Additive Manufacturing of Metal-Infilled Polylactic Acid-Based Sustainable Biocomposites—A Review of Methods, Properties and Applications Abetted with Patent Landscape Analysis

Abstract

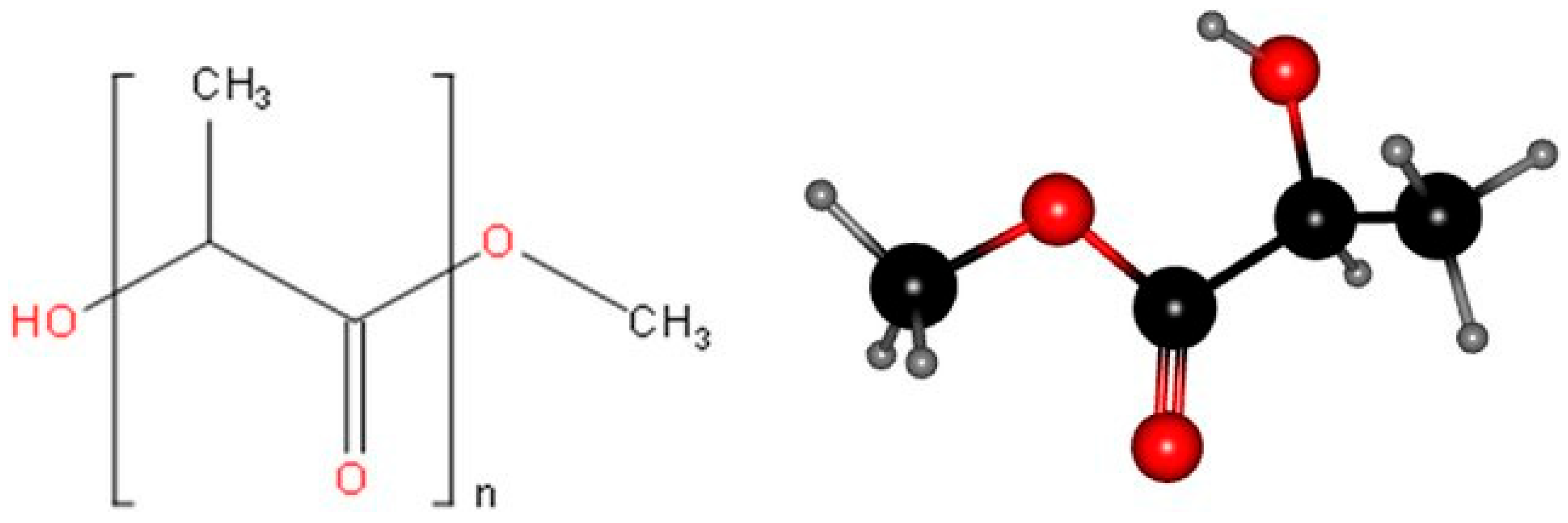

1. Introduction

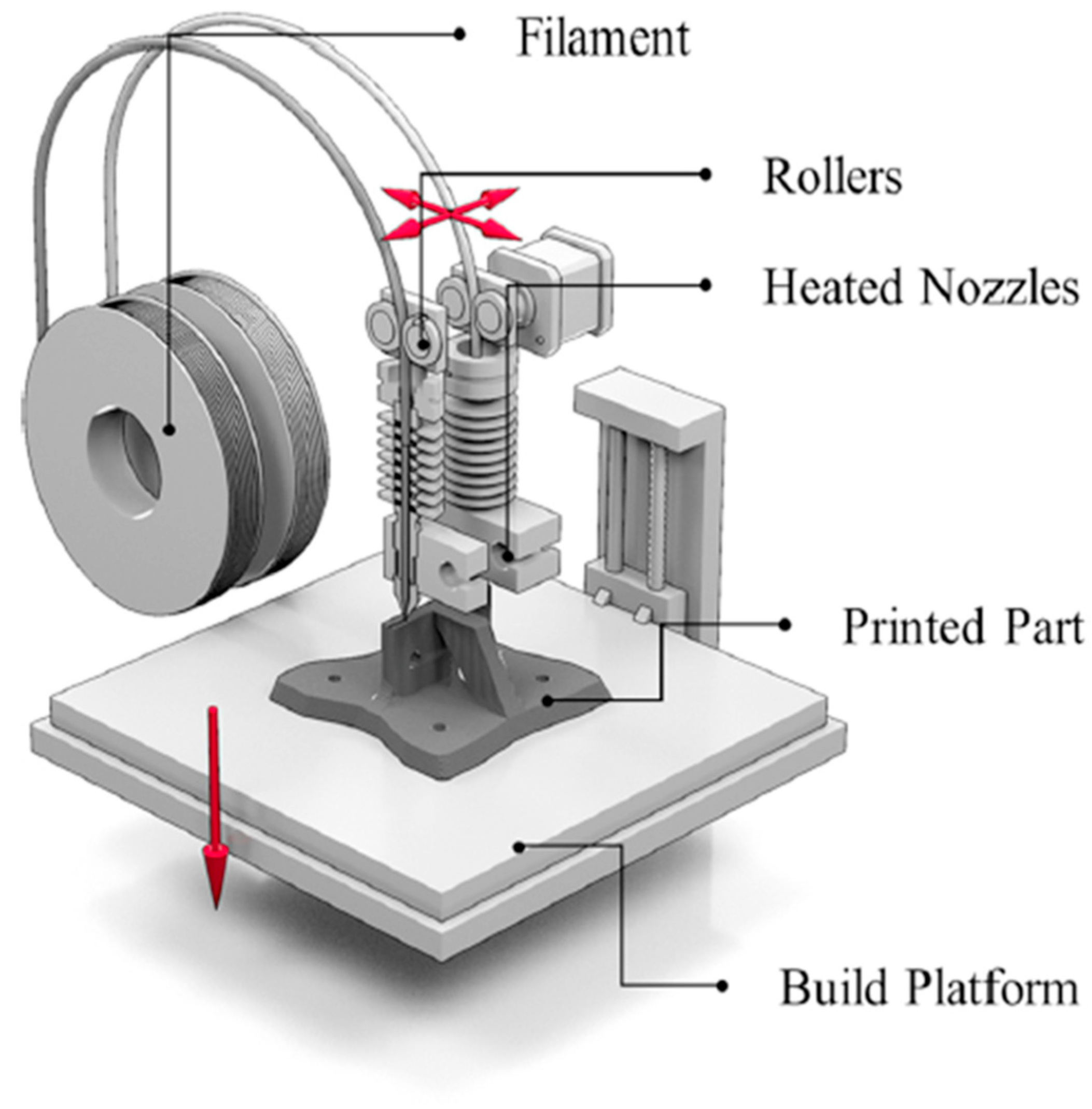

2. Filament Extrusion for 3D Printing of Composites

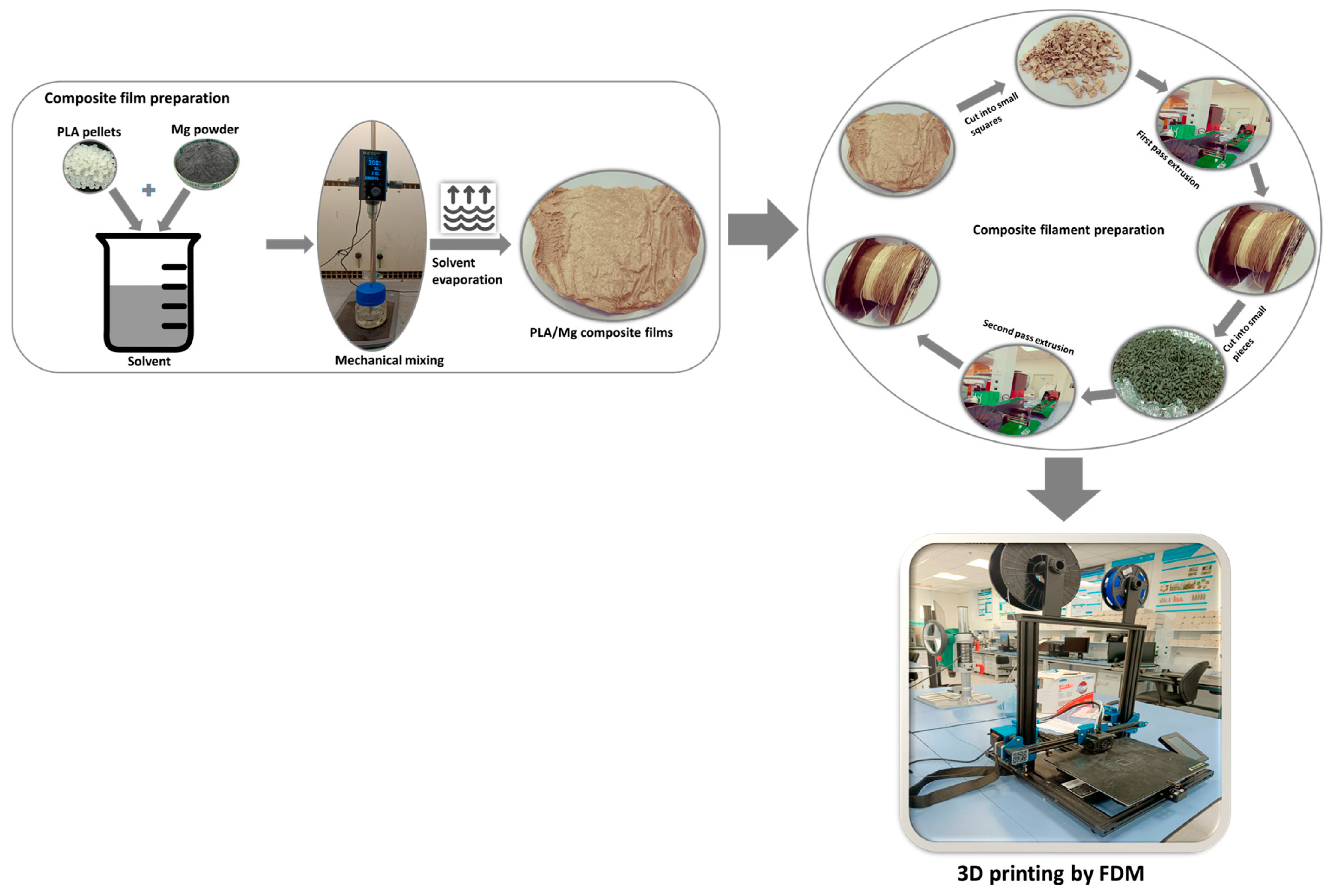

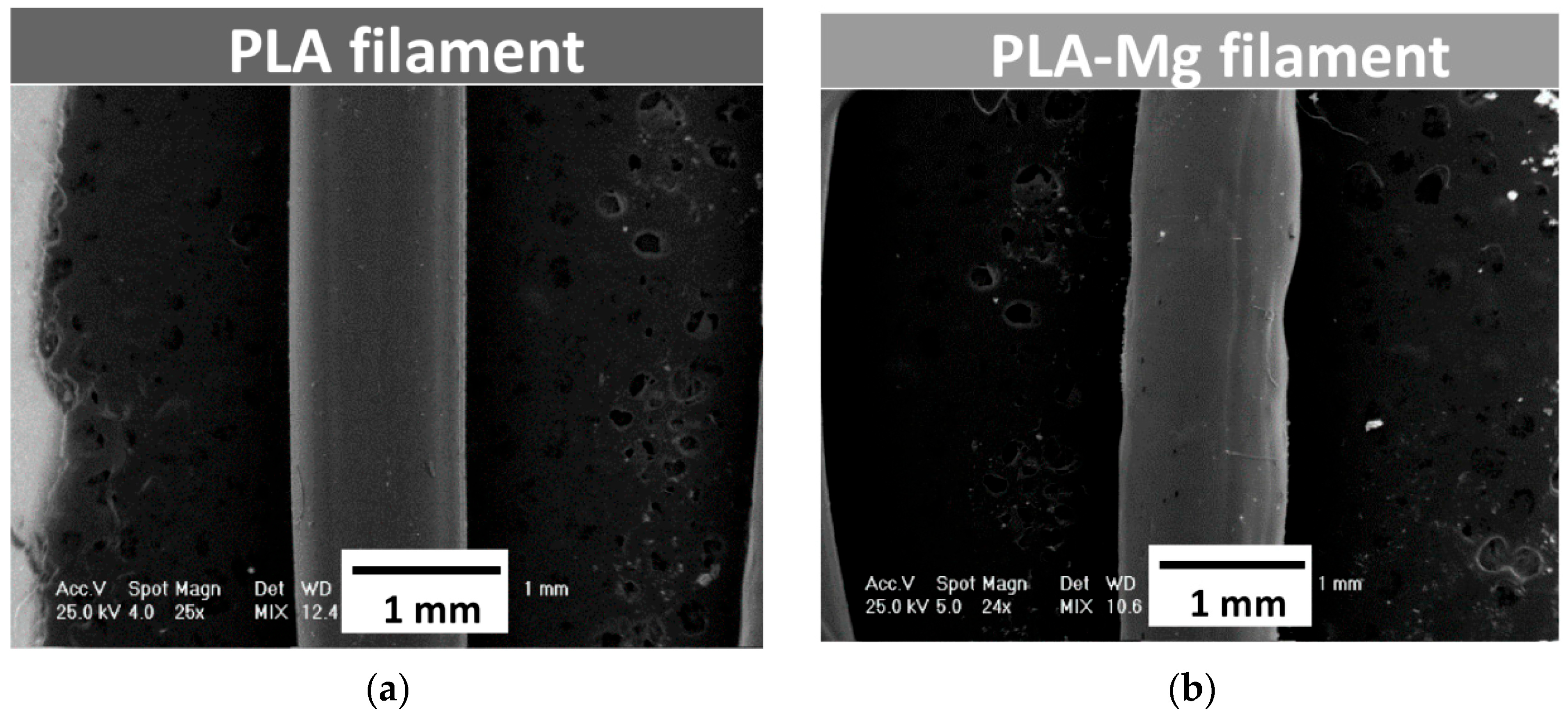

2.1. PLA–Magnesium

2.2. PLA Zinc

2.3. PLA Copper

2.4. PLA Bronze

2.5. PLA Brass

2.6. PLA Titanium

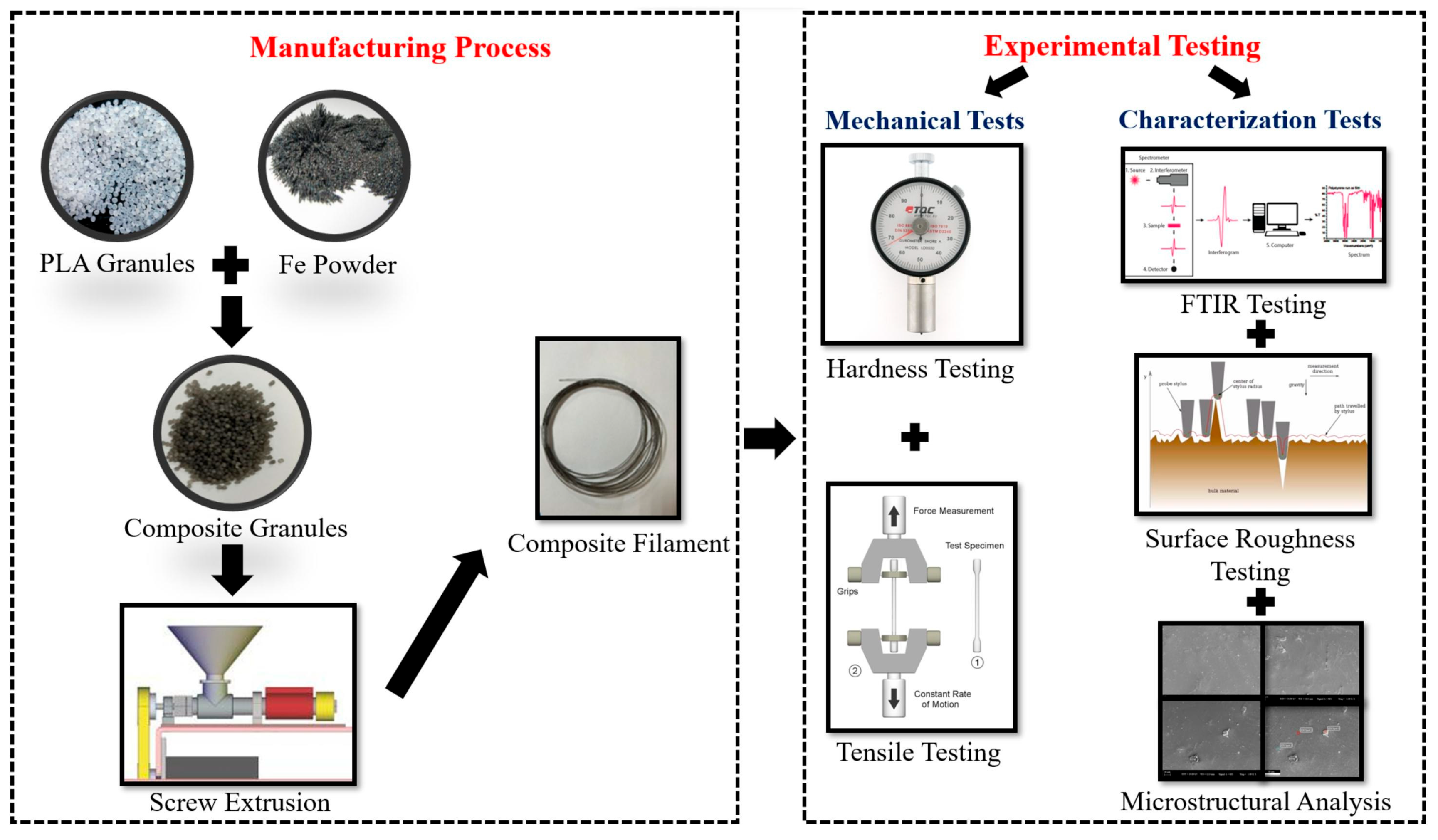

2.7. PLA Iron

2.8. PLA Silver

