Mechanical Behavior and Durability Performance of Concrete Reinforced with Hybrid Date Palm and Polypropylene Polymer Fibers

Abstract

1. Introduction

2. Materials and Methods

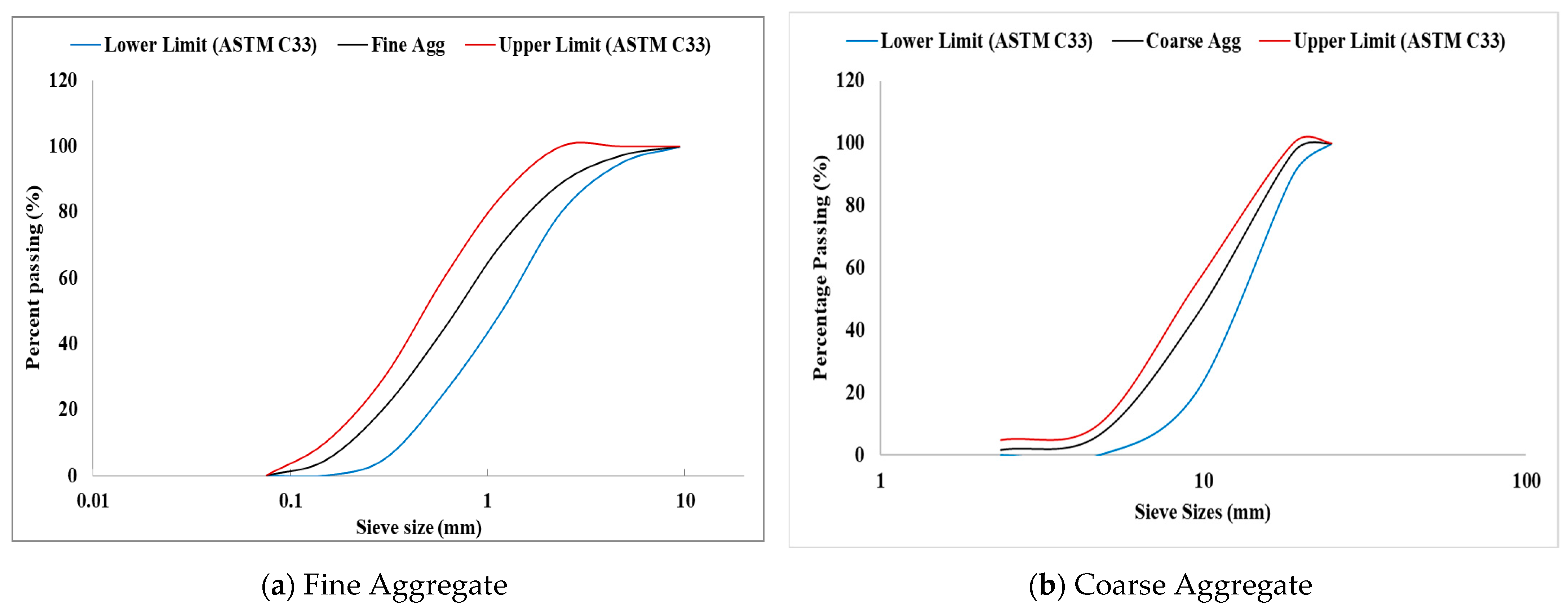

2.1. Materials

2.2. Mix Proportioning

