Biodegradable Carbohydrate-Based Films for Packaging Agricultural Products—A Review

Abstract

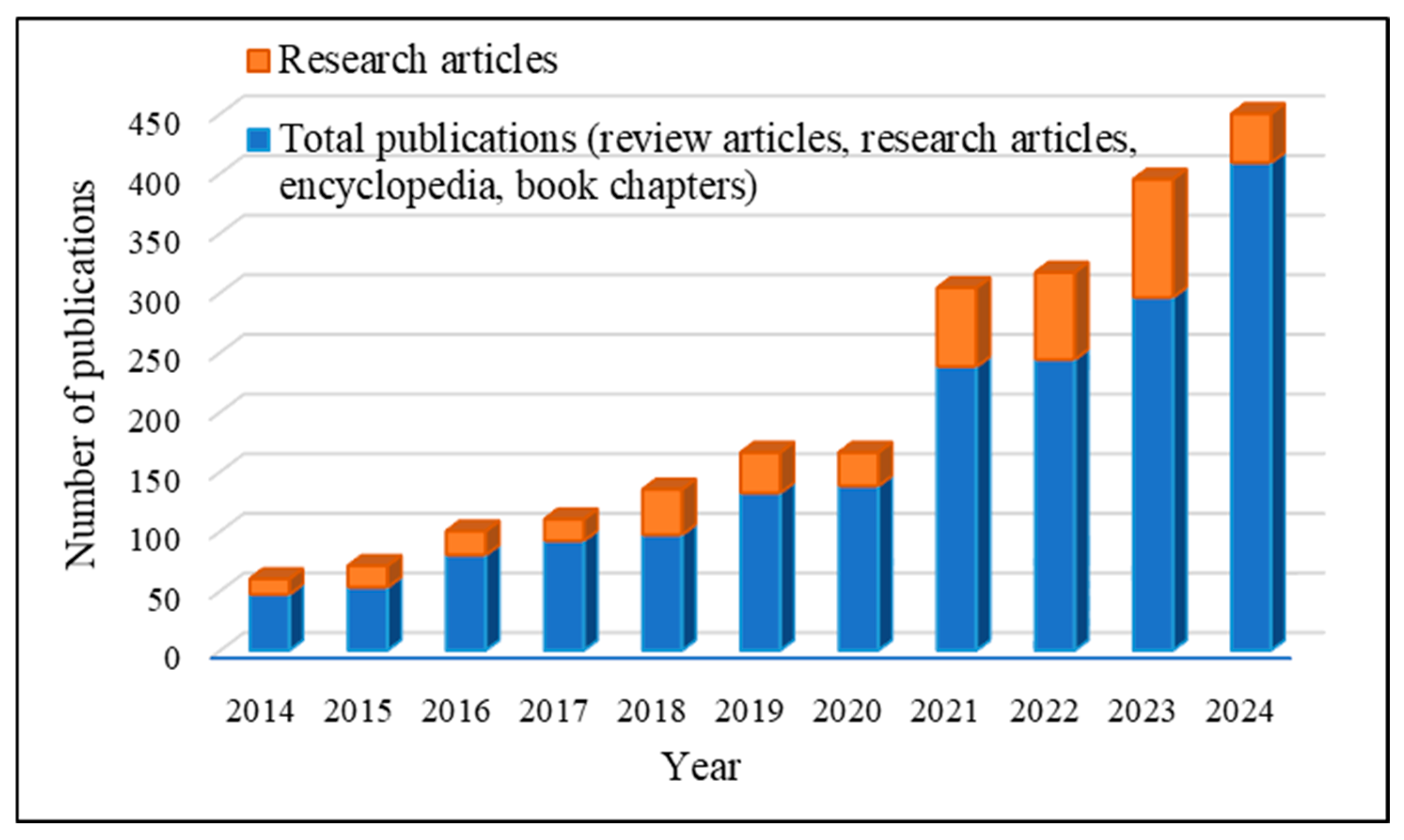

1. Introduction

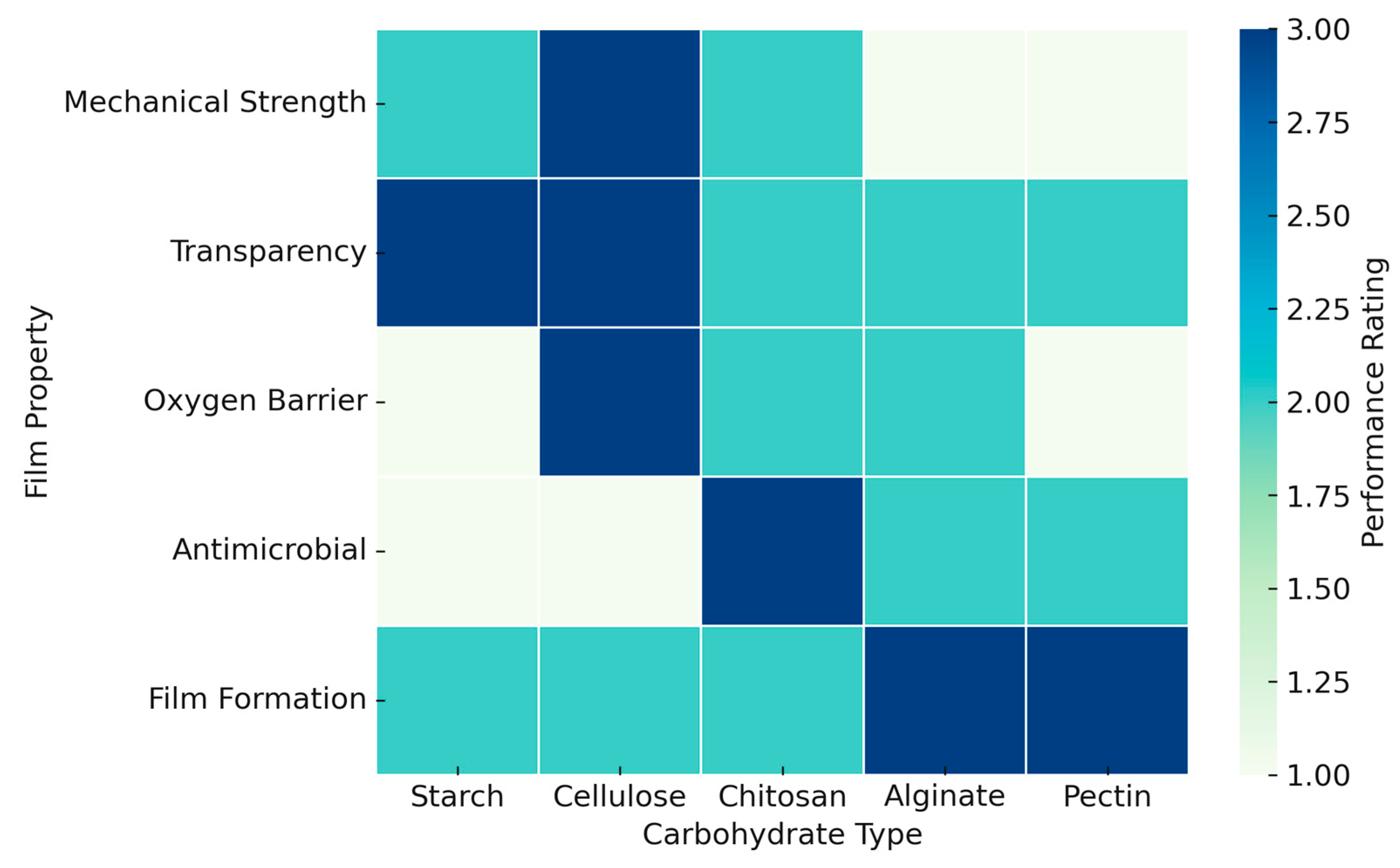

2. An Overview of the Different Types of Carbohydrates and Their Sources

2.1. Pectin

2.2. Starch

2.3. Cellulose

2.4. Chitosan

2.5. Alginate

2.6. Other Polysaccharides

3. Enhancements in Carbohydrate-Based Bio-Film Fabrication and Characterization

4. Applications in Agricultural Commodity Packaging

5. Advantages of Carbohydrate-Based Bio-Degradable Films

5.1. Environmental Benefits

5.2. Economic Benefits

5.3. Technical Benefits

6. Challenges and Future Perspectives

6.1. Economic Challenges and Cost Competitiveness

6.2. Technological Limitations and Industrial Scale-Up

6.3. Material Performance and Property Enhancement

6.4. Consumer Acceptance and Market Adoption

6.5. Authors’ Hypothesis and Innovation Pathways

6.6. Future Research Directions

6.7. Next-Generation Packaging and Regulatory Needs

7. Conclusions

- Overall Summary

- Carbohydrate polymers offer eco-friendly alternatives to plastic food packaging.

- Each biopolymer shows unique strengths and limits for specific food applications.

- Innovative additives improve film flexibility, barrier function, and durability.

- Antimicrobial films can extend shelf life, especially when enhanced with agents.A shift to biofilms supports the circular economy and reduces plastic pollution.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Louis, F.; Saleh, M. Post-Harvest Handling and Storage: Preserving Quality, Reducing Losses, and Extending Shelf Life. 26 May 2024. Available online: https://easychair.org/publications/preprint/8bKSG (accessed on 5 May 2025).

- Urugo, M.M.; Yohannis, E.; Teka, T.A.; Gemede, H.F.; Tola, Y.B.; Forsido, S.F.; Tessema, A.; Suraj, M.; Abdu, J. Addressing Post-Harvest Losses through Agro-Processing for Sustainable Development in Ethiopia. J. Agric. Food Res. 2024, 18, 101316. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, J. Visual Analysis of Brand Packaging Design Data Based on CAD and Big Data Technology. Comput. Aided Des. Appl. 2024, 21, 309–324. [Google Scholar] [CrossRef]

- OECD. Plastics: Production, Use and Waste Statistics. 2023. Available online: https://www.oecd.org/environment/plastics (accessed on 25 April 2025).

- UNEP. From Pollution to Solution: A Global Assessment of Marine Litter and Plastic Pollution. United Nations Environment Programme. 2021. Available online: https://www.unep.org/resources/pollution-solution-global-assessment-marine-litter-and-plastic-pollution (accessed on 5 May 2025).

- OECD. Global Plastics Outlook: Policy Scenarios to 2060. Organisation for Economic Co-Operation and Development. 2022. Available online: https://www.oecd.org/en/publications/global-plastics-outlook_aa1edf33-en.html (accessed on 5 May 2025).