2.9. PLA Cobalt

2.10. PLA Nickel

3. Additive Manufacturing of Pla–Metal Biodegradable Composites

4. Properties of 3D Printed Pla–Metal Biocomposites

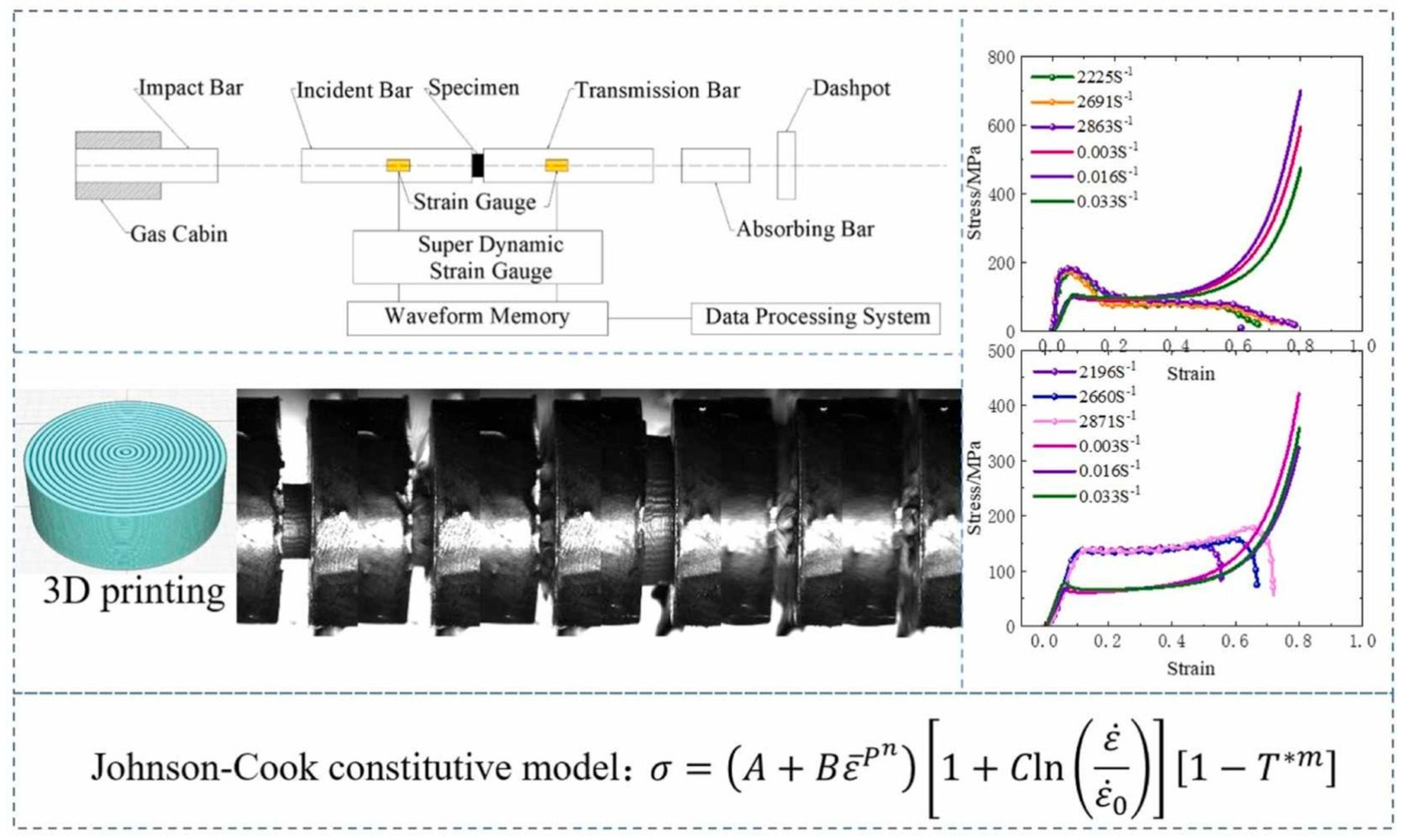

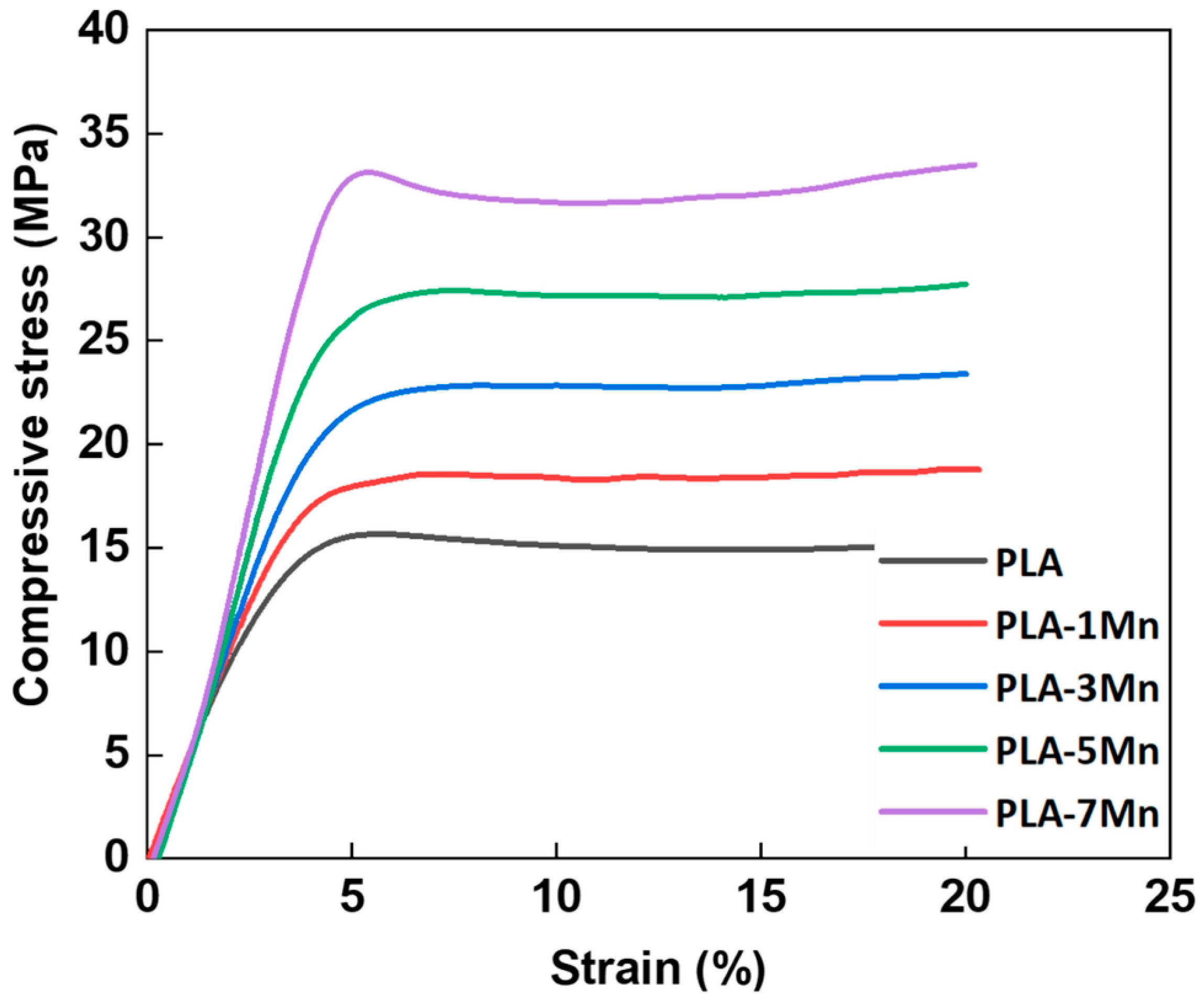

4.1. Mechanical Properties

4.2. Thermal Properties

4.3. Characterization

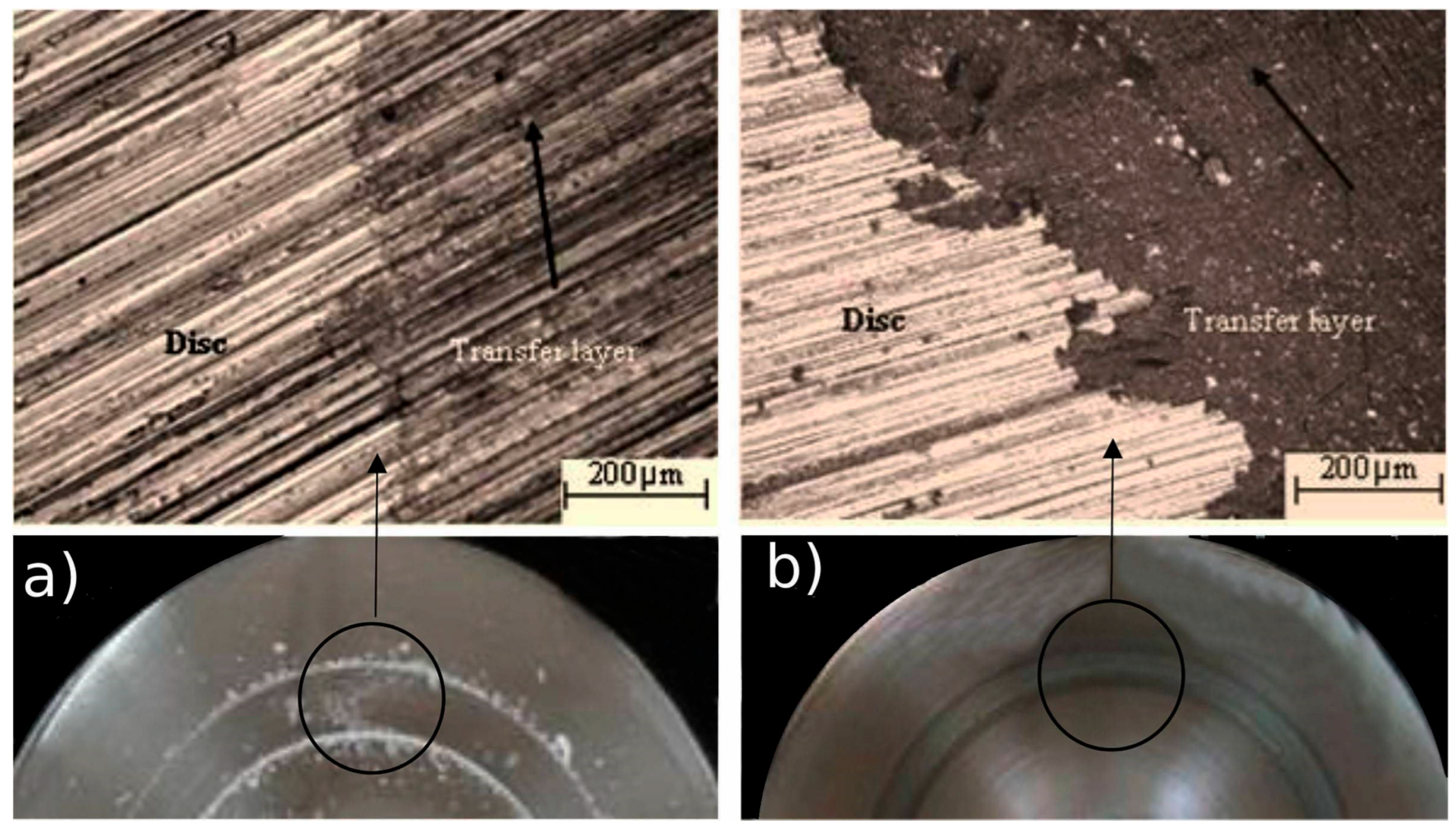

4.4. Tribological Properties

4.5. Biodegradability and Biocompatibility

4.6. Acoustic Properties

4.7. Physical Properties

5. Applications of Pla/Metal Biocomposites

6. Implications

6.1. Limitations

6.2. Future Prospects

