Influence of Polymer Fibers on the Structure and Properties of Modified Variatropic Vibrocentrifuged Concrete

Abstract

1. Introduction

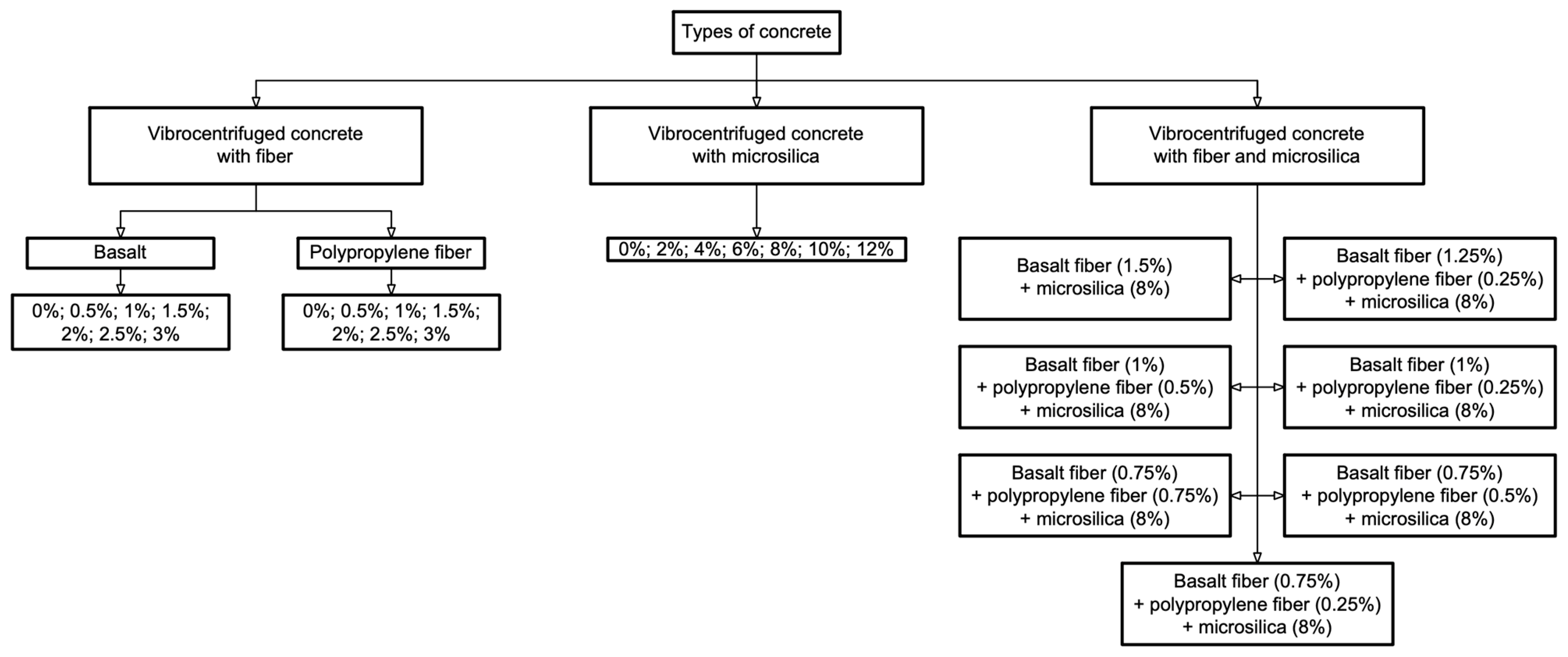

2. Materials and Methods

2.1. Meterials

- -

- Portland cement CEM I 52.5N (PC);

- -

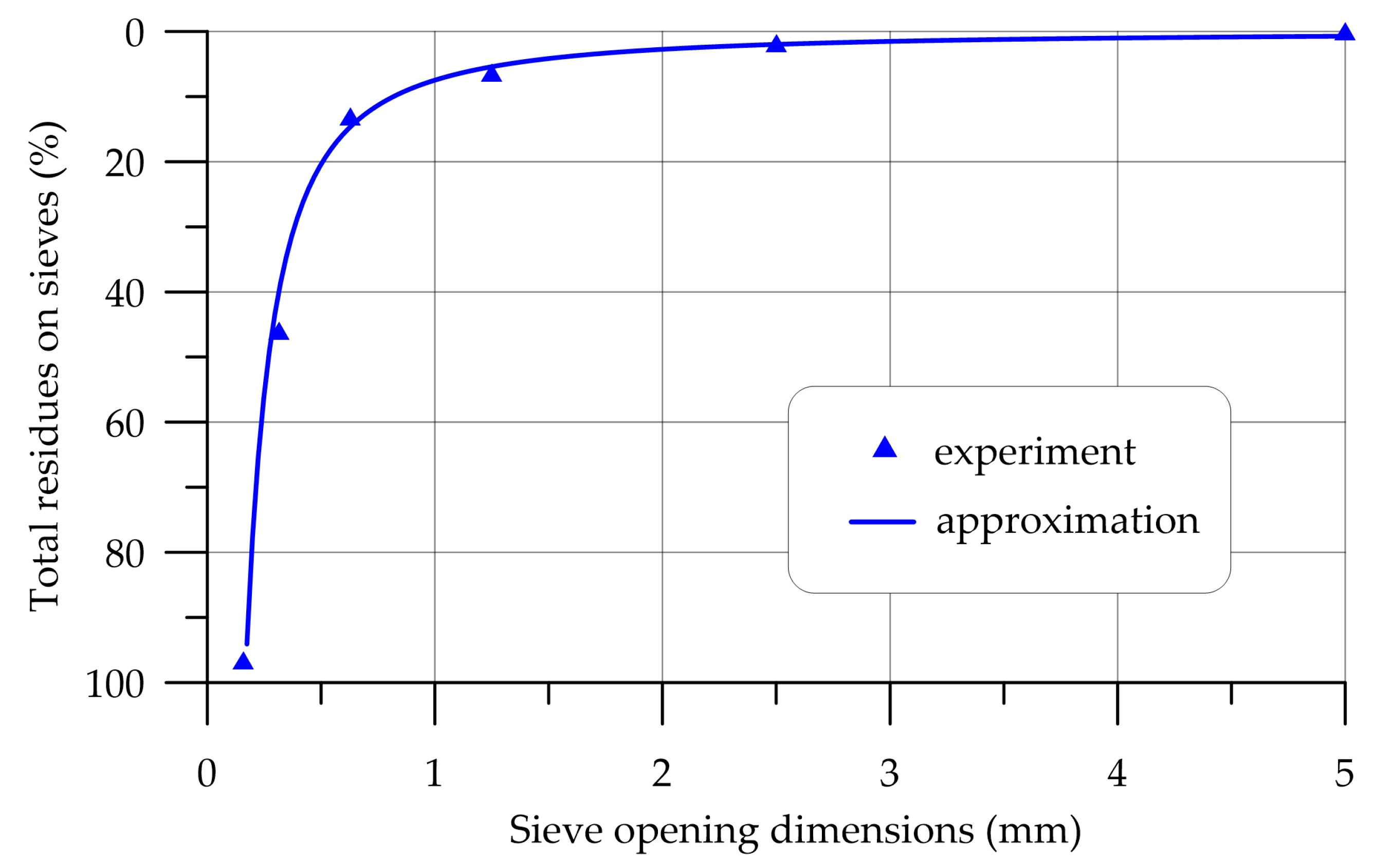

- Crushed sandstone (CrS);

- -

- Quartz sand (QS);

- -

- Microsilica MK-85 (MS) (NLMK, Lipetsk, Russia);

- -

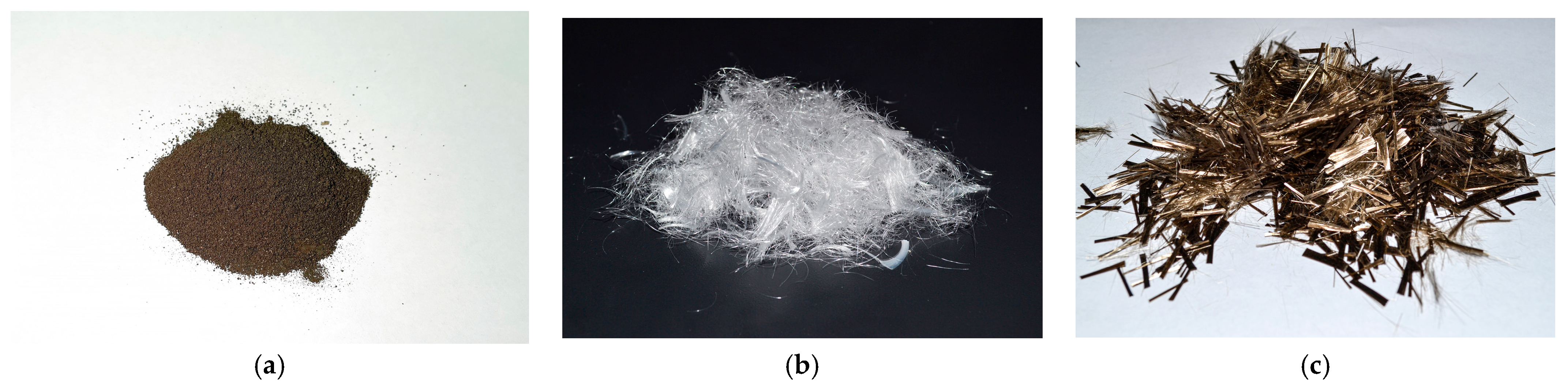

- Plasticizer Poliplast PC (P) (Poliplast-YUG, Russia);

- -

- Polypropylene fiber (PF) (Pascal, Dzerzhinsk, Russia);

- -

- Basalt fiber (BF) (Pascal, Dzerzhinsk, Russia).

