1. Introduction

Expanded polystyrene (EPS) foam is widely utilized across various industries due to its distinctive characteristics, including low density, excellent energy absorption, and low thermal conductivity [

1,

2,

3,

4,

5]. Its primary application lies in packaging, where it serves as a liner or filling material, benefiting from its superior energy absorption under impact loading [

6]. However, accurately characterizing the mechanical behavior of EPS foam remains a significant challenge due to its complex and randomly distributed cellular structure.

To better understand the mechanical response of EPS foam, both static and dynamic experiments have been conducted over the past decades. For example, Ouellet [

7] examined the dynamic compressive behavior at a strain rate of approximately 2500 s

−1, demonstrating that both the plateau stress and densification strain are strain rate-sensitive and dependent on foam density. In tension, EPS foam exhibits creep behavior influenced by both applied stress and density, which can be effectively described using viscoelastic models [

8]. Zou [

9] studied the time-dependent creep behaviors of EPS geofoam, and the data obtained were employed to calibrate the viscoelastic models, giving an accurate prediction of mechanical performance. Park [

10] analyzed the time-dependent creep behavior of EPS foam, and the computational accuracy of FEA model will be improved when the creep properties are included. Chen [

6] subsequently conducted a comprehensive study on the compressive and tensile behaviors of EPS foams with densities of 13.5 kg/m

3 and 28 kg/m

3, revealing pronounced rate sensitivity in their mechanical properties through experimental testing.

In packaging applications, fatigue resistance is also critical. Ozturk [

11,

12] investigated the response of EPS foam under repeated compressive loading and unloading, showing that both energy absorption and absorption efficiency decrease with the number of loading cycles. Nevertheless, EPS foam is often subjected to more complex multiaxial loading conditions in real-world scenarios, necessitating further investigation into its behavior under varying stress states and loading rates. For instance, Farajzadeh [

13] studied EPS foam under biaxial loading and observed that shear stiffness increases with axial strain, resulting in higher shear stresses. Similar findings were reported by Arnesen [

14], who analyzed foam response under V-shaped impact conditions and noted that higher-density EPS foam exhibited reduced elastic rebound and increased residual deformation under shear.

Ling [

15,

16] further explored the coupled compression–shear response of EPS foam under both static and dynamic loading using a novel experimental system capable of decoupling compressive and shear effects. Their results indicated that the yield stress under combined loading could be up to 40% lower than that under uniaxial compression and that it decreases further with increasing impact angle, depending on both foam density and strain rate. Krundaeva [

17] investigated the dynamic compression of spherical EPS foam to simulate helmet applications. A related study by Kumar [

18] modeled the performance of EPS foam in actual bicycle helmets subjected to lateral impacts on flat and hemispherical anvils. More recently, Yan [

19] examined the impact response of EPS foam in rockfall protection galleries, focusing on fracture and energy dissipation mechanisms. Although these studies provide a comprehensive understanding of the mechanical behavior of EPS foam under uniaxial and biaxial loading, there is a notable lack of research specifically addressing its dynamic response in the context of packaging engineering, the most prevalent application scenario.

To address these challenges, several constitutive models have been proposed in the literature. For example, Tang [

20] utilized a linear fitting constitutive model to simulate three-point bending tests. In this approach, the tensile response was assumed to follow linear elasticity, while the compressive response was modeled using a bilinear phenomenological representation. However, this simplified formulation falls short in capturing the inherent nonlinearities of EPS foam. To better represent the rate-dependent and nonlinear behavior, Zouzias [

21] employed the Avalle constitutive model [

22]—originally designed for compressive behavior—to predict the tensile response of EPS foam. While it offered some improvements, its predictive accuracy remained limited due to the model’s original focus on compressive regimes. Rodríguez-Sánchez [

23] explored the hyperfoam model under various strain rates and demonstrated its ability to accurately capture the energy absorption characteristics of EPS foam in compression.

With the advent of machine learning, data-driven models have emerged as powerful tools for predicting foam behavior. Rodríguez-Sánchez [

24,

25] investigated how loading rate and foam density influence compressive response and hysteresis, while Pech-Mendoza [

26] examined the role of bead size distribution on the mechanical response, further enhancing predictive modeling capabilities. However, as noted by Arnesen [

14], several built-in constitutive models in commercial simulation software (e.g., LS-DYNA) fail to reproduce the complex response of EPS foam under combined compression–shear loading conditions. Many traditional models either oversimplify the deformation mechanisms or rely on parameters that are difficult to calibrate experimentally.

To overcome these limitations, anisotropic constitutive models have shown increasing promise in capturing the directional dependencies inherent in cellular materials [

27,

28,

29]. For example, refs. [

30,

31] studied the anisotropic compressive response of polyurethane foam and developed a general rate-sensitive model to describe its mechanical performance. Building on this foundation, the present study aims to enhance an anisotropic constitutive framework to account for the tension–compression asymmetry and tensile damage observed in EPS foam, particularly under dynamic loading scenarios. The proposed model is validated through drop tests simulating packaging conditions, providing a comprehensive assessment of its practical applicability.

4. Prediction of Mechanical Performance of EPS Foam

To calibrate the parameters of the proposed constitutive model, uniaxial tension, compression, and shear tests were conducted. Subsequently, static three-point bending and dynamic impact experiments were performed to validate the predictive capability of the rate-sensitive constitutive model.

