1. Introduction

Continuous fiber-reinforced thermoplastics (CFRTPs) are becoming increasingly prominent in the automated production of lightweight components due to their potential for rapid processing and circular material economy. In production, flat preforms built up from individual UD tapes or fabrics can be formed into a geometry under heat and pressure within seconds. Overmolding the composite base structure in an injection molding process enables its functionalization with geometrically complex features [

1,

2,

3,

4,

5,

6].

In today’s CFRTP component development, modeling and simulation of the forming process provides a powerful approach for defect prediction and verification, as well as optimization of manufacturability. To ensure accurate simulation results, material-specific input data are a basic prerequisite in addition to a suitable material modeling approach [

7,

8,

9]. These material data must be determined under processing conditions. Depending on the type of thermoplastic matrix material, testing temperatures up to 400 °C are required [

10]. At these temperatures, the material consists of continuous, stiff fibers embedded in a molten polymer matrix. Under these testing conditions, conventional testing methods, as known from the standard mechanical testing of composites [

11], are no longer applicable due to the increased demands on temperature management, instrumentation, and specimen handling or clamping. However, the emergence of new CFRTP grades incentivizes the search for efficient and reliable testing methods for high-temperature material characterization.

During the forming process of composite laminates, several deformation mechanisms take place simultaneously. Bending, in-plane shear, and slippage (ply/ply interactions and tool/ply interactions) mechanisms can be classified as the three primary modes of deformation in UD composites that determine the forming result [

9,

12,

13]. Moreover, simulation studies have shown that the temperature dependence of the composite material influences the geometric accuracy of the final component and that the bending rigidity plays a significant role in the formation of wrinkles [

14,

15,

16].

Several researchers have already addressed different methods to characterize the thermo-coupled bending behavior of CFRTP. In general, the current test configurations can be categorized into approaches based on the Cantilever test, the Kawabata test, and the Vee-bending test [

17]. Reviews of the characterization approaches used by several researchers to obtain experimental bending material data for molten thermoplastic composites are provided in the literature [

17,

18]. Furthermore, Fernandez et al. presented in their work the so-called column bending test (CBT), which is applicable for large-deformation bending testing of thin-ply coupons [

19]. However, studies under high-temperature conditions are not yet available for the CBT approach. It has to be noted that obtaining bending material data at process-relevant levels of curvature, deformation rate, and temperature, as well as dealing with low specimen integrity at high temperatures, is a challenging task and is not achievable with every test approach presented in the literature.

The Kawabata-inspired bending test, proposed by Sachs et al. [

20,

21] (referred to as the rotation bending test in this study), is gaining increasing acceptance in the scientific community. It is based on a custom-built fixture applied to a commercial rheometer. The rotation bending test allows for high-curvature deformation with rate and temperature dependence, high data acquisition accuracy, and a small test environment to perform test programs in a time-efficient manner. Several CFRTP materials have already been characterized using this approach by several research groups for material modeling and validation purposes, including published data [

14,

18,

22,

23,

24,

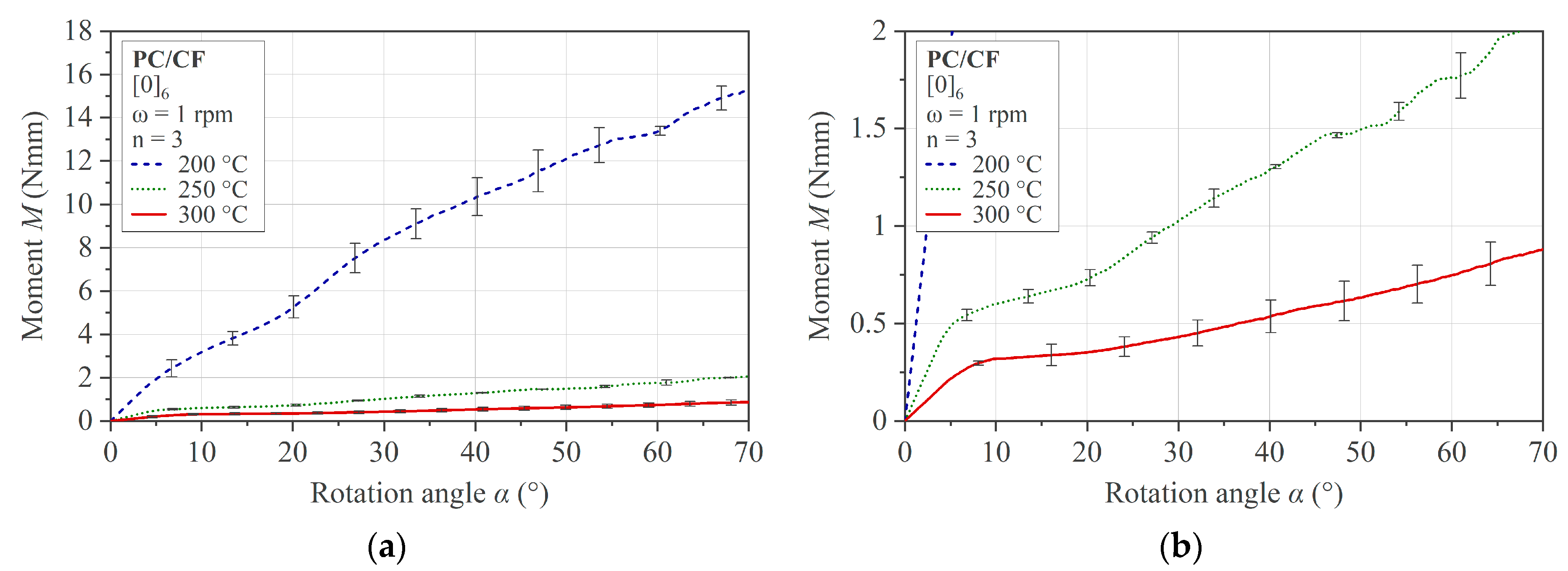

25]. Typical bending moments for single-tape specimens at processing temperatures are in the range of 10

−4 Nm.