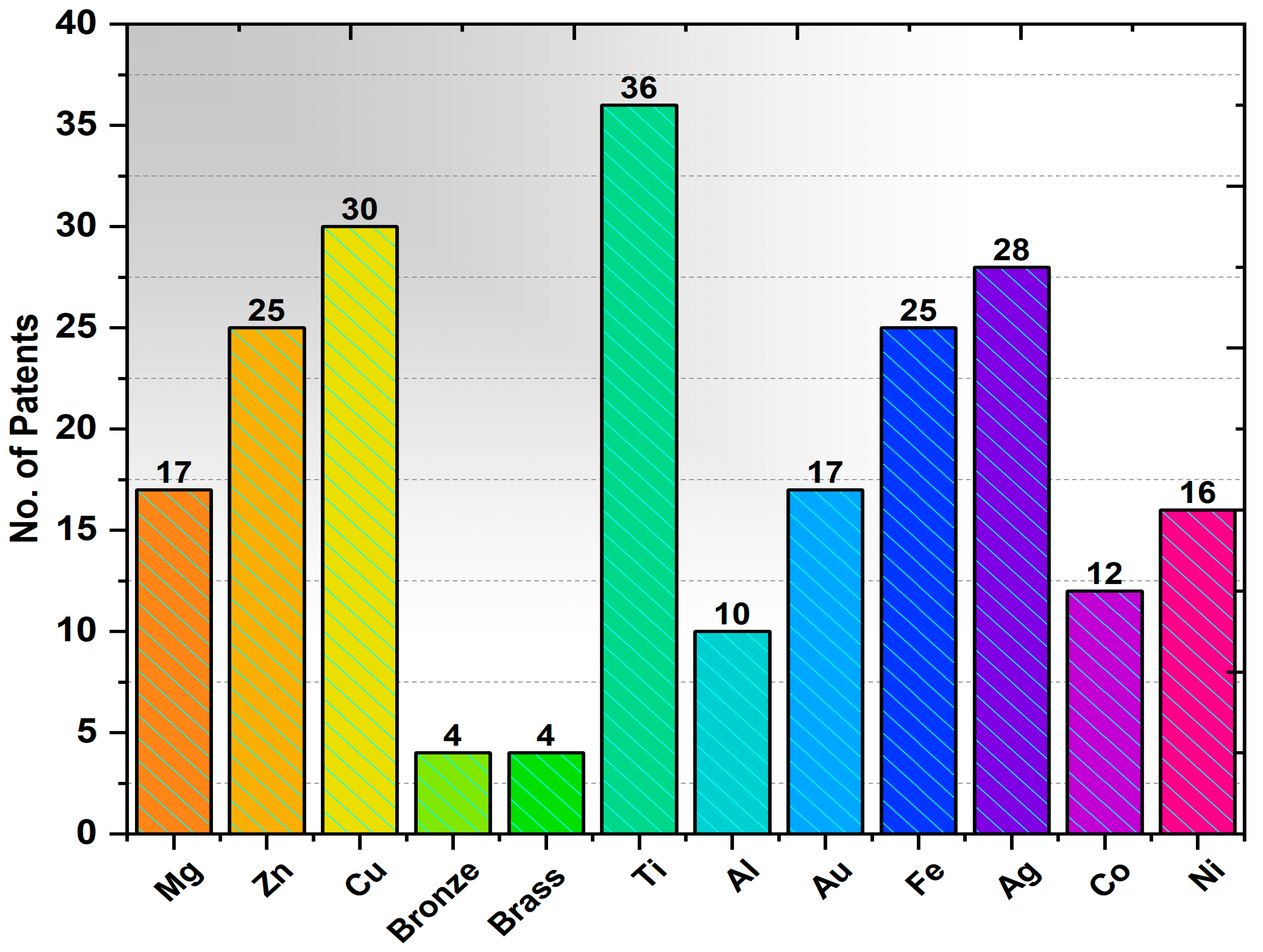

Envisage Using the Patent Landscape for PLA Metal Composite

7. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Horn, T.J.; Harrysson, O.L.A. Overview of Current Additive Manufacturing Technologies and Selected Applications. Sci. Prog. 2012, 95, 255–282. [Google Scholar] [CrossRef] [PubMed]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Vaezi, M.; Seitz, H.; Yang, S. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Eynde, M.V.D.; Van Puyvelde, P. 3D Printing of Poly(Lactic Acid); Springer: Berlin/Heidelberg, Germany, 2017; pp. 139–158. [Google Scholar] [CrossRef]