2.3. Sample Preparation

2.4. Testing Methods

3. Results and Discussion

3.1. Workability

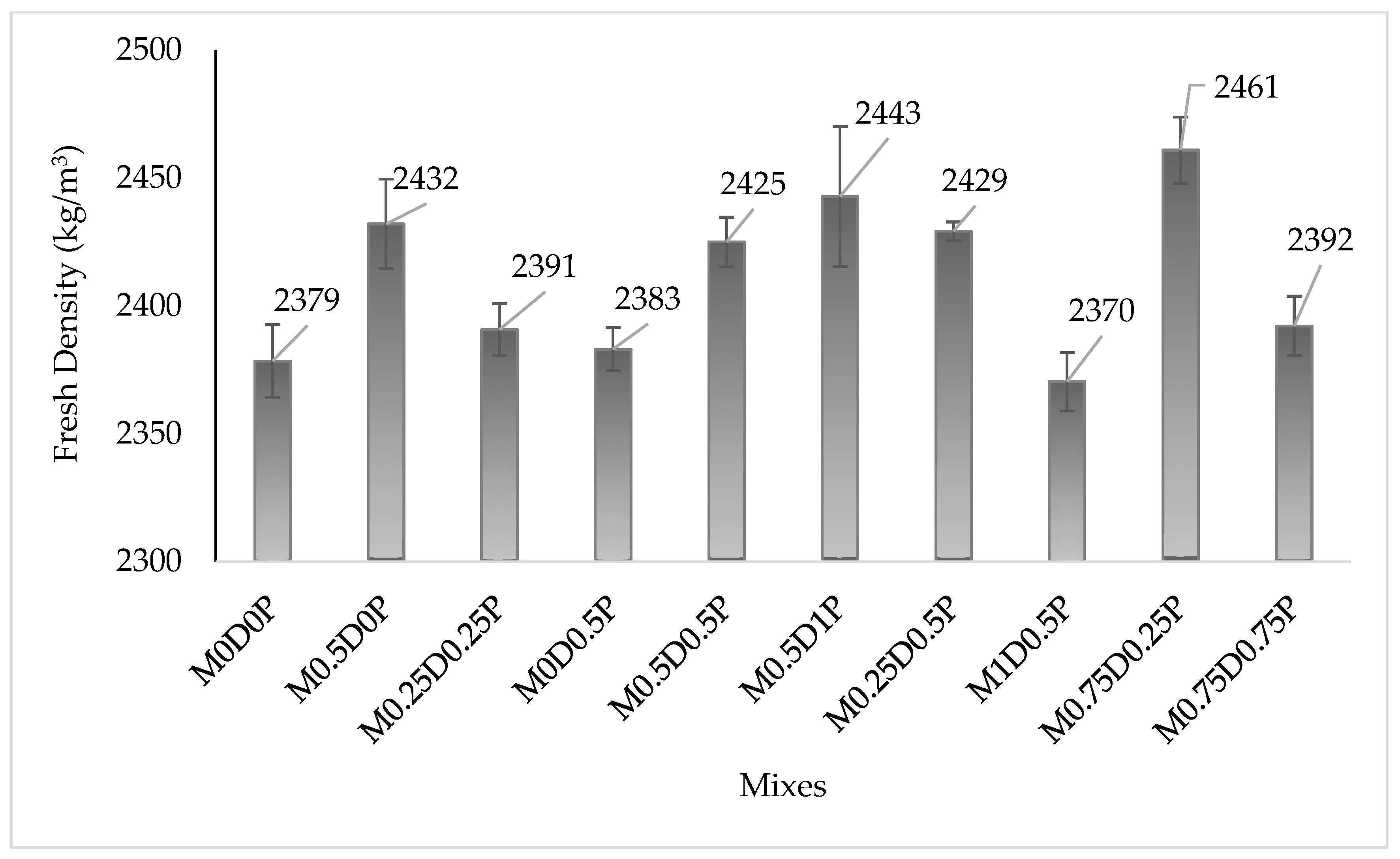

3.2. Fresh Density

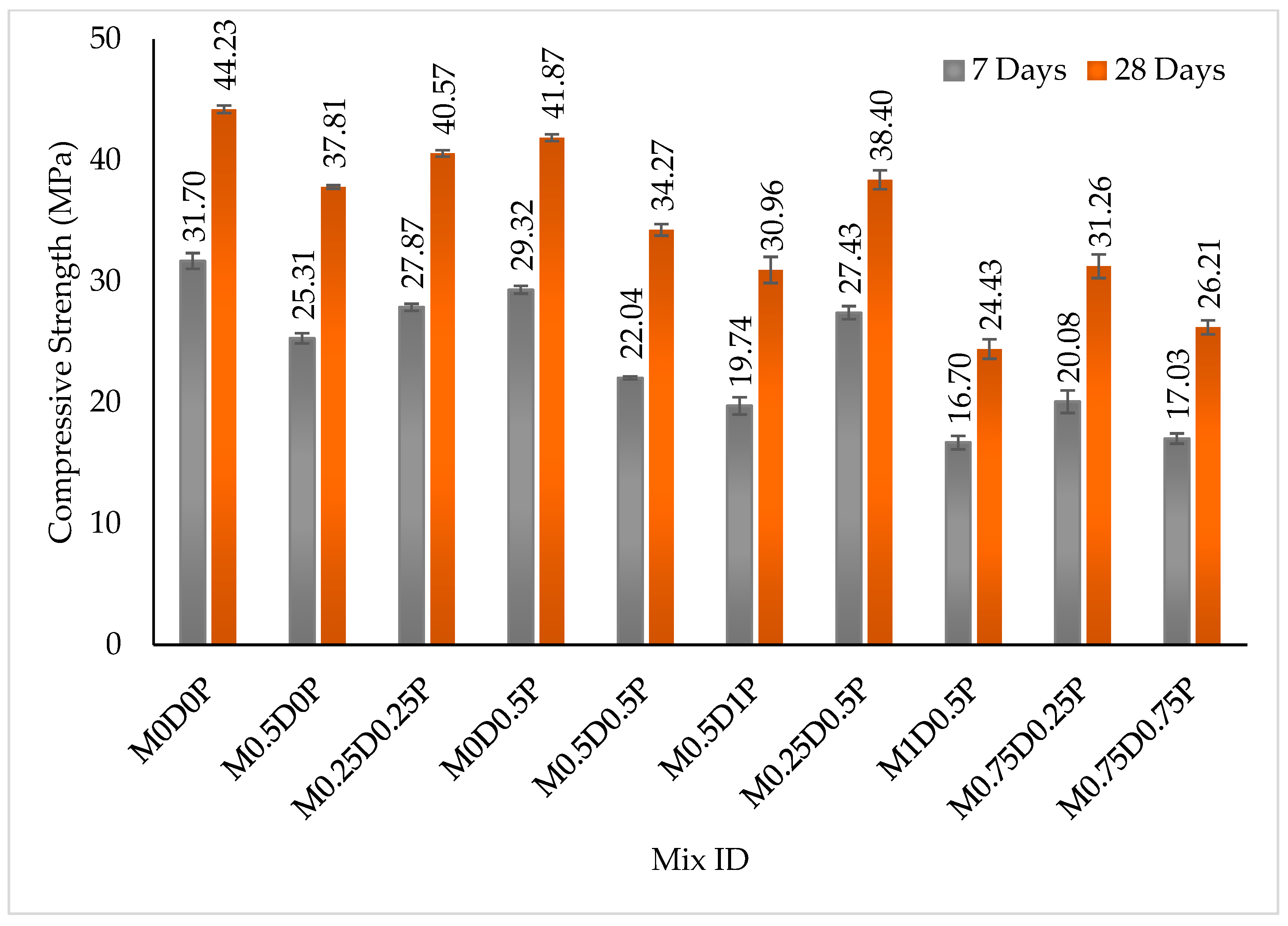

3.3. Compressive Strength

