Mechanical Performance of Biocomposites Based on Straw Fiber Self-Reinforced Plasticized Flours of Bread Wheat Grown with Different Nitrogen Fertilization Management Strategies

Abstract

1. Introduction

2. Materials and Methods

2.1. Origin of the Wheat Straw: The Field Trial and Crop N Fertilization Treatments

2.2. Origin of the Wheat Flour Used for Plasticization

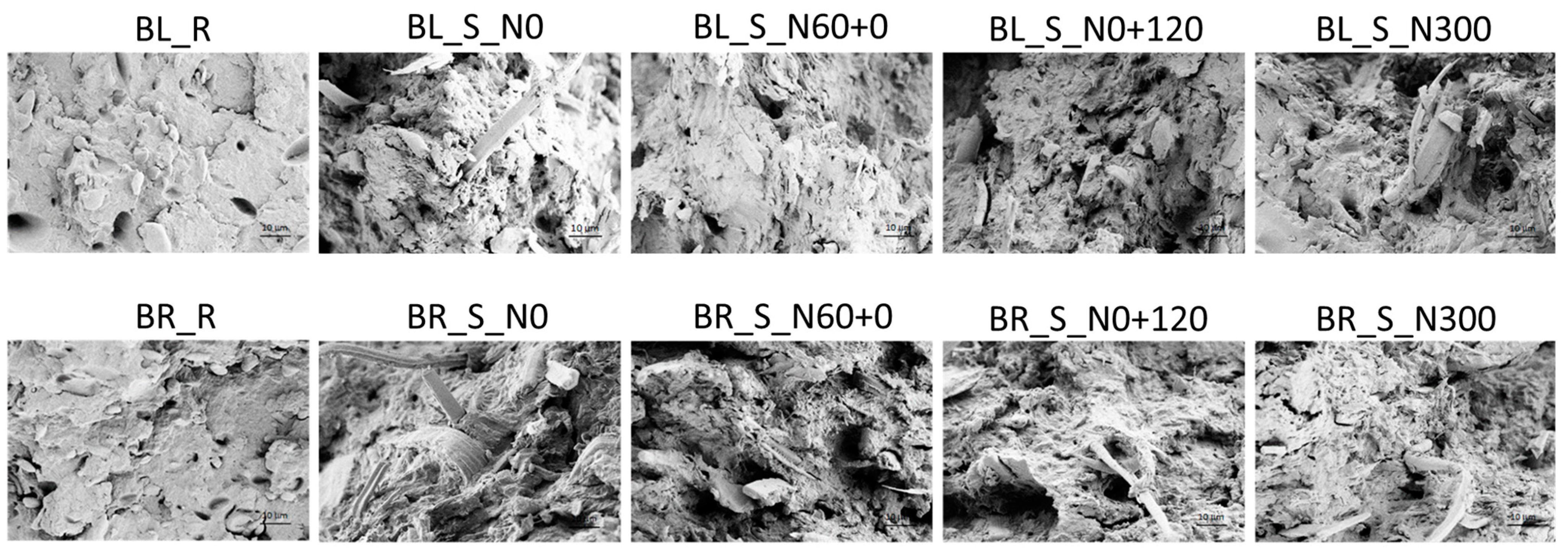