- Baran, E.H.; Erbil, H.Y. Surface Modification of 3D Printed PLA Objects by Fused Deposition Modeling: A Review. Colloids Interfaces 2019, 3, 43. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Villadiego, K.M.; Tapia, M.J.A.; Useche, J.; Macías, D.E. Thermoplastic Starch (TPS)/Polylactic Acid (PLA) Blending Methodologies: A Review. J. Polym. Environ. 2022, 30, 75–91. [Google Scholar] [CrossRef]

- Okolie, O.; Kumar, A.; Edwards, C.; Lawton, L.A.; Oke, A.; McDonald, S.; Thakur, V.K.; Njuguna, J. Bio-Based Sustainable Polymers and Materials: From Processing to Biodegradation. J. Compos. Sci. 2023, 7, 213. [Google Scholar] [CrossRef]

- Lozano, A.B.; Álvarez, S.H.; Isaza, C.V.; Montealegre-Rubio, W. Analysis and Advances in Additive Manufacturing as a New Technology to Make Polymer Injection Molds for World-Class Production Systems. Polymers 2022, 14, 1646. [Google Scholar] [CrossRef]

- Odera, R.S.; Idumah, C.I. Novel advancements in additive manufacturing of PLA: A review. Polym. Eng. Sci. 2023, 63, 3189–3208. [Google Scholar] [CrossRef]

- Mathias, D.; Snider, C.; Hicks, B.; Ranscombe, C. Accelerating product prototyping through hybrid methods: Coupling 3D printing and LEGO. Des. Stud. 2019, 62, 68–99. [Google Scholar] [CrossRef]

- Ghaffar, A.; Riaz, M.T.; Rehman, A.; Al Mahmud, M.M.S. An Optimized 3D Printer by Enhancing Material Properties and Surface Finish of PLA Through Modifications. J. Eng. 2024, 2024, 9198329. [Google Scholar] [CrossRef]

- Joseph, T.M.; Kallingal, A.; Suresh, A.M.; Mahapatra, D.K.; Hasanin, M.S.; Haponiuk, J.; Thomas, S. 3D printing of polylactic acid: Recent advances and opportunities. Int. J. Adv. Manuf. Technol. 2023, 125, 1015–1035. [Google Scholar] [CrossRef]

- Tripathi, N.; Misra, M.; Mohanty, A.K. Durable Polylactic Acid (PLA)-Based Sustainable Engineered Blends and Biocomposites: Recent Developments, Challenges, and Opportunities. ACS Eng. Au 2021, 1, 7–38. [Google Scholar] [CrossRef]

- Arunkumar, P.; Balaji, D.; Radhika, N.; Rajeshkumar, L.; Rangappa, S.M.; Siengchin, S. Effect of infill pattern on mechanical properties of 3D printed PLA-Zn composites for drone frame structures: A topology optimization integrated application study. Results Eng. 2025, 25, 104107. [Google Scholar] [CrossRef]

- Rajeshkumar, G.; Seshadri, S.A.; Devnani, G.; Sanjay, M.; Siengchin, S.; Maran, J.P.; Al-Dhabi, N.A.; Karuppiah, P.; Mariadhas, V.A.; Sivarajasekar, N.; et al. Environment friendly, renewable and sustainable poly lactic acid (PLA) based natural fiber reinforced composites—A comprehensive review. J. Clean. Prod. 2021, 310, 127483. [Google Scholar] [CrossRef]

- Sathies, T.; Senthil, P.; Anoop, M. A review on advancements in applications of fused deposition modelling process. Rapid Prototyp. J. 2020, 26, 669–687. [Google Scholar] [CrossRef]

- Khan, I.; Tariq, M.; Abas, M.; Shakeel, M.; Hira, F.; Al Rashid, A.; Koç, M. Parametric investigation and optimisation of mechanical properties of thick tri-material based composite of PLA-PETG-ABS 3D-printed using fused filament fabrication. Compos. Part C Open Access 2023, 12, 100392. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-Based 3D Printing Applications of PLA Composites: A Review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Lunt, J. Large-scale production, properties and commercial applications of polylactic acid polymers. Polym. Degrad. Stab. 1998, 59, 145–152. [Google Scholar] [CrossRef]

- Gonzalez-Calderon, J.A.; Mendoza, G.; Peña-Juárez, M.G.; Perez, E. Use of Chemically Modified Titanium Dioxide Particles to Mediate the Non-isothermal Cold Crystallization of Poly (latic acid). J. Mex. Chem. Soc. 2020, 64, 117–136. [Google Scholar] [CrossRef]

- Shekhar, N.; Mondal, A. Synthesis, properties, environmental degradation, processing, and applications of Polylactic Acid (PLA): An overview. Polym. Bull. 2024, 81, 11421–11457. [Google Scholar] [CrossRef]

- Rydz, J.; Sikorska, W.; Kyulavska, M.; Christova, D. Polyester-Based (Bio)degradable Polymers as Environmentally Friendly Materials for Sustainable Development. Int. J. Mol. Sci. 2014, 16, 564–596. [Google Scholar] [CrossRef]

- Sharma, A.; Rai, A. Fused deposition modelling (FDM) based 3D & 4D Printing: A state of art review. Mater. Today Proc. 2022, 62, 367–372. [Google Scholar] [CrossRef]

- Garlotta, D. A literature review of poly (lactic acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Balletti, C.; Ballarin, M.; Guerra, F. 3D printing: State of the art and future perspectives. J. Cult. Herit. 2017, 26, 172–182. [Google Scholar] [CrossRef]

- Liu, C.; Wang, L.; Liu, S.; Tong, L.; Liu, X. Fabrication strategies of polymer-based electromagnetic interference shielding materials. Adv. Ind. Eng. Polym. Res. 2020, 3, 149–159. [Google Scholar] [CrossRef]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef]

- Subramaniam, S.R.; Samykano, M.; Selvamani, S.K.; Ngui, W.K.; Kadirgama, K.; Sudhakar, K.; Idris, M.S. 3D printing: Overview of PLA progress. In Proceedings of the 3rd International Conference on Automotive Innovation Green Energy Vehicle: Aigev 2018, Kuantan, Malaysia, 25–26 July 2018; p. 020015. [Google Scholar] [CrossRef]

- Chen, G.; Chen, L.; Wang, W.; Chen, S.; Wang, H.; Wei, Y.; Hong, F.F. Improved bacterial nanocellulose production from glucose without the loss of quality by evaluating thirteen agitator configurations at low speed. Microb. Biotechnol. 2019, 12, 1387–1402. [Google Scholar] [CrossRef] [PubMed]

- Dickson, A.N.; Abourayana, H.M.; Dowling, D.P. 3D Printing of Fibre-Reinforced Thermoplastic Composites Using Fused Filament Fabrication—A Review. Polymers 2020, 12, 2188. [Google Scholar] [CrossRef] [PubMed]

- Ghilan, A.; Chiriac, A.P.; Nita, L.E.; Rusu, A.G.; Neamtu, I.; Chiriac, V.M. Trends in 3D Printing Processes for Biomedical Field: Opportunities and Challenges. J. Polym. Environ. 2020, 28, 1345–1367. [Google Scholar] [CrossRef]

- Zub, K.; Hoeppener, S.; Schubert, U.S. Inkjet Printing and 3D Printing Strategies for Biosensing, Analytical, and Diagnostic Applications. Adv. Mater. 2022, 34, e2105015. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Berto, F. 3D Printing of polymer composites: A short review. Mater. Des. Process. Commun. 2020, 2, e97. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. Effects of raster layup and printing speed on strength of 3D-printed structural components. Procedia Struct. Integr. 2020, 28, 720–725. [Google Scholar] [CrossRef]

- Vinay, D.L.; Keshavamurthy, R.; Tambrallimath, V. Enhanced Mechanical Properties of Metal filled 3D Printed Polymer Composites. J. Inst. Eng. Ser. D 2023, 104, 181–195. [Google Scholar] [CrossRef]

- Mulla, M.Z.; Rahman, M.R.T.; Marcos, B.; Tiwari, B.; Pathania, S. Poly Lactic Acid (PLA) Nanocomposites: Effect of Inorganic Nanoparticles Reinforcement on Its Performance and Food Packaging Applications. Molecules 2021, 26, 1967. [Google Scholar] [CrossRef]

- Rahman, M.; Dutta, N.K.; Choudhury, N.R. Magnesium Alloys With Tunable Interfaces as Bone Implant Materials. Front. Bioeng. Biotechnol. 2020, 8, 564. [Google Scholar] [CrossRef]

- Residori, S.; Dul, S.; Pegoretti, A.; Fambri, L.; Pugno, N.M. Three Dimensional Printing of Multiscale Carbon Fiber-Reinforced Polymer Composites Containing Graphene or Carbon Nanotubes. Nanomaterials 2022, 12, 2064. [Google Scholar] [CrossRef]

- Leonés, A.; Salaris, V.; Aranda, I.R.; Lieblich, M.; López, D.; Peponi, L. Thermal Properties and In Vitro Biodegradation of PLA-Mg Filaments for Fused Deposition Modeling. Polymers 2023, 15, 1907. [Google Scholar] [CrossRef] [PubMed]

- Antoniac, I.; Popescu, D.; Zapciu, A.; Antoniac, A.; Miculescu, F.; Moldovan, H. Magnesium Filled Polylactic Acid (PLA) Material for Filament Based 3D Printing. Materials 2019, 12, 719. [Google Scholar] [CrossRef] [PubMed]

- Ali, F.; Kalva, S.N.; Mroue, K.H.; Keyan, K.S.; Tong, Y.; Khan, O.M.; Koç, M. Degradation assessment of Mg-Incorporated 3D printed PLA scaffolds for biomedical applications. Bioprinting 2023, 35, e00302. [Google Scholar] [CrossRef]

- Kalva, S.N.; Ali, F.; Velasquez, C.A.; Koç, M. 3D-Printable PLA/Mg Composite Filaments for Potential Bone Tissue Engineering Applications. Polymers 2023, 15, 2572. [Google Scholar] [CrossRef]

- Fatchurrohman, N.; Muhida, R.; Maidawati. From Corn to Cassava: Unveiling PLA Origins for Sustainable 3D Printing. J. Teknol. 2023, 13, 87–93. [Google Scholar] [CrossRef]

- Tan, M.A.; Yeoh, C.K.; Teh, P.L.; Rahim, N.A.A.; Song, C.C.; Voon, C.H. Effect of zinc oxide suspension on the overall filler content of the PLA/ZnO composites and cPLA/ZnO composites. E-Polymers 2023, 23, 20228113. [Google Scholar] [CrossRef]

- Rodriguez-Pacheco, L.C.; Lardizabal-Gutierrez, D.; Pantoja-Espinoza, J.C.; de la Torre-Saenz, L.; Estrada-Moreno, I.A.; Paraguay-Delgado, F. Novel 3D printing filaments: PLA and zinc carbonate basic composites for laser-assisted thermal decomposition. J. Mater. Res. Technol. 2024, 31, 2266–2278. [Google Scholar] [CrossRef]

