Design and Manufacturing of Experimental Solid Propellant Rocket Motor Cases Made of Carbon Composite Materials

Abstract

:1. Introduction

2. Materials and Methodology

2.1. Materials

2.2. Methods

3. Results

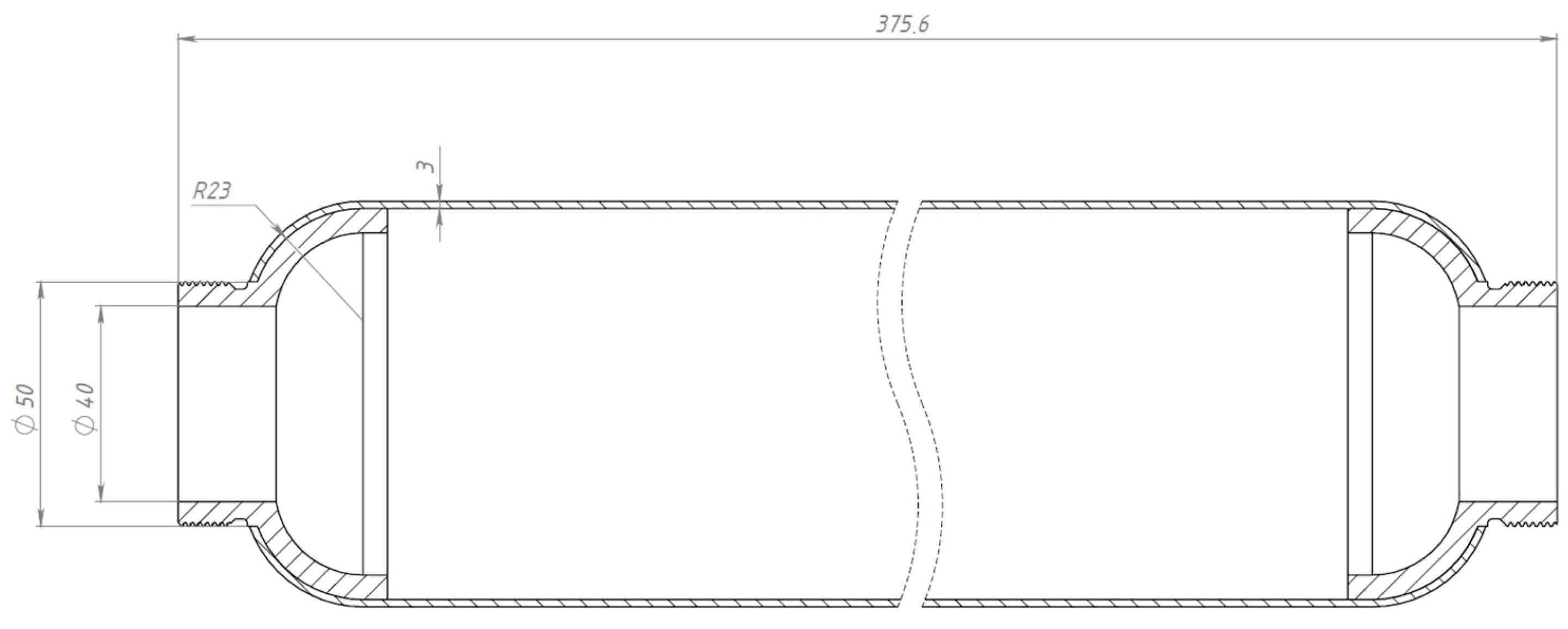

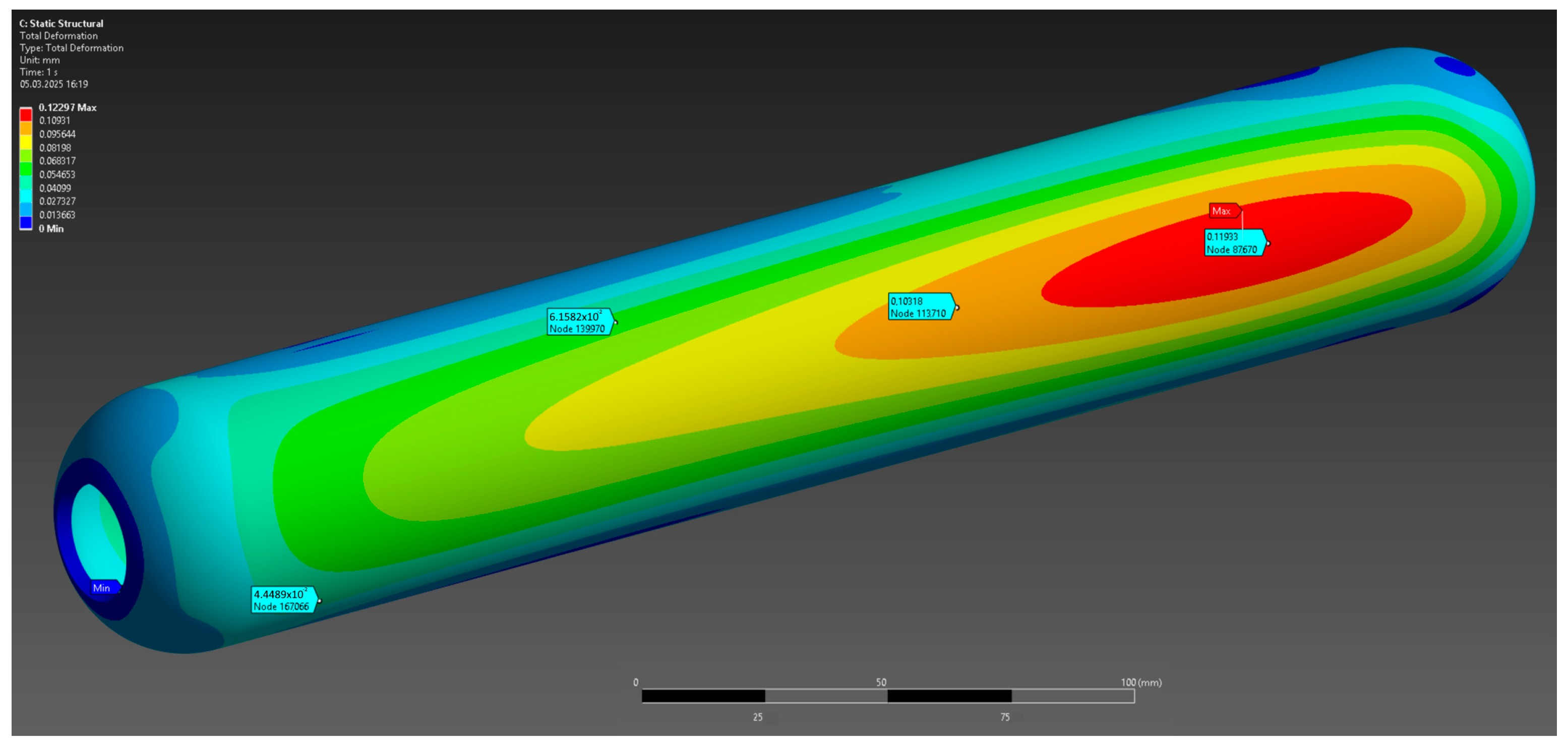

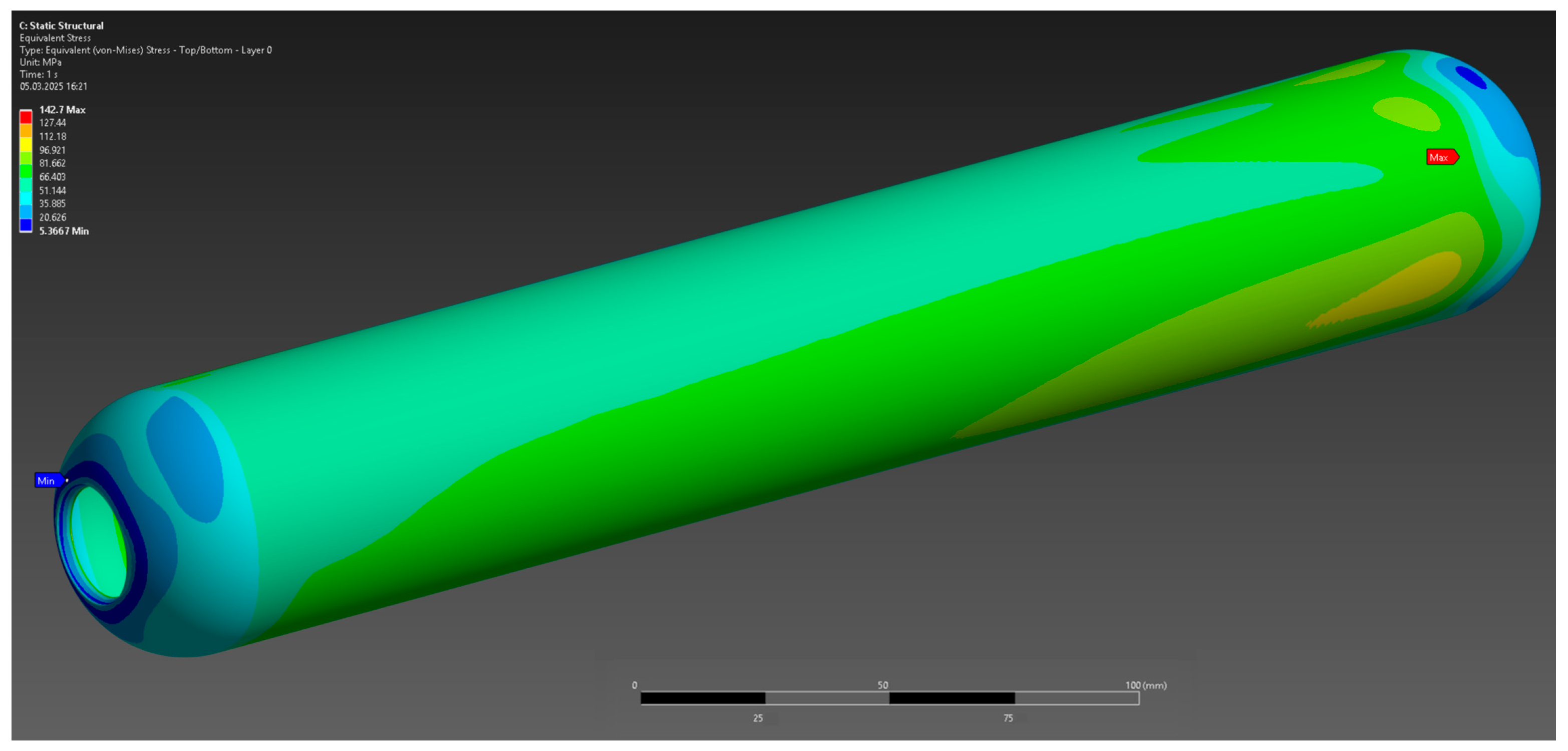

