Stacking Sequence Effect of Basalt/Carbon Hybrid Laminated Composites on Solid Particle Erosion Behavior: From Ambient to Elevated Temperatures

Abstract

:1. Introduction

2. Materials and Methods

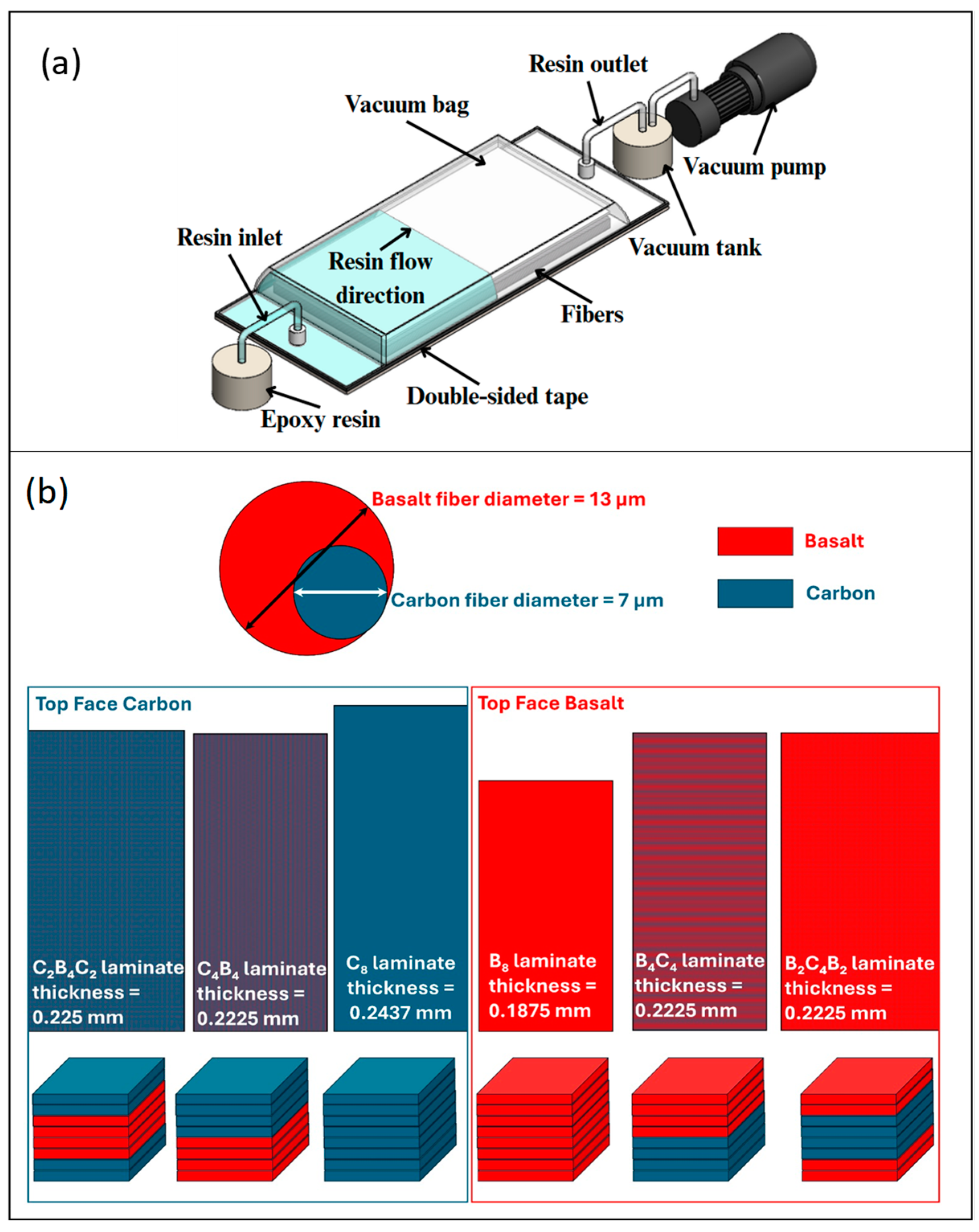

2.1. Materials and Manufacturing of the Composites

