Mechanical Characterization and Interface Evaluation of Multi-Material Composites Manufactured by Hybrid Fused Deposition Modeling (HFDM)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

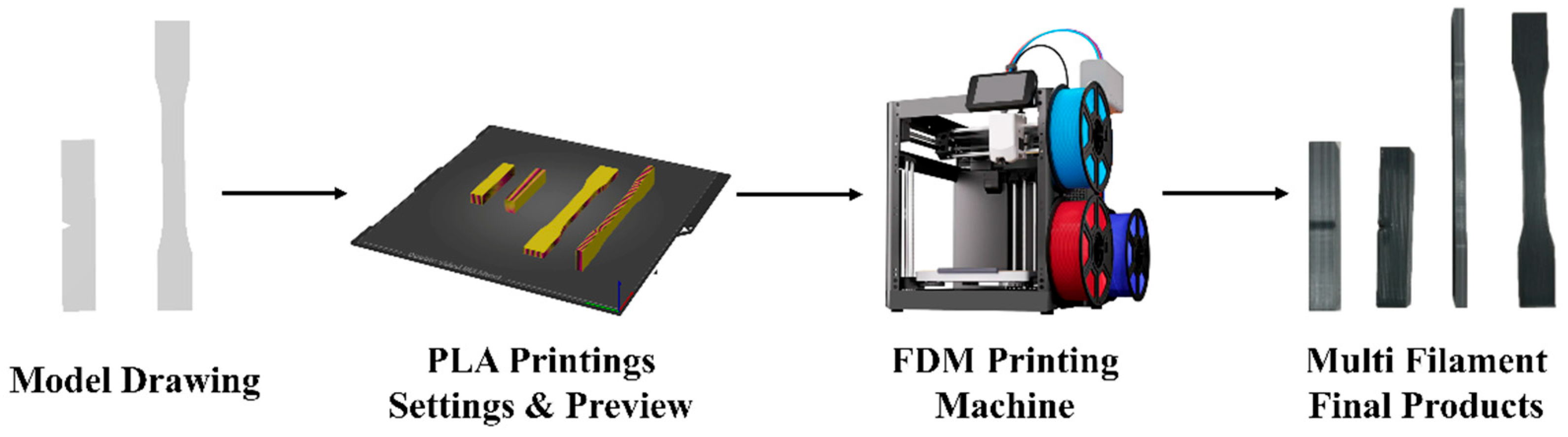

2.2. Specimen Preparation

2.3. Mechanical Testing

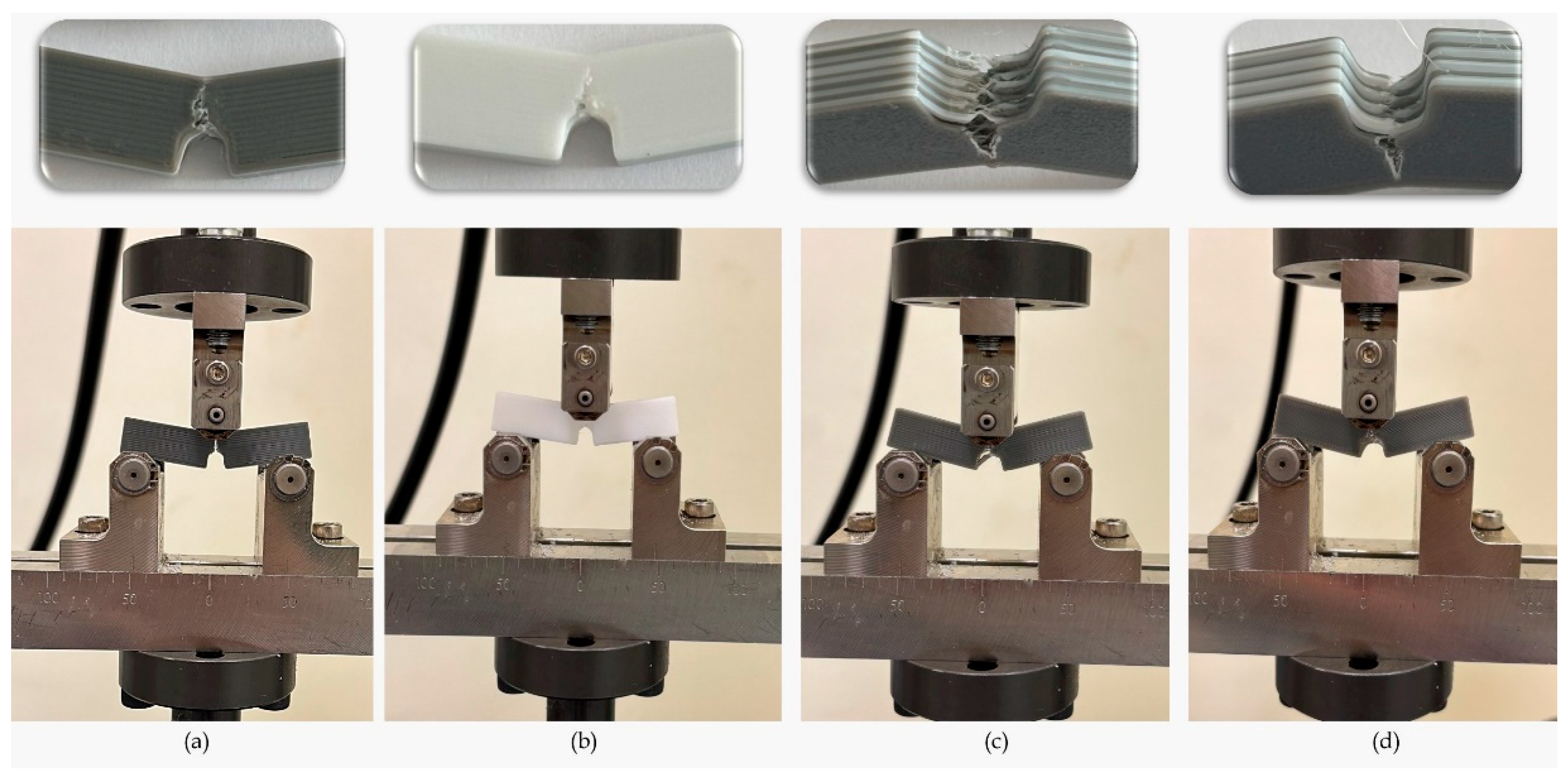