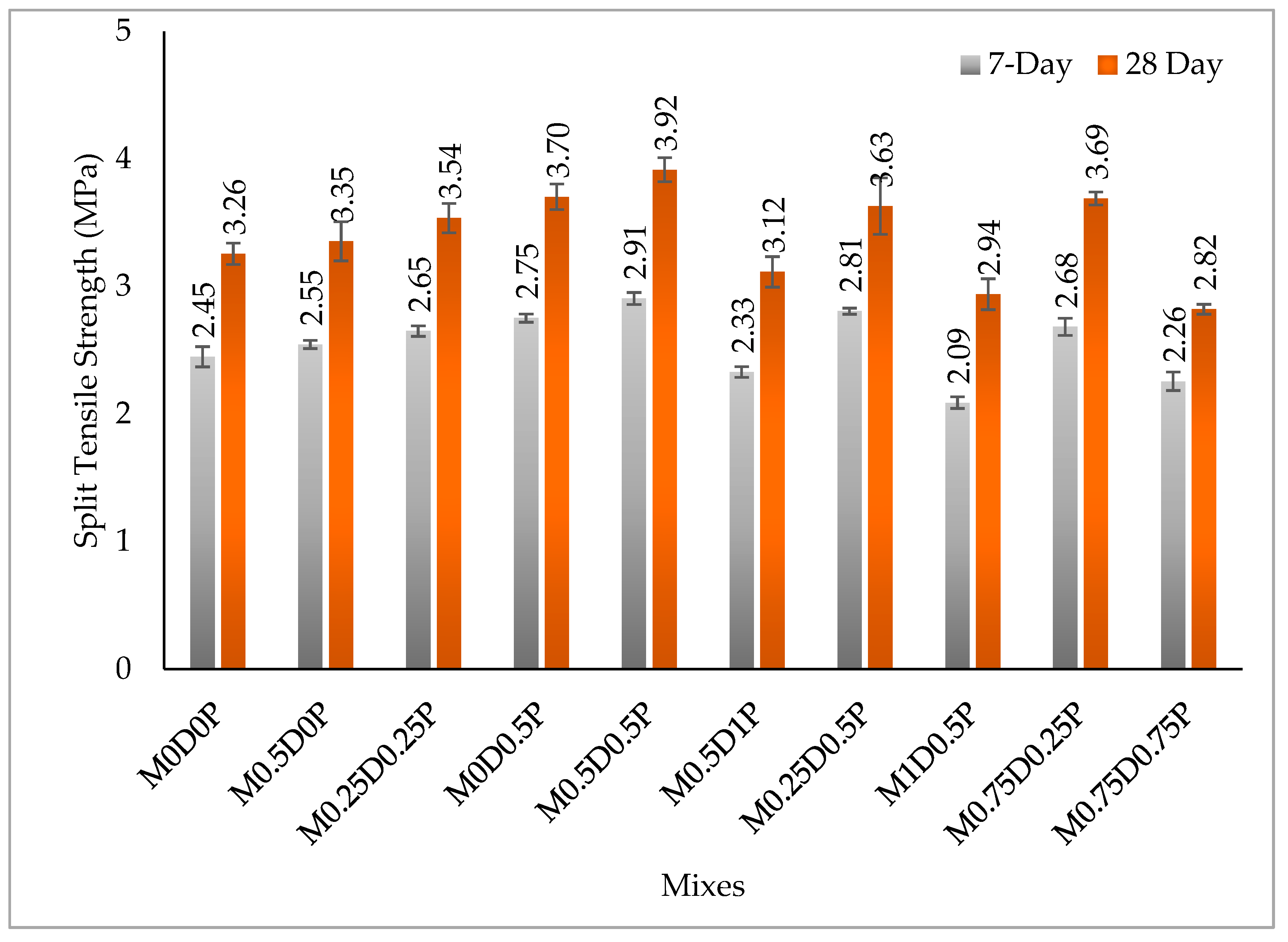

3.4. Splitting Tensile Strength

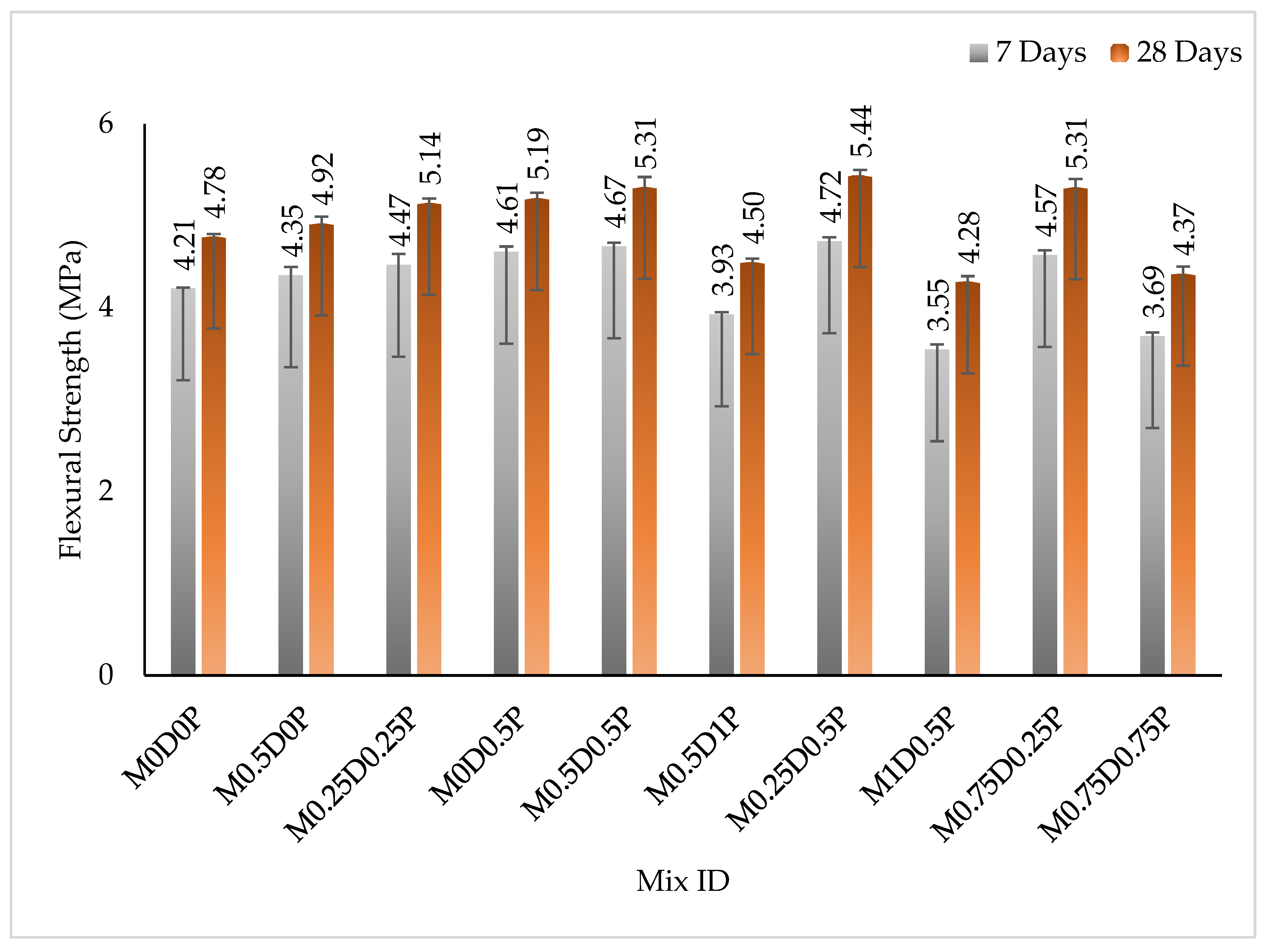

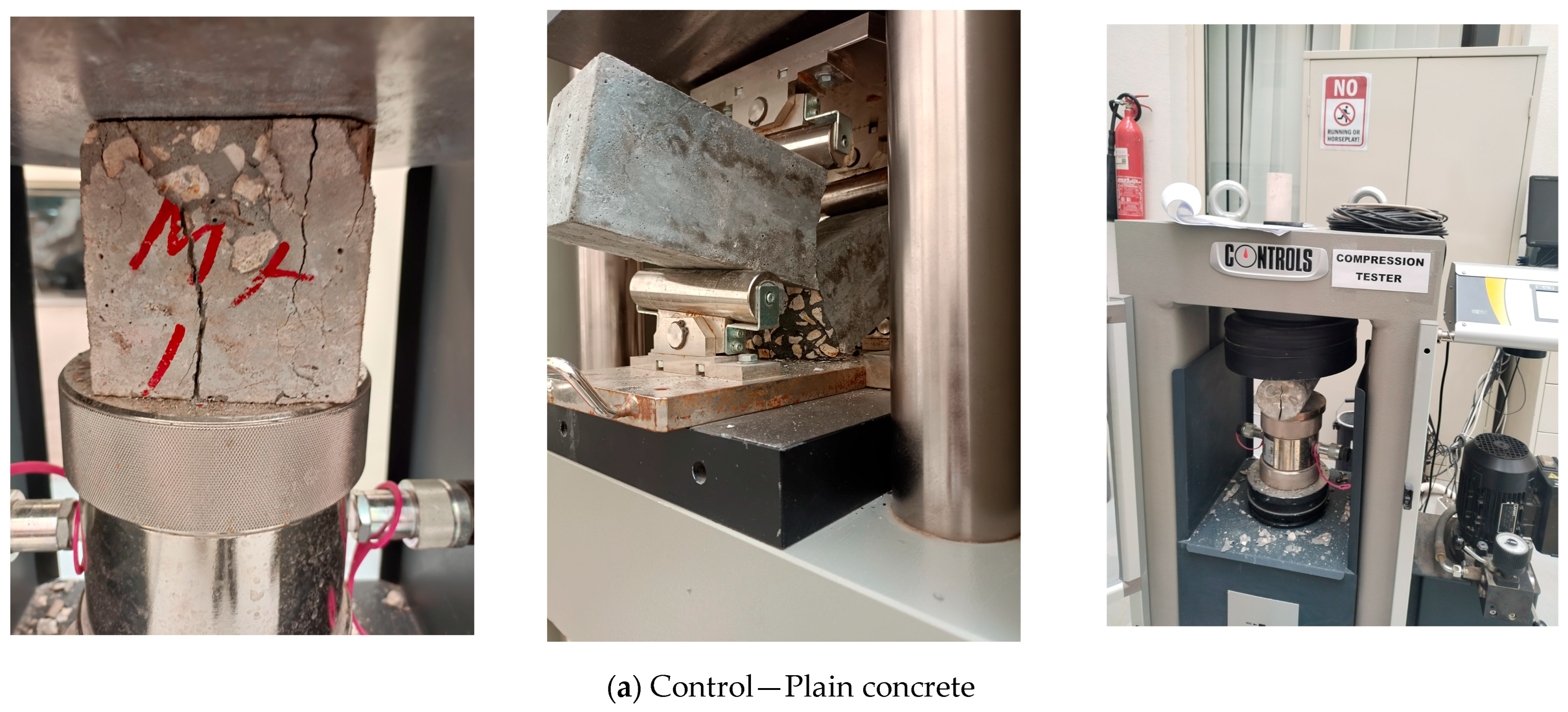

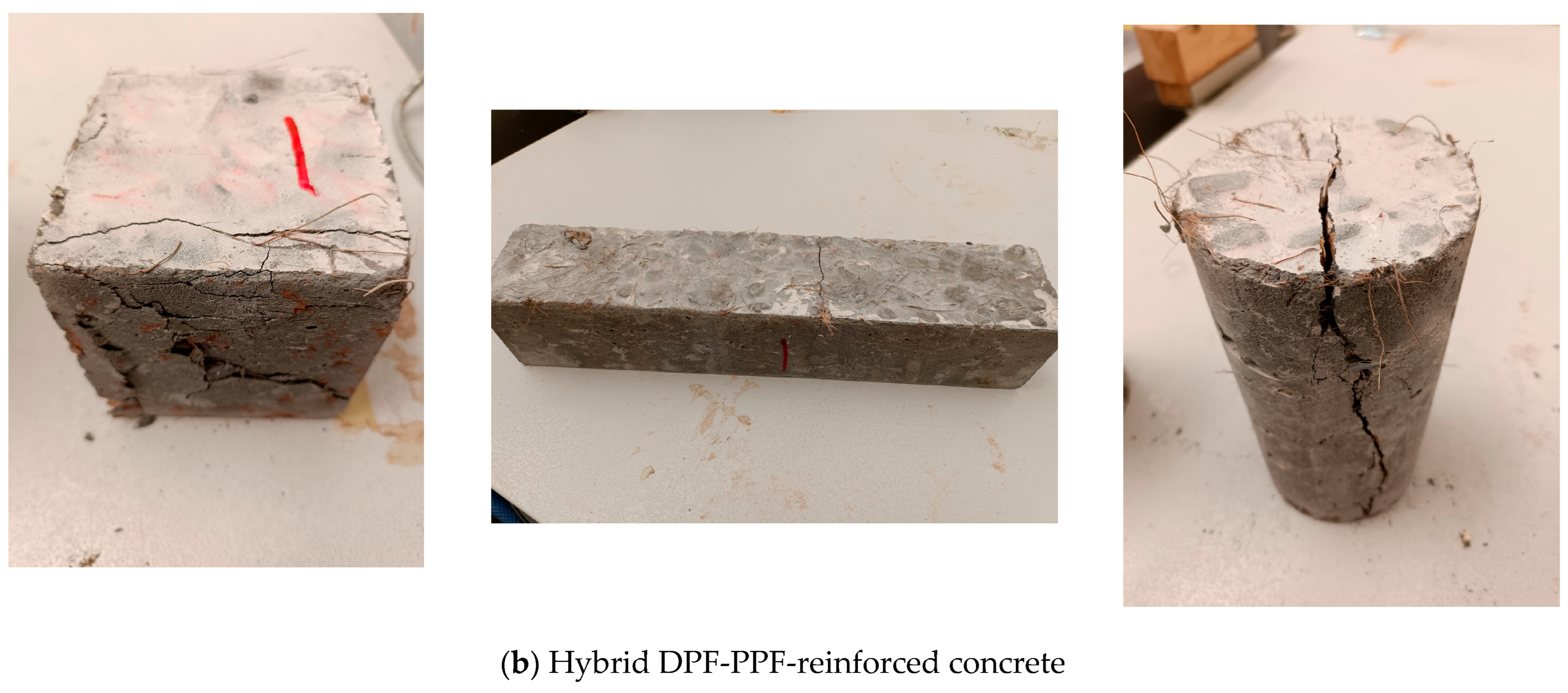

3.5. Flexural Strength

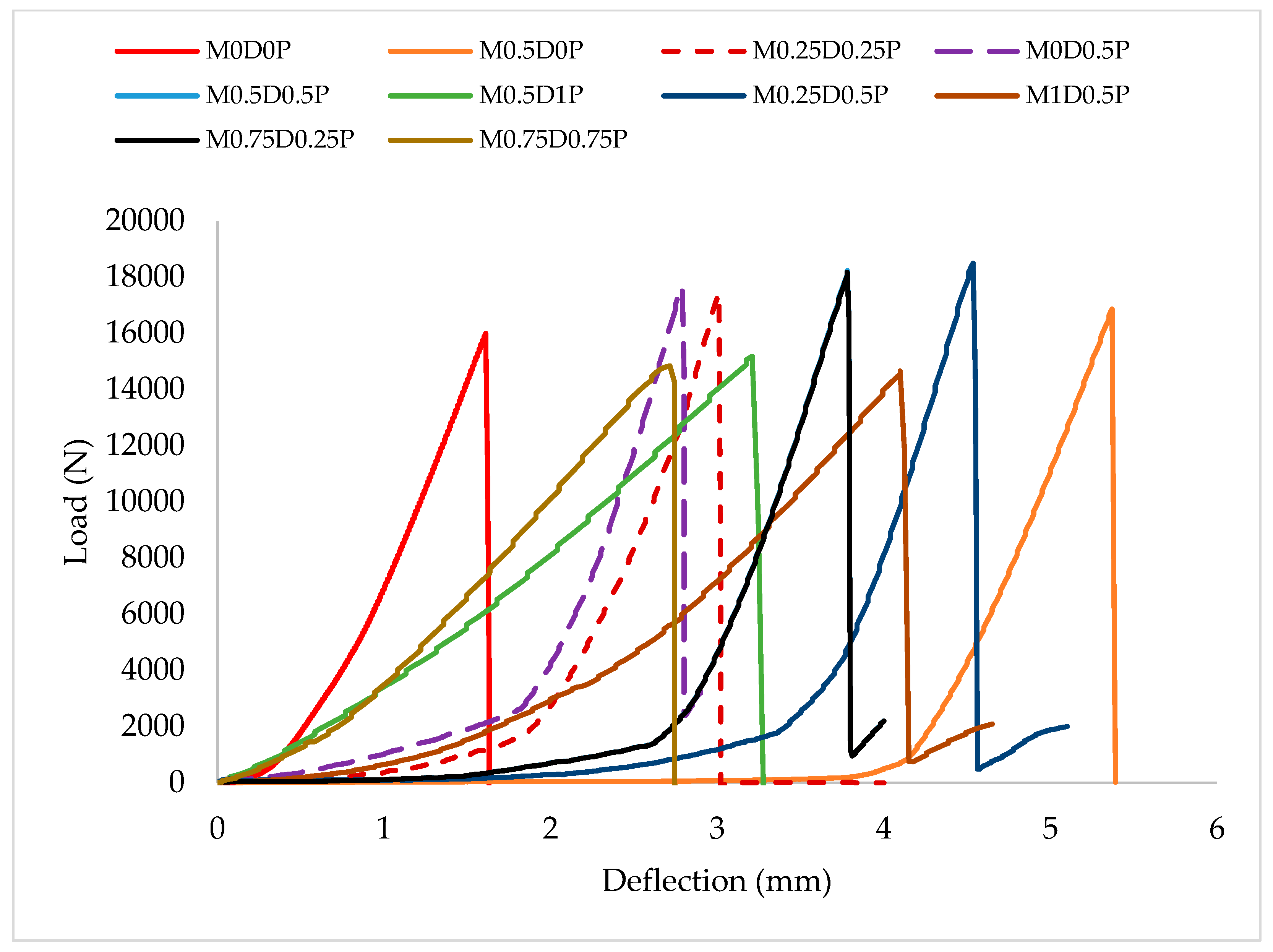

