Investigating the Characteristics of Nano-Graphite Composites Additively Manufactured Using Stereolithography

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of the Specimens

2.2. Viscosity Analysis

2.3. UV Spectroscopy

2.4. Moisture Content

2.5. Water Absorption

2.6. Gel Content

2.7. Chemical Resistance

2.8. The Tensile Test

2.9. The Bending Test

2.10. The Hardness Test

2.11. Microstructural Characterization

3. Results and Discussions

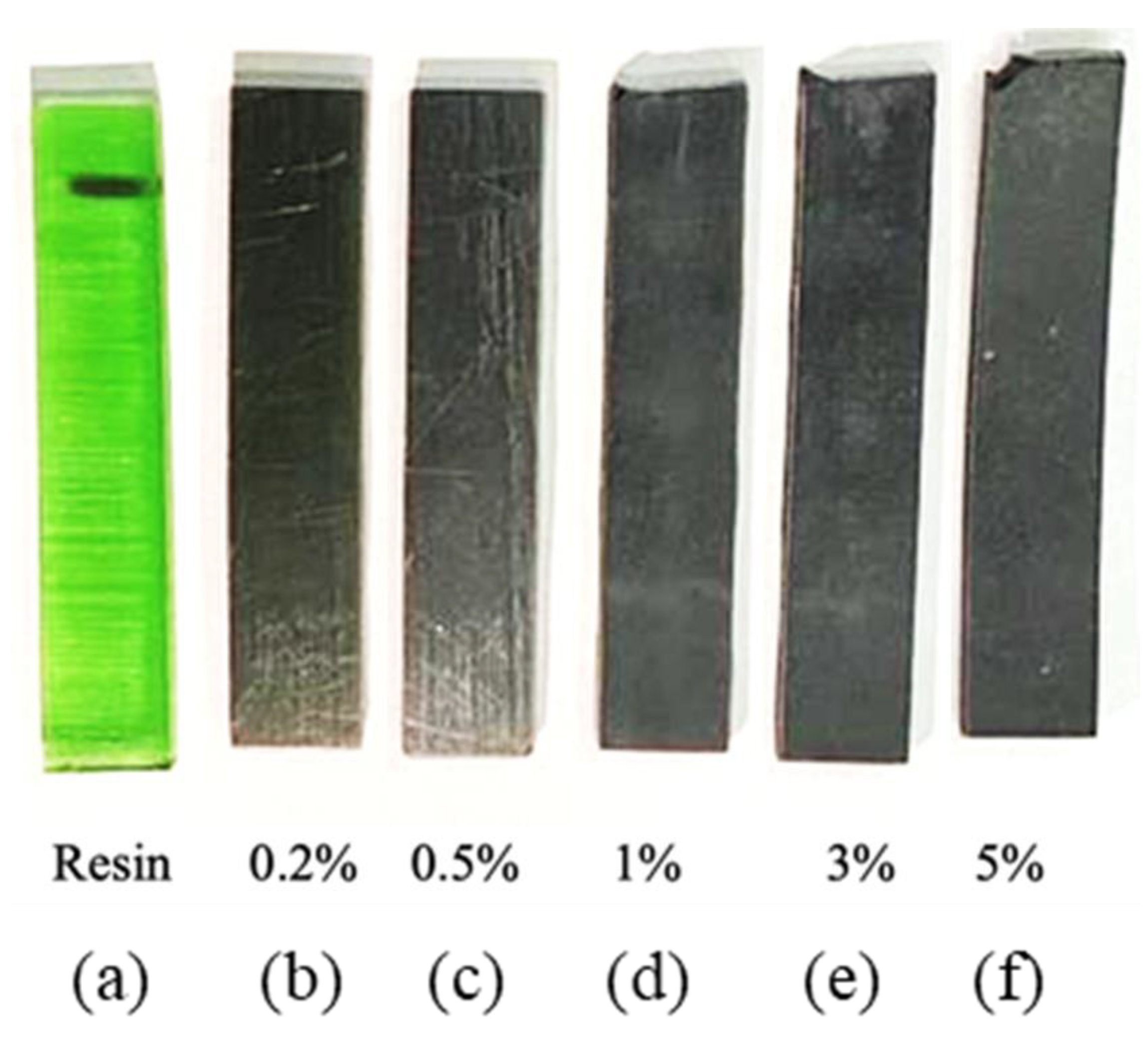

3.1. Specimen Properties

3.2. Viscosity Analysis

