Fully Bio-Based Polymer Composites: Preparation, Characterization, and LCD 3D Printing

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Bio-Based Composites Preparation

2.3. 3D Printing of AESO-Based Samples by LCD 3D Printer

2.4. Characterization Techniques

3. Results and Discussion

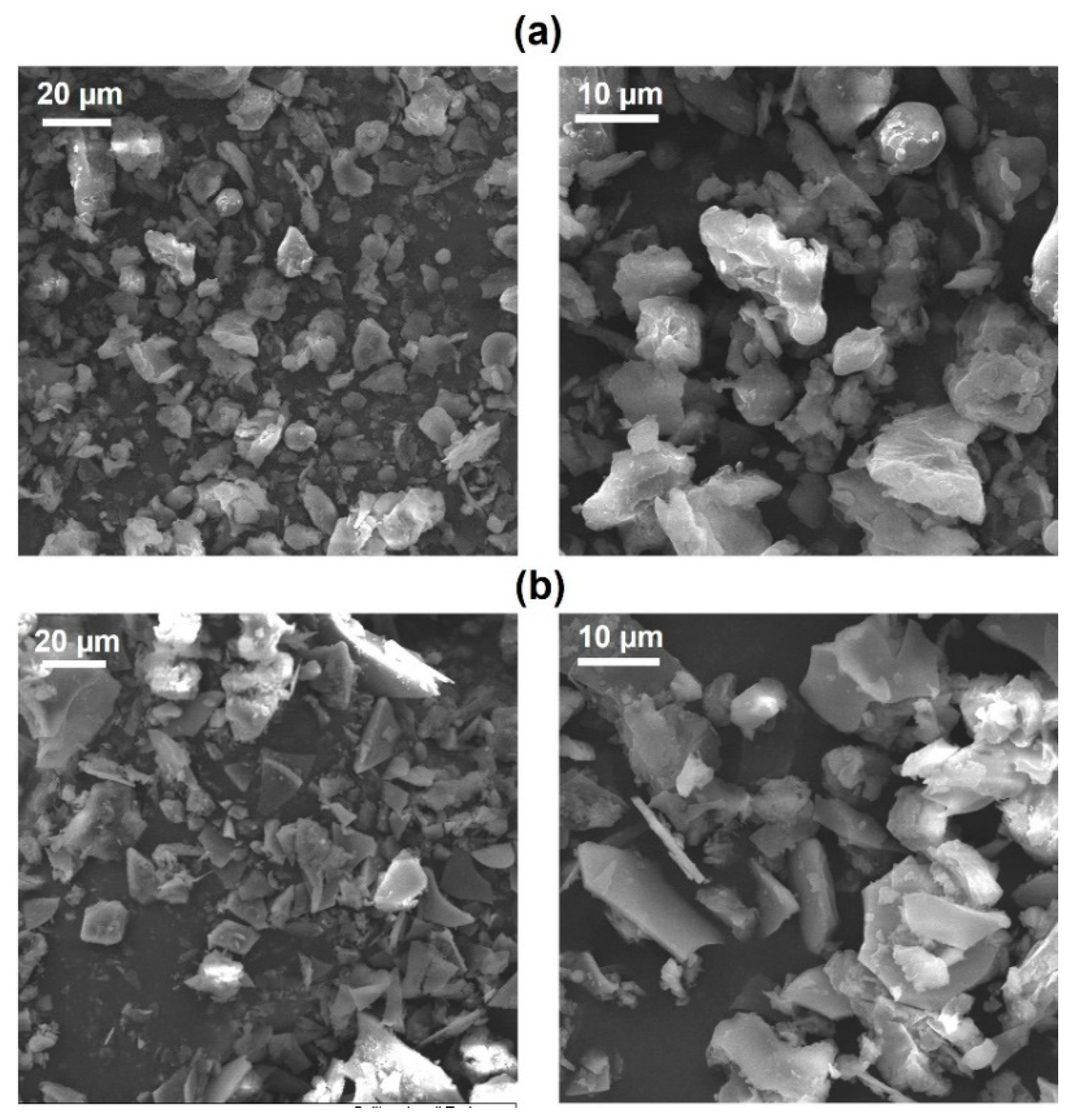

3.1. Biofillers’ Characterization

3.2. AESO-Based Photocurable Formulations

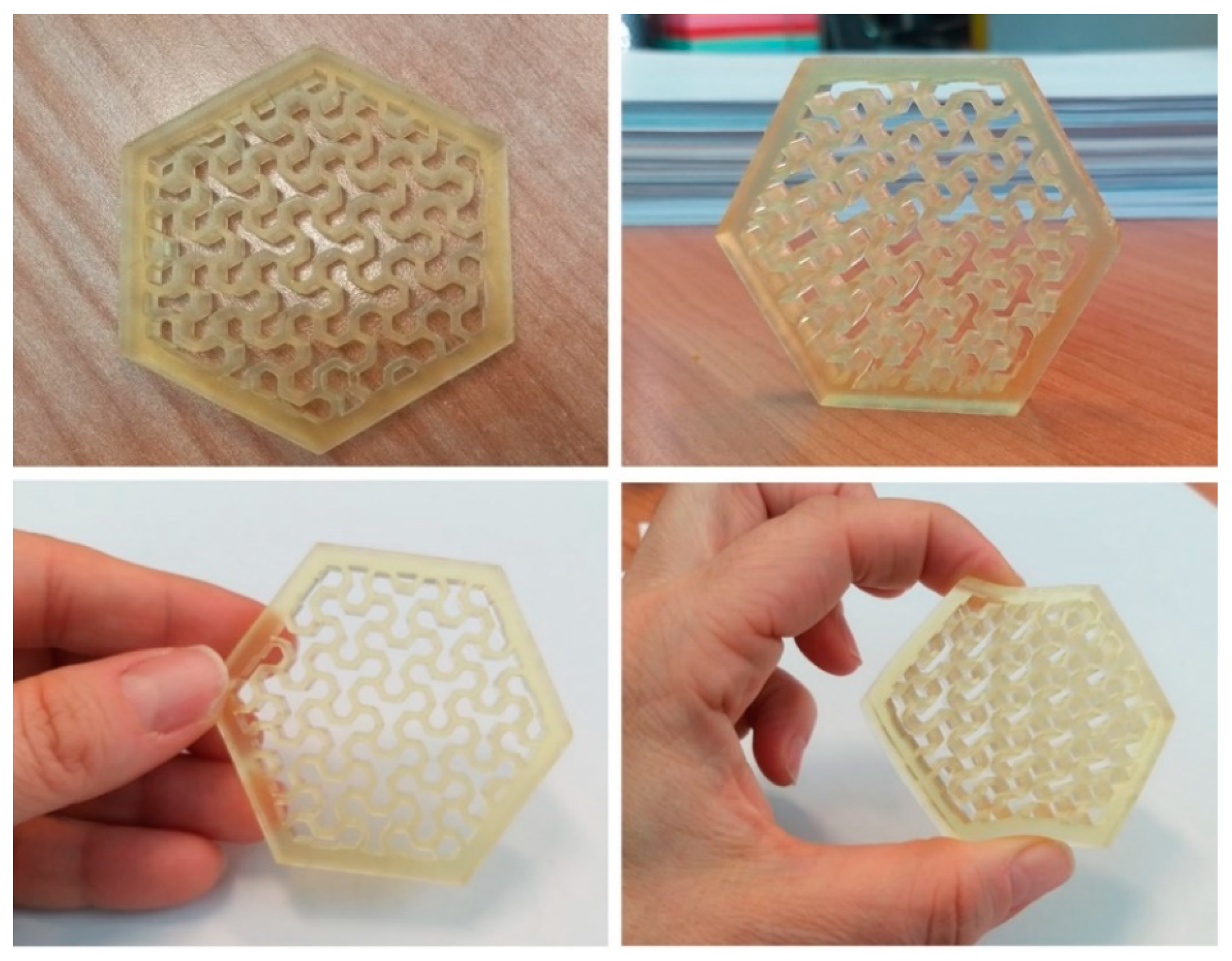

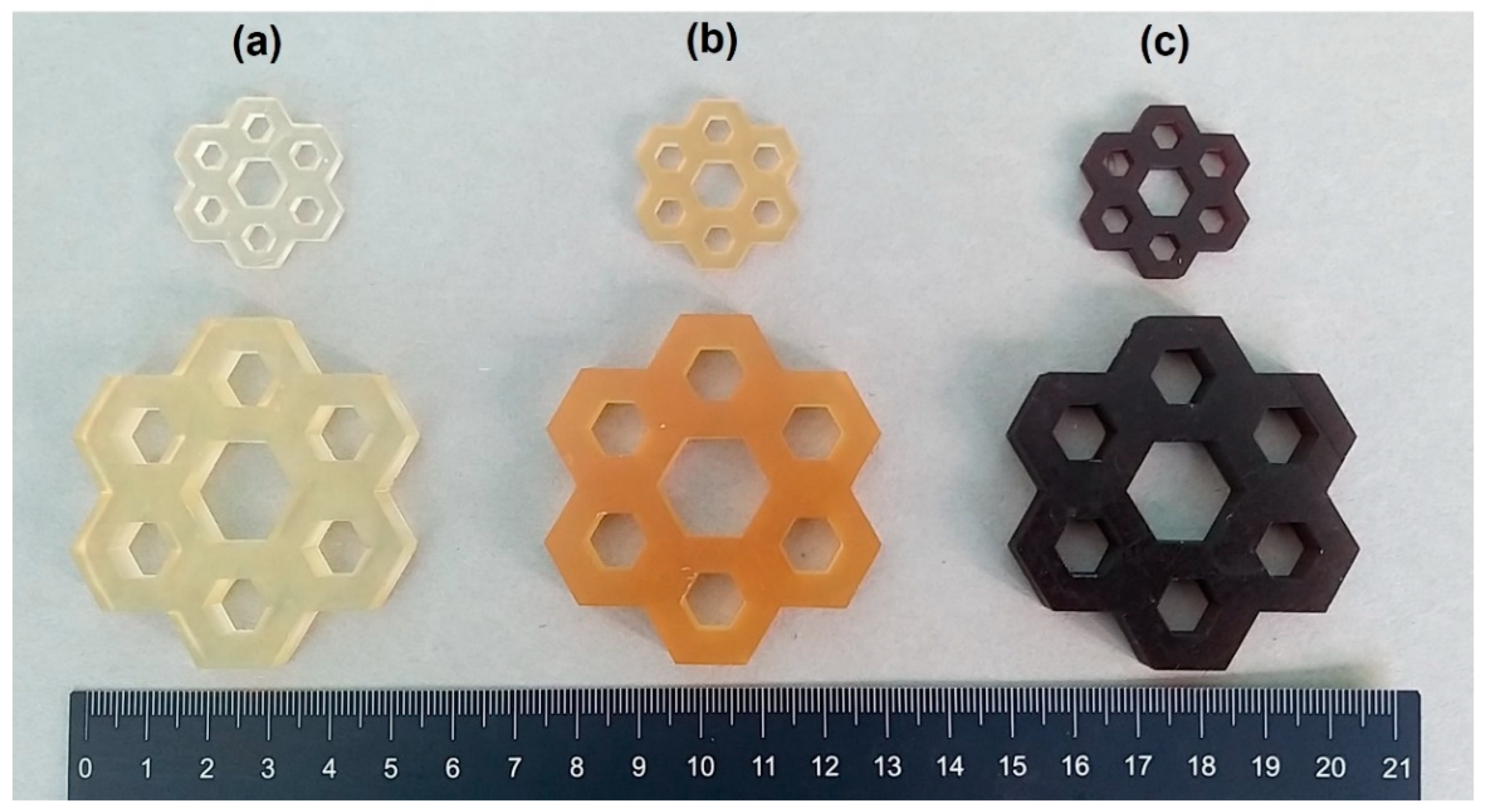

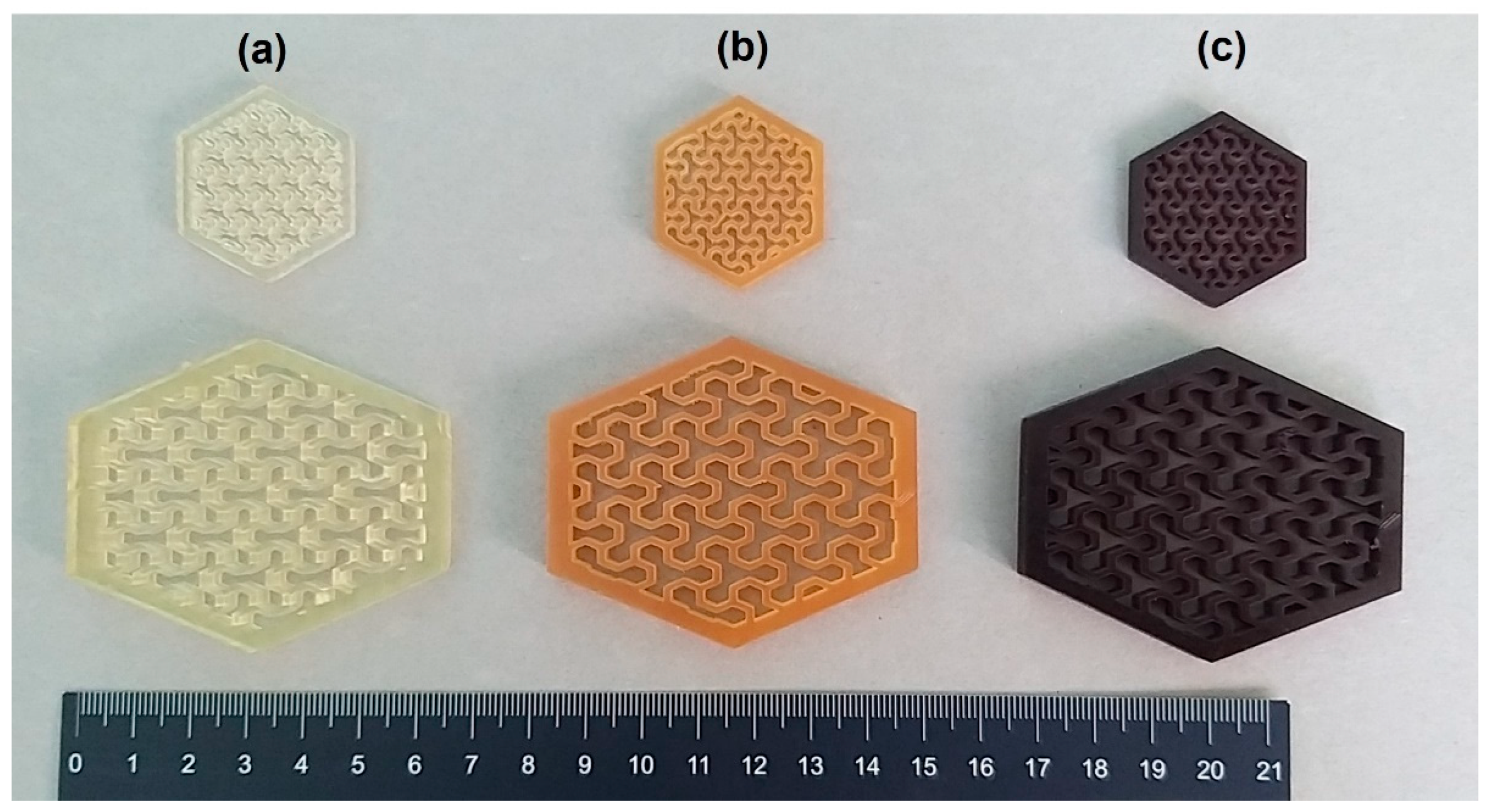

3.3. 3D Printing of AESO-Based Liquid Formulations by LCD

3.4. Insoluble Fraction

