Enhancing Technical Performance of PVC Production: A WEP-Based Energy and Water Assessment

Abstract

1. Introduction

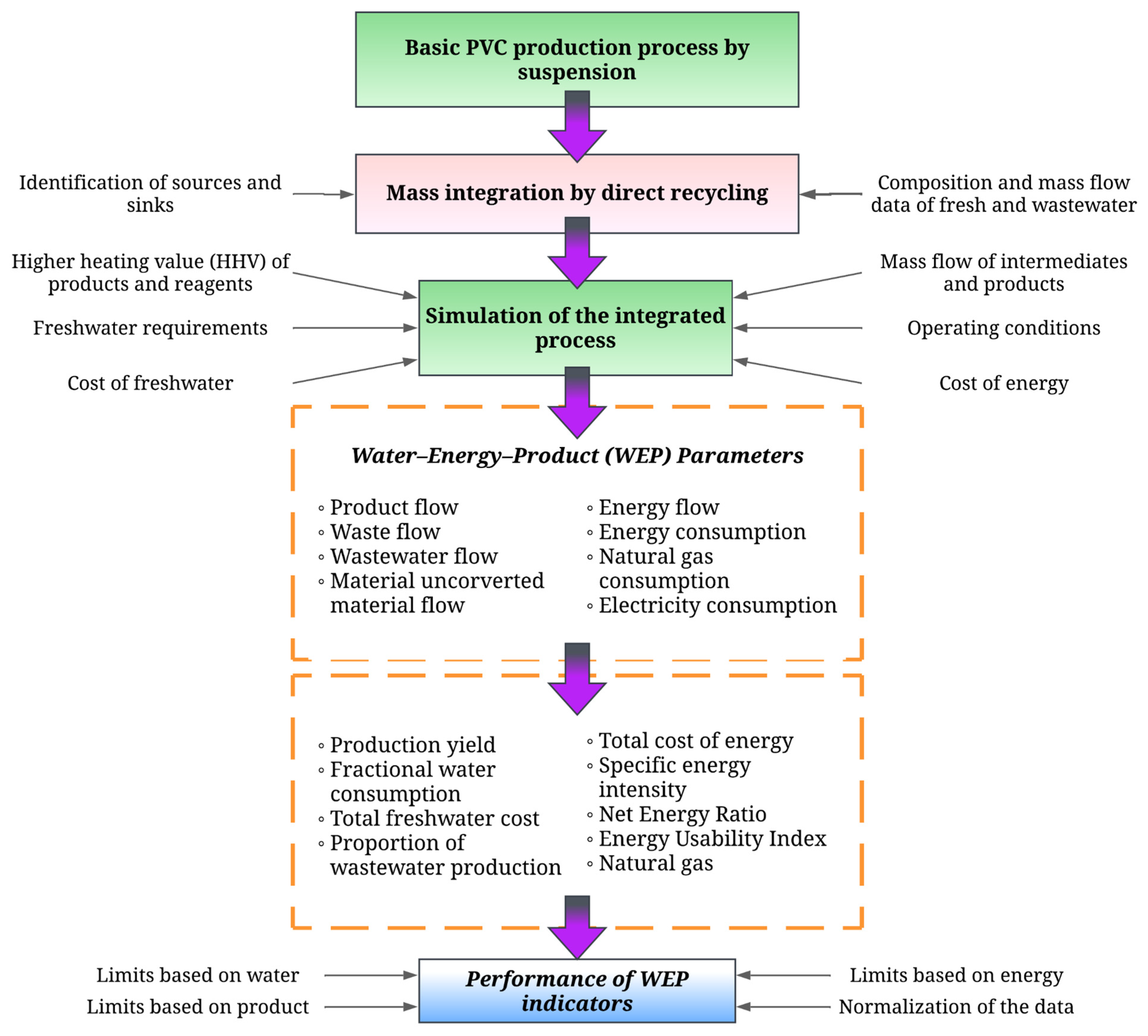

2. Materials and Methods

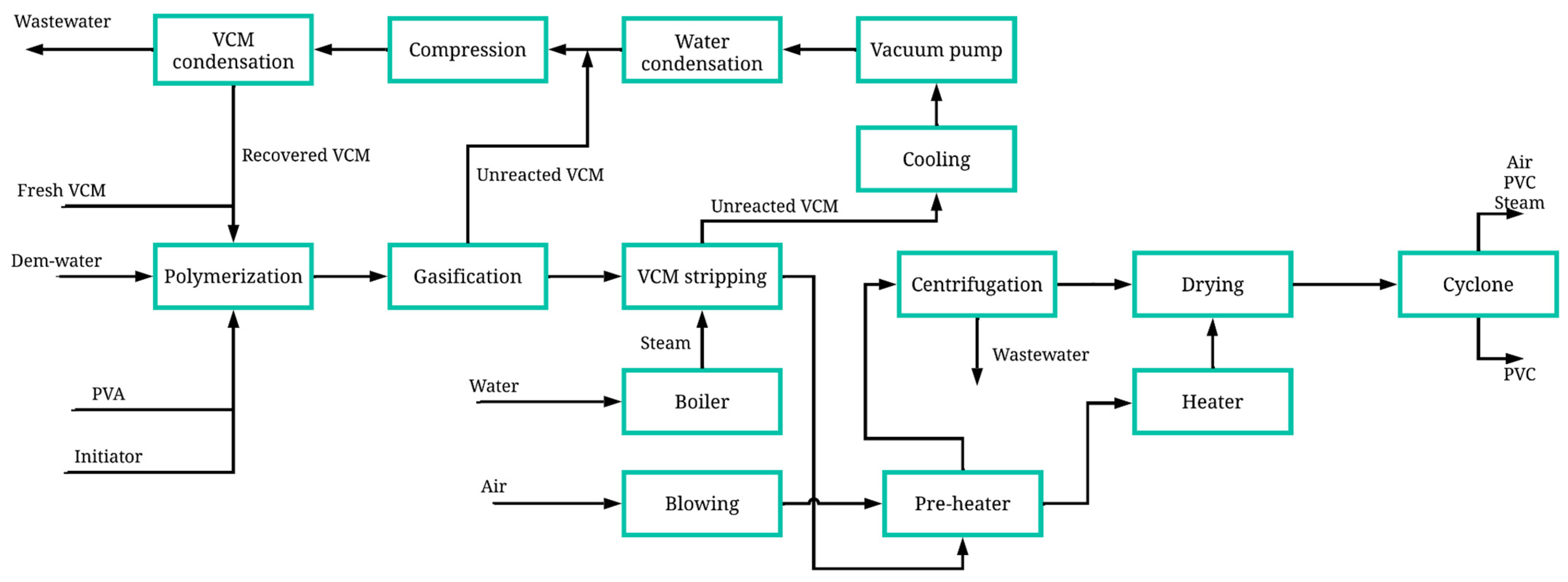

2.1. Process Description

2.2. Water Integration Through Direct Recycling

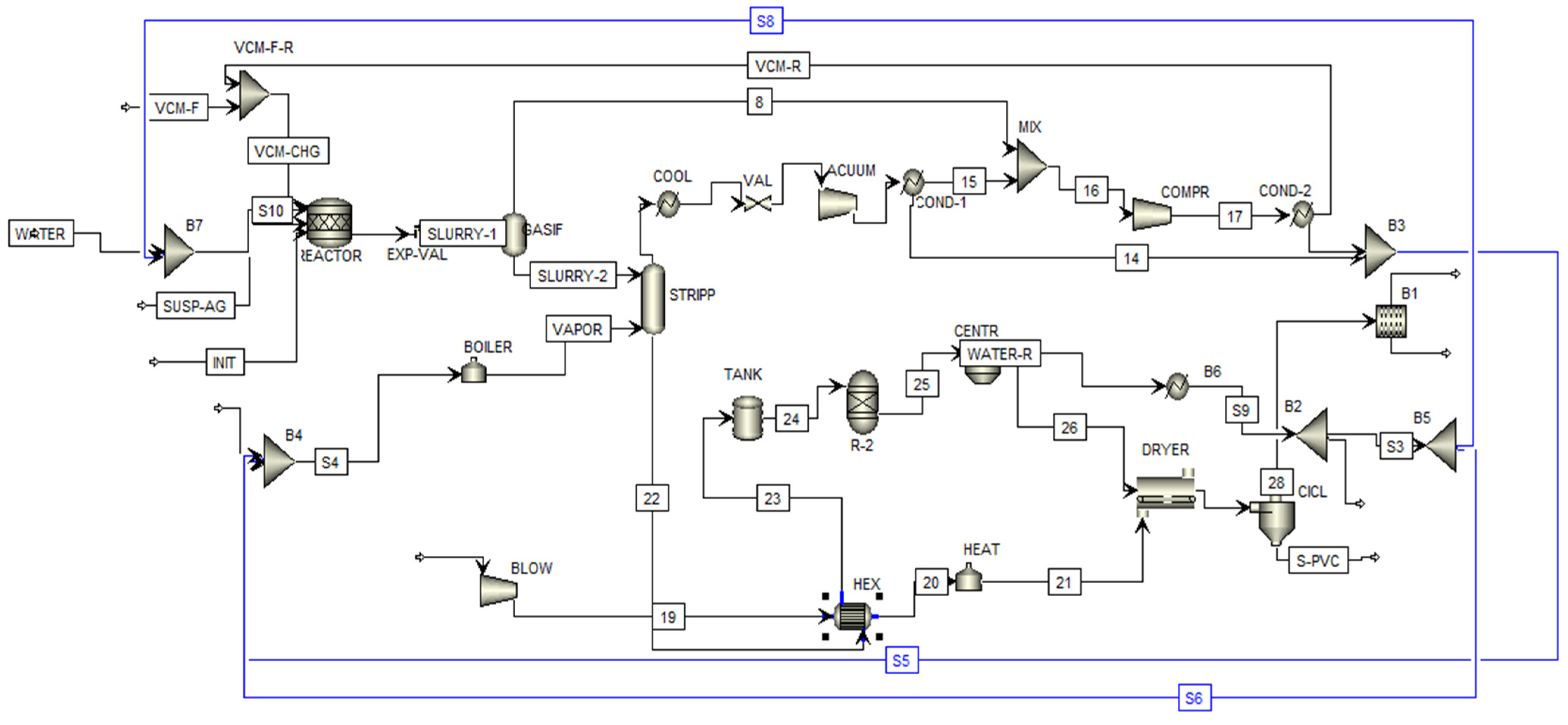

2.3. Process Simulation of the Energy- and Water-Integrated Case

2.4. WEP Technical Evaluation of the Energy- and Water-Integrated Process

3. Results

3.1. Water Integration of the PVC Production Process with Direct Recycling

3.2. Simulation of the Water-Integrated Suspension PVC Production Process with Direct Recycling