2.3. Crop Vegetative Growth, Straw Sampling, Composition and Fiber Structure

2.4. X-Ray Diffraction Analysis of Flours and Straws

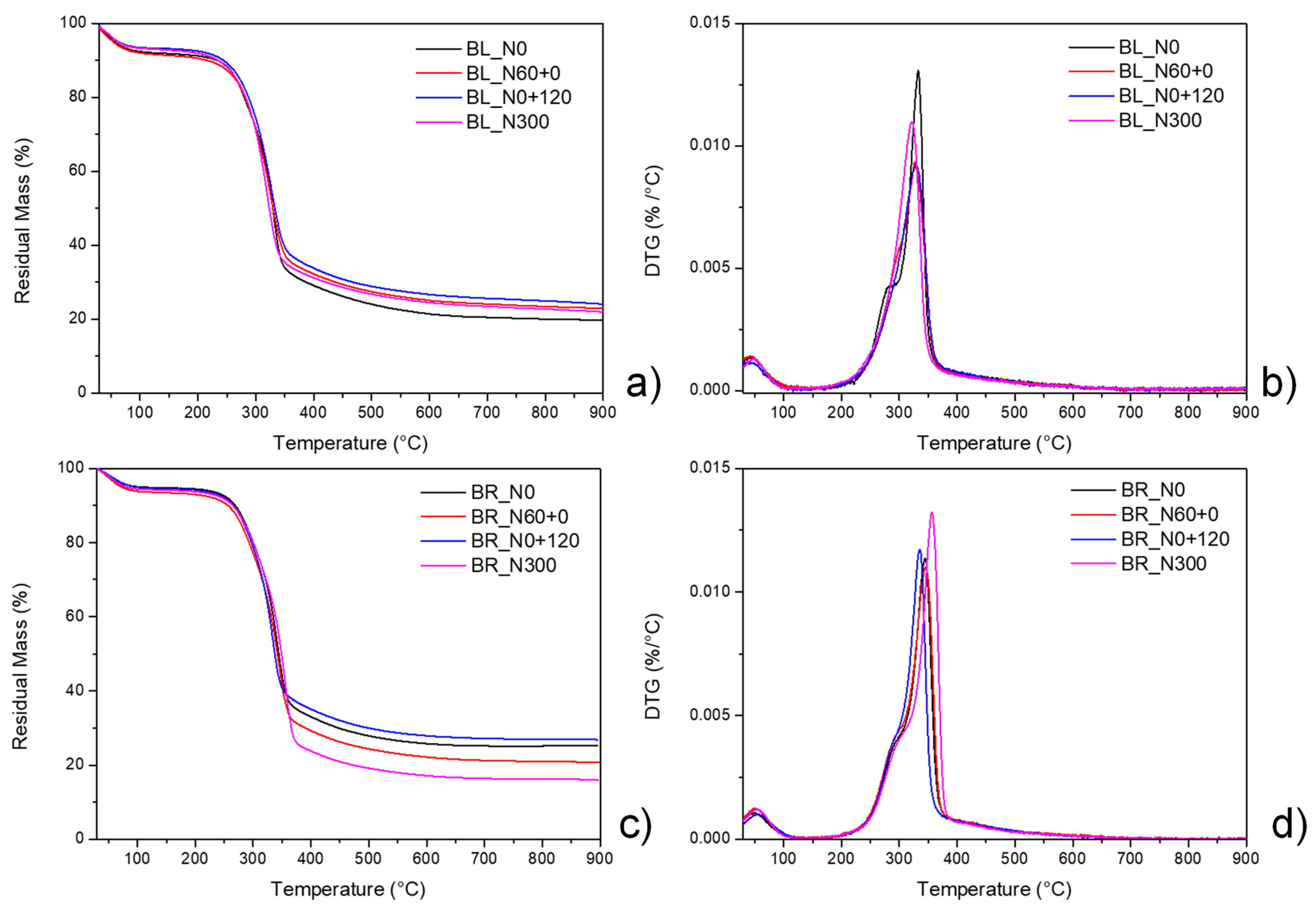

2.5. Thermal Analysis of Wheat Straw

2.6. Plasticization, Injection Molding and Measurements on Bulk Samples

2.7. Tensile Properties of Bulk Samples

2.8. Statistical Analysis

3. Results

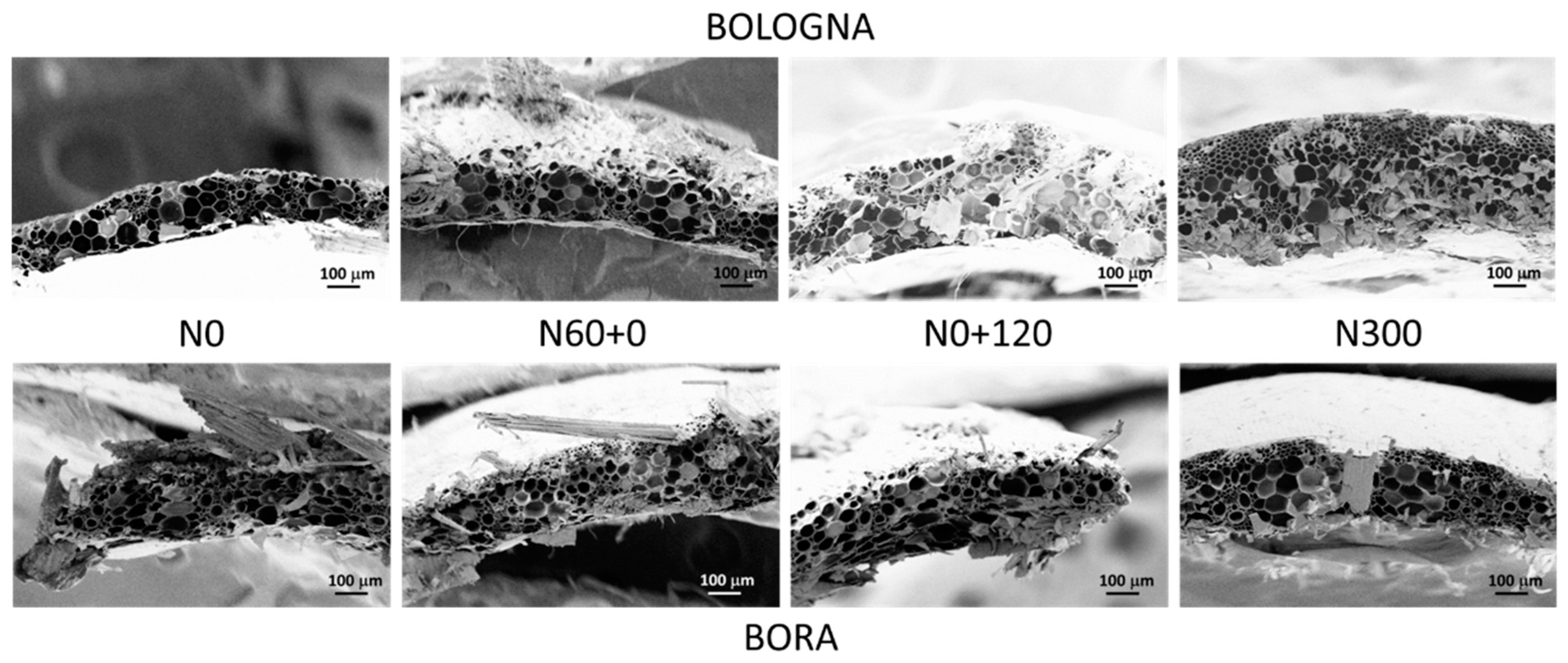

3.1. Crop Vegetative Growth, Straw Stem Morphology and Microstructure