Due to this low bending resistance, it must be considered that the accuracy of the measurement outcome may be sensitive to certain influencing factors. These falsify the basic assumption that the measuring moment on the rotating shaft results solely from the bending deformation of the specimen. In the PhD thesis of Sachs [

20], the influences of the coefficient of friction between specimen and fixture and the clearance between the fixtures were evaluated. This was performed assuming a purely elastic beam model that deforms by bending or by shear. In conclusion, it is stated that these effects are negligible for deformation angles under 30° [

20].

However, this analysis leaves a gap between the assumed ideal model conditions and the real experimental conditions. For example, the clearance during testing is fundamentally unknown due to the thermal expansion of the specimen and fixture during heating, but it can have a significant influence on the measurement [

18]. Therefore, one aim of the present work is to provide further verification of the rotation bending test approach based on experimental and simulation results considering real test conditions. Based on the theoretical principles reviewed in this study, a custom-built fixture and a corresponding FE model were implemented. Following a validation procedure with a brass specimen, the focus is on the determination of the sensitivity of the test results with respect to the clearance and with respect to a pivot offset. A pivot offset may occur depending on the design of the customized fixture and when testing different specimen thicknesses.

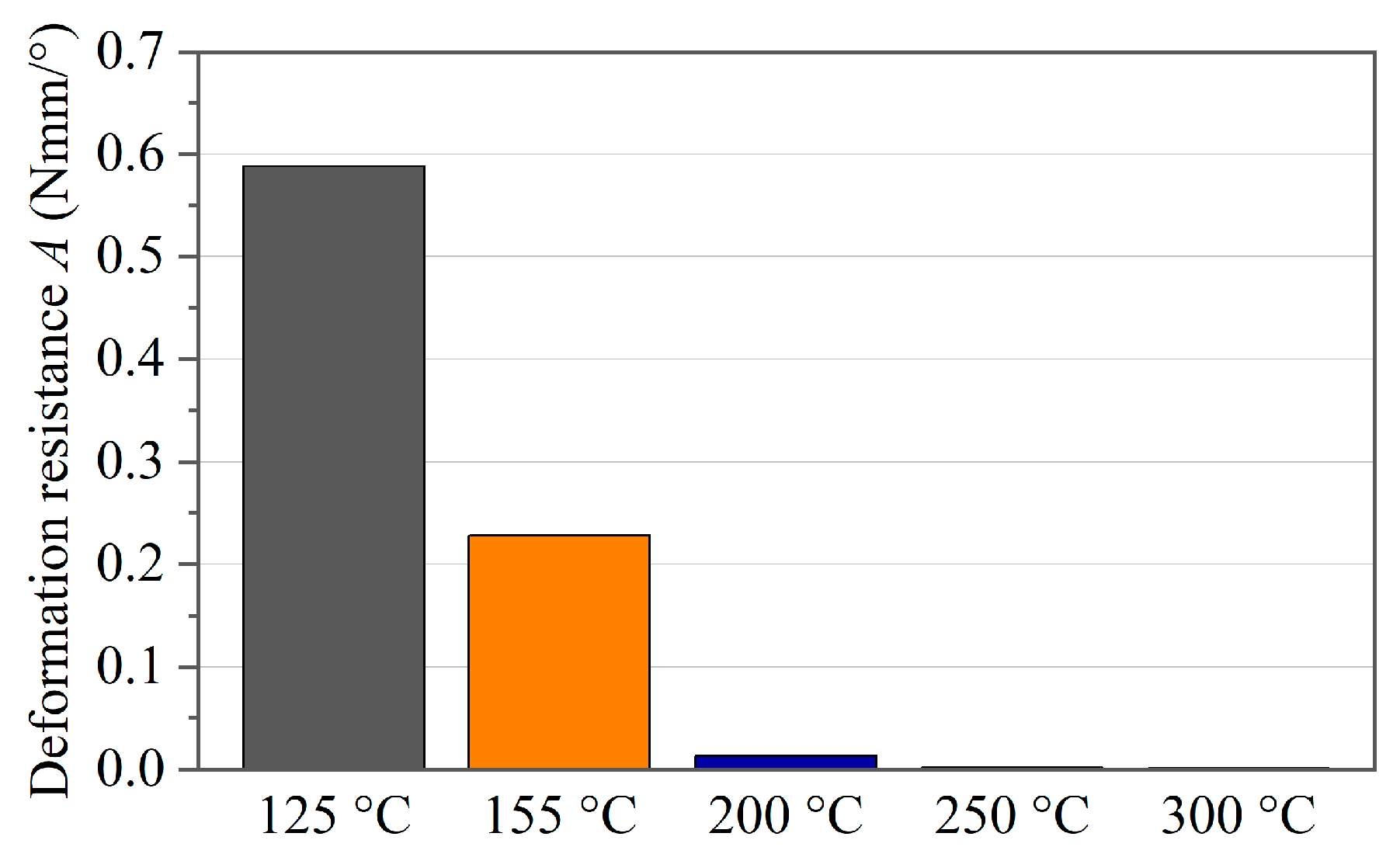

The main objective is the characterization of the bending behavior of the PC/CF UD tape under process conditions. To the best of the authors’ knowledge, PC/CF has not been studied in this context before. Experimental testing over a wide temperature range relevant to processing allows the temperature sensitivity of the material to be determined and quantified in terms of its resistance to deformation. The data provide a basis for the optimization and analysis of the forming processes for components made of PC/CF. In addition, the data can be used to calibrate material models in non-isothermal forming simulation models.