2.3.1. Tensile Testing

2.3.2. Flexural Testing

2.3.3. Impact Testing

2.4. Microstructural Characterization

3. Results and Discussion

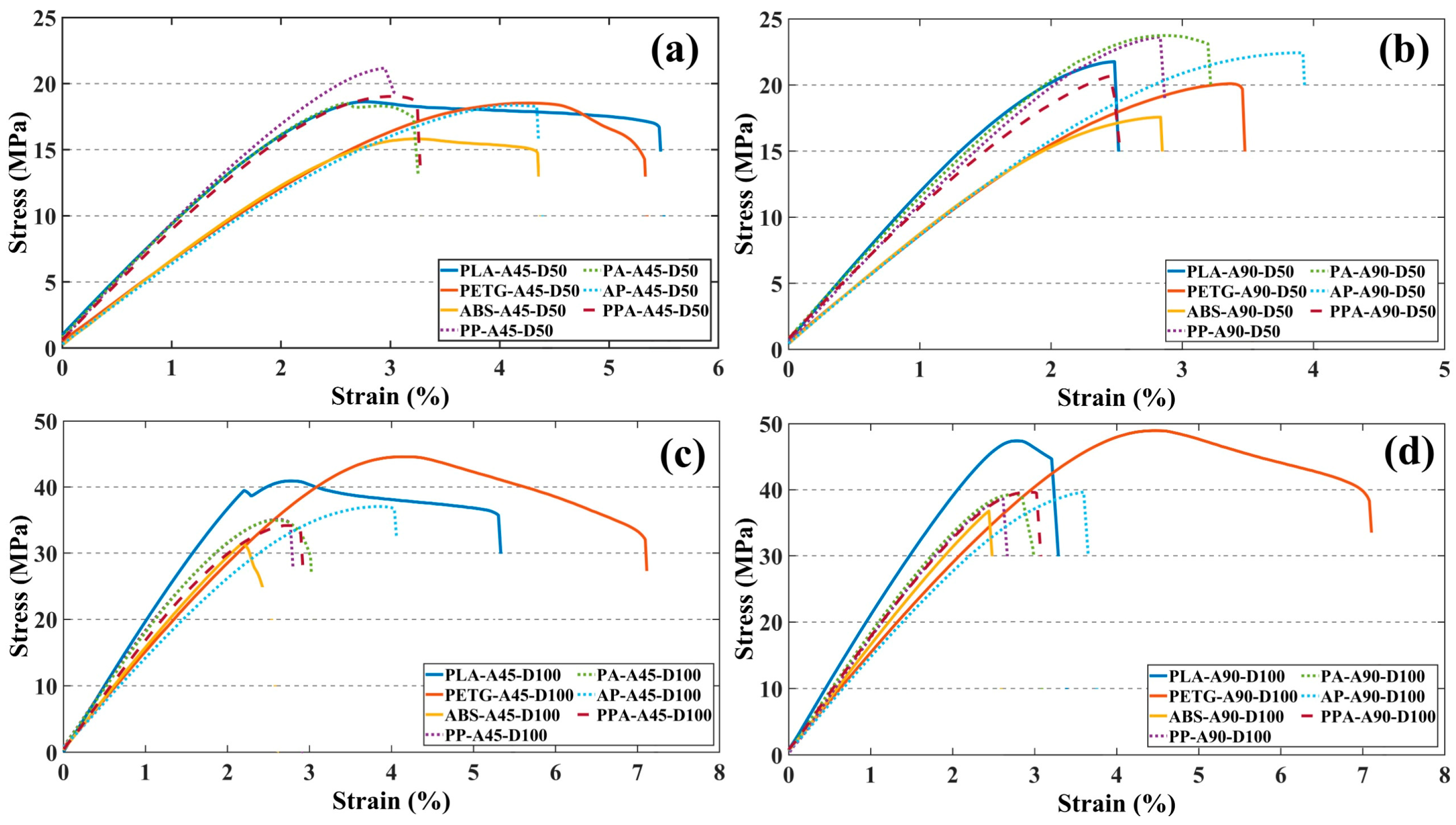

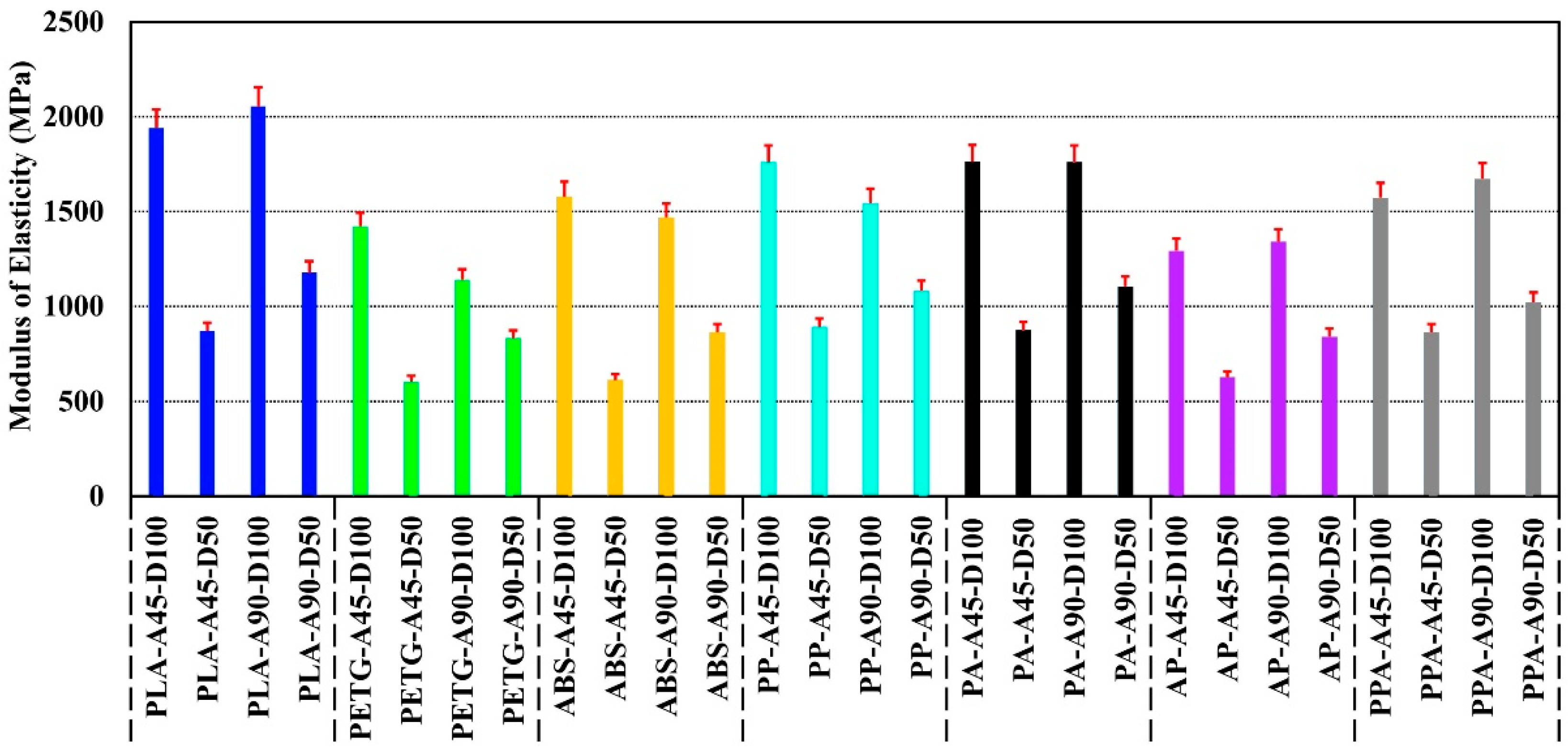

3.1. Tensile Test Results

3.2. Flexural Test Results

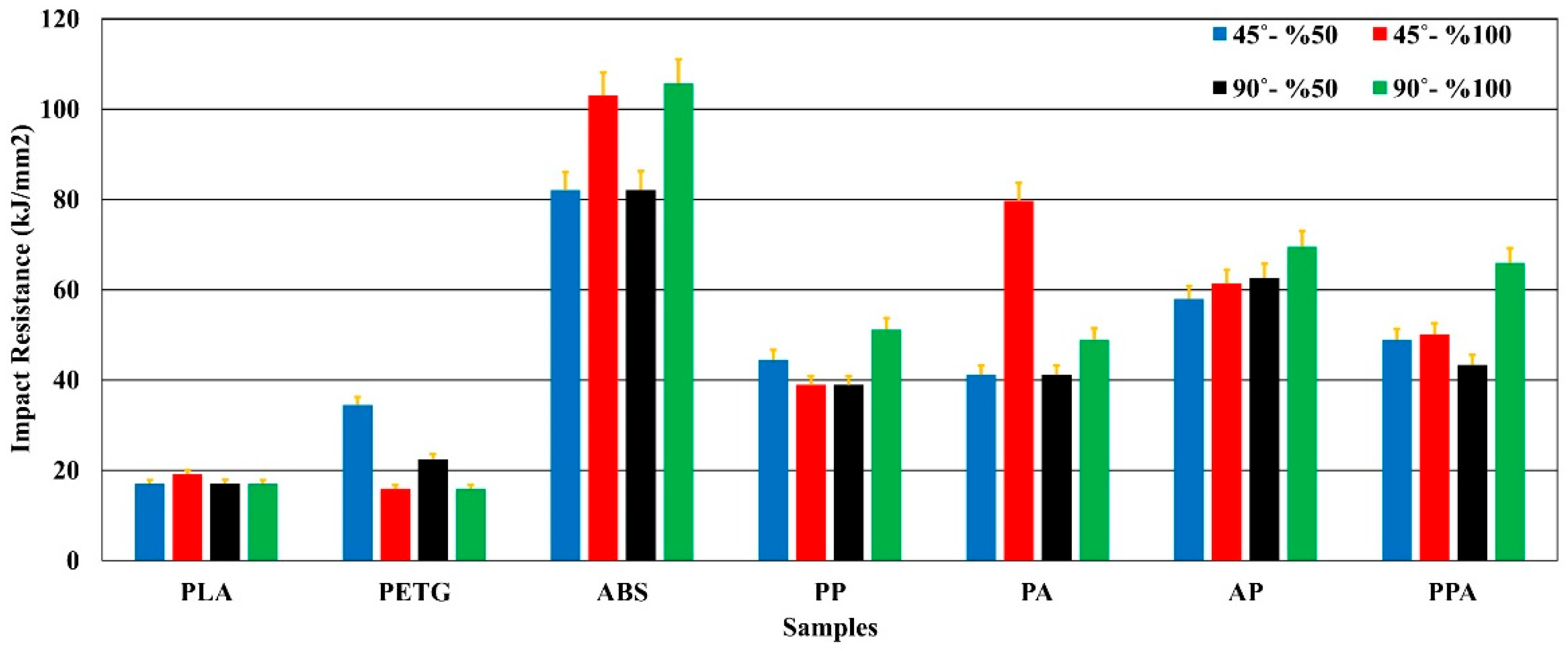