3.2. Straw Composition

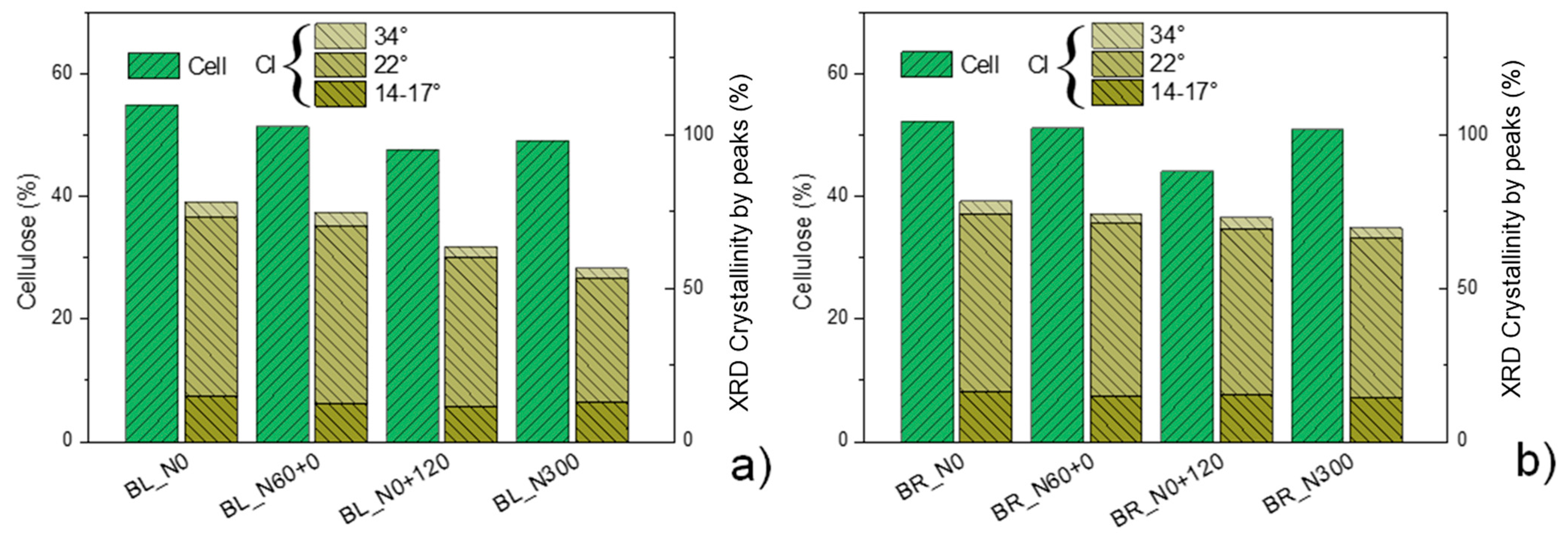

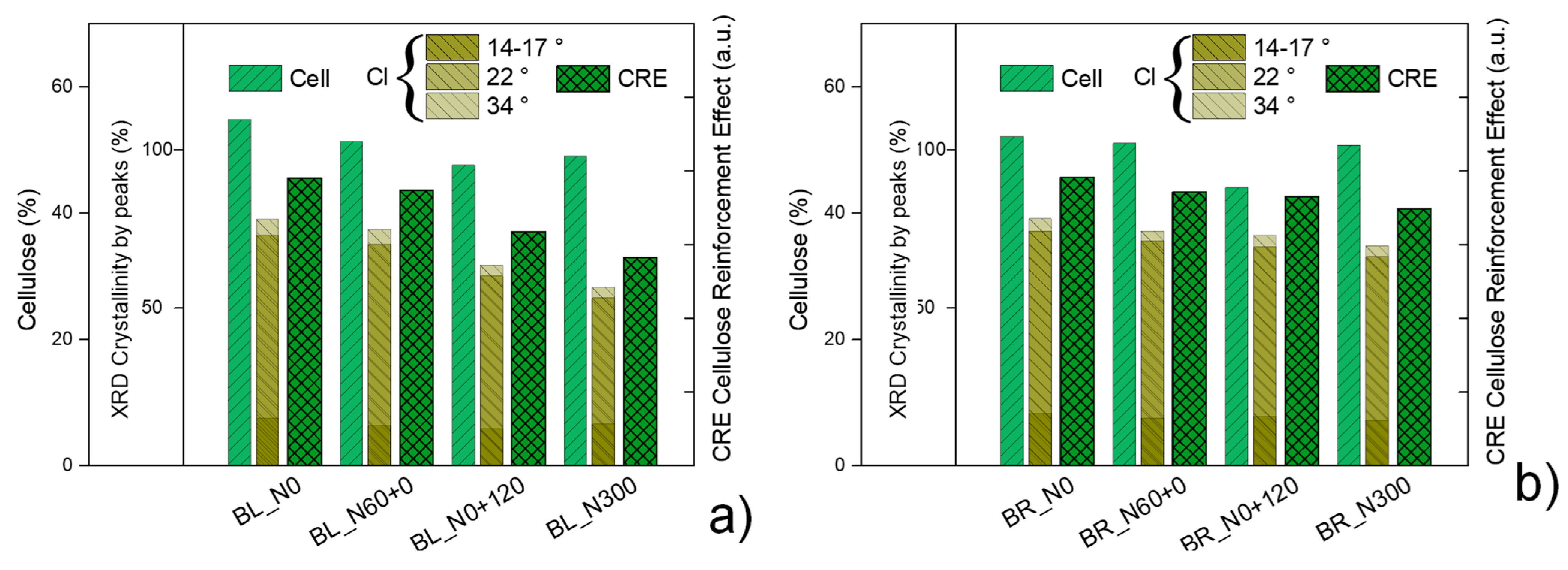

3.3. X-Ray Diffraction Analysis of Straw

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Bioplastics e.V. Bioplastics Market Development Update. 2023. Available online: https://docs.european-bioplastics.org/publications/market_data/2023/EUBP_Market_Data_Report_2023.pdf (accessed on 21 October 2024).

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Coppola, G.; Gaudio, M.T.; Lopresto, C.G.; Calabro, V.; Curcio, S.; Chakraborty, S. Bioplastic from Renewable Biomass: A Facile Solution for a Greener Environment. Earth Syst. Environ. 2021, 5, 231–251. [Google Scholar] [CrossRef]

- FAO. Wheat Production cc3020en_Wheat. Available online: https://openknowledge.fao.org/server/api/core/bitstreams/99104ca7-2045-4299-99f2-2a866bbbfebb/content (accessed on 21 October 2024).