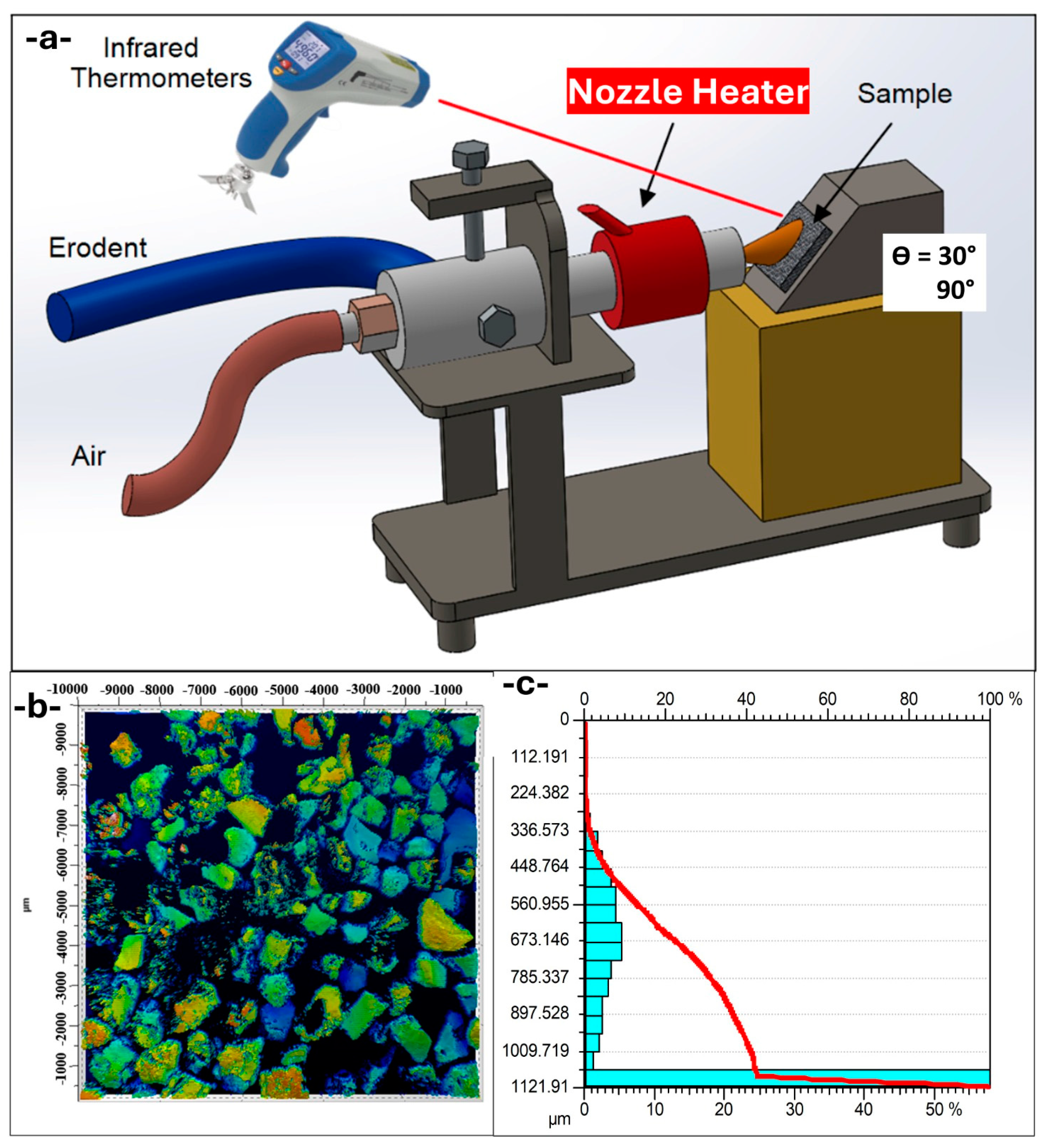

2.2. Solid Particle Erosion Tests

2.3. Erosion Crater Depth Analysis

3. Results

3.1. Solid Particle Erosion Results

3.2. Erosion Crater Depth and Roughness Characterization

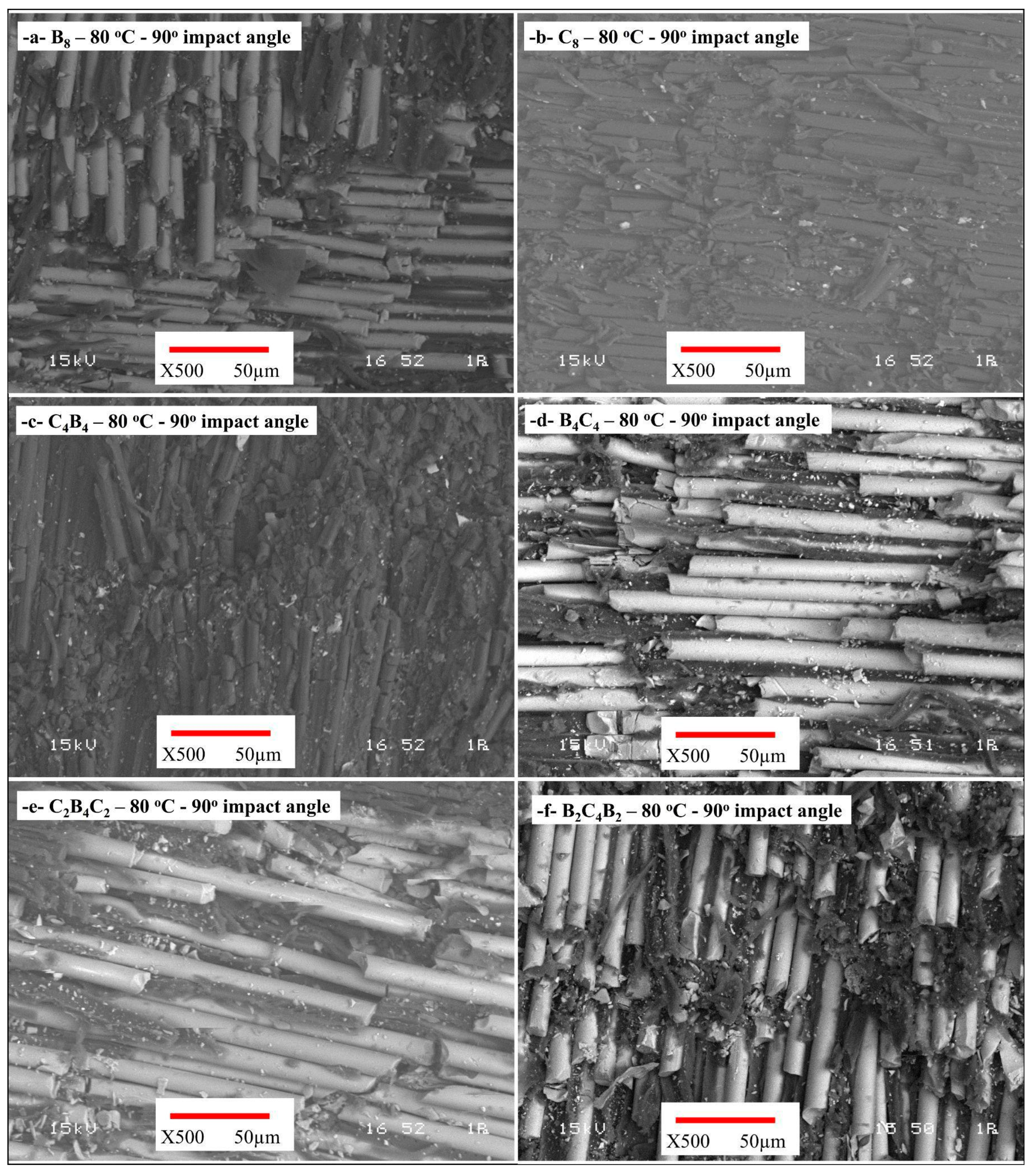

