Nanocelluloses and Their Applications in Conservation and Restoration of Historical Documents

Abstract

1. Introduction

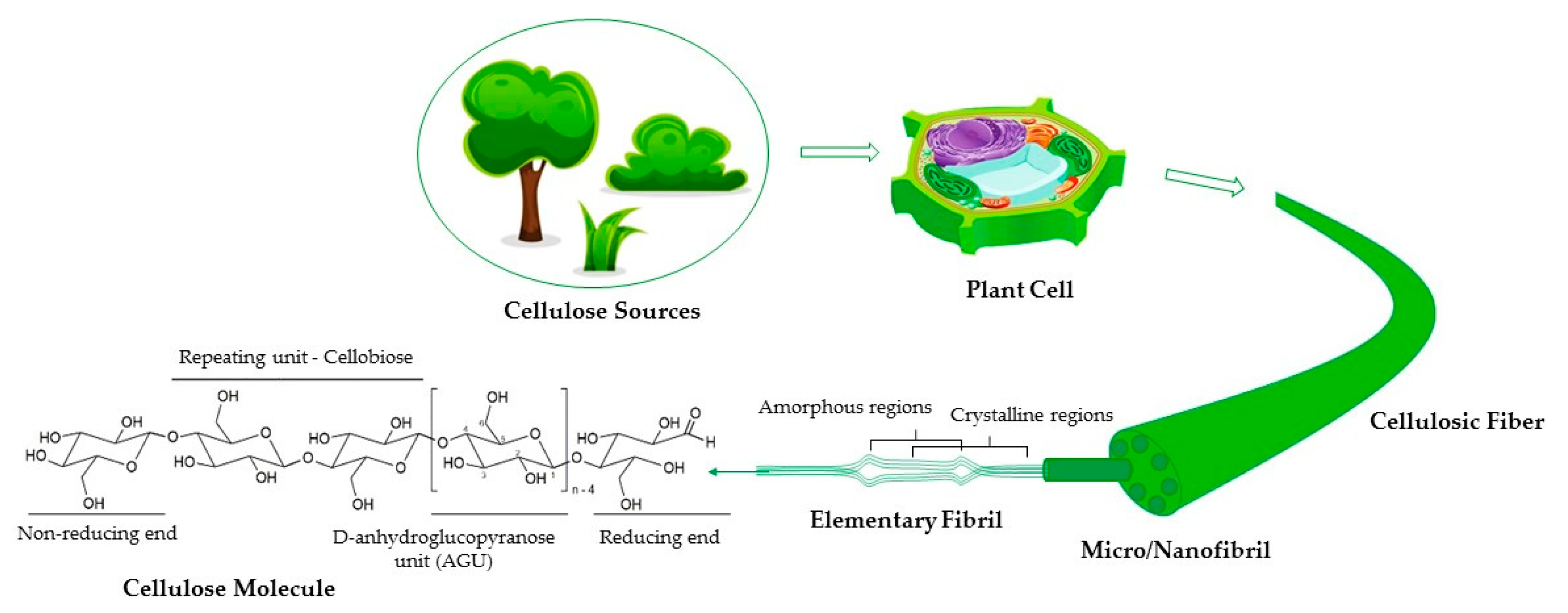

2. Cellulose and Its Isolation

3. Nanocelluloses

3.1. Cellulose Nanocrystals

3.1.1. Acid Hydrolysis

3.1.2. Enzymatic Hydrolysis

3.2. Cellulose Nanofibrils

3.2.1. Mechanical Methods

3.2.2. Combination of Methods

3.3. Bacterial Nanocellulose

3.4. Properties and Applications

4. Conservation and Restoration of Historical Documents

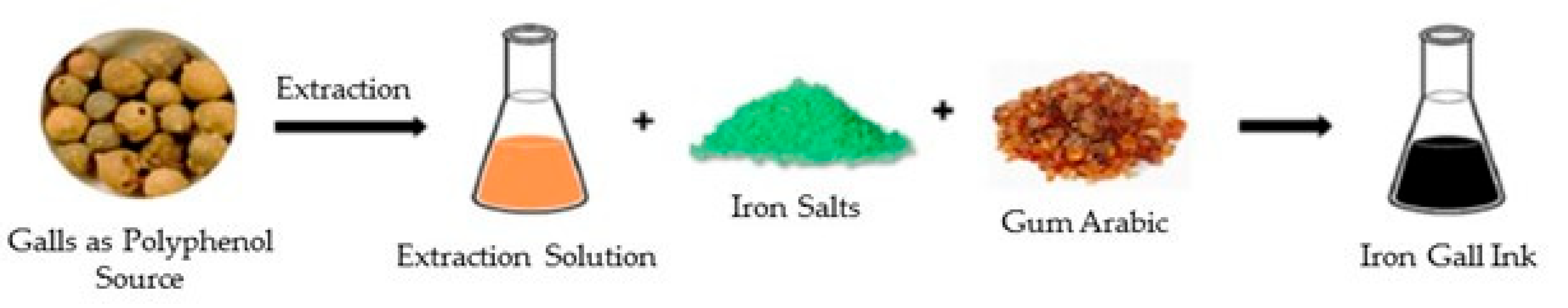

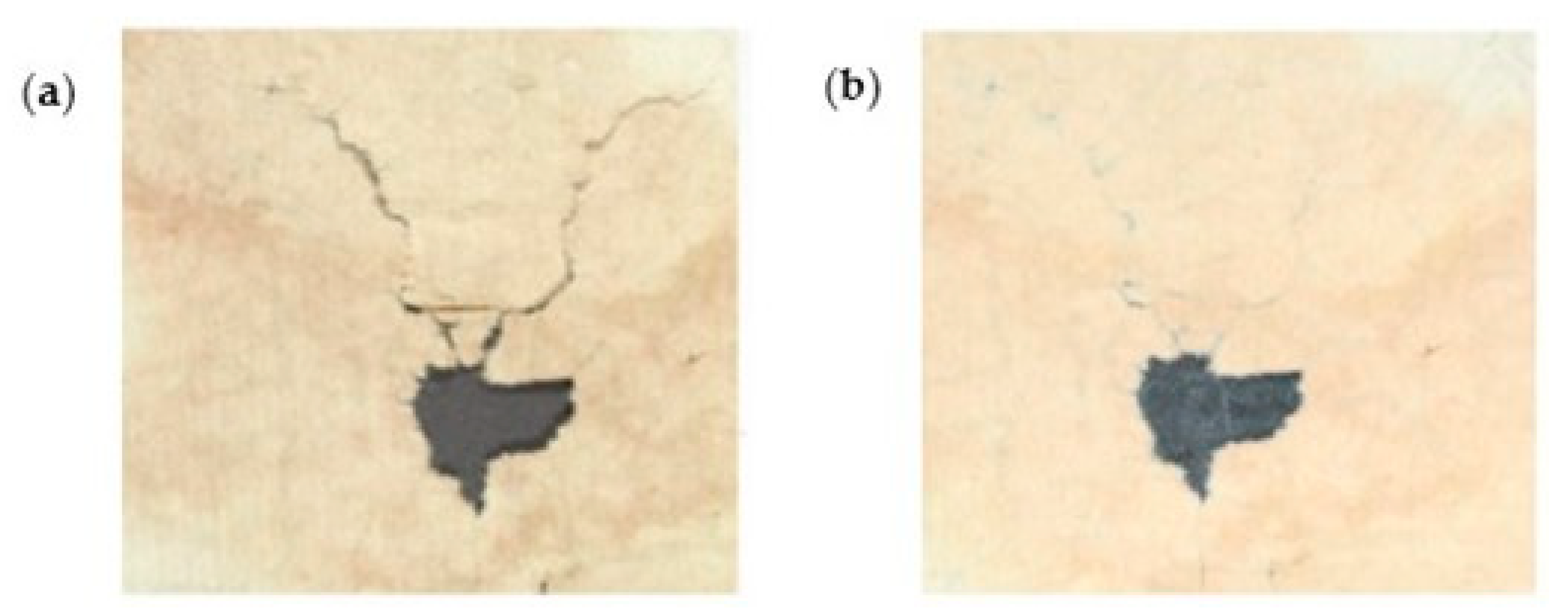

4.1. Iron Gall Ink

4.2. Conservation and Restoration Methods

4.2.1. Surface Cleaning

4.2.2. Deacidification

4.2.3. Japanese Paper

4.2.4. Calcium Phytate Method

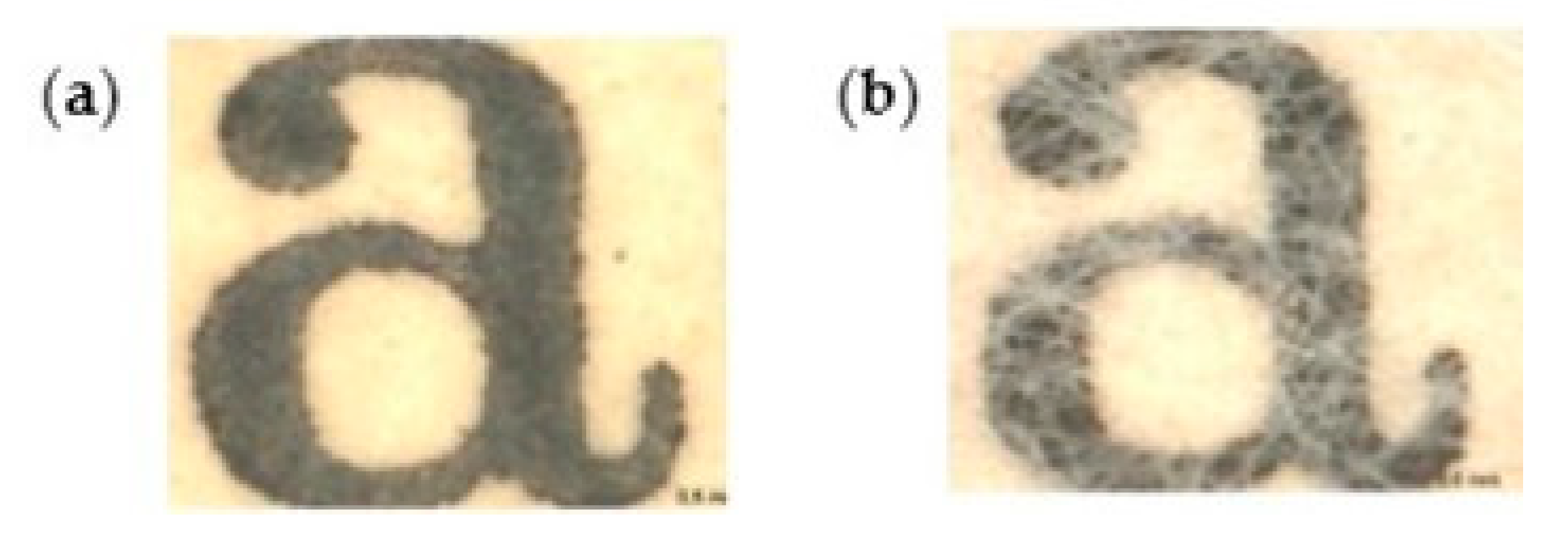

5. Nanocelluloses in Historical Documents

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Li, F.; Mascheroni, E.; Piergiovanni, L. The potential of nanocellulose in the packaging field: A review. Packag. Technol. Sci. 2015, 28, 475–508. [Google Scholar] [CrossRef]

- Milwich, M.; Speck, T.; Speck, O.; Stegmaier, T.; Planck, H. Biomimetics and technical textiles: Solving engineering problems with the help of nature’s wisdom. Am. J. Bot. 2006, 93, 1455–1465. [Google Scholar] [CrossRef]

- Thomas, B.; Raj, M.C.; Athira, K.B.; Rubiyah, M.H.; Joy, J.; Moores, A.; Drisko, G.L.; Sanchez, C. Nanocellulose, a versatile green platform: From biosources to materials and their applications. Chem. Rev. 2018, 118, 11575–11625. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Hou, G.; Chen, C.; Hu, L. Nanocellulose-based films and their emerging applications. Curr. Opin. Solid State Mater. Sci. 2019, 23, 100764. [Google Scholar] [CrossRef]

- Phanthong, P.; Reubroycharoen, P.; Hao, X.; Xu, G.; Abudula, A.; Guan, G. Nanocellulose: Extraction and application. Carbon Resour. Convers. 2018, 1, 32–43. [Google Scholar] [CrossRef]

- Rajinipriya, M.; Nagalakshmaiah, M.; Robert, M.; Elkoun, S. Importance of agricultural and industrial waste in the field of nanocellulose and recent industrial developments of wood based nanocellulose: A review. ACS Sustain. Chem. Eng. 2018, 6, 2807–2828. [Google Scholar] [CrossRef]

