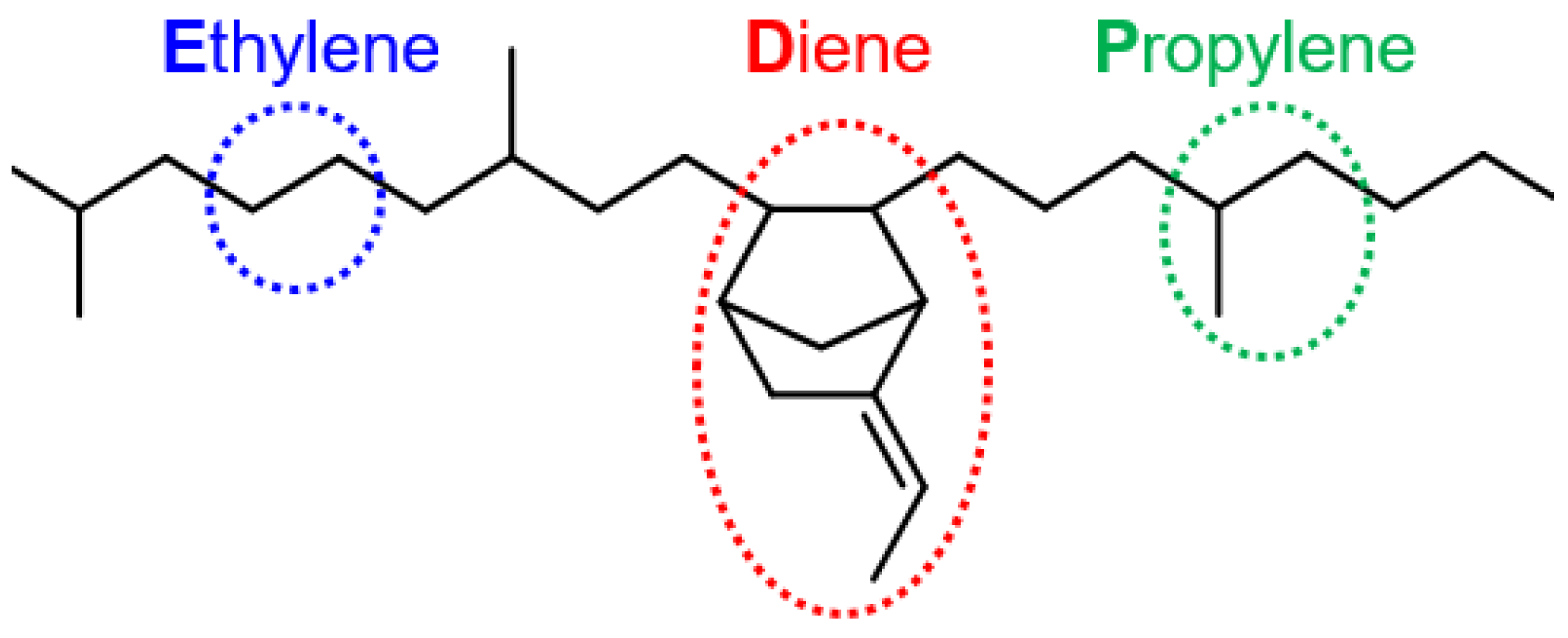

A Systematic Investigation of the Kinetic Models Applied to the Transport Behaviors of Aromatic Solvents in Unfilled Hydrogenated Nitrile Rubber/Ethylene Propylene Diene Monomer Composites