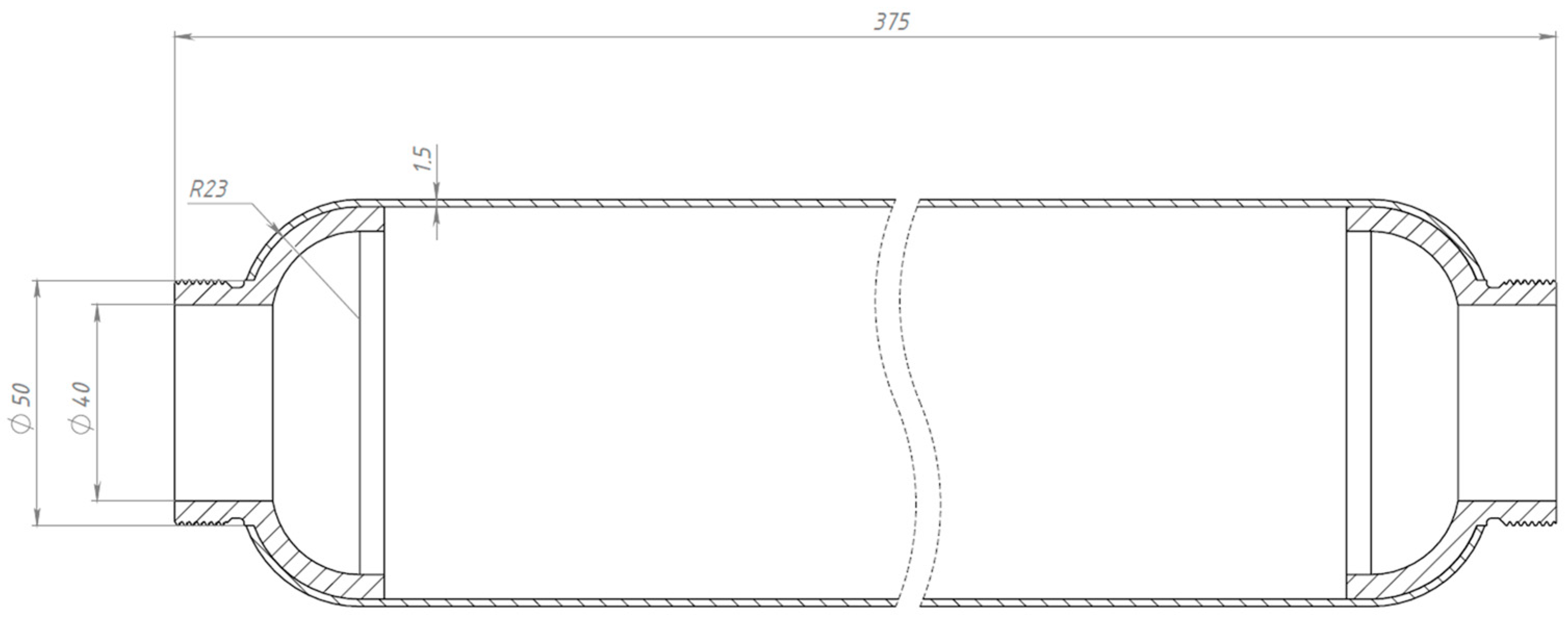

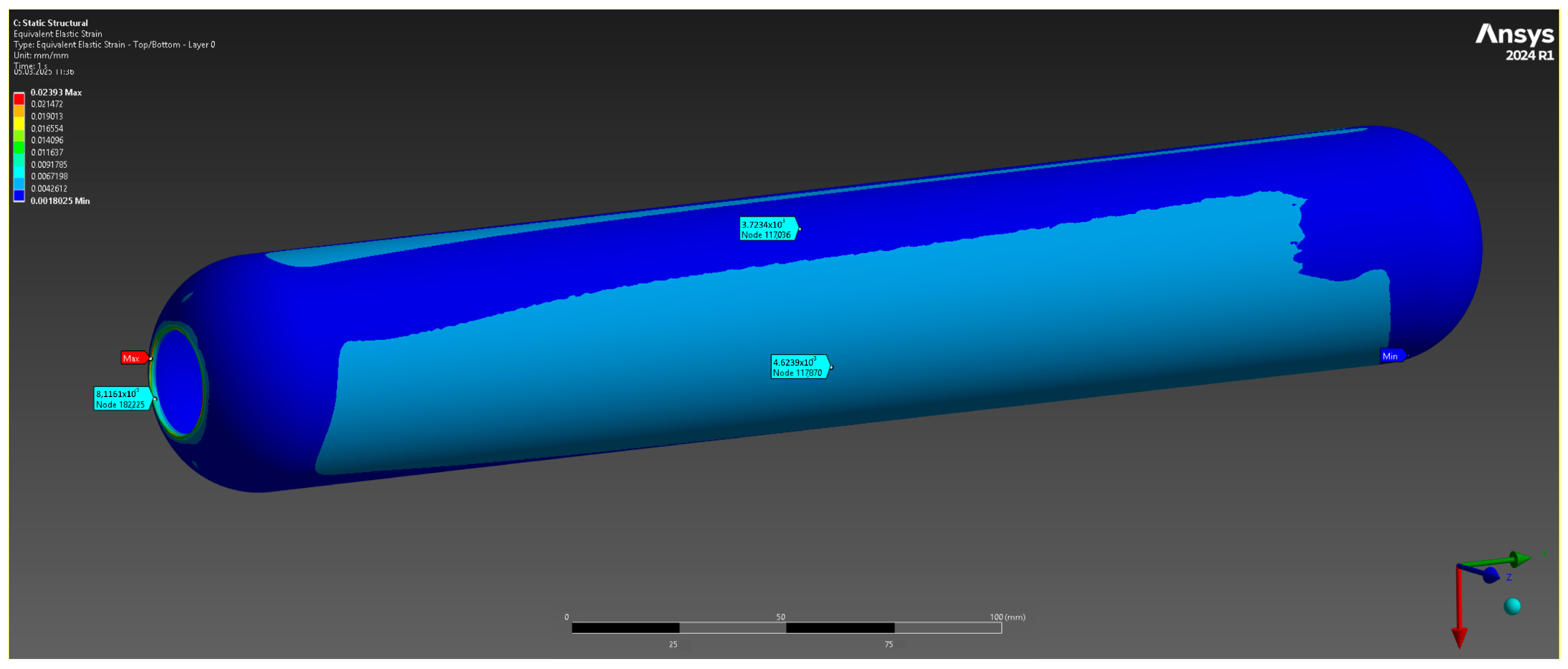

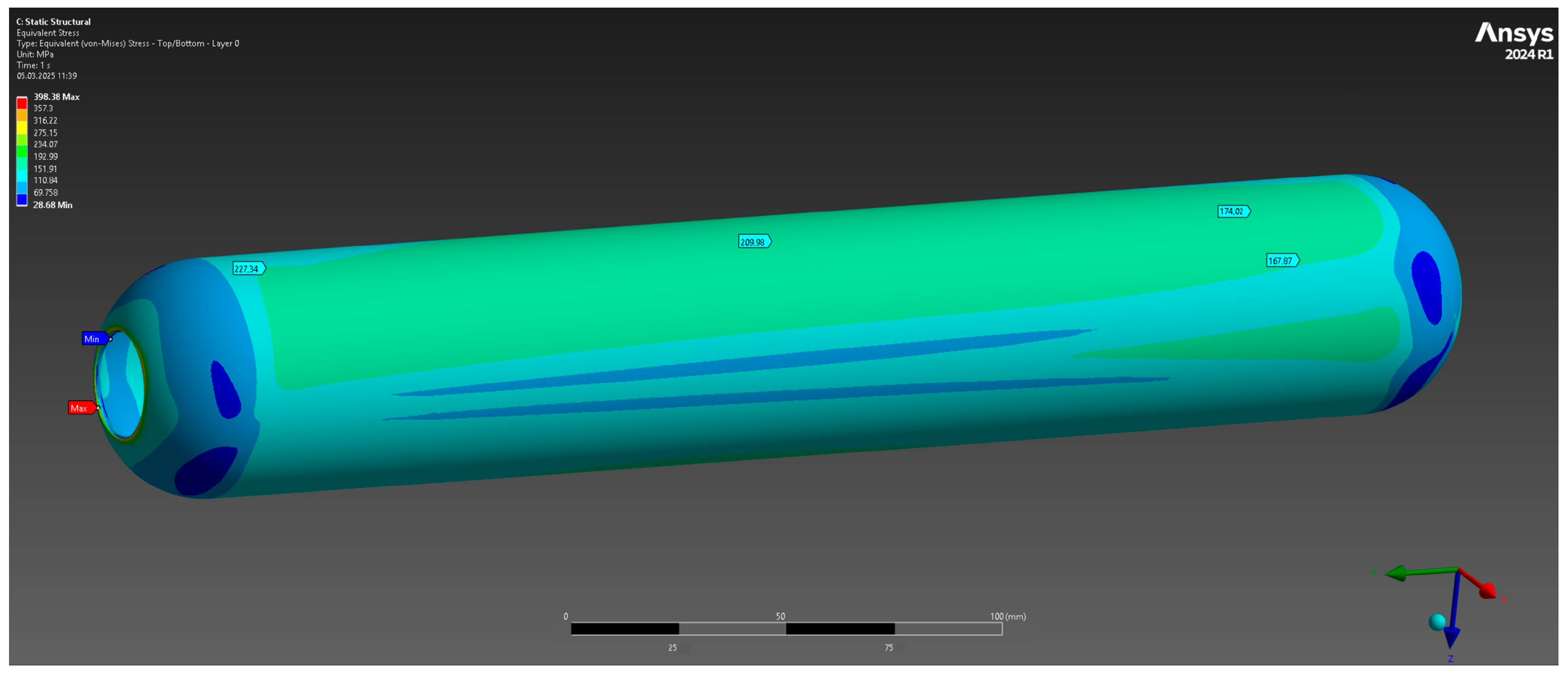

3.1. Design of a Lightweight, High-Strength Composite SRM Casing

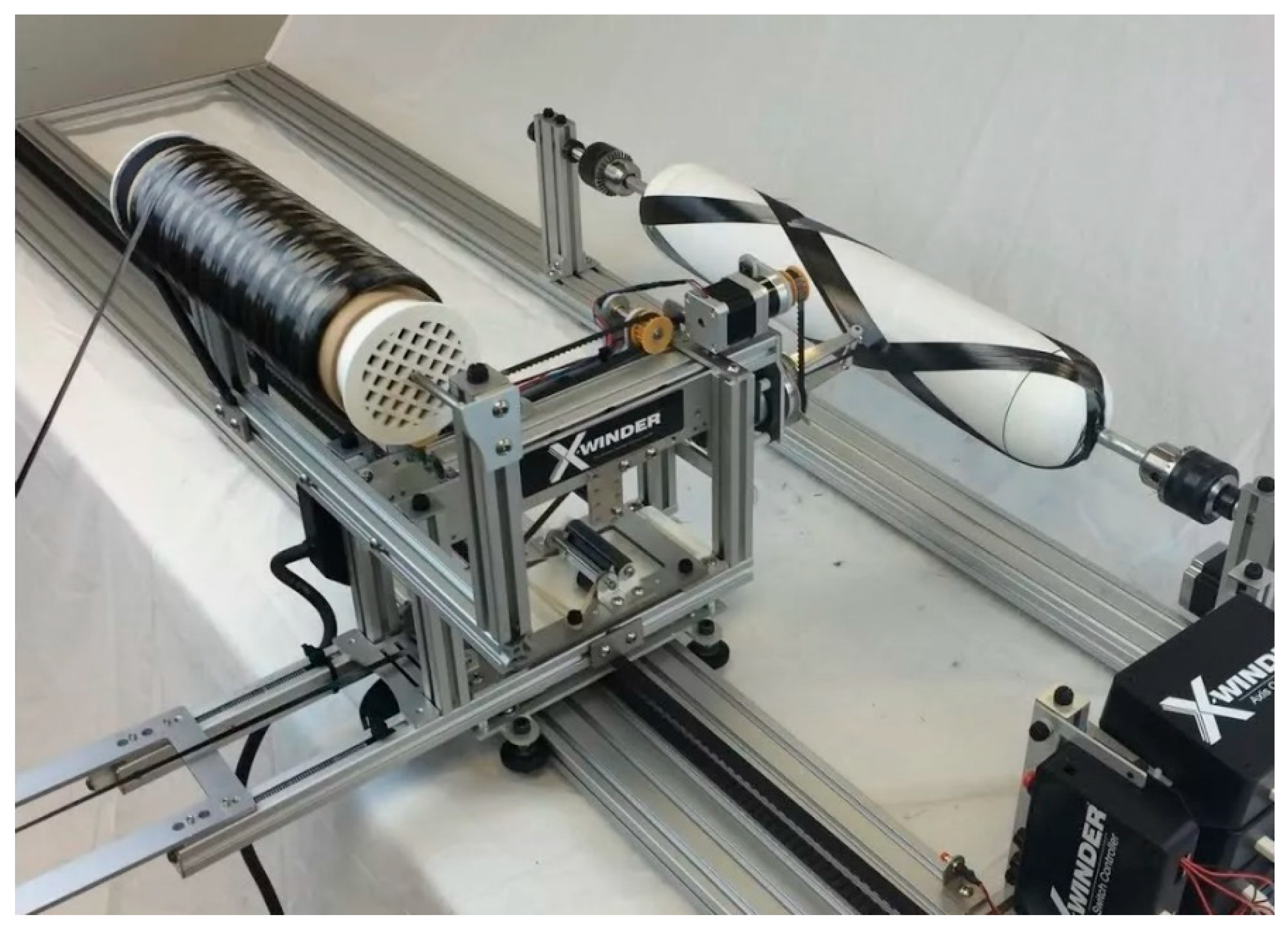

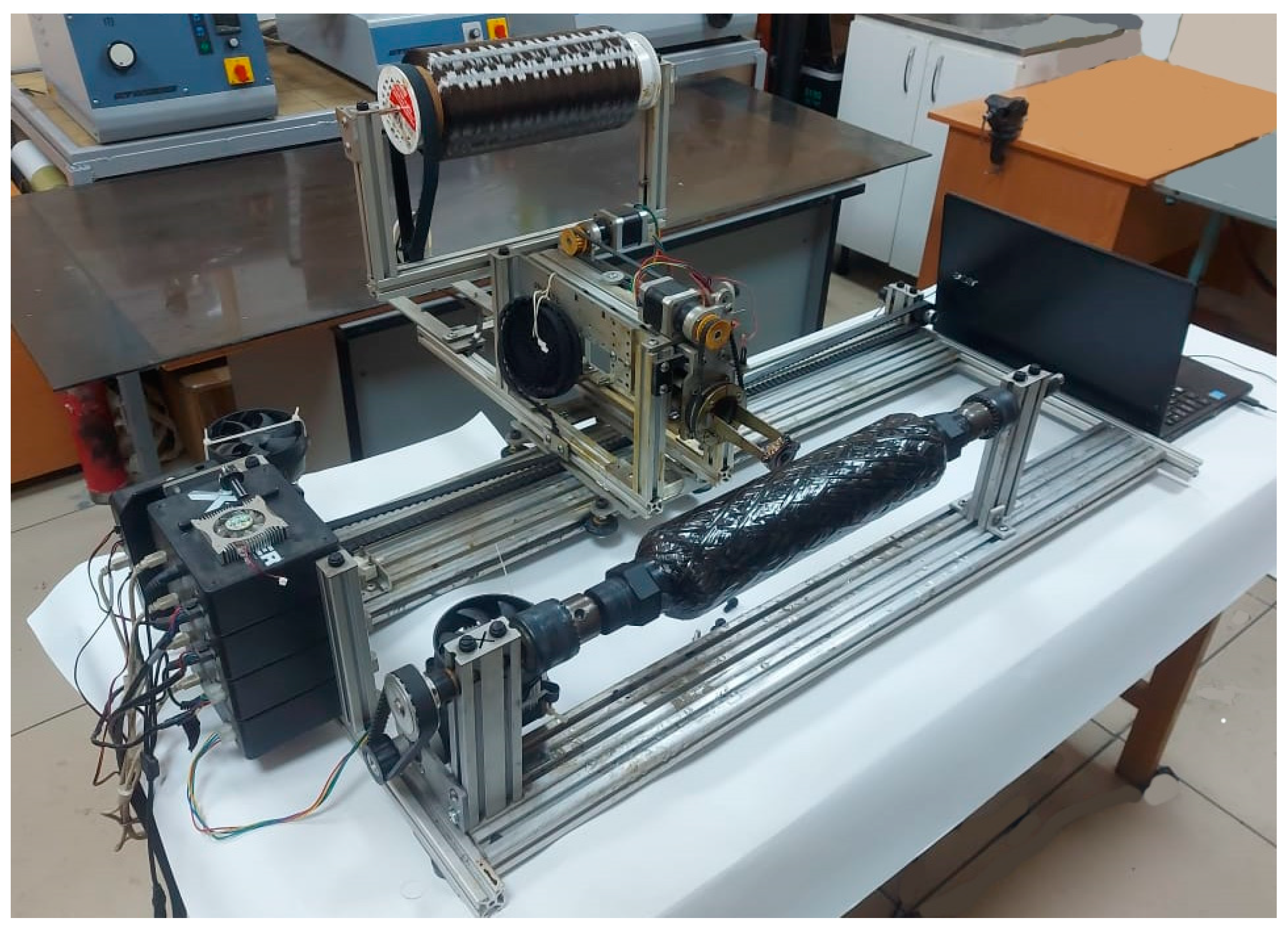

3.2. Design and Fabrication of Winding Process Tooling