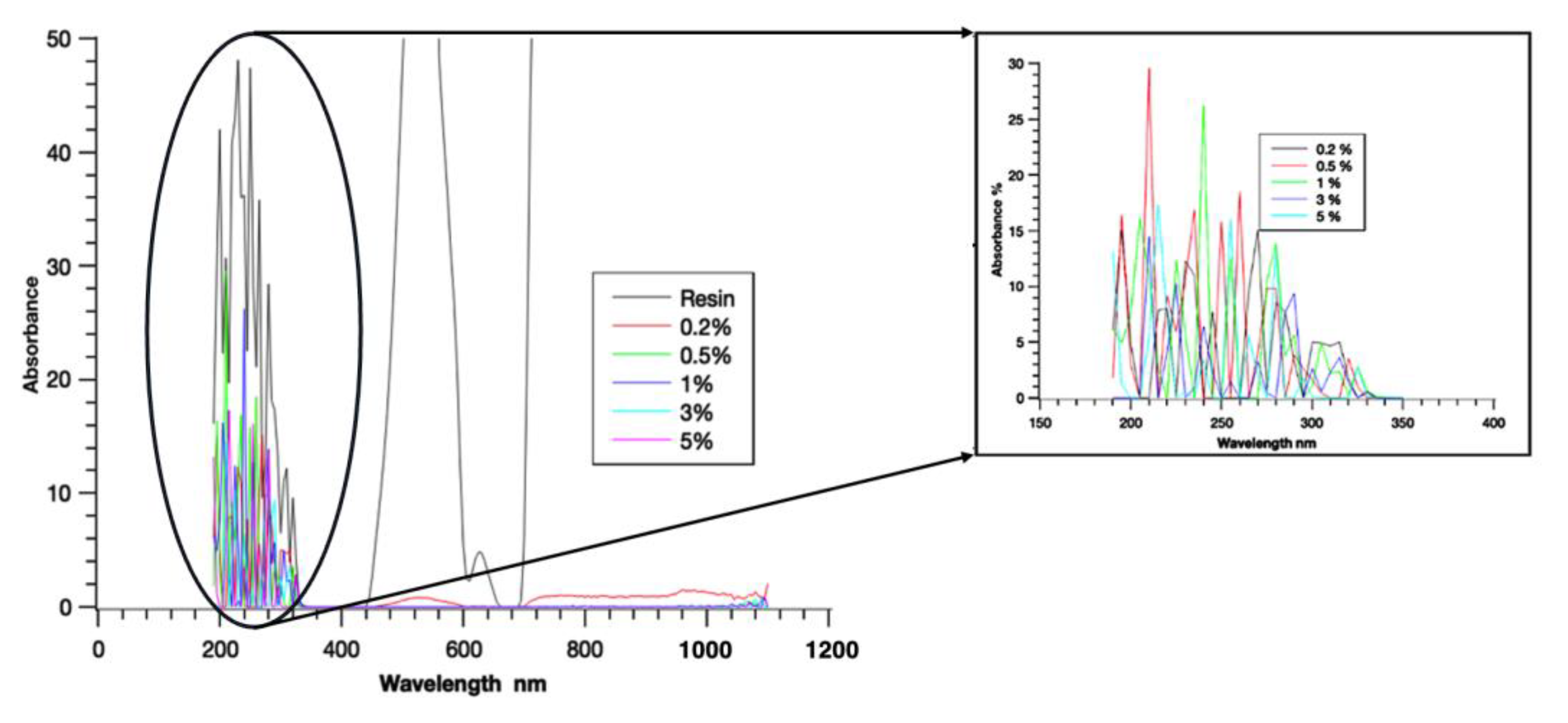

3.3. UV Spectroscopy

3.4. Moisture Content

3.5. Water Absorption

3.6. Gel Content

3.7. Chemical Resistance

3.8. The Tensile Test

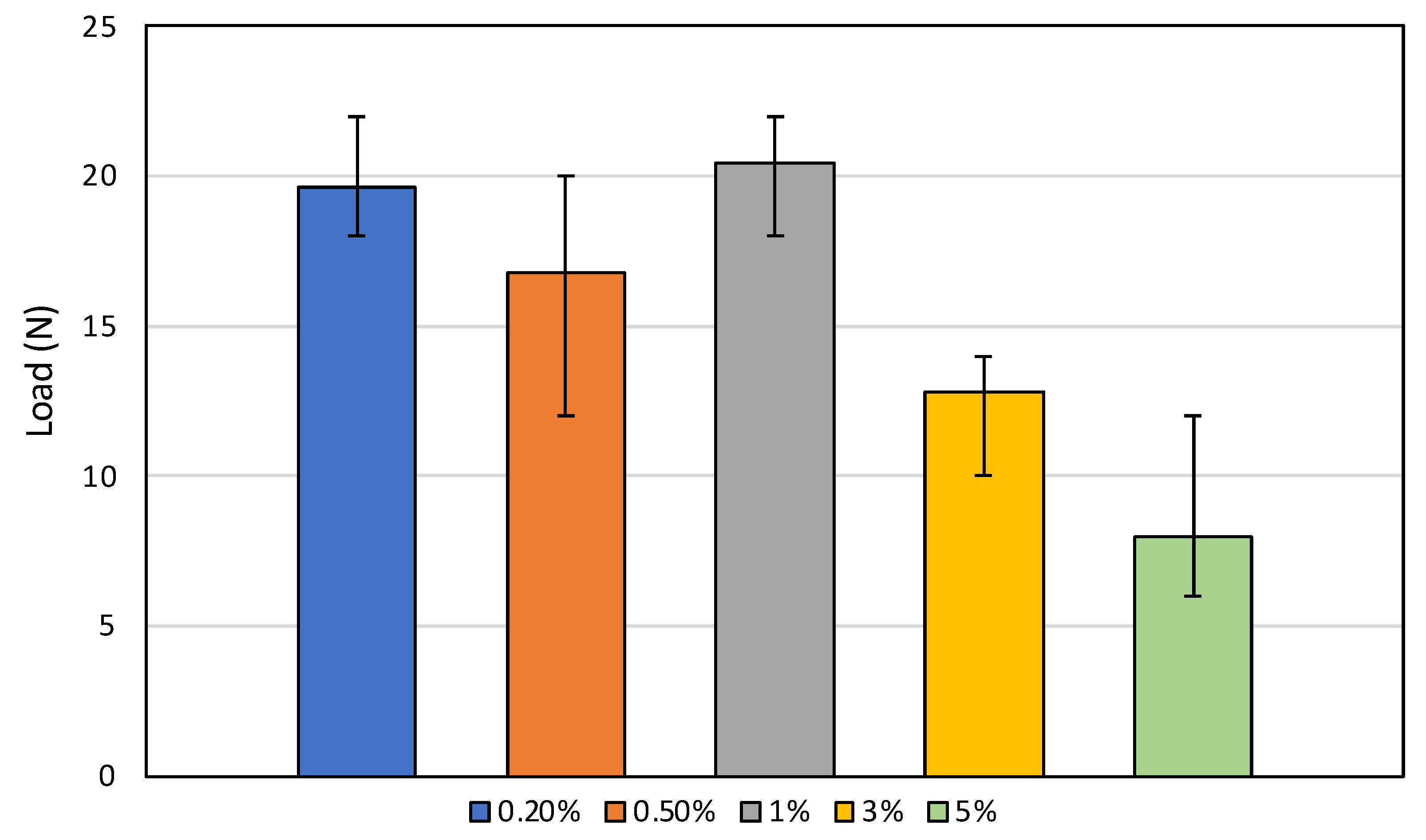

3.9. The Bending Test

3.10. The Hardness Test