3.3. Damage Mechanisms of Erosion Craters (SEM)

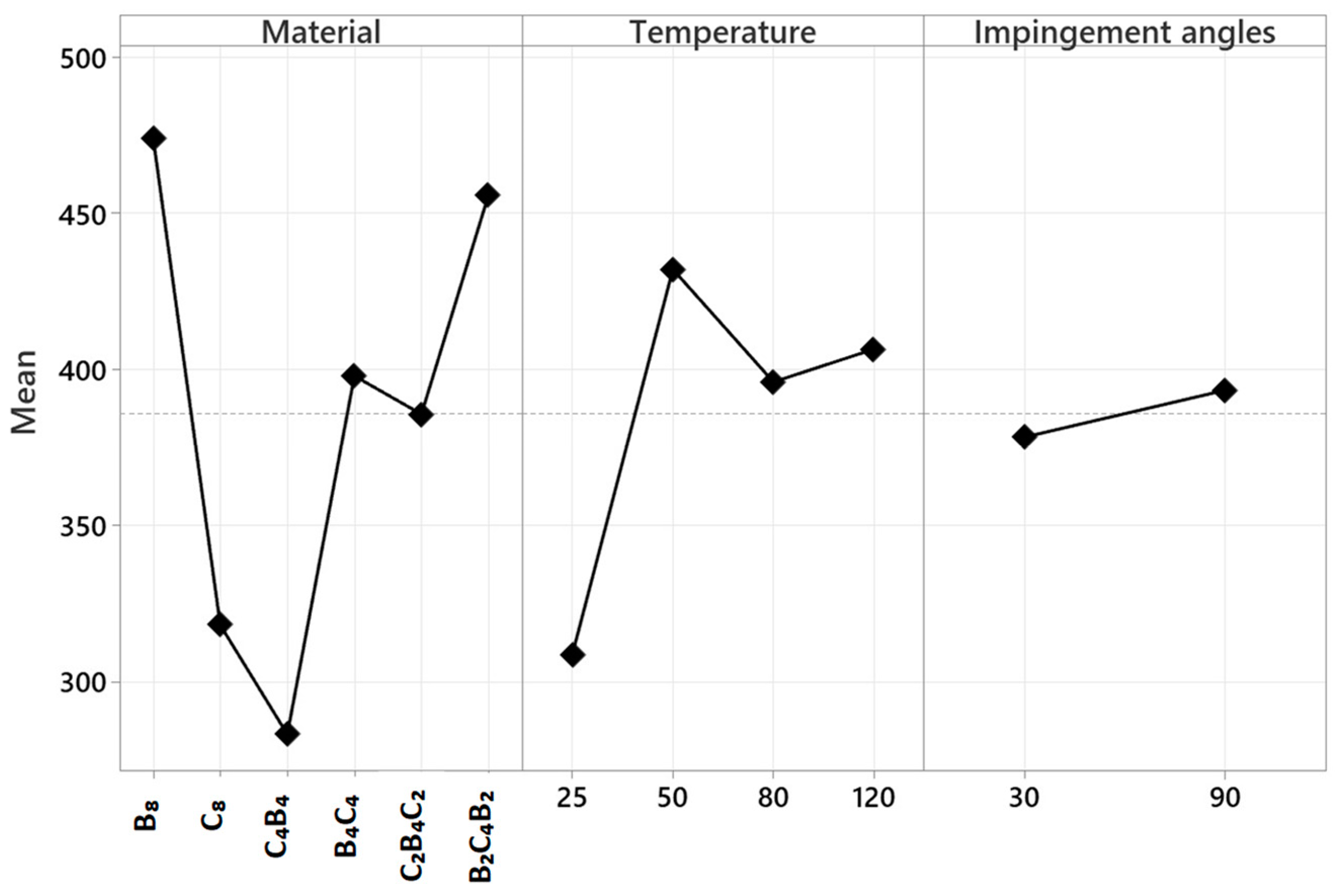

3.4. Factorial Design and Analysis of Variance (ANOVA)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FRP | Fiber-reinforced polymer |

| SEM | Scanning electron microscope |

| ANOVA | Analysis of Variance |

References

- Bonu, V.; Barshilia, H.C. High-Temperature Solid Particle Erosion of Aerospace Components: Its Mitigation Using Advanced Nanostructured Coating Technologies. Coatings 2022, 12, 1979. [Google Scholar] [CrossRef]