- Vineeth, S.; Gadhave, R.V.; Gadekar, P.T. Chemical modification of nanocellulose in wood adhesive. Open J. Polym. Chem. 2019, 9, 86–99. [Google Scholar] [CrossRef]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A new family of nature-based materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef] [PubMed]

- Vazquez, A.; Foresti, M.L.; Moran, J.I.; Cyras, V.P. Extraction and production of cellulose nanofibers. In Handbook of Polymer Nanocomposites. Processing, Performance and Application; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Antonelli, F.; Galotta, G.; Sidoti, G.; Zikeli, F.; Nisi, R.; Davidde Petriaggi, B.; Romagnoli, M. Cellulose and lignin nano-scale consolidants for waterlogged archaeological wood. Front. Chem. 2020, 8, 32. [Google Scholar] [CrossRef] [PubMed]

- Böhme, N.; Anders, M.; Reichelt, T.; Schuhmann, K.; Bridarolli, A.; Chevalier, A. new treatments for canvas consolidation and conservation. Herit. Sci. 2020, 8, 16. [Google Scholar] [CrossRef]

- Baglioni, P.; Chelazzi, D.; Giorgi, R. Nanotechnologies in the Conservation of Cultural Heritage: A Compendium of Materials and Techniques; Springer: Dordrecht, The Netherlands, 2015. [Google Scholar]

- Mateo, S.; Peinado, S.; Morillas-Gutiérrez, F.; La Rubia, M.D.; Moya, A.J. Nanocellulose from agricultural wastes: Products and applications—A review. Processes 2021, 9, 1594. [Google Scholar] [CrossRef]

- Buchanan, S.A. The brittle book problem: Approaches by research libraries in the United States. Pap. Conserv. 1987, 11, 69–72. [Google Scholar] [CrossRef]

- Sobucki, W.; Drewniewska-Idziak, B. Survey of the preservation status of the 19th and 20th century collections at the national library in Warsaw. Restaurator 2003, 24, 189–201. [Google Scholar] [CrossRef]

- Zyska, B. Permanence of paper in Polish books of the period 1900–1994. Restaurator 1996, 17, 214–228. [Google Scholar] [CrossRef]

- Lee, S.Y.; Baty, J.; Minter, W. Study of the aging behavior of rosin-alum sized papers by analysis of mechanical strength, optical properties, and chemical composition following accelerated aging. Book Pap. Group Annu. 2010, 29, 127–128. [Google Scholar]

- Díaz Hidalgo, R.J.; Cordoba, R.; Nabais, P.; Silva, V.; Melo, M.J.; Pina, F.; Teixeira, N.; Freitas, V. New insights into iron-gall inks through the use of historically accurate reconstructions. Herit. Sci. 2018, 6, 63. [Google Scholar] [CrossRef]