4.1. Experiments for Calibration of the Constitutive Model

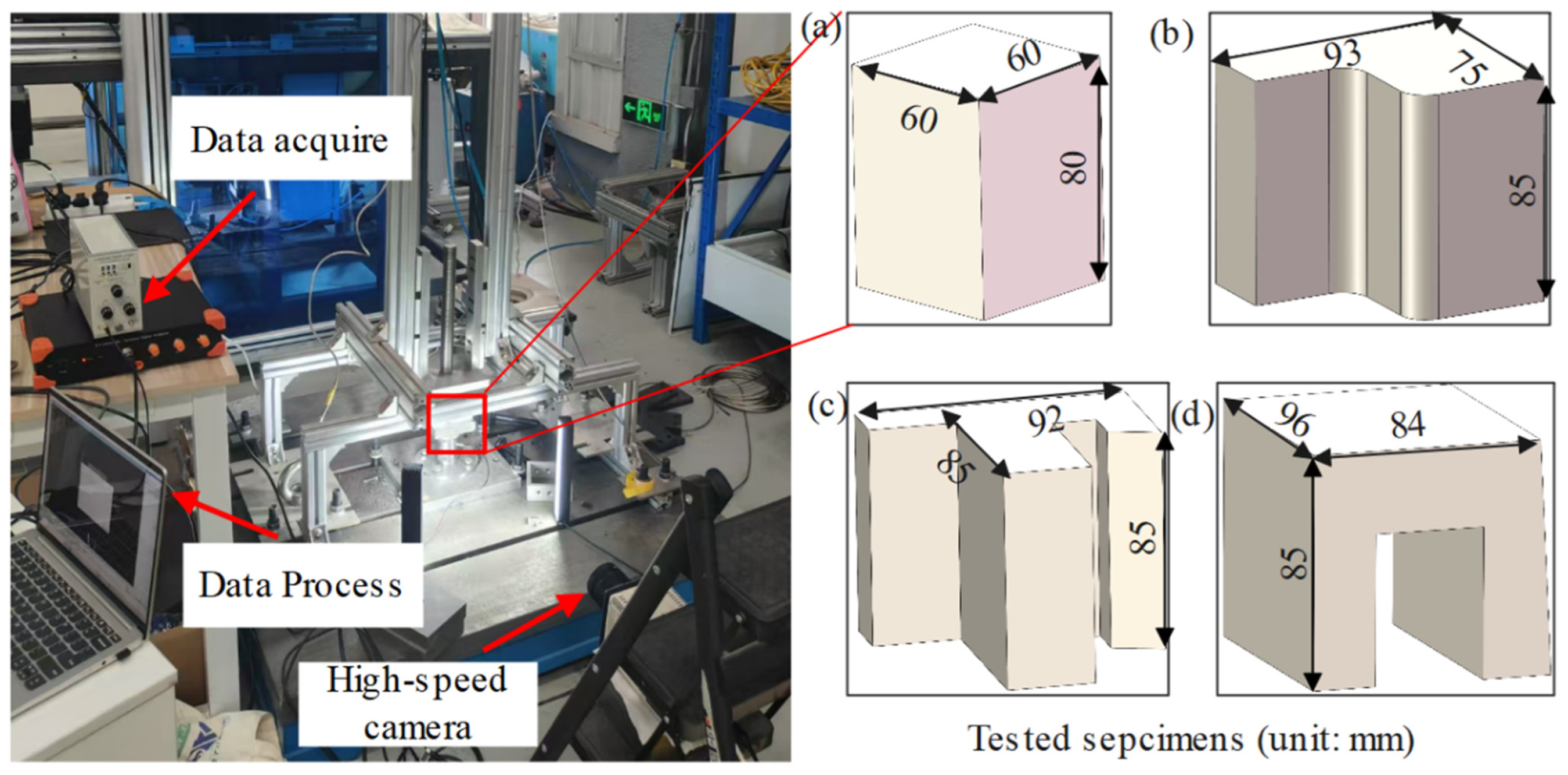

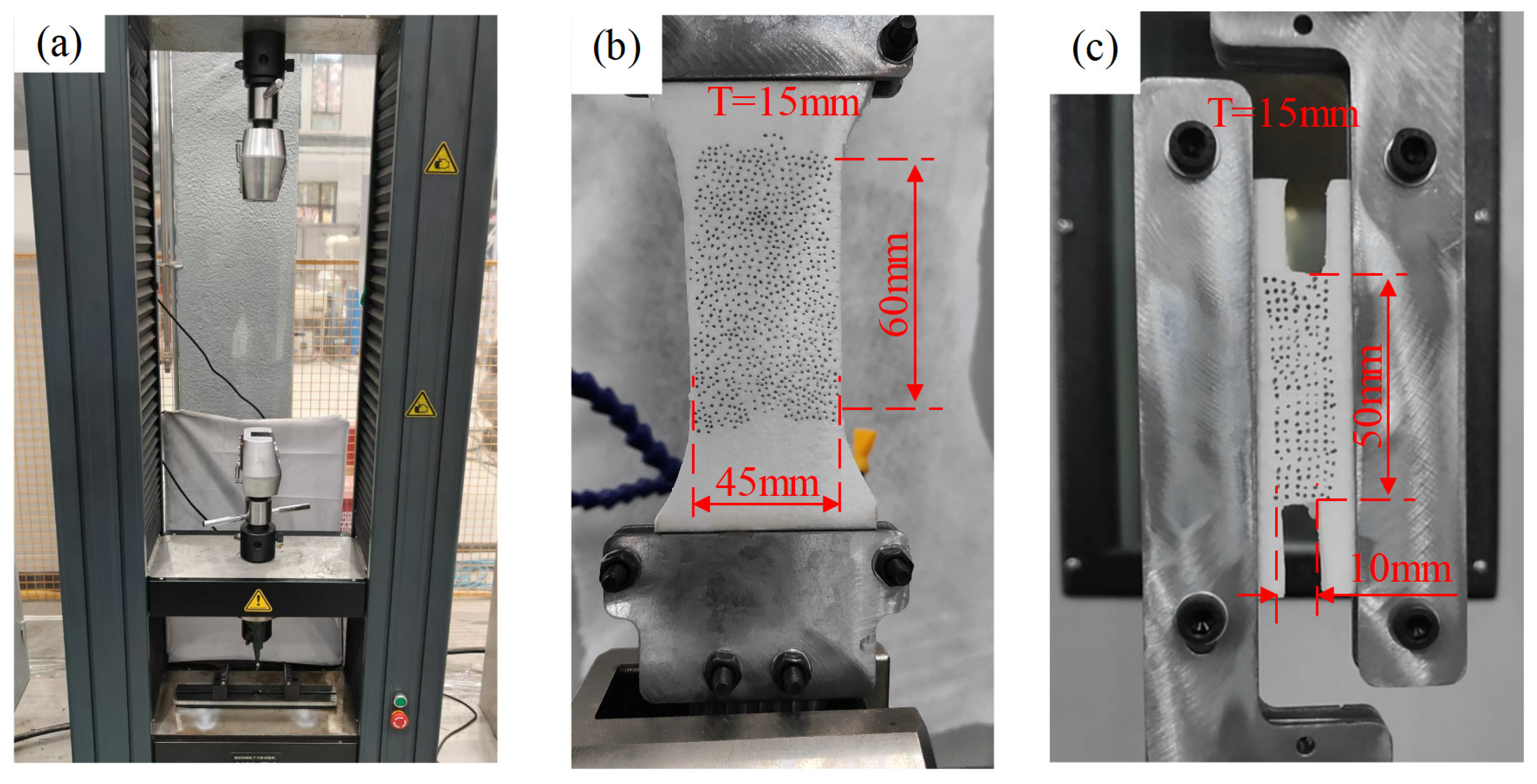

4.1.1. Experimental Procedures

Uniaxial compression tests were carried out using a universal testing machine (WDW-100M, Jinan Chenda Testing Machine Manufacturing Co., Ltd. in Jinan City, China). The loading velocities were varied to achieve different strain rates: 0.001 s

−1, 0.01 s

−1, and 0.05 s

−1. To simulate high strain-rate loading conditions, dynamic compression tests at a strain rate of 55.9 s

−1 were performed using a drop-weight impact tester (see

Figure 1). The EPS foam specimens used in all tests had a density of 18.1 kg/m

3 and were manually cut, which may introduce some unavoidable geometric inaccuracies. For each test condition, five specimens were prepared to ensure repeatability and minimize experimental errors.