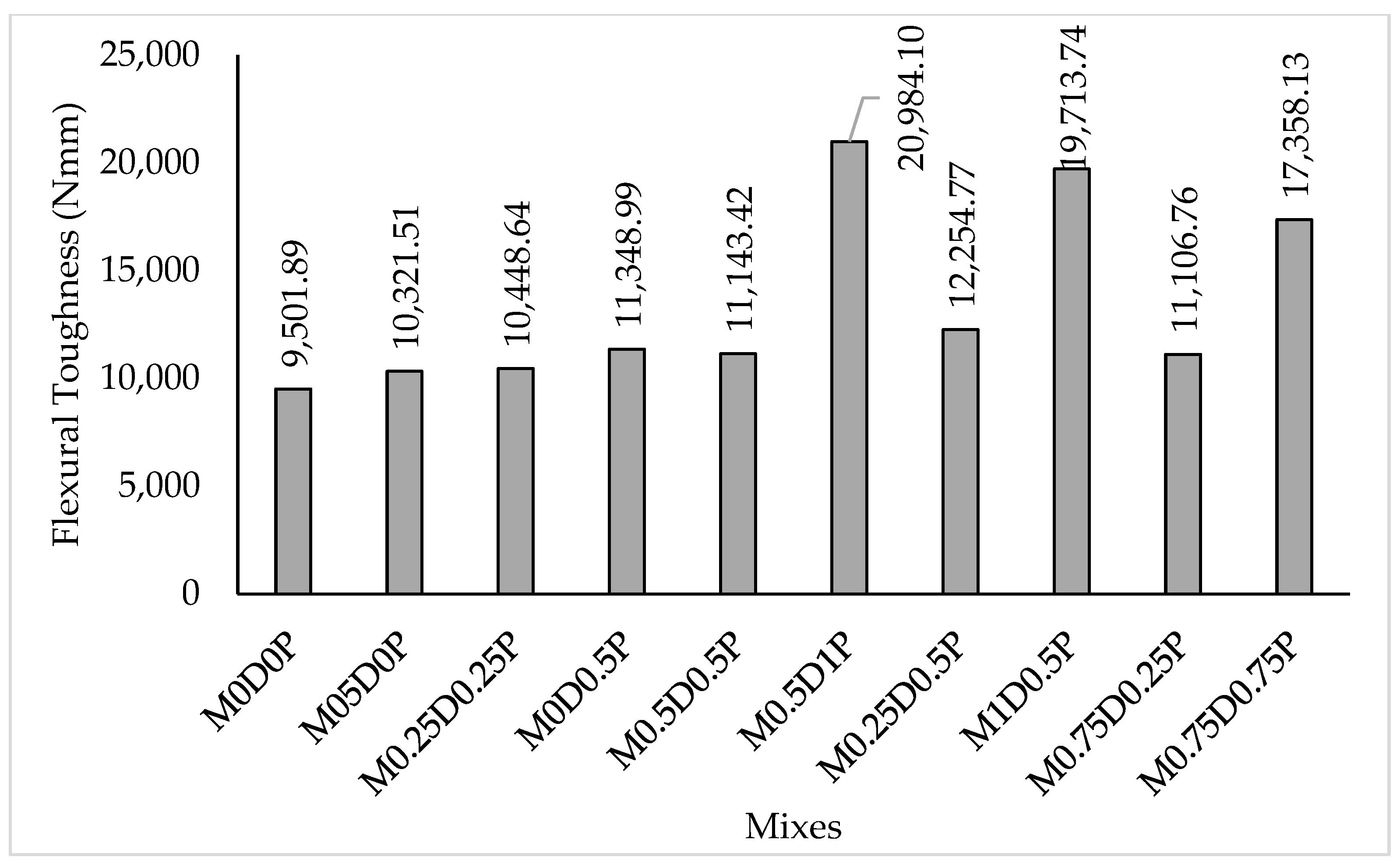

Flexural Toughness and Ductility

3.6. Water Absorption

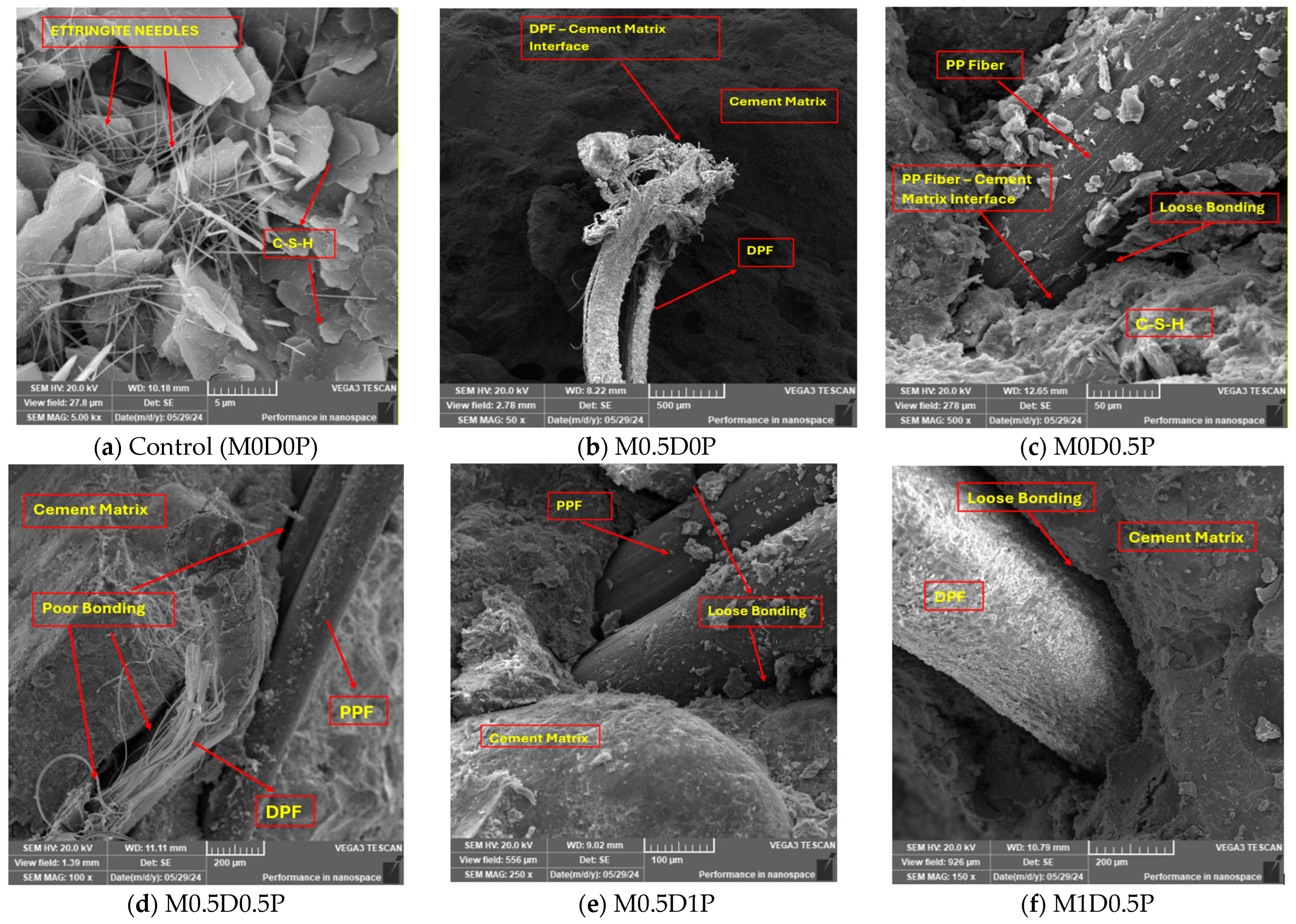

3.7. FESEM Analysis

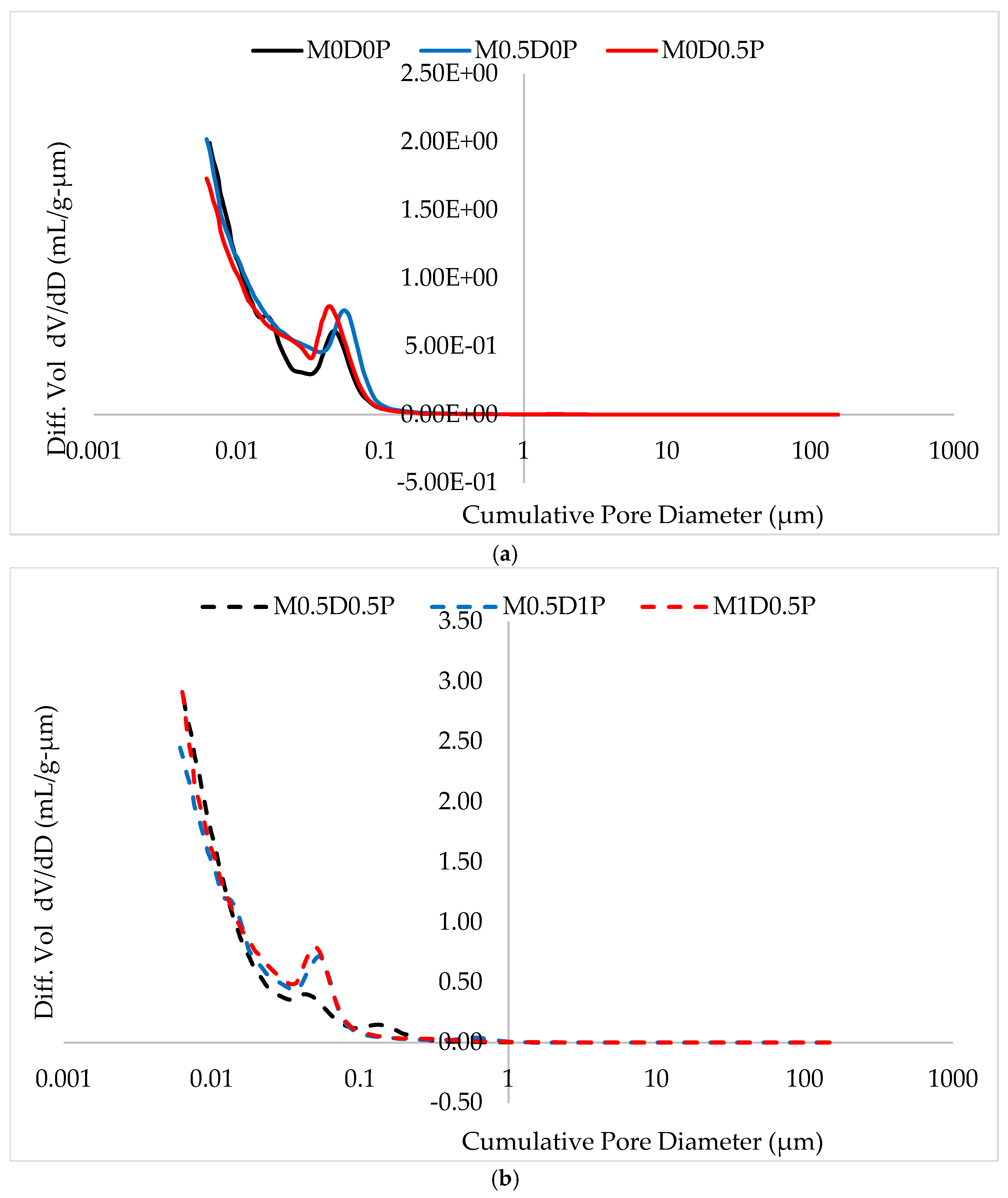

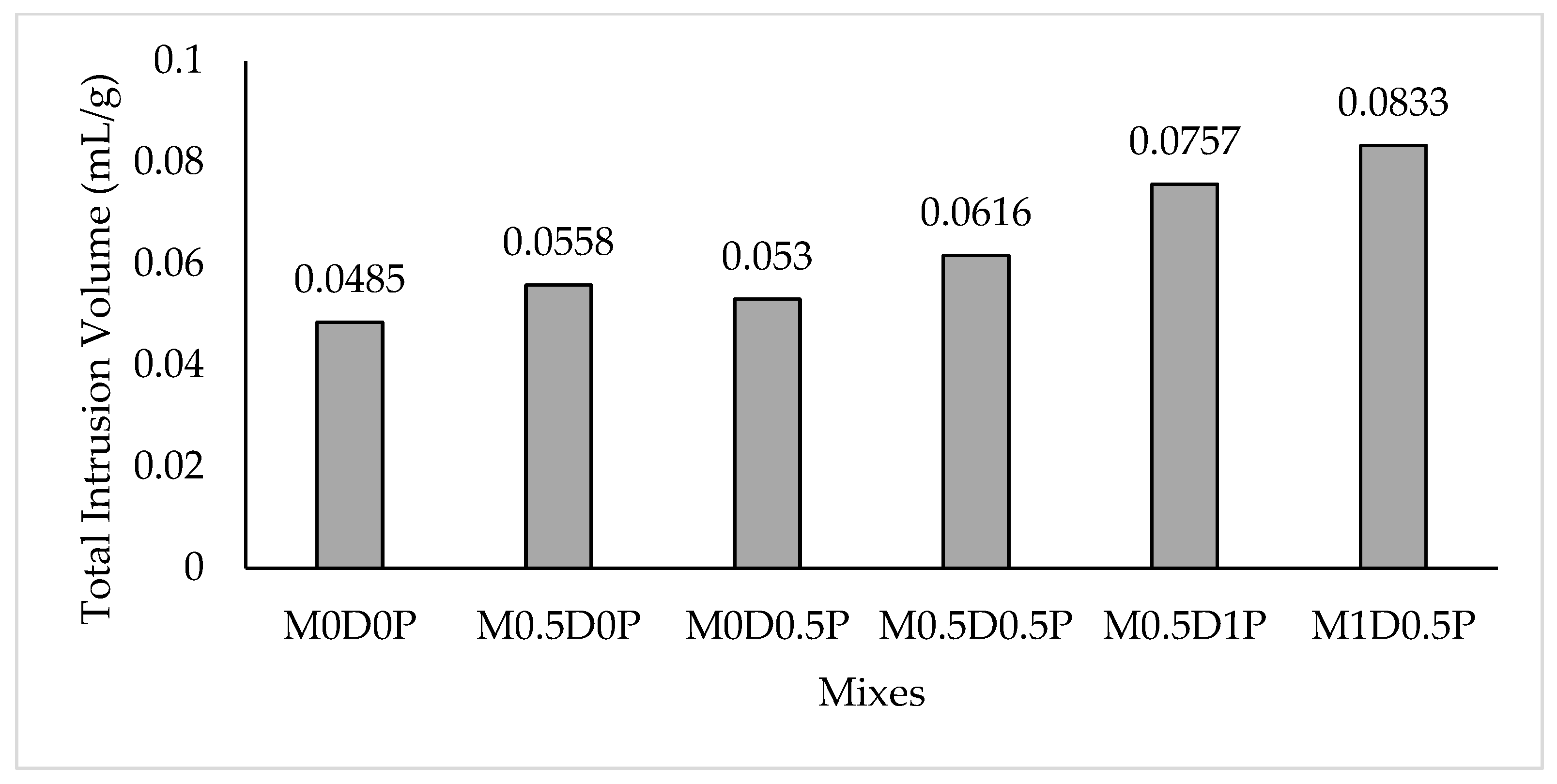

3.8. Mercury Intrusion Porosimetry (MIP)

3.9. Discussion

4. Conclusions

- Adding DPF and PPF reduced the workability and fresh density of concrete, with DPF exhibiting a more significant reduction due to its higher hydrophilicity and hemicellulose content.