- Agarwal, A.; Shaida, B.; Rastogi, M.; Singh, N.B. Food Packaging Materials with Special Reference to Biopolymers-Properties and Applications. Chem. Afr. 2023, 6, 117–144. [Google Scholar] [CrossRef]

- Babaremu, K.; Oladijo, O.P.; Akinlabi, E. Biopolymers: A Suitable Replacement for Plastics in Product Packaging. Adv. Ind. Eng. Polym. Res. 2023, 6, 333–340. [Google Scholar] [CrossRef]

- Sharma, S.; Sharma, V.; Chatterjee, S. Contribution of Plastic and Microplastic to Global Climate Change and Their Conjoining Impacts on the Environment-A Review. Sci. Total Environ. 2023, 875, 162627. [Google Scholar] [CrossRef] [PubMed]

- Kumar, G.; Vyas, S.; Sharma, S.N.; Dehalwar, K. Challenges of Environmental Health in Waste Management for Peri-Urban Areas. In Solid Waste Management; Nasr, M., Negm, A., Eds.; Sustainable Development Goals Series; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 149–168. ISBN 978-3-031-60683-0. [Google Scholar]

- Kibria, M.d.G.; Masuk, N.I.; Safayet, R.; Nguyen, H.Q.; Mourshed, M. Plastic Waste: Challenges and Opportunities to Mitigate Pollution and Effective Management. Int. J. Environ. Res. 2023, 17, 20. [Google Scholar] [CrossRef]

- Dey, S.; Veerendra, G.T.N.; Babu, P.S.S.A.; Manoj, A.V.P.; Nagarjuna, K. Degradation of Plastics Waste and Its Effects on Biological Ecosystems: A Scientific Analysis and Comprehensive Review. Biomed. Mater. Dev. 2024, 2, 70–112. [Google Scholar] [CrossRef]

- Enyoh, C.E.; Devi, A.; Kadono, H.; Wang, Q.; Rabin, M.H. The Plastic Within: Microplastics Invading Human Organs and Bodily Fluids Systems. Environments 2023, 10, 194. [Google Scholar] [CrossRef]

- Ghosh, S.; Sinha, J.K.; Ghosh, S.; Vashisth, K.; Han, S.; Bhaskar, R. Microplastics as an Emerging Threat to the Global Environment and Human Health. Sustainability 2023, 15, 10821. [Google Scholar] [CrossRef]

- Singh, N.; Walker, T.R. Plastic Recycling: A Panacea or Environmental Pollution Problem. npj Mater. Sustain. 2024, 2, 17. [Google Scholar] [CrossRef]

- Santos, G.; Esmizadeh, E.; Riahinezhad, M. Recycling Construction, Renovation, and Demolition Plastic Waste: Review of the Status Quo, Challenges and Opportunities. J. Polym. Environ. 2024, 32, 479–509. [Google Scholar] [CrossRef]

- Directive (EU) 2019/904 (2019), Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Plastic Products on the Environment. Available online: https://www.legislation.gov.uk/eudr/2019/904#:~:text=The%20objectives%20of%20this%20Directive,products%20and%20materials%2C%20thus%20also (accessed on 25 April 2025).

- Central Pollution Control Board: CPCB (2022). Available online: https://cpcb.nic.in/uploads/plasticwaste/PWM-Amendment-Rules-2022.pdf (accessed on 2 May 2025).