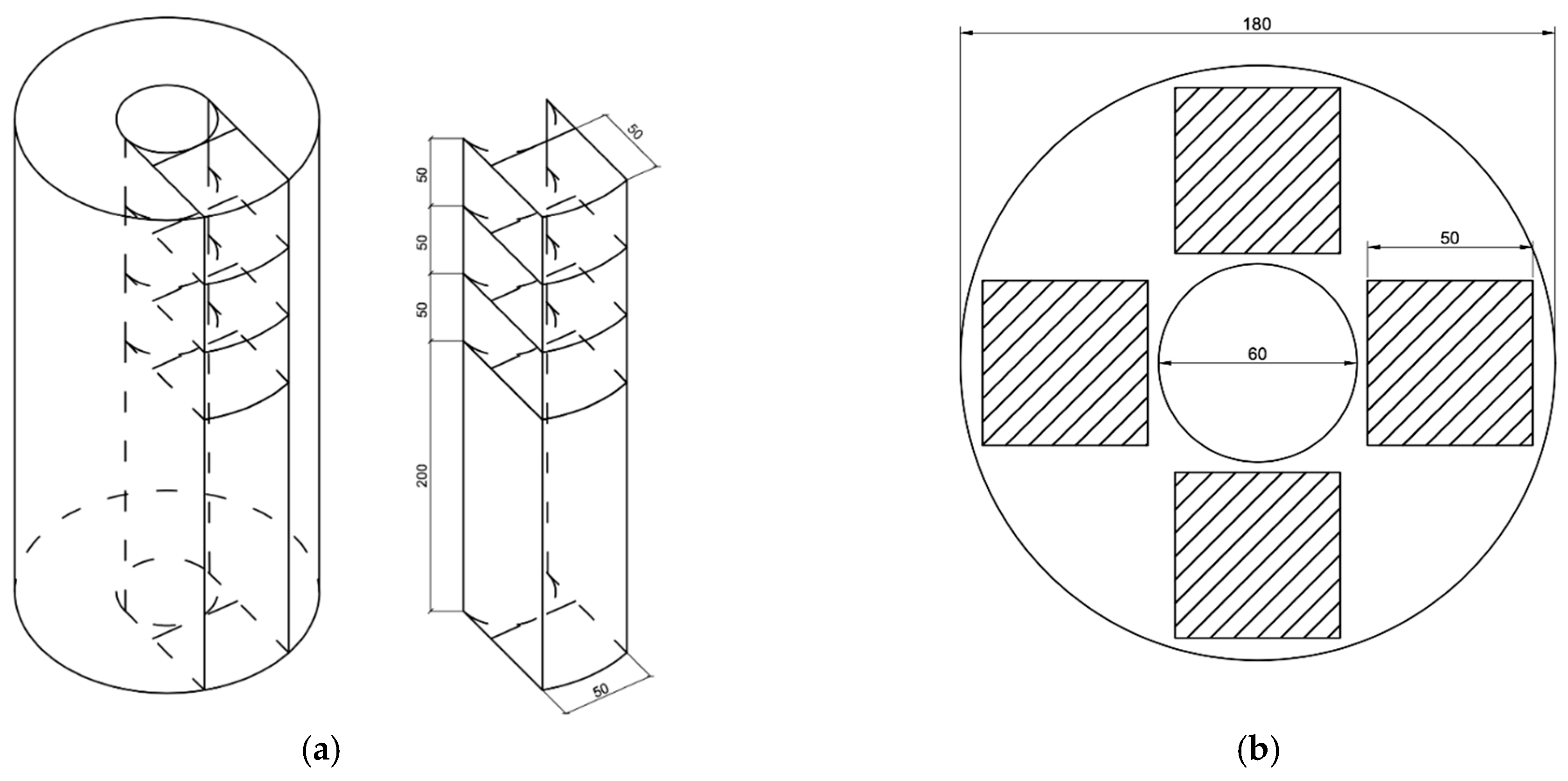

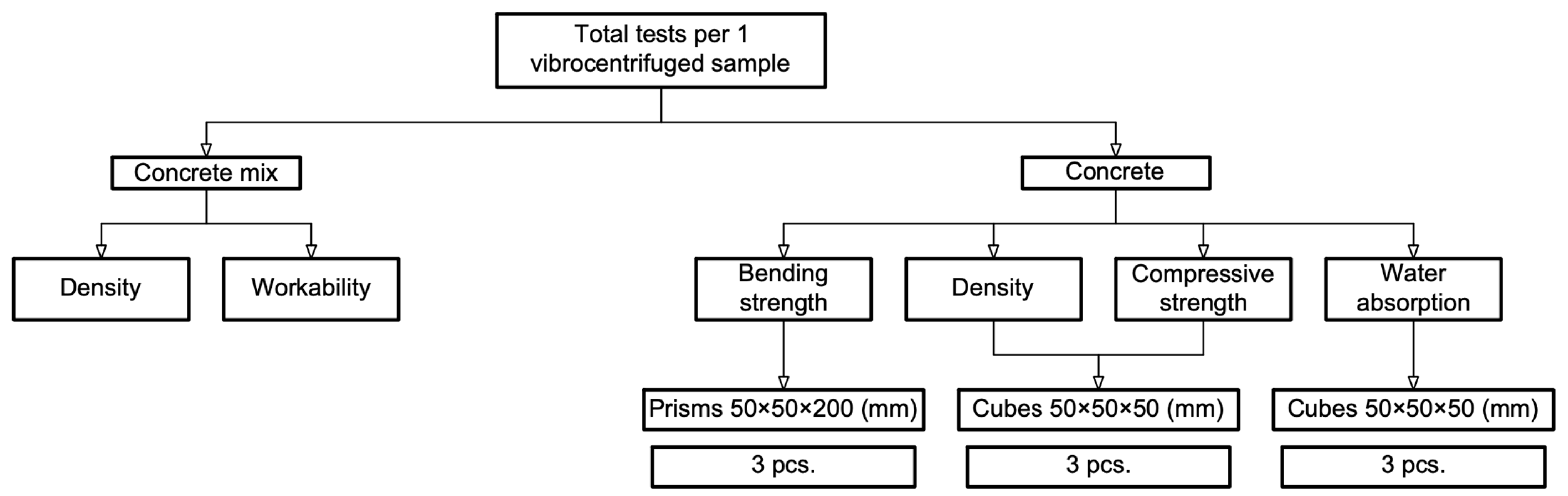

2.2. Methods

- -

- Outer diameter D = 180 mm;

- -

- Internal diameter d = 60 mm;

- -

- Height h = 350 mm.