Abstract

1. Introduction

2. Experiment

2.1. Materials

2.2. Preparation of Samples

2.3. Swelling Experiment

3. Results and Discussion

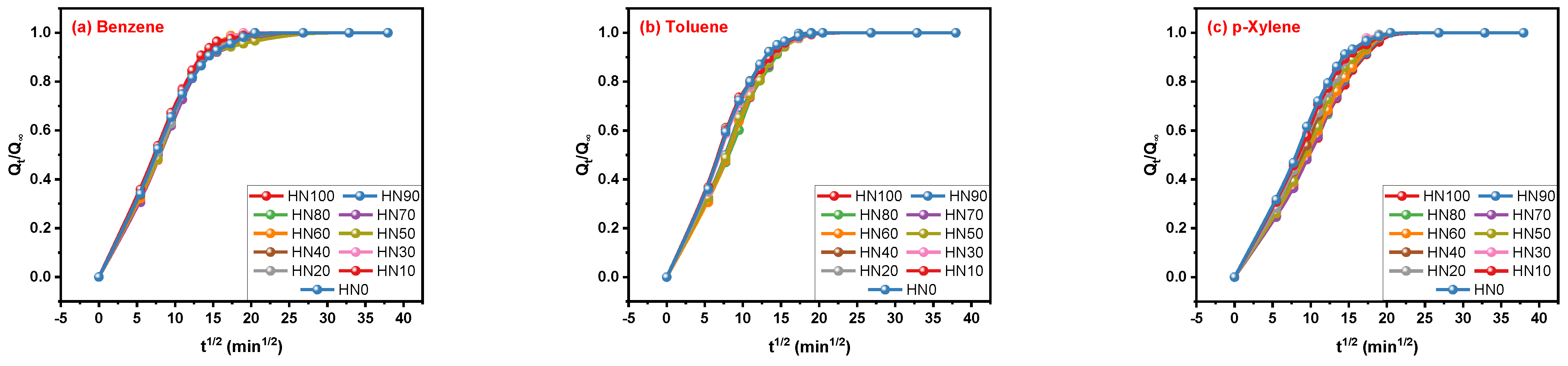

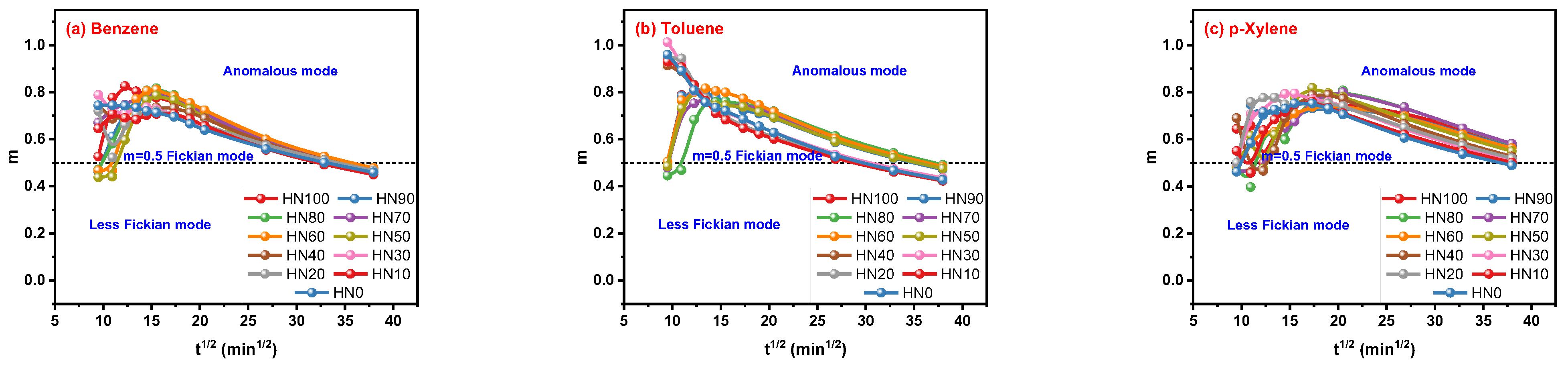

3.1. Transport Process of Aromatic Solvents in HNBR/EPDM Blends

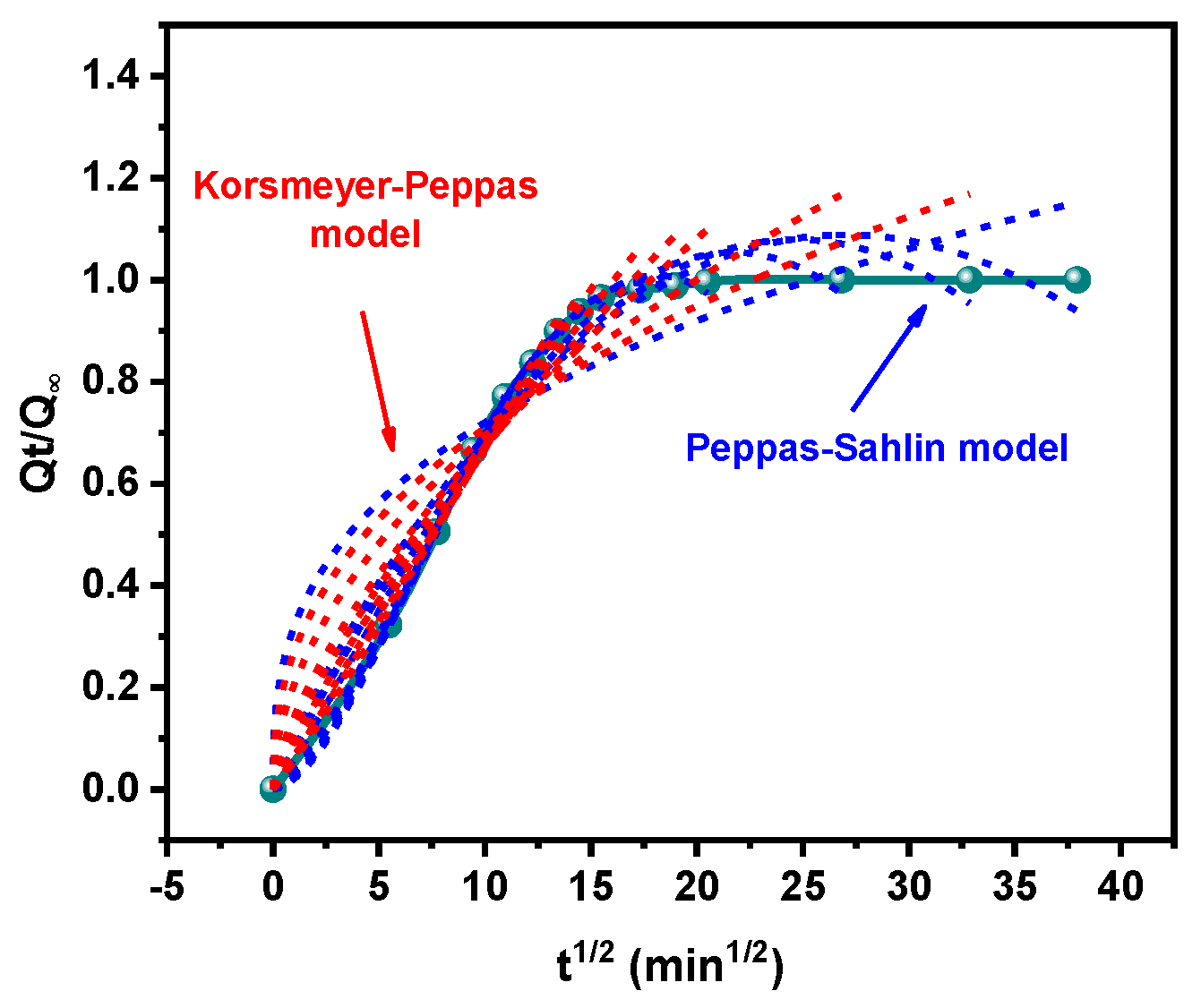

3.2. Fitting Process

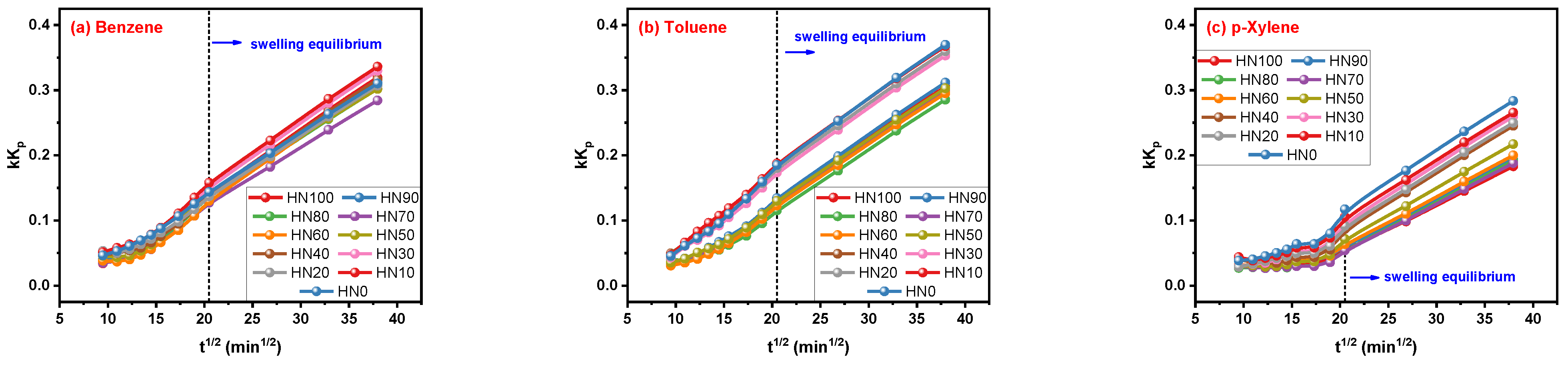

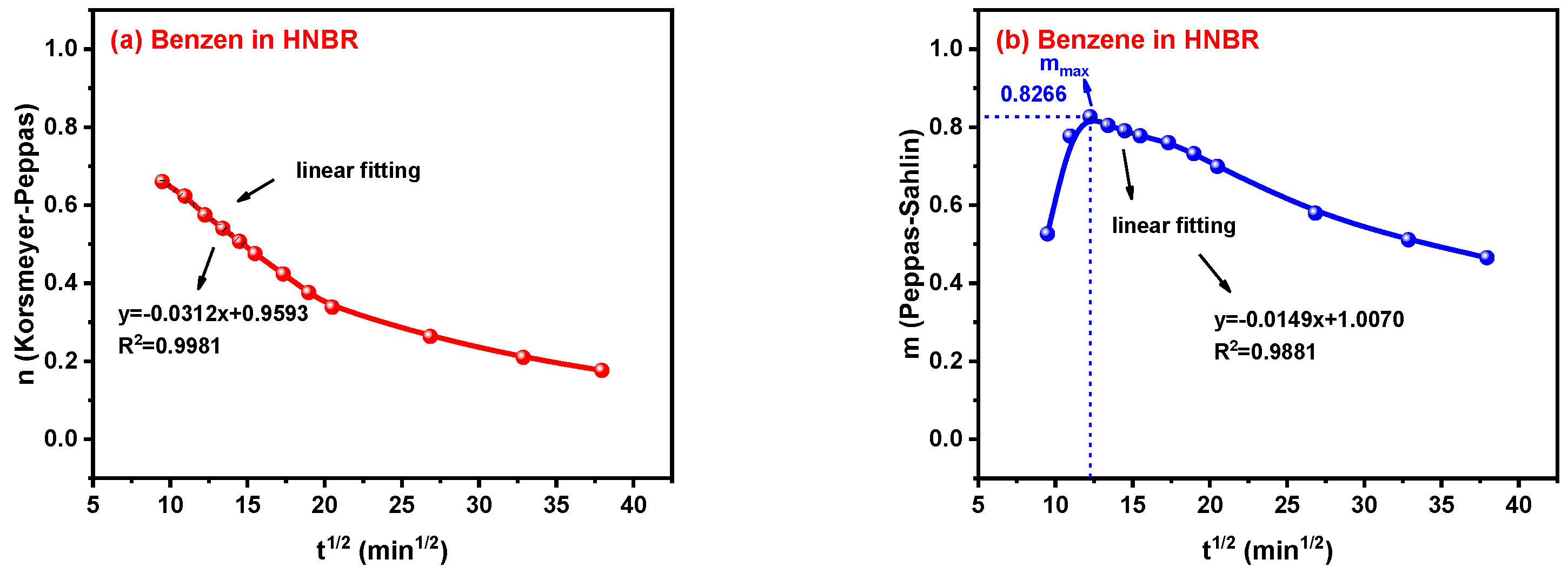

3.3. Results of Fitting by Korsmeyer–Peppas Model

3.4. Results of Fitting by Peppas–Sahlin Model

3.5. A Way to Obtain n and m Parameters at ti = 0

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Mark, J.E.; Erman, B.; Roland, C.M. The Science and Technology of