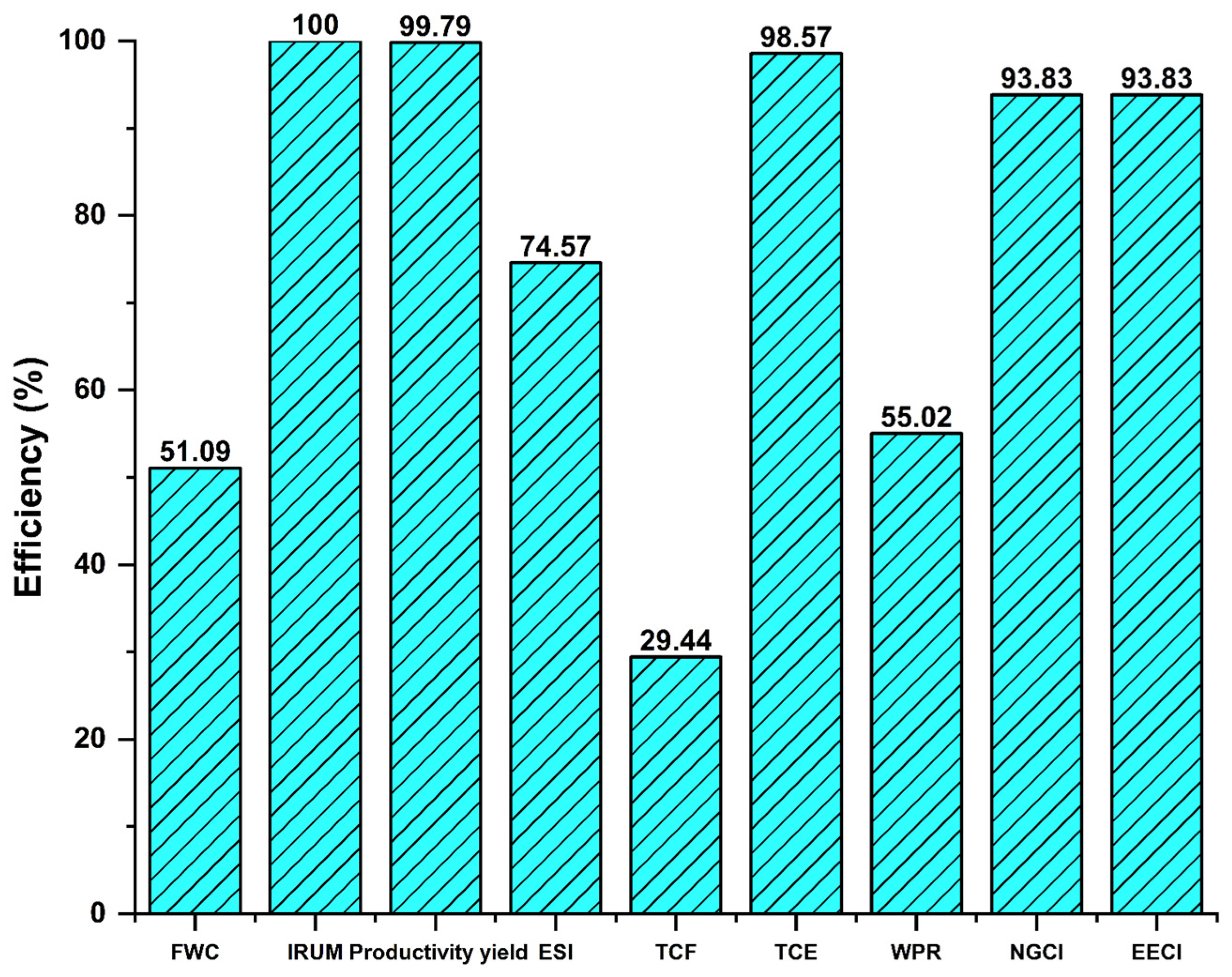

3.3. Technical Evaluation of the Water-Integrated Suspension PVC Production with Direct Recycling Using WEP Indicators

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| VCM | vinyl monochloride |

| PVC | polyvinyl chloride |

| WEP | water–energy–product |

| FWC | fractional water consumption |

| TCF | total freshwater cost |

| WPR | wastewater production ratio |

| IRUM | unreacted material reuse index |

| TCE | total energy cost |

| ESI | energy-specific intensity |

| NGCI | natural gas consumption index |

| EECI | electricity energy consumption index |