Figure 5 shows a typical compression specimen with dimensions of 60 mm × 60 mm × 80 mm. To examine possible anisotropy, compression loading was applied at different angles: 0°, 45°, and 90° relative to the specimen orientation.

In addition to compression tests, uniaxial tensile tests were conducted to characterize the engineering stress–strain response, particularly focusing on the brittle fracture behavior. Dog-bone-shaped specimens were clamped using a custom fixture, as shown in

Figure 6b, and loaded at a constant rate corresponding to a strain rate of 0.001 s

−1. The lower fixture remained stationary, while the upper fixture applied the tensile force.

Simple shear experiments were also performed using a universal testing machine. Butterfly-shaped specimens were clamped using a custom-designed fixture, as illustrated in

Figure 6c. The left clamp was fixed, while the right clamp moved vertically at a constant velocity to induce shear deformation.

4.1.2. Experimental Results

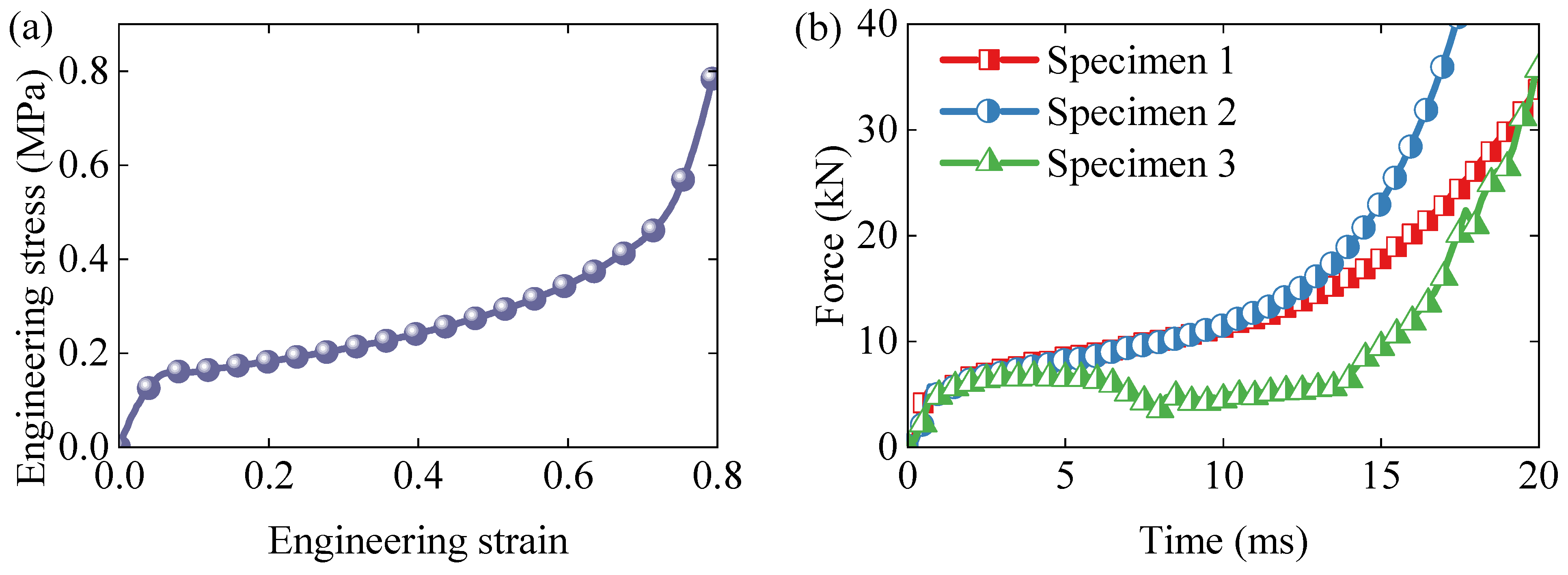

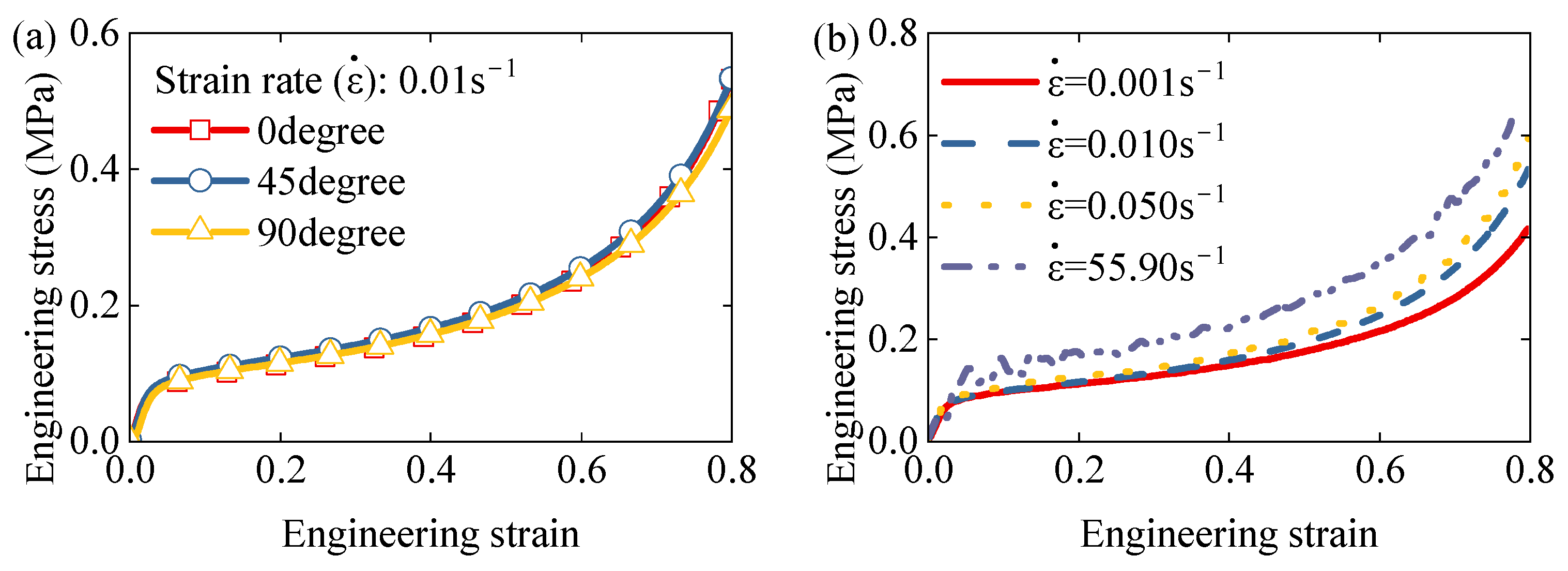

Figure 7a presents the engineering stress–strain curves for compression tests at various loading angles at a strain rate of 0.01 s

−1. All curves exhibit comparable behavior during the elastic, plateau, and densification stages, suggesting negligible direction-dependence. Thus, the EPS foam can be reasonably assumed to behave as a quasi-isotropic material in subsequent modeling.