Rubber; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Das, P.K.; Ambatkar, S.U.; Sarma, K.S.S.; Sabharwal, S.; Banerji, M.S. Electron beam processing of nylon 6 and hydrogenated nitrile rubber (HNBR) blends: 1. Development of high strength heat-and oil-resistant thermoplastic elastomers. Polym. Int. 2006, 55, 118–123. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Jia, H.; Yin, B.; Ding, L.; Xu, Z.; Ji, Q. Polyvinyl pyrrolidone modified graphene oxide for improving the mechanical, thermal conductivity and solvent resistance properties of natural rubber. RSC Adv. 2016, 6, 54668–54678. [Google Scholar] [CrossRef]

- Liu, G.; Wang, H.; Ren, T.; Chen, Y.; Liu, S. Systematic Investigation of the Degradation Properties of Nitrile-Butadiene Rubber/Polyamide Elastomer/Single-Walled Carbon Nanotube Composites in Thermo-Oxidative and Hot Oil Environments. Polymers 2024, 16, 226. [Google Scholar] [CrossRef] [PubMed]

- Müller, M.; Šleger, V.; Čedík, J.; Pexa, M. Research on the material compatibility of elastomer sealing O-rings. Polymers 2022, 14, 3323. [Google Scholar] [CrossRef]

- Maria, H.J.; Lyczko, N.; Nzihou, A.; Mathew, C.; George, S.C.; Joseph, K.; Thomas, S. Transport of organic solvents through natural rubber/nitrile rubber/organically modified montmorillonite nanocomposites. J. Mater. Sci. 2013, 48, 5373–5386. [Google Scholar] [CrossRef]

- Korsmeyer, R.W.; Gurny, R.; Doelker, E.; Buri, P.; Peppas, N.A. Mechanisms of solute release from porous hydrophilic polymers. Int. J. Pharm. 1983, 15, 25–35. [Google Scholar] [CrossRef]

- Peppas, N.A.; Sahlin, J.J. A simple equation for the description of solute release. III. Coupling of diffusion and relaxation. Int. J. Pharm. 1989, 57, 169–172. [Google Scholar] [CrossRef]

- Li, N.N.; Fu, C.P.; Zhang, L.M. Using casein and oxidized hyaluronic acid to form biocompatible composite hydrogels for controlled drug release. Mater. Sci. Eng. C 2014, 36, 287–293. [Google Scholar] [CrossRef] [PubMed]

- Rezaei, A.; Nasirpour, A. Evaluation of release kinetics and mechanisms of curcumin and curcumin-β-cyclodextrin inclusion complex incorporated in electrospun almond gum/PVA nanofibers in simulated saliva and simulated gastrointestinal conditions. BioNanoScience 2019, 9, 438–445. [Google Scholar] [CrossRef]