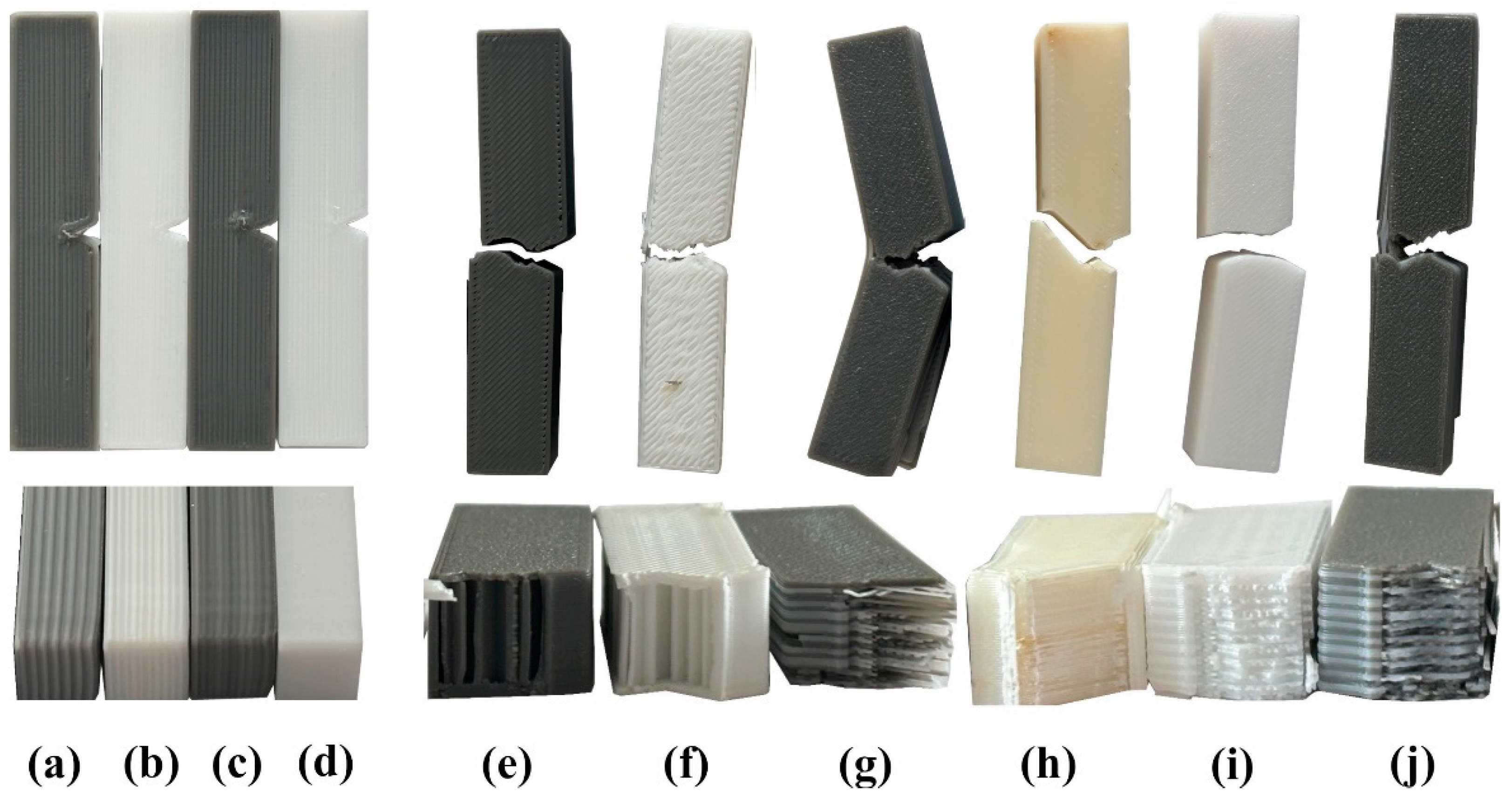

3.3. Impact Test Results

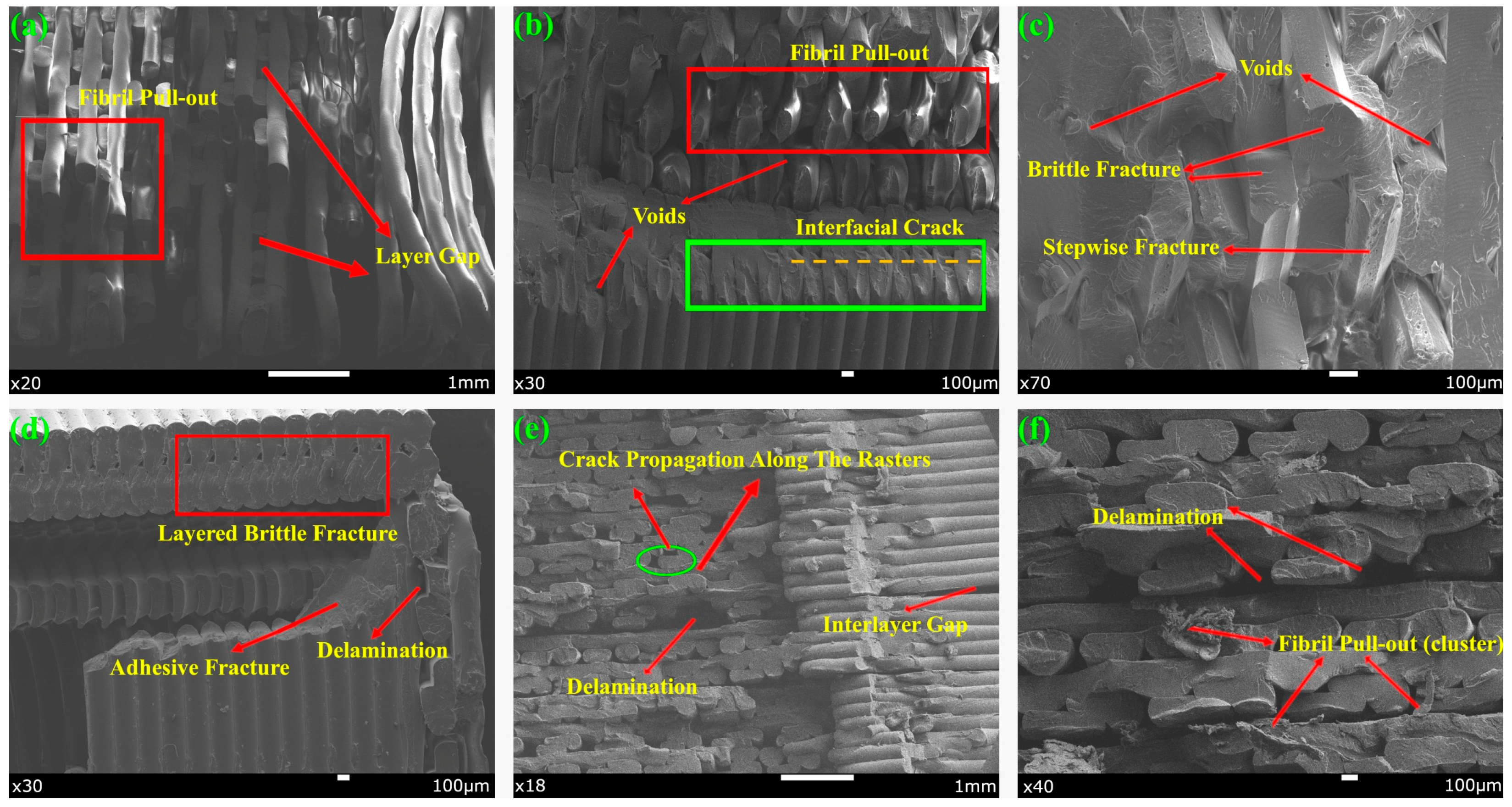

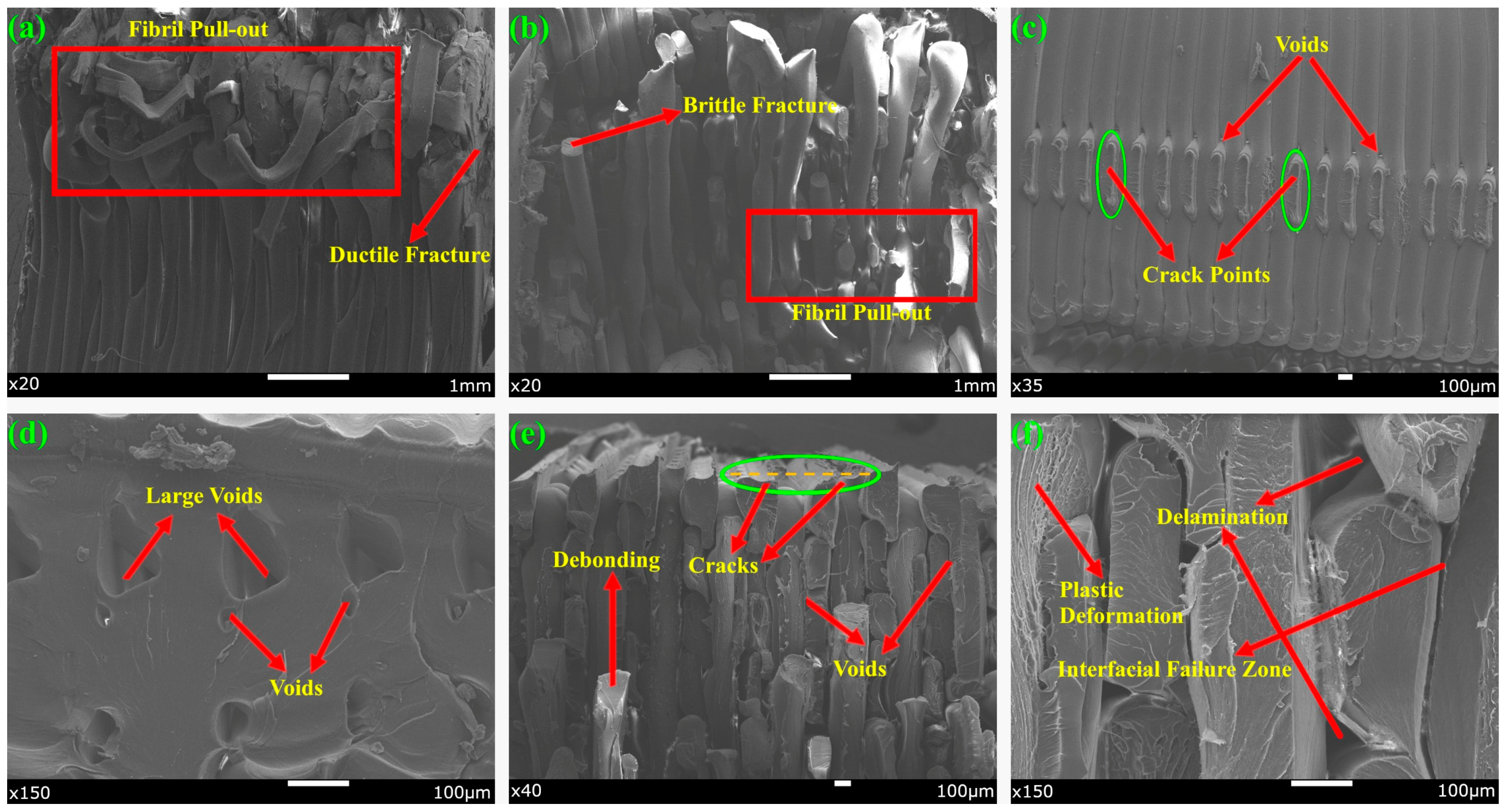

3.4. Microstructural Analysis

4. Conclusions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abdulhameed, O.; Al-Ahmari, A.; Ameen, W.; Mian, S.H. Additive Manufacturing: Challenges, Trends, and Applications. Adv. Mech. Eng. 2019, 11, 1687814018822880. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Başcıl Önler, D.; Dağlı, S.; Hartomacıoğlu, S.; Günay, M.; Królczyk, G.M. A Review on Aluminum Alloys Produced by Wire Arc Additive Manufacturing (WAAM): Applications, Benefits, Challenges and Future Trends. J. Mater. Res. Technol. 2024, 33, 5643–5670. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material Issues in Additive Manufacturing: A Review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. Int. Sch. Res. Not. 2012, 2012, 208760. [Google Scholar] [CrossRef]