- Kolar, J.; Strlic, M. Iron Gall Inks: On Manufacture, Characterisation, Degradation and Stabilisation; National and University Library of Slovenia: Ljubljana, Slovenia, 2006. [Google Scholar]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Mehelli, O.; Hussin, M.H.; Bessa, W. Cellulose fibers and nanocrystals: Preparation, characterization and surface modification. In Functionalized Nanomaterials I: Fabrication; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Kumar, V.; Pathak, P.; Bhardwaj, N.K. Waste paper: An underutilized but promising source for nanocellulose mining. Waste Manag. 2020, 102, 281–303. [Google Scholar] [CrossRef] [PubMed]

- Nandi, S.; Guha, P. A review on preparation and properties of cellulose nanocrystal-incorporated natural biopolymer. J. Packag. Technol. Res. 2018, 2, 149–166. [Google Scholar] [CrossRef]

- Lavoine, N.; Desloges, I.; Dufresne, A.; Bras, J. Microfibrillated cellulose–its barrier properties and applications in cellulosic materials: A review. Carbohydr. Polym. 2012, 90, 735–764. [Google Scholar] [CrossRef] [PubMed]

- Hon, D.N.-S.; Shiraishi, N. Wood and Cellulosic Chemistry; Marcel Dekker, Inc.: New York, NY, USA, 1991. [Google Scholar]

- Mishra, R.K.; Sabu, A.; Tiwari, S.K. Materials chemistry and the futurist eco-friendly applications of nanocellulose: Status and prospect. J. Saudi Chem. Soc. 2018, 22, 949–978. [Google Scholar] [CrossRef]

- Dufresne, A.; Belgacem, M.N. Cellulose-Reinforced Composites: From Micro-to Nanoscale. Polímeros 2013, 23, 277–286. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Ahmad, I.; Thomas, S.; Dufresne, A. Handbook of Nanocellulose and Cellulose Nanocomposites; John Wiley & Sons: Weinheim, Germany, 2017. [Google Scholar]

- Wertz, J.L.; Mercier, J.P.; Bédué, O. Cellulose Science and Technology; CRC Press: Lausanne, Switzerland, 2010. [Google Scholar]

- Habibi, Y. Key advances in the chemical modification of nanocelluloses. Chem. Soc. Rev. 2014, 43, 1519–1542. [Google Scholar] [CrossRef] [PubMed]

- Almeida, R.O.; Maloney, T.C.; Gamelas, J.A.F. Production of functionalized nanocelluloses from different sources using deep eutectic solvents and their applications. Ind. Crop. Prod. 2023, 199, 116583. [Google Scholar] [CrossRef]

- He, X.; Deng, H.; Hwang, H. The current application of nanotechnology in food and agriculture. J. Food Drug Anal. 2019, 27, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Suryanegara, L.; Nakagaito, A.N.; Yano, H. Thermo-mechanical properties of microfibrillated cellulose-reinforced partially crystallized PLA composites. Cellulose 2010, 17, 771–778. [Google Scholar] [CrossRef]

- Thomas, S.K.; Begum, S.; Midhun Dominic, C.D.; Salim, N.V.; Hameed, N.; Rangappa, S.M.; Siengchin, S.; Parameswaranpillai, J. Isolation and characterization of cellulose nanowhiskers from Acacia caesia plant. J. Appl. Polym. Sci. 2021, 138, 50213. [Google Scholar] [CrossRef]

- Fornari, A.; Rossi, M.; Rocco, D.; Mattiello, L. A review of applications of nanocellulose to preserve and protect cultural heritage wood, paintings, and historical papers. Appl. Sci. 2022, 12, 12846. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S.; Atikah, M.S.N. Nanocellulose reinforced starch polymer composite: A review of preparation, properties and application. In Proceedings of the 5th International Conference on Applied Sciences and Engineering Application (ICASEA, 2018), Capthorne Hotel, Cameron Highlands, Malaysia, 7–8 April 2018; Volume 17. [Google Scholar]

- Kaur, P.; Sharma, N.; Munagala, M.; Rajkhowa, R.; Aallardyce, B.; Shastri, Y.; Agrawal, R. Nanocellulose: Resources, physio-chemical properties, current uses and future applications. Front. Nanotechnol. 2021, 3, 747329. [Google Scholar] [CrossRef]

- Mokhena, T.C.; John, M.J. Cellulose nanomaterials: New generation materials for solving global issues. Cellulose 2020, 27, 1149–1194. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crop. Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Iguchi, M.; Yamanaka, S.; Budhiono, A. Bacterial cellulose a masterpiece of nature’s arts. J. Mater. Sci. 2000, 35, 261–270. [Google Scholar] [CrossRef]

- Liu, W.; Liu, K.; Du, H.; Zheng, T.; Zhang, N.; Xu, T.; Pang, B.; Zhang, X.; Si, C.; Zhang, K. Cellulose nanopaper: Fabrication, functionalization, and applications. Nano-Micro Lett. 2022, 14, 104. [Google Scholar] [CrossRef]

- de Amorim, J.D.P.; de Souza, K.C.; Duarte, C.R.; Duarte, I.S.; Ribeiro, F.A.S.; Silva, G.S.; de Farias, P.M.A.; Stingl, A.; Costa, A.F.S.; Vinhas, G.M.; et al. Plant and bacterial nanocellulose: Production, properties and applications in medicine, food, cosmetics, electronics and engineering: A review. Environ. Chem. Lett. 2020, 18, 851–869. [Google Scholar] [CrossRef]

- Pecoraro, É.; Manzani, D.; Messaddeq, Y.; Ribeiro, S.J.L. Bacterial cellulose from Glucanacetobacter xylinus: Preparation, properties and applications. In Monomers, Polymers and Composites from Renewable Resources; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar]

- Oksman, K.; Aitomäki, Y.; Mathew, A.P.; Siqueira, G.; Zhou, Q.; Butylina, S.; Tanpichai, S.; Zhou, X.; Hooshmand, S. Review of the recent developments in cellulose nanocomposite processing. Compos. Part A Appl. Sci. Manuf. 2016, 83, 2–18. [Google Scholar] [CrossRef]

- Poulose, A.; Parameswaranpillai, J.; George, J.J.; Gopi, J.A.; Krishnasamy, S.; Dominic, C.D.M.; Hameed, N.; Salim, N.V.; Radoor, S.; Sienkiewicz, N. Nanocellulose: A fundamental material for science and technology applications. Molecules 2022, 27, 8032. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.; Thakur, M.; Bhattacharya, M.; Mandal, T. Commercial application of cellulose nano-composites—A review. Biotechnol. Rep. 2019, 21, e00316. [Google Scholar] [CrossRef] [PubMed]

- Brinchi, L.; Cotana, F.; Fortunati, E.; Kenny, J.M. Production of nanocrystalline cellulose from lignocellulosic biomass: Technology and applications. Carbohydr. Polym. 2013, 94, 154–169. [Google Scholar] [CrossRef] [PubMed]

- Vanderfleet, O.M.; Cranston, E.D. Production routes to tailor the performance of cellulose nanocrystals. Nat. Rev. Mater. 2021, 6, 124–144. [Google Scholar] [CrossRef]

- Liu, D.; Zhong, T.; Chang, P.R.; Li, K.; Wu, Q. Starch composites reinforced by bamboo cellulosic crystals. Bioresour. Technol. 2010, 101, 2529–2536. [Google Scholar] [CrossRef] [PubMed]

- Punnadiyil, R.K.; Sreejith, M.; Purushothaman, E. Isolation of microcrystalline and nano cellulose from peanut shells. J. Chem. Pharm. Sci. 2016, 974, 12–16. [Google Scholar]

- Gopi, S.; Balakrishnan, P.; Chandradhara, D.; Poovathankandy, D.; Thomas, S. General Scenarios of cellulose and its use in the biomedical field. Mater. Today Chem. 2019, 13, 59–78. [Google Scholar] [CrossRef]