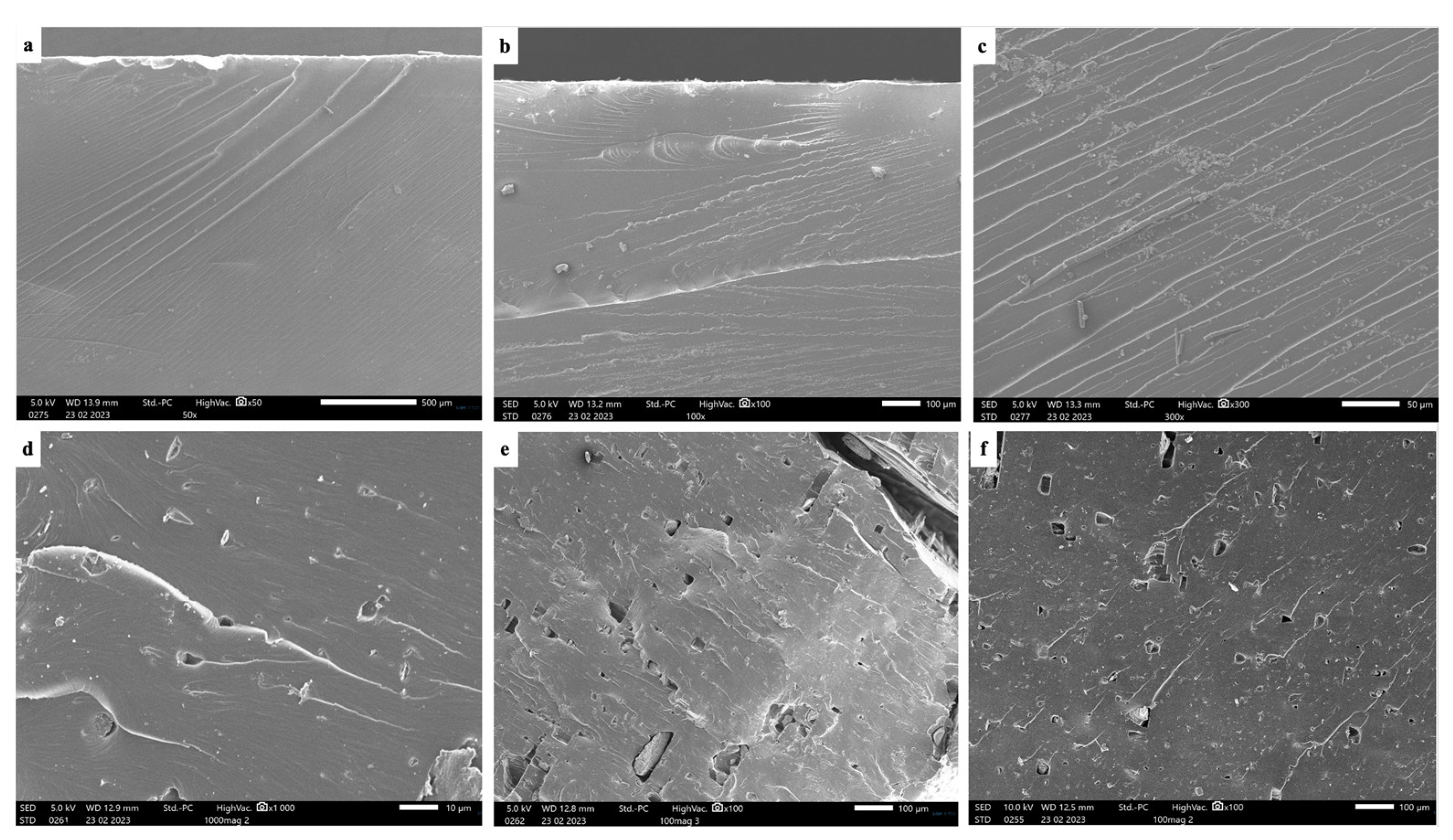

3.11. Microstructural Characterization

4. Conclusions

- o

- Viscosity analysis revealed that higher concentrations of nano-graphite (5% NG) resulted in a lower viscosity (130 mPa.s) of the composite material, potentially improving printability.