Figure 7b shows the effect of strain rate on the stress–strain response. Although the overall shape of the curves remains similar, increasing strain rates lead to higher yield stress and lower densification strain, indicating that EPS foam exhibits rate-dependent mechanical behavior.

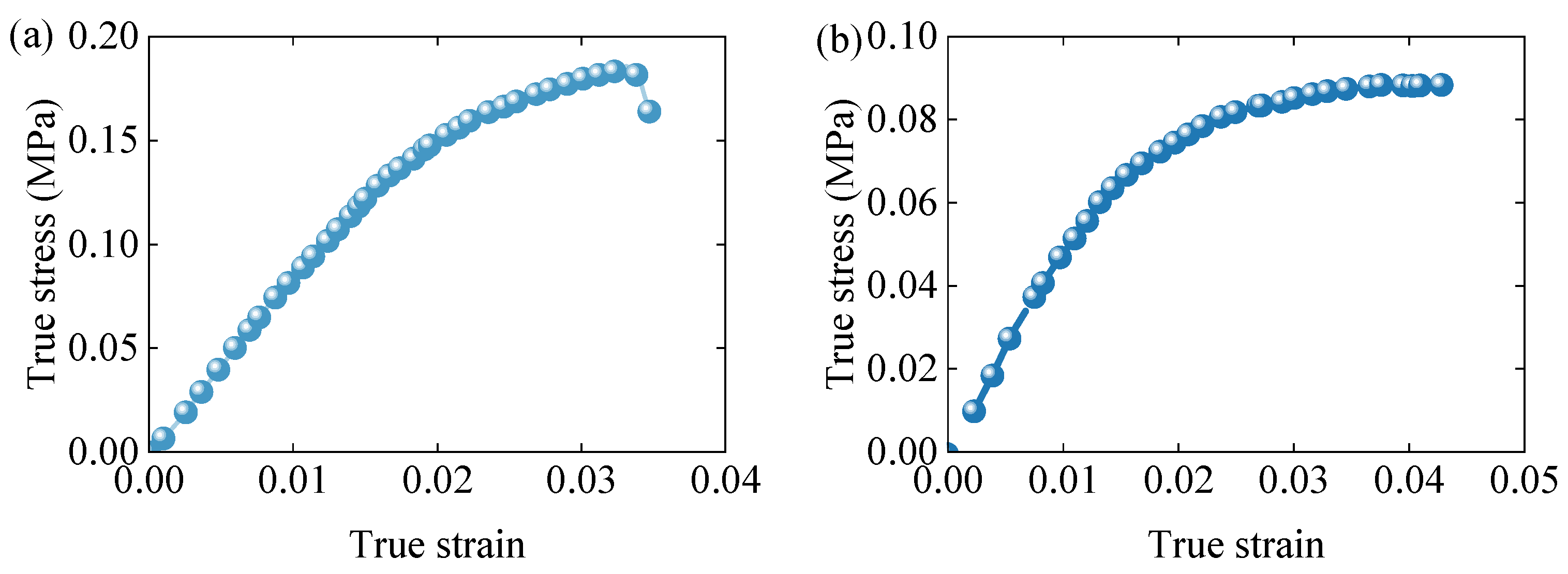

Figure 8a presents the tensile stress–strain curve at a strain rate of 0.001 s

−1. The material demonstrates very limited plastic deformation before experiencing brittle fracture, with a fracture strain of approximately 0.035 and an ultimate tensile strength of about 0.18 MPa.

Figure 8b depicts the shear stress–strain response. Only the initial linear portion of the curve is considered valid due to potential inaccuracies in the nonlinear portion introduced by plastic deformation at the clamped edges and stress concentration at the specimen corners. These effects distort the nonlinear response, which is thus excluded from the model calibration.

4.1.3. Calibration

Based on the experimental results from uniaxial compression, tension, and shear tests, the parameters of the quasi-isotropic constitutive model were calibrated and summarized in

Table 1. To capture both compressive and tensile responses within a unified framework, the anisotropic yield tensor and hardening functions were calibrated separately. The dimensionless hardening functions

are provided in

Table 2.

The parameters listed above were integrated into the proposed rate-sensitive constitutive model and implemented through the explicit user-defined subroutine VUMAT in ABAQUS. Since the subroutine operates in a local coordinate system while boundary conditions are defined in the global system, a second-order rotation tensor was used to transform between coordinate systems (for more details, see [

1]).