| NER | net energy ratio |

| EUI | energy usability index |

References

- Klemeš, J.J.; Fan, Y.V.; Jiang, P. Plastics: Friends or Foes? The Circularity and Plastic Waste Footprint. Energy Sources Part Recovery Util. Environ. Eff. 2021, 43, 1549–1565. [Google Scholar] [CrossRef]

- Hahladakis, J.; Iacovidou, E.; Gerasimidou, S. Plastic Waste in a Circular Economy. In Plastic Waste and Recycling; Letcher, T.M., Ed.; Academic Press/Elsevier: Cambridge, MA, USA, 2020; pp. 481–512. ISBN 978-0-12-817880-5. [Google Scholar]

- Brooks, B. Suspension polymerization processes. Chem. Eng. Technol. 2010, 33, 1737–1744. [Google Scholar] [CrossRef]

- Saeki, Y.; Emura, T. Technical progresses for PVC production. Prog. Polym. Sci. 2002, 27, 2055–2131. [Google Scholar] [CrossRef]

- González-Delgado, Á.D.; Moreno-sader, K.A.; Martínez-Consuegra, J.D. Biorrefinación Sostenible del Camarón: Desarrollos Desde la Ingeniería de Procesos Asistida por Computador; Corporación Universitaria Minuto de Dios-UNIMINUTO: Bogotá, Colombia, 2022; ISBN 978-958-763-559-1. [Google Scholar]

- Chaudhary, V.; Sharma, S. Suspension polymerization technique: Parameters affecting polymer properties and application in oxidation reactions. J. Polym. Res. 2019, 26, 102. [Google Scholar] [CrossRef]