- Verma, S.K.; Prasad, A.; Katiyar, V. State of Art Review on Sustainable Biodegradable Polymers with a Market Overview for Sustainability Packaging. Mater. Today Sustain. 2024, 26, 100776. [Google Scholar] [CrossRef]

- Cheng, J.; Gao, R.; Zhu, Y.; Lin, Q. Applications of Biodegradable Materials in Food Packaging: A Review. Alex. Eng. J. 2024, 91, 70–83. [Google Scholar] [CrossRef]

- La Fuente, C.I.A.; Maniglia, B.C.; Tadini, C.C. Biodegradable Polymers: A Review about Biodegradation and Its Implications and Applications. Packag. Technol. Sci. 2023, 36, 81–95. [Google Scholar] [CrossRef]

- Grzybek, P.; Dudek, G.; van der Bruggen, B. Cellulose-Based Films and Membranes: A Comprehensive Review on Preparation and Applications. Chem. Eng. J. 2024, 495, 153500. [Google Scholar] [CrossRef]

- Matheus, J.R.V.; Dalsasso, R.R.; Rebelatto, E.A.; Andrade, K.S.; Andrade, L.M.D.; Andrade, C.J.D.; Monteiro, A.R.; Fai, A.E.C. Biopolymers as Green-based Food Packaging Materials: A Focus on Modified and Unmodified Starch-based Films. Comp. Rev. Food Sci. Food Safe 2023, 22, 1148–1183. [Google Scholar] [CrossRef]

- Swetha, T.A.; Ananthi, V.; Bora, A.; Sengottuvelan, N.; Ponnuchamy, K.; Muthusamy, G.; Arun, A. A Review on Biodegradable Polylactic Acid (PLA) Production from Fermentative Food Waste-Its Applications and Degradation. Int. J. Biol. Macromol. 2023, 234, 123703. [Google Scholar] [CrossRef] [PubMed]

- Kumari, P.; Singh, A. Polyhydroxyalkanoates (PHA): Production, Properties, and Packaging Applications. In Biopolymer-Based Films and Coatings; CRC Press: Boca Raton, FL, USA, 2023; pp. 241–264. [Google Scholar]

- Thambiliyagodage, C.; Jayanetti, M.; Mendis, A.; Ekanayake, G.; Liyanaarachchi, H.; Vigneswaran, S. Recent Advances in Chitosan-Based Applications—A Review. Materials 2023, 16, 2073. [Google Scholar] [CrossRef]

- Roy, S.; Priyadarshi, R.; Łopusiewicz, Ł.; Biswas, D.; Chandel, V.; Rhim, J.-W. Recent Progress in Pectin Extraction, Characterization, and Pectin-Based Films for Active Food Packaging Applications: A Review. Int. J. Biol. Macromol. 2023, 239, 124248. [Google Scholar] [CrossRef]

- Thiviya, P.; Gamage, A.; Liyanapathiranage, A.; Makehelwala, M.; Dassanayake, R.S.; Manamperi, A.; Merah, O.; Mani, S.; Koduru, J.R.; Madhujith, T. Algal Polysaccharides: Structure, Preparation and Applications in Food Packaging. Food Chem. 2023, 405, 134903. [Google Scholar] [CrossRef]

- Liu, X.; Qin, Z.; Ma, Y.; Liu, H.; Wang, X. Cellulose-Based Films for Food Packaging Applications: Review of Preparation, Properties, and Prospects. J. Renew. Mater. 2023, 11, 3203–3225. [Google Scholar] [CrossRef]

- Nath, P.C.; Sharma, R.; Debnath, S.; Sharma, M.; Inbaraj, B.S.; Dikkala, P.K.; Nayak, P.K.; Sridhar, K. Recent Trends in Polysaccharide-Based Biodegradable Polymers for Smart Food Packaging Industry. Int. J. Biol. Macromol. 2023, 253, 127524. [Google Scholar] [CrossRef]

- Casalini, S.; Giacinti Baschetti, M. The Use of Essential Oils in Chitosan or Cellulose-based Materials for the Production of Active Food Packaging Solutions: A Review. J. Sci. Food Agric. 2023, 103, 1021–1041. [Google Scholar] [CrossRef] [PubMed]

- Yapo, B.M. Pectic Substances: From Simple Pectic Polysaccharides to Complex Pectins—A New Hypothetical Model. Carbohydr. Polym. 2011, 86, 373–385. [Google Scholar] [CrossRef]

- Surolia, R.; Singh, A. Pectin—Structure, Specification, Production, Applications and Various Emerging Sources: A Review. In Sustainable Food Systems (Volume II); Thakur, M., Ed.; World Sustainability Series; Springer Nature Switzerland: Cham, Switzerland, 2024; pp. 267–282. ISBN 978-3-031-46045-6. [Google Scholar]

- Christensen, S.H. Pectins. In Food Hydrocolloids; CRC Press: Boca Raton, FL, USA, 2020; pp. 205–230. [Google Scholar]

- Belkheiri, A.; Forouhar, A.; Ursu, A.V.; Dubessay, P.; Pierre, G.; Delattre, C.; Djelveh, G.; Abdelkafi, S.; Hamdami, N.; Michaud, P. Extraction, Characterization, and Applications of Pectins from Plant by-Products. Appl. Sci. 2021, 11, 6596. [Google Scholar] [CrossRef]

- Yi, L.; Cheng, L.; Yang, Q.; Shi, K.; Han, F.; Luo, W.; Duan, S. Source, Extraction, Properties, and Multifunctional Applications of Pectin: A Short Review. Polymers 2024, 16, 2883. [Google Scholar] [CrossRef] [PubMed]

- Gurev, A.; Cesko, T.; Dragancea, V.; Ghendov-Mosanu, A.; Pintea, A.; Sturza, R. Ultrasound-and Microwave-Assisted Extraction of Pectin from Apple Pomace and Its Effect on the Quality of Fruit Bars. Foods 2023, 12, 2773. [Google Scholar] [CrossRef]

- Cui, J.; Zhao, C.; Feng, L.; Han, Y.; Du, H.; Xiao, H.; Zheng, J. Pectins from Fruits: Relationships between Extraction Methods, Structural Characteristics, and Functional Properties. Trends Food Sci. Technol. 2021, 110, 39–54. [Google Scholar] [CrossRef]

- Liu, D.; Zhao, P.; Chen, J.; Yan, Y.; Wu, Z. Recent Advances and Applications in Starch for Intelligent Active Food Packaging: A Review. Foods 2022, 11, 2879. [Google Scholar] [CrossRef]

- Li, Z.; Wei, C. Morphology, Structure, Properties and Applications of Starch Ghost: A Review. Int. J. Biol. Macromol. 2020, 163, 2084–2096. [Google Scholar] [CrossRef]

