A Study on the Preparation of a Vulcanizing Mixture and Its Application in Natural Rubber Latex

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Samples

2.2.1. Preparation of the Vulcanization Mixture

2.2.2. Preparation of Film under Different Dosages of the Vulcanization Mixture

2.2.3. Preparation of Latex with Different Pre-Vulcanization Times

2.2.4. Preparation of Films under Different Vulcanization Conditions

2.3. Characterization Methods

3. Results

3.1. Preparation of the Vulcanization Mixture

3.2. Influence and Analysis of Curing Mixture Dosage on the Mechanical Properties of the Film

3.3. Effects and Analysis of Different Pre-Vulcanization Times on the Properties of Latex and Film

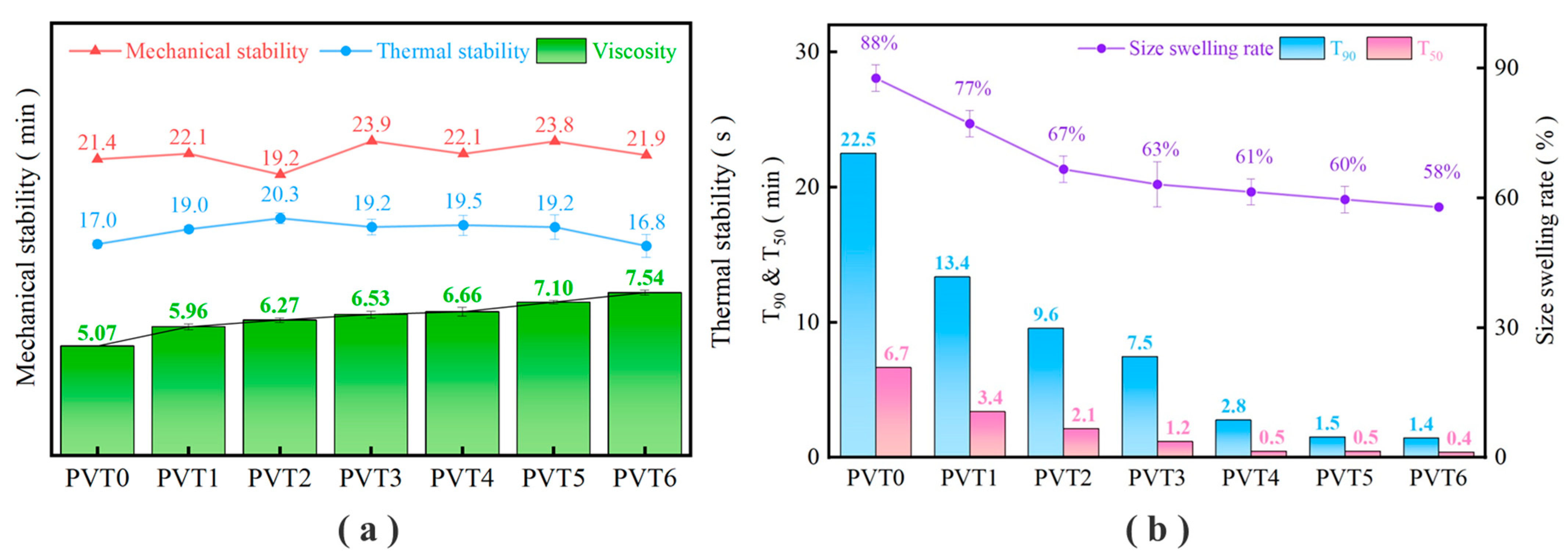

3.3.1. Effect and Analysis of Different Pre-Vulcanization Times on the Properties of Latex and Unvulcanized Film

3.3.2. Effect and Analysis of Different Pre-Vulcanization Times on the Mechanical Properties of the Vulcanized Film

3.4. Test and Analysis of the Mechanical Properties of Rubber Film under Different Curing Times

4. Conclusions

- (1)

- The rubber additives were subjected to step-by-step mixing, grinding, and ultrasonic dispersion treatment. The particle size D90 of the prepared mixed vulcanization mixture was reduced to 2.49 μm, and D50 was reduced to 1.08 μm. The particle size is equivalent to the size of latex particles, and the fine treatment of rubber additives is realized.