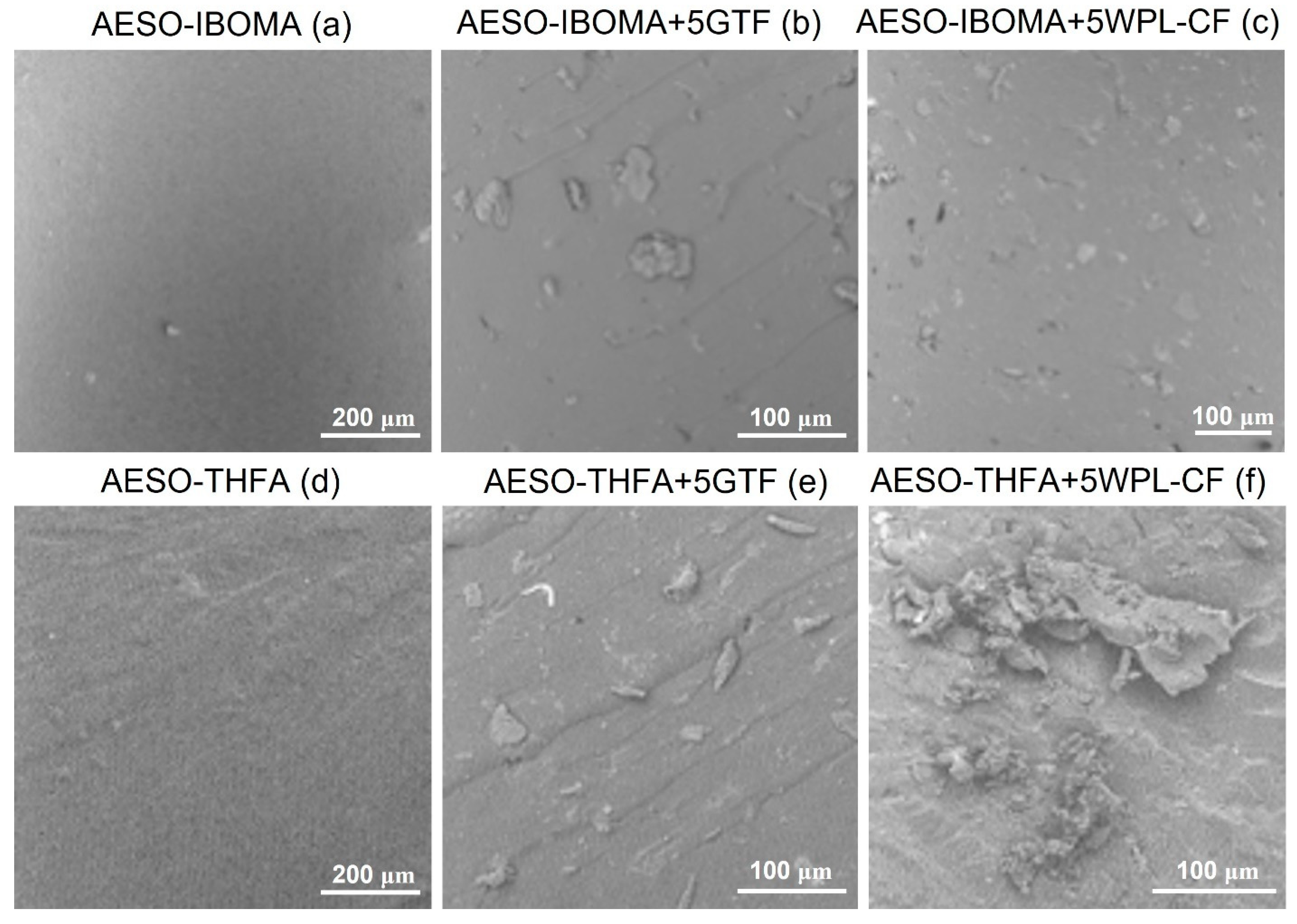

3.5. Microstructure of AESO-Based Composites

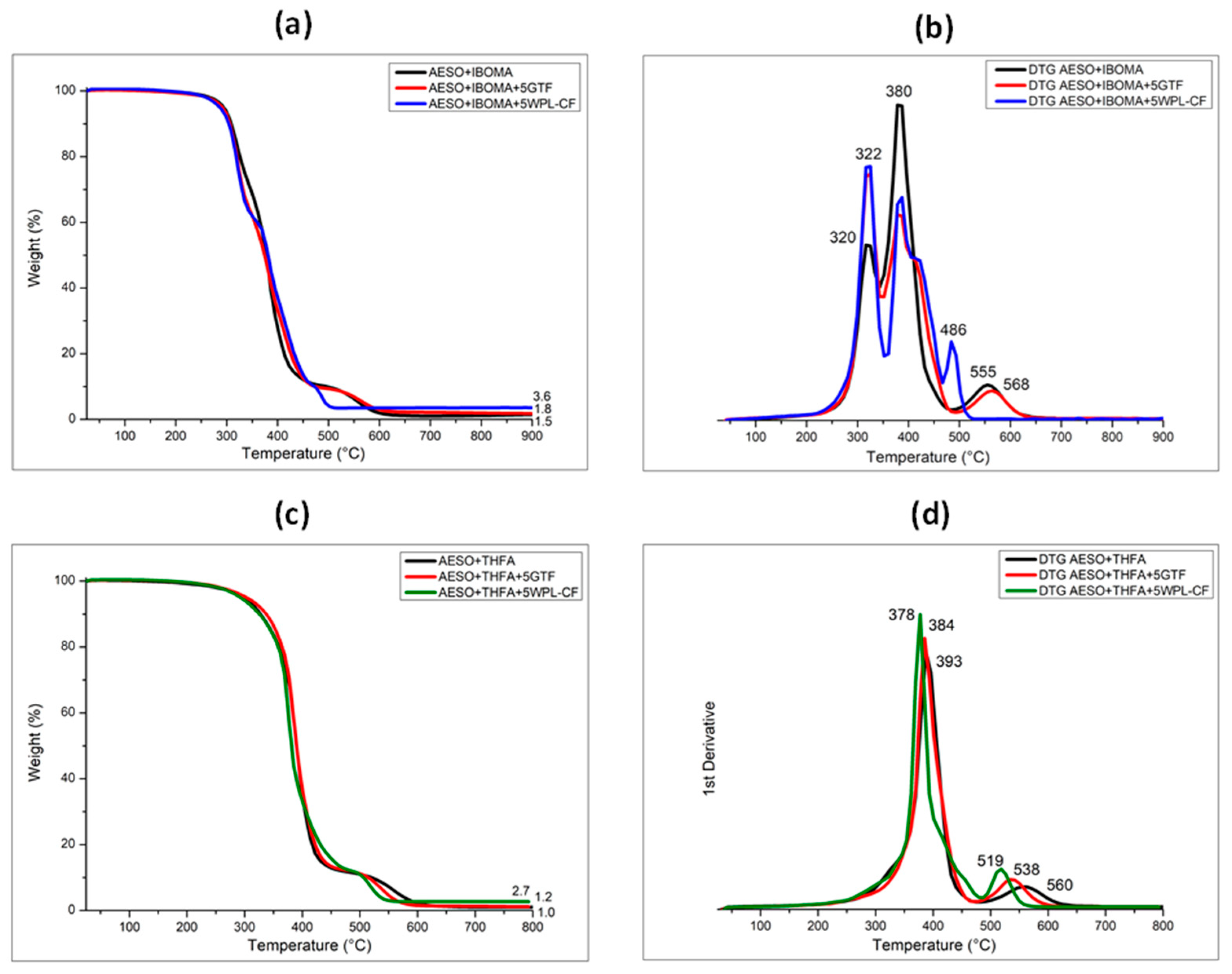

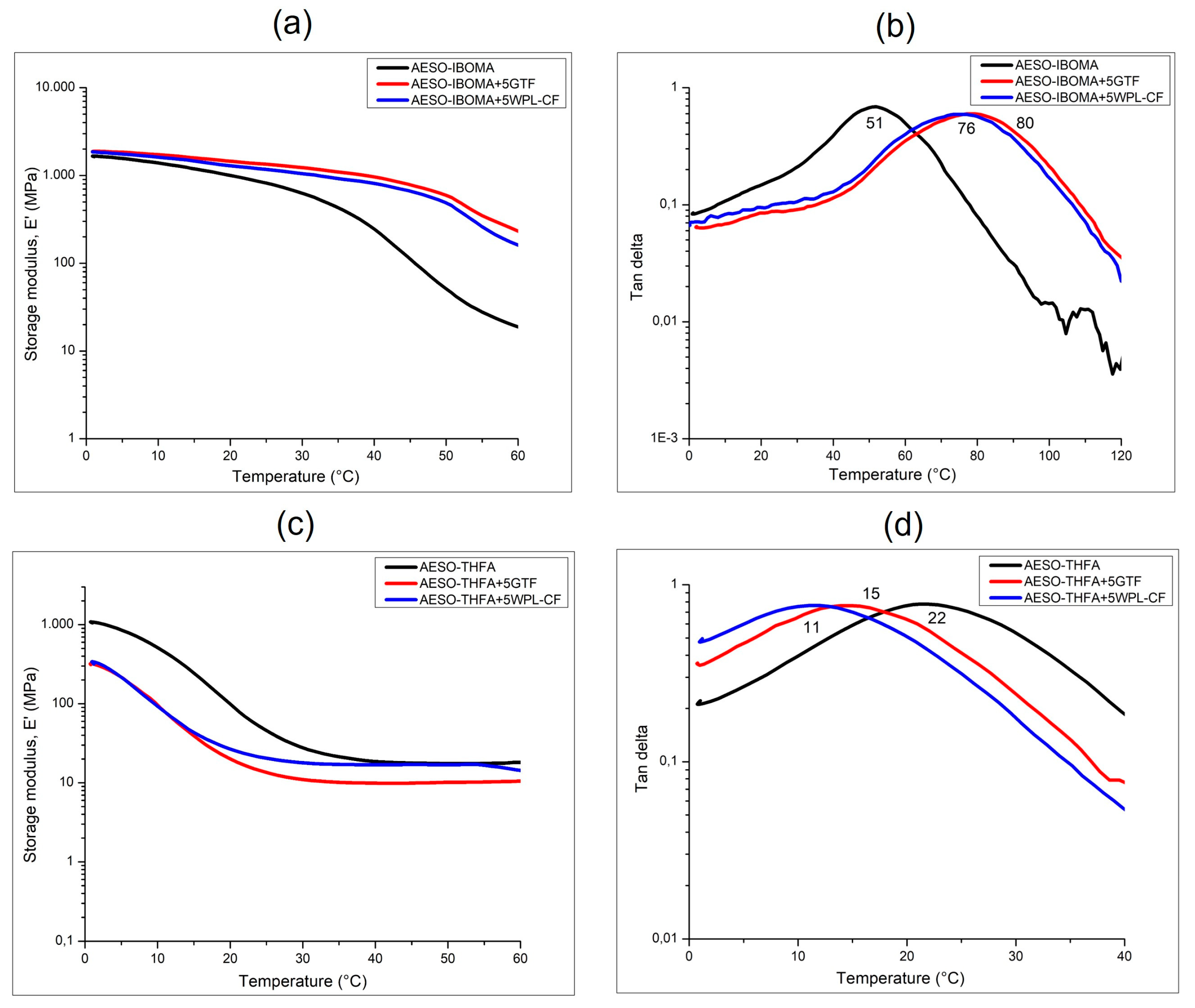

3.6. Thermal and Viscoelastic Properties

3.7. Tensile Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anketa, J.; Ikshita, C.; Ishika, W.; Ankush, R.; Ul Haq, M.I. 3D printing—A review of processes, materials and applications in industry 4.0. Sustain. Oper. Comput. 2022, 3, 33–42. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-curing 3D printing technique and its challenges. Bioact. Mater. 