2. Background of the Rotation Bending Test Method

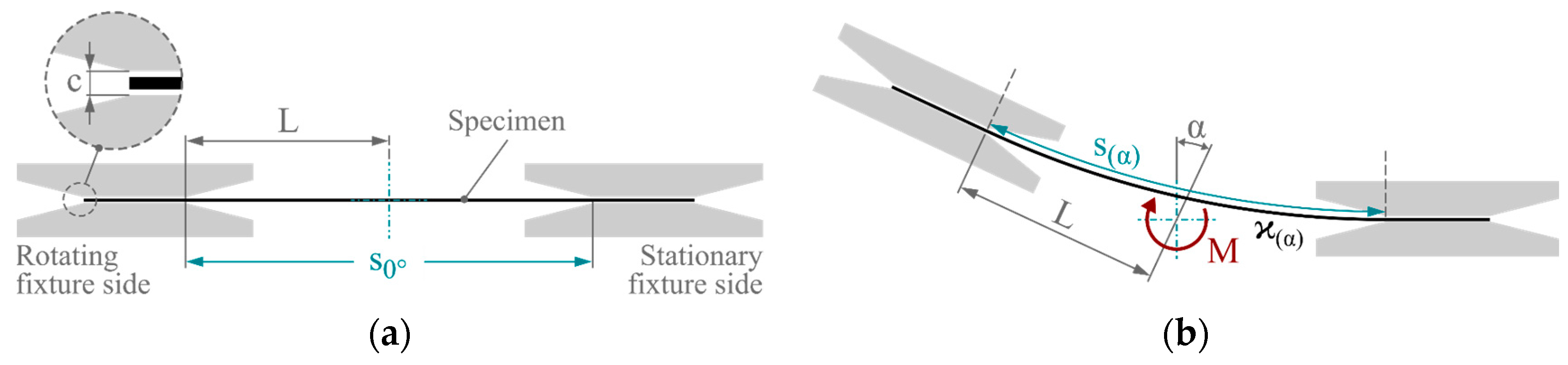

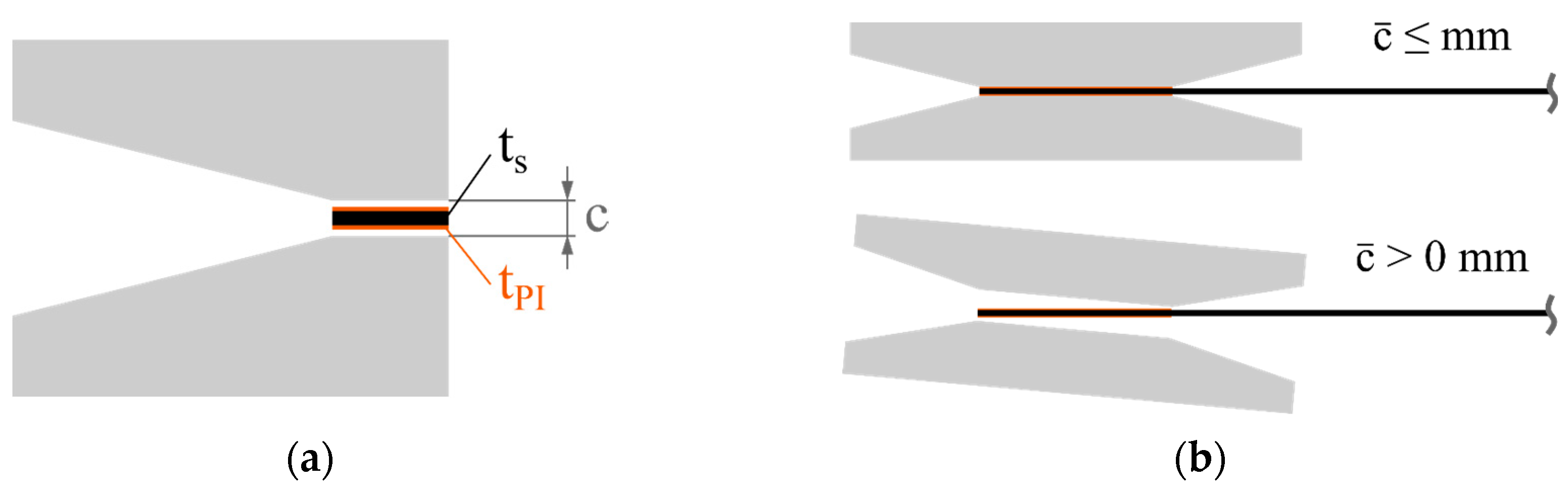

The fundamental concept of the test method is to impose a bending deformation on a specimen using a torsional moment. For this purpose, a rectangular specimen is positioned in a two-part fixture in a gap with an adjustable clearance

c (

Figure 1a). The sample is not firmly clamped on either side. This prevents clamping effects and the superposition of spurious loads by allowing lateral movement of the specimen during bending deformation. One side of the fixture is stationary, while the second side is rotated about an axis of rotation by the angle α. During this, the specimen is bent, and the torque

M is measured at the torsion shaft. This principle is illustrated in

Figure 1b.