- (2)

- The effects of different amounts of the vulcanization mixture on the mechanical properties of latex film were compared. With the increase in the amount of the vulcanization mixture, the mechanical properties of latex film were greatly improved. The tensile strength of the latex film increased from 5.96 MPa to 29.28 MPa, and the tear strength increased from 7.59 kN/m to 52.81 kN/m.

- (3)

- With the prolongation of the pre-vulcanization time, the viscosity of latex gradually increased, the vulcanization characteristic values of unvulcanized film T90 and T50 decreased, and the mechanical properties of vulcanized film improved. The appropriate pre-vulcanization time was determined to be 90 min and 120 min, respectively.

- (4)

- Increasing the vulcanization temperature can greatly reduce the vulcanization time of the film, and after the vulcanization temperature rises from 80 °C to 100 °C, the vulcanization time can be shortened by five to six times. Vulcanized film with good mechanical properties can be obtained when the vulcanization temperature is 100 °C and the vulcanization time is 20~30 min.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Radabutra, S.; Srisombat, S.; Khemthong, P.; Saengsuwan, S.; Youngjan, S.; Butburee, T.; Thedsakhulwong, A. Superhydrophobic and superoleophiclic natural rubber latex foam coated by hexadecyltrimethoxysilane modified halloysite nanotube for oil/water separation. Mater. Today Commun. 2022, 33, 104376. [Google Scholar] [CrossRef]

- Chen, J.; Liao, L.S.; Zhang, F.Q.; Gao, T.M.; Yang, Z.N.; Ma, Y.K.; Lin, Q.X.; Lin, Y.J.; Xue, M.Y. The mechanical and heat aging properties of natural rubber latex modified by carbon nanodots. Polym. Compos. 2023, 45, 3507–3519. [Google Scholar] [CrossRef]

- Sarih, N.M.; Dzulkafly, N.S.; Maher, S.; Rashid, A.A. Wearable Natural Rubber Latex Gloves with Curcumin for Torn Glove Detection in Clinical Settings. Polymers 2022, 14, 3048. [Google Scholar] [CrossRef]

- Lazim, N.H.; Shamsudin, S.A.; Hidzir, N.M.; Keong, C.C.; Ichinose, I. Optimizing natural rubber blends for examination gloves: Vacuum radiation for mechanical strength and solvent barrier. J. Appl. Polym. Sci. 2023, 141, 54741. [Google Scholar] [CrossRef]

- Thumwong, A.; Darachai, J.; Thamrongsiripak, N.; Tokonami, S.; Ishikawa, T.; Saenboonruang, K. Fruit Peel Powder as Natural Antioxidant and Reinforcing Bio-Filler in Natural Rubber Latex Gloves: Cases of Mangosteen, Pomelo and Durian. Antioxidants 2023, 12, 1119. [Google Scholar] [CrossRef]

- Lovato, M.J.; del Valle, L.J.; Puiggalí, J.; Franco, L. Performance-Enhancing Materials in Medical Gloves. J. Funct. Biomater. 2023, 14, 349. [Google Scholar] [CrossRef]

- Wei, Y.C.; Zhu, D.; Xie, W.Y.; Xia, J.H.; He, M.F.; Liao, S.Q. In-situ observation of spatial organization of natural rubber latex particles and exploring the relationship between particle size and mechanical properties of natural rubber. Ind. Crop. Prod. 2022, 180, 114737. [Google Scholar] [CrossRef]

- Song, Y.H.; Wu, G.X.; Peng, J.B.; Zhang, C.S.; Wang, D.L.; Zheng, Q. Vulcanization kinetics of natural rubber and strain softening behaviors of gum vulcanizates tailored by deep eutectic solvents. Polymer 2022, 263, 125504. [Google Scholar] [CrossRef]

- Chen, M.M.; Zhou, Y.; Shen, Z.X.; Liu, J.; Gao, R.; Li, X.L.; Zhang, L.Q.; Li, F.Z. A crosslinking kinetic model considering reversion effect with verification and its application in thick rubber vulcanization process. Polymer 2023, 287, 126443. [Google Scholar] [CrossRef]

