhong, G.C.; Li, J.; Zhang, X.M.; Chen, W.X. An investigation and comparison of the blending of LDPE and PP with different intrinsic viscosities of PET. Polymers 2018, 10, 147. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Rocha, C.R.; Perez, A.R.T.; Roberson, D.A.; Shemelya, C.M.; Macdonald, E.; Wicker, R.B. Novel ABS-based binary and ternary polymer blends for material extrusion 3D printing. J. Mater. Res. 2014, 29, 1859–1866. [Google Scholar] [CrossRef]

- Sam-Daliri, O.; Flanagan, T.; Modi, V.; Finnegan, W.; Harrison, N.; Ghabezi, P. Composite upcycling: An experimental study on mechanical behaviour of injection moulded parts prepared from recycled material extrusion printed parts, previously prepared using glass fibre polypropylene composite industry waste. J. Clean. Prod. 2025, 499, 145280. [Google Scholar] [CrossRef]

- Ghabezi, P.; Sam-Daliri, O.; Flanagan, T.; Walls, M.; Harrison, N.M. Mechanical and microstructural analysis of glass Fibre-Reinforced high density polyethylene thermoplastic waste composites manufactured by material extrusion 3D printing technology. Compos. Part. A Appl. Sci. Manuf. 2025, 194, 108930. [Google Scholar] [CrossRef]

- Toth, L.; Slezák, E.; Bocz, K.; Ronkay, F. Progress in 3D printing of recycled PET. Mater. Today Sustain. 2024, 26, 100757. [Google Scholar] [CrossRef]

- Innovative Plastic Recycling|Post Plastics. Available online: https://www.postplastics.com/ (accessed on 22 May 2025).

- Oceanworks|Recycled Plastic Solutions|Ocean Plastic Marketplace. Available online: https://oceanworks.co/ (accessed on 22 May 2025).

- D638 Standard Test Method for Tensile Properties of Plastics. Available online: https://store.astm.org/d0638-14.html (accessed on 22 May 2025).

- Vaucher, J.; Demongeot, A. Recycling of Bottle Grade PET: Influence of HDPE Contamination on the Microstructure and Mechanical Performance of 3D Printed Parts. Polymers 2022, 14, 5507. [Google Scholar] [CrossRef]

- Chen, R.S.; Ghani, M.H.A.; Salleh, M.N.; Ahmad, S.; Gan, S. Influence of blend composition and compatibilizer on mechanical and morphological properties of recycled HDPE/PET blends. Mater. Sci. Appl. 2014, 5, 943. [Google Scholar] [CrossRef]

- Feregrino, C.; Ospina, S.A.; Flórez, L.; Henao, A.; López, B.L. Study of HDPE/PET/E-GMA blends: Toughening, rigidity, and thermal and morphology behavior. In Proceedings of the 39th International Conference of the Polymer Processing Society (PPS-39), Cartagena, Colombia, 19–23 May 2024. [Google Scholar]

- Di Lorenzo, M.L. Crystallization of Poly(ethylene terephthalate): A Review. Polymers 2024, 16, 1975. [Google Scholar] [CrossRef]

- Kalfoglou, N.K.; Skafidas, D.S.; Sotiropoulou, D.D. Compatibilization of blends of poly(ethylene terephthalate) and linear low density polyethylene with the ionomer of poly(ethylene-co-methacrylic acid). Polymer 1994, 35, 3624–3630. [Google Scholar] [CrossRef]

- Mishra, J.; Tiwari, S.K.; Abolhasani, M.M.; Azimi, S.; Nayak, G.C. Fundamental of polymer blends and its thermodynamics. In Micro and Nano Fibrillar Composites (MFCs and NFCs) from Polymer Blends; Elsevier: Amsterdam, The Netherlands, 2017; pp. 27–55. [Google Scholar]

- Russell, T.P.; Hjelm, R.P., Jr.; Seeger, P.A. Temperature dependence of the interaction parameter of polystyrene and poly (methyl methacrylate). Macromolecules 1990, 23, 890–893. [Google Scholar] [CrossRef]

- Manias, E.; Utracki, L.A. Thermodynamics of polymer blends. Polym. Blends Handb. 2014, 282, 171–289. [Google Scholar]

- Tariq, A.; Afzal, A.; Rashid, I.A.; Shakir, M.F. Study of thermal, morphological, barrier and viscoelastic properties of PP grafted with maleic anhydride (PP-g-MAH) and PET blends. J. Polym. Res. 2020, 27, 309. [Google Scholar] [CrossRef]

- Available online: https://www.researchgate.net/publication/345748808_Study_of_thermal_morphological_barrier_and_viscoelastic_properties_of_PP_grafted_with_maleic_anhydride_PP-g-MAH_and_PET_blends (accessed on 2 May 2025).

- Thirtha, V.; Lehman, R.; Nosker, T. Morphological effects on glass transition behavior in selected immiscible blends of amorphous and semicrystalline polymers. Polymer 2006, 47, 5392–5401. [Google Scholar] [CrossRef]

- Serhatkulu, T.; Erman, B.; Bahar, I.; Fakirov, S.; Evstatiev, M.; Sapundjieva, D. Dynamic mechanical study of amorphous phases in poly(ethylene terephthalate)/nylon-6 blends. Polymer 1995, 36, 2371–2377. [Google Scholar] [CrossRef]

| Sample | Tm (°C) | Tc (°C) |

|---|---|---|

| r-PET | 247.0 | 175 |

| r-PET/r-HDPE (no compatibilizer) | 248.0 | 203 |

| r-PET/r-HDPE + 2 php | 248.5 | 201 |

| r-PET/r-HDPE + 5 php | 250.0 | 204 |

| r-PET/r-HDPE + 7 php | 252 | 206 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bozorgnia Tabary, S.A.A.; Bresse, J.-P.; Fayazfar, H. From Waste to Function: Compatibilized r-PET/r-HDPE Blends for Pellet Extrusion 3D Printing. Polymers 2025, 17, 1638. https://doi.org/10.3390/polym17121638

Bozorgnia Tabary SAA, Bresse J-P, Fayazfar H. From Waste to Function: Compatibilized r-PET/r-HDPE Blends for Pellet Extrusion 3D Printing. Polymers. 2025; 17(12):1638. https://doi.org/10.3390/polym17121638

Chicago/Turabian StyleBozorgnia Tabary, Seyed Amir Ali, Jean-Pierre Bresse, and Haniyeh (Ramona) Fayazfar. 2025. "From Waste to Function: Compatibilized r-PET/r-HDPE Blends for Pellet Extrusion 3D Printing" Polymers 17, no. 12: 1638. https://doi.org/10.3390/polym17121638

APA StyleBozorgnia Tabary, S. A. A., Bresse, J.-P., & Fayazfar, H. (2025). From Waste to Function: Compatibilized r-PET/r-HDPE Blends for Pellet Extrusion 3D Printing. Polymers, 17(12), 1638. https://doi.org/10.3390/polym17121638