- Bárkányi, Á.; Németh, S.; Lakatos, B.G. Modelling and simulation of a batch poly(vinyl chloride) reactor. Chem. Eng. Trans. 2013, 32, 769–774. [Google Scholar] [CrossRef]

- dos Santos Silva, J.; Albuquerque Melo, P.; Pinto, J.C. Modeling of Particle Size Distributions in Industrial Poly(vinyl chloride) Suspension Polymerization Reactors. Processes 2023, 11, 1440. [Google Scholar] [CrossRef]

- Kiparissides, C.; Pladis, P. On the prediction of suspension viscosity, grain morphology, and agitation power in SPVC reactors. Can. J. Chem. Eng. 2021, 100, 714–730. [Google Scholar] [CrossRef]

- Kiparissides, C. Modeling of Suspension Vinyl Chloride Polymerization: From Kinetics to Particle Size Distribution and PVC Grain Morphology. Adv. Polym. Sci. 2017, 1, 121–193. [Google Scholar] [CrossRef]

- Gao, S.Z.; Wang, J.S.; Gao, X.W. Modeling and advanced control method of PVC polymerization process. J. Polym. Con. 2013, 23, 664–681. [Google Scholar] [CrossRef]

- Wieme, J.; De Roo, T.; Marin, G.B.; Heynderickx, G.J. Simulation of Pilot- and Industrial-Scale Vinyl Chloride Batch Suspension Polymerization Reactors. Ind. Eng. Chem. Res. 2007, 46, 1179–1196. [Google Scholar] [CrossRef]

- Krallis, A.; Kotoulas, C.; Papadopoulos, S.; Kiparissides, C.; Bousquet, J.; Bonardi, C. A Comprehensive Kinetic Model for the Free-Radical Polymerization of Vinyl Chloride in the Presence of Monofunctional and Bifunctional Initiators. Ind. Eng. Chem. Res. 2004, 43, 6382–6399. [Google Scholar] [CrossRef]

- Aguilar-Vásquez, E.; Ramos-Olmos, M.; González-Delgado, Á.D. A Joint Computer-Aided Simulation and Water-Energy-Product (WEP) Approach for Technical Evaluation of PVC Production. Sustainability 2023, 15, 8096. [Google Scholar] [CrossRef]

- Leadbitter, J. PVC and sustainability. Prog. Polym. Sci. 2002, 27, 2197–2226. [Google Scholar] [CrossRef]

- González-Delgado, Á.D.; Cogollo-Cárcamo, G.; Bertel-Pérez, F. Mass-Integration and Environmental Evaluation of Chitosan Microbeads Production Modified with of Thiourea and Magnetite Nanoparticles. Processes 2023, 11, 2208. [Google Scholar] [CrossRef]

- Klemes, J.J. Industrial Water Recycle/Reuse. Curr. Opin. Chem. Eng. 2012, 1, 238–245. [Google Scholar] [CrossRef]

- Mughees, W.; Al-Ahmad, M. Application of Water Pinch Technology in Minimization of Water Consumption at a Refinery. Comput. Chem. Eng. 2015, 73, 34–42. [Google Scholar] [CrossRef]

- Ponce-Ortega, J.M.; Nápoles-Rivera, F.; El-Halwagi, M.M.; Jiménez-Gutiérrez, A. An Optimization Approach for the Synthesis of Recycle and Reuse Water Integration Networks. Clean Technol. Environ. Policy 2012, 14, 133–151. [Google Scholar] [CrossRef]

- Chan, R.K.S.; Langsam, M.; Hamielec, A.E. Calculation and Applications of VCM Distribution in Vapor/Water/Solid Phases during VCM Polymerization. J. Macromol. Sci. Chem. 1982, 17, 969–981. [Google Scholar] [CrossRef]

- Zheng, P.; Feng, X.; Qian, F.; Cao, D. Water System Integration of a Chemical Plant. Energy Convers. Manag. 2016, 47, 2470–2478. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Foo, D.C.Y. Simultaneous Targeting and Scheduling for Batch Water Networks. Ind. Eng. Chem. Res. 2017, 56, 1559–1569. [Google Scholar] [CrossRef]