3.3. Development of Technology for Manufacturing SRM Case Power Shell from High-Strength Fibers Applying Combined Reinforcement

- -

- Preparation of the mandrel for winding;

- -

- Preparation of the winding binder: modified epoxy compound Ethal Inject T;

- -

- Filling the impregnation bath with binder;

- -

- Preparation of carbon roving: drying of the roving roll at 100 °C for 2 h;

- -

- Installation of the roving roll into the impregnation line;

- -

- In X-Winder software V420 4.2, setting the necessary winding parameters: winding angles, layers of angles, roving parameters;

- -

- Winding the casing at the specified laying angles;

- -

- Finalizing the winding and extracting the finished cured casing.

3.4. Research of Composite Power Casing Shell Stability to Internal Pressure and Achievement of Stability up to 10 MPa

- -

- The specimen with wall thickness of 1.5 mm withstood the working pressure up to 10 MPa. At a further increase in the load up to 11 MPa, the cylindrical part of the casing reached failure point.

- -

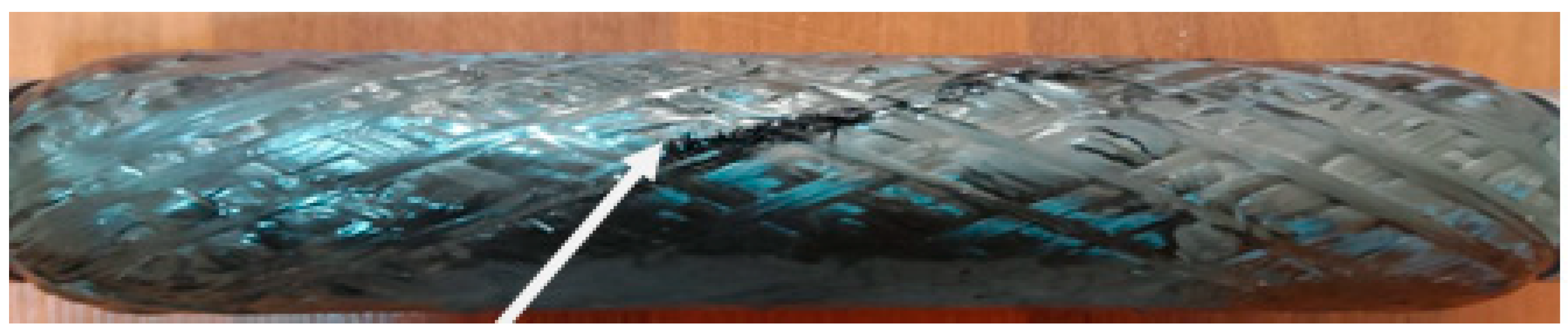

- The sample with a wall thickness of 3 mm demonstrated resistance to internal pressure up to 18 MPa, while the casing failure took place when this pressure level was exceeded (Figure 14).