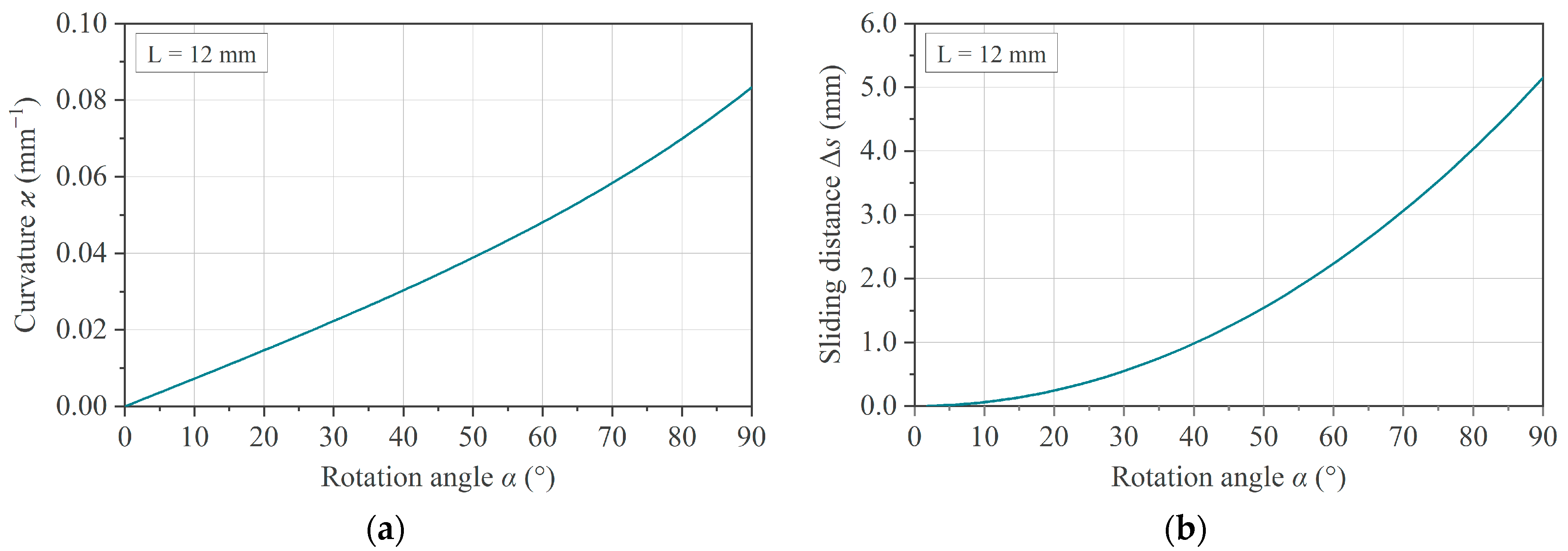

2.1. Kinematic Considerations

Based on the stationary axis of rotation and a constant arm length

L, the rotating side of the fixture follows a circular arc. In an idealized view, the curvature

ϰ of a specimen under pure bending can be derived according to kinematic considerations by

as the reciprocal of the bending radius

r. The effective arc length

s of the specimen can be calculated as a function of the rotation angle α according to

where α is expressed in degrees, as determined during the experiments. Based on these considerations, an increasing rotation angle leads to a reduction in the effective arc length. This change in

s during deflection with respect to the initial position follows

and can be interpreted as an indicator for the lateral movement of the specimen in the fixture. As implied by Equations (1) and (3), the dependence of

ϰ and Δ

s on the rotation angle α is non-linear, as shown in

Figure 2.

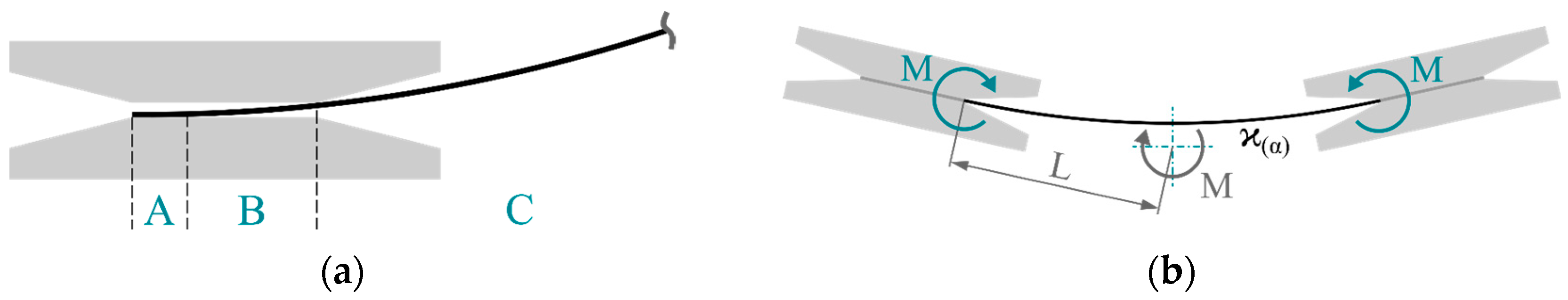

2.2. Specimen Mechanics

For an overall mechanical description of the system, three sections are to be distinguished, as illustrated in

Figure 3a. In section

A, the specimen is straight and in full contact with the holder, while in section

B, the specimen is bent up to the point of contact with the edge of the chamfer. The pure bending starts in section

C. The analytical mechanical solution of this testing configuration requires a complex system of related equations and a numerical method with an iterative scheme to obtain a converged solution [

20].

For a simplified analytical approach with respect to specimen mechanics, an idealized assumption can be made that disregards the friction effects and the space between specimen and fixture, as illustrated in

Figure 3b. By applying the Euler–Bernoulli beam theory and the constant bending moment along the bending line, a relation between the bending moment

M and the deflection angle

α can be given by Equation (4), where

E refers to the Young’s modulus and

I to the area moment of inertia:

According to classical mechanics, the strain (

) and stress (

) value in the outer fiber of a specimen of thickness

t along the bending direction can be expressed by Equations (5) and (6):

These considerations apply only for thin, homogeneous, shear-stiff, elastic test specimens (based on the Euler–Bernoulli assumptions). For inhomogeneous, shear-soft, rheology-driven samples (i.e., molten thermoplastic UD tapes), these equations do not rigorously describe the physical behavior. However, it provides a basis for the validation of the experimental set-up and a starting point for macroscopic phenomenological modeling of the bending behavior.