- García-Maza, S.; Herrera-Rodríguez, T.C.; González-Delgado, Á.D. Process Simulation and Technical Evaluation Using Water-Energy-Product (WEP) Analysis of an Extractive-Based Biorefinery of Creole-Antillean Avocado Produced in the Montes De María. Sustainability 2024, 16, 9575. [Google Scholar] [CrossRef]

- Moreno-Sader, K.A.; Martínez-Consuegra, J.; González-Delgado, Á.D. An Integrated Biorefinery Approach Via Material Recycle/Reuse Networks for the Extraction of Value-Added Components from Shrimp: Computer-aided simulation and environmental assessment. Food Bioprod. Process 2021, 127, 443–453. [Google Scholar] [CrossRef]

- Mendivil-Arrieta, A.; Aguilar-Vasquez, E.A.; Diaz-Perez, J.M.; Ramos-Olmos, M.; Gonzaléz-Delgado, Á.D. Energy Integration and WEP Technical Evaluation of a Large-Scale PVC Production Process. Sci 2025, 7, 41. [Google Scholar] [CrossRef]

- El-Halwagi, M. Process Systems Engineering. In Process Integration; Academic Press: San Diego, CA, USA, 2006; Volume 7, p. 4. ISBN 978-0123705327. [Google Scholar]

- Chen, C.L.; Lee, J.Y. A Graphical Technique for the Design of Water-Using Networks in Batch Processes. Chem. Eng. Sci. 2008, 63, 3740–3754. [Google Scholar] [CrossRef]

- Blanco, L.; Hermosilla, D.; Negro, C.; Swinnen, N.; Prieto, D.; Blanco, Á. Assessing Demineralization Treatments for PVC Effluent Reuse in the Resin Polymerization Step. Environ. Sci. Pollut. Res. 2017, 24, 16631–16638. [Google Scholar] [CrossRef]

- Rolsky, C.; Kelkar, V. Degradation of Polyvinyl Alcohol in Us Wastewater Treatment Plants and Subsequent Nationwide Emission Estimate. Int. J. Environ. Res. Public Health 2021, 18, 6027. [Google Scholar] [CrossRef]

- European Commission. Reference Document on Best Available Techniques in the Production of Polymers. Available online: https://eippcb.jrc.ec.europa.eu/reference/production-polymers (accessed on 14 December 2024).

- Prieto, D.; Swinnen, N.; Blanco, L.; Hermosilla, D.; Cauwenberg, P.; Blanco, Á.; Negro, C. Drivers and Economic Aspects for the Implementation of Advanced Wastewater Treatment and Water Reuse in a PVC Plant. Water Resour. Ind. 2016, 14, 26–30. [Google Scholar] [CrossRef]

- American Chemistry Council. Cradle-to-Gate Life Cycle Analysis of Polyvinyl Chloride (PVC) Resin. Available online: https://www.americanchemistry.com/better-policy-regulation/plastics/resources/cradle-to-gate-life-cycle-analysis-of-polyvinyl-pvc-resin (accessed on 14 December 2024).

- Chul-Hyun, P.; Ho-Seok, J.; Jai-Koo, P. PVC Removal from Mixed Plastics by Triboelectrostatic Separation. J. Hazard. Mater. 2007, 144, 470–476. [Google Scholar] [CrossRef]

- Ministerio de Ambiente; Vivienda y Desarrollo Territorial; ACOPLASTICOS. Available online: https://justiciaambientalcolombia.org/wp-content/uploads/2012/09/guias-ambientales-sector-plc3a1sticos.pdf (accessed on 14 December 2024).

| Variable | Units | Equation |

|---|---|---|

| Production yield | % | |

| Fractional water consumption (FWC) | m3/t | |

| Total cost of freshwater (TCF) | USD/day | |

| Wastewater production ratio (WPR) | % | |

| Index of reused unconverted material (IRUM) | % | |

| Total cost of energy (TCE) | USD/day | |

| Energy-specific intensity (ESI) | MJ/t | |

| Net energy ratio (NER) | Dimensionless | |

| Energy usability index (EUI) | Dimensionless | |

| Natural gas consumption index (NGCI) | m3/t | |

| Electric energy consumption index (EECI) | kWh/t |

| Variable | Worst Case | Best Case |

|---|---|---|

| Production yield | 0% | 100% |

| Fractional water consumption (FWC) | 4 | 0.5 |

| Total freshwater cost (TCF) | 2514 USD/day | 193 USD/day |

| Wastewater production ratio (WPR) | 100% | 0% |

| Index of reused unconverted material (IRUM) | 0% | 100% |

| Total cost of energy (TCE) | 0.41 USD/kWh (100% of the energy used comes from electricity) | 10 USD/MMBTU (100% of the energy used comes from natural gas) |