- o

- UV spectroscopy showed differences in the absorbance and transmittance spectra between the resin and NG composites, indicating potential changes in light-curing behavior.

- o

- Moisture content tests indicated that the 0.5% NG composite exhibited higher water absorption due to interfacial differences and the presence of pores.

- o

- Gel content tests demonstrated a nearly 4.5-fold increase in gel content for the 5% NG composite compared to plain resin, suggesting potential brittleness and property reduction at higher filler concentrations.

- o

- Chemical resistance tests showed no visible reaction or surface changes when the resin and NG composites were exposed to HCl acid and NaOH base.

- o

- Tensile testing revealed that higher nano-graphite percentages reduced the maximum load, with the 5% NG composite exhibiting the lowest tensile load (4.05 kN), possibly due to stress concentration and faster fracture initiation.

- o

- Bending tests indicated that 1% NG composites could increase the bending load compared to the resin only (20.4 kN), while higher concentrations (3% and 5% NG) significantly reduced the bending load, likely due to excessive filler content increasing the chance of crack initiation.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Kang, W.-S.; Rhee, K.Y.; Park, S.-J. Thermal, Impact and Toughness Behaviors of Expanded Graphite/Graphite Oxide-Filled Epoxy Composites. Compos. Part B Eng. 2016, 94, 238–244. [Google Scholar] [CrossRef]

- Tran, T.Q.; Lee, J.K.Y.; Chinnappan, A.; Jayathilaka, W.A.D.M.; Ji, D.; Kumar, V.V.; Ramakrishna, S. Strong, Lightweight, and Highly Conductive CNT/Au/Cu Wires from Sputtering and Electroplating Methods. J. Mater. Sci. Technol. 2020, 40, 99–106. [Google Scholar] [CrossRef]

- Vijay, V.; Sankunny, S.; Ramakrishna, S.; Tran, T.Q.; Kumar, V.V.; Nikhil, N.S.; George, G.; Surendran, S. Flammability and Fire Retardancy of Composites. J. Text. Appar. Technol. Manag. 2022, 12, 1. [Google Scholar]

- Nugroho, A.D.; Alandro, D.; Herianto; Jamasri; Thirumalai, S.; Nugraha, A.D.; Kusumawanto, A.; Prawara, B.; Muflikhun, M.A. Excellent Hybrid Polyurethane-Graphite Filler Micro Powder as a Lightweight Structure. J. Compos. Sci. 2023, 7, 433. [Google Scholar] [CrossRef]

- Colorado, H.A.; Gutierrez-Velasquez, E.I.; Gil, L.D.; de Camargo, I.L. Exploring the advantages and applications of nanocomposites produced via vat photopolymerization in additive manufacturing: A review. Adv. Compos. Hybrid Mater. 2024, 7, 1. [Google Scholar] [CrossRef]

- Kumar, V.V.; Balaganesan, G.; Lee, J.K.Y.; Neisiany, R.E.; Surendran, S.; Ramakrishna, S. A Review of Recent Advances in Nanoengineered Polymer Composites. Polymers 2019, 11, 644. [Google Scholar] [CrossRef]

- Simchi, A.; Pohl, H. Direct laser sintering of iron–graphite powder mixture. Mater. Sci. Eng. A 2004, 383, 191–200. [Google Scholar] [CrossRef]