3. Results and Discussion

- -

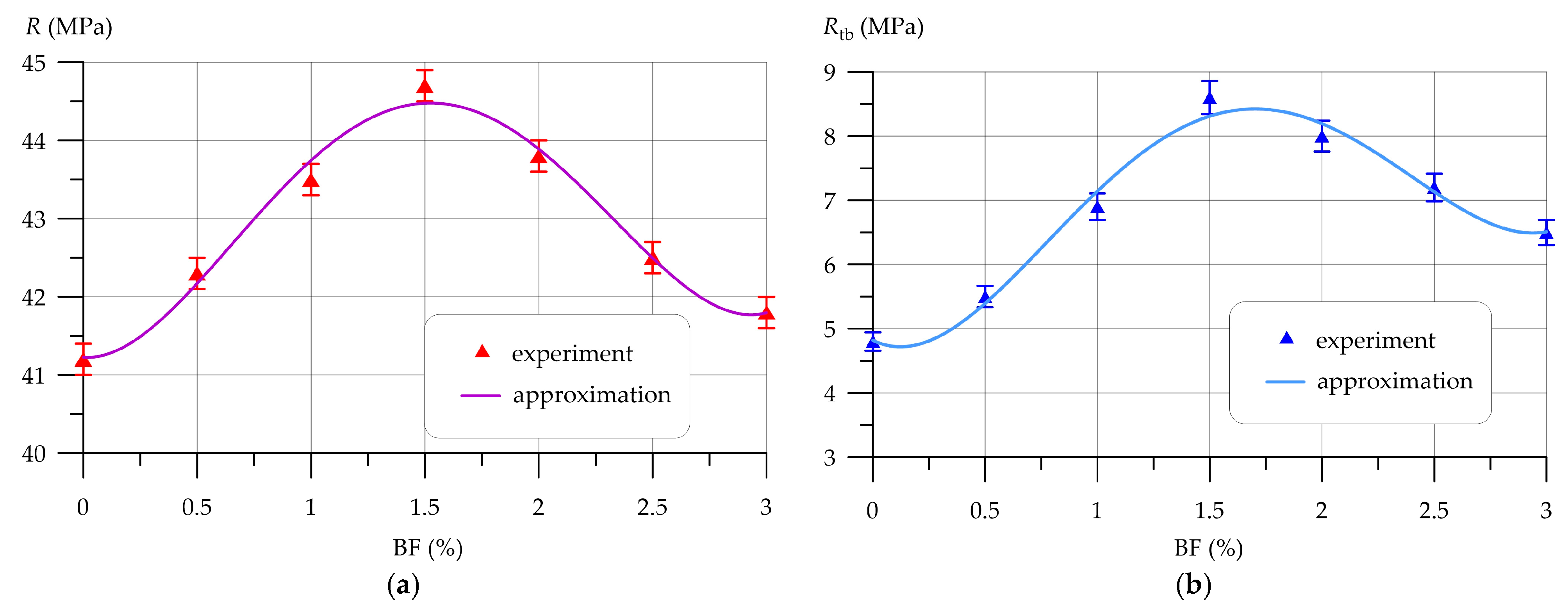

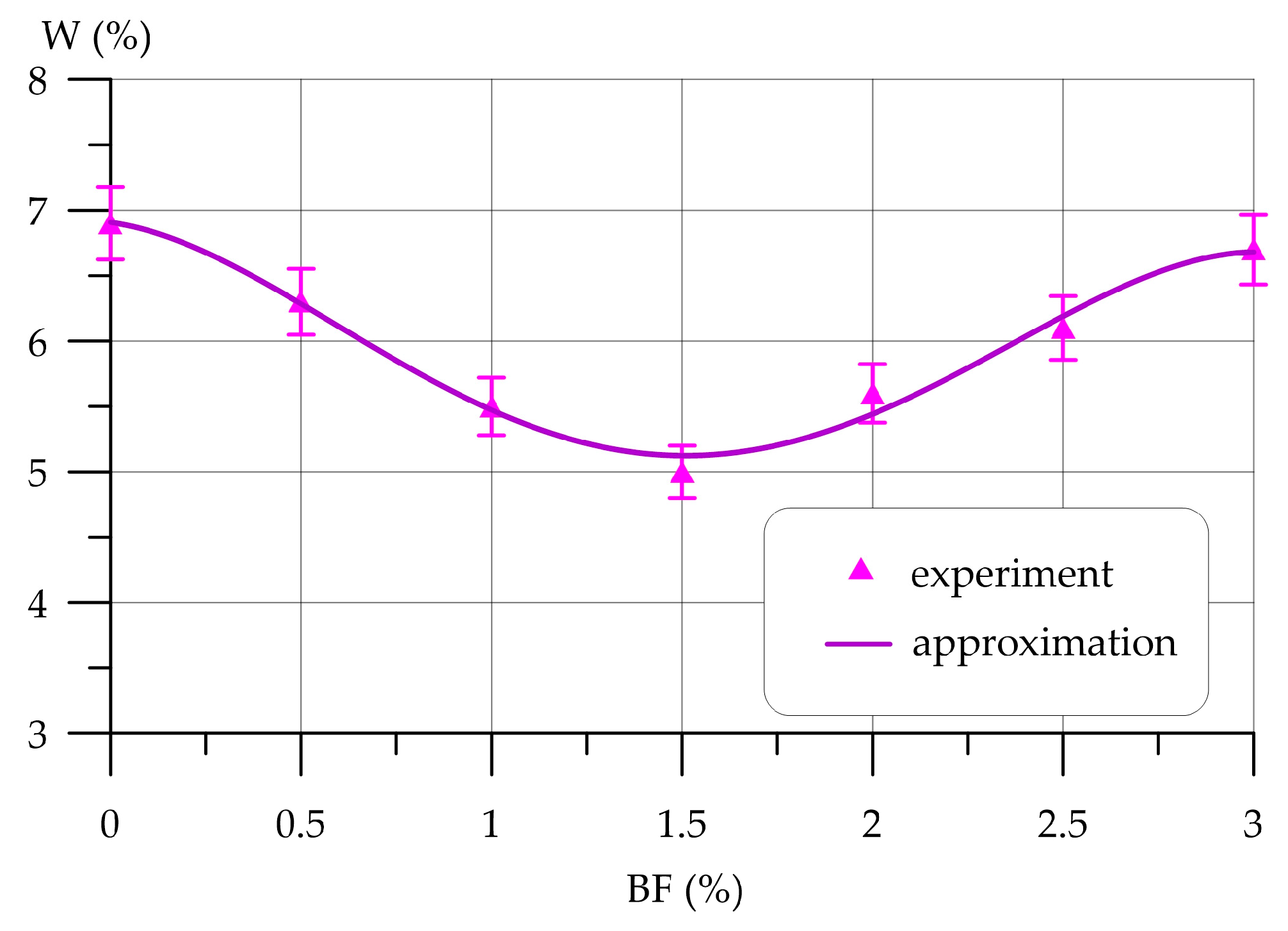

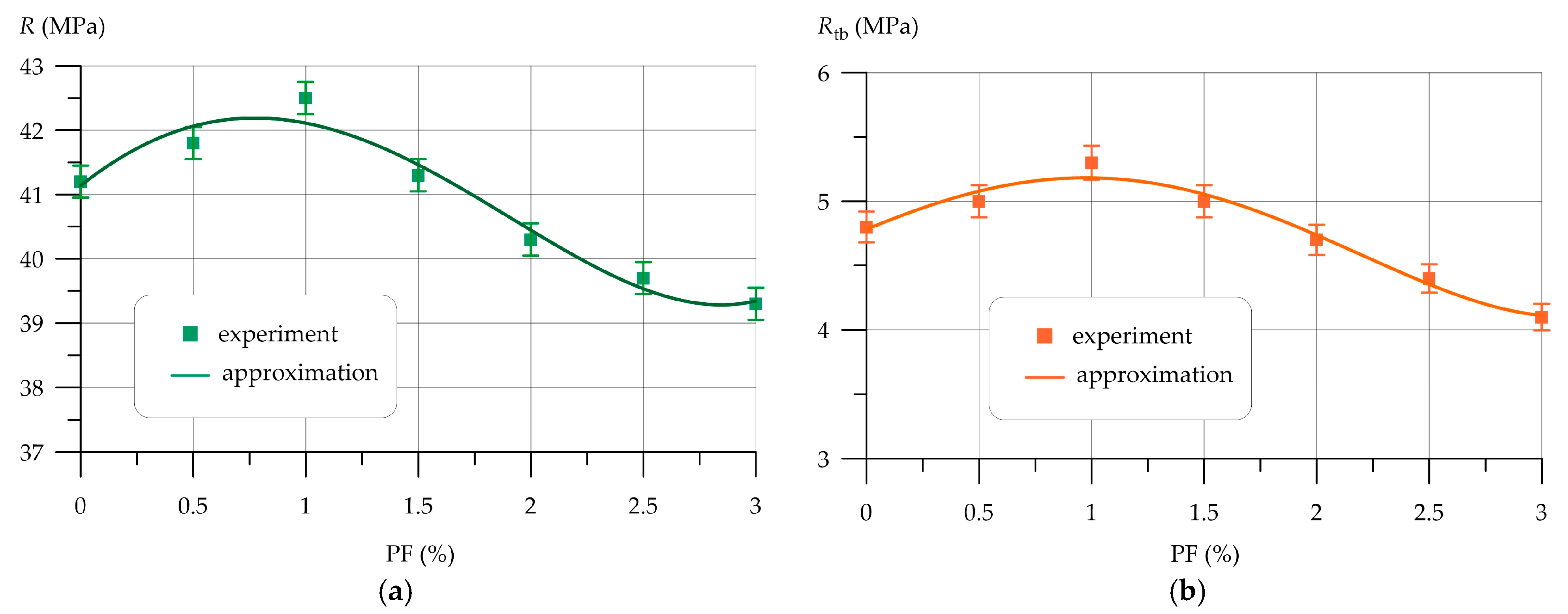

- The introduction of fiber in an optimal dosage makes it possible to improve the physical and mechanical characteristics of VCC;

- -

- Basalt fiber is more effective in comparison with polypropylene fiber; the increases in compressive and flexural strength VCC with 1.5% BF were 8.5% and 79.17%, respectively, and water absorption decreased by 27.54%; the increases in compressive and flexural strength at 1.0% PF were 3.16% and 10.42%, respectively, and water absorption decreased by 17.39%.

- -

- The content of basalt fiber was 1.5% by weight of cement;

- -

- The content of polypropylene fiber was 1.0% by weight of cement;

- -

- The microsilica content was 8% instead of part of the cement by weight.

4. Conclusions

- (1)

- The addition of fiber and silica fume in all quantities considered does not have any significant effect on the density of vibrocentrifuged concrete. However, the use of these recipe solutions reduces the workability of concrete mixtures. The decrease in workability is direct in nature, that is, with an increase in the amount of fiber and microsilica content, the cone settlement decreases. In the case of fiber reinforcement, the decrease in cone settlement is explained by the fact that friction forces arise between the surface of the fiber and the cement–sand mortar, and part of the cement paste is used to lubricate the introduced fibers. These factors increase the viscosity of the concrete mixture. In the case of microsilica, the reduction in cone settlement is justified by the introduction of particles with a high specific surface area, the wetting of which requires more freely bound water.

- (2)

- In vibrocentrifuged concrete, the greatest efficiency is achieved with dispersed reinforcement with basalt fiber in an amount of 1.5%. Compared to the control composition, the increase in compressive strength was 8.50%, flexural strength was 79.17%, and water absorption decreased by 27.54%.