2020, 5, 110–111. [Google Scholar] [CrossRef] [PubMed]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mulhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.; Kashani, A.; Imbalzano, G.; Nguyen, K.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Thakar, C.M.; Parkhe, S.S.; Jain, A.; Phasinam, K.; Murugesan, G.; Joy, R.; Ventayen, M. 3d Printing: Basic principles and applications. Mater. Today Proc. 2022, 51, 842–849. [Google Scholar] [CrossRef]

- Christina, K.; Subbiah, K.; Arulraj, P.; Kumar Krishnan, S.; Sathishkumar, P. A sustainable and eco-friendly approach for environmental and energy management using biopolymers chitosan, lignin and cellulose-A review. Int. J. Biol. Macromol. 2024, 257, 128550. [Google Scholar] [CrossRef] [PubMed]

- Alammar, A.; Kois, J.C.; Revilla-León, M.; Att, W. Additive Manufacturing Technologies: Current Status and Future Perspectives. J. Prosthodont. 2022, 31, 4–12. [Google Scholar] [CrossRef] [PubMed]

- Sanchez-Rexach, E.; Johnston, T.G.; Jehanno, C.; Sardon, H.; Nelson, A. Sustainable Materials and Chemical Processes for Additive Manufacturing. Chem. Mater. 2020, 32, 7105–7119. [Google Scholar] [CrossRef]

- Voet, V.S.D.; Guit, J.; Loos, K. Sustainable photopolymers in 3d printing: A review on biobased, biodegradable, and recyclable alternatives. Macromol. Rapid Commun. 