- Thomas, S.P.; Ettoli, M.J. Investigation on Synergic Activity of Benzylimine Aminothioformamide Binary Accelerator System in Sulfur Vulcanization of Natural Rubber. J. Appl. Polym. Sci. 2010, 116, 2976–2981. [Google Scholar] [CrossRef]

- Kim, S.M.; Kim, K.J. Thiazole Type Accelerator Effects on Silane/Silica Filled Natural Rubber Compound upon Vulcanization and Mechanical Properties. Polym. Korea 2012, 36, 235–244. [Google Scholar] [CrossRef][Green Version]

- Nabil, H.; Ismail, H.; Azura, A.R. Optimisation of accelerators and vulcanising systems on thermal stability of natural rubber/recycled ethylene-propylene-diene-monomer blends. Mater. Des. 2014, 53, 651–661. [Google Scholar] [CrossRef]

- He, S.M.; Zhang, F.Q.; Liu, S.; Cui, H.P.; Chen, S.; Peng, W.F.; Chen, G.J.; Liao, X.X.; Liao, L.S. Influence of sizes of rubber particles in latex on mechanical properties of natural rubber filled with carbon black. Polymer 2022, 261, 125393. [Google Scholar] [CrossRef]

- Azli, I.S.; Hipeni, A.R.H.; Amin, K.N.M. Cellulose Nanocrystals Derived from Oil Palm Empty Fruit Bunch Reinforced Natural Rubber Latex Nanocomposites. J. Oil Palm Res. 2022, 34, 497–505. [Google Scholar] [CrossRef]

- Jansomboon, W.; Loykulnant, S.; Dittanet, P.; Prapainainar, P. Electron beam radiation crosslinking of natural rubber filled with silica-graphene blend prepared by latex mixing: Dynamic mechanical analysis, volume resistivity, and degradation. J. Rubber Res. 2023, 26, 329–342. [Google Scholar] [CrossRef]

- Xiao, Y.; Xu, Z.C.; Gong, Z.; Li, B.; Huang, Y.G.; Bian, H.G.; Wang, C.S. Self-flocculation and its mechanism of natural rubber latex by accelerant-modified silica. J. Appl. Polym. Sci. 2023, 140, 54049. [Google Scholar] [CrossRef]

- Kim, D.; Park, J.W.; Lee, D.Y.; Seo, K.H. Correlation between the Crosslink Characteristics and Mechanical Properties of Natural Rubber Compound via Accelerators and Reinforcement. Polymers 2020, 12, 2020. [Google Scholar] [CrossRef]

- Ngudsuntear, K.; Limtrakul, S.; Vatanatham, T.; Arayapranee, W. Mechanical and Aging Properties of Hydrogenated Epoxidized Natural Rubber and Its Lifetime Prediction. ACS Omega 2022, 7, 36448–36456. [Google Scholar] [CrossRef] [PubMed]

- Bose, S.; Das, P.P.; Banerjee, S.; Chakraborty, P. A comprehensive review on natural products caused allergy and its mechanism. J. Herb. Med. 2023, 42, 100778. [Google Scholar] [CrossRef]

- Zhong, B.; Dong, H.; Lin, J.; Jia, Z.; Luo, Y.; Jia, D.; Liu, F. Preparation of Halloysite Nanotubes–Silica Hybrid Supported Vulcanization Accelerator for Enhancing Interfacial and Mechanical Strength of Rubber Composites. Ind. Eng. Chem. Res. 2017, 56, 9135–9142. [Google Scholar] [CrossRef]

- Carvalho, L.R.; Venturelli, L.G.; Lopes, T.C.; Filho, E.V.; Fontenelle, V.G.S.; de Lima, G.F.; Visconte, L.L.Y.; Tavares, E.d.C. Tetraphenylphosphonium Allyldithiocarbimates: A Novel Safe Amine Class of Morita–Baylis–Hillman-Derived NBR Vulcanization Accelerators. ACS Sustain. Chem. Eng. 2023, 11, 14507–14517. [Google Scholar] [CrossRef]