- (3)

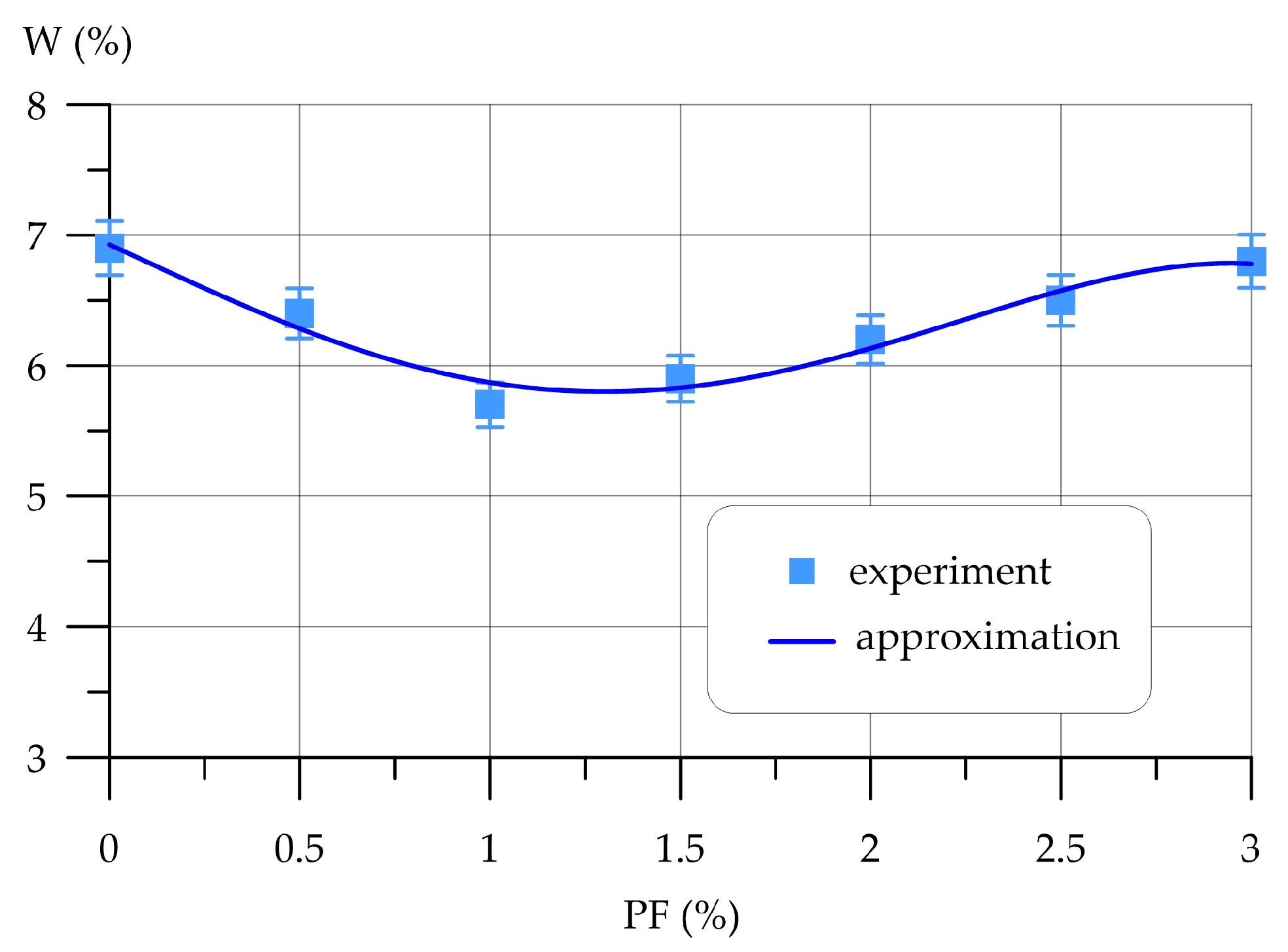

- When modified with polypropylene fiber, the greatest effect was recorded at a dosage of 1.0%. The increase in compressive strength was 3.16%, flexural strength was 10.42%, and water absorption decreased by 17.39%.

- (4)

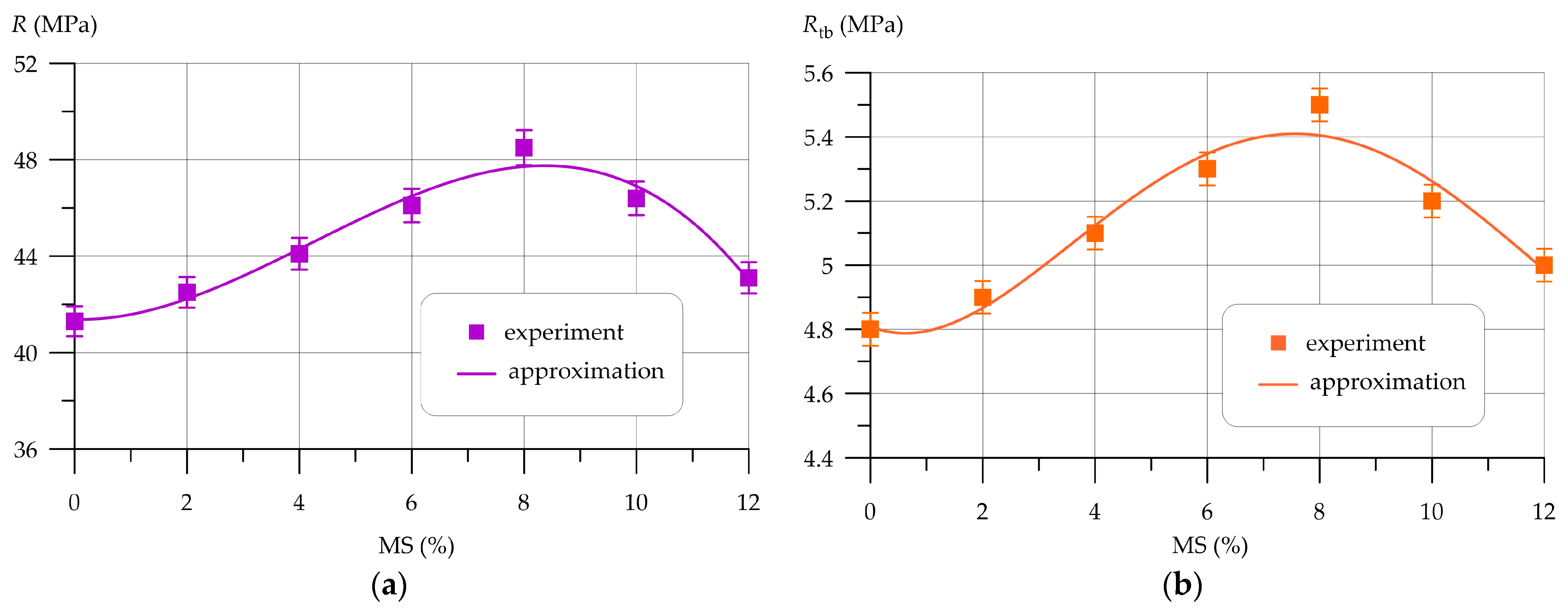

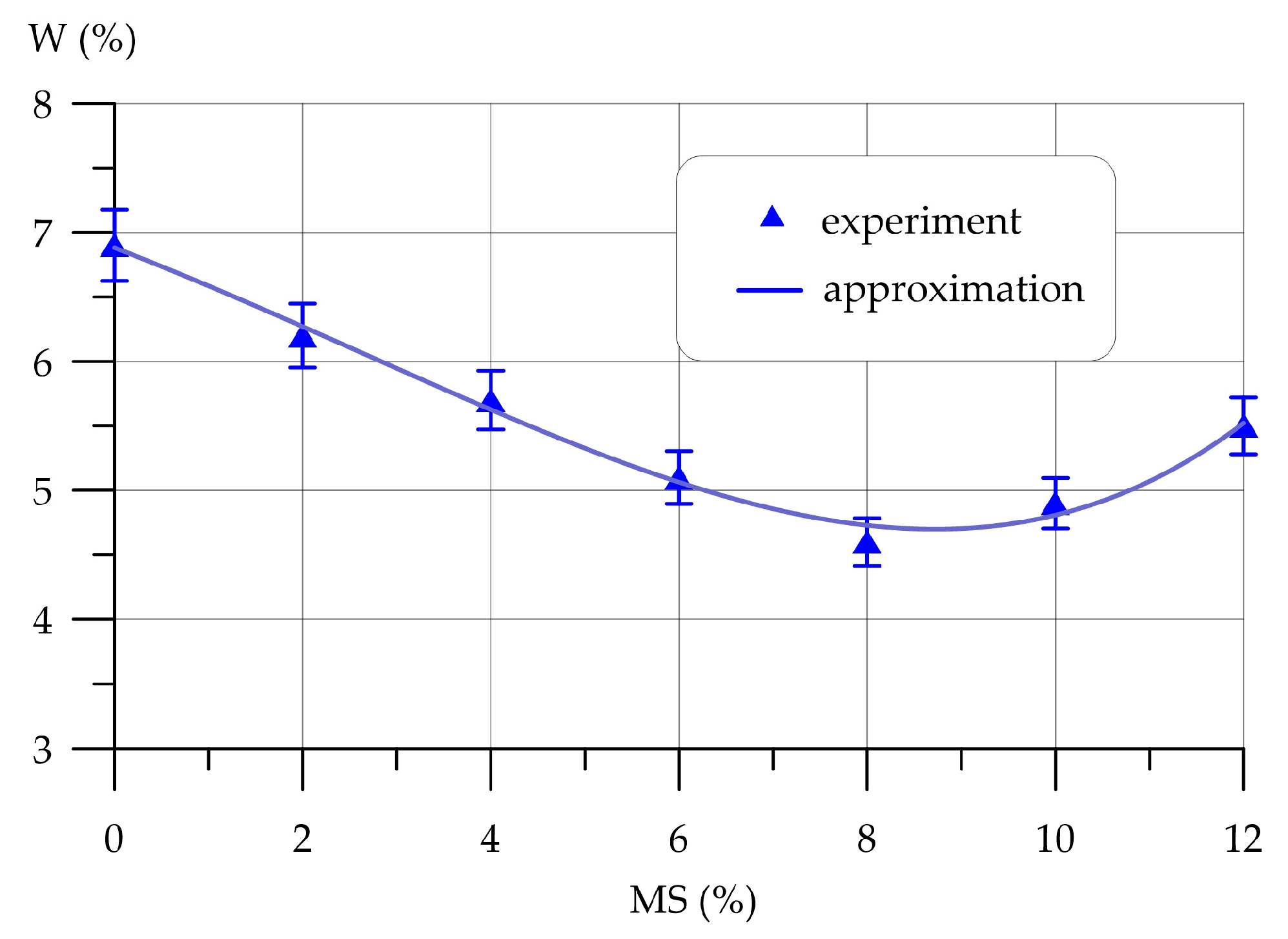

- Modification with microsilica showed the best effect with 8% replacement of part of the cement. The increase in compressive strength was 17.43%, flexural strength was 14.58%, and water absorption decreased by 33.30%.