2021, 42, 2000475. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, Y.; Simon-Masseron, A.; Lalevee, J. Radical photoinitiation with LEDs and applications in the 3D printing of composites. Chem Soc Rev 2021, 42, 3824–3841. [Google Scholar] [CrossRef]

- Medellin, A.; Du, W.; Miao, G.; Zou, J.; Pei, Z.; Ma, C. Vat photopolymerization 3d printing of nanocomposites: A literature review. J. Micro Nano-Manuf. 2019; 7, 031006–031017. [Google Scholar] [CrossRef]

- Skliutas, E.; Lebedevaite, M.; Kasetaite, S.; Rekštytė, S.; Lileikis, S.; Ostrauskaite, J.; Malinauskas, M. A Bio-Based Resin for a Multi-Scale Optical 3D Printing. Sci. Rep. 2020, 10, 9758. [Google Scholar] [CrossRef] [PubMed]

- Galià, M.; Montero de Espinosa, L.; Carles Ronda, J.; Lligadas, G.; Cádiz, V. Vegetable oil-based thermosetting polymers. Eur. J. Lipid Sci. Technol. 2009, 111, 87–96. [Google Scholar] [CrossRef]

- Lebedevaite, M.; Talacka, V.; Ostrauskaite, J. High biorenewable content acrylate photocurable resins for DLP 3D printing. J Appl. Polym. Sci. 2021, 138, 50233. [Google Scholar] [CrossRef]

- Fernandes, F.C.; Kirwan, K.; Lehane, D.; Coles, S.R. Epoxy resin blends and composites from waste vegetable oil. Eur. Polym. J. 2017, 89, 449–460. [Google Scholar] [CrossRef]