- Kumar, R.; Rai, B.; Gahlyan, S.; Kumar, G. A comprehensive review on production, surface modification and characterization of nanocellulose derived from biomass and its commercial applications. Express Polym. Lett. 2021, 15, 104–120. [Google Scholar] [CrossRef]

- Henriksson, M.; Berglund, L.A. Structure and properties of cellulose nanocomposite films containing melamine formaldehyde. J. Appl. Polym. Sci. 2007, 106, 2817–2824. [Google Scholar] [CrossRef]

- Keerati-U-Rai, M.; Corredig, M. Effect of dynamic high Pressure homogenization on the aggregation state of soy protein. J. Agric. Food Chem. 2009, 57, 3556–3562. [Google Scholar] [CrossRef] [PubMed]

- Kargarzadeh, H.; Mariano, M.; Gopakumar, D.; Ahmad, I.; Thomas, S.; Dufresne, A.; Huang, J.; Lin, N. Advances in cellulose nanomaterials. Cellulose 2018, 25, 2151–2189. [Google Scholar] [CrossRef]

- Petroudy, S.R.D.; Chabot, B.; Loranger, E.; Naebe, M.; Shojaeiarani, J.; Gharehkhani, S.; Ahvazi, B.; Hu, J.; Thomas, S. Recent advances in cellulose nanofibers preparation through energy-efficient approaches: A review. Energies 2021, 14, 6792. [Google Scholar] [CrossRef]

- Spence, K.L.; Venditti, R.A.; Rojas, O.J.; Habibi, Y.; Pawlak, J.J. A comparative study of energy consumption and physical properties of microfibrillatedcellulose produced by different processing methods. Cellulose 2011, 18, 1097–1111. [Google Scholar] [CrossRef]

- Missoum, K.; Belgacem, M.; Bras, J. Nanofibrillated cellulose surface modification: A review. Materials 2013, 6, 1745–1766. [Google Scholar] [CrossRef]

- Ghasemi, S.; Behrooz, R.; Ghasemi, I. Extraction and characterization of nanocellulose structures from linter dissolving pulp using ultrafine grinder. J. Nanosci. Nanotechnol. 2016, 16, 5791–5797. [Google Scholar] [CrossRef] [PubMed]

- Rambabu, N.; Panthapulakkal, S.; Sain, M.; Dalai, A.; Dalai, K. Production of nanocellulose fibers from pinecone biomass: Evaluation and optimization of chemical and mechanical treatment conditions on mechanical properties of nanocellulose films. Ind. Crop. Prod. 2016, 83, 746–754. [Google Scholar] [CrossRef]

- Wang, S.; Cheng, Q. A novel process to isolate fibrils from cellulose fibers by high-intensity ultrasonication. Part 1: Process optimization. J. Appl. Polym. Sci. 2009, 113, 1270–1275. [Google Scholar] [CrossRef]

- Berlin, A.; Balakshin, M.; Gilkes, N.; Kadla, J.; Maximenko, V.; Kubo, S.; Saddler, J. Inhibition of cellulase, xylanase and-glucosidase activities by softwood lignin preparations. J. Biotechnol. 2006, 125, 198–209. [Google Scholar] [CrossRef] [PubMed]

- Arantes, V.; Dias IK, R.; Berto, G.L.; Pereira, B.; Marotti, B.S.; Nogueira, C.F.O. The current status of the enzyme-mediated isolation and functionalization of nanocelluloses: Production, properties, techno-economics, and opportunities. Cellulose 2020, 27, 10571–10630. [Google Scholar] [CrossRef]

- Saito, T.; Kimura, S.; Nishiyama, Y.; Isogai, A. Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 2007, 8, 2485–2491. [Google Scholar] [CrossRef] [PubMed]

- Lourenço, A.F.; Martins, D.; Dourado, F.; Ferreira, P.J.T.; Gamelas, J.A.F. Impact of bacterial cellulose on the physical properties and printing quality of fine papers. Carbohydr. Polym. 2023, 314, 120915. [Google Scholar] [CrossRef] [PubMed]

- Ullaha, M.W.; Ul-Islam, M.; Khan, S.; Kim, Y.; Park, J.K. Structural and physico-mechanical characterization of bio-cellulose produced by a cell-free system. Carbohydr. Polym. 2016, 136, 908–916. [Google Scholar] [CrossRef]

- Klemm, D.; Schumann, D.; Kramer, F.; Hessler, N.; Hornung, M.; Schmauder, H.P.; Marsch, S. Nanocelluloses as innovative polymers in research and application. Polysaccharides 2006, 205, 49–96. [Google Scholar]

- Gatenholm, P.; Klemm, D. Bacterial nanocellulose as a renewable material for biomedical applications. MRS Bull. 2010, 35, 208–213. [Google Scholar] [CrossRef]

- Mondal, S. Preparation, properties and applications of nanocellulosic materials. Carbohydr. Polym. 2017, 163, 301–316. [Google Scholar] [CrossRef] [PubMed]

- Siqueira, G.; Bras, J.; Dufresne, A. Cellulosic bionanocomposites: A review of preparation, properties and applications. Polymer 2010, 2, 728–765. [Google Scholar] [CrossRef]

- Nasir, M.; Hashim, R.; Sulaiman, O.; Asim, M. Nanocellulose: Preparation methods and applications. In Cellulose-Reinforced Nanofibre Composites; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar]

- Sánchez Hernampérez, A. Políticas de Conservación en Bibliotecas; Arco Libros: Madrid, Spain, 1999. [Google Scholar]

- Zhang, X.; Yan, Y.; Yao, J.; Jin, S.; Tang, Y. Chemistry directs the conservation of paper cultural relics. Polym. Degrad. Stab. 2003, 207, 110228. [Google Scholar] [CrossRef]

- Liu, J.; Xing, H.; Wang, J.; Cao, J.; Chao, X.; Jia, Z.; Li, Y. A new reinforcement method for the conservation of fragile, double-sided, printed paper cultural relics. Herit. Sci. 2021, 9, 123. [Google Scholar] [CrossRef]

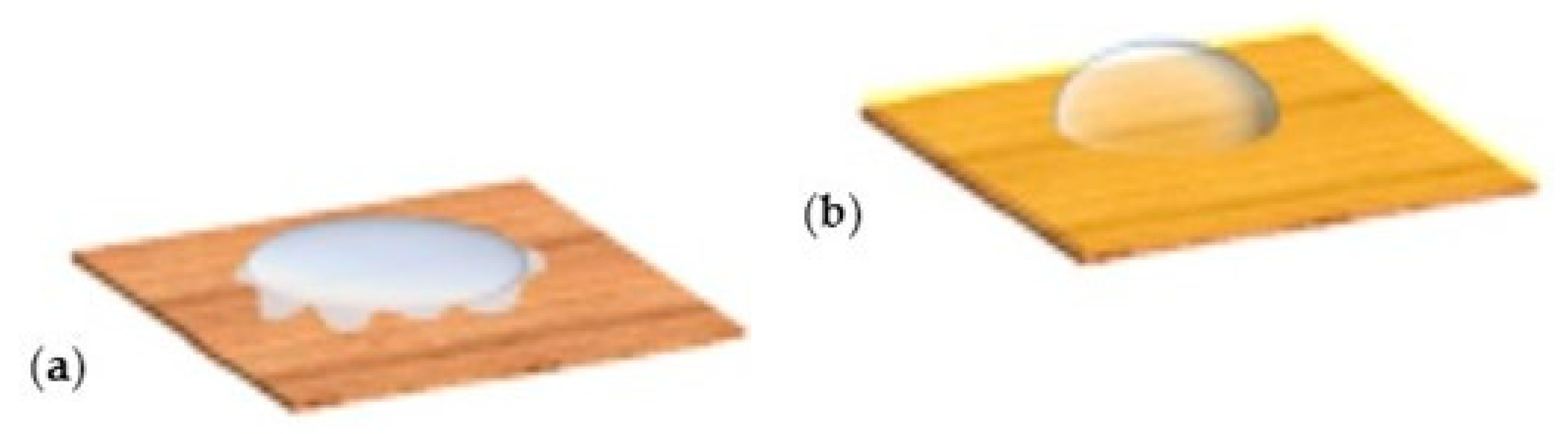

- Völkel, L.; Ahn, K.; Hähner, U.; Gindl-Altmutter, W.; Potthast, A. Nano meets the sheet: Adhesive-free application of nanocellulosic suspensions in paper conservation. Herit. Sci. 2017, 5, 23. [Google Scholar] [CrossRef]