- Majeed, T.; Dar, A.H.; Pandey, V.K.; Dash, K.K.; Srivastava, S.; Shams, R.; Jeevarathinam, G.; Singh, P.; Echegaray, N.; Pandiselvam, R. Role of Additives in Starch-Based Edible Films and Coating: A Review with Current Knowledge. Prog. Org. Coat. 2023, 181, 107597. [Google Scholar] [CrossRef]

- Onyeaka, H.; Obileke, K.; Makaka, G.; Nwokolo, N. Current Research and Applications of Starch-Based Biodegradable Films for Food Packaging. Polymers 2022, 14, 1126. [Google Scholar] [CrossRef]

- Luciano, C.G.; Caicedo Chacon, W.D.; Valencia, G.A. Starch-Based Coatings for Food Preservation: A Review. Starch-Stärke 2022, 74, 2100279. [Google Scholar] [CrossRef]

- Sun, H.; Cao, Y.; Kim, D.; Marelli, B. Biomaterials Technology for AgroFood Resilience. Adv. Funct. Mater. 2022, 32, 2201930. [Google Scholar] [CrossRef]

- Gunawardene, O.H.; Gunathilake, C.; Amaraweera, S.M.; Fernando, N.M.; Wanninayaka, D.B.; Manamperi, A.; Kulatunga, A.K.; Rajapaksha, S.M.; Dassanayake, R.S.; Fernando, C.A. Compatibilization of Starch/Synthetic Biodegradable Polymer Blends for Packaging Applications: A Review. J. Compos. Sci. 2021, 5, 300. [Google Scholar] [CrossRef]

- Romão, S.; Bettencourt, A.; Ribeiro, I.A.C. Novel Features of Cellulose-Based Films as Sustainable Alternatives for Food Packaging. Polymers 2022, 14, 4968. [Google Scholar] [CrossRef] [PubMed]

- Deshwal, G.K.; Alam, T.; Panjagari, N.R.; Bhardwaj, A. Utilization of Cereal Crop Residues, Cereal Milling, Sugarcane and Dairy Processing By-Products for Sustainable Packaging Solutions. J. Polym. Environ. 2021, 29, 2046–2061. [Google Scholar] [CrossRef]

- Wang, W.; Xue, C.; Mao, X. Chitosan: Structural Modification, Biological Activity and Application. Int. J. Biol. Macromol. 2020, 164, 4532–4546. [Google Scholar] [CrossRef] [PubMed]

- Yan, D.; Li, Y.; Liu, Y.; Li, N.; Zhang, X.; Yan, C. Antimicrobial Properties of Chitosan and Chitosan Derivatives in the Treatment of Enteric Infections. Molecules 2021, 26, 7136. [Google Scholar] [CrossRef]

- Mujtaba, M.; Morsi, R.E.; Kerch, G.; Elsabee, M.Z.; Kaya, M.; Labidi, J.; Khawar, K.M. Current advancements in chitosan-based film production for food technology: A review. Int. J. Biol. Macromol. 2019, 121, 889–904. [Google Scholar] [CrossRef]

- Priyadarshi, R.; Rhim, J.-W. Chitosan-Based Biodegradable Functional Films for Food Packaging Applications. Innov. Food Sci. Emerg. Technol. 2020, 62, 102346. [Google Scholar] [CrossRef]

- Nisha, V.; Monisha, C.; Ragunathan, R.; Johney, J. Use of Chitosan as Edible Coating on Fruits and in Micro Biological Activity-an Ecofriendly Approach. Int. J. Pharm. Sci. Invent. 2016, 5, 7–14. [Google Scholar]

- Pandit, P.; Gayatri, T.N.; Regubalan, B. Alginates Production, Characterization and Modification. Alginates Appl. Biomed. Food Ind. 2019, 2, 21–44. [Google Scholar]

- Abka-Khajouei, R.; Tounsi, L.; Shahabi, N.; Patel, A.K.; Abdelkafi, S.; Michaud, P. Structures, Properties and Applications of Alginates. Mar. Drugs 2022, 20, 364. [Google Scholar] [CrossRef] [PubMed]

- Panou, A.; Karabagias, I.K. Biodegradable Packaging Materials for Foods Preservation: Sources, Advantages, Limitations, and Future Perspectives. Coatings 2023, 13, 1176. [Google Scholar] [CrossRef]

- Kumar, P.; Kumar, B.; Gihar, S.; Kumar, D. Review on emerging trends and challenges in the modification of xanthan gum for various applications. Carbohydr. Res. 2024, 531, 109070. [Google Scholar] [CrossRef] [PubMed]

- Chaturvedi, S.; Kulshrestha, S.; Bhardwaj, K.; Jangir, R. A review on properties and applications of xanthan gum. In Microbial Polymers: Applications and Ecological Perspectives; Springer: Singapore, 2021; pp. 87–107. [Google Scholar]

- Agarwal, N.; Thakur, M.; Mishra, B.B.; Singh, S.P. Preparation and characterization of biodegradable films based on levan polysaccharide blended with gellan gum. Environ. Technol. Innov. 2023, 31, 103231. [Google Scholar] [CrossRef]

- Aquinas, N.; Bhat, M.R.; Selvaraj, S. A review presenting production, characterization, and applications of biopolymer curdlan in food and pharmaceutical sectors. Polym. Bull. 2022, 79, 6905–6927. [Google Scholar] [CrossRef]

- Rai, M.; Wypij, M.; Ingle, A.P.; Trzcińska-Wencel, J.; Golińska, P. Emerging Trends in Pullulan-Based Antimicrobial Systems for Various Applications. Int. J. Mol. Sci. 2021, 22, 13596. [Google Scholar] [CrossRef]

- Patel, J.; Maji, B.; Moorthy, N.H.N.; Maiti, S. Xanthan Gum Derivatives: Review of Synthesis, Properties and Diverse Applications. RSC Adv. 2020, 10, 27103–27136. [Google Scholar] [CrossRef]

- Díaz-Montes, E. Polysaccharides: Sources, Characteristics, Properties, and Their Application in Biodegradable Films. Polysaccharides 2022, 3, 480–501. [Google Scholar] [CrossRef]

- Theagarajan, R.; Dutta, S.; Moses, J.A.; Anandharamakrishnan, C. Alginates for Food Packaging Applications. In Alginates: Applications in the Biomedical and Food Industries; Wiley: Hoboken, NJ, USA, 2019; pp. 207–232. [Google Scholar]

- Roy, S.; Malik, B.; Chawla, R.; Bora, S.; Ghosh, T.; Santhosh, R.; Thakur, R.; Sarkar, P. Biocompatible Film Based on Protein/Polysaccharides Combination for Food Packaging Applications: A Comprehensive Review. Int. J. Biol. Macrogols. 2024, 278, 134658. [Google Scholar] [CrossRef]

- Flórez, M.; Cazón, P.; Vázquez, M. Selected Biopolymers’ Processing and Their Applications: A Review. Polymers 2023, 15, 641. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Rhim, J.-W. Preparation of Carbohydrate-Based Functional Composite Films Incorporated with Curcumin. Food Hydrocoll. 2020, 98, 105302. [Google Scholar] [CrossRef]