- Vera-Cardenas, E.E.; Mendoza-Mendoza, J.C.; Martinez-Perez, A.I.; Ledesma-Ledesma, S.; Rubio-González, C.; Vite-Torres, M. Solid particle erosive wear study of polymer composite materials for wind turbine applications. Polym. Compos. 2021, 42, 1988–1999. [Google Scholar] [CrossRef]

- Choudhary, M.; Singh, T.; Dwivedi, M.; Patnaik, A. Waste marble dust-filled glass fiber-reinforced polymer composite Part I: Physical, thermomechanical, and erosive wear properties. Polym. Compos. 2019, 40, 4113–4124. [Google Scholar] [CrossRef]

- Tejyan, S.; Patnaik, A. Erosive wear behavior and dynamic mechanical analysis of textile material reinforced polymer composites. Polym. Compos. 2017, 38, 2201–2211. [Google Scholar] [CrossRef]

- Okutan, M.S.; Genel, K. Effect of inner reinforcement on the torsional load-bearing performance of holed aluminum/composite thin-walled tubes. Thin-Walled Struct. 2025, 208, 112805. [Google Scholar] [CrossRef]

- Ekşi, S.; Salman, L.; Beşiroğlu, M.F.; Memişoğlu, M. Open hole strength and damage behavior of GFRP and CFRP composites. Eng. Fail. Anal. 2025, 176, 109584. [Google Scholar] [CrossRef]

- Baysalli, O.C.; Cambaz, A.; Görgülü, Y.F.; Uluoğlu, A.; Harman, U.U. Repair Analysis of Overlay Woven Fabric CFRP Laminates. Sak. Univ. J. Sci. 2024, 28, 333–343. [Google Scholar] [CrossRef]

- Kanberoğlu, B.; Teşneli, A.Y. Shielding Performance of Composite Materials Used in Air Vehicles. Sak. Univ. J. Sci. 2021, 25, 554–562. [Google Scholar] [CrossRef]

- Eren, Ş.; Çağlar, Ö.; Gökçe, N.; Subaşı, A.; Subaşı, S. Effect of Grain Distribution on Resin Consumption and Mechanical Performance of GRP Pipes. Sak. Univ. J. Sci. 2021, 25, 1136–1147. [Google Scholar] [CrossRef]

- Mishnev, M.; Korolev, A.; Ulrikh, D.; Gorechneva, A.; Sadretdinov, D.; Grinkevich, D. Solid Particle Erosion of Filled and Unfilled Epoxy Resin at Room and Elevated Temperatures. Polymers 2023, 15, 1. [Google Scholar] [CrossRef]

- Usha, P.H.; Rani, B.M.; Rajaprakash, N.; Mohan, M.; Prasad, M.A. Study on thermal and erosive wear behaviour of hard powders filled glass-epoxy composite. Mater. Today Proc. 2020, 27, 2011–2016. [Google Scholar] [CrossRef]

- Mahesha, C.R.; Shivarudraiah, R.C.C.; Suprabha, R. Effect of Nano TiO2/clay on the Erosive Wear Behavior of Basalt-Epoxy Hybrid Composites at Elevated Temperatures. Appl. Mech. Mater. 2015, 40, 813–814. [Google Scholar] [CrossRef]

- Biswas, S.; Satapathy, A. Tribo-performance analysis of red mud filled glass-epoxy composites using Taguchi experimental design. Mater. Des. 2009, 30, 2841–2853. [Google Scholar] [CrossRef]