- Sadeghian, H.; Ayatollahi, M.R.; Yahya, M.Y. Effects of copper additives on load carrying capacity and micro mechanisms of fracture in 3D-printed PLA specimens. Theor. Appl. Fract. Mech. 2023, 127, 104027. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Sivatte-Adroer, M. An Experimental Investigation about the Dimensional Accuracy and the Porosity of Copper-Filled PLA Fused Filament Fabrication Parts. Metals 2023, 13, 1608. [Google Scholar] [CrossRef]

- Liu, Y.; Ouyang, P.; Zhang, Z.; Zhu, H.; Chen, X.; Wang, Y.; Li, B.; Xu, K.; Wang, J.; Lu, J. Developments, challenges and future trends in advanced sustainable machining technologies for preparing array micro-holes. Nanoscale 2024, 16, 19938–19969. [Google Scholar] [CrossRef]

- Sneha, P.; Balamurugan, K.; Jyothi, Y.; Krishnan, S. Microdrilling Studies PLA/Bronze Composite Samples Printed Using Fused Deposition Model. Adv. Mater. Sci. Eng. 2023, 2023, 9456717. [Google Scholar] [CrossRef]

- Wei, X.; Behm, I.; Winkler, T.; Bähr, R. Optimization of extrusion-based additive manufacturing of bronze metal parts using a CuSn10/Polylactic acid composite. J. Mater. Res. Technol. 2024, 30, 3602–3610. [Google Scholar] [CrossRef]

- Mudakavi, D.; Sreesha, R.B.; Kumar, V.; Adinarayanappa, S.M. A comprehensive experimental investigation on mechanical properties and fracture morphology of particulate composites via material extrusion-based 3D printing. Results Mater. 2022, 16, 100348. [Google Scholar] [CrossRef]

- Darsin, M.; Jatisukamto, G.; Ramadhan, D.M.; Ramadhan, M.E.; Wibowo, R.K.; Basuki, H.A.; Djumhariyanto, D.; Choiron, M.A. The Effect of 3D Printing Filament Extrusion Process Parameters on Dimensional Accuracy and Strength Using PLA-Brass Filaments. J. Eng. Sci. Technol. 2023, 18, 145–155. [Google Scholar]

- Darsin, M.; Rifky, M.K.; Asrofi, M.; Basuki, H.A.; Wibowo, R.K.K.; Djumhariyanto, D.; Choiron, M.A. The effect of 3D printing parameter variations on tensile strength using filament made of PLA-Titanium. In Proceedings of the International Conference on Advanced Technology and Multidiscipline (ICATAM2022): Supporting Sustainable Development Goals Through Innovation on Advanced Technology and Multidisciplinary Research, Surabaya, Indonesia, 12–13 October 2022; p. 040001. [Google Scholar] [CrossRef]

- Guan, X.-N.; Xu, X.-N.; Kuniyoshi, R.; Zhou, H.-H.; Zhu, Y.-F. Electromagnetic and mechanical properties of carbonyl iron powders-PLA composites fabricated by fused deposition modeling. Mater. Res. Express 2018, 5, 115303. [Google Scholar] [CrossRef]

- Memiş, M.; Gök, D.A. Development of Fe-reinforced PLA-based composite filament for 3D printing: Process parameters, mechanical and microstructural characterization. Ain Shams Eng. J. 2025, 16, 103279. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Tzounis, L. Three-Dimensional Printed Antimicrobial Objects of Polylactic Acid (PLA)-Silver Nanoparticle Nanocomposite Filaments Produced by an In-Situ Reduction Reactive Melt Mixing Process. Biomimetics 2020, 5, 42. [Google Scholar] [CrossRef]

- Walker, J.S.; Arnold, J.; Shrestha, C.; Smith, D. Antibacterial silver submicron wire-polylactic acid composites for fused filament fabrication. Rapid Prototyp. J. 2020, 26, 32–38. [Google Scholar] [CrossRef]

- Ploetz, E.; Engelke, H.; Lächelt, U.; Wuttke, S. The Chemistry of Reticular Framework Nanoparticles: MOF, ZIF, and COF Materials. Adv. Funct. Mater. 2020, 30, 1909062. [Google Scholar] [CrossRef]

- Neijhoft, J.; Henrich, D.; Kammerer, A.; Janko, M.; Frank, J.; Marzi, I. Sterilization of PLA after Fused Filament Fabrication 3D Printing: Evaluation on Inherent Sterility and the Impossibility of Autoclavation. Polymers 2023, 15, 369. [Google Scholar] [CrossRef]

- Podstawczyk, D.; Skrzypczak, D.; Połomska, X.; Stargała, A.; Witek-Krowiak, A.; Guiseppi-Elie, A.; Galewski, Z. Preparation of antimicrobial 3D printing filament: In situ thermal formation of silver nanoparticles during the material extrusion. Polym. Compos. 2020, 41, 4692–4705. [Google Scholar] [CrossRef]

- Chaiya, N.; Daranarong, D.; Worajittiphon, P.; Somsunan, R.; Meepowpan, P.; Tuantranont, A.; Rakbamrung, N.; Topham, P.D.; Tighe, B.J.; Mahomed, A.; et al. 3D-printed PLA/PEO blend as biodegradable substrate coating with CoCl2 for colorimetric humidity detection. Food Packag. Shelf Life 2022, 32, 100829. [Google Scholar] [CrossRef]

- Ibrahim, Y.; Melenka, G.W.; Kempers, R. Additive manufacturing of Continuous Wire Polymer Composites. Manuf. Lett. 2018, 16, 49–51. [Google Scholar] [CrossRef]

- Ramesh, M.; Niranjana, K.; Bhoopathi, R.; Rajeshkumar, L. Additive manufacturing (3D printing) technologies for fiber-reinforced polymer composite materials: A review on fabrication methods and process parameters. E-Polymers 2024, 24, 20230114. [Google Scholar] [CrossRef]

- Chong, W.J.; Wright, P.; Simunec, D.P.; Jayashree, S.; Liew, W.; Heazlewood, C.; Trinchi, A.; Kyratzis, I.; Li, Y.; Shen, S.; et al. A comprehensive study on the biodegradability, biocompatibility, and antibacterial properties of additively manufactured PLA-ZnO nanocomposites. Smart Mater. Manuf. 2025, 3, 100069. [Google Scholar] [CrossRef]

- Friedrich, L.M.; Gunther, R.T.; Seppala, J.E. Suppression of Filament Defects in Embedded 3D Printing. ACS Appl. Mater. Interfaces 2022, 14, 32561–32578. [Google Scholar] [CrossRef]

- Huynh, H.N.; Vo, H.D.H.; Nguyen, H.T.; Bui, T.H.; Thai, T.T.H. Numerical Simulation of Flow Behaviour of PLA and PLA-Copper during Fused Deposition Modeling Process. Mater. Sci. Forum 2022, 1064, 53–63. [Google Scholar] [CrossRef]

- Tanveer, Q.; Mishra, G.; Mishra, S.; Sharma, R. Effect of infill pattern and infill density on mechanical behaviour of FDM 3D printed Parts- a current review. Mater. Today Proc. 2022, 62, 100–108. [Google Scholar] [CrossRef]

- Birosz, M.T.; Ledenyák, D.; Ando, M. Effect of FDM infill patterns on mechanical properties. Polym. Test. 2022, 113, 107654. [Google Scholar] [CrossRef]

- Kamaal, M.; Anas, M.; Rastogi, H.; Bhardwaj, N.; Rahaman, A. Effect of FDM process parameters on mechanical properties of 3D-printed carbon fibre–PLA composite. Prog. Addit. Manuf. 2021, 6, 63–69. [Google Scholar] [CrossRef]

- Balamurugan, K.; Pavan, M.V.; Ali, S.A.; Kalusuraman, G. Compression and flexural study on PLA-Cu composite filament using FDM. Mater. Today Proc. 2021, 44, 1687–1691. [Google Scholar] [CrossRef]

- Hanon, M.M.; Alshammas, Y.; Zsidai, L. Effect of print orientation and bronze existence on tribological and mechanical properties of 3D-printed bronze/PLA composite. Int. J. Adv. Manuf. Technol. 2020, 108, 553–570. [Google Scholar] [CrossRef]

- Samykano, M.; Selvamani, S.K.; Kadirgama, K.; Ngui, W.K.; Kanagaraj, G.; Sudhakar, K. Mechanical property of FDM printed ABS: Influence of printing parameters. Int. J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Soms, N.; Ravi Kumar, K.; Naveen Kumar, M. Machine learning algorithms based approach on prediction of mechanical behaviour of PLA/brass composites manufactured by additive manufacturing. Proc. Instit. Mech. Eng. Part E J Process Mech. Eng. 2025, 09544089241312642. [Google Scholar] [CrossRef]

- Zink, P.; Schmid, A.; Klotzbach, A.; Harre, K.; Gobel, G. Joining and Characterization of PLA Aluminium Compounds for Industrial Applications. In Proceedings of the 2020 43rd International Spring Seminar on Electronics Technology (ISSE), Demanovska Valley, Slovakia, 14–15 May 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–7. [Google Scholar] [CrossRef]

- Hernandez-Martinez, A.R.; Molina, G.A.; Esparza, R.; Rodríguez, Á.L.; Cruz-Soto, M.; León, E.R.-D.; Rangel, D.; Estévez, M. Novel Biocompatible and Biodegradable PCL-PLA/Iron Oxide NPs Marker Clip Composite for Breast Cancer Biopsy. Polymers 2018, 10, 1307. [Google Scholar] [CrossRef]

- Yin, H.; Chow, G. Effects of oleic acid surface coating on the properties of nickel ferrite nanoparticles/PLA composites. J. Biomed. Mater. Res. A 2009, 91A, 331–341. [Google Scholar] [CrossRef]

- Marino, G.P.; De la Pierre, S.; Salvo, M.; Lantada, A.D.; Ferraris, M. Modelling, additive layer manufacturing and testing of interlocking structures for joined components. Sci. Rep. 2022, 12, 2526. [Google Scholar] [CrossRef]

- Carkaci, M.E.; Secmen, M. The Prototype of a Wideband Ku-Band Conical Corrugated Horn Antenna with 3-D Printing Technology. Adv. Electromagn. 2019, 8, 39–47. [Google Scholar] [CrossRef]

- Rezanezhad, S.; Azadi, M. The influence of 3D-printed PLA coatings on pure and fretting fatigue properties of AM60 magnesium alloys under cyclic bending loads. Heliyon 2024, 10, e29552. [Google Scholar] [CrossRef]

- Rajan, D.; Samykano, M.; Suraparaju, S.K.; Moorthy, K.; Kadirgama, K.; Ramasamy, D.; Pandey, A.K. Materials Behaviour Analysis of 3D Printed Brass-PLA Filament. J. Phys. Conf. Ser. 2024, 2688, 012003. [Google Scholar] [CrossRef]

- Flaata, T.; Michna, G.J.; Letcher, T. Thermal conductivity testing apparatus for 3D printed materials. In Proceedings of the ASME 2017 Heat Transfer Summer Conference, Bellevue, WA, USA, 9–12 July 2017; Volume 2. [Google Scholar] [CrossRef]