| Energy-specific intensity (ESI) | 5000 MJ/t | 3500 MJ/t |

| Natural gas consumption index (NGCI) | 0% | 100% of the energy entering the process |

| Electric energy consumption index (EECI) | 100% | 0% of the energy required |

| Source | Mass Flow [t/Day] | PVA [mg × L−1] | Mass Fraction | Load [t/Day] |

|---|---|---|---|---|

| Sr1 | 17.87 | 17,923.77 | 0 | 0 |

| Sr2 | 387.659 | 388,825.47 | 0 | 0 |

| Sr3 | 1145.92 | 1,145,506.49 | 1131.37 | 1296 |

| Source | Mass Flow [t/Day] | PVA [mg × L−1] | Mass Fraction | Load [t/Day] |

| Sk1 | 1440 | 1 | 1.00301 × 10−6 | 0.0014 |

| Sk2 | 480 | 10 | 1.00301 × 10−5 | 0.0048 |

| Parameter | Units | Description | Value |

|---|---|---|---|

| Mass flow of raw material (VCM) | t/day | total flow of VCM entering the process | 1152 |

| Total mass feed flow | t/day | total flow of substances entering the process, including water, reactants, etc. | 9003 |

| Mass flow of recycled raw material | t/day | total flow of VCM being recycled to the process | 288 |

| Mass flow of product | t/day | total flow of PVC leaving the process | 1150 |

| Total volumetric flow of water | /day | volume of freshwater used in the process | 1623 |

| Total volumetric flow of wastewater | /day | volume of wastewater used in the process | 1144 |

| Total energy consumed | GJ/day | total energy used during the process (includes cooling and heating) | 3861.8 |

| Indicators | Units | Value |

|---|---|---|

| Production yield | % | 99.8 |

| Fractional water consumption (FWC) | 2.2 | |

| Total freshwater cost (TCF) | 584,285 | |

| Wastewater production ratio (WPR) | % | 45 |

| Index of reused unconverted material (IRUM) | % | 100 |

| Total cost of energy (TCE) | 12,707,134 | |

| Energy-specific intensity (ESI) | MJ/t | 3359 |

| Natural gas consumption index (NGCI) | 52.5 | |

| Electric energy consumption index (EECI) | kWh/t | 1.6 |

| Net energy ratio (NER) | - | 0.9 |

| Energy usability index (EUI) | - | 5.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guardo-Ruiz, R.M.; Puello-Castellón, L.M.; Ortega-Toro, R.; Aguilar-Vásquez, E.A.; González-Delgado, Á.D. Enhancing Technical Performance of PVC Production: A WEP-Based Energy and Water Assessment. Polymers 2025, 17, 1561. https://doi.org/10.3390/polym17111561

Guardo-Ruiz RM, Puello-Castellón LM, Ortega-Toro R, Aguilar-Vásquez EA, González-Delgado ÁD. Enhancing Technical Performance of PVC Production: A WEP-Based Energy and Water Assessment. Polymers. 2025; 17(11):1561. https://doi.org/10.3390/polym17111561

Chicago/Turabian StyleGuardo-Ruiz, Rolando Manuel, Linda Mychell Puello-Castellón, Rodrigo Ortega-Toro, Eduardo Andrés Aguilar-Vásquez, and Ángel Darío González-Delgado. 2025. "Enhancing Technical Performance of PVC Production: A WEP-Based Energy and Water Assessment" Polymers 17, no. 11: 1561. https://doi.org/10.3390/polym17111561

APA StyleGuardo-Ruiz, R. M., Puello-Castellón, L. M., Ortega-Toro, R., Aguilar-Vásquez, E. A., & González-Delgado, Á. D. (2025). Enhancing Technical Performance of PVC Production: A WEP-Based Energy and Water Assessment. Polymers, 17(11), 1561. https://doi.org/10.3390/polym17111561