- Shankar, S.; Wang, L.-F.; Rhim, J.-W. Preparation and Properties of Carbohydrate-Based Composite Films Incorporated with CuO Nanoparticles. Carbohydr. Polym. 2017, 169, 264–271. [Google Scholar] [CrossRef] [PubMed]

- Bierhalz, A.C.K.; da Silva, M.A.; Kieckbusch, T.G. Fundamentals of Two-Dimensional Films and Membranes. In Biopolymer Membranes and Films; Elsevier: Amsterdam, The Netherlands, 2020; pp. 35–66. [Google Scholar]

- Borbolla-Jiménez, F.V.; Peña-Corona, S.I.; Farah, S.J.; Jiménez-Valdés, M.T.; Pineda-Pérez, E.; Romero-Montero, A.; Del Prado-Audelo, M.L.; Bernal-Chávez, S.A.; Magaña, J.J.; Leyva-Gómez, G. Films for Wound Healing Fabricated Using a Solvent Casting Technique. Pharmaceutics 2023, 15, 1914. [Google Scholar] [CrossRef] [PubMed]

- Fitch-Vargas, P.R.; Aguilar-Palazuelos, E.; De Jesús Zazueta-Morales, J.; Vega-García, M.O.; Valdez-Morales, J.E.; Martínez-Bustos, F.; Jacobo-Valenzuela, N. Physicochemical and Microstructural Characterization of Corn Starch Edible Films Obtained by a Combination of Extrusion Technology and Casting Technique. J. Food Sci. 2016, 81, E2224–E2232. [Google Scholar] [CrossRef]

- Sun, S.; Liu, P.; Ji, N.; Hou, H.; Dong, H. Effects of Low Polyhydroxyalkanoate Content on the Properties of Films Based on Modified Starch Acquired by Extrusion Blowing. Food Hydrocoll. 2017, 72, 81–89. [Google Scholar] [CrossRef]

- Lei, X.; Lv, G.; Xie, X.; Mei, L.; Zhou, Y.; Liao, L. Manufacturing Strategies and Emerging Directions of Mixed-Matrix Membranes Based on Natural Halloysite Nanotubes. Sustain. Mater. Technol. 2023, 38, e00766. [Google Scholar] [CrossRef]

- Richardson, J.J.; Cui, J.; Björnmalm, M.; Braunger, J.A.; Ejima, H.; Caruso, F. Innovation in Layer-by-Layer Assembly. Chem. Rev. 2016, 116, 14828–14867. [Google Scholar] [CrossRef]

- Shahbazi, M.; Jäger, H. Current Status in the Utilization of Biobased Polymers for 3D Printing Process: A Systematic Review of the Materials, Processes, and Challenges. ACS Appl. Bio Mater. 2021, 4, 325–369. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Y.; Zhuang, C.; Gu, W.; Zhao, Y. Effect of Molecular Weight on the Properties of Chitosan Films Prepared Using Electrostatic Spraying Technique. Carbohydr. Polym. 2019, 212, 197–205. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, S. Major Factors Affecting the Characteristics of Starch Based Biopolymer Films. Eur. Polym. J. 2021, 160, 110788. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Gardner, D.J.; Shaler, S.M.; Cai, Z. Towards a Cellulose-Based Society: Opportunities and Challenges. Cellulose 2021, 28, 4511–4543. [Google Scholar] [CrossRef]

- Olonisakin, K.; Wen, A.; He, S.; Lin, H.; Tao, W.; Chen, S.; Lin, W.; Li, R.; Zhang, X.; Yang, W. The Development of Biodegradable PBAT-Lignin-Tannic Acid Composite Film: Properties, Biodegradability, and Potential Barrier Application in Food Packaging. Food Bioprocess. Technol. 2023, 16, 1525–1540. [Google Scholar] [CrossRef]

- Fasihi, H.; Noshirvani, N.; Hashemi, M.; Fazilati, M.; Salavati, H.; Coma, V. Antioxidant and Antimicrobial Properties of Carbohydrate-Based Films Enriched with Cinnamon Essential Oil by Pickering Emulsion Method. Food Packag. Shelf Life 2019, 19, 147–154. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Rayung, M.; Abu, F.; Ahmad, S.; Fadil, F.; Karim, A.A.; Norizan, M.N.; Sarifuddin, N.; Mat Desa, M.S.Z.; Mohd Basri, M.S. A Review on Antimicrobial Packaging from Biodegradable Polymer Composites. Polymers 2022, 14, 174. [Google Scholar] [CrossRef]

- Paudel, S.; Regmi, S.; Janaswamy, S. Effect of Glycerol and Sorbitol on Cellulose-Based Biodegradable Films. Food Packag. Shelf Life 2023, 37, 101090. [Google Scholar] [CrossRef]

- Boetje, L.; Lan, X.; van Dijken, J.; Woortman, A.J.; Popken, T.; Polhuis, M.; Loos, K. Starch Ester Film Properties: The Role of the Casting Temperature and Starch Its Molecular Weight and Amylose Content. Carbohydr. Polym. 2023, 316, 121043. [Google Scholar] [CrossRef]

- Li, Z.; Wang, C.; Liu, T.; Ye, X.; He, M.; Zhao, L.; Li, H.; Ren, J.; Algadi, H.; Li, Y.; et al. Interfacial Interaction Enhancement between Biodegradable Poly (Butylene Adipate-Co-Terephthalate) and Microcrystalline Cellulose Based on Covalent Bond for Improving Puncture, Tearing, and Enzymatic Degradation Properties. Adv. Compos. Hybrid. Mater. 2023, 6, 69. [Google Scholar] [CrossRef]

- Shin, H.; Thanakkasaranee, S.; Sadeghi, K.; Seo, J. Preparation and Characterization of Ductile PLA/PEG Blend Films for Eco-Friendly Flexible Packaging Application. Food Packag. Shelf Life 2022, 34, 100966. [Google Scholar] [CrossRef]

- Cazón, P.; Vázquez, M.; Velazquez, G. Composite Films with UV-Barrier Properties of Bacterial Cellulose with Glycerol and Poly(Vinyl Alcohol): Puncture Properties, Solubility, and Swelling Degree. Biomacromolecules 2019, 20, 3115–3125. [Google Scholar] [CrossRef]

- Xue, W.; Zhu, J.; Sun, P.; Yang, F.; Wu, H.; Li, W. Permeability of Biodegradable Film Comprising Biopolymers Derived from Marine Origin for Food Packaging Application: A Review. Trends Food Sci Technol. 2023, 136, 295–307. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Banerjee, A.; Saurabh, C.K.; Tye, Y.Y.; Suriani, A.B.; Mohamed, A.; Karim, A.A.; Rizal, S.; Paridah, M.T. Biodegradable Films for Fruits and Vegetables Packaging Application: Preparation and Properties. Food Eng. Rev. 2018, 10, 139–153. [Google Scholar] [CrossRef]