- Leblanc, N.; Saiah, R.; Beucher, E.; Gattin, R.; Castandet, M.; Saiter, J.M. Structural investigation and thermal stability of new extruded wheat flour based polymeric materials. Carbohydr. Polym. 2008, 73, 548–557. [Google Scholar] [CrossRef] [PubMed]

- Puglia, D.; Dominici, F.; Kenny, J.M.; Santulli, C.; Governatori, C.; Tosti, G.; Benincasa, P. Tensile Behavior of Thermoplastic Films from Wheat Flours as Function of Raw Material Baking Properties. J. Polym. Environ. 2016, 24, 37–47. [Google Scholar] [CrossRef]

- Benincasa, P.; Dominici, F.; Bocci, L.; Governatori, C.; Panfili, I.; Tosti, G.; Torre, L.; Puglia, D. Relationships between wheat flour baking properties and tensile characteristics of derived thermoplastic films. Ind. Crops Prod. 2017, 100, 138–145. [Google Scholar] [CrossRef]

- Benincasa, P.; Dominici, F.; Luzi, F.; Governatori, C.; Gazza, L.; Galassi, E.; Tosti, G.; Puglia, D. Crop Nitrogen Fertilization Schedule in Bread Wheat Affects the Mechanical Performances of Thermoplastic Films Obtained by Plasticization of Flours. Agronomy 2023, 13, 697. [Google Scholar] [CrossRef]

- Wang, X.; He, M.; Li, F.; Liu, Y.; Zhang, H.; Liu, C. Coupling effects of irrigation and nitrogen fertilization on grain protein and starch quality of strong-gluten winter wheat. Front. Agric. China 2008, 2, 274–280. [Google Scholar] [CrossRef]

- Dupont, F.M.; Altenbach, S.B. Molecular and biochemical impacts of environmental factors on wheat grain development and protein synthesis. J. Cereal Sci. 2003, 38, 133–146. [Google Scholar] [CrossRef]

- Dominici, F.; Luzi, F.; Benincasa, P.; Torre, L.; Puglia, D. Biocomposites based on plasticized wheat flours: Effect of bran content on thermomechanical behavior. Polymers 2020, 12, 2248. [Google Scholar] [CrossRef]

- Dominici, F.; Puglia, D.; Luzi, F.; Governatori, C.; Tosti, G.; Benincasa, P. The Bran and Grain Grinding Level Affect the Tensile Characteristics of Bioplastics Derived from Wholegrain Wheat Flours. Polymers 2023, 15, 4381. [Google Scholar] [CrossRef]

- Bangar, S.P.; Whiteside, W.S. Nano-cellulose reinforced starch bio composite films- A review on green composites. Int. J. Biol. Macromol. 2021, 185, 849860. [Google Scholar] [CrossRef]

- Chen, J.; Wang, X.; Long, Z.; Wang, S.; Zhang, J.; Wang, L. Preparation and performance of thermoplastic starch and microcrystalline cellulose for packaging composites: Extrusion and hot pressing. Int. J. Biol. Macromol. 2020, 165, 2295–2302. [Google Scholar] [CrossRef] [PubMed]

- González, K.; Retegi, A.; González, A.; Eceiza, A.; Gabilondo, N. Starch and cellulose nanocrystals together into thermoplastic starch bionanocomposites. Carbohydr. Polym. 2015, 117, 83–90. [Google Scholar] [CrossRef]

- Kaushik, A.; Singh, M.; Verma, G. Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carbohydr. Polym. 2010, 82, 337–345. [Google Scholar] [CrossRef]

- Ji, M.; Li, J.; Li, F.; Wang, X.; Man Li, J.; Zhang, C.; Peng, S. A biodegradable chitosan-based composite film reinforced by ramie fibre and lignin for food packaging. Carbohydr. Polym. 2022, 281, 119078. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Li, Y.; Zhang, J.; Man, J.; Nie, Y.; Ji, M.; Chen, H.; Li, F.; Zhang, C. Treatment and mechanism for hot melting starch by reducing the molecular chain winding and crystallinity. Carbohydr. Polym. 2024, 325, 121574. [Google Scholar] [CrossRef]

- Puglia, D.; Luzi, F.; Lilli, M.; Sbardella, F.; Pauselli, M.; Torre, L.; Benincasa, P. Straw fibres from barley hybrid lines and their reinforcement effect in polypropylene based composites. Ind. Crops Prod. 2020, 154, 112736. [Google Scholar] [CrossRef]