- (5)

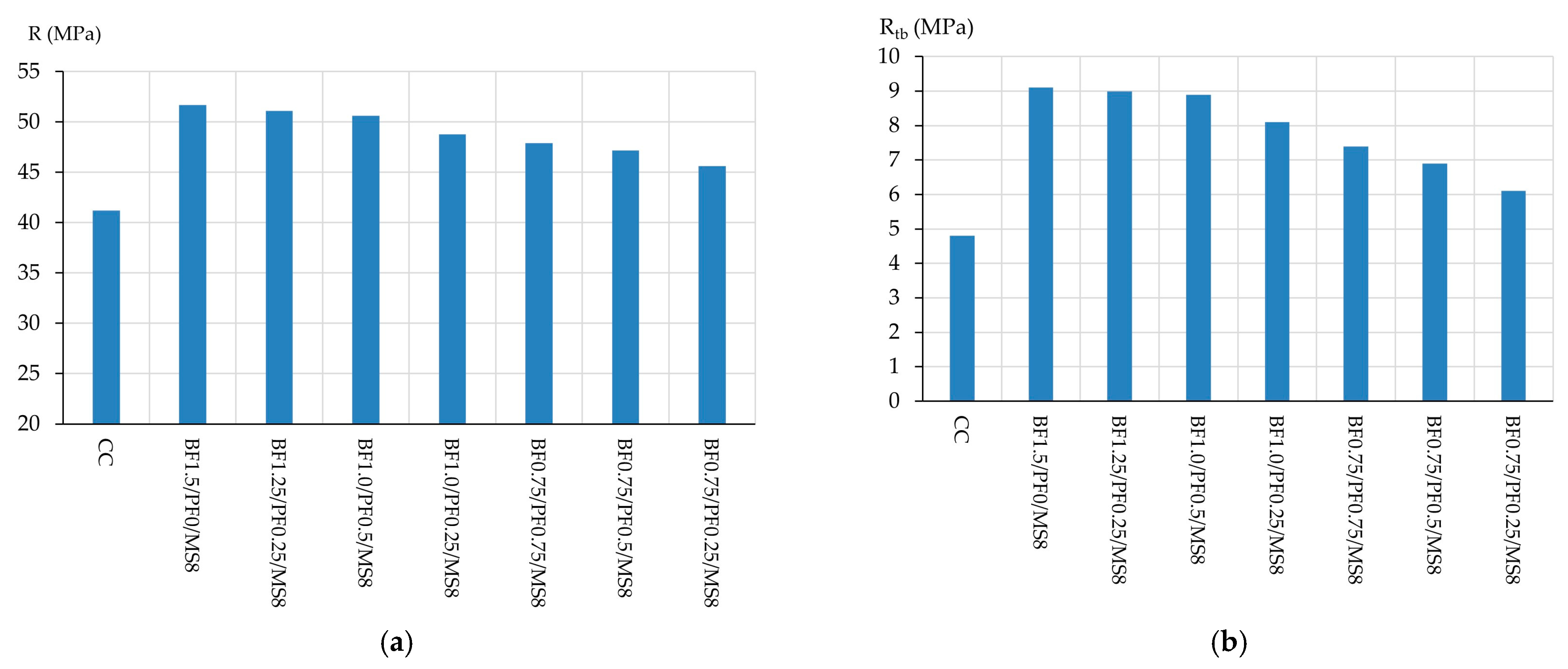

- The most effective and economically rational formulation solution for vibrocentrifuged concrete is combined fiber reinforcement in combination with modification with microsilica in the following quantities: basalt fiber—1.0%; polypropylene fiber—0.5%; microsilica—8%. The increase in compressive strength was 22.82%, flexural strength 85.42%, and water absorption decreased by 37.68%.

- (6)

- The effect of combined reinforcement using polymer fiber and modification with microsilica has a complex effect on the structure and properties of the vibrocentrifuged composite and makes it possible to obtain variatropic concrete with improved compressive strength, flexural strength, and reduced water absorption.

- (7)

- The prospects for the practical application and implementation of the results obtained are in the sphere of interest of manufacturers of concrete and reinforced concrete products, since such proposals can lead to a reduction in the percentage of defects in production and the production of high-quality products without a significant change in costs. Construction organizations will be stakeholders in this case, since they will receive safer and more reliable building products and structures that will be more resistant to various impacts, and due to the more viscous nature of destruction, will be more likely to allow the operation of buildings and structures erected in complex conditions. Prospects for the development of this research lie in the direction of testing other types of fibers, including polymer fibers made from other materials.

- (8)

- The results obtained are pointwise for specific cases. The use of polymer fiber in vibrocentrifuged concrete, like any scientific or industrial discovery or innovation, has its limitations. Limitations on the applicability of the proposed scientific developments lie in the need for additional checks if they go beyond the presented areas. In particular, the proposed formulations are applicable for specific variatropic vibrocentrifuged products and structures, and the dosage of fiber, if it is replaced from polymer to other types, also needs to be clarified. Therefore, the specific accuracy of the results obtained in the studies performed should be taken into account.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abed, M.A.; Anagreh, A.; Tošić, N.; Alkhabbaz, O.; Alshwaiki, M.E.; Černý, R. Structural Performance of Lightweight Aggregate Concrete Reinforced by Glass or Basalt Fiber Reinforced Polymer Bars. Polymers 2022, 14, 2142. [Google Scholar] [CrossRef] [PubMed]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Development of lignocellulosic fiber reinforced cement composite panels using semi-dry technology. Cellulose 2021, 28, 3631–3645. [Google Scholar] [CrossRef]

- Nemessanyi, C. Brief History of Fiber Reinforced Polymers as Structural Material. Period. Polytech. Archit. 2023, 54, 193–206. [Google Scholar] [CrossRef]

- Marquardt, E. Centrifuged concrete and reinforced concrete tubes. Centrifugal Concr. 1934, 14, 37–100. [Google Scholar]

- Mailyan, L.R.; Stel’makh, S.A.; Shcherban’, E.M.; Khalyushev, A.K.; Smolyanichenko, A.S.; Sysoev, A.K.; Parinov, I.A.; Cherpakov, A.V. Investigation of Integral and Differential Characteristics of Variatropic Structure Heavy Concretes by Ultrasonic Methods. Appl. Sci. 2021, 11, 3591. [Google Scholar] [CrossRef]

- Korolev, E.V.; Bazhenov, Y.M.; Smirnov, V.A. Building Materials of Variatropic Frame Structure; National Research Moscow State University of Civil Engineering: Moscow, Russia, 2011; p. 304. [Google Scholar]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Butko, D.; Smolyanichenko, A.S. Influence of Composition and Technological Factors on Variatropic Efficiency and Constructive Quality Coefficients of Lightweight Vibro-Centrifuged Concrete with Alkalized Mixing Water. Appl. Sci. 2021, 11, 9293. [Google Scholar] [CrossRef]

- Kos, Ž.; Kroviakov, S.; Kryzhanovskyi, V.; Hedulian, D. Strength, Frost Resistance, and Resistance to Acid Attacks on Fiber-Reinforced Concrete for Industrial Floors and Road Pavements with Steel and Polypropylene Fibers. Materials 2022, 15, 8339. [Google Scholar] [CrossRef]

- Nanditha, M.; Saikumar, S. Examine on mechanical properties of steel fiber strengthened concrete with silica fume. Mater. Today Proc. 2021, 45, 3564–3567. [Google Scholar] [CrossRef]

- Wen, B.; Gao, G.; Huang, D.; Zheng, H. Adhesion and Sliding Constitutive Relationship between Basalt–Polypropylene Hybrid Fiber-Reinforced Concrete and Steel Bars. Appl. Sci. 2023, 13, 12108. [Google Scholar] [CrossRef]

- Song, K.; Yu, Y.; Liu, Y.; Zhao, J. Flexural Performance Study of Basalt-Fiber-Reinforced Polymer Bar Basalt-Fiber-Reinforced Concrete Beams. Buildings 2023, 13, 2583. [Google Scholar] [CrossRef]

- Zhang, X.; Luo, C.; Wang, J.; Kuang, X.; Huang, Y. The Axial Compression Behavior of Basalt Fiber-Reinforced Recycled Aggregate Concrete-Filled Circular Steel-Tubular Column. Sustainability 2023, 15, 14351. [Google Scholar] [CrossRef]

- Zhang, X.; Niu, J.; Qiao, S.; Luo, C.; Fan, Y.; Kuang, X.; Huang, Y. Study on Eccentric Compression Mechanical Characteristics of Basalt Fiber-Reinforced Recycled Aggregate Concrete-Filled Circular Steel Tubular Column. Coatings 2023, 13, 1923. [Google Scholar] [CrossRef]

- Dvorkin, L.; Konkol, J.; Marchuk, V.; Huts, A. Efficient, Fine-Grained Fly Ash Concrete Based on Metal and Basalt Fibers. Materials 2023, 16, 3969. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Helal, K.A.; Youssf, O. Chopped Basalt Fiber-Reinforced High-Performance Concrete: An Experimental and Analytical Study. J. Compos. Sci. 2023, 7, 250. [Google Scholar] [CrossRef]

- Liao, W.; Wu, P.; Huang, J.; Chen, G.; Lin, J.; Guo, Y.; Chen, R. Cost-Effective Engineered Cementitious Composites with Hybrid PVA and Basalt/PP Fiber: A Study on Compressive, Tensile and Impact Performance. Materials 2023, 16, 5172. [Google Scholar] [CrossRef]

- Zhuang, J.; Shen, S.; Yang, Y.; Xu, K.; Ni, P. Mechanical performance of basalt and PVA fiber reinforced hybrid-fiber engineered cementitious composite with superimposed basalt fiber content. Constr. Build. Mater. 2022, 353, 129183. [Google Scholar] [CrossRef]