- The compressive strength of concrete is reduced by adding either single DPF or PPF or their hybrid to the concrete. Furthermore, DPF exhibits a more detrimental effect on the strength of concrete due to its poor compatibility with the cement matrix and high hydrophilicity. On the other hand, the concrete’s tensile strengths (flexural and split tensile strengths) improved with the addition of either single fiber (DPF or PPF) or their hybrid. These improvements were limited to when the dosage of the single fiber or hybrid fibers did not exceed 1%. PPF demonstrated superior improvements in hybrid fiber-reinforced concrete and single-fiber-reinforced concrete compared to DPF due to its higher tensile strengths and elasticity.

- Adding either DPF or PPF or their hybrid enhanced the energy absorption capacity, toughness, and ductility of the concrete, which increases with an increment in fiber addition. Therefore, adding either a single DPF or PPF or hybridization of DPF and PPF into the concrete promotes post-cracking behavior and inhibits crack propagation, which means they can be used in plain or reinforced concrete. Comparing the two fibers, PPF demonstrated higher improvement due to its superior elasticity and tensile strength compared to DPF.

- The durability of the concrete measured in terms of water absorption and mercury intrusion porosimetry showed that the fibers increased the water absorption and escalated the pore volume in the concrete matrix. The DPF, owing to its high hemicellulose and hydrophilicity, caused a higher increment in the porosity and absorption of the concrete, raising potential durability concerns.

- The best performance was observed in hybrid mixes with controlled proportions of PPF and DPF, balancing mechanical properties and durability. Excessive fiber content (>1.5%) reduced strength due to fiber agglomeration and increased porosity.

- The microstructural morphology showed that both DPF and PPF were poorly bonded with the cement matrix, resulting in premature failure and reduced compressive strength. The DPF exhibits the worst bonding with the cement matrix due to its high hydrophilicity, aiding in a more pronounced reduction in strength and increased porosity.

- To reduce the water absorption of DPF, it is recommended to explore fiber treatment methods such as alkali treatment, silane treatment, or acetylation to decrease hydrophilicity. Applying hydrophobic coatings or sizing (e.g., epoxy resins, nano-silica suspensions) may also serve as an effective moisture barrier. Additionally, optimizing fiber dosage and combining DPF with hydrophobic synthetic fibers like polypropylene (PPF) could help balance water absorption while maintaining mechanical performance.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fuzail Hashmi, A.; Shariq, M.; Baqi, A. Successive sustained loading effect on the long-term deflection of flat slab. SN Appl. Sci. 2020, 2, 1896. [Google Scholar] [CrossRef]

- Shah, S.P.; Swartz, S.E.; Ouyang, C. Fracture Mechanics of Concrete: Applications of Fracture Mechanics to Concrete, Rock and Other Quasi-Brittle Materials; John Wiley & Sons: Hoboken, NJ, USA, 1995. [Google Scholar]

- Hosseinzadeh, H.; Salehi, A.M.; Mehraein, M.; Asadollahfardi, G. The effects of steel, polypropylene, and high-performance macro polypropylene fibers on mechanical properties and durability of high-strength concrete. Constr. Build. Mater. 2023, 386, 131589. [Google Scholar] [CrossRef]

- Hou, L.; Wen, B.; Huang, W.; Zhang, X.; Zhang, X. Mechanical Properties and Microstructure of Polypropylene–Glass-Fiber-Reinforced Desert Sand Concrete. Polymers 2023, 15, 4675. [Google Scholar] [CrossRef] [PubMed]

- Li, F.; Jin, S.; Cheng, P.; Wang, Z.; Yang, Z. Study on Mechanical Properties and Carbon Emission Analysis of Polypropylene Fiber-Reinforced Brick Aggregate Concrete. Polymers 2024, 16, 3535. [Google Scholar] [CrossRef]

- Del Savio, A.A.; La Torre Esquivel, D.; García Landeo, J.M. Post-Cracking Properties of Concrete Reinforced with Polypropylene Fibers through the Barcelona Test. Polymers 2023, 15, 3718. [Google Scholar] [CrossRef]

- Yaqin, C.; Haq, S.U.; Iqbal, S.; Khan, I.; Room, S.; Khan, S.A. Performance evaluation of indented macro synthetic polypropylene fibers in high strength self-compacting concrete (SCC). Sci. Rep. 2024, 14, 20844. [Google Scholar] [CrossRef]

- Balea, A.; Fuente, E.; Monte, M.C.; Blanco, Á.; Negro, C. Fiber reinforced cement based composites. In Fiber Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 597–648. [Google Scholar]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Al-Oqla, F.M.; Alothman, O.Y.; Jawaid, M.; Sapuan, S.; Es-Saheb, M. Processing and properties of date palm fibers and its composites. In Biomass and Bioenergy: Processing and Properties; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–25. [Google Scholar]

- Ibrahim, Y.E.; Adamu, M.; Marouf, M.L.; Ahmed, O.S.; Drmosh, Q.; Malik, M.A. Mechanical performance of date-palm-fiber-reinforced concrete containing silica fume. Buildings 2022, 12, 1642. [Google Scholar] [CrossRef]

- Adamu, M.; Alanazi, F.; Ibrahim, Y.E.; Alanazi, H.; Khed, V.C. A comprehensive review on sustainable natural fiber in cementitious composites: The date palm fiber case. Sustainability 2022, 14, 6691. [Google Scholar] [CrossRef]

- Benaniba, S.; Driss, Z.; Djendel, M.; Raouache, E.; Boubaaya, R. Thermo-mechanical characterization of a bio-composite mortar reinforced with date palm fiber. J. Eng. Fibers Fabr. 2020, 15, 1558925020948234. [Google Scholar] [CrossRef]

- Menyhárd, A.; Menczel, J.D.; Abraham, T. Polypropylene fibers. In Thermal Analysis of Textiles and Fibers; Elsevier: Amsterdam, The Netherlands, 2020; pp. 205–222. [Google Scholar]

- Hsie, M.; Tu, C.; Song, P. Mechanical properties of polypropylene hybrid fiber-reinforced concrete. Mater. Sci. Eng. A 2008, 494, 153–157. [Google Scholar] [CrossRef]

- Ali-Boucetta, T.; Ayat, A.; Laifa, W.; Behim, M. Treatment of date palm fibres mesh: Influence on the rheological and mechanical properties of fibre-cement composites. Constr. Build. Mater. 2021, 273, 121056. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Chai, J.; Xu, Z.; Li, S. Experimental study of compressive behavior of polypropylene-fiber-reinforced and polypropylene-fiber-fabric-reinforced concrete. Constr. Build. Mater. 2019, 194, 216–225. [Google Scholar] [CrossRef]

- Bentegri, I.; Boukendakdji, O.; Kadri, E.; Ngo, T.; Soualhi, H. Rheological and tribological behaviors of polypropylene fiber reinforced concrete. Constr. Build. Mater. 2020, 261, 119962. [Google Scholar] [CrossRef]

- Yong, Z.C.; Yew, M.K.; Yew, M.C.; Beh, J.H.; Lee, F.W.; Lim, S.K.; Saw, L.H. Utilizing bio-based and industrial waste aggregates to improve mechanical properties and thermal insulation in lightweight foamed macro polypropylene fibre-reinforced concrete. J. Build. Eng. 2024, 91, 109588. [Google Scholar] [CrossRef]

- Leong, G.W.; Mo, K.H.; Loh, Z.P.; Ibrahim, Z. Mechanical properties and drying shrinkage of lightweight cementitious composite incorporating perlite microspheres and polypropylene fibers. Constr. Build. Mater. 2020, 246, 118410. [Google Scholar] [CrossRef]

- Yuan, Z.; Jia, Y. Mechanical properties and microstructure of glass fiber and polypropylene fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2021, 266, 121048. [Google Scholar] [CrossRef]