- Rosati, A.; Benincasa, P. Revisiting source versus sink limitations of wheat yield during grain filling. Agron. J. 2023, 115, 3197–3205. [Google Scholar] [CrossRef]

- Benincasa, P.; Reale, L.; Tedeschini, E.; Ferri, V.; Cerri, M.; Ghitarrini, S.; Falcinelli, B.; Frenguelli, G.; Ferranti, F.; Ayano, B.E.; et al. The relationship between grain and ovary size in wheat: An analysis of contrasting grain weight cultivars under different growing conditions. Field Crops Res. 2017, 210, 175–182. [Google Scholar] [CrossRef]

- Bonciarelli, U.; Onofri, A.; Benincasa, P.; Farneselli, M.; Guiducci, M.; Pannacci, E.; Tosti, G.; Tei, F. Long-term evaluation of productivity, stability and sustainability for cropping systems in Mediterranean rainfed conditions. Eur. J. Agron. 2016, 77, 146–155. [Google Scholar] [CrossRef]

- Arzu, V.; Kumar, S.; Singh, S.K.; Maurya, D.K.; Kumar, M. Effect of Nitrogen and Phosphorus Fertilization on the Growth and Yield of Wheat (Triticum aestivum L.). Int. J. Environ. Clim. Change 2024, 14, 552–557. [Google Scholar] [CrossRef]

- Shaghaleh, H.; Zhu, Y.; Shi, X.; Alhaj Hamoud, Y.; Ma, C. Co-Effects of Nitrogen Fertilizer and Straw-Decomposing Microbial Inoculant on Decomposition and Transformation of Field Composted Wheat Straw. Life 2023, 13, 1993. [Google Scholar] [CrossRef]

- Liu, J.; Zhong, Y.; Jia, X.; Yan, W.; Cao, J.; Shangguan, Z. Wheat Straw Decomposition Patterns and Control Factors Under Nitrogen Fertilization. J. Soil. Sci. Plant Nutr. 2021, 21, 3110–3121. [Google Scholar] [CrossRef]

- Murozuka, E.; Laursen, K.H.; Lindedam, J.; Shield, I.F.; Bruun, S.; Magid, J.; Møller, I.S.; Schjoerring, J.K. Nitrogen fertilization affects silicon concentration, cell wall composition and biofuel potential of wheat straw. Biomass Bioenergy 2014, 64, 291–298. [Google Scholar] [CrossRef]

- Benincasa, P.; Reale, L.; Cerri, M.; Tedeschini, E.; Tosti, G.; Falcinelli, B.; Rosati, A. Nitrogen fertilization levels and timing affect the plasticity of yield components in bread wheat (Triticum aestivum L.). Field Crops Res. 2022, 289, 108734. [Google Scholar] [CrossRef]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy. Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef] [PubMed]

- AOAC International 2002. AOAC Official Method 2001.11, Protein (Crude) in Animal Feed, Forage (Plant Tissue), Grain, and Oilseeds Block Digestion Method; AOAC International: Rockville, MD, USA, 2002. [Google Scholar]

- ISO 527-2:2012; Plastics-Determination of Tensile Properties-Part 2: Test Conditions for Moulding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- Cerri, M.; Reale, L.; Roscini, F.; Fornaciari da Passano, M.; Orlandi, F. Fibers development in a dioecious hemp cultivar: The role of plant sex and cultivation conditions. Plant Biosyst. 2023, 157, 140–146. [Google Scholar] [CrossRef]

- Liu, R.; Yu, H.; Huang, Y. Structure and morphology of cellulose in wheat straw. Cellulose 2005, 12, 25–34. [Google Scholar] [CrossRef]

- Xian, X.; Wang, X.; Zhu, Y.; Guo, Y.; Tian, Y. Effects of MCC Content on the Structure and Performance of PLA/MCC Biocomposites. J. Polym. Environ. 2018, 26, 3484–3492. [Google Scholar] [CrossRef]

- Kassaye, S.; Pant, K.K.; Jain, S. Synergistic effect of ionic liquid and dilute sulphuric acid in the hydrolysis of microcrystalline cellulose. Fuel Process. Technol. 2016, 148, 289–294. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose crystallinity index: Measurement techniques and their impact on interpreting cellulase performance. Biotechnol. Biofuels 2010, 3, 10. [Google Scholar] [CrossRef]