- Li, Y.; Gu, Z.; Zhao, B.; Zhang, J.; Zou, X. Experimental Study on Mechanical Properties of Basalt Fiber Concrete after Cryogenic Freeze−Thaw Cycles. Polymers 2023, 15, 196. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhang, S.; Xin, S. Performance Test and Thermal Insulation Effect Analysis of Basalt-Fiber Concrete. Materials 2022, 15, 8236. [Google Scholar] [CrossRef]

- Afroz, M.; Patnaikuni, I.; Venkatesan, S. Chemical durability and performance of modified basalt fiber in concrete medium. Constr. Build. Mater. 2017, 154, 191–203. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, W.; Yang, R.; Lu, J.; Li, X. Study on corrosion law and characteristics of composite modified basalt fiber concrete in acid environment. Polym. Test. 2023, 128, 108201. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B. Influence of Mechanochemical Activation of Concrete Components on the Properties of Vibro-Centrifugated Heavy Concrete. Appl. Sci. 2021, 11, 10647. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Evtushenko, A.; Varavka, V.; Beskopylny, N. Nano-Modified Vibrocentrifuged Concrete with Granulated Blast Slag: The Relationship between Mechanical Properties and Micro-Structural Analysis. Materials 2022, 15, 4254. [Google Scholar] [CrossRef] [PubMed]

- Vijayan, D.S.; Devarajan, P.; Sivasuriyan, A. A review on eminent application and performance of nano based silica and silica fume in the cement concrete. Sustain. Energy Technol. Assess. 2023, 56, 103105. [Google Scholar] [CrossRef]

- Khan, M.I.; Abbas, Y.M.; Fares, G. Enhancing Cementitious Concrete Durability and Mechanical Properties through Silica Fume and Micro-Quartz. Sustainability 2023, 15, 15913. [Google Scholar] [CrossRef]

- Oyunbileg, D.; Amgalan, J.; Batbaatar, T.; Temuujin, J. Evaluation of thermal and freeze-thaw resistances of the concretes with the silica fume addition at different water-cement ratio. Case Stud. Constr. Mater. 2023, 19, e02633. [Google Scholar] [CrossRef]

- Tak, S.; Gupta, P.; Kumar, A.; Sofi, A.; Yun, C.M. Effect of using silica fume as a partial replacement of cement in concrete. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Revathi, S.; Sathis kumar, P.; Suresh, D.; Thowfick Anvar, S. Behaviour of concrete with PET bottles as fibers & silica fume as partial replacement of cement. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Iqbal, M.; Zhang, D.; Khan, K.; Amin, M.N.; Ibrahim, M.; Salami, B.A. Evaluating mechanical, microstructural and durability performance of seawater sea sand concrete modified with silica fume. J. Build. Eng. 2023, 72, 106583. [Google Scholar] [CrossRef]

- Nguyen, L.K.; Trinh Nguyen, T.T.; Nguyen, S.T.; Ngo, T.Q.; Le, T.H.; Dang, V.Q.; Ho, L.S. Mechanical properties and service life analysis of high strength concrete using different silica fume contents in marine environment in Vietnam. J. Eng. Res. 2023; in press. [Google Scholar] [CrossRef]

- Gao, Y.; Zhou, B.; Yao, X.; Guan, J.; Han, X. The Influence of Metakaolin and Polypropylene Fiber Concrete on Mechanics Properties and Microstructure Combined Action under Multi-Salt Soaking and Freeze–Thaw. Materials 2023, 16, 5525. [Google Scholar] [CrossRef]

- Alomayri, T.; Ali, B.; Raza, S.S.; Ahmed, H.; Hamad, M. Investigating the Effects of Polypropylene Fibers on the Mechanical Strength, Permeability, and Erosion Resistance of Freshwater and Seawater Mixed Concretes. J. Mar. Sci. Eng. 2023, 11, 1224. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, B.; Kong, X.; Fu, Y. Investigation of Impact Resistance of High-Performance Polypropylene Fiber-Reinforced Recycled Aggregate Concrete. Crystals 2022, 12, 669. [Google Scholar] [CrossRef]

- Hedjazi, S.; Castillo, D. Utilizing Polypropylene Fiber in Sustainable Structural Concrete Mixtures. CivilEng 2022, 3, 562–572. [Google Scholar] [CrossRef]

- Ahmad, J.; Burduhos-Nergis, D.D.; Arbili, M.M.; Alogla, S.M.; Majdi, A.; Deifalla, A.F. A Review on Failure Modes and Cracking Behaviors of Polypropylene Fibers Reinforced Concrete. Buildings 2022, 12, 1951. [Google Scholar] [CrossRef]

- Chen, X.; Li, T.; Zhan, M.; Ding, Y.; Leng, F.; Sun, J. Analysis of Erosion Characteristics and Erosion Mechanism of Polypropylene Fiber Tailings Recycled Concrete in Salt Spray Environment. Polymers 2022, 14, 5137. [Google Scholar] [CrossRef] [PubMed]

- Youm, K.; Moon, J. Experimental Study on Impact Behavior of Concrete Panel with and without Polypropylene Macrofibers. Buildings 2023, 13, 303. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Varavka, V.; Chernil’nik, A.; Pogrebnyak, A. Improved Fly Ash Based Structural Foam Concrete with Polypropylene Fiber. J. Compos. Sci. 2023, 7, 76. [Google Scholar] [CrossRef]

- Li, T.; Zhan, M.; Chen, X.; Xu, F.; Wang, S.; Liu, X. Study on Carbonization Characteristics and Deterioration Mechanism of Recycled Concrete with Tailings and Polypropylene Fiber. Polymers 2022, 14, 2758. [Google Scholar] [CrossRef]

- Ali, A.B.; Sharif, M.B.; Irfan-ul-Hassan, M.; Iqbal, Y.; Akmal, U.; Alabduljabbar, H.; Deifalla, A.F. Coupled Effect of Polypropylene Fibers and Slag on the Impact Resistance and Mechanical Properties of Concrete. Materials 2022, 15, 5654. [Google Scholar] [CrossRef]

- Del Savio, A.A.; La Torre Esquivel, D.; Carrillo, J.; Chi Yep, E. Determination of Polypropylene Fiber-Reinforced Concrete Compressive Strength and Elasticity Modulus via Ultrasonic Pulse Tests. Appl. Sci. 2022, 12, 10375. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, H.; Zhao, B.; Wang, B.; Zhao, Q.; Sun, M. Experimental Investigation on Physical Properties of Concrete Containing Polypropylene Fiber and Water-Borne Epoxy for Pavement. Coatings 2023, 13, 452. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, B.; Yan, Z.; Huang, Z. Properties of hybrid basalt-polypropylene fiber reinforced mortar at different temperatures. Constr. Build. Mater. 2022, 346, 128433. [Google Scholar] [CrossRef]

- Zhu, H.; Wen, S.; Li, X.; Li, Y.; Fu, Z. Damage Evolution of Polypropylene–Basalt Hybrid Fiber Ceramsite Concrete under Chloride Erosion and Dry–Wet Cycle. Polymers 2023, 15, 4179. [Google Scholar] [CrossRef] [PubMed]

- Ran, T.; Pang, J.; Yu, J. Performance of Rubber Concrete Containing Polypropylene and Basalt Fibers under Coupled Sulfate Attack and Freeze–Thaw Conditions: An Experimental Evaluation. Polymers 2023, 15, 2066. [Google Scholar] [CrossRef]

- Su, D.; Pang, J.; Han, C.; Huang, J.; Hu, X.; Shi, W. Influence of Basalt/Polypropylene Fiber on Permeability and Uniaxial Compressive Properties of Waste Tire Rubberized Concrete. Materials 2023, 16, 481. [Google Scholar] [CrossRef] [PubMed]

- Fu, Q.; Xu, W.; Bu, M.X.; Guo, B.; Niu, D. Effect and action mechanism of fibers on mechanical behavior of hybrid basalt-polypropylene fiber-reinforced concrete. Structures 2021, 34, 3596–3610. [Google Scholar] [CrossRef]

- Yan, S.; Dong, Q.; Chen, X.; Li, J.; Wang, X.; Shi, B. An experimental and numerical study on the hybrid effect of basalt fiber and polypropylene fiber on the impact toughness of fiber reinforced concrete. Constr. Build. Mater. 2024, 411, 134270. [Google Scholar] [CrossRef]

- Mao, J.; Liang, N.; Liu, X.; Zhong, Z.; Zhou, C. Investigation on early-age cracking resistance of basalt-polypropylene fiber reinforced concrete in restrained ring tests. J. Build. Eng. 2023, 70, 106155. [Google Scholar] [CrossRef]

- Liang, N.; Geng, S.; Mao, J.; Liu, X.; Zhou, X. Investigation on cracking resistance mechanism of basalt-polypropylene fiber reinforced concrete based on SEM test. Constr. Build. Mater. 2024, 411, 134102. [Google Scholar] [CrossRef]

- Wang, D.; Ju, Y.; Shen, H.; Xu, L. Mechanical properties of high performance concrete reinforced with basalt fiber and polypropylene fiber. Constr. Build. Mater. 2019, 197, 464–473. [Google Scholar] [CrossRef]

- Manoharan, S.; Shihab, A.I.; Alemandar, A.S.A.; Ganesh Babu, L.; Vijay, R.; Lenin Singaravelu, D. Influence of recycled basalt-aramid fibres integration on the mechanical and thermal properties of brake friction composites. Mater. Res. Express 2019, 6, 115310. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; El’shaeva, D. Influence of the Chemical Activation of Aggregates on the Properties of Lightweight Vibro-Centrifuged Fiber-Reinforced Concrete. J. Compos. Sci. 2022, 6, 273. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Beskopylny, N.; El’shaeva, D.; Kotenko, M. The Investigation of Compacting Cement Systems for Studying the Fundamental Process of Cement Gel Formation. Gels 2022, 8, 530. [Google Scholar] [CrossRef]

- VSN 1-90; Fabrication Requirements for Centrifugal-Cast Support Pillars for Contact Lines, Communications Lines, and Lock-Out Systems. TsNIIS Ministry of Transport of the USSR: Moscow, Russia, 1990. Available online: https://meganorm.ru/Index2/1/4294851/4294851029.htm (accessed on 12 January 2024).