- Jiang, X.; Hao, Y.; Wang, H.; Tu, J.; Liu, G. Application of Three-Dimensional Solubility Parameter in Diffusion Behavior of Rubber-Solvent System and Its Predictive Power in Calculating the Key Parameters. Macromol. Res. 2022, 30, 271–278. [Google Scholar] [CrossRef]

- Unnikrishnan, G.; Thomas, S. Diffusion and transport of aromatic hydrocarbons through natural rubber. Polymer 1994, 35, 5504–5510. [Google Scholar] [CrossRef]

- Aminabhavi, T.M.; Phayde, H.T. Molecular transport characteristics of Santoprene thermoplastic rubber in the presence of aliphatic alkanes over the temperature interval of 25 to 70 °C. Polymer 1995, 36, 1023–1033. [Google Scholar] [CrossRef]

- Moly, K.A.; Bhagawan, S.S.; George, S.C.; Thomas, S. Sorption and diffusion of aromatic solvents through linear low density polyethylene–ethylene vinyl acetate blend membranes. J. Mater. Sci. 2007, 42, 4552–4561. [Google Scholar] [CrossRef]

- Kaliyathan, A.V.; Rane, A.V.; Jackson, S.; Thomas, S. Analysis of diffusion characteristics for aromatic solvents through carbon black filled natural rubber/butadiene rubber blends. Polym. Compos. 2021, 42, 375–396. [Google Scholar] [CrossRef]

- Abraham, J.; Muraleedharan, K.; Radhesh Kumar, C.; Thomas, S.; George, S.C. Solvent transport characteristics of thermoplastic elastomer blends based on nylon and NBR. Polym. Eng. Sci. 2017, 57, 231–236. [Google Scholar] [CrossRef]

- James, J.; Thomas, G.V.; Pramoda, K.P.; Thomas, S. Transport behaviour of aromatic solvents through styrene butadiene rubber/poly [methyl methacrylate] (SBR/PMMMA) interpenetrating polymer network (IPN) membranes. Polymer 2017, 116, 76–88. [Google Scholar] [CrossRef]

- Ashok, N.; Prakash, K.; Selvakumar, D.; Balachandran, M. Synergistic enhancement of mechanical, viscoelastic, transport, thermal, and radiation aging characteristics through chemically bonded interface in nanosilica reinforced EPDM-CIIR blends. J. Appl. Polym. Sci. 2021, 138, 50082. [Google Scholar] [CrossRef]

- Siepmann, J.; Peppas, N.A. Higuchi equation: Derivation, applications, use and misuse. Int. J. Pharm. 2011, 418, 6–12. [Google Scholar] [CrossRef] [PubMed]

- Kömmling, A.; Jaunich, M.; Wolff, D. Effects of heterogeneous aging in compressed HNBR and EPDM O-ring seals. Polym. Degrad. Stab. 2016, 126, 39–46. [Google Scholar] [CrossRef]

- Alcock, B.; Olafsen, K.; Huse, J.; Grytten, F. The low temperature crystallization of hydrogenated nitrile butadiene rubber (HNBR). Polym. Test. 2018, 66, 228–234. [Google Scholar] [CrossRef]

- Ahmadi, S.J.; Huang, Y.; Li, W. Fabrication and physical properties of EPDM–organoclay nanocomposites. Compos. Sci. Technol. 2005, 65, 1069–1076. [Google Scholar] [CrossRef]

- Kim, Y.S.; Hwang, E.S.; Jeon, E.S. Optimization of shape design of grommet through analysis of physical properties of EPDM materials. Appl. Sci. 2019, 9, 133. [Google Scholar] [CrossRef]

- Shi, X.; Zhu, Z.; Jia, L.; Li, Q.; Bi, W. HNBR/EPDM blends: Covulcanization and compatibility. J. Appl. Polym. Sci. 2013, 129, 3054–3060. [Google Scholar] [CrossRef]

- Sirisinha, C.; Sae-Oui, P.; Guaysomboon, J. Mechanical properties, oil resistance, and thermal aging properties in chlorinated polyethylene/natural rubber blends. J. Appl. Polym. Sci. 2002, 84, 22–28. [Google Scholar] [CrossRef]