- Wang, Z.; Cheng, C.; Cheng, Y.; Zheng, L.; Hu, D. Quaternary alloy quantum dots as fluorescence probes for total acidity detection of paper-based relics. Nanomaterials 2021, 11, 1726. [Google Scholar] [CrossRef] [PubMed]

- Jablonsky, M.; Šima, J.; Lelovsky, M. Considerations on factors influencing the degradation of cellulose in alumrosin sized paper. Carbohydr. Polym. 2000, 245, 116534. [Google Scholar] [CrossRef] [PubMed]

- Banik, G. Scientific conservation: Transfer of scientific research on ink corrosion to conservation practice–does it take place? Restaurator 2009, 30, 131–146. [Google Scholar] [CrossRef]

- da Costa, A.C.A.; Corrêa, F.N.; Sant’Anna, G.S.; Tonietto, G.B.; Godoy, J.M.O.; Gonçalves, R.A.; Lutterbach, M.T.S. Kinetic study of non-reactive iron removal from iron-gall inks. Chem. Pap. 2016, 70, 602–609. [Google Scholar] [CrossRef]

- Scholten, S. Proceedings of the European Workshop on Iron-Gall Ink Corrosion; Instituut Collectie Nederland: Amsterdam, The Netherlands, 1997; pp. 9–12. [Google Scholar]

- Reissland, B. Visible progress of paper degradation caused by iron gall inks. In The Iron Gall Ink Meeting; University of Northumbria: Newcastle upon Tyne, UK, 2000. [Google Scholar]

- Reissland, B. Ink corrosion: Side-effects caused by aqueous treatments for paper objects. In The Iron Gall Ink Meeting; University of Northumbria: Newcastle upon Tyne, UK, 2001. [Google Scholar]

- Van Gulik, R.; Kersten, P. Closer look at iron gall ink burn. Restaurator 1994, 15, 173–178. [Google Scholar] [CrossRef]

- Neevel, J.G.; Mensch, C.T.J. The behaviour of iron and sulphuric acid during iron-gall ink corrosion. In Proceedings of the ICOM Committee for Conservation 12th Triennial Meeting, Lyon, France, 29 August–3 September 1999. [Google Scholar]

- Botti, L.; Mantovani, O.; Ruggiero, D. Calcium phytate in the treatment of corrosion caused by iron gall inks: Effects on paper. Restaurator 2005, 26, 44–62. [Google Scholar] [CrossRef]

- Reißland, B.; Graaff, J.H. Condition rating for paper objects with iron gall ink. In ICN-Information Instituut Collectie Nederland; Netherlands Institute for Cultural Heritage: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Zervos, S.; Alexopoulou, I. Paper conservation methods: A literature review. Cellulose 2015, 22, 2859–2897. [Google Scholar] [CrossRef]

- Cappitelli, F.; Catto, C.; Villa, F. The control of cultural heritage microbial deterioration. Microorganisms 2020, 8, 1542. [Google Scholar] [CrossRef] [PubMed]

- Choi, J.-I.; Chung, Y.J.; Kang, D.I.; Lee, K.S.; Lee, J.-W. Effect of radiation on disinfection and mechanical properties of Korean traditional paper, Hanji. Radiat. Phys. Chem. 2012, 81, 1051–1054. [Google Scholar] [CrossRef]

- Baty, J.W.; Maitland, C.L.; Minter, W.; Hubbe, M.A.; Jordan-Mowery, S.K. Deacidification for the conservation and preservation of paper-based works: A review. Bioresources 2010, 5, 1955–2023. [Google Scholar] [CrossRef]

- Cedzova, M.; Gallova, I.; Katuscak, S. Patents for paper deacidification. Restaurator 2006, 27, 35–45. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Smith, R.D.; Zou, X.J.; Katuscak, S.; Potthast, A.; Ahn, K. Deacidification of acidic books and paper by means of non-aqueous dispersions of alkaline particles: A review focusing on completeness of the reaction. Bioresources 2017, 12, 4410–4477. [Google Scholar] [CrossRef]

- Cunha, G.M. Mass deacidification for libraries. Libr. Technol. Rep. 1987, 23, 361–472. [Google Scholar]

- Malešič, J.; Marinsek, M.; Cigic, I.K. Evaluation of bookkeeper mass deacidification based on historical book papers. Cellulose 2022, 29, 6889–6905. [Google Scholar] [CrossRef]

- Tkalčec, M.M.; Bistričić, L.; Leskovac, M. Influence of adhesive layer on the stability of kozo paper. Cellulose 2016, 23, 853–872. [Google Scholar] [CrossRef]

- Jacobi, E.; Reissland, B.; Luu, C.P.T.; van Velzen, B.; Ligterink, F. Rendering the invisible visible: Preventing solvent-induced migration during local repairs on iron gall ink. J. Pap. Conserv. 2011, 12, 25–34. [Google Scholar]

- Neevel, J. Development of a new conservation treatment for ink corrosion, based on the natural anti-oxidant phytate. Int. J. Forensic Doc. Exam. 1999, 5, 130–137. [Google Scholar]

- Rouchon, V.; Pellizzi, E.; Duranton, M.; Vanmeert, F.; Janssens, K. Combining XANES, ICP-AES and SEM/EDS for the study of phytate chelating treatments used on iron gall ink damaged manuscripts. J. Anal. At. Spectrom. 2011, 26, 2434–2441. [Google Scholar] [CrossRef]

- Melo, M.J.; Otero, V.; Nabais, P.; Teixeira, N.; Pina, F.; Casanova, C.; Fragoso, S.; Sequeira, S.O. Iron-gall inks: A review of their degradation mechanisms and conservation treatments. Herit. Sci. 2022, 10, 145. [Google Scholar] [CrossRef]

- Kolbe, G. Gelatine in historical paper production and as inhibiting agent for iron-gall ink corrosion on paper. Restaurator 2004, 25, 26–39. [Google Scholar] [CrossRef]

- Henniges, U.; Potthast, A. Phytate treatment of metallo-gallate inks: Investigation of its effectiveness on model and historic paper samples. Restaurator 2008, 29, 219–234. [Google Scholar] [CrossRef]

- Henniges, U.; Reibke, R.; Banik, G.; Huhsmann, E.; Hähner, U.; Prohaska, T.; Potthast, A. Iron gall ink-induced corrosion of cellulose: Aging, degradation and stabilization. Part 2: Application on historic sample material. Cellulose 2008, 15, 861–870. [Google Scholar] [CrossRef]

- Bansa, H.; Ishii, R. The effect of different strengthening methods on different kinds of paper. Restaurator 1997, 18, 51–72. [Google Scholar] [CrossRef]

- Gómez, N.; Santos, S.M.; Carbajo, J.M.; Villar, J.C. Use of bacterial cellulose in degraded paper restoration: Effect on visual appearance of printed paper. BioResources 2017, 12, 9130–9142. [Google Scholar] [CrossRef]

- Ferrer, A.; Pal, L.; Hubbe, M. Nanocellulose in packaging: Advances in barrier layer technologies. Ind. Crop. Prod. 2017, 95, 574–582. [Google Scholar] [CrossRef]