- Razmi, A.; Mirsayar, M. On the mixed mode I/II fracture properties of jute fiber-reinforced concrete. Constr. Build. Mater. 2017, 148, 512–520. [Google Scholar] [CrossRef]

- Hasan, R.; Sobuz, M.H.R.; Akid, A.S.M.; Awall, M.R.; Houda, M.; Saha, A.; Meraz, M.M.; Islam, M.S.; Sutan, N.M. Eco-friendly self-consolidating concrete production with reinforcing jute fiber. J. Build. Eng. 2023, 63, 105519. [Google Scholar] [CrossRef]

- Veerappan, P.; Mani, I.; John, A.; Madhavan, H. Experimental studies of coir and jute-fiber reinforced concrete with M-sand. MatériaJa 2024, 29, e20240115. [Google Scholar] [CrossRef]

- Nawab, M.S.; Ali, T.; Qureshi, M.Z.; Zaid, O.; Kahla, N.B.; Sun, Y.; Anwar, N.; Ajwad, A. A study on improving the performance of cement-based mortar with silica fume, metakaolin, and coconut fibers. Case Stud. Constr. Mater. 2023, 19, e02480. [Google Scholar] [CrossRef]

- Vélez, E.; Rodríguez, R.; Yanchapanta Gómez, N.B.; Mora, E.D.; Hernández, L.; Albuja-Sánchez, J.; Calvo, M.I. Coconut-fiber composite concrete: Assessment of mechanical performance and environmental benefits. Fibers 2022, 10, 96. [Google Scholar] [CrossRef]

- Kiamahalleh, M.V.; Gholampour, A.; Ngo, T.D.; Ozbakkaloglu, T. Mechanical, durability and microstructural properties of waste-based concrete reinforced with sugarcane fiber. Structures 2024, 67, 107019. [Google Scholar] [CrossRef]

- Abdulkareem, M.; Ayeronfe, F.; Jassam, T.M.; AlAteah, A.H.; Al-Sodani, K.A.A.; Al-Tholaia, M.M.; Yam, H.; Ganiyu, A.; Alih, S.C. Compressive and flexural strengths of bio-recycled concrete incorporated with kenaf fibre. J. Nat. Fibers 2024, 21, 2296913. [Google Scholar] [CrossRef]

- Antwi-Afari, B.A.; Mutuku, R.; Kabubo, C.; Mwero, J.; Mengo, W.K. Influence of fiber treatment methods on the mechanical properties of high strength concrete reinforced with sisal fibers. Heliyon 2024, 10, e29760. [Google Scholar] [CrossRef]

- Wang, R.; Qiao, Z.; Deng, X.; Shen, X.; Yang, Y.; Wang, P.; Zhang, J. Experimental Investigation on Freeze–Thaw Durability of Polyacrylonitrile Fiber-Reinforced Recycled Concrete. Materials 2025, 18, 1548. [Google Scholar] [CrossRef]

- Zhao, X.; Cai, L.; Ji, X.; Zeng, W.; Liu, J. Mechanical properties of polyethylene fiber reinforced ultra high performance concrete (UHPC). Materials 2022, 15, 8734. [Google Scholar] [CrossRef]

- Flores Nicolás, A.; Menchaca Campos, E.C.; Flores Nicolás, M.; Martínez González, J.J.; González Noriega, O.A.; Uruchurtu Chavarín, J. Influence of Recycled High-Density Polyethylene Fibers on the Mechanical and Electrochemical Properties of Reinforced Concrete. Fibers 2024, 12, 24. [Google Scholar] [CrossRef]

- Sridhar, M.; Kumar, M.V.; Nagaprasad, N.; Bhagat, S.K.; Ramaswamy, K. Microstructural and statistical analysis on mechanical performance of novel flattened end nylon fibre reinforced concrete. Sci. Rep. 2025, 15, 8483. [Google Scholar] [CrossRef]

- Ahmad, J.; Zaid, O.; Aslam, F.; Martínez-García, R.; Alharthi, Y.M.; Hechmi EI Ouni, M.; Tufail, R.F.; Sharaky, I.A. Mechanical properties and durability assessment of nylon fiber reinforced self-compacting concrete. J. Eng. Fibers Fabr. 2021, 16, 15589250211062833. [Google Scholar] [CrossRef]

- Chandrasekhar, C.; Ransinchung RN, G.; Rajkumar, G. Development and performance analysis of PVA-polyester fiber reinforced cementitious composites incorporating manufactured sand. Eur. J. Environ. Civ. Eng. 2025, 29, 1628–1648. [Google Scholar] [CrossRef]

- Alawar, A.; Hamed, A.M.; Al-Kaabi, K. Characterization of treated date palm tree fiber as composite reinforcement. Compos. Part B Eng. 2009, 40, 601–606. [Google Scholar] [CrossRef]

- Adamu, M.; Marouf, M.L.; Ibrahim, Y.E.; Ahmed, O.S.; Alanazi, H.; Marouf, A.L. Modeling and optimization of the mechanical properties of date fiber reinforced concrete containing silica fume using response surface methodology. Case Stud. Constr. Mater. 2022, 17, e01633. [Google Scholar] [CrossRef]

- Ali, A.; Hussain, Z.; Akbar, M.; Elahi, A.; Bhatti, S.; Imran, M.; Zhang, P.; Leslie Ndam, N. Influence of Marble Powder and Polypropylene Fibers on the Strength and Durability Properties of Self-Compacting Concrete (SCC). Adv. Mater. Sci. Eng. 2022, 2022, 9553382. [Google Scholar] [CrossRef]

- Derdour, D.; Behim, M.; Benzerara, M. Effect of date palm and polypropylene fibers on the characteristics of self-compacting concretes: Comparative study. Frat. Ed Integrità Strutt. 2023, 17, 31–50. [Google Scholar] [CrossRef]

- Ahmad, J.; Burduhos-Nergis, D.D.; Arbili, M.M.; Alogla, S.M.; Majdi, A.; Deifalla, A.F. A review on failure modes and cracking behaviors of polypropylene fibers reinforced concrete. Buildings 2022, 12, 1951. [Google Scholar] [CrossRef]

- Osman, K.M.; ALyamany, M.A.; Tawab, A.; Thabet, A. Effect of Using Natural and Polypropylene Fibers on Fresh and Hardened Concrete Properties. J. Mech. Civ. Eng. 2020, 17, 25–36. [Google Scholar]

- Abdelmajeed Labib, W. Utilisation of date palm fibres in cement-based composites: A feasibility study. In Proceedings of the IOP Conference Series: Materials Science And Engineering, Tatranske Matliare, High Tatras, Slovakia, 15 August 2019; p. 012028. [Google Scholar]

- Al-Sulaiman, F.A. Mechanical properties of date palm fiber reinforced composites. Appl. Compos. Mater. 2002, 9, 369–377. [Google Scholar] [CrossRef]

- Labib, W.A. Plant-based fibres in cement composites: A conceptual framework. J. Eng. Fibers Fabr. 2022, 17, 15589250221078922. [Google Scholar] [CrossRef]

- Labib, W.A. Evaluation of hybrid fibre-reinforced concrete slabs in terms of punching shear. Constr. Build. Mater. 2020, 260, 119763. [Google Scholar] [CrossRef]

- Aît-Mokhtar, A.; Belarbi, R.; Benboudjema, F.; Burlion, N.; Capra, B.; Carcassès, M.; Colliat, J.-B.; Cussigh, F.; Deby, F.; Jacquemot, F. Experimental investigation of the variability of concrete durability properties. Cem. Concr. Res. 2013, 45, 21–36. [Google Scholar] [CrossRef]

- Amran, M.; Al-Fakih, A.; Chu, S.; Fediuk, R.; Haruna, S.; Azevedo, A.; Vatin, N. Long-term durability properties of geopolymer concrete: An in-depth review. Case Stud. Constr. Mater. 2021, 15, e00661. [Google Scholar] [CrossRef]

- ASTM C 150; Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C33/C33M; Standard Specification for Concrete Aggregates. ASTM International: West Conshohocken, PA, USA, 2023.

- BS EN 14889-2; Fibres for Concrete—Polymer Fibres. Definitions, Specifications and Conformity. British Standard Institution: London, UK, 2006.

- ASTM C1116; Standard Specification for Fiber-Reinforced Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM 211.1R; Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. American Concrete Institute: Farmington Hills, MI, USA, 1991.

- ASTM C192; Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM Internationa: West Conshohocken, PA, USA, 2018.

- ASTM C143/143M; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C138/C138M; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- BS EN 12390-3:2009; Testing Hardened Concrete. Compressive Strength of Test Specimens. British Standards Institution: London, UK, 2009.

- BS EN 12390-6; Testing Hardened Concrete-Tensile Splitting Strength Of Test Specimens. British Standards Institution: London, UK, 2009.