- Liu, J.; Li, B.; Jiang, Y.; Zhang, X.; Yu, G.; Sun, C.; Zhao, S. Investigation of filler network percolation in carbon black (CB) filled hydrogenated butadiene-acrylonitrile rubber (HNBR). Polym. Bull. 2022, 79, 87–96. [Google Scholar] [CrossRef]

- Thomas, S.; Wilson, R.; Anil Kumar, S.; George, S.C. Transport Properties of Polymeric Membranes; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Stephen, R.; Joseph, K.; Oommen, Z.; Thomas, S. Molecular transport of aromatic solvents through microcomposites of natural rubber (NR), carboxylated styrene butadiene rubber (XSBR) and their blends. Compos. Sci. Technol. 2007, 67, 1187–1194. [Google Scholar] [CrossRef]

- Mathew, L.; Joseph, K.U.; Joseph, R. Swelling behaviour of isora/natural rubber composites in oils used in automobiles. Bull. Mater. Sci. 2006, 29, 91–99. [Google Scholar] [CrossRef]

- Thomas, S.P.; Thomas, S.; Mathew, E.J.; Marykutty, C.V. Transport and electrical properties of natural rubber/nitrile rubber blend composites reinforced with multiwalled carbon nanotube and modified nano zinc oxide. Polym. Compos. 2014, 35, 956–963. [Google Scholar] [CrossRef]

- Jiang, X.; Yuan, X.; Guo, X.; Zeng, F.; Liu, G. Determination of three-dimensional solubility parameters of HNBR/EPDM blends and the transport behaviors in ester solvents. J. Appl. Polym. Sci. 2022, 139, e52881. [Google Scholar] [CrossRef]

| Solvent | Chemical Formula | Molar Mass (g/mol) | Density (g/cm3) | Molar Volume (cm3/mol) | Structure |

|---|---|---|---|---|---|

| Benzene | C6H6 | 78.11 | 0.87 | 89.50 |  |

| Toluene | C7H8 | 92.14 | 0.86 | 106.60 |  |

| p-Xylene | C8H10 | 106.17 | 0.88 | 121.10 |  |

| Materials | HN100 | HN90 | HN80 | HN70 | HN60 | HN50 | HN40 | HN30 | HN20 | HN10 | HN0 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| HNBR | 100 | 90 | 80 | 70 | 60 | 50 | 40 | 30 | 20 | 10 | 0 |

| EPDM | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 |

| DCP | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| TAIC | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Jing, Y.; Liu, G. A Systematic Investigation of the Kinetic Models Applied to the Transport Behaviors of Aromatic Solvents in Unfilled Hydrogenated Nitrile Rubber/Ethylene Propylene Diene Monomer Composites. Polymers 2024, 16, 892. https://doi.org/10.3390/polym16070892

Liu S, Jing Y, Liu G. A Systematic Investigation of the Kinetic Models Applied to the Transport Behaviors of Aromatic Solvents in Unfilled Hydrogenated Nitrile Rubber/Ethylene Propylene Diene Monomer Composites. Polymers. 2024; 16(7):892. https://doi.org/10.3390/polym16070892

Chicago/Turabian StyleLiu, Susu, Yiran Jing, and Guangyong Liu. 2024. "A Systematic Investigation of the Kinetic Models Applied to the Transport Behaviors of Aromatic Solvents in Unfilled Hydrogenated Nitrile Rubber/Ethylene Propylene Diene Monomer Composites" Polymers 16, no. 7: 892. https://doi.org/10.3390/polym16070892

APA StyleLiu, S., Jing, Y., & Liu, G. (2024). A Systematic Investigation of the Kinetic Models Applied to the Transport Behaviors of Aromatic Solvents in Unfilled Hydrogenated Nitrile Rubber/Ethylene Propylene Diene Monomer Composites. Polymers, 16(7), 892. https://doi.org/10.3390/polym16070892