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hossam, I.; Saleh, S.; Kamel, H. Review of Challenges of the Design of Rocket Motor Case Structures. In Proceedings of the International Conference on Aerospace Sciences and Aviation Technology, Cairo, Egypt, 9–11 April 2019. [Google Scholar] [CrossRef]

- Baldieri, F.; Martelli, E.; Riccio, A. A Numerical Study on Carbon-Fiber-Reinforced Composite Cylindrical Skirts for Solid Propeller Rockets. Polymers 2023, 15, 908. [Google Scholar] [CrossRef] [PubMed]

- Niharika, B.; Varma, B.B. Design and analysis of composite rocket motor casing. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 012034. [Google Scholar] [CrossRef]

- Willis, P.B.; Hsieh, C.H. Space applications of polymeric materials. Polymers 2000, 49, 52–56. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; De Cillis, F. Mechanical comparison of new composite materials for aerospace applications. Compos. Part B Eng. 2019, 162, 122–128. [Google Scholar] [CrossRef]

- Hamed, A.; Khalid, Y.; Sapuan, S.; Hamdan, M.; Younis, T.; Sahari, B. Effects of winding angles on the strength of filament wound composite tubes subjected to different loading modes. Polym. Polym. Compos. 2007, 15, 199–206. [Google Scholar] [CrossRef]

- Hocine, A.; Chapelle, D.; Boubakar, M.; Benamar, A.; Bezazi, A. Experimental and analytical investigation of the cylindrical part of a metallic vessel reinforced by filament winding while submitted to internal pressure. Int. J. Press. Vessel. Pip. 2009, 86, 649–655. [Google Scholar] [CrossRef]

- Azeem, M.; Ya, H.H.; Alam, M.A.; Kumar, M.; Sajid, Z.; Gohery, S.; Maziz, A.; Gemi, L.; Abdullah, S.I.B.S.; Khan, S.H. Influence of winding angles on hoop stress in composite pressure vessels: Finite element analysis. Results Eng. 2024, 21, 101667. [Google Scholar] [CrossRef]

- Liu, Z.; Hui, W.; Chen, G.; Cao, P. Multiscale analyses of the damage of composite rocket motor cases. Front. Mater. 2023, 10, 1198493. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, Z.; Tang, C.; Hu, D.; Liu, P.; Xia, L. Analytical solution of the thermo-mechanical stresses in a multilayered composite pressure vessel considering the influence of the closed ends. Int. J. Press. Vessel. Pip. 2012, 98, 102–110. [Google Scholar] [CrossRef]

- Reddy, C.V.; Babu, P.; Ramaswamy, K. Structural Design and Analysis of Composite Rocket Motor Casing (CRMC) For High Strength Applications. J. Emerg. Technol. Innov. Res. 2018, 5, 612–617. [Google Scholar]

- Meiirbekov, M.N.; Ismailov, M.B.; Kenzhegulov, A.K.; Mustafa, L.M.; Tashmukhanbetova, I.B. Study of the effect of combined reinforcement and modification of epoxy resin with rubbers on the impact strength of carbon fiber-reinforced plastic. Eurasian J. Phys. Funct. Mater. 2024, 48, 23–32. [Google Scholar] [CrossRef]

- Meiirbekov, M.; Yermekov, A.; Nurguzhin, M.; Kulbekov, A. Identifying the influence of winding angles on the strength properties of carbon fiber-reinforced plastic tubes. East.-Eur. J. Enterp. Technol. 2025, 1, 26–32. [Google Scholar] [CrossRef]

- Baiserikov, B.M.; Yermakhanova, A.M.; Ismailov, M.B.; Kenzhegulov, A.K.; Kenzhaliyev, B.K. Study of prepregs lifetime based on epoxy resin with aromatic amine hardener. Eurasian Phys. Tech. J. 2023, 20, 62–69. [Google Scholar] [CrossRef]

- Yermakhanova, A.M.; Kenzhegulov, A.K.; Meiirbekov, M.N.; Baiserikov, B.M. Comparative study of dielectric characteristics and radio transparency of composite materials. J. Elastomers Plast. 2024, 56, 843–857. [Google Scholar] [CrossRef]

- Mustafa, L.; Ismailov, M.; Tashmukhanbetova, I.; Ablakatov, I.; Zhumakanova, V. The Effect of Modifiers on the Strength and Impact Toughness of Carbon Fiber Reinforced Plastics. J. Multidiscip. Appl. Nat. Sci. 2025, 5, 130–140. [Google Scholar] [CrossRef]

- Mustafa, L.M.; Ablakatov, I.K.; Baiserikov, B.M.; Ismailov, M.B.; Zhumakanova, V.R. Research on armor steel technology and ways to Improve its mechanical properties. News Natl. Acad. Sci. Repub. Kazakhstan 2025, 1, 140–154. [Google Scholar] [CrossRef]

- Rebeca, D.E.; Wyller, M.; Hanaa, D. Aerochair Integrative design methodologies for lightweight carbon fiber furniture design. In Proceedings of the eCAADe 37/SIGraDi Conference (eCAADe: Education and Research in Computer Aided Architectural Design in Europe) and (SIGraDi: Sociedad Iberoamericana de Gráfica Digital), Porto, Portugal, 11–13 September 2019; Volume 7, pp. 691–700. [Google Scholar] [CrossRef]