- Ambruş, S.; Muntean, R.; Codrean, C.; Uţu, I.-D. Influence of printing conditions on the mechanical properties of copper-polylactic acid composites obtained by 3D printing fused deposition modelling. Mater. Today Proc. 2023, 72, 580–585. [Google Scholar] [CrossRef]

- Calamak, S.; Ermis, M. In situ silver nanoparticle synthesis on 3D-printed polylactic acid scaffolds for biomedical applications. J. Mater. Res. 2021, 36, 166–175. [Google Scholar] [CrossRef]

- Tzounis, L.; Bangeas, P.I.; Exadaktylos, A.; Petousis, M.; Vidakis, N. Three-Dimensional Printed Polylactic Acid (PLA) Surgical Retractors with Sonochemically Immobilized Silver Nanoparticles: The Next Generation of Low-Cost Antimicrobial Surgery Equipment. Nanomaterials 2020, 10, 985. [Google Scholar] [CrossRef]

- Zárybnická, L.; Pagáč, M.; Ševčík, R.; Pokorný, J.; Marek, M. Effect of Topology Parameters on Physical–Mechanical Properties of Magnetic PLA 3D-Printed Structures. Magnetochemistry 2023, 9, 232. [Google Scholar] [CrossRef]

- Jiang, D.; Ning, F.; Wang, Y. Additive manufacturing of biodegradable iron-based particle reinforced polylactic acid composite scaffolds for tissue engineering. J. Mater. Process Technol. 2021, 289, 116952. [Google Scholar] [CrossRef]

- Ershov, P.; Salnikov, V.; Vorontsov, P.; Omelyanchik, A.; Amirov, A.; Zhansitov, A.; Musov, K.; Khashirova, S.; Senatov, F.; Raikher, Y.; et al. Mechanical and magnetic properties of polylactide-cobalt ferrite nanocomposite for 3D printing. Mater. Lett. 2025, 382, 137913. [Google Scholar] [CrossRef]

- Karimi, N.; Fayazfar, H. Development of highly filled nickel-polymer feedstock from recycled and biodegradable resources for low-cost material extrusion additive manufacturing of metals. J. Manuf. Process. 2023, 107, 506–514. [Google Scholar] [CrossRef]

- Ji, Q.; Wang, Z.; Yi, J.; Tang, X. Mechanical Properties and a Constitutive Model of 3D-Printed Copper Powder-Filled PLA Material. Polymers 2021, 13, 3605. [Google Scholar] [CrossRef]

- Arora, N.; Dua, S.; Singh, V.K.; Singh, S.K.; Senthilkumar, T. A comprehensive review on fillers and mechanical properties of 3D printed polymer composites. Mater. Today Commun. 2024, 40, 109617. [Google Scholar] [CrossRef]

- Ji, Q.; Wei, J.; Yi, J.; Zhang, L.; Ma, J.; Wang, Z. Study on the static and dynamic mechanical properties and constitutive models of 3D printed PLA and PLA-Cu materials. Mater. Today Commun. 2024, 39, 108690. [Google Scholar] [CrossRef]

- Yaman, P.; Ekşi, O.; Karabeyoğlu, S.S.; Feratoğlu, K. Effect of build orientation on tribological and flexural properties of FDM-printed composite PLA parts. J. Reinf. Plast. Compos. 2024, 43, 97–110. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, K.; Soms, N. Mechanical properties and failure analysis of PLA/copper composites fabricated by fused deposition modelling. J. Min. Metall. Sect. B Metall. 2024, 60, 33–44. [Google Scholar] [CrossRef]

- Hamoud, M.; Elshalakany, A.B.; Gamil, M.; Mohamed, H. Investigating the influence of 3D printing parameters on the mechanical characteristics of FDM fabricated (PLA/Cu) composite material. Int. J. Adv. Manuf. Technol. 2024, 134, 3769–3785. [Google Scholar] [CrossRef]

- Kumaresan, R.; Kottasamy, A.; Mogan, J.; Sandanamsamy, L.; Samykano, M.; Kadirgama, K.; Harun, W.S.W. Preliminary investigation on the tensile properties of FDM printed PLA/copper composite. Mater. Today Proc. 2024, 109, 87–92. [Google Scholar] [CrossRef]

- Rouf, S.; Raina, A.; Haq, M.I.U.; Naveed, N.; Jeganmohan, S.; Kichloo, A.F. 3D printed parts and mechanical properties: Influencing parameters, sustainability aspects, global market scenario, challenges and applications. Adv. Ind. Eng. Polym. Res. 2022, 5, 143–158. [Google Scholar] [CrossRef]

- Anbuchezhiyan, G.; Vignesh, M. Implication of machining characteristics of PLA/BRONZE intermixture synthesized by additive manufacturing. Mater. Lett. 2023, 351, 135065. [Google Scholar] [CrossRef]

- Aveen, K.P.; Bhajathari, F.V.; Jambagi, S.C. 3D Printing & Mechanical Characteristion of Polylactic Acid and Bronze Filled Polylactic Acid Components. IOP Conf. Ser. Mater. Sci. Eng. 2018, 376, 012042. [Google Scholar] [CrossRef]

- Doungkeaw, K.; Tungtrongpairoj, J. Printability and Mechanical Properties of PLA/Iron Composites for FDM 3D Printing. Key Eng. Mater. 2024, 978, 47–51. [Google Scholar] [CrossRef]

- Vardhan, H.; Kumar, R.; Chohan, J.S. Investigation of tensile properties of sprayed aluminium based PLA composites fabricated by FDM technology. Mater. Today Proc. 2020, 33, 1599–1604. [Google Scholar] [CrossRef]

- Kesavarma, S.; Lee, E.H.; Samykano, M.; Kadirgama, K.; Rahman, M.M.; Sofiah, A.G.N. Flextural properties of 3D printed Copper-Filler Polylactic Acid (Cu-PLA). IOP Conf. Ser. Mater. Sci. Eng. 2020, 788, 012051. [Google Scholar] [CrossRef]

- Yaghoobi, H.; Fereidoon, A. Modeling and optimization of tensile strength and modulus of polypropylene/kenaf fiber biocomposites using Box–Behnken response surface method. Polym. Compos. 2018, 39, E463–E479. [Google Scholar] [CrossRef]

- Ebrahimi, N.D.; Ju, Y.S. Thermal conductivity of sintered copper samples prepared using 3D printing-compatible polymer composite filaments. Addit. Manuf. 2018, 24, 479–485. [Google Scholar] [CrossRef]

- Sava, M.; Nagy, R.; Menyhardt, K. Characteristics of 3D Printable Bronze PLA-Based Filament Composites for Gaskets. Materials 2021, 14, 4770. [Google Scholar] [CrossRef]

- Selvamani, S.; Ngui, W.; Rajan, K.; Samykano, M.; R, R.K.; Badadhe, A.M. Investigation of bending and compression properties on PLA-brass composite using FDM. Phys. Chem. Earth Parts A/B/C 2022, 128, 103251. [Google Scholar] [CrossRef]

- Nonato, R.C.; Mei, L.H.; Bonse, B.C.; Leal, C.V.; Levy, C.E.; Oliveira, F.A.; Delarmelina, C.; Duarte, M.C.; Morales, A.R. Nanocomposites of PLA/ZnO nanofibers for medical applications: Antimicrobial effect, thermal, and mechanical behavior under cyclic stress. Polym. Eng. Sci. 2022, 62, 1147–1155. [Google Scholar] [CrossRef]

- McKeown, P.; Román-Ramírez, L.A.; Bates, S.; Wood, J.; Jones, M.D. Zinc Complexes for PLA Formation and Chemical Recycling: Towards a Circular Economy. ChemSusChem 2019, 12, 5233–5238. [Google Scholar] [CrossRef]

- Selvamani, S.K.; Rajan, K.; Samykano, M.; Kumar, R.R.; Kadirgama, K.; Mohan, R.V. Investigation of tensile properties of PLA–brass composite using FDM. Prog. Addit. Manuf. 2022, 7, 839–851. [Google Scholar] [CrossRef]

- Dehghan-Toranposhti, S.; Bakhshi, R.; Alizadeh, R.; Bohlouli, M. Fabrication, characterization and evaluating properties of 3D printed PLA-Mn scaffolds. Sci. Rep. 2024, 14, 16592. [Google Scholar] [CrossRef]

- John, J.; Devjani, D.; Ali, S.; Abdallah, S.; Pervaiz, S. Optimization of 3D printed polylactic acid structures with different infill patterns using Taguchi-grey relational analysis. Adv. Ind. Eng. Polym. Res. 2023, 6, 62–78. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Mihankhah, P.; Azdast, T.; Bodaghi, M.; Moradi, M. Process-property relationship in polylactic acid composites reinforced by iron microparticles and 3D printed by fused filament fabrication. Polym. Eng. Sci. 2024, 64, 399–411. [Google Scholar] [CrossRef]

- Olam, M. Determining of process parameters of the PLA/titanium dioxide/hydroxyapatite filament. Adv. Mater. Process. Technol. 2022, 8, 4776–4787. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S. Microstructure and Tensile Performance of Iron-Reinforced Polylactic Acid Composite Manufactured Using Fused Filament Fabrication. Engineering 2024, 1–21. [Google Scholar] [CrossRef]

- Cifuentes, S.; Gavilán, R.; Lieblich, M.; Benavente, R.; González-Carrasco, J. In vitro degradation of biodegradable polylactic acid/magnesium composites: Relevance of Mg particle shape. Acta Biomater. 2016, 32, 348–357. [Google Scholar] [CrossRef] [PubMed]

- Jana, A.; Das, M.; Balla, V.K. In vitro and in vivo degradation assessment and preventive measures of biodegradable Mg alloys for biomedical applications. J. Biomed. Mater. Res. A 2022, 110, 462–487. [Google Scholar] [CrossRef]

- Leigh, S.J.; Bradley, R.J.; Purssell, C.P.; Billson, D.R.; Hutchins, D.A. A Simple, Low-Cost Conductive Composite Material for 3D Printing of Electronic Sensors. PLoS ONE 2012, 7, e49365. [Google Scholar] [CrossRef]

- Kim, T.Y.; Kim, S.I.; Park, J. Fabrication of Thermally Stable Silver–Organic Complex (TS-SOC) Based Conductible Filament Materials for 3D Printing. Adv. Mater. Technol. 2017, 2, 1700079. [Google Scholar] [CrossRef]

- Carkaci, M.E.; Secmen, M. Design and prototype manufacturing of a feed system for Ku-band satellite communication by using 3D FDM/PLA printing and conductive paint technology. Int. J. RF Microw. Comput. Aided Eng. 2020, 30. [Google Scholar] [CrossRef]

- Mohammadizadeh, M.; Lu, H.; Fidan, I.; Tantawi, K.; Gupta, A.; Hasanov, S.; Zhang, Z.; Alifui-Segbaya, F.; Rennie, A. Mechanical and Thermal Analyses of Metal-PLA Components Fabricated by Metal Material Extrusion. Inventions 2020, 5, 44. [Google Scholar] [CrossRef]

- Birčáková, Z.; Kollár, P.; Füzer, J.; Bureš, R.; Fáberová, M.; Jakubčin, M. Energy loss and hysteresis of reversible magnetization processes in iron-based soft magnetic composites. J. Magn. Magn. Mater. 2023, 587, 171291. [Google Scholar] [CrossRef]