- Hartomacıoğlu, S.; Kaya, E.; Eker, B.; Dağlı, S.; Sarıkaya, M. Characterization, Generative Design, and Fabrication of a Carbon Fiber-Reinforced Industrial Robot Gripper via Additive Manufacturing. J. Mater. Res. Technol. 2024, 33, 3714–3727. [Google Scholar] [CrossRef]

- Zotti, A.; Paduano, T.; Napolitano, F.; Zuppolini, S.; Zarrelli, M.; Borriello, A. Fused Deposition Modeling of Polymer Composites: Development, Properties and Applications. Polymers 2025, 17, 1054. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Haghighi, A. Large-Scale Automated Additive Construction: Overview, Robotic Solutions, Sustainability, and Future Prospect. Sustainability 2022, 14, 9782. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive Manufacturing of Multi-Material Structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Jamal, M.A.; Shah, O.R.; Ghafoor, U.; Qureshi, Y.; Bhutta, M.R. Additive Manufacturing of Continuous Fiber-Reinforced Polymer Composites via Fused Deposition Modelling: A Comprehensive Review. Polymers 2024, 16, 1622. [Google Scholar] [CrossRef] [PubMed]

- Chand, R.; Sharma, V.S.; Trehan, R.; Gupta, M.K.; Sarikaya, M. Investigating the Dimensional Accuracy and Surface Roughness for 3D Printed Parts Using a Multi-Jet Printer. J. Mater. Eng. Perform. 2023, 32, 1145–1159. [Google Scholar] [CrossRef]

- Alarifi, I.M. Mechanical Properties and Numerical Simulation of FDM 3D Printed PETG/Carbon Composite Unit Structures. J. Mater. Res. Technol. 2023, 23, 656–669. [Google Scholar] [CrossRef]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef]

- Brancewicz-Steinmetz, E.; Sawicki, J. Bonding and Strengthening the PLA Biopolymer in Multi-Material Additive Manufacturing. Materials 2022, 15, 5563. [Google Scholar] [CrossRef]

- Khan, S.A.; Khan, H.A.; Khan, A.; Salamat, S.; Javaid, S.S.; Khan, R.M.A. Investigation of the Mechanical Behavior of FDM Processed CFRP/Al Hybrid Joint at Elevated Temperatures. Thin-Walled Struct. 2023, 192, 111135. [Google Scholar] [CrossRef]

- Al-Tamimi, A.A.; Tlija, M.; Alhamidi, A.; Abidi, M.H.; Al-Ahmari, A.; Al-Zahrani, S.M. A Novel Reinforced PLA Locking Compression Plate to Eliminate Stress Shielding Using Design for Additive Manufacturing. J. Mater. Res. Technol. 2024, 32, 2127–2139. [Google Scholar] [CrossRef]

- Pazhamannil, R.V.; Jishnu, N.V.N.; Govindan, P.; Edacherian, A. Property Enhancement Approaches of Fused Filament Fabrication Technology: A Review. Polym. Eng. Sci. 2022, 62, 1356–1376. [Google Scholar] [CrossRef]

- Hwang, S.; Reyes, E.I.; Moon, K.; Rumpf, R.C.; Kim, N.S. Thermo-Mechanical Characterization of Metal/Polymer Composite Filaments and Printing Parameter Study for Fused Deposition Modeling in the 3D Printing Process. J. Electron. Mater. 2015, 44, 771–777. [Google Scholar] [CrossRef]

- Sethu, S.; Kalimuthu, M.; Nagarajan, R.; Krishnan, K.; Mohammad, F.; Arul Kumar, M. Hybrid Fabrication and Characterization of Biocompatible Bamboo/PLA Composites. J. Mater. Res. Technol. 2024, 29, 2656–2666. [Google Scholar] [CrossRef]

- Shi, X.; Chen, B.; Tuo, X.; Gong, Y.; Guo, J. Study on Performance Characteristics of Fused Deposition Modeling 3D-Printed Composites by Blending and Lamination. J. Appl. Polym. Sci. 2021, 138, 32495. [Google Scholar] [CrossRef]

- Yin, J.; Lu, C.; Fu, J.; Huang, Y.; Zheng, Y. Interfacial Bonding during Multi-Material Fused Deposition Modeling (FDM) Process Due to Inter-Molecular Diffusion. Mater. Des. 2018, 150, 104–112. [Google Scholar] [CrossRef]

- Patel, K.S.; Shah, D.B.; Joshi, S.J.; Aldawood, F.K.; Kchaou, M. Effect of Process Parameters on the Mechanical Performance of FDM Printed Carbon Fiber Reinforced PETG. J. Mater. Res. Technol. 2024, 30, 8006–8018. [Google Scholar] [CrossRef]

- Tanveer, M.Q.; Mishra, G.; Mishra, S.; Sharma, R. Effect of Infill Pattern and Infill Density on Mechanical Behaviour of FDM 3D Printed Parts-a Current Review. Mater. Today Proc. 2022, 62, 100–108. [Google Scholar] [CrossRef]

- Kontaxis, L.C.; Zachos, D.; Georgali-Fickel, A.; Portan, D.V.; Zaoutsos, S.P.; Papanicolaou, G.C. 3D-Printed PLA Mechanical and Viscoelastic Behavior Dependence on the Nozzle Temperature and Printing Orientation. Polymers 2025, 17, 913. [Google Scholar] [CrossRef]

- Ahmed, S.W.; Hussain, G.; Al-Ghamdi, K.A.; Altaf, K. Mechanical Properties of an Additive Manufactured CF-PLA/ABS Hybrid Composite Sheet. J. Thermoplast. Compos. Mater. 2021, 34, 1577–1596. [Google Scholar] [CrossRef]

- Tamburrino, F.; Serena, G.; Bordegoni, M. The Influence of Slicing Parameters on the Multi-Material Adhesion Mechanisms of FDM Printed Parts: An Exploratory Study. Virtual Phys. Prototyp. 2019, 14, 316–332. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Rodríguez, G.P. Impact Damage Resistance of 3D Printed Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling. Compos. Part B Eng. 2018, 148, 93–103. [Google Scholar] [CrossRef]

- Eyri, B.; Gul, O.; Yilmaz, S.; Karsli, N.G.; Yilmaz, T. Characterization of ABS/PETG Multi-Material Composites 3D Printed by Print-Pause-Print Method. Polym. Eng. Sci. 2025, 65, 2353–2369. [Google Scholar] [CrossRef]

- ASTM D638-01; Standard Test Method for Tensile Properties of Plastics. Available online: https://store.astm.org/d0638-01.html (accessed on 8 June 2025).