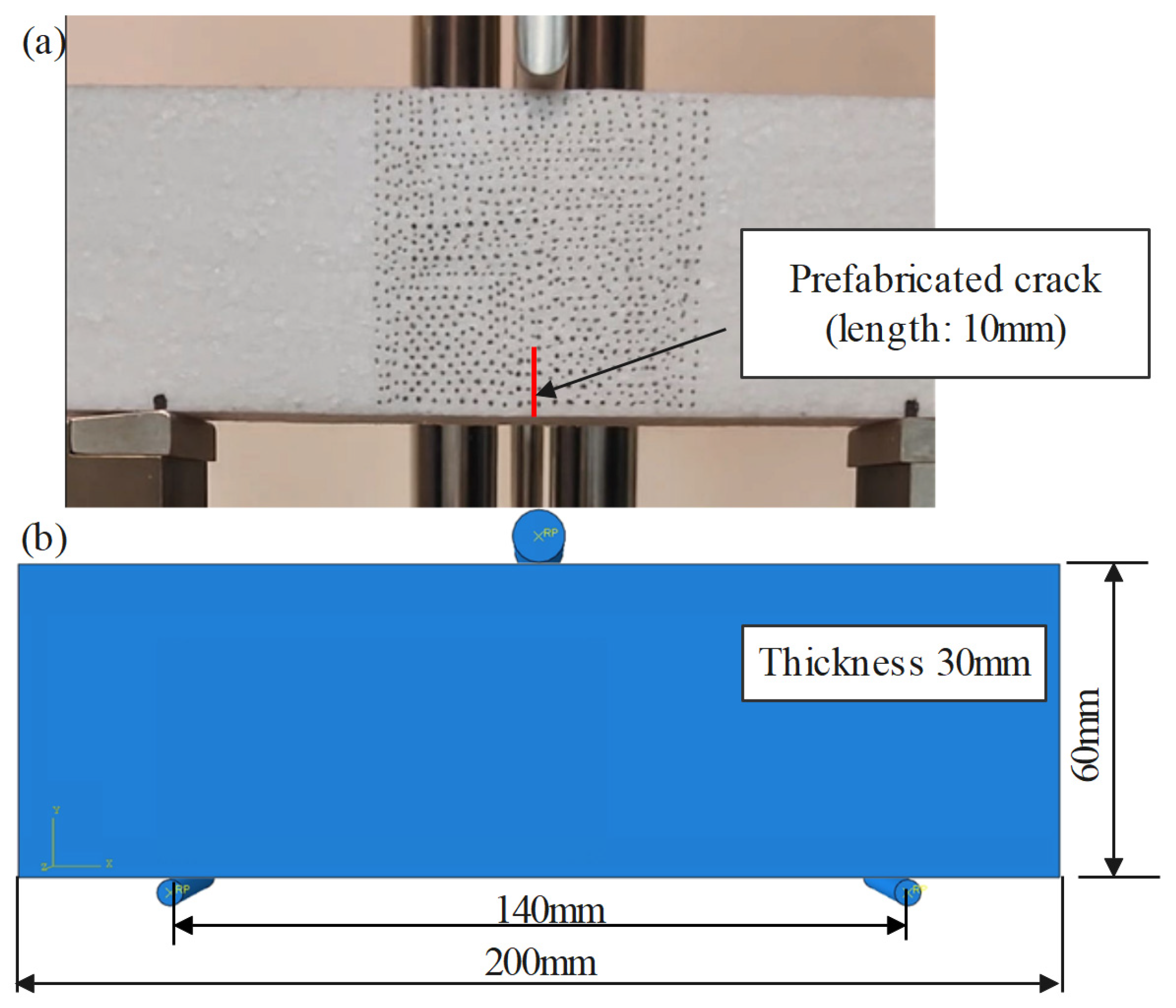

4.2. Prediction of Static Three-Point Bending

A cuboidal EPS foam specimen with dimensions of 200 mm × 60 mm × 30 mm was subjected to a three-point bending test using a universal testing machine equipped with a custom fixture, as shown in

Figure 9. A prefabricated notch with a depth of 10 mm was introduced at the center of the specimen to study localized deformation. A constant loading velocity of 0.06 mm/s was applied to the upper loading head, producing a concentrated force at the midpoint. The foam rise direction coincided with the loading direction. The displacement and force of the upper loading head were collected by the in-built data acquisition in the machine.

To validate the model, a numerical simulation was carried out in ABAQUS using the same geometry and boundary conditions. The specimen was discretized using C3D8 brick elements with an element size of 2 mm, verified by a mesh sensitivity study. A constant loading velocity was applied to the upper surface, and mass scaling was used to improve computational efficiency. Contact interactions were defined using hard contact in the normal direction and frictional contact (coefficient = 0.3) in the tangential direction. The constitutive model was incorporated via the VUMAT subroutine. Note that since the explicit solver in ABAQUS does not directly support simulation of crack propagation, only the elastic and plastic response stages were simulated. The displacement and reaction force of the reference point in the top rigid body were collected to obtain the predicted force–displacement curve.

Figure 9 compares the three-point bending simulation with the experimental procedure, highlighting the presence of a prefabricated crack in the experimental specimens. Significant tensile strain localization will be observed at the mid-bottom region of the specimens. During the initial stages of the bending test, both elastic and plastic deformation occur, accompanied by crack propagation. In the experiments, this leads to a rapid reduction in structural stiffness once the crack initiates. While the simulation accurately captures the initial elastic and plastic responses, it does not account for crack-induced failure. As a result, plastic deformation continues in the simulation even after the experimental specimen fractures, leading to an overestimation of the stress.

The predicted result in

Figure 10 exhibits a lower initial force compared to the experimental results. This discrepancy may be attributed to the smaller radius of the lower support in simulation, leading to higher stress concentration and reduced apparent stiffness compared to experimental results. Nevertheless, the proposed model accurately predicts the force–displacement response up to a displacement of 6 mm. Beyond this point, deformation is primarily driven by crack propagation, a mechanism not captured by the current model.

As predicted, the simulation model fails to capture the reduction in structural stiffness observed in the experiments due to crack propagation. Consequently, the simulated stress continues to increase during the plastic stage, diverging from the experimental results. Despite this limitation, the proposed constitutive model accurately reproduces the elastic and plastic behavior of the material, with the exception of crack propagation, which arises from the presence of prefabricated cracks in the experimental specimens.

4.3. Prediction of Dynamic Compression of Non-Standard Specimens

The standard and non-standard compressive specimens used in the experiments were also modeled in ABAQUS to simulate their dynamic compression behavior. The geometries were meshed using C3D8 solid elements with a global element size of 4 mm. A rigid plate was used to compress the specimens at an initial velocity of 4.5 m/s. Contact between the rigid plate and the foam was defined using a friction coefficient of 0.3 in the tangential direction and “hard” contact in the normal direction.