2.3. Spurious Effects

In this section, a description of the sources of spurious effects is given. Spurious effects refer to circumstances that influence the measured moment curve and lead to deviations compared to the ideal situation described above.

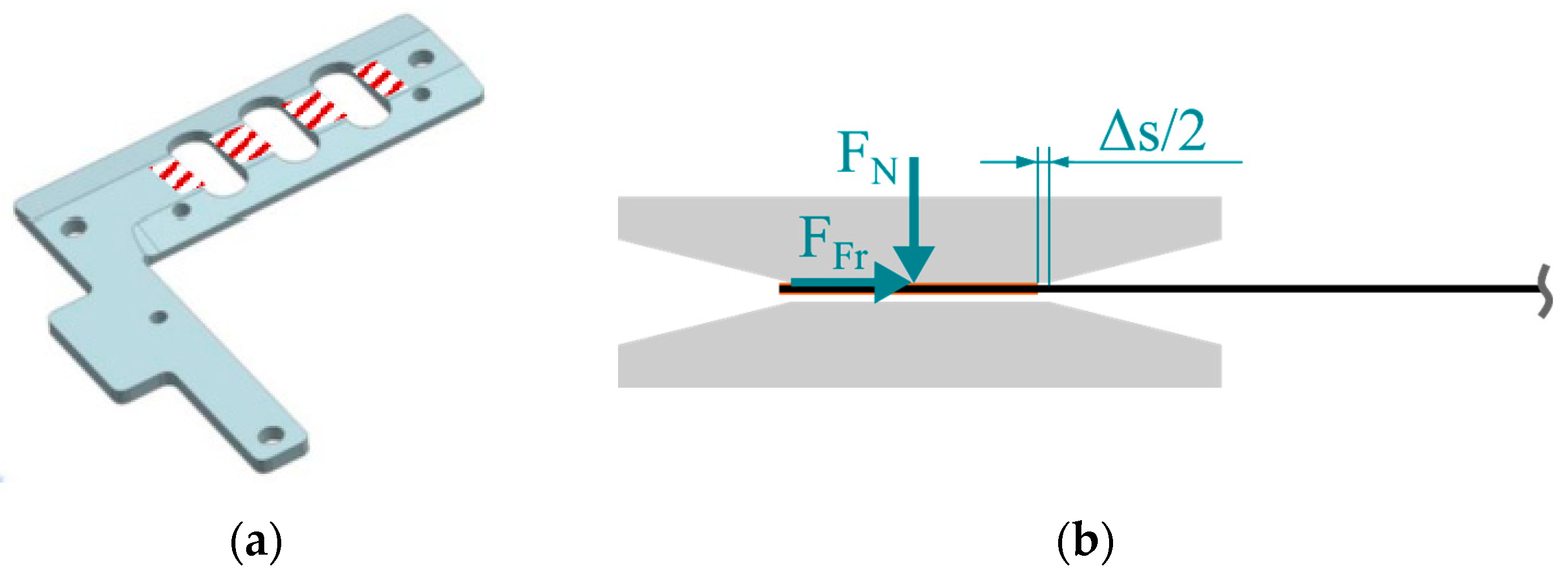

2.3.1. Friction

As implied by Equation (3), the effective arc length of the specimen shortens, causing a lateral movement in the fixture with an increasing rotation angle

α. This generates a frictional force

FFr in the contact areas between fixture and specimen (

Figure 4a), which acts as a compressive force during the deflection process, as shown schematically in

Figure 4b.

The force

FFr is non-constant, as the normal force

FN increases with the increasing bending resistance during deflection. This leads to an undesirable overestimation of the measured torque, which is dependent on the coefficient of friction (

COF) between the specimen and fixture. As shown by Sachs [

20], a

COF = 0.5 leads to an overestimation of the torque of about 20% at a deflection angle of α = 60°, compared to the frictionless case. By applying a heat resistant polyimide (PI) tape to the contact areas of the specimen, reproducible tribological conditions can be expected. The metal/PI material pairing prevents the molten specimen from sticking and lowers the

COF [

20]. However, a valid

COF for this material pairing, especially under high-temperature test conditions, is unknown.

2.3.2. Effective Clearance

Based on the specimen thickness, the clearance

c of the fixture must be adjusted at the beginning of a test program at ambient temperatures. During heating up to the test temperature, the specimen and the fixture are subject to thermal expansion. The effective clearance

is introduced according to Equation (7) as a temperature-dependent measure of the effective free space under test conditions.

It refers to the difference between the clearance

c and the specimen thickness

tS, including the thickness of the polyimide tape

tPI that is applied on both sides. This is illustrated in

Figure 5a.

In practice, two scenarios become possible, as shown in

Figure 5b. On the one hand, if

≤ 0, the specimen comes into full contact with the fixture and can become stuck. On the other hand, if

> 0, an idle torque in the start-up phase of the test is to be expected as long as the specimen is not in full contact with the contact surfaces of the fixture. This leads to a shift in the moment curves to higher rotation angles, as shown by Sachs with an elastic beam model [

20].

2.3.3. Pivot Offset

To install the bending device on the rotational rheometer, the clamping unit for rectangular samples must be used. The pivot of the machine runs centrally in the parting plane of the clamping jaws in a closed position. When opening the clamping jaws, only the front jaw changes position and the rear one remains fixed. In combination with a custom-made fixture, this can result in an offset

k between the pivot of the machine and the neutral plane of the specimen in initial position, as illustrated in

Figure 6a. In this study, the offset

k is derived as

where

is the thickness of the fixture at the attachment area. The consequence of the eccentricity pivot is shown in

Figure 6b. A deviation of the circular path of the rotating fixture and thus of the curvature compared to the theoretical considerations in

Section 2.1 occurs.