- ASTM D5045-14; Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials. Available online: https://store.astm.org/d5045-14.html (accessed on 8 June 2025).

- ASTM D256-04; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. Available online: https://store.astm.org/d0256-04.html (accessed on 8 June 2025).

- Shanmugam, V.; Das, O.; Babu, K.; Marimuthu, U.; Veerasimman, A.; Johnson, D.J.; Neisiany, R.E.; Hedenqvist, M.S.; Ramakrishna, S.; Berto, F. Fatigue Behaviour of FDM-3D Printed Polymers, Polymeric Composites and Architected Cellular Materials. Int. J. Fatigue 2021, 143, 106007. [Google Scholar] [CrossRef]

- Arora, N.; Dua, S.; Singh, V.K.; Singh, S.K.; Senthilkumar, T. A Comprehensive Review on Fillers and Mechanical Properties of 3D Printed Polymer Composites. Mater. Today Commun. 2024, 40, 109617. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical Properties of Components Fabricated with Open-Source 3-D Printers under Realistic Environmental Conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Torrado, A.R.; Roberson, D.A. Failure Analysis and Anisotropy Evaluation of 3D-Printed Tensile Test Specimens of Different Geometries and Print Raster Patterns. J. Fail. Anal. Prev. 2016, 16, 154–164. [Google Scholar] [CrossRef]

- Adarsh, S.H.; Nagamadhu, M. Effect of Printing Parameters on Mechanical Properties and Warpage of 3D-Printed PEEK/CF-PEEK Composites Using Multi-Objective Optimization Technique. J. Compos. Sci. 2025, 9, 208. [Google Scholar] [CrossRef]

- Liu, Z.; Lei, Q.; Xing, S. Mechanical Characteristics of Wood, Ceramic, Metal and Carbon Fiber-Based PLA Composites Fabricated by FDM. J. Mater. Res. Technol. 2019, 8, 3741–3751. [Google Scholar] [CrossRef]

- Rodríguez-Reyna, S.; Mata, C.; Díaz-Aguilera, J.; Acevedo-Parra, H.; Tapia, F. Mechanical Properties Optimization for PLA, ABS and Nylon+ CF Manufactured by 3D FDM Printing. Mater. Today Commun. 2022, 33, 104774. [Google Scholar] [CrossRef]

- Algarni, M.; Ghazali, S. Comparative Study of the Sensitivity of PLA, ABS, PEEK, and PETG’s Mechanical Properties to FDM Printing Process Parameters. Crystals 2021, 11, 995. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Mechtcherine, V.; Tzounis, L. On the Strain Rate Sensitivity of Fused Filament Fabrication (Fff) Processed Pla, Abs, Petg, Pa6, and Pp Thermoplastic Polymers. Polymers 2020, 12, 2924. [Google Scholar] [CrossRef]

- Daly, M.; Tarfaoui, M.; Chihi, M.; Bouraoui, C. Dynamic Analysis of 3D-Printed CF-PETG Composites with Different Infill Densities. Prog. Addit. Manuf. 2025, 10, 1629–1657. [Google Scholar] [CrossRef]

- dos Reis, M.Q.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Effect of the Infill Density on 3D-Printed Geometrically Graded Impact Attenuators. Polymers 2024, 16, 3193. [Google Scholar] [CrossRef]

- Zhou, L.-Y.; Fu, J.; He, Y. A Review of 3D Printing Technologies for Soft Polymer Materials. Adv. Funct. Mater. 2020, 30, 2000187. [Google Scholar] [CrossRef]

- Saleh, M.; Anwar, S.; AlFaify, A.Y.; Al-Ahmari, A.M.; Abd Elgawad, A.E.E. Development of PLA/Recycled-Desized Carbon Fiber Composites for 3D Printing: Thermal, Mechanical, and Morphological Analyses. J. Mater. Res. Technol. 2024, 29, 2768–2780. [Google Scholar] [CrossRef]

- Hsueh, M.-H.; Lai, C.-J.; Wang, S.-H.; Zeng, Y.-S.; Hsieh, C.-H.; Pan, C.-Y.; Huang, W.-C. Effect of Printing Parameters on the Thermal and Mechanical Properties of 3d-Printed Pla and Petg, Using Fused Deposition Modeling. Polymers 2021, 13, 1758. [Google Scholar] [CrossRef]

- Soltanmohammadi, K.; Rahmatabadi, D.; Aberoumand, M.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Effects of TPU on the Mechanical Properties, Fracture Toughness, Morphology, and Thermal Analysis of 3D-Printed ABS-TPU Blends by FDM. J. Vinyl Addit. Technol. 2024, 30, 958–968. [Google Scholar] [CrossRef]

- Xiao, L.; Mu, K.; Liu, S.; Song, W. Experimental Study on the Fracture Behavior of 3D Printed Interpenetrating Phase Composites with Triply Periodic Minimal Surface Architectures. Thin-Walled Struct. 2025, 208, 112847. [Google Scholar] [CrossRef]

- Sathish Kumar, K.; Soundararajan, R.; Shanthosh, G.; Saravanakumar, P.; Ratteesh, M. Augmenting Effect of Infill Density and Annealing on Mechanical Properties of PETG and CFPETG Composites Fabricated by FDM. Mater. Today Proc. 2021, 45, 2186–2191. [Google Scholar] [CrossRef]