- Muflikhun, M.A.; Syahril, M.; Mamba’udin, A.; Santos, G.N. A Novel of Hybrid Laminates Additively Manufactured via Material Extrusion—Vat Photopolymerization. J. Eng. Res. 2023, 11, 498–508. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Zhang, X.; Zhang, Y.; Hou, D. Recent Progress of the Vat Photopolymerization Technique in Tissue Engineering: A Brief Review of Mechanisms, Methods, Materials, and Applications. Polymers 2023, 15, 3940. [Google Scholar] [CrossRef]

- Nugraha, A.D.; Mamba’udin, A.; Susanto, B.; Kusni, M.; Darmanto, S.; Santos, G.N.; Muflikhun, M.A. The Influence of Long-term Hydrothermal and Physical Ageing on the Characteristics of Additively Manufactured Bio-based Photopolymer Resin. Results Mater. 2023, 20, 100499. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Ma, G.; Hu, T.; Li, Z. Binder Jetting 3D Printing Rock Analogs Using Magnesium Phosphate Cement. Constr. Build. Mater. 2024, 420, 135620. [Google Scholar] [CrossRef]

- Safari, F.; Kami, A.; Abedini, V. 3D printing of continuous fiber reinforced composites: A review of the processing, pre-and post-processing effects on mechanical properties. Polym. Polym. Compos. 2022, 30, 1–26. [Google Scholar] [CrossRef]

- Ambrosio, D.; Gabrion, X.; Malécot, P.; Amiot, F.; Thibaud, S. Influence of Manufacturing Parameters on the Mechanical Properties of Projection Stereolithography–Manufactured Specimens. Int. J. Adv. Manuf. Technol. 2020, 106, 265–277. [Google Scholar] [CrossRef]

- Palaganas, J.O.; Palaganas, N.B.; Ramos, L.J.I.; David, C.P.C. 3D Printing of Covalent Functionalized Graphene Oxide Nanocomposite via Stereolithography. ACS Appl. Mater. Interfaces 2019, 11, 46034–46043. [Google Scholar] [CrossRef] [PubMed]

- Tsai, S.-C.; Chen, L.-H.; Chu, C.-P.; Chao, W.-C.; Liao, Y.-C. Photo Curable Resin for 3D Printed Conductive Structures. Addit. Manuf. 2022, 51, 102590. [Google Scholar] [CrossRef]

- Feng, X.; Yang, Z.; Chmely, S.; Wang, Q.; Wang, S.; Xie, Y. Lignin-Coated Cellulose Nanocrystal Filled Methacrylate Composites Prepared via 3D Stereolithography Printing: Mechanical Reinforcement and Thermal Stabilization. Carbohydr. Polym. 2017, 169, 272–281. [Google Scholar] [CrossRef] [PubMed]

- Şevik, S.; Çiçek, B.; Özdilli, Ö.; Aydoğmuş, T.; Özer, Z. Thermal Performance Analysis of Aluminum, Copper, and Graphene Nanoplatelets-Doped Nanocomposite Heat Sinks Manufactured via Stereolithography. Appl. Therm. Eng. 2023, 226, 120315. [Google Scholar] [CrossRef]

- Markandan, K.; Lai, C.Q. Fabrication, Properties and Applications of Polymer Composites Additively Manufactured with Filler Alignment Control: A Review. Compos. B Eng. 2023, 256, 110661. [Google Scholar] [CrossRef]

- Memarzadeh, A.; Safaei, B.; Tabak, A.; Sahmani, S.; Kizilors, C. Advancements in Additive Manufacturing of Polymer Matrix Composites: A Systematic Review of Techniques and Properties. Mater. Today Commun. 2023, 36, 106449. [Google Scholar] [CrossRef]

- Zakeri, S.; Vippola, M.; Levänen, E. A Comprehensive Review of the Photopolymerization of Ceramic Resins Used in Stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- Aryaswara, L.G.; Kusni, M.; Wijanarko, D.; Muflikhun, M.A. Advanced Properties and Failure Characteristics of Hybrid GFRP-Matrix Thin Laminates Modified by Micro Glass Powder Filler for Hard Structure Applications. J. Eng. Res. 2023; in press. [Google Scholar] [CrossRef]