The corrected curvature due to this induced offset

k can be determined by an extension of Equation (1) according to

3. Materials and Methods

In this section, the manufactured and implemented fixture is presented. In addition, information about the finite element (FE) model, the material to be characterized, and the experimental testing activities are given.

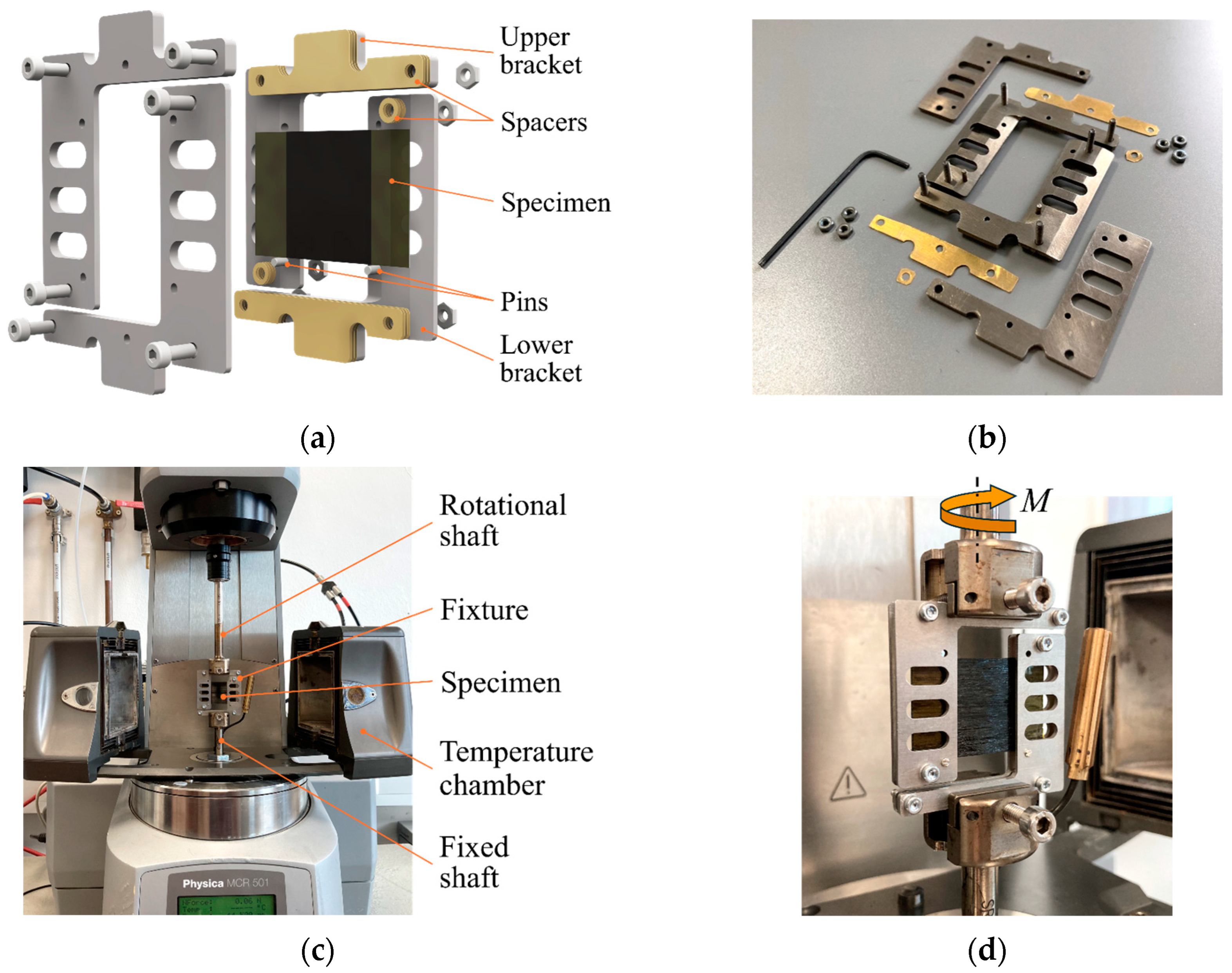

3.1. Experimental Set-Up

In the presented work, the rotational rheometer Anton Paar Physica MCR 501 (Anton Paar GmbH, Graz, Austria) was combined with the thermal chamber CTD 600 (Anton Paar GmbH, Graz, Austria). Considering the spatial limitations of the thermal chamber and the given clamping conditions,

Figure 7a illustrates the concept of the fixture. The design is oriented to those used in the studies cited in

Section 1 and is compatible with specimen dimensions of 22 mm × 36 mm. It consists of two parts, the upper and lower brackets, which are aligned with each other. Depending on the specimen thickness, the clearance

c can be adjusted by metal spacers in increments of 0.1 mm. Vertical positioning of the specimen is ensured by a pin on each side. Due to the filigree characteristic of the set-up and operating temperatures of up to 400 °C, a material with a low coefficient of thermal expansion is considered beneficial for the fixture. Thus, it was made of titanium Ti-6Al-4V by laser cutting. The fixture is shown in a disassembled state in

Figure 7b.

Figure 7c shows the assembled and mounted fixture in its initial state with the thermal chamber open.

Figure 7d gives a detailed view of the installed fixture. The lower part of the fixture is attached to the fixed shaft, and the upper part of the fixture is attached to the rotating shaft of the rheometer.