- Ramezani Dana, H.; Ebrahimi, F. Synthesis, Properties, and Applications of Polylactic Acid-Based Polymers. Polym. Eng. Sci. 2023, 63, 22–43. [Google Scholar] [CrossRef]

- Birosz, M.T.; Ledenyák, D.; Andó, M. Effect of FDM Infill Patterns on Mechanical Properties. Polym. Test. 2022, 113, 107654. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive Manufacturing of PLA Structures Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties and Their Optimal Selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Tunçel, O. Optimization of Charpy Impact Strength of Tough PLA Samples Produced by 3D Printing Using the Taguchi Method. Polymers 2024, 16, 459. [Google Scholar] [CrossRef]

- Alarifi, I.M. PETG/Carbon Fiber Composites with Different Structures Produced by 3D Printing. Polym. Test. 2023, 120, 107949. [Google Scholar] [CrossRef]

- Kalaimagal, S.; Vasumathi, M.; Rashia Begum, S.; Saravana Kumar, M.; Romanovski, V.; Salah, B. Evaluation of Impact Resistance of Sustainable Sandwich Structures with Optimized FDM Core Geometries Using Low-Velocity Drop Impact Tests. Polym. Compos. 2025, 7, 5. [Google Scholar] [CrossRef]

- Domingo-Espin, M.; Puigoriol-Forcada, J.M.; Garcia-Granada, A.-A.; Llumà, J.; Borros, S.; Reyes, G. Mechanical Property Characterization and Simulation of Fused Deposition Modeling Polycarbonate Parts. Mater. Des. 2015, 83, 670–677. [Google Scholar] [CrossRef]

- Ma, Q.; Rejab, M.R.M.; Song, Y.; Zhang, X.; Hanon, M.M.; Abdullah, M.H.; Kumar, A.P. Effect of Infill Pattern of Polylactide Acid (PLA) 3D-Printed Integral Sandwich Panels under Ballistic Impact Loading. Mater. Today Commun. 2024, 38, 107626. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A Critical Review on the Fused Deposition Modeling of Thermoplastic Polymer Composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Naveen Kumar, C.; Venkatesan, S. A Review on the Fused Deposition Modelling of Fibre-Reinforced Polymer Composites: Influence of Process Parameters, Pre-Processing and Post Processing Techniques. Proc. Inst. Mech. Eng. Part L 2024, 238, 2096–2119. [Google Scholar] [CrossRef]

| Feature | PLA | PETG | ABS |

|---|---|---|---|

| Print temperature (°C) | 220 | 235 | 235 |

| Bed temperature (°C) | 60 | 80 | 80 |

| Density (g/cm3) | 1.23 | 1.27 | 1.06 |

| Tensile strength (MPa) | 61 | 52.2 | 40 |

| Flexural strength (MPa) | 40.7 | 58.1 | 68 |

| Elongation at break (%) | 42.5 | 83 | 30 |

| Hardness (D-Shore) | 80 | 71 | 75 |

| Properties | Parameter |

|---|---|

| Filament diameter (mm) | 1.75 |

| Nozzle diameter (mm) | 0.4 |

| Layer Thickness (mm) | 0.2 |

| Raster angle (°) | 45–90 |

| İnfill ratio (%) | 50–100 |

| Cooling speed (%) | PLA = 98, PETG = 50, ABS = 0 |

| Surface pattern | Line |

| Material | Raster Angle (°) | Infill Density (%) | Sample Code |

|---|---|---|---|

| PLA-PETG | 45 | 50 | PP-A45-D50 |

| 100 | PP-A45-D100 | ||

| 90 | 50 | PP-A90-D50 | |

| 100 | PP-A90-D100 | ||

| PLA-ABS | 45 | 50 | PA-A45-D50 |

| 100 | PA-A45-D100 | ||

| 90 | 50 | PA-A90-D50 | |

| 100 | PA-A90-D100 | ||

| ABS-PETG | 45 | 50 | AP-A45-D50 |

| 100 | AP-A45-D100 | ||

| 90 | 50 | AP-A90-D50 | |

| 100 | AP-A90-D100 | ||

| PLA-PETG-ABS | 45 | 50 | PPA-A45-D50 |

| 100 | PPA-A45-D100 | ||

| 90 | 50 | PPA-A90-D50 | |

| 100 | PPA-A90-D100 |

| Code | 45°–%50 | 45°–%100 | 90°–%50 | 90°–%100 |

|---|---|---|---|---|

| PLA | 18.56 | 40.93 | 21.76 | 47.40 |

| PETG | 18.53 | 44.58 | 20.10 | 48.94 |

| ABS | 15.82 | 31.53 | 17.57 | 36.95 |

| PP | 21.20 | 35.10 | 23.67 | 38.64 |

| PA | 18.58 | 34.96 | 23.74 | 39.29 |

| AP | 18.36 | 37.05 | 22.44 | 39.65 |

| PPA | 19.03 | 34.19 | 20.68 | 39.64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dağlı, S. Mechanical Characterization and Interface Evaluation of Multi-Material Composites Manufactured by Hybrid Fused Deposition Modeling (HFDM). Polymers 2025, 17, 1631. https://doi.org/10.3390/polym17121631

Dağlı S. Mechanical Characterization and Interface Evaluation of Multi-Material Composites Manufactured by Hybrid Fused Deposition Modeling (HFDM). Polymers. 2025; 17(12):1631. https://doi.org/10.3390/polym17121631

Chicago/Turabian StyleDağlı, Salih. 2025. "Mechanical Characterization and Interface Evaluation of Multi-Material Composites Manufactured by Hybrid Fused Deposition Modeling (HFDM)" Polymers 17, no. 12: 1631. https://doi.org/10.3390/polym17121631

APA StyleDağlı, S. (2025). Mechanical Characterization and Interface Evaluation of Multi-Material Composites Manufactured by Hybrid Fused Deposition Modeling (HFDM). Polymers, 17(12), 1631. https://doi.org/10.3390/polym17121631