- Padhi, P.K.; Alok, S. Prediction and Simulation of Erosion Wear Behavior of Glass-Epoxy Composites Filled with Blast Furnace Slag. Adv. Mater. Res. 2012, 585, 549–553. [Google Scholar] [CrossRef]

- Panda, P.; Mantry, S.; Mohapatra, S.; Singh, S.; Satapathy, A. A study on erosive wear analysis of glass fiber–epoxy–AlN hybrid composites. J. Compos. Mater. 2012, 48, 107–118. [Google Scholar] [CrossRef]

- Mahapatra, S.K.; Satapathy, A. Development of machine learning models for the prediction of erosion wear of hybrid composites. Polym. Compos. 2024, 45, 7950–7966. [Google Scholar] [CrossRef]

- Jamali, N.; Khosravi, H.; Rezvani, A.; Tohidlou, E.; Poulis, J. Viscoelastic and dry-sliding wear properties of basalt fiber-reinforced composites based on a surface-modified graphene oxide/epoxy matrix. J. Ind. Text. 2019, 50, 939–953. [Google Scholar] [CrossRef]

- Drensky, G.; Hamed, A.; Tabakoff, W.; Abot, J. Experimental investigation of polymer matrix reinforced composite erosion characteristics. Wear 2011, 270, 146–151. [Google Scholar] [CrossRef]

- Wu, Y.; Zeng, M.; Xu, Q.; Hou, S.; Jin, H.; Fan, L. Effects of glass-to-rubber transition of thermosetting resin matrix on the friction and wear properties of friction materials. Tribol. Int. 2012, 54, 51–57. [Google Scholar] [CrossRef]

- Pihtili, H. An experimental investigation of wear of glass fibre–epoxy resin and glass fibre-polyester resin composite materials. Eur. Polym. J. 2009, 45, 149–154. [Google Scholar] [CrossRef]

- Boggarapu, V.; Gujjala, R.; Shakuntla, O. A critical review on erosion wear characteristics of polymer matrix composites. Mater. Res. Express 2020, 7, 022002. [Google Scholar] [CrossRef]

- Ekşi, S.; Danyildiz, F.E.; Özsoy, N.; Özsoy, M. Tensile, bending, and impact properties of laminated carbon/aramid/glass hybrid fiber composites. Mater. Test 2023, 65, 1826–1835. [Google Scholar] [CrossRef]

- Erkliğ, A.; Çakır, M.V.; Bozkurt, Ö.Y. Nano Clay Additive Effect on Shear Strength of GFRP Joints. Sak. Univ. J. Sci. 2019, 23, 1115–1122. [Google Scholar] [CrossRef]

- Öztürk, H.O.; Kahraman, Y. Effects of glass fiber reinforcement to tensile strength in epoxy matrix granular composite materials. Sak. Univ. J. Sci. 2019, 23, 736–743. [Google Scholar] [CrossRef]

- Özsoy, M.İ. Investigation of the energy absorption behavior and damage mechanisms of aramid/carbon/jute fiber hybrid epoxy composites. Polym. Compos. 2024, 45, 11515–11531. [Google Scholar] [CrossRef]

- Özsoy, M.İ.; Fidan, S.; Bora, M.Ö.; Ürgün, S. Understanding the Damage Mechanisms of Basalt/Carbon Fiber Hybrid Composites Under Quasi-Static and Dynamic Loadings. Polymers 2025, 17, 866. [Google Scholar] [CrossRef] [PubMed]

- Jesthi, D.K.; Mandal, P.; Rout, A.K.; Nayak, R.K. Enhancement of mechanical and specific wear properties of glass/carbon fiber reinforced polymer hybrid composite. Procedia Manuf. 2018, 20, 536–541. [Google Scholar] [CrossRef]

- Mohanty, S.S.; Rout, A.K.; Jesthi, D.K.; Routara, B.C.; Nayak, R.K. Evaluation of mechanical and wear performance of glass/carbon fiber reinforced polymer hybrid composite. Mater. Today Proc. 2018, 5, 19854–19861. [Google Scholar] [CrossRef]