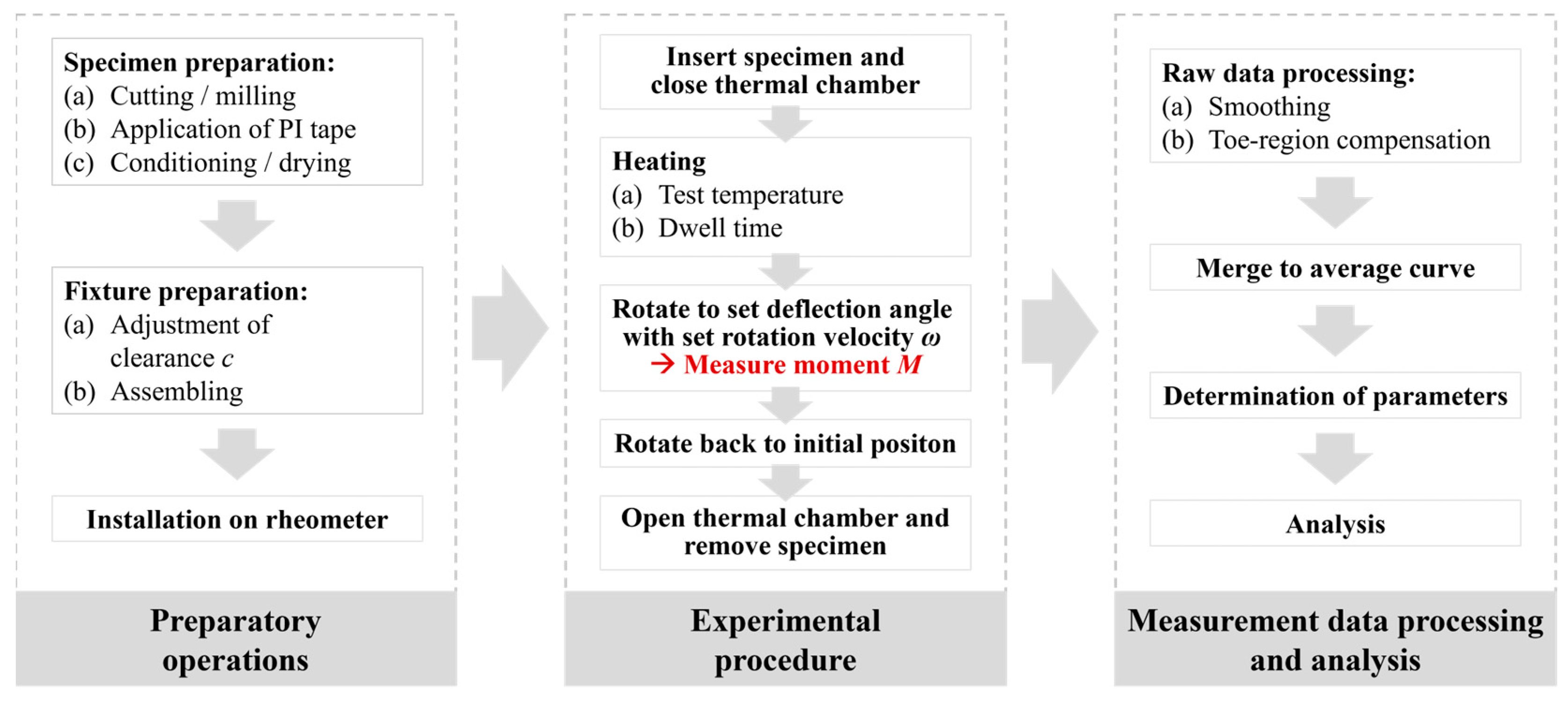

Once the preparatory work has been completed, the experimental procedure can be started, as shown in

Figure 8. For testing, a specimen is positioned laterally through the clearance into the fixture. After closing the thermal chamber, it is purged with nitrogen to minimize matrix material degradation, and the specimen is heated. The total heating time prior to each test is composed of the heating time of the thermal chamber to the target testing temperature plus a set dwell time to ensure a homogeneous temperature throughout the specimen. By rotating the upper shaft at a defined rotation velocity up to a defined angle of rotation, the specimen is bent. During this deflection, the applied bending moment

M is measured. After rotating the upper bracket back to its initial position, the chamber is opened, the test specimen is removed, and a new test run can be started. The resulting moment vs. rotation angle raw data sets are finally available for processing and analysis.

3.2. Materials and Specimens

Two different materials were used in this study: (i) a metallic material for verification and validation of the method, and (ii) a thermoplastic composite material with a polycarbonate matrix as the material to be characterized at processing temperatures.

For the metal specimen, brass in the form of a commercially available sheet with a thickness of 0.1 mm and a specified material designation of CuZn37 was used. The material properties are summarized in

Table 1 and refer to published data for the alloy used in the form of strips or sheets in accordance with DIN EN 1652 at room temperature [

26,

27]. Brass specimens measuring 22 mm × 36 mm were cut from the sheet.