- Torres, M.; Diaz, S.; Idareta, I.; García, C. New composite fuselages manufacturing processes. Rev. Mater. Compuestos 2018, 3, 1–6. [Google Scholar] [CrossRef]

- Ramsey, J.K. Calculating Factors of Safety and Margins of Safety from Interaction Equations; NASA/TM-2019-220153; Technical Report for NASA Glenn Research Center: Cleveland, OH, USA, 2019. [CrossRef]

- Kumar, D.; Nayana, B.S.; Shree, D.S. Design and structural analysis of solid rocket motor casing hardware used in aerospace applications. J. Aeronaut. Aerosp. Eng. 2016, 5, 1–7. [Google Scholar] [CrossRef]

- Karpovich, I.I.; Myhovych, Y.S. Selection jf Mandrel Type for Winding Rocket Engine Casings. Syst. Des. Anal. Aerosp. Tech. Charact. 2023, 32, 61–71. [Google Scholar] [CrossRef]

- Thi, T.B.N.; Yokoyama, A.; Ota, K.; Kodama, K.; Yamashita, K.; Isogai, Y.; Furuichi, K.; Nonomura, C. Numerical approach of the injection molding process of fiber-reinforced composite with considering fiber orientation. AIP Conf. Proc. 2014, 1593, 571–577. [Google Scholar] [CrossRef]

- Abdalla, M.A.; Elsheikh, M.T. Optimization of multilayer composite for solid rocket motor case using genetic algorithm. Eur. Acad. Res. 2018, 6, 1–11. [Google Scholar]

- Bakaiyan, H.; Hosseini, H.; Ameri, E. Analysis of multi-layered filament-wound composite pipes under combined internal pressure and thermomechanical loading with thermal variations. Compos. Struct. 2009, 88, 532–541. [Google Scholar] [CrossRef]

| Parameters | Properties |

|---|---|

| Resin part/hardener ratio (weight parts) | 100:49.9/100:51.5 |

| Type | Viscous liquid |

| Epoxy number of the resin part | 32–34 |

| Bruckfeld viscosity of the compound at 45 °C | 160 ± 50 cPs |

| Bruckfeld viscosity of the resin part—component A at 25 °C | no more: 460 ± 30 cPs/400 ± 30 cPs |

| Bruckfeld viscosity of hardener—component B at 25 °C | no more: 200 cPs/450 ± 50 cPs |

| Martens heat resistance | no more 180 °C |

| Recommended temperature of components A and B before mixing, °C | 40–45/40–45 |

| Tensile strength, MPa | no more 100/120 |

| Static bending strength, MPa | no more 140/150 |

| Glass transition temperature, Tg | 199 °C |

| Curing mode | 4 h at 150 °C, +1 h at 180 °C |

| Parameters | Properties |

|---|---|

| Appearance | Transparent oily liquid |

| Chemical formula | C21H21O4P; (CH3C6H4O) 3PO |

| color by APHA | 50 max |

| Acid number, mg KOH/g | 0.1 max |

| Density (пpи 20 °C), g/cm3 | 1.17–1.18 |

| Mass fraction of free phenol, % | 0.1 max |

| Flash point, °C | 228 max |

| Boiling point, °C | 280–290 |

| Ignition temperature, °C | 249 |

| Self-ignition temperature, °C | 369 |

| Mass fraction of volatile substances, % | 0.1 max |

| Parameters | Properties |

|---|---|

| Density, g/cm3 | 1.8 |

| Tensile strength, MPa | 4900 |

| Tensile modulus, GPa | 230 |

| Relative elongation at break, % | 2.1 |

| Number of filaments | 12,000 = 12k |

| Filament diameter, µm | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baiserikov, B.; Ismailov, M.; Mustafa, L.; Yesbolov, N.; Kulbekov, A.; Yermekov, A.; Meiirbekov, M.; Ablakatov, I. Design and Manufacturing of Experimental Solid Propellant Rocket Motor Cases Made of Carbon Composite Materials. Polymers 2025, 17, 1352. https://doi.org/10.3390/polym17101352

Baiserikov B, Ismailov M, Mustafa L, Yesbolov N, Kulbekov A, Yermekov A, Meiirbekov M, Ablakatov I. Design and Manufacturing of Experimental Solid Propellant Rocket Motor Cases Made of Carbon Composite Materials. Polymers. 2025; 17(10):1352. https://doi.org/10.3390/polym17101352

Chicago/Turabian StyleBaiserikov, Berdiyar, Marat Ismailov, Laura Mustafa, Nurmakhan Yesbolov, Arman Kulbekov, Abussaid Yermekov, Mohammed Meiirbekov, and Ilyas Ablakatov. 2025. "Design and Manufacturing of Experimental Solid Propellant Rocket Motor Cases Made of Carbon Composite Materials" Polymers 17, no. 10: 1352. https://doi.org/10.3390/polym17101352

APA StyleBaiserikov, B., Ismailov, M., Mustafa, L., Yesbolov, N., Kulbekov, A., Yermekov, A., Meiirbekov, M., & Ablakatov, I. (2025). Design and Manufacturing of Experimental Solid Propellant Rocket Motor Cases Made of Carbon Composite Materials. Polymers, 17(10), 1352. https://doi.org/10.3390/polym17101352