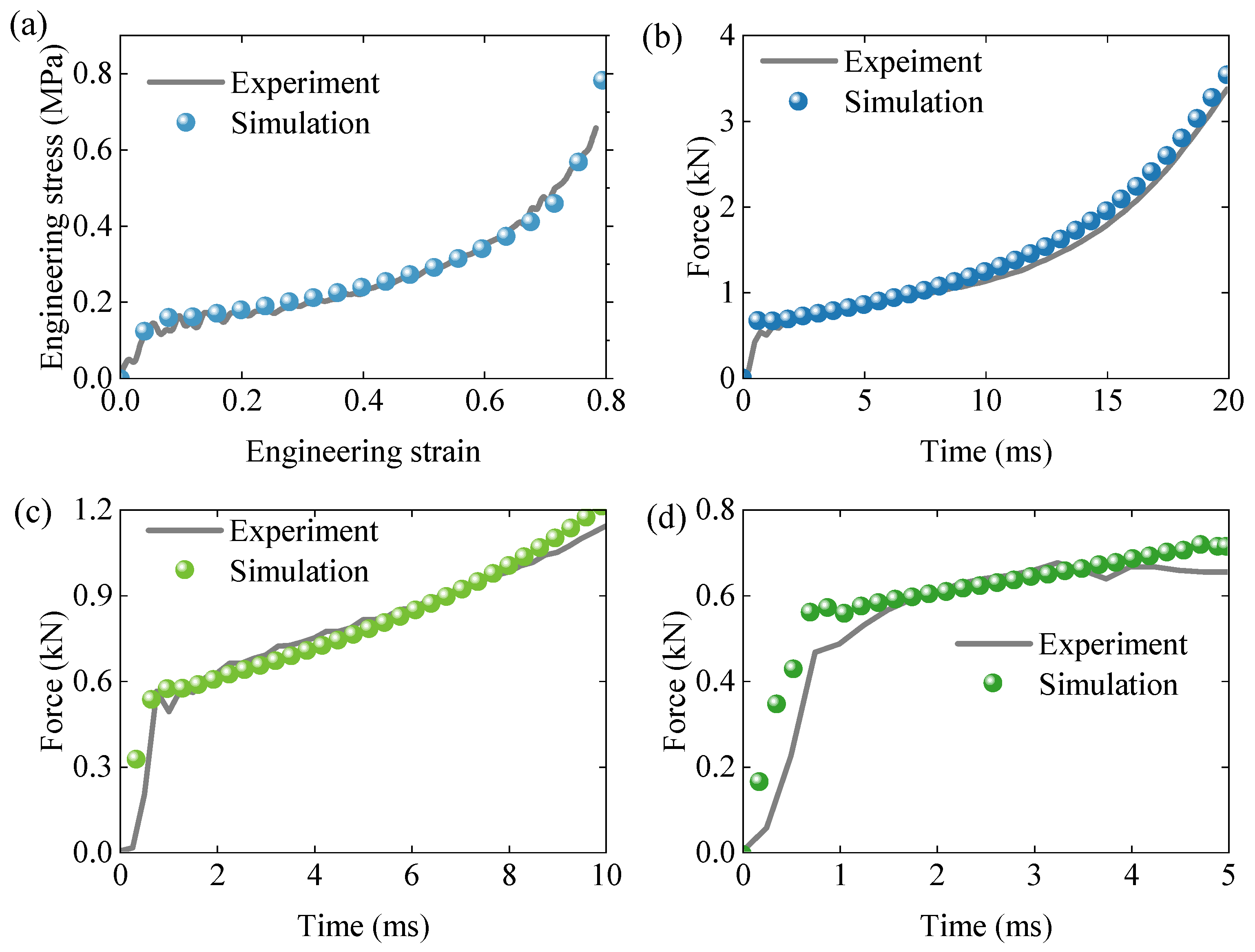

Figure 11a illustrates the engineering stress–strain response of the standard compression specimen. Good agreement is observed in both the initial elastic and subsequent plateau stages, indicating that the proposed constitutive model effectively captures the dynamic response of EPS foam.

Figure 11b–d present the force–time curves for three additional non-standard specimens. While the model accurately predicts the early response phase, discrepancies appear at later stages due to differences in the deformation patterns between the simulations and experiments.

In addition to force and strain responses, the deformation patterns observed in experiments and simulations are compared in

Figure 12.

Figure 12a,b show that for the standard and first non-standard specimen, the predicted deformation modes closely match experimental observations. In both cases, the deformation is uniform with negligible transverse expansion.

For non-standard specimen 2, shown in

Figure 12c, in the initial stage (left), both simulation and experiment show that the specimen remains largely undeformed under low compressive load. The middle stage reveals uniform axial compression with minimal lateral displacement, indicating that the material is primarily undergoing elastic deformation and early-stage cell wall collapse. In the final stage (right) at

t = 10 ms, localized lateral deformation is observed, particularly in the central web region of the component. This is evidenced by visible curvature and out-of-plane displacements in both the experimental and simulated results, consistent with a classical buckling mode due to the minimal height thickness ratio (85 mm/15 mm = 5.6). The region highlighted in red clearly marks the onset of buckling, demonstrating lateral instability due to the compressive stresses exceeding the critical load of the slender web section. In contrast to the experimental result, the simulated upper loading plate exhibits a slight tilt due to uneven contact force distribution, introducing noticeable differences between the two results.

When specimen 3 was subject to the compressive loading condition shown in

Figure 12d, in the initial stage (left), both the numerical and experimental results show that the EPS component remains largely undeformed, indicating the onset of loading and uniform stress distribution. In the intermediate stage (middle), moderate deformation is observed primarily in the vertical struts of the component, where the foam begins to compress and local buckling effects start to emerge due to the cell wall bending and progressive collapse. The final stage (right) captures a pronounced deformation and localized failure. The experimental image clearly reveals damage initiation at the inner edge of the arch, identified by a red marker, resulting in lower contact forces that were not fully captured by the simulation. This damage is attributed to stress concentration and local densification, resulting in material fracture and crushing.

The proposed constitutive model accurately captured the deformation behavior of standard specimens. However, it exhibited computational discrepancies when applied to non-standard specimens, primarily due to unstable structural responses such as buckling in

Figure 12c and fracture in

Figure 12d. The primary objective of the model is to represent the elastic and plastic behavior of EPS foam structures. The favorable agreement with the experimental results demonstrates its strong potential for capturing complex deformation in large-scale structures, such as TV packaging, as discussed in the following section.

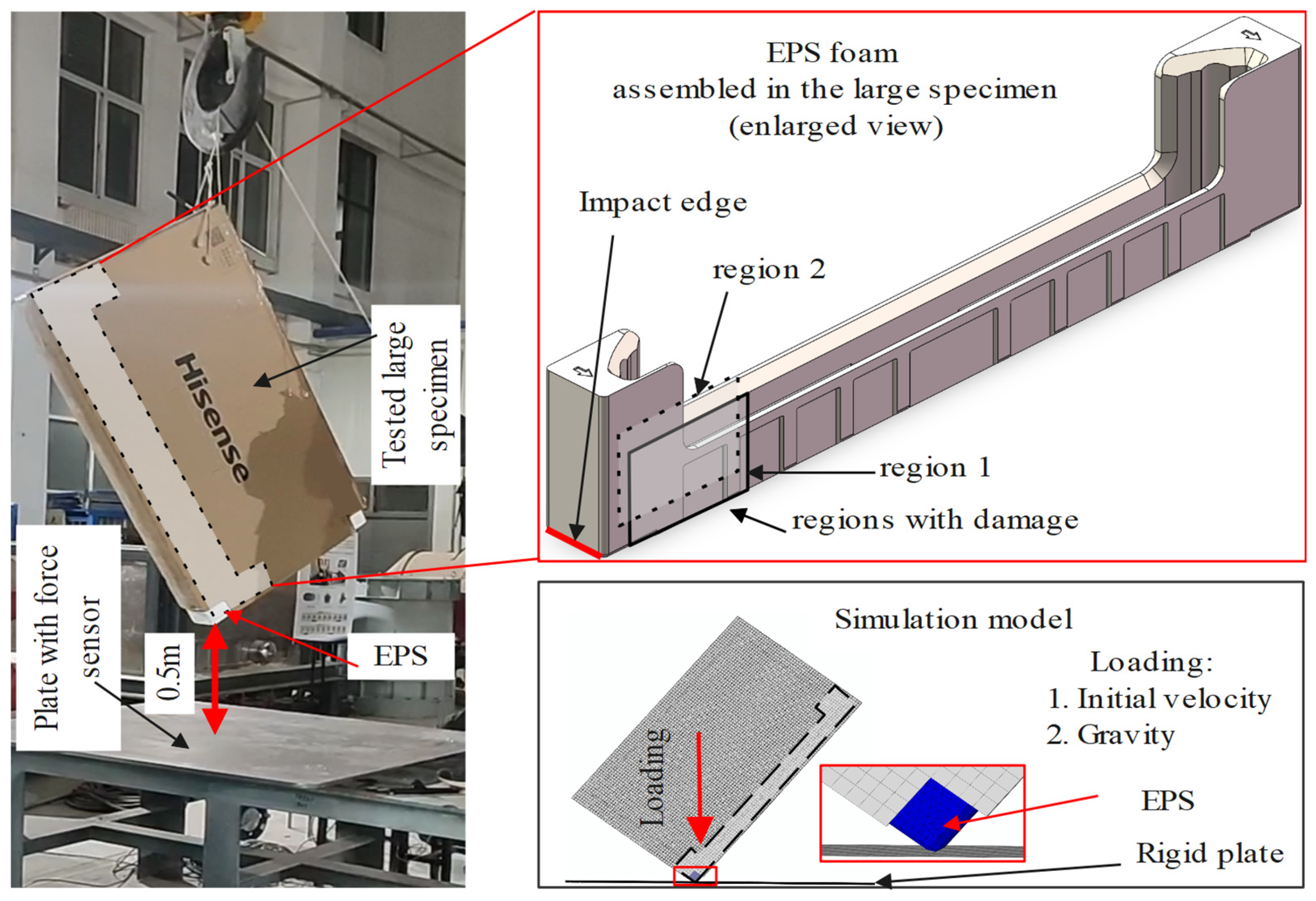

4.4. Prediction of Mechanical Performance of TV Package

A numerical model of the assembled TV package (which also includes a corrugated cardboard shell and a dummy TV model; see