- Saroj, S.; Nayak, R.K. Improvement of Mechanical and Wear Resistance of Natural Fiber Reinforced Polymer Composites Through Synthetic Fiber (Glass/Carbon) Hybridization. Trans. Indian Inst. Met. 2021, 74, 2651–2658. [Google Scholar] [CrossRef]

- Sanman, S.; Manjunath, A.; Prashanth, K.P.; Shadakshari, R.; Sunil, S.K. An experimental study on two body abrasive wear behavior of natural fiber reinforced hybrid polymer matrix composites using Taguchi analysis. Mater. Today Proc. 2023, 72, 2021–2026. [Google Scholar] [CrossRef]

- Sathish, T.; Mohanavel, V.; Raja, T.; Djearamane, S.; Velmurugan, P.; Nasif, O.; Alfarraj, S.; Wong, L.S.; Manikandan, V.; Ravichandran, M. Influence of Compression Molding Process Parameters in Mechanical and Tribological Behavior of Hybrid Polymer Matrix Composites. Polymers 2021, 13, 4195. [Google Scholar] [CrossRef]

- Antil, S.K.; Antil, P.; Singh, S.; Kumar, A.; Pruncu, C.I. Artificial Neural Network and Response Surface Methodology Based Analysis on Solid Particle Erosion Behavior of Polymer Matrix Composites. Materials 2020, 13, 1381. [Google Scholar] [CrossRef]

- Mahapatra, S.K.; Satapathy, A. Parametric appraisal and wear prediction of hybrid composites using an integrated soft computing approach. Polym. Compos. 2024, 45, 10155–10171. [Google Scholar] [CrossRef]

- ASTM G76-18; Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement Using Gas Jets. ASTM International: West Conshohocken, PA, USA, 2018.

- Avcu, E.; Fidan, S.; Bora, M.Ö.; Çoban, O.; Taşkıran, I.; Sınmazçelik, T. Solid particle erosive Wear behavior of glass mat reinforced PPS composites: Influence of erodent particle size, pressure, particle impingement angle, and velocity. Adv. Polym. Technol. 2013, 32, E386–E398. [Google Scholar] [CrossRef]

- ISO 25178-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Areal. Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 4287:1997; Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 1997.

| Exp. No | Sequence | Temperature (°C) | Impingement Angles (°) | Erosion Rate (mg/g * 1000) | Exp. No | Sequence | Temperature (°C) | Impingement Angles (°) | Erosion Rate (mg/g * 1000) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | B8 | 25 | 30 | 440.4 | 25 | B4C4 | 25 | 30 | 343.6 |