- Lebedevaite, M.; Gineika, A.; Talacka, V.; Baltakys, K.; Ostrauskaite, J. Development and optical 3D printing of acrylated epoxidized soybean oil-based composites with functionalized calcium silicate hydrate filler derived from aluminium fluoride production waste. Compos. Part A 2022, 157, 106929. [Google Scholar] [CrossRef]

- Navaruckiene, A.; Skliutas, E.; Kasetaite, S.; Rekštyte, S.; Raudoniene, V.; Bridziuviene, D.; Malinauskas, M.; Ostrauskaite, J. Vanillin Acrylate-Based Resins for Optical 3D Printing. Polymers 2020, 12, 397. [Google Scholar] [CrossRef] [PubMed]

- Noé, C.; Cosola, A.; Tonda-Turo, C.; Sesana, R.; Delprete, C.; Chiappone, A.; Hakkarainen, M.; Sangermano, M. DLP-printable fully biobased soybean oil composites. Polymer 2022, 247, 124779. [Google Scholar] [CrossRef]

- Bragaglia, M.; Paleari, L.; Passaro, J.; Russo, P.; Fabbrocino, F.; Luciano, R.; Nanni, F. 3D printing of biodegradable and self-monitoring SWCNT-loaded biobased resin. Compos. Sci. Technol. 2023, 243, 110253. [Google Scholar] [CrossRef]

- Mondal, D.; Haghpanah, Z.; Huxman, C.J.; Tanter, S.; Sun, D.; Gorbet, M.; Willett, T.L. mSLA-based 3D printing of acrylated epoxidized soybean oil—Nano-hydroxyapatite composites for bone repair. Mater. Sci. Eng. C 2021, 130, 112456. [Google Scholar] [CrossRef]

- Kang, H.W.; Lee, S.J.; Ko, I.K.; Kengla, C.; Yoo, J.J.; Atala, A. A 3D bioprinting system to produce human-scale tissue constructs with structural integrity. Nat. Biotechnol. 2016, 34, 312–319. [Google Scholar] [CrossRef]

- Chia, H.N.; Wu, B.M. Recent advances in 3D printing of biomaterials. J. Biol. Eng. 2015, 9, 4. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Zhang, Q.; Yang, Z.; Bian, Y.; Chen, G.; Li, D.; Zheng, W.; Wei, Y.; Bi, Y.; Ding, K.; et al. Fabrication and characterization of light-curing soybean oil-based epoxy resin applied for LCD additive manufacturing. Ind. Crop. Prod. 2023, 202, 117037. [Google Scholar] [CrossRef]

- Batarseh, S.; Goldsberry, N.; Handysides, C.; Nemat-Bakhsh, L.; Valenzuela, C.; Caruso, J.; Rungcharasaeng, K.; Oyoyo, U. Comparison of Volumetric Change in Objects Printed with LCD and DLP 3D Printers. J. Calif. Dent. Assoc. 2023, 51, 2271641. [Google Scholar] [CrossRef]

- Singh, T.; Gangil, B.; Patnaik, A.; Biswas, D.; Fekete, G. Agriculture waste reinforced corn starch-based biocomposites: Effect of rice husk/walnut shell on physicomechanical, biodegradable and thermal properties. Mater. Res. Express 2019, 6, 045702. [Google Scholar] [CrossRef]

- Lastovickova, D.N.; Toulan, F.R.; Mitchell, J.R.; VanOosten, D.; Clay, A.M.; Stanzione, J.F.; Palmese, G.R.; La Scala, J.J. Resin, cure, and polymer properties of photopolymerizable resins containing bio-derived isosorbide. J. Appl. Polym. Sci. 2021, 138, 50574. [Google Scholar] [CrossRef]

- Vyas, A.; Garg, V.; Bandhu Ghosh, S.; Bandyopadhyay-Ghosh, S. Photopolymerizable resin-based 3D printed biomedical composites: Factors affecting resin viscosity. Mater. Today Proc. 2022, 62, 1435–1439. [Google Scholar] [CrossRef]

- Guerra, A.J.; Lammel-Lindemann, J.; Katko, A.; Kleinfehn, A.; Rodriguez, C.A.; Catalani, L.H.; Beckerc, M.L.; Ciurana, J.; Dean, D. Optimization of photocrosslinkable resin components and 3D printing process parameters. Acta Biomater. 2019, 97, 154–161. [Google Scholar] [CrossRef]

- Liu, Y.; Lin, Y.; Jiao, T.; Lu, G.; Liu, J. Photocurable modification of inorganic fillers and their application in photopolymers for 3D printing. Polym. Chem. 2019, 10, 6350–6359. [Google Scholar] [CrossRef]

- Barkane, A.; Platnieks, O.; Jurinovs, M.; Gaidukovs, S. Thermal stability of UV cured vegetable oil epoxidized acrylate-based polymer system for 3D printing application. Polym. Degrad. Stab. 2020, 181, 109347. [Google Scholar] [CrossRef]

- Shogren, R.L.; Petrovic, Z.; Liu, Z.; Erhan, S.Z. Biodegradation behavior of some vegetable oil-based polymers. J. Polym. Environ. 2004, 12, 173–178. [Google Scholar] [CrossRef]

- Savini, G.; Orefice, R.L. Comparative study of HDPE composites reinforced with microtalc and nanotalcs: High performance filler for improving ductility at low concentration levels. J. Mater. Res. Technol. 2020, 9, 16387–16398. [Google Scholar] [CrossRef]