Section 2.2) was also established to predict the mechanical performance of EPS foam in TV packaging, as illustrated in

Figure 3. The mechanical behavior of EPS foam was predicted using the proposed constitutive model via the explicit user subroutine VUMAT in ABAQUS, and the parameters used in this model were listed in

Table 1 and

Table 2. Other components, such as the corrugated board and the TV model, were given the proper material properties suggested by Hisense Virtual Technology Co., Ltd. (Qingdao, China), and these may be made available via direct contact with them. EPS foams were meshed using C3D4 tetrahedral elements with a global mesh size of 9 mm. Contact interactions among the components were defined using the “General Contact” algorithm in ABAQUS. Tangential behavior was modeled with a friction coefficient of 0.4, and normal behavior was set as “hard” contact. Loading conditions included an initial velocity of 3.1 m/s and a gravitational acceleration of 9.8 m/s

2, applied to the entire model. Mass scaling was used to enhance computational efficiency.

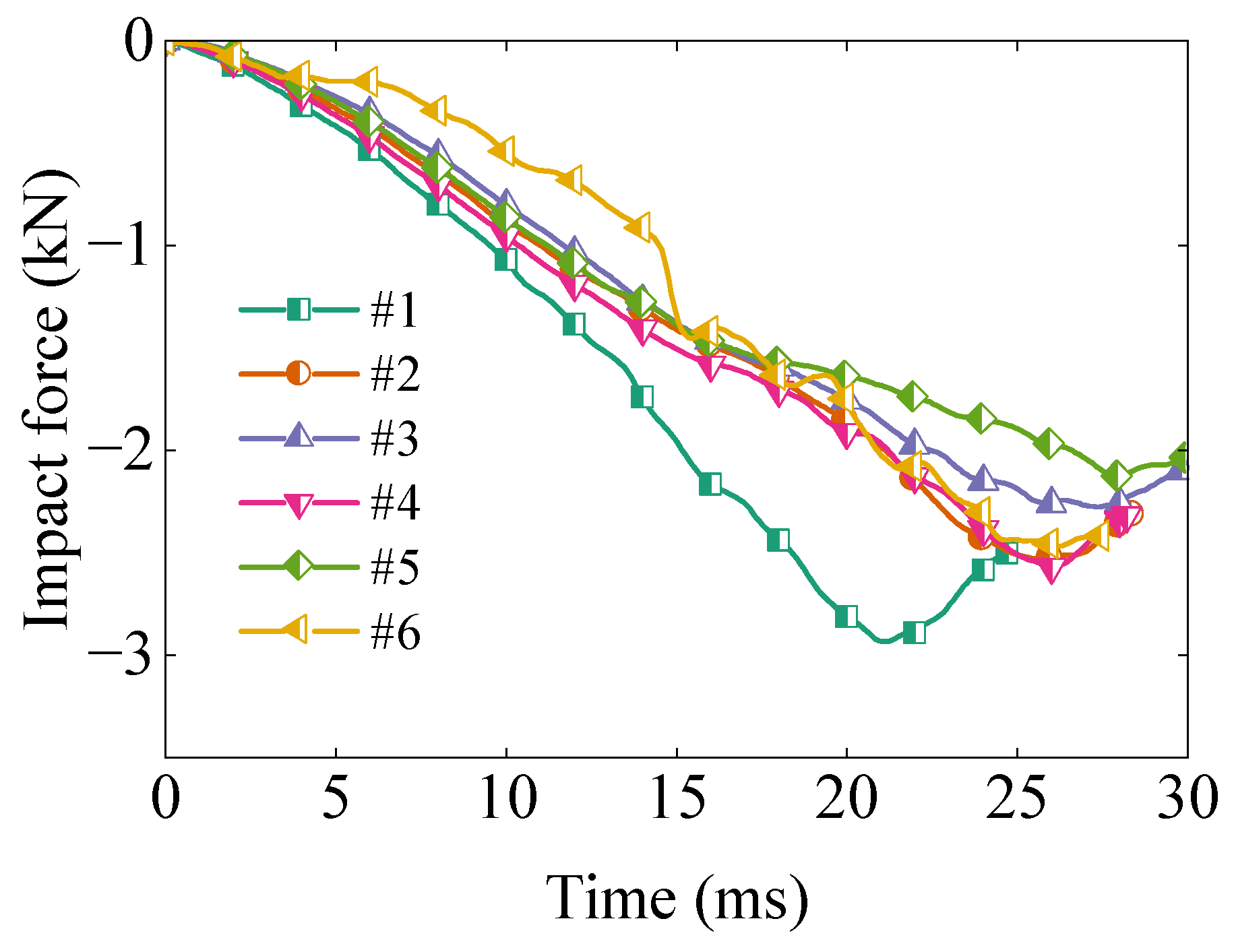

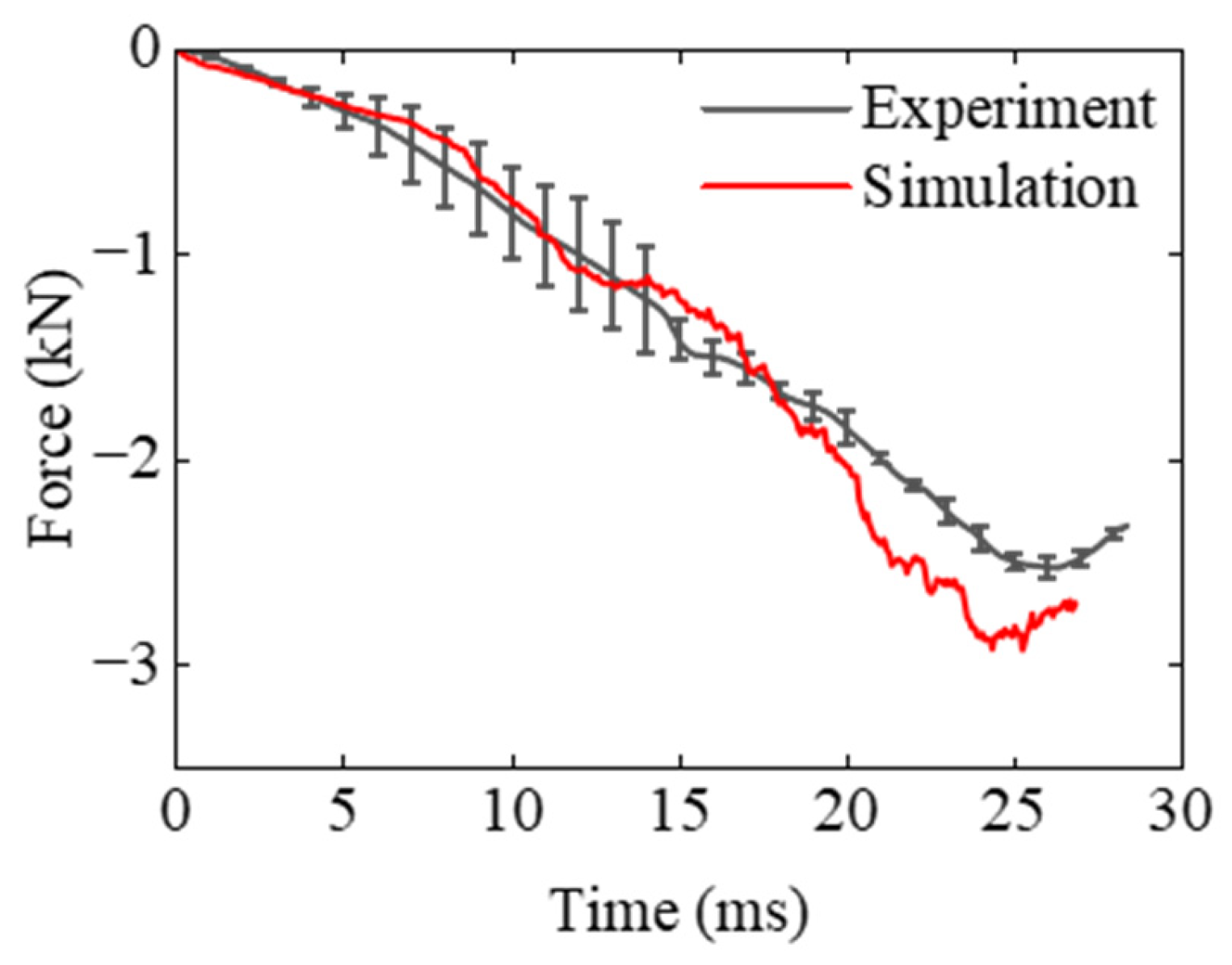

The force shown in

Figure 13 initially increases sharply upon impact, followed by a gradual decay as the EPS foam undergoes deformation and energy dissipation. The numerical results closely follow the experimental trend in the early phase of impact but diverge slightly in the later stage, possibly due to the complex contact behavior between components. The results also reveal a favorable correlation between simulation and experiment, indicating that the constitutive model captures the rate-sensitive mechanical response of EPS foam. The peak force predicted by the simulation is slightly higher than that observed experimentally. This discrepancy may result from localized damage near the corners, as illustrated in

Figure 14.

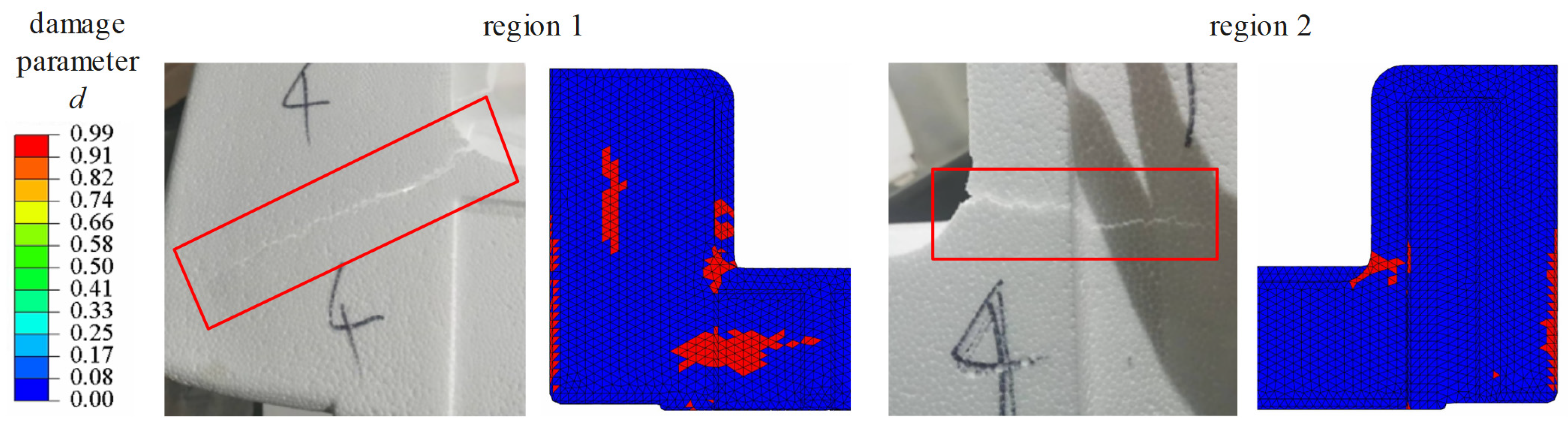