- Li, Y.; Wu, J.; Zhang, Q.; Dong, F.; Xiong, Y. Novel Architecture of ZnO Nanobundles Grown on Porous Silica as High Performance Vulcanization Accelerators that Reinforce Rubber Composites. Ind. Eng. Chem. Res. 2020, 59, 4493–4503. [Google Scholar] [CrossRef]

- Sarkar, P.; Bhowmick, A.K. Terpene-Based Sustainable Elastomers: Vulcanization and Reinforcement Characteristics. Ind. Eng. Chem. Res. 2018, 57, 5197–5206. [Google Scholar] [CrossRef]

- Sun, Y.; Yan, X.; Liang, H.; Böhm, G.; Jia, L. Rubber Recycling: Mending the Interface between Ground Rubber Particles and Virgin Rubber. ACS Appl. Mater. Interface 2020, 12, 47957–47965. [Google Scholar] [CrossRef]

- Lin, G.Y.; Wang, H.; Qu, G.K.; Qu, S.Y.; Liang, Z.N.; Yu, K.B.; Xu, N.N. Properties and process optimization of nanocomposites with organically modified montmorillonite as environment-friendly flocculants for natural rubber latex. Mater. Express 2020, 10, 2108–2121. [Google Scholar] [CrossRef]

- Joshi, M.; Dwivedi, C.; Manjare, S. A renewable cellulose-rich biofiller material extracted from waste banana stem fibers for reinforcing natural rubber composites. J. Mater. Sci. 2023, 59, 519–534. [Google Scholar] [CrossRef]

- Lima, D.R.D.; Vieira, I.R.S.; da Rocha, E.B.D.; de Sousa, A.M.F.; da Costa, A.C.A.; Furtado, C.R.G. Biodegradation of natural rubber latex films by highlighting the crosslinked bond. Ind. Crop. Prod. 2023, 204, 117290. [Google Scholar] [CrossRef]

- Rui, W.; Sun, Y.W.; Tian, Y.; Li, X.X.; Han, J.J. Poly(dopamine)-modified microcrystalline cellulose, a green reinforcing filler for natural rubber latex with high performance. Compos. Interface 2023, 30, 361–375. [Google Scholar] [CrossRef]

- Xiao, Y.; Huang, Y.G.; Li, B.; Xu, Y.F.; Wang, H.; Wang, C.S.; Bian, H.G. Wet continuous mixing technology and extrusion rheological properties of carbon black/natural rubber composites. Polym. Eng. Sci. 2023, 64, 1222–1234. [Google Scholar] [CrossRef]

- GB/T 528-2009; Rubber, Vulcanized or Thermoplastic-Determination of Tensile Stress-Strain Properties. Standardization Administration of China: Beijing, China, 2009.

- GB/T 529-2008; Rubber, Vulcanized or Thermoplastic-Determination of Tear Strength(Trouser, angle and crescent test picces). Standardization Administration of China: Beijing, China, 2008.

- GB/T 16584-1996; Rubber-Measurement of Vulcanization Characteristics with Rotorless Curemeters. China Petroleum and Chemical Industry Federation: Shanghai, China, 1996.

- Klajn, K.; Gozdek, T.; Bielinski, D.M. Metal Organic Frameworks: Current State and Analysis of Their Use as Modifiers of the Vulcanization Process and Properties of Rubber. Materials 2023, 16, 7631. [Google Scholar] [CrossRef]

- Kaesaman, A.; Lamleah, S.; Nakason, C. Influence of vulcanization system on curing, mechanical, dynamic and morphological properties of maleated natural rubber and its thermoplastic vulcanizate with thermoplastic copolyester elastomer. Express Polym. Lett. 2023, 17, 675–689. [Google Scholar] [CrossRef]

- Song, W.X.; Wang, Z.X.; Wang, M.; Zhang, G.G.; Li, F.Z.; Zhang, X.; Lu, Y.L.; Zhang, L.Q. Comparative study of vulcanization system on strain-induced crystallization of epoxidized natural rubber. Polymer 2023, 274, 125911. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Guo, F.; Ke, Y.C.; Xiang, C.; Jia, X.H. Effect of vulcanization on deformation behavior of rubber seals: Thermal-mechanical-chemical coupling model, numerical studies, and experimental validation. Mater. Des. 2022, 224, 111314. [Google Scholar] [CrossRef]