- Huntley, C.J.; Crews, K.D.; Abdalla, M.A.; Russell, A.E.; Curry, M.L. Influence of strong acid hydrolysis processing on the thermal stability and crystallinity of cellulose isolated from wheat straw. Int. J. Chem. Eng. 2015, 2015, 658163. [Google Scholar] [CrossRef]

- Tishler, Y.; Samach, A.; Rogachev, I.; Elbaum, R.; Levy, A.A. Analysis of Wheat Straw Biodiversity for Use as a Feedstock for Biofuel Production. Bioenergy Res. 2015, 8, 1831–1839. [Google Scholar] [CrossRef]

- Bouasker, M.; Belayachi, N.; Hoxha, D.; Al-Mukhtar, M. Physical characterization of natural straw fibers as aggregates for construction materials applications. Materials 2014, 7, 3034–3048. [Google Scholar] [CrossRef]

- Jang, B.W.L.; Gläser, R.; Dong, M.; Liu, C.J. Fuels of the future. Energy Environ. Sci. 2010, 3, 253. [Google Scholar] [CrossRef]

- Gajera, B.; Tyagi, U.; Sarma, A.K.; Jha, M.K. Impact of torrefaction on thermal behavior of wheat straw and groundnut stalk biomass: Kinetic and thermodynamic study. Fuel Commun. 2022, 12, 100073. [Google Scholar] [CrossRef]

- Mulligan, C.J.; Strezov, L.; Strezov, V. Thermal decomposition of wheat straw and mallee residue under pyrolysis conditions. Energy Fuels 2010, 24, 46–52. [Google Scholar] [CrossRef]

- Nasri, K.; Loranger, É.; Toubal, L. Effect of cellulose and lignin content on the mechanical properties and drop-weight impact damage of injection-molded polypropylene-flax and -pine fiber composites. J. Compos. Mater. 2023, 57, 3347–3364. [Google Scholar] [CrossRef]

- Yang, W.; Fortunati, E.; Dominici, F.; Giovanale, G.; Mazzaglia, A.; Balestra, G.M.; Kenny, J.M.; Puglia, D. Synergic effect of cellulose and lignin nanostructures in PLA based systems for food antibacterial packaging. Eur. Polym. J. 2016, 79, 1–12. [Google Scholar] [CrossRef]