| 2 | B8 | 25 | 90 | 432.4 | 26 | B4C4 | 25 | 90 | 283.1 |

| 3 | B8 | 50 | 30 | 477.3 | 27 | B4C4 | 50 | 30 | 481.3 |

| 4 | B8 | 50 | 90 | 531.1 | 28 | B4C4 | 50 | 90 | 380.4 |

| 5 | B8 | 80 | 30 | 501.0 | 29 | B4C4 | 80 | 30 | 461.0 |

| 6 | B8 | 80 | 90 | 464.9 | 30 | B4C4 | 80 | 90 | 458.7 |

| 7 | B8 | 120 | 30 | 544.9 | 31 | B4C4 | 120 | 30 | 433.3 |

| 8 | B8 | 120 | 90 | 400.0 | 32 | B4C4 | 120 | 90 | 341.0 |

| 9 | C8 | 25 | 30 | 176.9 | 33 | C2B4C2 | 25 | 30 | 233.3 |

| 10 | C8 | 25 | 90 | 284.0 | 34 | C2B4C2 | 25 | 90 | 319.1 |

| 11 | C8 | 50 | 30 | 282.7 | 35 | C2B4C2 | 50 | 30 | 383.1 |

| 12 | C8 | 50 | 90 | 428.9 | 36 | C2B4C2 | 50 | 90 | 531.1 |

| 13 | C8 | 80 | 30 | 205.3 | 37 | C2B4C2 | 80 | 30 | 392.4 |

| 14 | C8 | 80 | 90 | 372.0 | 38 | C2B4C2 | 80 | 90 | 410.0 |

| 15 | C8 | 120 | 30 | 252.9 | 39 | C2B4C2 | 120 | 30 | 368.9 |

| 16 | C8 | 120 | 90 | 541.3 | 40 | C2B4C2 | 120 | 90 | 446.2 |

| 17 | C4B4 | 25 | 30 | 200.0 | 41 | B2C4B2 | 25 | 30 | 373.8 |

| 18 | C4B4 | 25 | 90 | 207.1 | 42 | B2C4B2 | 25 | 90 | 408.4 |

| 19 | C4B4 | 50 | 30 | 284.9 | 43 | B2C4B2 | 50 | 30 | 576.9 |

| 20 | C4B4 | 50 | 90 | 265.8 | 44 | B2C4B2 | 50 | 90 | 560.4 |

| 21 | C4B4 | 80 | 30 | 308.0 | 45 | B2C4B2 | 80 | 30 | 491.6 |

| 22 | C4B4 | 80 | 90 | 310.0 | 46 | B2C4B2 | 80 | 90 | 375.6 |

| 23 | C4B4 | 120 | 30 | 336.4 | 47 | B2C4B2 | 120 | 30 | 526.2 |

| 24 | C4B4 | 120 | 90 | 352.0 | 48 | B2C4B2 | 120 | 90 | 333.8 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS |

|---|---|---|---|---|---|

| Model | 47 | 518.709 | 100.00% | 518.709 | 11.036 |

| Linear | 9 | 330.234 | 63.66% | 330.234 | 36.693 |

| Material | 5 | 223.916 | 43.17% | 223.916 | 44.783 |

| Temperature | 3 | 103.599 | 19.97% | 103.599 | 34.533 |

| Impingement angles | 1 | 2718 | 0.52% | 2718 | 2718 |

| 2-Way Interactions | 23 | 149.506 | 28.82% | 149.506 | 6500 |

| Material × Temperature | 15 | 51.382 | 9.91% | 51.382 | 3425 |

| Material × Impingement angles | 5 | 94.531 | 18.22% | 94.531 | 18.906 |

| Temperature × Impingement angles | 3 | 3593 | 0.69% | 3593 | 1198 |

| 3-Way Interactions | 15 | 38.969 | 7.51% | 38.969 | 2598 |

| Material × Temperature × Impingement angles | 15 | 38.969 | 7.51% | 38.969 | 2598 |

| Error | 0 | 0 | 0 | 0 | 0 |

| Total | 47 | 518.709 | 100.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Özsoy, M.İ.; Fidan, S.; Bora, M.Ö.; Ürgün, S. Stacking Sequence Effect of Basalt/Carbon Hybrid Laminated Composites on Solid Particle Erosion Behavior: From Ambient to Elevated Temperatures. Polymers 2025, 17, 1349. https://doi.org/10.3390/polym17101349

Özsoy Mİ, Fidan S, Bora MÖ, Ürgün S. Stacking Sequence Effect of Basalt/Carbon Hybrid Laminated Composites on Solid Particle Erosion Behavior: From Ambient to Elevated Temperatures. Polymers. 2025; 17(10):1349. https://doi.org/10.3390/polym17101349

Chicago/Turabian StyleÖzsoy, Mehmet İskender, Sinan Fidan, Mustafa Özgür Bora, and Satılmış Ürgün. 2025. "Stacking Sequence Effect of Basalt/Carbon Hybrid Laminated Composites on Solid Particle Erosion Behavior: From Ambient to Elevated Temperatures" Polymers 17, no. 10: 1349. https://doi.org/10.3390/polym17101349

APA StyleÖzsoy, M. İ., Fidan, S., Bora, M. Ö., & Ürgün, S. (2025). Stacking Sequence Effect of Basalt/Carbon Hybrid Laminated Composites on Solid Particle Erosion Behavior: From Ambient to Elevated Temperatures. Polymers, 17(10), 1349. https://doi.org/10.3390/polym17101349