- Wang, Q.; Yao, Q.; Liu, J.; Sun, J.; Zhu, Q.; Chen, H. Processing nanocellulose to bulk materials: A review. Cellulose 2019, 26, 7585–7617. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, T.; Jiang, Y.; Yang, D.; Qiu, F.; Chen, Q.; Yu, Z. Preparation of self-healing acrylic copolymer composite coatings for application in protection of paper cultural relics. Polym. Eng. Sci. 2020, 60, 288–296. [Google Scholar] [CrossRef]

- Bridarolli, A.; Nechyporchuk, O.; Odlyha, M.; Oriola, M.; Bordes, R.; Holmberg, K.; Anders, M.; Chevalier, A.; Bozec, L. Nanocellulose-based materials for the reinforcement of modern canvas-supported paintings. Stud. Conserv. 2018, 63, 332–334. [Google Scholar] [CrossRef]

- Nechyporchuk, O.; Kolman, K.; Bridarolli, A.; Odlyha, M.; Bozec, L.; Oriola, M.; Campo-Francés, G.; Persson, M.; Holmberg, K.; Bordes, R. On the potential of using nanocellulose for consolidation of painting canvases. Carbohydr. Polym. 2018, 194, 161–169. [Google Scholar] [CrossRef] [PubMed]

- Santos, S.M.; Carbajo, J.M.; Gómez, N.; Quintana, E.; Ladero, M.; Sánchez, A.; Chinga-Carrasco, G.; Villar, J.C. Use of bacterial cellulose in degraded paper restoration. Part I: Application on model papers. J. Mater. Sci. 2016, 51, 1541–1552. [Google Scholar] [CrossRef]

- Dufresne, A. Nanocellulose: A new ageless bionanomaterial. Mater. Today 2013, 16, 220–227. [Google Scholar] [CrossRef]

- Santos, S.M.; Carbajo, J.M.; Gómez, N.; Quintana, E.; Ladero, M.; Sánchez, A.; Chinga-Carrasco, G.; Villar, J.C. Use of bacterial cellulose in degraded paper restoration. Part II: Application on real samples. J. Mater. Sci. 2016, 51, 1553–1561. [Google Scholar] [CrossRef]

- Jia, M.; Zhanga, X.; Wenga, J.; Zhanga, J.; Zhang, M. Protective coating of paper works: ZnO/cellulose nanocrystal composites and analytical characterization. J. Cult. Herit. 2019, 38, 64–74. [Google Scholar] [CrossRef]

- Camargos, C.H.M.; Figueiredo Junior, J.C.D.; Pereira, F.V. Cellulose nanocrystal-based composite for restoration of lacunae on damaged documents and artworks on paper. J. Cult. Herit. 2017, 23, 170–175. [Google Scholar] [CrossRef]

- Dreyfuss-Deseigne, R. Nanocellulose films in art conservation: A new and promising mending material for translucent paper objects. J. Pap. Conserv. 2017, 18, 18–29. [Google Scholar] [CrossRef]

- Dreyfuss-Deseigne, R. Nanocellulose films: Properties, development, and new applications for translucent and transparent artworks and documents. Book Pap. Group Annu. 2017, 36, 108–114. [Google Scholar]

- Völkel, L.; Prohaska, T.; Potthast, A. Combining phytate treatment and nanocellulose stabilization for mitigating iron gall ink damage in historic papers. Herit. Sci. 2020, 8, 86. [Google Scholar] [CrossRef]

- Operamolla, A.; Mazzuca, C.; Capodieci, L.; Di Benedetto, F.; Severini, L.; Titubante, M.; Martinelli, A.; Castelvetro, V.; Micheli, L. Toward a reversible consolidation of paper materials using cellulose nanocrystals. ACS Appl. Mater. Interfaces 2021, 13, 44972–44982. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Tian, S.; Li, X.; Fan, H.; Fu, S. Combined polyhexamethylene guanidine and nanocellulose for the conservation and enhancement of ancient paper. Cellulose 2021, 28, 8027–8042. [Google Scholar] [CrossRef]

- Henniges, U.; Angelova, L.; Schwoll, S.; Smith, H.; Brückle, I. Microfibrillated cellulose films for mending translucent paper: An assessment of film preparation and treatment application options. J. Inst. Conserv. 2022, 45, 36–51. [Google Scholar] [CrossRef]

- Völkel, L.; Beaumont, M.; Johansson, L.-S.; Czibula, C.; Rusakov, D.; Mautner, A.; Teichert, C.; Kontturi, E.; Rosenau, T.; Potthast, A. Assessing fire-damage in historical papers and alleviating damage with soft cellulose nanofibers. Small 2022, 18, 2105420. [Google Scholar] [CrossRef] [PubMed]

- Camargos, C.H.M.; Poggi, G.; Chelazzi, D.; Baglioni, P.; Rezende, C.A. Protective coatings based on cellulose nanofibrils, cellulose nanocrystals, and lignin nanoparticles for the conservation of cellulosic artifacts. ACS Appl. Nano Mater. 2022, 5, 13245–13259. [Google Scholar] [CrossRef]

- Ma, X.; Zhu, Z.; Zhang, H.; Tian, S.; Li, X.; Fan, H.; Fu, S. Superhydrophobic and deacidified cellulose/CaCO3-derived granular coating toward historic paper preservation. Int. J. Biol. Macromol. 2022, 207, 232–241. [Google Scholar] [CrossRef] [PubMed]

- Elmetwaly, T.E.; Darwish, S.S.; Attia, N.F.; Hassan, R.R.A.; El Ebissy, A.A.; Eltaweil, A.S.; Omer, A.M.; El-Seedi, H.R.; Elashery, S.E.A. Cellulose nanocrystals and its hybrid composite with inorganic nanotubes as green tool for historical paper conservation. Prog. Org. Coat. 2022, 168, 106890. [Google Scholar] [CrossRef]

- Li, A.; Xu, D.; Luo, L.; Zhou, Y.; Yan, W.; Leng, X.; Dai, D.; Zhou, Y.; Ahmad, H.; Rao, J.; et al. Overview of nanocellulose as additives in paper processing and paper products. Nanotechnol. Rev. 2021, 10, 264–281. [Google Scholar] [CrossRef]

- Perdoch, W.; Cao, Z.; Florczak, P.; Markiewicz, R.; Jarek, M.; Olejnik, K.; Mazela, B. Influence of nanocellulose structure on paper reinforcement. Molecules 2022, 27, 4696. [Google Scholar] [CrossRef] [PubMed]

- Rouchon, V.; Desroches, M.; Duplat, V.; Letouzey, M.; Stordiau-Pallot, J. Methods of aqueous treatments: The last resort for badly damaged iron gall ink manuscripts. J. Pap. Conserv. 2012, 13, 7–13. [Google Scholar]