- Nugroho, A.D.; Nugraha, A.D.; Muflikhun, M.A. Novel Hybrid Tube Consists of GFRP-PU-Graphite Powder for Lightweight Structure Applications. Mater. Lett. 2024, 357, 135772. [Google Scholar] [CrossRef]

- Lalire, T.; Longuet, C.; Taguet, A. Electrical properties of graphene/multiphase polymer nanocomposites: A review. Carbon 2024, 119055. [Google Scholar] [CrossRef]

- Kandare, E.; Khatibi, A.A.; Yoo, S.; Wang, R.; Ma, J.; Olivier, P.; Gleizes, N.; Wang, C.H. Composites: Part A Improving the through-Thickness Thermal and Electrical Conductivity of Carbon Fibre/Epoxy Laminates by Exploiting Synergy between Graphene and Silver Nano-Inclusions. Compos. Part A 2015, 69, 72–82. [Google Scholar] [CrossRef]

- Zhao, H.; Xing, H.; Lai, Q.; Zhao, Y.; Chen, Q.; Zou, B. Additive manufacturing of graphene oxide/hydroxyapatite bioceramic scaffolds with reinforced osteoinductivity based on digital light processing technology. Mater. Des. 2022, 223, 111231. [Google Scholar] [CrossRef]

- Ievlev, V.M.; Putlyaev, V.I.; Safronova, T.V.; Evdokimov, P.V. Additive technologies for making highly permeable inorganic materials with tailored morphological architectonics for medicine. Inorg. Mater. 2015, 51, 1297–1315. [Google Scholar] [CrossRef]

- Quanchao, G.; Sun, L.; Xiaoyu, J.; Wang, H.; Jinshan, Y.; Zhou, X. High-performance and high-precision Al2O3 architectures enabled by high-solid-loading, graphene-containing slurries for top-down DLP 3D printing. J. Eur. Ceram. Soc. 2023, 43, 130–142. [Google Scholar]

- ASTM D-570; Standard Test Method for Water Absorption of Plastics. American Society for Testing and Materials: West Conshohocken, PA, USA, 2022; 2022 Book of Standards Volume: 08.01. p. 4.

- ASTM D543; Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021; 2021 Book of Standards Volume 08.01. p. 8.

- ASTM D 638; Standard Test Methods for Tensile Properties of Plastics. Annual Book of ASTM Standards. American Society for Testing and Materials: West Conshohocken, PA, USA, 2007; Volume 8, p. 1.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017; 2017 Book of Standards Volume 08.01. p. 12.

- ASTM D-2240; Standard Test Method for Rubber Property—Durometer Hardness. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021; 2021 Book of Standards Volume 09.01. p. 13.

- Dhanunjayarao, B.; Sanivada, U.K.; Naidu, N.S.; Fangueiro, R. Effect of graphite particulate on mechanical characterization of hybrid polymer composites. J. Ind. Text. 2022, 51, 2594S–2615S. [Google Scholar] [CrossRef]

- Sevriugina, V.; Pavliňák, D.; Ondreáš, F.; Jašek, O.; Štaffová, M.; Lepcio, P. Matching Low Viscosity with Enhanced Conductivity in Vat Photopolymerization 3D Printing: Disparity in the Electric and Rheological Percolation Thresholds of Carbon-Based Nanofillers Is Controlled by the Matrix Type and Filler Dispersion. ACS Omega 2023, 8, 45566–45577. [Google Scholar] [CrossRef]

- Anwar, Z.; Kausar, A.; Muhammad, B. Polymer and graphite-derived nanofiller composite: An overview of functional applications. Polym. Technol. Eng. 2016, 55, 1765–1784. [Google Scholar] [CrossRef]

- Kasgoz, A.; Akın, D.; Ayten, A.I.; Durmus, A. Effect of different types of carbon fillers on mechanical and rheological properties of cyclic olefin copolymer (COC) composites. Compos. Part B Eng. 2014, 66, 126–135. [Google Scholar] [CrossRef]