- GOST R 57345-2016/EN 206-1:2013; Concrete. General Specifications. Standardinform: Moscow, Russia, 2017. Available online: https://docs.cntd.ru/document/1200142845 (accessed on 26 February 2024).

- Stel’makh, S.A.; Shcherban’, E.M.; Kholodnyak, M.G.; Nasevich, A.S.; Yanovskaya, A.V. Device for the Manufacture of Products from Vibrocentrifuged Concrete. Russian. Federation Patent 197,610, 29 January 2020. Available online: https://patentimages.storage.googleapis.com/99/a7/e4/7331df00d4bdba/RU197610U1.pdf (accessed on 12 January 2024).

- GOST R 57813-2017/EN 12350-6:2009; Testing Fresh Concrete. Part 6. Density. Standardinform: Moscow, Russia, 2019. Available online: https://docs.cntd.ru/document/1200157335 (accessed on 22 November 2023).

- GOST R 57809-2017/EN 12350-2:2009; Testing Fresh Concrete. Part 2. Slump Test. Standardinform: Moscow, Russia, 2019. Available online: https://docs.cntd.ru/document/1200157288 (accessed on 22 November 2023).

- EN 12390-7:2019; Testing Hardened Concrete—Part 7: Density of Hardened Concrete. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/811a0cf3-55e3-495a-b06e-5c302d5f2806/en-12390-7-2019 (accessed on 22 November 2023).

- EN 12390-1:2021; Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements of Specimens and Moulds. iTeh Standards: Etobicoke, ON, Canada, 2021. Available online: https://standards.iteh.ai/catalog/standards/cen/d1c9ccee-2e5a-425e-a964-961da95d2f99/en-12390-1-2021 (accessed on 22 November 2023).

- EN 12390-2:2019; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/ae7e6a86-1cbc-455e-8b2a-8964be9087f9/en-12390-2-2019 (accessed on 22 November 2023).

- EN 12390-3:2019; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/7eb738ef-44af-436c-ab8e-e6561571302c/en-12390-3-2019 (accessed on 22 November 2023).

- EN 12390-4:2019; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. iTeh Standards: Etobicoke, ON, Canada, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/10b1c613-819b-42d7-8f94-480cd37a666a/en-12390-4-2019 (accessed on 22 November 2023).

- GOST 12730.3-2020; Concretes. Method of Determination of Water Absorption. Gost Standard: Moscow, Russia, 2020. Available online: https://docs.cntd.ru/document/1200177301 (accessed on 22 November 2023).

- BS 1881-122:2011+A1:2020; Testing Concrete Method for Determination of Water Absorption. European Standards: Plzen, Czech Republic, 2020. Available online: https://www.en-standard.eu/bs-1881-122-2011-a1-2020-testing-concrete-method-for-determination-of-water-absorption/ (accessed on 22 November 2023).

- Korovkin, M.O.; Eroshkina, N.A.; Sadenko, S.M.; Krainova, K.A. Study of effect of fiber dosage and duration of mixing on properties of fine-grained concreate. Eng. Constr. Bull. Casp. Sea 2020, 3, 22–26. [Google Scholar] [CrossRef]

- Shoaib, S.; El-Hassan, H.; El-Maaddawy, T. Properties and Tensile Softening Laws of Hybrid Basalt Fiber Reinforced Recycled Aggregate Concrete. Buildings 2023, 13, 975. [Google Scholar] [CrossRef]

- Wu, H.; Qin, X.; Huang, X.; Kaewunruen, S. Engineering, Mechanical and Dynamic Properties of Basalt Fiber Reinforced Concrete. Materials 2023, 16, 623. [Google Scholar] [CrossRef] [PubMed]

- Panteleev, D.A. The deformation and strength characteristics of polyreinforced fiber concrete. News Kazan State Univ. Archit. Constr. 2015, 3, 133–139. [Google Scholar]

- Pukharenko, Y.V.; Panteleev, D.A.; Morozov, V.I.; Magdeev, U.H. The Strength and Deformability of Polyreinforcement with Amorphous Metallic Fiber. Acad. Archit. Constr. 2016, 1, 107–111. [Google Scholar]

- Pukharenko, Y.V.; Zhavoronkov, M.I.; Panteleev, D.A. Improvement of Methods for Determining Power and Energy Characteristics of Fibre Reinforced Concrete Crack Resistance. Bull. Irkutsk. State Tech. Univ. 2019, 14, 301–310. [Google Scholar] [CrossRef]

- Li, F.; Lv, T.; Wei, S. Performance, Mechanical Properties and Durability of a New Type of UHPC—Basalt Fiber Reinforced Reactive Powder Concrete: A Review. Polymers 2023, 15, 3129. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, G.; Xu, P.; Fu, L.; Deng, D.; Kuang, X.; Fan, Y. Mechanical Properties under Compression and Microscopy Analysis of Basalt Fiber Reinforced Recycled Aggregate Concrete. Materials 2023, 16, 2520. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyüncü, V.; Chowdhury, S.; Akça, A.H. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Urkhanova, L.A.; Lkhasaranov, S.A.; Rozina, V.E.; Buyantuev, S.L.; Bardakhanov, S.P. Basalt Fiber Reinforced Concrete with Improved Physico-Mechanical and Performance Properties Using Nanodispersed Modifiers. Bull. Irkutsk. State Tech. Univ. 2014, 11, 175–180. [Google Scholar]

- Adamczak-Bugno, A.; Lipiec, S.; Adamczak, J.; Vičan, J.; Bahleda, F. Identification of Destruction Processes and Assessment of Deformations in Compressed Concrete Modified with Polypropylene Fibers Exposed to Fire Temperatures Using Acoustic Emission Signal Analysis, Numerical Analysis, and Digital Image Correlation. Materials 2023, 16, 6786. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Liu, X.; Ma, L.; Li, Z. Effects of polypropylene fibers and aggregate contents on the impact performance of coral aggregate concrete. J. Build. Eng. 2024, 81, 108140. [Google Scholar] [CrossRef]

- Kistan, A.; Kanchana, V.; Parthiban, E.; Vadivel, S.; Sridhar, B. Study on flexural behaviour of polypropylene fiber reinforced fly ash concrete beam. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Sugandhini, H.K.; Nayak, G.; Shetty, K.K.; Kudva, L.P. The Durability of High-Volume Fly Ash-Based Cement Composites with Synthetic Fibers in a Corrosive Environment: A Long-Term Study. Sustainability 2023, 15, 11481. [Google Scholar] [CrossRef]

- Kanishka, D.; Ramesh Kumar, G.B. Compressive strength of novel polymer coated concrete with polypropylene fiber. Mater. Today Proc. 2023, 77, 401–404. [Google Scholar] [CrossRef]

- Klyuev, A.V.; Kashapov, N.F.; Klyuev, S.V.; Zolotareva, S.V.; Shchekina, N.A.; Shorstova, E.S.; Lesovik, R.V.; Ayubov, N.A. Experimental studies of the processes of structure formation of composite mixtures with technogenic mechanoactivated silica component. Constr. Mater. Prod. 2023, 6, 5–18. [Google Scholar] [CrossRef]

- Šoukal, F.; Bocian, L.; Novotný, R.; Dlabajová, L.; Šuleková, N.; Hajzler, J.; Koutný, O.; Drdlová, M. The Effects of Silica Fume and Superplasticizer Type on the Properties and Microstructure of Reactive Powder Concrete. Materials 2023, 16, 6670. [Google Scholar] [CrossRef]

- Harichane, A.; Seghir, N.T.; Niewiadomski, P.; Sadowski, Ł.; Cisiński, M. Effectiveness of the Use of Polymers in High-Performance Concrete Containing Silica Fume. Polymers 2023, 15, 3730. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; He, W.; Niu, D.; Zhang, L.; Su, L.; Wang, X. Resistivity Prediction Model for Basalt–Polypropylene Fiber-Reinforced Concrete. Buildings 2023, 13, 84. [Google Scholar] [CrossRef]

- Deng, Z.; Liu, X.; Liang, N.; de la Fuente, A.; Peng, H. Flexural Performance of a New Hybrid Basalt-Polypropylene Fiber-Reinforced Concrete Oriented to Concrete Pipelines. Fibers 2021, 9, 43. [Google Scholar] [CrossRef]

- Shcherban’, E.M.; Stel’makh, S.A.; Beskopylny, A.; Mailyan, L.R.; Meskhi, B.; Varavka, V. Nanomodification of Lightweight Fiber Reinforced Concrete with Micro Silica and Its Influence on the Constructive Quality Coefficient. Materials 2021, 14, 7347. [Google Scholar] [CrossRef] [PubMed]

- Klyuev, A.V.; Kashapov, N.F.; Klyuev, S.V.; Lesovik, R.V.; Ageeva, M.S.; Fomina, E.V.; Ayubov, N.A. Development of alkali-activated binders based on technogenic fibrous materials. Constr. Mater. Prod. 2023, 6, 60–73. [Google Scholar] [CrossRef]

- Novoselov, O.G.; Sabitov, L.S.; Sibgatullin, K.E.; Sibgatullin, E.S.; Klyuev, A.V.; Klyuev, S.V.; Shorstova, E.S. Method for calculating the strength of massive structural elements in the general case of their stress-strain state (parametric equations of the strength surface). Constr. Mater. Prod. 2023, 6, 104–120. [Google Scholar] [CrossRef]