- Shao, L.; Xu, R.; Wang, J.; Ma, Z.; Ji, Z.; Zhang, W.; Wei, H.; Zhu, C.; Wang, C.; Ma, J. Recyclable and Reprocessable Crosslinked Rubber Enabled by Constructing Ionic Crosslinked Networks. ACS Sustain. Chem. Eng. 2020, 8, 12999–13006. [Google Scholar] [CrossRef]

- Wei, Y.-C.; Liu, G.-X.; Zhang, L.; Xu, W.-Z.; Liao, S.; Luo, M.-C. Mimicking the Mechanical Robustness of Natural Rubber Based on a Sacrificial Network Constructed by Phospholipids. ACS Appl. Mater. Interface 2020, 12, 14468–14475. [Google Scholar] [CrossRef]

- Kawahara, S.; Sae-Heng, K.; Kosugi, K. Mechanism of Prevulcanization of Natural Rubber through Latex-State NMR Spectroscopy. Kgk-Kaut. Gummi Kunst. 2019, 72, 26–30. [Google Scholar]

- Veiga, V.D.A.; Guerra, N.B.; Crespo, J.D.; Carli, L.N. Influence of the pre-vulcanization inhibitor on the properties of non-vulcanized rubber compositions for vulcanized reformers applications. J. Elastom. Plast. 2022, 54, 620–634. [Google Scholar] [CrossRef]

- Honorato, L.R.; Visconte, L.L.Y.; Nunes, R.C.R. Effect of different cure systems on natural rubber/nanocellulose nanocomposites in rheological, physical-mechanical, aging, and mechanical properties. J. Elastom. Plast. 2022, 54, 676–692. [Google Scholar] [CrossRef]

- de Lima, D.R.; Rocha, E.B.D.; de Sousa, A.M.F.; da Costa, A.C.A.; Furtado, C.R.G. Effect of vulcanization systems on the properties of natural rubber latex films. Polym. Bull. 2021, 78, 3943–3957. [Google Scholar] [CrossRef]

- Karim, A.F.A.; Ismail, H.; Ariff, Z.M. Effects of Prevulcanization Time of Natural Rubber on Kenaf Filled Natural Rubber Foam. Iop Conf. Ser.-Mater. Sci. 2018, 374, 012095. [Google Scholar] [CrossRef]

- Wiroonpochit, P.; Keawmaungkom, S.; Chisti, Y.; Hansupalak, N. Compositing prevulcanized natural rubber with multiwalled carbon nanotubes to make antistatic films. Polym. Adv. Technol. 2022, 33, 1591–1605. [Google Scholar] [CrossRef]

- Rojruthai, P.; Payungwong, N.; Sakdapipanich, J.T. A model study on the impact of metal ions on pre-vulcanization of concentrated natural rubber latex and dipped-products. Prog. Rubber Plast. Recycl. Technol. 2022, 38, 125–138. [Google Scholar] [CrossRef]

- Bunsanong, A.; Thongnuanchan, B.; Ninjan, R.; Salaeh, S.; Lopattananon, N.; Masa, A. Accelerator and zinc-free prevulcanized latex based on natural rubber-bearing benzyl chloride groups. Express Polym. Lett. 2024, 18, 229–242. [Google Scholar] [CrossRef]

- Bindu, P.; Joseph, R.; Thomas, S. Nanoscale ZnO as a Reinforcing Filler in Prevulcanized Natural Rubber Latex. Sci. Adv. Mater. 2013, 5, 116–126. [Google Scholar] [CrossRef]

- Varghese, N.; Varghese, S.; Shybi, A.A.; Kurian, T. Effect of nanofillers on radiation crosslinked natural rubber latex vulcanisates. Radiat. Eff. Defects Solids 2021, 176, 1003–1020. [Google Scholar] [CrossRef]

- Wang, X.M.; Xiao, Y.; Zhu, D.L.; Qu, S.Q.; Wang, C.A.S.; Wang, Z.F.; Bian, H.G. In situ generation of sulfur using silica as a carrier in the wet mixing of natural rubber latex. J. Appl. Polym. Sci. 2021, 138, 50932. [Google Scholar] [CrossRef]