- Bianchi, I.; Forcellese, A.; Mancia, T.; Simoncini, M. Tensile properties and sustainability assessment of vat photopolymerization 3D printed components with recovered plastic filler. Int. J. Adv. Manuf. Technol. 2023, 129, 2171–2182. [Google Scholar] [CrossRef]

- Kausar, A.; Anwar, S. Graphite Filler-Based Nanocomposites with Thermoplastic Polymers: A Review. Polym. Technol. Eng. 2018, 57, 565–580. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Hardness | 79 D |

| Viscosity (25 °C) | 552 mPa.s |

| Curing wavelength | 405 nm |

| Liquid density | 1.1 |

| Solid density | 1.184 g/cm3 |

| Shrinkage | 7.10% |

| Tensile strength | 23.4 MPa |

| Curing time | 6–10 s |

| Elongation at break | 14.20% |

| Property | Value |

|---|---|

| Mesh size | 150 |

| Shape | Flake Graphite powder |

| Min ash | 1.50% |

| Size | 0.1–0.5 nm |

| Carbon content | 98% |

| Property | Unit | Value |

|---|---|---|

| Layer thickness | mm | 0.05 |

| Normal exposure time | s | 2 |

| Off time | s | 0.5 |

| Bottom exposure time | s | 30 |

| Bottom layers | No | 6 |

| Z lift distance | mm | 6 |

| Z lift speed | mm/s | 4 |

| Z retract speed | mm/s | 6 |

| Material | Viscosity (mPa.s) | Torq (%) |

|---|---|---|

| Resin | 138 | 70 |

| 0.2% NG | 137 | 69 |

| 0.5% NG | 136 | 68 |

| 1% NG | 134 | 67 |

| 3% NG | 132 | 66 |

| 5% NG | 130 | 65 |

| Specimen | Load (kN) | Average Max Displacement (mm) |

|---|---|---|

| Resin | 16.81 | 2.7756 |

| 0.2% | 16.70 | 3.3928 |

| 0.5% | 14.61 | 3.7564 |

| 1% | 13.44 | 1.897 |

| 3% | 8.82 | 2.308 |

| 5% | 4.05 | 1.6516 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nugraha, A.D.; Kumar, V.V.; Gautama, J.P.; Wiranata, A.; Mangunkusumo, K.G.H.; Rasyid, M.I.; Dzanzani, R.; Muflikhun, M.A. Investigating the Characteristics of Nano-Graphite Composites Additively Manufactured Using Stereolithography. Polymers 2024, 16, 1021. https://doi.org/10.3390/polym16081021

Nugraha AD, Kumar VV, Gautama JP, Wiranata A, Mangunkusumo KGH, Rasyid MI, Dzanzani R, Muflikhun MA. Investigating the Characteristics of Nano-Graphite Composites Additively Manufactured Using Stereolithography. Polymers. 2024; 16(8):1021. https://doi.org/10.3390/polym16081021

Chicago/Turabian StyleNugraha, Ariyana Dwiputra, Vishnu Vijay Kumar, Jessie Puteri Gautama, Ardi Wiranata, Kevin Gausultan Hadith Mangunkusumo, Muhammad Ibnu Rasyid, Rachmat Dzanzani, and Muhammad Akhsin Muflikhun. 2024. "Investigating the Characteristics of Nano-Graphite Composites Additively Manufactured Using Stereolithography" Polymers 16, no. 8: 1021. https://doi.org/10.3390/polym16081021

APA StyleNugraha, A. D., Kumar, V. V., Gautama, J. P., Wiranata, A., Mangunkusumo, K. G. H., Rasyid, M. I., Dzanzani, R., & Muflikhun, M. A. (2024). Investigating the Characteristics of Nano-Graphite Composites Additively Manufactured Using Stereolithography. Polymers, 16(8), 1021. https://doi.org/10.3390/polym16081021