- Baghi, F.; Gharsallaoui, A.; Dumas, E.; Ghnimi, S. Advancements in Biodegradable Active Films for Food Packaging: Effects of Nano/Microcapsule Incorporation. Foods 2022, 11, 760. [Google Scholar] [CrossRef]

- Simmonds, G.; Spence, C. Food Imagery and Transparency in Product Packaging. In Multisensory Packaging; Velasco, C., Spence, C., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 49–77. ISBN 978-3-319-94976-5. [Google Scholar]

- Cheng, Y.; Tian, W.; Mi, Q.; Zheng, X.; Zhang, J. Highly Transparent All-Polysaccharide Composite Films with Tailored Transmission Haze for Light Manipulation. Adv. Mater. Technol. 2020, 5, 2000378. [Google Scholar] [CrossRef]

- Chang, S.; Zou, X.; Zhu, B.; You, L.; Zhao, Z.; Hileuskaya, K. The Characteristics of Polysaccharide from Gracilaria Chouae and Its Application in Food Packaging with Carboxymethyl Cellulose and Lysozyme. Food Hydrocoll. 2023, 135, 108109. [Google Scholar] [CrossRef]

- Dilkes-Hoffman, L.S.; Lane, J.L.; Grant, T.; Pratt, S.; Lant, P.A.; Laycock, B. Environmental Impact of Biodegradable Food Packaging When Considering Food Waste. J. Clean. Prod. 2018, 180, 325–334. [Google Scholar] [CrossRef]

- Samantaray, P.K.; Little, A.; Wemyss, A.M.; Iacovidou, E.; Wan, C. Design and Control of Compostability in Synthetic Biopolyesters. ACS Sustain. Chem. Eng. 2021, 9, 9151–9164. [Google Scholar] [CrossRef]

- Kocira, A.; Kozłowicz, K.; Panasiewicz, K.; Staniak, M.; Szpunar-Krok, E.; Hortyńska, P. Polysaccharides as Edible Films and Coatings: Characteristics and Influence on Fruit and Vegetable Quality—A Review. Agronomy 2021, 11, 813. [Google Scholar] [CrossRef]

- Moreno, O.; Atarés, L.; Chiralt, A.; Cruz-Romero, M.C.; Kerry, J. Starch-Gelatin Antimicrobial Packaging Materials to Extend the Shelf Life of Chicken Breast Fillets. Lwt 2018, 97, 483–490. [Google Scholar] [CrossRef]

- Sánchez-Ortega, I.; García-Almendárez, B.E.; Santos-López, E.M.; Amaro-Reyes, A.; Barboza-Corona, J.E.; Regalado, C. Antimicrobial Edible Films and Coatings for Meat and Meat Products Preservation. Sci. World J. 2014, 2014, 248935. [Google Scholar] [CrossRef] [PubMed]

- Biegańska, M. Packaging of Dairy Products: Emerging Strategies. In Food Packaging: The Smarter Way; Shukla, A.K., Ed.; Springer Nature Singapore: Singapore, 2022; pp. 127–164. ISBN 978-981-16-7195-1. [Google Scholar]

- Angiolillo, L.; Lucera, A.; Del Nobile, M.A.; Conte, A. Antimicrobial Compounds Applied to Dairy Food. In Advances in Dairy Products; Conto, F., Ed.; Wiley: Hoboken, NJ, USA, 2017; pp. 274–294. ISBN 978-1-118-90643-9. [Google Scholar]

- Tajeddin, B. Cellulose-Based Polymers for Packaging Applications. In Lignocellulosic Polymer Composites; Thakur, V.K., Ed.; Wiley: Hoboken, NJ, USA, 2014; pp. 477–498. ISBN 978-1-118-77357-4. [Google Scholar]

- Liu, Y.; Ahmed, S.; Sameen, D.E.; Wang, Y.; Lu, R.; Dai, J.; Li, S.; Qin, W. A Review of Cellulose and Its Derivatives in Biopolymer-Based for Food Packaging Application. Trends Food Sci. Technol. 2021, 112, 532–546. [Google Scholar] [CrossRef]

- Gupta, V.; Biswas, D.; Roy, S. A comprehensive review of biodegradable polymer-based films and coatings and their food packaging applications. Materials 2022, 15, 5899. [Google Scholar] [CrossRef]

- Gürler, N.; Paşa, S.; Temel, H. Silane Doped Biodegradable Starch-PLA Bilayer Films for Food Packaging Applications: Mechanical, Thermal, Barrier and Biodegradability Properties. J. Taiwan Inst. Chem. Eng. 2021, 123, 261–271. [Google Scholar] [CrossRef]

- Rahman, S.; Batsh, C.; Gurumayam, S.; Borah, J.C.; Chowdhury, D. Sodium alginate-nanocellulose-based active composite film for edible oils packaging applications. Mater. Adv. 2024, 5, 9314–9329. [Google Scholar] [CrossRef]

- Ncube, L.K.; Ude, A.U.; Ogunmuyiwa, E.N.; Zulkifli, R.; Beas, I.N. Environmental Impact of Food Packaging Materials: A Review of Contemporary Development from Conventional Plastics to Polylactic Acid Based Materials. Materials 2020, 13, 4994. [Google Scholar] [CrossRef]

- Kabir, E.; Kaur, R.; Lee, J.; Kim, K.-H.; Kwon, E.E. Prospects of Biopolymer Technology as an Alternative Option for Non-Degradable Plastics and Sustainable Management of Plastic Wastes. J. Clean. Prod. 2020, 258, 120536. [Google Scholar] [CrossRef]

- Kwan, T.H.; Hu, Y.; Lin, C.S.K. Techno-Economic Analysis of a Food Waste Valorisation Process for Lactic Acid, Lactide and Poly (Lactic Acid) Production. J. Clean. Prod. 2018, 181, 72–87. [Google Scholar] [CrossRef]

- Tesfaye, T.; Ayele, M.; Ferede, E.; Gibril, M.; Kong, F.; Sithole, B. A Techno-Economic Feasibility of a Process for Extraction of Starch from Waste Avocado Seeds. Clean. Technol. Environ. Policy 2021, 23, 581–595. [Google Scholar] [CrossRef]

- Jafarzadeh, S.; Jafari, S.M. Impact of Metal Nanoparticles on the Mechanical, Barrier, Optical and Thermal Properties of Biodegradable Food Packaging Materials. Crit. Rev. Food Sci. Nutr. 2021, 61, 2640–2658. [Google Scholar] [CrossRef]

- Ediyilyam, S.; George, B.; Shankar, S.S.; Dennis, T.T.; Wacławek, S.; Černík, M.; Padil, V.V. Chitosan/Gelatin/Silver Nanoparticles Composites Films for Biodegradable Food Packaging Applications. Polymers 2021, 13, 1680. [Google Scholar] [CrossRef]