- ASTM C293; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading). ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C1723; Standard Guide for Examination of Hardened Concrete Using Scanning Electron Microscopy. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D4284; Standard Test Method for Determining Pore Volume Distribution of Catalysts by Mercury Intrusion Porosimetry. ASTM International: West Conshohocken, PA, USA, 2003.

- Acosta-Calderon, S.; Gordillo-Silva, P.; García-Troncoso, N.; Bompa, D.V.; Flores-Rada, J. Comparative evaluation of sisal and polypropylene fiber reinforced concrete properties. Fibers 2022, 10, 31. [Google Scholar] [CrossRef]

- Rachedi, M.; Kriker, A. Thermal properties of plaster reinforced with date palm fibers. Civ. Environ. Eng. 2020, 16, 259–266. [Google Scholar] [CrossRef]

- Vantadori, S.; Carpinteri, A.; Zanichelli, A. Lightweight construction materials: Mortar reinforced with date-palm mesh fibres. Theor. Appl. Fract. Mech. 2019, 100, 39–45. [Google Scholar] [CrossRef]

- Boumhaout, M.; Boukhattem, L.; Hamdi, H.; Benhamou, B.; Ait Nouh, F. Thermomechanical characterization of a bio-composite building material: Mortar reinforced with date palm fibers mesh. Constr. Build. Mater. 2017, 135, 241–250. [Google Scholar] [CrossRef]

- Adamu, M.; Ibrahim, Y.E.; Ahmed, O.S.; Drmosh, Q.A. Mechanical performance of date palm fiber-reinforced concrete modified with nano-activated carbon. Nanotechnol. Rev. 2023, 12, 20220564. [Google Scholar] [CrossRef]

- Abaeian, R.; Behbahani, H.P.; Moslem, S.J. Effects of high temperatures on mechanical behavior of high strength concrete reinforced with high performance synthetic macro polypropylene (HPP) fibres. Constr. Build. Mater. 2018, 165, 631–638. [Google Scholar] [CrossRef]

- Althoey, F.; Hakeem, I.Y.; Hosen, M.A.; Qaidi, S.; Isleem, H.F.; Hadidi, H.; Shahapurkar, K.; Ahmad, J.; Ali, E. Behavior of concrete reinforced with date palm fibers. Materials 2022, 15, 7923. [Google Scholar] [CrossRef]

- Blazy, J.; Blazy, R. Polypropylene fiber reinforced concrete and its application in creating architectural forms of public spaces. Case Stud. Constr. Mater. 2021, 14, e00549. [Google Scholar] [CrossRef]

- Ozerkan, N.G.; Ahsan, B.; Mansour, S.; Iyengar, S.R. Mechanical performance and durability of treated palm fiber reinforced mortars. Int. J. Sustain. Built Environ. 2013, 2, 131–142. [Google Scholar] [CrossRef]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Hannawi, K.; Bian, H.; Prince-Agbodjan, W.; Raghavan, B. Effect of different types of fibers on the microstructure and the mechanical behavior of ultra-high performance fiber-reinforced concretes. Compos. Part B Eng. 2016, 86, 214–220. [Google Scholar] [CrossRef]

| Oxides/Property | Composition/Value |

|---|---|

| SiO2 (%) | 19.71 |

| Al2O3 (%) | 5.39 |

| Fe2O3 (%) | 3.40 |

| CaO (%) | 65.18 |

| SO3 (%) | 3.51 |

| K2O (%) | 1.22 |

| MgO (%) | 0.91 |

| TiO2 (%) | 0.24 |

| Na2O (%) | 0.17 |

| MnO (%) | 0.18 |

| P2O5 (%) | 0.09 |

| Specific gravity | 3.15 |

| Bulk density (kg/m3) | 1440 |

| Properties | Values | |

|---|---|---|

| PPF 1 | DPF 2 | |

| Appearance/Color | Colorless | Light to dark brown |

| Apparent density (kg/m3) | 910 | 877.43 ± 4.8 |

| Diameter (mm) | 1.0 ± 5% | 0.2–1.0 |

| Fiber length (mm) | 56 ± 5% | 20–30 |

| Aspect ratio | 56 ± 5% | 30–100 |

| Tensile strength (MPa) | 500 ± 7.5% | 203.24 ± 30 |

| Elastic modulus (GPa) | 10.0 ± 10% | 3.35 ± 1.5 |

| Elongation at break (%) | 21 ± 1.5 | 13.5 ± 2 |

| Melting point (°C) | 160–165 | − |

| Mix ID | Variables (%) | Quantities of Materials in kg/m3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| DPF | PPF | Cement | Fine Agg | Coarse Agg | DPF | PPF | Water | S.P | |

| M0D0P (Control) | 0 | 0 | 420 | 755 | 975 | 0.00 | 0.00 | 157.25 | 4.20 |

| M0.5D0P | 0.5 | 0 | 420 | 755 | 975 | 2.10 | 0.00 | 157.25 | 4.20 |

| M0.25D0.25P | 0.25 | 0.25 | 420 | 755 | 975 | 1.05 | 1.05 | 157.25 | 4.20 |

| M0D0.5P | 0 | 0.5 | 420 | 755 | 975 | 0.00 | 2.10 | 157.25 | 4.20 |

| M0.5D0.5P | 0.5 | 0.5 | 420 | 755 | 975 | 2.10 | 2.10 | 157.25 | 4.20 |

| M0.5D1P | 0.5 | 1 | 420 | 755 | 975 | 2.10 | 4.20 | 157.25 | 4.20 |

| M0.25D0.5P | 0.25 | 0.5 | 420 | 755 | 975 | 1.05 | 2.10 | 157.25 | 4.20 |

| M1D0.5P | 1 | 0.5 | 420 | 755 | 975 | 4.20 | 2.10 | 157.25 | 4.20 |

| M0.75D0.25P | 0.75 | 0.25 | 420 | 755 | 975 | 3.15 | 1.05 | 157.25 | 4.20 |

| M0.75D0.75P | 0.75 | 0.75 | 420 | 755 | 975 | 3.15 | 3.15 | 157.25 | 4.20 |

| Factor/Mix | M0D0P (Control) | M0.5D0P | M0D0.5P | M0.5D0.5P | M0.5D1P | M1D0.5P |

|---|---|---|---|---|---|---|

| Total Intrusion Volume | 0.0485 mL/g | 0.0558 mL/g | 0.0530 mL/g | 0.0616 mL/g | 0.0757 mL/g | 0.0833 mL/g |

| Total Pore Area | 7.604 sq-m/g | 8.621 sq-m/g | 7.809 sq-m/g | 10.183 sq-m/g | 10.122 sq-m/g | 10.998 sq-m/g |

| Median Pore Diameter (Volume) | 0.0464 μm | 0.0476 μm | 0.0441 μm | 0.0491 μm | 0.0554 μm | 0.0550 μm |

| Median Pore Diameter (Area) | 0.0114 μm | 0.0137 μm | 0.0140 μm | 0.0105 μm | 0.0122 μm | 0.0119 μm |

| Average Pore Diameter (4 v/A) | 0.0255 μm | 0.0259 μm | 0.0271 μm | 0.0242 μm | 0.0299 μm | 0.0303 μm |

| Bulk Density | 2.3112 g/mL | 2.2149 g/mL | 2.2837 g/mL | 2.3081 g/mL | 2.1994 g/mL | 2.1005 g/mL |

| Apparent (Skeletal) Density | 2.6028 g/mL | 2.5270 g/mL | 2.5978 g/mL | 2.6906 g/mL | 2.6388 g/mL | 2.5460 g/mL |

| Porosity | 11.20% | 12.35% | 12.09% | 14.22% | 16.65% | 17.50% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamu, M.; Labib, W.A.; Ibrahim, Y.E.; Alanazi, H. Mechanical Behavior and Durability Performance of Concrete Reinforced with Hybrid Date Palm and Polypropylene Polymer Fibers. Polymers 2025, 17, 1350. https://doi.org/10.3390/polym17101350

Adamu M, Labib WA, Ibrahim YE, Alanazi H. Mechanical Behavior and Durability Performance of Concrete Reinforced with Hybrid Date Palm and Polypropylene Polymer Fibers. Polymers. 2025; 17(10):1350. https://doi.org/10.3390/polym17101350

Chicago/Turabian StyleAdamu, Musa, Wafa Abdelmajeed Labib, Yasser E. Ibrahim, and Hani Alanazi. 2025. "Mechanical Behavior and Durability Performance of Concrete Reinforced with Hybrid Date Palm and Polypropylene Polymer Fibers" Polymers 17, no. 10: 1350. https://doi.org/10.3390/polym17101350

APA StyleAdamu, M., Labib, W. A., Ibrahim, Y. E., & Alanazi, H. (2025). Mechanical Behavior and Durability Performance of Concrete Reinforced with Hybrid Date Palm and Polypropylene Polymer Fibers. Polymers, 17(10), 1350. https://doi.org/10.3390/polym17101350