- Che, J.T.; Toki, S.; Valentin, J.L.; Brasero, J.; Nimpaiboon, A.; Rong, L.X.; Hsiao, B.S. Chain Dynamics and Strain-Induced Crystallization of Pre- and Postvulcanized Natural Rubber Latex Using Proton Multiple Quantum NMR and Uniaxial Deformation by Synchrotron X-ray Diffraction. Macromolecules 2012, 45, 6491–6503. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Jia, X.H.; Guo, F.; Huang, X.; Wang, Y.M. Numerical Analysis of Heat Transfer and Chemical Reaction Coupling in the Rubber Seal Vulcanization Process. Rubber Chem. Technol. 2022, 95, 342–358. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Liu, H.C.; Zheng, T.T.; Peng, Z.; Wang, R.; Yu, H.P.; Wang, Q.F.; Liao, S.Q.; Liao, L.S. Strain-induced crystallization behavior and tensile properties of natural rubber with different vulcanization bond types. Polym. Test. 2023, 129, 108289. [Google Scholar] [CrossRef]

- Akahori, Y.; Kawahara, S. Effect of water on the accelerated sulfur vulcanization of natural rubber. Polym. Test. 2023, 123, 108030. [Google Scholar] [CrossRef]

- Han, Y.; Zheng, H.; Liu, Y.; Wang, M.; Wang, J.; Xie, Q.; Jing, S.; Qin, X.; Zhang, L. Synergistic Development of Natural Rubber/Butyl Rubber Composites for Improved Interfacial Bonding and Enhanced Shock-Absorbing Capabilities. ACS Omega 2024, 9, 13897–13905. [Google Scholar] [CrossRef] [PubMed]

| Material | Sulfur | Silica | Antioxidant 264 | Accelerator PX | Accelerator M | Zinc Carbonate | Dispersing Agent NNO |

|---|---|---|---|---|---|---|---|

| Proportion (phr) | 1.20 | 1.00 | 0.50 | 0.60 | 0.30 | 0.50 | 0.10 |

| Sample | NRL1 | NRL2 | NRL3 | NRL4 | NRL5 | NRL6 | NRL7 | NRL8 | NRL9 |

|---|---|---|---|---|---|---|---|---|---|

| Natural latex (phr) | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| Vulcanization mixture (phr) | 1.2 | 1.8 | 2.4 | 3.0 | 3.6 | 4.2 | 4.8 | 5.4 | 6.0 |

| Aqua ammonia (mL) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Sample | PVT0 | PVT1 | PVT2 | PVT3 | PVT4 | PVT5 | PVT6 |

|---|---|---|---|---|---|---|---|

| Pre-vulcanization time (min) | / | 0 | 30 | 60 | 90 | 120 | 150 |

| Sample | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|---|---|---|

| Sample group 1 | Temperature (80 °C) | TTV10 | TTV11 | TTV12 | TTV13 | TTV14 | TTV15 | TTV16 | TTV17 |

| Time (min) | 0 | 30 | 60 | 90 | 120 | 150 | 180 | 210 | |

| Sample group 2 | Temperature (90 °C) | TTV20 | TTV21 | TTV22 | TTV23 | TTV24 | TTV25 | TTV26 | TTV27 |

| Time (min) | 0 | 20 | 40 | 60 | 80 | 100 | 120 | 140 | |

| Sample group 3 | Temperature (100 °C) | TTV30 | TTV31 | TTV32 | TTV33 | TTV34 | TTV35 | TTV36 | TTV37 |

| Time (min) | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | |

| Sample | 300% Tensile Strength (MPa) | 500% Tensile Strength (MPa) | 700% Tensile Strength (MPa) | Elongation at Break (%) | Tensile Strength (MPa) | Tear Strength (kN/m) |