- Wu, X.; Liu, P.; Shi, H.; Wang, H.; Huang, H.; Shi, Y.; Gao, S. Photo Aging and Fragmentation of Polypropylene Food Packaging Materials in Artificial Seawater. Water Res. 2021, 188, 116456. [Google Scholar] [CrossRef]

- Asgher, M.; Qamar, S.A.; Bilal, M.; Iqbal, H.M. Bio-Based Active Food Packaging Materials: Sustainable Alternative to Conventional Petrochemical-Based Packaging Materials. Food Res. Int. 2020, 137, 109625. [Google Scholar] [CrossRef]

- Siracusa, V.; Lotti, N.; Munari, A.; Dalla Rosa, M. Poly (Butylene Succinate) and Poly (Butylene Succinate-Co-Adipate) for Food Packaging Applications: Gas Barrier Properties after Stressed Treatments. Polym. Degrad. Stab. 2015, 119, 35–45. [Google Scholar] [CrossRef]

- Cazón, P.; Vázquez, M. Bacterial Cellulose as a Biodegradable Food Packaging Material: A Review. Food Hydrocoll. 2021, 113, 106530. [Google Scholar] [CrossRef]

- Zhao, Q.; Shi, Y.; Wang, X.; Huang, A. Characterization of a Novel Antimicrobial Peptide from Buffalo Casein Hydrolysate Based on Live Bacteria Adsorption. J. Dairy Sci. 2020, 103, 11116–11128. [Google Scholar] [CrossRef]

- Detzel, A.; Krüger, M. Life Cycle Assessment of PLA: A Comparison of Food Packaging Made from NatureWorks PLA and Alternative Materials; Institut für Energie-und Umweltforschung: Heidelberg, Germany, 2006. [Google Scholar]

- Ureña, M.; Phùng, T.T.; Gerometta, M.; de Siqueira Oliveira, L.; Chanut, J.; Domenek, S.; Dole, P.; Roudaut, G.; Lagorce, A.; Karbowiak, T. Potential of Polysaccharides for Food Packaging Applications: An Experimental Review of the Functional Properties of Polysaccharide Coatings (Part 1/2). Food Hydrocoll. 2023, 144, 108955. [Google Scholar] [CrossRef]

- Cazón, P.; Velázquez, G.; Ramírez, J.A.; Vázquez, M. Polysaccharide-Based Films and Coatings for Food Packaging: A Review. Food Hydrocoll. 2017, 68, 136–148. [Google Scholar] [CrossRef]

- Zhao, Y.; Li, B.; Li, C.; Xu, Y.; Luo, Y.; Liang, D.; Huang, C. Comprehensive Review of Polysaccharide-Based Materials in Edible Packaging: A Sustainable Approach. Foods 2021, 10, 1845. [Google Scholar] [CrossRef]

- Chen, G.; Li, J.; Sun, Y.; Wang, Z.; Leeke, G.A.; Moretti, C.; Cheng, Z.; Wang, Y.; Li, N.; Mu, L. Replacing Traditional Plastics with Biodegradable Plastics: Impact on Carbon Emissions. Engineering 2024, 32, 152–162. [Google Scholar] [CrossRef]

- Dalastra, C.; Klanovicz, N.; Kubeneck, S.; Stefanski, F.S.; Argenta, D.F.; Rauber, G.S.; Caon, T.; Cadamuro, R.D.; Fongaro, G.; Treichel, H. Carbohydrate-Based Economy: Perspectives and Challenges. In Polysaccharide-Degrading Biocatalysts; Academic Press (Elsevier): Cambridge, MA, USA, 2023; pp. 409–434. [Google Scholar]

- National Research Council (US) Committee on Biobased Industrial Products. Biobased Industrial Products: Research and Commercialization Priorities; National Academies Press: Washington, DC, USA, 2000. [Google Scholar]

- do Val Siqueira, L.; Arias, C.I.L.F.; Maniglia, B.C.; Tadini, C.C. Starch-Based Biodegradable Plastics: Methods of Production, Challenges and Future Perspectives. Curr. Opin. Food Sci. 2021, 38, 122–130. [Google Scholar] [CrossRef]

- Ghosh, K.; Jones, B.H. Roadmap to Biodegradable Plastics—Current State and Research Needs. ACS Sustain. Chem. Eng. 2021, 9, 6170–6187. [Google Scholar] [CrossRef]

- Tajik, S.; Maghsoudlou, Y.; Khodaiyan, F.; Jafari, S.M.; Ghasemlou, M.; Aalami, M. Soluble Soybean Polysaccharide: A New Carbohydrate to Make a Biodegradable Film for Sustainable Green Packaging. Carbohydr. Polym. 2013, 97, 817–824. [Google Scholar] [CrossRef] [PubMed]

- Janik, W.; Jakubski, Ł.; Kudła, S.; Dudek, G. Modified Polysaccharides for Food Packaging Applications: A Review. Int. J. Biol. Macromol. 2024, 258, 128916. [Google Scholar] [CrossRef]

- Versino, F.; Ortega, F.; Monroy, Y.; Rivero, S.; López, O.V.; García, M.A. Sustainable and Bio-Based Food Packaging: A Review on Past and Current Design Innovations. Foods 2023, 12, 1057. [Google Scholar] [CrossRef]

- Zubair, M.; Pradhan, R.A.; Arshad, M.; Ullah, A. Recent Advances in Lipid Derived Bio-Based Materials for Food Packaging Applications. Macro Mater. Eng. 2021, 306, 2000799. [Google Scholar] [CrossRef]

- Suderman, N.; Isa, M.I.N.; Sarbon, N.M. The Effect of Plasticizers on the Functional Properties of Biodegradable Gelatin-Based Film: A Review. Food Biosci. 2018, 24, 111–119. [Google Scholar] [CrossRef]

- Liu, J.; Sun, L.; Xu, W.; Wang, Q.; Yu, S.; Sun, J. Current Advances and Future Perspectives of 3D Printing Natural-Derived Biopolymers. Carbohydr. Polym. 2019, 207, 297–316. [Google Scholar] [CrossRef]

- Ottman, J.A.; Stafford, E.R.; Hartman, C.L. Avoiding Green Marketing Myopia: Ways to Improve Consumer Appeal for Environmentally Preferable Products. Environ. Sci. Policy Sustain. Dev. 2006, 48, 22–36. [Google Scholar] [CrossRef]