- Akbar, I.; Basri, H.; Yanis, M.; Ammarullah, M.I. Optimization of PLA/Mg/PEG biocomposite filaments for 3D-printed bone scaffolds using response surface methodology (RSM). Adv. Manuf. Polym. Compos. Sci. 2025, 11, 2448648. [Google Scholar] [CrossRef]

- Ferrández-Montero, A.; Lieblich, M.; Benavente, R.; González-Carrasco, J.; Ferrari, B. Study of the matrix-filler interface in PLA/Mg composites manufactured by Material Extrusion using a colloidal feedstock. Addit. Manuf. 2020, 33, 101142. [Google Scholar] [CrossRef]

- Naveed, N.; Anwar, M.N. Optimising 3D printing parameters through experimental techniques and ANOVA-Based statistical analysis. SPE Polym. 2024, 5, 228–240. [Google Scholar] [CrossRef]

- Sukindar, N.A.; Yasir, A.S.H.M.; Azhar, M.A.M.; Halim, N.F.H.A.; Sulaiman, M.H.; Sabli, A.S.H.A.; Ariffin, M.K.A.M. Evaluation of the surface roughness and dimensional accuracy of low-cost 3D-printed parts made of PLA–aluminum. Heliyon 2024, 10, e25508. [Google Scholar] [CrossRef]

- Palanisamy, C.; Aaron Tay Hong Kiat, H.K. Experimental study and modeling the tensile strength of 3D-printed aluminium polylactic acid (PLA) parts using artificial neural networks. F1000Research 2021, 10, 1286. [Google Scholar] [CrossRef]

- Ficici, F.; Ozdemir, I.; Grund, T.; Lampke, T. Investigation of Tribological Behavior of PTFE Composites Reinforced with Bronze Particles by Taguchi Method. J. Compos. Sci. 2024, 8, 398. [Google Scholar] [CrossRef]

- Sneha, P.; Balamurugan, K. Investigation on Wear Characteristics of a PLA-14% Bronze Composite Filament; Springer: Berlin/Heidelberg, Germany, 2023; pp. 453–461. [Google Scholar] [CrossRef]

- Buj-Corral, I.; Sanz-Fraile, H.; Ulldemolins, A.; Tejo-Otero, A.; Domínguez-Fernández, A.; Almendros, I.; Otero, J. Characterization of 3D Printed Metal-PLA Composite Scaffolds for Biomedical Applications. Polymers 2022, 14, 2754. [Google Scholar] [CrossRef]

- Hussain, M.; Khan, S.M.; Shafiq, M.; Abbas, N. A review on PLA-based biodegradable materials for biomedical applications. Giant 2024, 18, 100261. [Google Scholar] [CrossRef]

- Shamsudin, S.; Ali, A.; Kamarudin, K.; Al-Alimi, S.; Altharan, Y.M.; Ibrahim, M. Biocompatibility and strength tests of PLA/SS316L composite material for orthopedic implant applications utilizing the 3D printing technique. In Proceedings of the 12th International Conference on Mechanical and Manufacturing Engineering 2022 (ICME’22), Parit Raja, Malaysia, 9–10 August 2022; p. 020030. [Google Scholar] [CrossRef]

- Chong, W.J.; Shen, S.; Li, Y.; Trinchi, A.; Simunec, D.P.; Kyratzis, I.; Sola, A.; Wen, C. Biodegradable PLA-ZnO nanocomposite biomaterials with antibacterial properties, tissue engineering viability, and enhanced biocompatibility. Smart Mater. Manuf. 2023, 1, 100004. [Google Scholar] [CrossRef]

- Asadollahi, M.; Gerashi, E.; Zohrevand, M.; Zarei, M.; Sayedain, S.S.; Alizadeh, R.; Labbaf, S.; Atari, M. Improving mechanical properties and biocompatibility of 3D printed PLA by the addition of PEG and titanium particles, using a novel incorporation method. Bioprinting 2022, 27, e00228. [Google Scholar] [CrossRef]

- Amirov, A.; Omelyanchik, A.; Murzin, D.; Kolesnikova, V.; Vorontsov, S.; Musov, I.; Musov, K.; Khashirova, S.; Rodionova, V. 3D printing of PLA/magnetic ferrite composites: Effect of filler particles on magnetic properties of filament. Processes 2022, 10, 2412. [Google Scholar] [CrossRef]

- Zhao, C.; Wu, H.; Ni, J.; Zhang, S.; Zhang, X. Development of PLA/Mg composite for orthopedic implant: Tunable degradation and enhanced mineralization. Compos. Sci. Technol. 2017, 147, 8–15. [Google Scholar] [CrossRef]

- Olonisakin, K.; Fan, M.; Xin-Xiang, Z.; Ran, L.; Lin, W.; Zhang, W.; Wenbin, Y. Key Improvements in Interfacial Adhesion and Dispersion of Fibers/Fillers in Polymer Matrix Composites; Focus on PLA Matrix Composites. Compos. Interfaces 2022, 29, 1071–1120. [Google Scholar] [CrossRef]

- Abdeljawad, M.B.; Carette, X.; Argentati, C.; Martino, S.; Gonon, M.-F.; Odent, J.; Morena, F.; Mincheva, R.; Raquez, J.-M. Interfacial Compatibilization into PLA/Mg Composites for Improved In Vitro Bioactivity and Stem Cell Adhesion. Molecules 2021, 26, 5944. [Google Scholar] [CrossRef]

- Wang, W.; Wang, L.; Zhang, B.; Shang, S.; Zhao, C.; Zhang, W.; Chen, J.; Zhou, C.; Zhou, H.; Feng, S. 3D printing of personalized magnesium composite bone tissue engineering scaffold for bone and angiogenesis regeneration. Chem. Eng. J. 2024, 484, 149444. [Google Scholar] [CrossRef]

- Lee, H.; Shin, D.Y.; Bang, S.-J.; Han, G.; Na, Y.; Kang, H.S.; Oh, S.; Yoon, C.-B.; Vijayavenkataraman, S.; Song, J.; et al. A strategy for enhancing bioactivity and osseointegration with antibacterial effect by incorporating magnesium in polylactic acid based biodegradable orthopedic implant. Int. J. Biol. Macromol. 2024, 254, 127797. [Google Scholar] [CrossRef]

- Ali, F.; Al Rashid, A.; Kalva, S.N.; Koç, M. Mg-Doped PLA Composite as a Potential Material for Tissue Engineering—Synthesis, Characterization, and Additive Manufacturing. Materials 2023, 16, 6506. [Google Scholar] [CrossRef]

- Wang, A.; Venezuela, J.; Dargusch, M.S. Enhancing the corrodibility of biodegradable iron and zinc using poly (lactic) acid (PLA) coating for temporary medical implant applications. Prog. Org. Coat. 2023, 174, 107301. [Google Scholar] [CrossRef]

- Popescu, V.; Prodan, D.; Cuc, S.; Saroşi, C.; Furtos, G.; Moldovan, A.; Carpa, R.; Bomboş, D. Antimicrobial Poly (Lactic Acid)/Copper Nanocomposites for Food Packaging Materials. Materials 2023, 16, 1415. [Google Scholar] [CrossRef]

- Kottasamy, A.; Samykano, M.; Kadirgama, K.; Rahman, M.; Noor, M.M. Experimental investigation and prediction model for mechanical properties of copper-reinforced polylactic acid composites (Cu-PLA) using FDM-based 3D printing technique. Int. J. Adv. Manuf. Technol. 2022, 119, 5211–5232. [Google Scholar] [CrossRef]

- Ulkir, O. Investigation on the mechanical and thermal properties of metal-PLA composites fabricated by FDM. Rapid Prototyp. J. 2024, 30, 2113–2122. [Google Scholar] [CrossRef]

- Moradi, M.; Moghadam, M.K.; Shamsborhan, M.; Bodaghi, M. The Synergic Effects of FDM 3D Printing Parameters on Mechanical Behaviors of Bronze Poly Lactic Acid Composites. J. Compos. Sci. 2020, 4, 17. [Google Scholar] [CrossRef]

- Gao, C.; Wang, F.; Hu, X.; Zhang, M. Research on the analysis and application of polymer materials in contemporary sculpture art creation. Polymers 2023, 15, 2727. [Google Scholar] [CrossRef]

- Rodríguez-González, P.; Zapico, P.; Peláez-Peláez, S.; Castro-Sastre, M.Á.; Fernández-Abia, A.I. Optimizing the Material Extrusion Process for Investment Casting Mould Production. J. Manuf. Mater. Process. 2024, 8, 265. [Google Scholar] [CrossRef]

- Tsegay, F.; Ghannam, R.; Daniel, N.; Butt, H. 3D Printing Smart Eyeglass Frames: A Review. ACS Appl. Eng. Mater. 2023, 1, 1142–1163. [Google Scholar] [CrossRef]

- Moradi, M.; Dezaki, M.L.; Kheyri, E.; Rasouli, S.A.; Attar, M.A.; Bodaghi, M. Simultaneous FDM 4D printing and magnetizing of iron-filled polylactic acid polymers. J. Magn. Magn. Mater. 2023, 568, 170425. [Google Scholar] [CrossRef]

- Sakthivel, N.; Bramsch, J.; Voung, P.; Swink, I.; Averick, S.; Vora, H.D. Investigation of 3D-printed PLA–stainless-steel polymeric composite through fused deposition modelling-based additive manufacturing process for biomedical applications. Med. Devices Sens. 2020, 3, e10080. [Google Scholar] [CrossRef]

- Rogkotis, K.; Matsia, S.; Likotrafiti, E.; Rhoades, J.; Kountouras, D.; Katakalos, K.; Pavlidou, E.; Ritzoulis, C.; Salifoglou, A. Selective antimicrobial food packaging of composite poly (lactic acid) cobalt-citrate films. Food Packag. Shelf Life 2022, 34, 100959. [Google Scholar] [CrossRef]

- Doan, T.C.; Muthukutty, B.; Yoo, H. High mass-loading of nickel-cobalt layered double hydroxide on 3D-printed electrode for cathode of asymmetric supercapacitor. J. Energy Storage 2023, 68, 107648. [Google Scholar] [CrossRef]

- Kumar, S.; Bodapati, B.R.; Vinay, G.; Kumar, K.V.; Chavan, N.M.; Babu, P.S.; Jyothirmayi, A. Estimation of inter-splat bonding and its effect on functional properties of cold sprayed coatings. Surf. Coat. Technol. 2021, 420, 127318. [Google Scholar] [CrossRef]

- Mackiewicz, E.; Wejrzanowski, T.; Adamczyk-Cieślak, B.; Oliver, G.J. Polymer–Nickel Composite Filaments for 3D Printing of Open Porous Materials. Materials 2022, 15, 1360. [Google Scholar] [CrossRef]

- Hüner, B.; Demir, N.; Kaya, M.F. Fabrication and characterization of Nickel-coated 3D printed electrodes for enhanced oxygen evolution reaction in acidic media at various temperatures. Fuel 2024, 366, 131172. [Google Scholar] [CrossRef]

- Liu, S.; Wu, H.; Chao, B.; Fu, W.; Deng, K.; Li, Y. Study on FDM preparation and properties of RGO/Ni/PLA/TPU composite materials. J. Alloys Compd. 2023, 968, 172119. [Google Scholar] [CrossRef]