|---|---|---|---|---|---|---|

| NRL1 | 0.25 | 0.61 | 2.75 | 863 | 5.96 ± 1.49 | 7.59 ± 0.61 |

| NRL2 | 0.47 | 0.77 | 3.40 | 943 | 13.82 ± 2.80 | 15.42 ± 1.87 |

| NRL3 | 0.64 | 1.04 | 5.04 | 944 | 20.22 ± 1.79 | 22.76 ± 2.14 |

| NRL4 | 0.69 | 1.13 | 5.38 | 955 | 23.58 ± 1.13 | 29.05 ± 3.21 |

| NRL5 | 0.76 | 1.18 | 5.41 | 928 | 26.82 ± 0.79 | 44.06 ± 2.93 |

| NRL6 | 0.82 | 1.32 | 6.23 | 936 | 27.43 ± 1.72 | 45.51 ± 2.32 |

| NRL7 | 0.89 | 1.58 | 7.59 | 925 | 29.28 ± 0.78 | 47.40 ± 3.64 |

| NRL8 | 1.09 | 2.29 | 12.01 | 859 | 29.13 ± 1.13 | 52.81 ± 3.68 |

| NRL9 | 1.12 | 2.31 | 12.02 | 863 | 27.75 ± 1.07 | 52.55 ± 2.40 |

| Sample | T10 (min) | T50 (min) | T90 (min) | MH (dN·m) | ML (dN·m) | MH-ML (dN·m) |

|---|---|---|---|---|---|---|

| PVT0 | 2.22 | 6.65 | 22.50 | 1.54 | 0.75 | 0.79 |

| PVT1 | 1.70 | 3.40 | 13.35 | 1.76 | 0.65 | 1.11 |

| PVT2 | 0.77 | 2.12 | 9.57 | 1.79 | 0.75 | 1.04 |

| PVT3 | 0.40 | 1.17 | 7.47 | 1.49 | 0.62 | 0.87 |

| PVT4 | 0.23 | 0.45 | 2.77 | 0.74 | 0.54 | 0.20 |

| PVT5 | 0.25 | 0.47 | 1.43 | 1.12 | 0.87 | 0.25 |

| PVT6 | 0.22 | 0.40 | 1.52 | 1.10 | 0.73 | 0.37 |

| Sample | 300% Tensile Strength MPa | 500% Tensile Strength MPa | 700% Tensile Strength MPa | Elongation at Break % | Tensile Strength MPa | Tear Strength kN/m |

|---|---|---|---|---|---|---|

| PVT0 | 0.67 | 0.97 | 3.56 | 965 | 17.11 ± 1.79 | 28.74 ± 4.50 |

| PVT1 | 0.76 | 1.09 | 4.09 | 918 | 17.82 ± 1.60 | 31.73 ± 3.61 |

| PVT2 | 0.76 | 1.12 | 4.16 | 973 | 23.30 ± 2.07 | 35.38 ± 2.87 |

| PVT3 | 0.72 | 1.07 | 4.63 | 968 | 25.42 ± 2.11 | 37.26 ± 2.55 |

| PVT4 | 0.80 | 1.19 | 5.32 | 976 | 26.66 ± 2.93 | 39.04 ± 2.28 |

| PVT5 | 0.85 | 1.32 | 6.11 | 945 | 28.62 ± 0.67 | 43.23 ± 3.39 |

| PVT6 | 0.80 | 1.25 | 6.10 | 936 | 26.86 ± 0.99 | 44.01 ± 2.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, H.; He, Y.; Li, Y.; Du, J. A Study on the Preparation of a Vulcanizing Mixture and Its Application in Natural Rubber Latex. Polymers 2024, 16, 1256. https://doi.org/10.3390/polym16091256

Fang H, He Y, Li Y, Du J. A Study on the Preparation of a Vulcanizing Mixture and Its Application in Natural Rubber Latex. Polymers. 2024; 16(9):1256. https://doi.org/10.3390/polym16091256

Chicago/Turabian StyleFang, Haobin, Yingping He, Yulan Li, and Jie Du. 2024. "A Study on the Preparation of a Vulcanizing Mixture and Its Application in Natural Rubber Latex" Polymers 16, no. 9: 1256. https://doi.org/10.3390/polym16091256

APA StyleFang, H., He, Y., Li, Y., & Du, J. (2024). A Study on the Preparation of a Vulcanizing Mixture and Its Application in Natural Rubber Latex. Polymers, 16(9), 1256. https://doi.org/10.3390/polym16091256