| Dough Label | Description |

|---|---|

| BL_R | Bologna refined flour of N300 (without straw) |

| BL_S_N0 | Bologna flour of N300 added with straw of N0 |

| BL_S_N60+0 | Bologna flour of N300 added with straw of N60+0 |

| BL_S_N0+120 | Bologna flour of N300 added with straw of N0+120 |

| BL_S_N300 | Bologna flour of N300 added with straw of N300 |

| BR_R | Bora refined flour of N300 (without straw) |

| BR_S_N0 | Bora flour of N300 added with straw of N0 |

| BR_S_N60+0 | Bora flour of N300 added with straw of N60+0 |

| BR_S_N0+120 | Bora flour of N300 added with straw of N0+120 |

| BR_S_N300 | Bora flour of N300 added with straw of N300 |

| Cultivar | N Fert | DM | NDF | ADF | Cell | ADL | CP |

|---|---|---|---|---|---|---|---|

| BL | N0 | 94.12 | 75.63 | 59.00 | 54.70 | 4.30 | 3.72 |

| BL | N60+0 | 94.42 | 73.35 | 58.74 | 51.23 | 7.51 | 3.52 |

| BL | N0+120 | 94.63 | 73.50 | 55.76 | 47.50 | 8.26 | 3.72 |

| BL | N300 | 94.33 | 74.44 | 56.51 | 48.96 | 7.55 | 4.84 |

| BR | N0 | 94.77 | 73.27 | 59.11 | 52.02 | 7.09 | 2.29 |

| BR | N60+0 | 95.42 | 72.91 | 57.76 | 50.94 | 6.82 | 2.12 |

| BR | N0+120 | 94.98 | 70.24 | 51.85 | 43.91 | 7.94 | 4.81 |

| BR | N300 | 94.72 | 75.18 | 55.62 | 50.67 | 4.95 | 4.84 |

| (a) | |||

| Sample (11RH) | σb (MPa) | εb (%) | E (MPa) |

| BL_R_N300 | 3.20 ± 0.30 a | 42.9 ± 1.6 a | 65 ± 10 a |

| BL_S_N0 | 8.41 ± 0.47 c | 12.0 ± 1.8 bc | 193 ± 35 c |

| BL_S_N60+0 | 8.09 ± 0.16 c | 9.0 ± 0.5 c | 177 ± 18 c |

| BL_S_N0+120 | 7.85 ± 0.16 c | 9.3 ± 1.8 bc | 168 ± 22 c |

| BL_S_N300 | 5.63 ± 0.19 b | 12.8 ± 1.6 b | 120 ± 13 b |

| BR_R_N300 | 2.73 ± 0.42 a | 58.8 ± 1.8 a | 52 ± 8 a |

| BR_S_N0 | 6.64 ± 0.43 b | 10.9 ± 0.6 b | 147 ± 7 c |

| BR_S_N60+0 | 6.52 ± 0.47 b | 10.1 ± 0.7 b | 131 ± 1 bc |

| BR_S_N0+120 | 5.45 ± 0.56 b | 11.5 ± 0.7 b | 120 ± 12 bc |

| BR_S_N300 | 5.61 ± 0.69 b | 12.7 ± 1.2 b | 111 ± 20 b |

| (b) | |||

| Sample (53RH) | σb (MPa) | εb (%) | E (MPa) |

| BL_R | 2.24 ± 0.06 a | 37.2 ± 0.4 a | 20.3 ± 0.4 a |

| BL_S_N0 | 3.51 ± 0.11 c | 15.2 ± 0.4 b | 63.8 ± 2.2 c |

| BL_S_N60+0 | 3.23 ± 0.17 bc | 15.6 ± 0.3 b | 60.9 ± 1.1 c |

| BL_S_N0+120 | 3.12 ± 0.06 b | 13.6 ± 0.4 c | 58.4 ± 1.2 c |

| BL_S_N300 | 3.04 ± 0.12 b | 15.8 ± 0.4 b | 51.3 ± 1.1 b |

| BR_R | 1.16 ± 0.11 a | 21.4 ± 3.2 a | 9.2 ± 0.4 a |

| BR_S_N0 | 2.41 ± 0.08 b | 8.9 ± 0.5 b | 51.4 ± 1.9 c |

| BR_S_N60+0 | 2.36 ± 0.12 b | 10.7 ± 0.8 b | 45.7 ± 2.5 bc |

| BR_S_N0+120 | 2.20 ± 0.26 b | 10.0 ± 1.0 b | 37.8 ± 5.4 b |

| BR_S_N300 | 2.08 ± 0.10 b | 9.9 ± 1.4 b | 35.7 ± 2.2 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benincasa, P.; Dominici, F.; Luzi, F.; Governatori, C.; Pauselli, M.; Tosti, G.; Sarasini, F.; Puglia, D. Mechanical Performance of Biocomposites Based on Straw Fiber Self-Reinforced Plasticized Flours of Bread Wheat Grown with Different Nitrogen Fertilization Management Strategies. Polymers 2025, 17, 1347. https://doi.org/10.3390/polym17101347

Benincasa P, Dominici F, Luzi F, Governatori C, Pauselli M, Tosti G, Sarasini F, Puglia D. Mechanical Performance of Biocomposites Based on Straw Fiber Self-Reinforced Plasticized Flours of Bread Wheat Grown with Different Nitrogen Fertilization Management Strategies. Polymers. 2025; 17(10):1347. https://doi.org/10.3390/polym17101347

Chicago/Turabian StyleBenincasa, Paolo, Franco Dominici, Francesca Luzi, Catia Governatori, Mariano Pauselli, Giacomo Tosti, Fabrizio Sarasini, and Debora Puglia. 2025. "Mechanical Performance of Biocomposites Based on Straw Fiber Self-Reinforced Plasticized Flours of Bread Wheat Grown with Different Nitrogen Fertilization Management Strategies" Polymers 17, no. 10: 1347. https://doi.org/10.3390/polym17101347

APA StyleBenincasa, P., Dominici, F., Luzi, F., Governatori, C., Pauselli, M., Tosti, G., Sarasini, F., & Puglia, D. (2025). Mechanical Performance of Biocomposites Based on Straw Fiber Self-Reinforced Plasticized Flours of Bread Wheat Grown with Different Nitrogen Fertilization Management Strategies. Polymers, 17(10), 1347. https://doi.org/10.3390/polym17101347