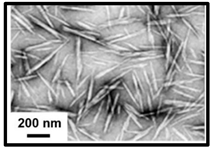

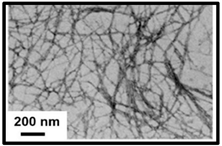

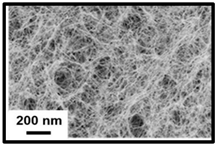

| Properties/Applications | Cellulose Nanocrystals | Cellulose Nanofibrils | Bacterial Nanocellulose | |

|---|---|---|---|---|

| Morphology [40] |  |  |  | |

| Preparation Process [39] | top–down | top–down | bottom–up | |

| Size [3] | Length (nm) | 50–500 | >1000 | 1000–5000 |

| Diameter (nm) | 3–50 | 5–100 | <100 | |

| Crystallinity Index (%) [30} | 54–88 | <50 | >88 | |

| Young’s Modulus (GPa) [41] | 50–100 | 39–78 | 15–30 | |

| Purity [42] | low | low | high | |

| Cost [3] | low | low | high | |

| Main Applications [3] | optical devices, composite materials, and coatings | packaging, energy storage, and flexible electronics | antimicrobial products and flexible supercapacitors | |

| Nanocellulose-Based Reinforcing Material | Nanocellulose Preparation Method | Document Type | Application Methodology | General Results | Reference |

|---|---|---|---|---|---|

| Bacterial nanocellulose (BNC) | BNC synthesized by Gluconacetobacter sucrofermentans | Book sheets from 1940 to 1960 | Lining according to the traditional Japanese method (wheat starch as adhesive) | High stability over time; Burst and tear strength were improved; High legibility of the text; The air permeability of the lined BNC book sheets was reduced; Improvement of deteriorated paper quality | [111] |

|

|

| Suspensions were applied with a brush or film applicator on a vacuum panel + drying for at least 12 h | Low impact on the optical and haptic properties of the paper samples; BNC and CNF treatment did not exhibit any long-term negative side effects; The use of BNC and CNF enabled the consolidation of the mechanically damaged areas of paper | [74] |

| Cellulose nanocrystals (CNC)/zinc oxide | CNC prepared from microcrystalline cellulose by sulfuric acid hydrolysis | School newspaper from 1960 | Suspensions applied by spraying and air-dried at room temperature (RT) (Klucel used as consolidating and dispersing agent) | Superior mechanical properties before and after aging; Antibacterial and antifungal activity; Increased resistance to dry-heat and UV light aging; Good color stability | [112] |

| Cellulose nanocrystals/propylene glycol/methylcellulose/calcium carbonate | CNC prepared from eucalyptus fibers by sulfuric acid hydrolysis | Two paper sheets from a book printed in the 20th century | The paper sheet holes were grafted with 3–5 layers of CNC-based composite suspension. Each layer was dried for 30–120 min under normal temperature and pressure conditions | The CNC-based composite graft exhibited a more regular and uniform surface compared to grafting with a suspension of cellulose fiber-based pulp | [113] |

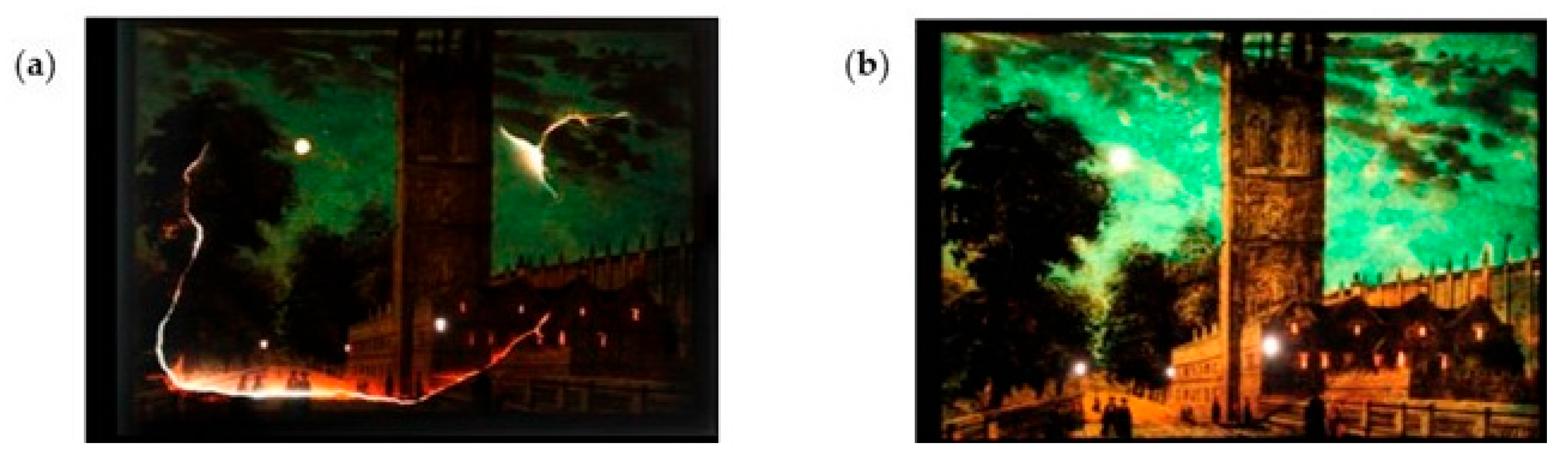

| Cellulose nanofibrils | Commercial CNF obtained from birch kraft pulp | Polyorama panoptique viewing slides from the French Museum of Cinema | CNF film combined with 5% of Klucel G® in ethanol (adhesive) | The CNF film with the 5% Klucel emerged as the better option for repairing the viewing slides, compared to four Japanese Papers and other adhesives; In terms of appearance, the tears in the viewing slides were effectively mended using the combination of CNF film and Klucel | [114] |

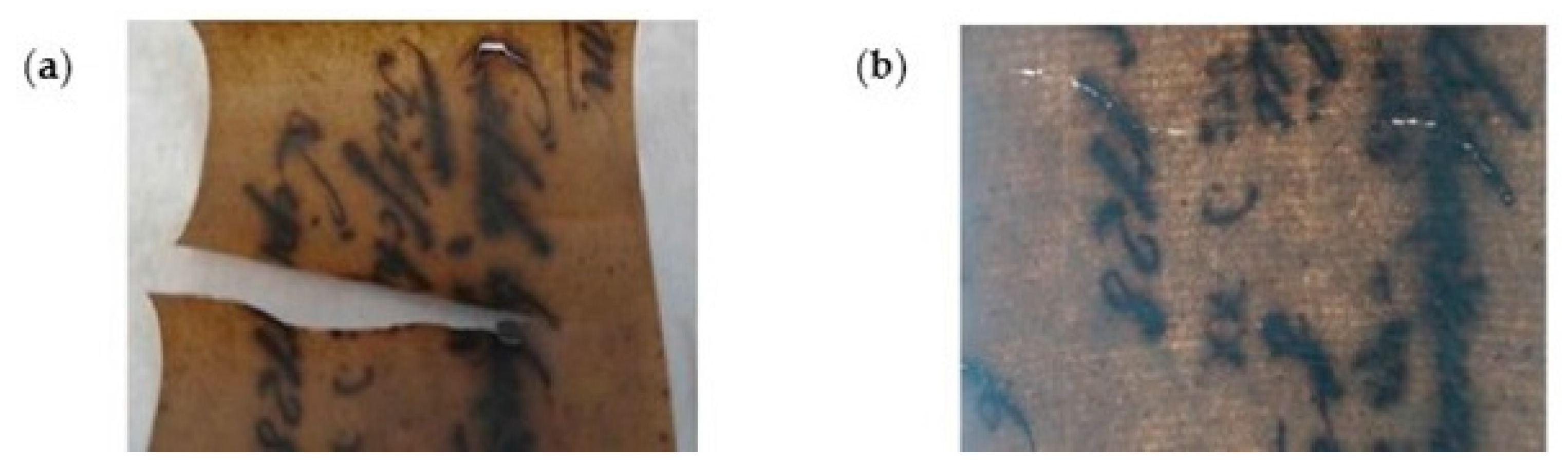

| Cellulose nanofibrils combined with calcium phytate/calcium hydrogen carbonate treatment | Commercial cellulose nanofibrils | Rag papers written with iron gall ink from a collection of sermons belonging to 1839 and 1840 | CNF suspensions were applied on both sides of the paper with a brush on a vacuum panel | The effectiveness of the phytate treatment was not compromised by the incorporation of CNF; CNF had minimal influence on the optical and haptic properties of the manuscripts | [116] |

| Neutral and sulfated cellulose nanocrystals (N-CNCs and S-CNCs, respectively) | N-CNCs and S-CNCs prepared from Avicel® by hydrochloric acid and sulfuric acid hydrolysis, respectively | Book pages from the 18th century | CNC suspensions were sonicated and then applied to the paper using a soft brush | The application of both types of CNCs did not affect the readability of the text on the book pages; N-CNCs treatment resulted in a stronger reinforcement of the paper compared to S-CNCs; The reversibility of the CNC coating was demonstrated | [117] |