- Panarin, I.I.; Fediuk, R.S.; Vykhodtsev, I.A.; Vavrenyuk, S.V.; Klyuev, A.V. Injection mortars based on composite cements for soil fixation. Constr. Mater. Prod. 2023, 6, 15–29. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Specific surface area (m2/kg) | 335 |

| Soundness (mm) | 0.3 |

| Fineness, passage through a sieve No 008 (%) | 97.3 |

| Setting times (min) - start - end | 190 270 |

| Compressive strength (MPa): - 2 days - 28 days | 26.2 56.7 |

| Property | Value |

|---|---|

| Bulk density (kg/m3) | 1338 |

| Apparent density (kg/m3) | 2631 |

| The content of dust and clay particles (%) | 0.06 |

| Content of clay in lumps (%) | 0.09 |

| Organic and contaminant content (%) | No |

| Fineness modulus (unit-less) | 1.64 |

| Property | Value |

|---|---|

| Bulk density (kg/m3) | 1409 |

| Apparent density (kg/m3) | 2653 |

| Resistance to fragmentation (wt %) | 11.3 |

| The content of lamellar and acicular grains (wt %) | 8.5 |

| Type of Fiber | Length, mm | Density, g/cm3 | Tensile Strength, MPa | Modulus of Elasticity, GPa |

|---|---|---|---|---|

| PF | 12–16 | 0.89 | 170 | 28 |

| BF | 12–24 | 2.6 | 1100 | 76 |

| Property | Value |

|---|---|

| Mass fraction of water (%) | 0.15 |

| Mass fraction of loss on ignition (%) | 0.80 |

| Bulk density (kg/m3) | 252 |

| SiO2 (%) | 93 |

| Al2O3 (%) | 1.68 |

| Fe2O3 (%) | 0.65 |

| CaO (%) | 2.17 |

| MgO (%) | 1.01 |

| K2O (%) | 1.23 |

| S (%) | 0.26 |

| Mixture Type | Concrete Mixture Proportion Per 1 m3 | ||||||

|---|---|---|---|---|---|---|---|

| PC (kg/m3) | W (L/m3) | CrS (kg/m3) | QS (kg/m3) | BF (kg/m3) | PF (kg/m3) | P (kg/m3) | |

| Control composition (CC) | 394 | 190 | 1287 | 546 | 0.0 | - | 3.9 |

| BF0.5 | 394 | 190 | 1287 | 546 | 2.0 | - | 3.9 |

| BF1.0 | 394 | 190 | 1287 | 546 | 3.9 | - | 3.9 |

| BF1.5 | 394 | 190 | 1287 | 546 | 5.9 | - | 3.9 |

| BF2.0 | 394 | 190 | 1287 | 546 | 7.9 | - | 3.9 |

| BF2.5 | 394 | 190 | 1287 | 546 | 9.9 | - | 3.9 |

| BF3.0 | 394 | 190 | 1287 | 546 | 11.8 | - | 3.9 |

| PF0.5 | 394 | 190 | 1287 | 546 | - | 2.0 | 3.9 |

| PF1.0 | 394 | 190 | 1287 | 546 | - | 3.9 | 3.9 |

| PF1.5 | 394 | 190 | 1287 | 546 | - | 5.9 | 3.9 |

| PF2.0 | 394 | 190 | 1287 | 546 | - | 7.9 | 3.9 |

| PF2.5 | 394 | 190 | 1287 | 546 | - | 9.9 | 3.9 |

| PF3.0 | 394 | 190 | 1287 | 546 | - | 11.8 | 3.9 |

| Mixture Type | Concrete Mixture Proportion Per 1 m3 | |||||

|---|---|---|---|---|---|---|

| PC (kg/m3) | W (L/m3) | CrS (kg/m3) | QS (kg/m3) | MS (kg/m3) | P (kg/m3) | |

| MS2 | 386.1 | 190 | 1287 | 546 | 7.9 | 3.9 |

| MS4 | 378.2 | 190 | 1287 | 546 | 15.8 | 3.9 |

| MS6 | 370.4 | 190 | 1287 | 546 | 23.6 | 3.9 |

| MS8 | 362.5 | 190 | 1287 | 546 | 31.5 | 3.9 |

| MS10 | 354.6 | 190 | 1287 | 546 | 39.4 | 3.9 |

| MS12 | 346.7 | 190 | 1287 | 546 | 47.3 | 3.9 |

| Mixture Type | Concrete Mixture Proportion per 1 m3 | |||||||

|---|---|---|---|---|---|---|---|---|

| PC (kg/m3) | W (L/m3) | CrS (kg/m3) | QS (kg/m3) | BF (kg/m3) | PF (kg/m3) | MS (kg/m3) | P (kg/m3) | |

| BF1.5/PF0/MS8 | 362.5 | 190 | 1287 | 546 | 5.4 | - | 31.5 | 3.9 |

| BF1.25/PF0.25/MS8 | 362.5 | 190 | 1287 | 546 | 4.5 | 0.9 | 31.5 | 3.9 |

| BF1.0/PF0.5/MS8 | 362.5 | 190 | 1287 | 546 | 3.6 | 1.8 | 31.5 | 3.9 |

| BF1.0/PF0.25/MS8 | 362.5 | 190 | 1287 | 546 | 3.6 | 0.9 | 31.5 | 3.9 |

| BF0.75/PF0.75/MS8 | 362.5 | 190 | 1287 | 546 | 2.7 | 2.7 | 31.5 | 3.9 |

| BF0.75/PF0.5/MS8 | 362.5 | 190 | 1287 | 546 | 2.7 | 1.9 | 31.5 | 3.9 |

| BF0.75/PF0.25/MS8 | 362.5 | 190 | 1287 | 546 | 2.7 | 0.9 | 31.5 | 3.9 |

| Composition | Density (kg/m3) | Slump (cm) |

|---|---|---|

| CC | 2235 | 3.8 |

| BF0.5 | 2241 | 3.7 |

| BF1.0 | 2233 | 3.5 |

| BF1.5 | 2237 | 3.2 |

| BF2.0 | 2242 | 2.6 |

| BF2.5 | 2238 | 2.1 |

| BF3.0 | 2234 | 1.7 |

| PF0.5 | 2235 | 3.7 |

| PF1.0 | 2240 | 3.6 |

| PF1.5 | 2238 | 3.0 |

| PF2.0 | 2246 | 2.7 |

| PF2.5 | 2241 | 2.0 |

| PF3.0 | 2239 | 1.4 |

| Composition | Density (kg/m3) | Slump (cm) |

|---|---|---|

| MS2 | 2237 | 3.6 |

| MS4 | 2234 | 3.1 |

| MS6 | 2241 | 2.7 |

| MS8 | 2243 | 2.5 |

| MS10 | 2245 | 2 |

| MS12 | 2240 | 1.7 |

| Composition | Density (kg/m3) | Δ (%) |

|---|---|---|

| CC | 2398 | 0 |

| BF0.5 | 2389 | –0.38 |

| BF1.0 | 2407 | 0.38 |

| BF1.5 | 2422 | 1.00 |

| BF2.0 | 2409 | 0.46 |

| BF2.5 | 2417 | 0.79 |

| BF3.0 | 2419 | 0.88 |

| PF0.5 | 2397 | –0.04 |

| PF1.0 | 2409 | 0.46 |

| PF1.5 | 2401 | 0.13 |

| PF2.0 | 2398 | 0.00 |

| PF2.5 | 2387 | –0.46 |

| PF3.0 | 2413 | 0.63 |

| MS2 | 2402 | 0.17 |

| MS4 | 2398 | 0.00 |

| MS6 | 2411 | 0.54 |

| MS8 | 2402 | 0.17 |

| MS10 | 2385 | –0.54 |

| MS12 | 2379 | –0.79 |

| Composition | Density (kg/m3) | Slump (cm) |

|---|---|---|

| BF1.5/PF0/MS8 | 2240 | 2.7 |

| BF1.25/PF0.25/MS8 | 2239 | 2.5 |

| BF1.0/PF0.5/MS8 | 2241 | 2.6 |

| BF1.0/PF0.25/MS8 | 2245 | 2.7 |

| BF0.75/PF0.75/MS8 | 2239 | 2.4 |

| BF0.75/PF0.5/MS8 | 2342 | 2.9 |

| BF0.75/PF0.25/MS8 | 2238 | 3.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Beskopylny, A.N.; Smolyanichenko, A.S.; Chernil’nik, A.; Elshaeva, D.; Beskopylny, N. Influence of Polymer Fibers on the Structure and Properties of Modified Variatropic Vibrocentrifuged Concrete. Polymers 2024, 16, 642. https://doi.org/10.3390/polym16050642

Shcherban’ EM, Stel’makh SA, Mailyan LR, Beskopylny AN, Smolyanichenko AS, Chernil’nik A, Elshaeva D, Beskopylny N. Influence of Polymer Fibers on the Structure and Properties of Modified Variatropic Vibrocentrifuged Concrete. Polymers. 2024; 16(5):642. https://doi.org/10.3390/polym16050642

Chicago/Turabian StyleShcherban’, Evgenii M., Sergey A. Stel’makh, Levon R. Mailyan, Alexey N. Beskopylny, Alla S. Smolyanichenko, Andrei Chernil’nik, Diana Elshaeva, and Nikita Beskopylny. 2024. "Influence of Polymer Fibers on the Structure and Properties of Modified Variatropic Vibrocentrifuged Concrete" Polymers 16, no. 5: 642. https://doi.org/10.3390/polym16050642

APA StyleShcherban’, E. M., Stel’makh, S. A., Mailyan, L. R., Beskopylny, A. N., Smolyanichenko, A. S., Chernil’nik, A., Elshaeva, D., & Beskopylny, N. (2024). Influence of Polymer Fibers on the Structure and Properties of Modified Variatropic Vibrocentrifuged Concrete. Polymers, 16(5), 642. https://doi.org/10.3390/polym16050642