- Vaezi, M.; Drescher, P.; Seitz, H. Beamless Metal Additive Manufacturing. Materials 2020, 13, 922. [Google Scholar] [CrossRef]

- Marega, F.M.; Klok, L.A.; Steffen, T.T.; Cunha, D.A.L.V.; Harb, S.V.; Kolanthai, E.; Seal, S.; Becker, D.; Pessan, L.A.; Costa, L.C. Development of surface-treated poly(lactic acid)/zinc oxide biocomposites for 3D printing in bone tissue engineering. J. Appl. Polym. Sci. 2024, 141, e55982. [Google Scholar] [CrossRef]

- Dias, W.S.; Demosthenes, L.C.d.C.; da Costa, J.C.M.; Pocrifka, L.A.; Nascimento, N.R.D.; Pinheiro, S.C.; del Pino, G.G.; Rivera, J.L.V.; Fernández, M.V.; Neto, J.C.d.M. 3D Printing of Virucidal Polymer Nanocomposites (PLA/Copper Nanoparticles). Polymers 2025, 17, 283. [Google Scholar] [CrossRef]

- Bashir, M.N.; Logesh, K.; Kannan, S.; Vijayan, D.; Kumar, S.S.; Al Obaid, S.; Lee, J.S. Studies on parametric optimization of PLA/graphene composites synthesized by fused filament fabrication for thermal applications. Therm. Sci. Eng. Prog. 2024, 54, 102788. [Google Scholar] [CrossRef]

- Mayén, J.; Gallegos-Melgar, A.D.C.; Pereyra, I.; Poblano-Salas, C.A.; Hernández-Hernández, M.; Betancourt-Cantera, J.A.; Mercado-Lemus, V.H.; Monroy, M.D.A. Descriptive and inferential study of hardness, fatigue life, and crack propagation on PLA 3D-printed parts. Mater. Today Commun. 2022, 32, 103948. [Google Scholar] [CrossRef]

- Darsin, M.; Susanti, R.P.; Sumarji, S.; Ramadhan, M.E.; Sidartawan, R.; Yudistiro, D.; Basuki, H.A.; Wibowo, R.K.K.; Djumhariyanto, D. Heat Treatment and Its Effect on Tensile Strength of Fused Deposition Modeling 3D-Printed Titanium-Polylactic Acid (PLA). ComTech Comput. Math. Eng. Appl. 2024, 15, 73–82. [Google Scholar] [CrossRef]

- Rivera, A.D.P.F.; Magalhães, F.d.C.; Rubio, J.C.C. Experimental characterization of PLA composites printed by fused deposition modelling. J. Compos. Mater. 2023, 57, 941–954. [Google Scholar] [CrossRef]

- Fidan, I.; Naikwadi, V.; Alkunte, S.; Mishra, R.; Tantawi, K. Energy Efficiency in Additive Manufacturing: Condensed Review. Technologies 2024, 12, 21. [Google Scholar] [CrossRef]

- Tabary, S.A.A.B.; Karimi, N.; Fayazfar, H. Recycled Carbonyl Iron-Biodegradable PLA Auxetic Composites: Investigating Mechanical Properties of 3D-Printed Parts Under Quasi-Static Loading. Appl. Sci. 2024, 14, 10973. [Google Scholar] [CrossRef]

- Ghomi, E.R.; Khosravi, F.; Ardahaei, A.S.; Dai, Y.; Neisiany, R.E.; Foroughi, F.; Wu, M.; Das, O.; Ramakrishna, S. The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material. Polymers 2021, 13, 1854. [Google Scholar] [CrossRef]

- Haylock, R.; Rosentrater, K.A. Cradle-to-Grave Life Cycle Assessment and Techno-Economic Analysis of Polylactic Acid Composites with Traditional and Bio-Based Fillers. J. Polym. Environ. 2018, 26, 1484–1503. [Google Scholar] [CrossRef]

- López-Camacho, A.; Magaña-García, D.; Grande, M.J.; Carazo-Álvarez, D.; La Rubia, M.D. Preliminary Study of the Bactericide Properties of Biodegradable Polymers (PLA) with Metal Additives for 3D Printing Applications. Bioengineering 2023, 10, 297. [Google Scholar] [CrossRef]

- Minetola, P.; Galati, M. A challenge for enhancing the dimensional accuracy of a low-cost 3D printer by means of self-replicated parts. Addit. Manuf. 2018, 22, 256–264. [Google Scholar] [CrossRef]

- García, E.; Núñez, P.; Chacón, J.; Caminero, M.; Kamarthi, S. Comparative study of geometric properties of unreinforced PLA and PLA-Graphene composite materials applied to additive manufacturing using FFF technology. Polym. Test. 2020, 91, 106860. [Google Scholar] [CrossRef]

- Li, X.; Qi, C.; Han, L.; Chu, C.; Bai, J.; Guo, C.; Xue, F.; Shen, B.; Chu, P.K. Influence of dynamic compressive loading on the in vitro degradation behavior of pure PLA and Mg/PLA composite. Acta Biomater. 2017, 64, 269–278. [Google Scholar] [CrossRef]

- Zamora-Mendoza, L.; Guamba, E.; Miño, K.; Romero, M.P.; Levoyer, A.; Alvarez-Barreto, J.F.; Machado, A.; Alexis, F. Antimicrobial Properties of Plant Fibers. Molecules 2022, 27, 7999. [Google Scholar] [CrossRef]

- Kudzin, M.H.; Giełdowska, M.; Mrozińska, Z.; Boguń, M. Poly(lactic acid)/Zinc/Alginate Complex Material: Preparation and Antimicrobial Properties. Antibiotics 2021, 10, 1327. [Google Scholar] [CrossRef]

- Liu, M.; Bauman, L.; Nogueira, C.L.; Aucoin, M.G.; Anderson, W.A.; Zhao, B. Antimicrobial polymeric composites for high-touch surfaces in healthcare applications. Curr. Opin. Biomed. Eng. 2022, 22, 100395. [Google Scholar] [CrossRef]

- Alipilakkotte, S.; Sreejith, L. Green synthesized PLA/silver nanoparticle probe for sensing of hydrogen peroxide in biological samples. Mater. Lett. 2018, 217, 33–38. [Google Scholar] [CrossRef]

| S.No. | Biocomposite | AM Technique | Process Parameters | Reference |

|---|---|---|---|---|

| 1 | PLA with 5–20% Mg biocomposites | FDM | Nozzle diameter—0.4 mm, Layer thickness—0.2 mm | [46] |

| 2 | PLA coated AM60 alloy biocomposites | FDM | Nozzle temperature—245 °C and bed temperature—60 °C, Infill speed—60 mm/s, Nozzle diameter—0.4 mm, Layer thickness—50 µm | [83] |

| 3 | PLA with 15% and 80% of brass biocomposites | FDM | Layer height—0.25—0.35 mm, Printing speed—20–40 mm/s, Infill percentage—50% | [84] |

| 4 | PLA Copper biocomposites | FDM | Nozzle temperature—200–230 °C, Bed temperature—70–110 °C, Printing speed—40 mm/s | [85] |

| 5 | PLA with Copper biocomposites | FDM | Nozzle diameter—0.4 mm, Layer height—0.2 mm, Nozzle temperature—215 °C, Bed temperature—60 °C | [86] |

| 6 | PLA with Silver biocomposites | FDM | Nozzle diameter—0.4 mm, Nozzle temperature—220 °C, Printing speed—90 mm/s | [87] |

| 7 | PLAwith AgNPs biocomposites | FDM | Nozzle diameter—0.4 mm, Layer height—0.2 mm, Printing speed—90 mm/s, Infill percentage—75%, Nozzle temperature—220 °C, | [88] |

| 8 | PLA with Iron microparticles biocomposites | FDM | Gyroid infill pattern, Nozzle temperature—215 °C, Bed temperature—60 °C, Printing speed—70 mm/s, | [89] |

| 9 | PLA with 10% of 316 L stainless-steel biocomposites | FDM | Filament diameter—2.85 mm, Screw speed—30 rpm, Nozzle temperature—185 °C | [90] |

| 10 | PLA with Cobalt ferrite nanoparticle biocomposites | FDM | Nozzle temperature—260 °C, Bed temperature—60 °C, Printing speed—20 mm/s | [91] |

| 11 | PLA with Nickel biocomposites | FDM | Layer thickness—0.15 mm, Print speed—10 mm/s, Infill—100% | [92] |

| Sl.No | Metal Infill | Applications | Ref. |

|---|---|---|---|

| 1. | Mg | Bone Tissue Engineering Scaffolds | [141] |

| 2. | Mg | 3D-Printable PLA/Mg Composite Filaments | [46] |

| 3. | Zn | Antibacterial Orthopedic Implants | [142] |

| 4. | Zn | Direct Ink Writing (DIW) for Scaffold Fabrication | [143] |

| 5. | Zn | Surgical Tools, Orthopedic Implants, Dental Applications | [144] |

| 6. | Cu | Food Packaging Materials | [145] |

| 7. | Cu | LED Housings | [146] |

| 8. | Bronze | Electromagnetic and Magnetic Applications, | [147] |

| 9. | Bronze | Fit and Form Testing | [148] |

| 10. | Bronze | Art, Sculpture, and Jewelry | [149] |

| 11. | Brass | Used in Investment Casting Workflows | [150] |

| 12. | Ti | Custom Gadgets, Phone Cases, Eyewear Frames | [151] |

| 13. | Fe | Sensing, and Magnetic Devices. | [152] |

| 14. | Fe | Biomedical Engineering | [153] |

| 15. | Ag | Low-Cost Antimicrobial Surgery Equipment | [154] |

| 16. | Co | Supercapacitors | [155] |

| 17. | Co | Surface Modification and Functional Coatings | [156] |

| 18. | Ni | Porous Structures | [157] |

| 19. | Ni | Catalysis | [158] |

| 20. | Ni | Electromagnetic Wave Absorption | [159] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sivalingam, S.; Bhuvaneswari, V.; Rajeshkumar, L.; Balaji, D. Additive Manufacturing of Metal-Infilled Polylactic Acid-Based Sustainable Biocomposites—A Review of Methods, Properties and Applications Abetted with Patent Landscape Analysis. Polymers 2025, 17, 1565. https://doi.org/10.3390/polym17111565

Sivalingam S, Bhuvaneswari V, Rajeshkumar L, Balaji D. Additive Manufacturing of Metal-Infilled Polylactic Acid-Based Sustainable Biocomposites—A Review of Methods, Properties and Applications Abetted with Patent Landscape Analysis. Polymers. 2025; 17(11):1565. https://doi.org/10.3390/polym17111565

Chicago/Turabian StyleSivalingam, Sengottaiyan, Venkateswaran Bhuvaneswari, Lakshminarasimhan Rajeshkumar, and Devarajan Balaji. 2025. "Additive Manufacturing of Metal-Infilled Polylactic Acid-Based Sustainable Biocomposites—A Review of Methods, Properties and Applications Abetted with Patent Landscape Analysis" Polymers 17, no. 11: 1565. https://doi.org/10.3390/polym17111565

APA StyleSivalingam, S., Bhuvaneswari, V., Rajeshkumar, L., & Balaji, D. (2025). Additive Manufacturing of Metal-Infilled Polylactic Acid-Based Sustainable Biocomposites—A Review of Methods, Properties and Applications Abetted with Patent Landscape Analysis. Polymers, 17(11), 1565. https://doi.org/10.3390/polym17111565