Figure 14 shows that in region 1, both the experimental image and the simulation output reveal damage localization along a plane oriented at approximately 45°, indicative of shear-dominated failure. The close correspondence between the simulated damage elements and the experimentally observed crack path demonstrates the model’s capability to predict the orientation and distribution of shear cracks under dynamic loading. In region 2, damage propagation is predominantly horizontal, as evidenced by both the simulation and experimental results, further underscoring the model’s ability to capture the evolution of dominant failure paths in complex geometries. However, discrepancies between the simulated and experimental damage zones may arise due to several factors, including limitations in the material constitutive models (e.g., the TV model), inaccuracies in simulating interfacial contact, and inherent experimental variabilities.

5. Conclusions

The dynamic mechanical behavior of foam was systematically investigated through a combination of experimental testing and advanced numerical simulations, with a specific focus on both individual structural components and a fully assembled TV packaging system subjected to impact loading. A novel, rate-sensitive, isotropic constitutive model was developed and implemented, uniquely capable of capturing the foam’s complex response by integrating tensile and compressive behavior into a single unified framework. This model was rigorously validated using quantitative results from three-point bending and dynamic compression tests on specimens with diverse geometrical features, yielding excellent correlation with experimental measurements, and force–time curves and deformation from simulation matched experimental values. Notably, the simulations accurately predicted damage initiation and propagation paths in the assembled packaging structure under impact, faithfully reproducing observed crack angles, failure modes, and energy absorption levels. As a result, the presented constitutive model provides a robust and reliable tool for simulating the dynamic performance of EPS foam, and in particular, it provides a reference for the impact response of engineering structures consisting of EPS foam.