| Cellulose nanocrystals/polyhexamethylene guanidine (PHMG) | CNC prepared from hardwood dissolving pulp by sulfuric acid hydrolysis | Paper samples from an old book published in 1954 | The CNC/PHMG suspensions were sprayed twice on paper, air-dried at RT for 6–7 h, and then vacuum-dried in an oven (0.08 MPa, 50 °C) for 12 h | Improved mechanical properties (e.g., tearing and tensile strength, folding endurance) before and after aging; The presence of PHMG imparted strong antifungal activity to the treated paper | [118] |

| Cellulose nanofibrils/methycellulose (MC) | Commercial CNF obtained from bleached sulfite pulp from Norway Spruce | Tracing papers of a volume of registered designs (BT 43/58) in a collection of The National Archives of UK dating from 1859 to 1882 | A strip of the CNF/MC film was single-sided brushed with 5% Klucel G® in isopropanol (w/v, adhesive) and then applied under the tear in the tracing paper | The repair with CNF/MC film was barely noticeable after application; Satisfactory mechanical properties were attained for the historical tracing papers | [119] |

| Cellulose nanofibrils | Commercial CNF obtained from bleached sulfite pulp | Fire-damaged papers from the 18th and 19th centuries, originating from the Duchess Anna Amalia Library (Germany) | The CNF suspensions were airbrushed from the center to the edge of the paper. The treated paper was then dried at RT under 50% of relative humidity | The CNF treatment successfully mechanically stabilized the fragile and charred areas of paper; Minor influence on the visual appearance and legibility of the treated paper | [120] |

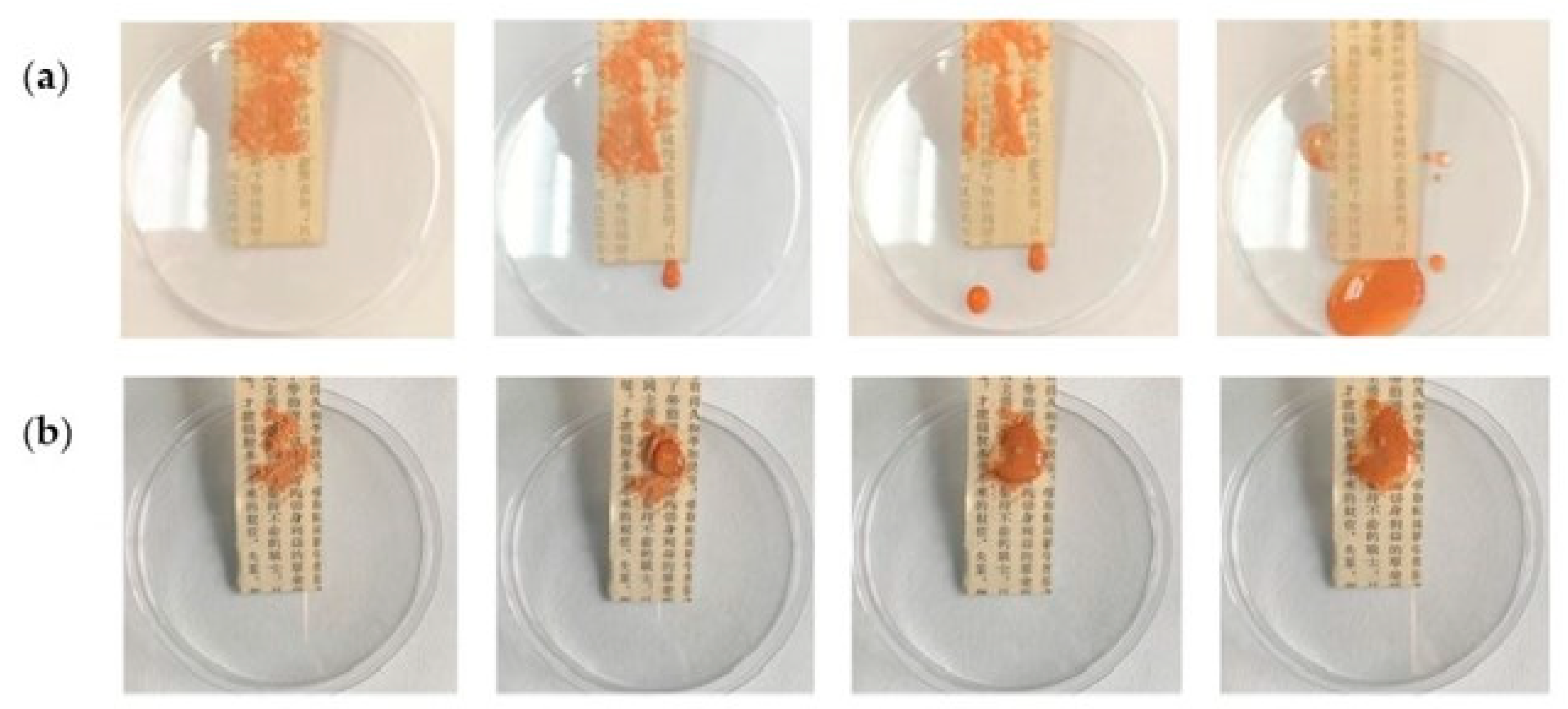

| Cellulose nanocrystals/calcium carbonate (CaCO3)/polydimethylsiloxane (PDMS) + Methyltrimethoxysilane (MTMS, hydrophobic modifier) | CNC prepared from hardwood dissolving pulp by sulfuric acid hydrolysis | Paper samples from an old book published in 1954 | The CNC and CaCO3/PDMS suspensions were first sprayed onto paper. Then, the paper was hydrophobically modified by chemical vapor deposition using MTMS | CaCO3 in the CNC/CaCO3/PDMS treatment neutralized acids in historical paper and added an alkaline reserve; The hydrophobization of the paper-treated samples was confirmed by contact angle measurements; The presence of CNCs enhanced both the tensile and tearing strength of the treated papers before and after aging | [122] |

| Cellulose nanocrystals/halloysite nanotubes (HNTs) | CNC prepared from cotton fibers by sulfuric acid hydrolysis | Real written historical paper from a private collection dating back to 1943 | The CNC/HNTs solutions were sprayed onto historical paper and then air- and oven-dried (90 °C; 30 min) | The CNC/HNTs coated layer had minimal impact on the optical properties of the historical paper and provided enhanced UV light protection; After coating, the tensile strength and elongation at the break of the historical paper were increased before and after thermal aging | [123] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marques, A.P.S.; Almeida, R.O.; Pereira, L.F.R.; Carvalho, M.G.V.S.; Gamelas, J.A.F. Nanocelluloses and Their Applications in Conservation and Restoration of Historical Documents. Polymers 2024, 16, 1227. https://doi.org/10.3390/polym16091227

Marques APS, Almeida RO, Pereira LFR, Carvalho MGVS, Gamelas JAF. Nanocelluloses and Their Applications in Conservation and Restoration of Historical Documents. Polymers. 2024; 16(9):1227. https://doi.org/10.3390/polym16091227

Chicago/Turabian StyleMarques, Ana P. S., Ricardo O. Almeida, Luís F. R. Pereira, Maria Graça V. S. Carvalho, and José A. F. Gamelas. 2024. "Nanocelluloses and Their Applications in Conservation and Restoration of Historical Documents" Polymers 16, no. 9: 1227. https://doi.org/10.3390/polym16091227

APA StyleMarques, A. P. S., Almeida, R. O., Pereira, L. F. R., Carvalho, M. G. V. S., & Gamelas, J. A. F. (2024). Nanocelluloses and Their Applications in Conservation and Restoration of Historical Documents. Polymers, 16(9), 1227. https://doi.org/10.3390/polym16091227