- Barkane, A.; Platnieks, O.; Jurinovs, M.; Kasetaite, S.; Ostrauskaite, J.; Gaidukovs, S.; Habibi, Y. UV-Light Curing of 3D Printing Inks from Vegetable Oils for Stereolithography. Polymers 2021, 13, 1195. [Google Scholar] [CrossRef] [PubMed]

| Sample Code | AESO (wt.%) | Diluent (wt.%) | Biofiller (phr) |

|---|---|---|---|

| AESO-IBOMA | 60 | 40 | 0 |

| AESO-IBOMA+5GTF | 60 | 40 | 5 |

| AESO-IBOMA+5WPL-CF | 60 | 40 | 5 |

| AESO-THFA | 60 | 40 | 0 |

| AESO-THFA+5GTF | 60 | 40 | 5 |

| AESO-THFA+5WPL-CF | 60 | 40 | 5 |

| Parameter | AESO-IBOMA | AESO-IBOMA +5GTF | AESO-IBOMA +5WPL-CF | AESO-THFA | AESO-THFA +5GTF | AESO-THFA +5WPL-CF |

|---|---|---|---|---|---|---|

| Layer height (mm) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Exposure time (s) | 12 | 18 | 18 | 18 | 25 | 25 |

| Bottom exposure time (s) | 30 | 40 | 40 | 40 | 45 | 45 |

| Rest time before lift (s) | 0 | 3 | 3 | 0 | 5 | 5 |

| Rest time after lift (s) | 4 | 8 | 8 | 5 | 8 | 8 |

| Rest time after retract (s) | 3 | 6 | 6 | 3 | 6 | 6 |

| Bottom lift distance (mm) | 7 | 8 | 8 | 6 | 8 | 8 |

| Lifting distance (mm) | 6 | 8 | 8 | 6 | 8 | 8 |

| Bottom retract distance (mm) | 7 | 8 | 8 | 6 | 8 | 8 |

| Retract distance (mm) | 6 | 8 | 8 | 6 | 8 | 6 |

| Bottom lift speed (mm/min) | 60 | 50 | 50 | 90 | 70 | 70 |

| Lifting speed (mm/min) | 60 | 50 | 50 | 90 | 70 | 70 |

| Bottom retract speed (mm/min) | 150 | 130 | 130 | 170 | 150 | 150 |

| Retract speed (mm/min) | 150 | 130 | 130 | 170 | 150 | 150 |

| Sample | Gel (%) | Tonset (°C) | Tmax deg (°C) | Ash (%) | E′@ 0 °C (MPa) | Tan Delta (°C) |

|---|---|---|---|---|---|---|

| AESO-IBOMA | 99.5 | 297 | 320–380 | 1.5 | 1633 | 51 |

| AESO-IBOMA + 5GTF | 99.5 | 292 | 320–380 | 1.8 | 1855 | 80 |

| AESO-IBOMA + 5WPL-CF | 98.5 | 285 | 320–380 | 3.6 | 1846 | 76 |

| AESO-THFA | 99.9 | 304 | 393 | 1.0 | 1040 | 22 |

| AESO-THFA + 5GTF | 99.1 | 308 | 384 | 1.2 | 308 | 15 |

| AESO-THFA + 5WPL-CF | 99.6 | 296 | 378 | 2.7 | 309 | 12 |

| Sample | Young’s Modulus (MPa) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|

| AESO-IBOMA | 443 ± 25 | 16 ± 0.5 | 12 ± 3.0 |

| AESO-IBOMA + 5GTF | 987 ± 42 | 30 ± 0.1 | 6 ± 0.7 |

| AESO-IBOMA + 5WPL-CF | 933 ± 34 | 27 ± 1.6 | 5 ± 0.7 |

| AESO-THFA | 15 ± 1.0 | 3 ± 1.2 | 22 ± 9.0 |

| AESO-THFA + 5GTF | 15 ± 0.4 | 2 ± 0.3 | 13 ± 2.0 |

| AESO-THFA + 5WPL-CF | 15 ± 0.6 | 2 ± 0.3 | 15 ± 2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colucci, G.; Sacchi, F.; Bondioli, F.; Messori, M. Fully Bio-Based Polymer Composites: Preparation, Characterization, and LCD 3D Printing. Polymers 2024, 16, 1272. https://doi.org/10.3390/polym16091272

Colucci G, Sacchi F, Bondioli F, Messori M. Fully Bio-Based Polymer Composites: Preparation, Characterization, and LCD 3D Printing. Polymers. 2024; 16(9):1272. https://doi.org/10.3390/polym16091272

Chicago/Turabian StyleColucci, Giovanna, Francesca Sacchi, Federica Bondioli, and Massimo Messori. 2024. "Fully Bio-Based Polymer Composites: Preparation, Characterization, and LCD 3D Printing" Polymers 16, no. 9: 1272. https://doi.org/10.3390/polym16091272

APA StyleColucci, G., Sacchi, F., Bondioli, F., & Messori, M. (2024). Fully Bio-Based Polymer Composites: Preparation, Characterization, and LCD 3D Printing. Polymers, 16(9), 1272. https://doi.org/10.3390/polym16091272