- Scott, L.; Vigar-Ellis, D. Consumer Understanding, Perceptions and Behaviours with Regard to Environmentally Friendly Packaging in a Developing Nation. Int. J. Consum. Stud. 2014, 38, 642–649. [Google Scholar] [CrossRef]

| Film Type | Properties | Food Products Packaged | Packaging Functionality | Challenges | Sources | Film Fabrication Methods | References |

|---|---|---|---|---|---|---|---|

| Pectin-based | Biocompatible, gelling ability, antioxidant-rich | Cheese, meats, seafood | Barrier to microbes and gases | Low mechanical strength, water sensitivity | Apple pomace, citrus peels | Solution casting, extrusion | [35,36] |

| Starch-based | Abundant, low-cost, flexible, biodegradable | Tomatoes, chicken, bakery | Moisture retention, transparency | High water vapor permeability | Corn, potato, cassava | Extrusion, thermo-compression | [39] |

| Cellulose-based | High mechanical strength, transparency, oxygen barrier | Fruits, vegetables, cereals | Strength, gas permeability control | Hydrophilic, poor thermal resistance | Wood pulp, cotton, agro-residues | Solvent casting, roll coating | [46] |

| Chitosan-based | Antimicrobial, biodegradable, edible | Poultry, cheese, berries | Antimicrobial action, preservation | Brittle at neutral pH, limited flexibility | Shrimp shells, insect chitin | Casting, layer-by-layer coating | [51] |

| Pullulan-based | Transparent, flexible, good oxygen barrier | Dried snacks, bakery items | Oxygen barrier, flexibility | High cost, water sensitivity | Fungal fermentation (A. pullulans) | Casting, spray drying | [55,60] |

| Xanthan gum-based | High viscosity, stable under pH and temperature variation | Sauces, dressings, jellies | Thickening and emulsifying | Poor mechanical strength, needs blends | Xanthomonas campestris | Solution casting, blending | [61,62] |

| Alginate-based | Film-forming, biocompatible, ionically cross-linkable | Oils, fruits, nutraceuticals | Moisture and aroma retention | Weak moisture barrier, complex gelation | Brown seaweed, bacterial alginate | Ionic gelation, solvent evaporation | [54,55,63] |

| Composite films | Tailored barrier and mechanical properties via blending | Meat, multilayer packaging | Improved durability and barrier | Formulation complexity, regulatory limits | Blends of biopolymers, nanomaterials | Extrusion, lamination | [64,65,66,67] |

| Gellan gum-based | Good thermal stability, forms firm gels | Meat gels, dairy, snacks | Firm texture, thermal control | Extraction complexity, high cost | Bacterial fermentation (Sphingomonas spp.) | Calcium cross-linking, drying | [58] |

| Curdlan-based | Forms thermally reversible gels, biodegradable | Soy-based foods, gluten-free items | Texturization, preservation | Thermal instability in some blends | Alkaline treatment of microbial polysaccharides | Heat-induced gelation, film pressing | [59] |

| Fabrication Technique | Film Characteristics | Material Compatibility | Enhancement Strategies | References |

|---|---|---|---|---|

| Solution Casting | Uniform thickness, good surface finish, suitable for lab-scale films | Starch, pectin, cellulose derivatives, xanthan gum | Plasticizers, nanofillers, cross-linkers, active agents | [69] |

| Extrusion | Continuous film production, specific shapes/textures, suitable for industrial scale | Starch, PLA blends, thermoplastic derivatives | Blending, nanocomposites, multilayer film integration | [70,71] |

| Electrospinning | High surface area, porous structure, ideal for functionalized films | Chitosan, cellulose nanofibers, PVA blends | Encapsulation of active compounds, nanofiber reinforcement | [72] |

| Layer-by-Layer Assembly | Nano-to-microscale multilayers, controlled composition, high barrier properties | Charged polysaccharides (e.g., chitosan, alginate) | Cross-linking, interfacial adsorption, layer functionalization | [73] |

| 3D Printing | Complex geometries, custom shapes and porosity, emerging technique | Starch-based hydrogels, alginate composites | Functional additives, multilayer constructs | [74] |

| Spray Coating | Thin and uniform coatings, scalable, low waste | Starch, pectin, and soluble carbohydrate solutions | Active ingredients, surfactants, stabilizers | [75] |

| Commodity | Film Type | Functional Role | Application Example | Packaging Requirement | Technical Challenges | Suggested Improvements | References |

|---|---|---|---|---|---|---|---|

| Fruits and Vegetables | Pectin, Starch, Chitosan | Gas and moisture barrier, antimicrobial | Pectin coating for apples | Breathability, light weight, transparency | Low mechanical strength, moisture sensitivity | Blend with lipids, add cellulose or nanofillers | [87,94] |

| Meat and Poultry | Chitosan, Composite Films | Oxidation and microbial inhibition | Chitosan wrap for beef/chicken | Puncture resistance, moisture retention | Film degradation in humid conditions | Composite films with proteins, cross-linking | [95,96] |

| Dairy Products | Starch, Chitosan | Moisture barrier, mold inhibition | Starch film for cheese aging | Control of humidity and microbial growth | Fat interaction reduces film integrity | Add hydrophobic agents or protein blends | [97,98] |

| Cereals and Grains | Cellulose, Alginate | Humidity and oxygen barrier | Cellulose wrap for rice | Stable moisture barrier under dry conditions | Brittleness in low RH environments | Use of plasticizers, multilayer structures | [99,100] |

| Nuts and Seeds | Pectin, Pullulan | Moisture/O2 barrier, oil retention | Pullulan film on roasted nuts | Aroma protection, oil migration resistance | Oil absorption reduces strength | Coatings with waxes, lamination | [27] |

| Dried Fruits | Xanthan gum, Alginate | Preservation of softness and appearance | Alginate-coated figs | Transparency, oxidation resistance | Cracking under storage stress | Incorporate glycerol or glycerides | [27] |

| Grain Snacks | Starch, Chitosan | Barrier to gas and texture degradation | Starch wrap for puffed snacks | Lightweight, rigid films | Poor tensile strength | Reinforce with nanocellulose | [101,102] |

| Vegetable Oils | Alginate, Composite | Spill resistance, oil absorption control | Alginate sachets | Hydrophobic and oxidation barriers | Oil permeability over time | Layered systems, surface coating | [103] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dhalsamant, K.; Dalai, A.; Pattnaik, F.; Acharya, B. Biodegradable Carbohydrate-Based Films for Packaging Agricultural Products—A Review. Polymers 2025, 17, 1325. https://doi.org/10.3390/polym17101325

Dhalsamant K, Dalai A, Pattnaik F, Acharya B. Biodegradable Carbohydrate-Based Films for Packaging Agricultural Products—A Review. Polymers. 2025; 17(10):1325. https://doi.org/10.3390/polym17101325

Chicago/Turabian StyleDhalsamant, Kshanaprava, Asutosh Dalai, Falguni Pattnaik, and Bishnu Acharya. 2025. "Biodegradable Carbohydrate-Based Films for Packaging Agricultural Products—A Review" Polymers 17, no. 10: 1325. https://doi.org/10.3390/polym17101325

APA StyleDhalsamant, K., Dalai, A., Pattnaik, F., & Acharya, B. (2025). Biodegradable Carbohydrate-Based Films for Packaging Agricultural Products—A Review. Polymers, 17(10), 1325. https://doi.org/10.3390/polym17101325