The carbon fiber-reinforced thermoplastic UD tape material Maezio

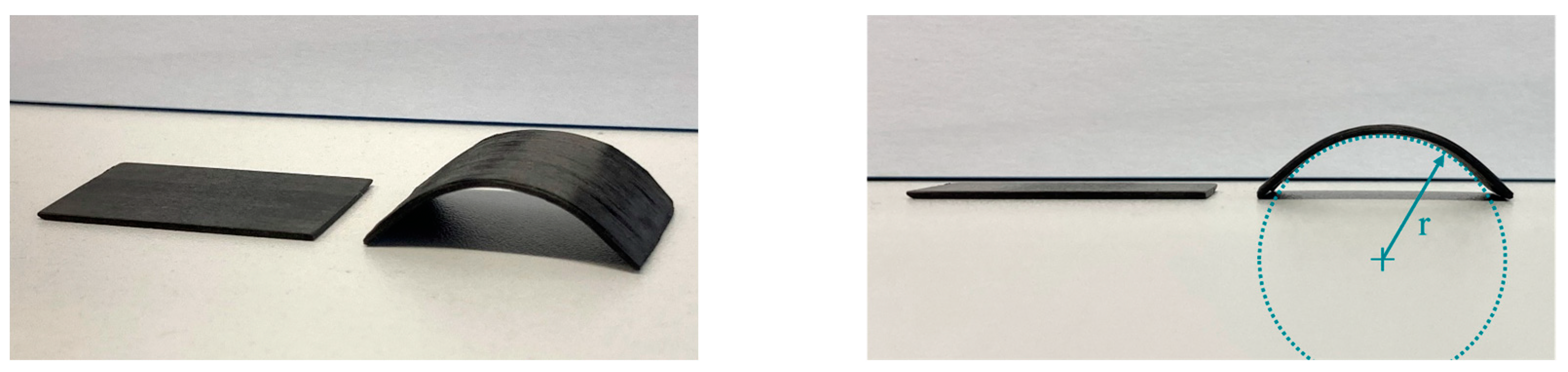

® (TACF170--44GP 1003T) from Covestro (Covestro AG, Leverkusen, Germany) was investigated in this work.

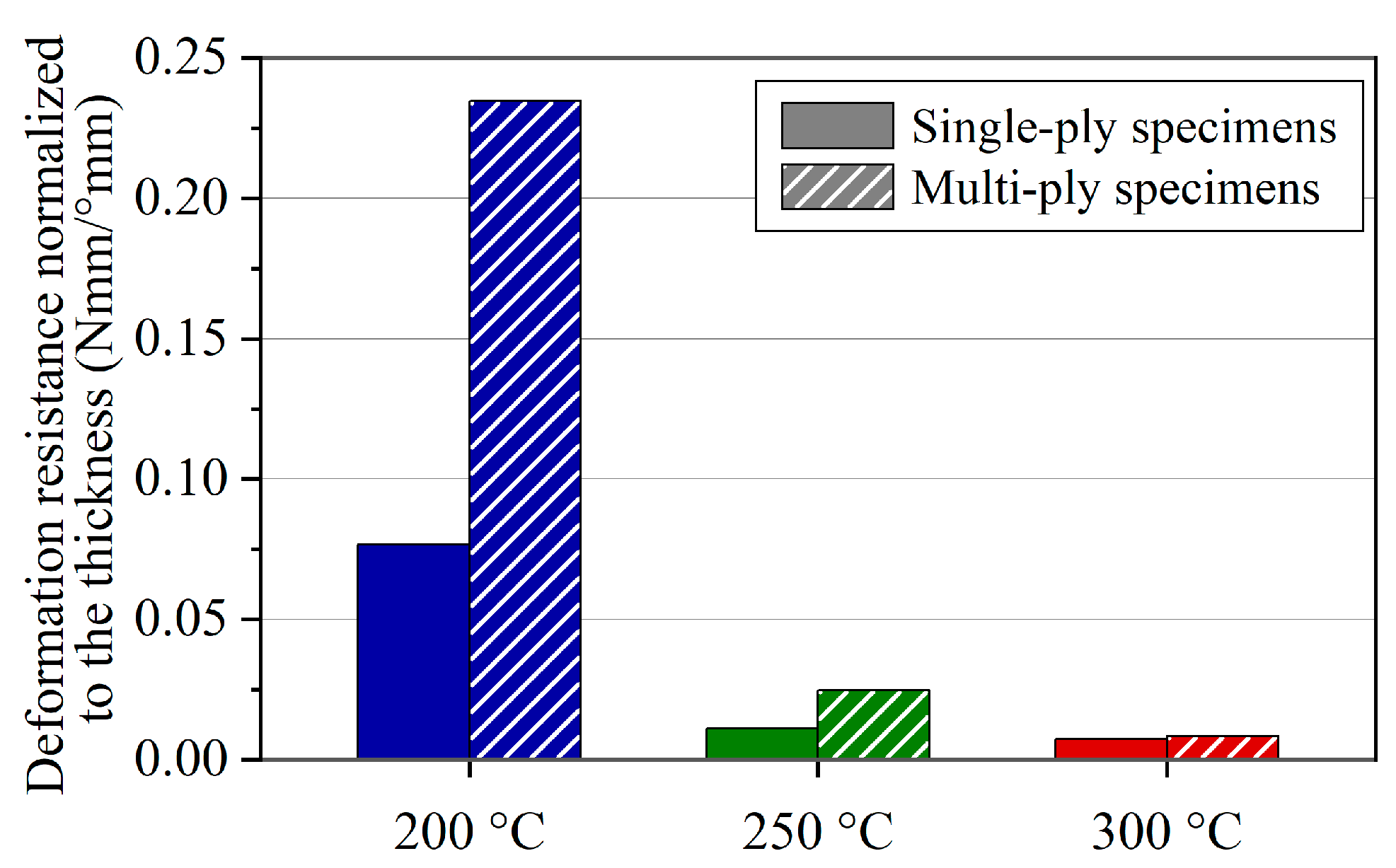

Table 2 gives an overview of the material characteristics provided by the manufacturer. Two specimen configurations with dimensions 22 mm × 36 mm were used. Single-ply UD tape specimens were cut from a supplied spool, and UD multi-ply specimens with the stacking sequence [0]

6 were cut using a CNC milling machine from consolidated plates provided by the manufacturer. The ends of the specimens were cleaned with isopropanol before applying the polyimide tape.

3.3. Experimental Procedure

The experimental investigations are divided into three test activities. The first activity focused on validating the experimental set-up. For this purpose, a material with known mechanical properties (brass), listed in

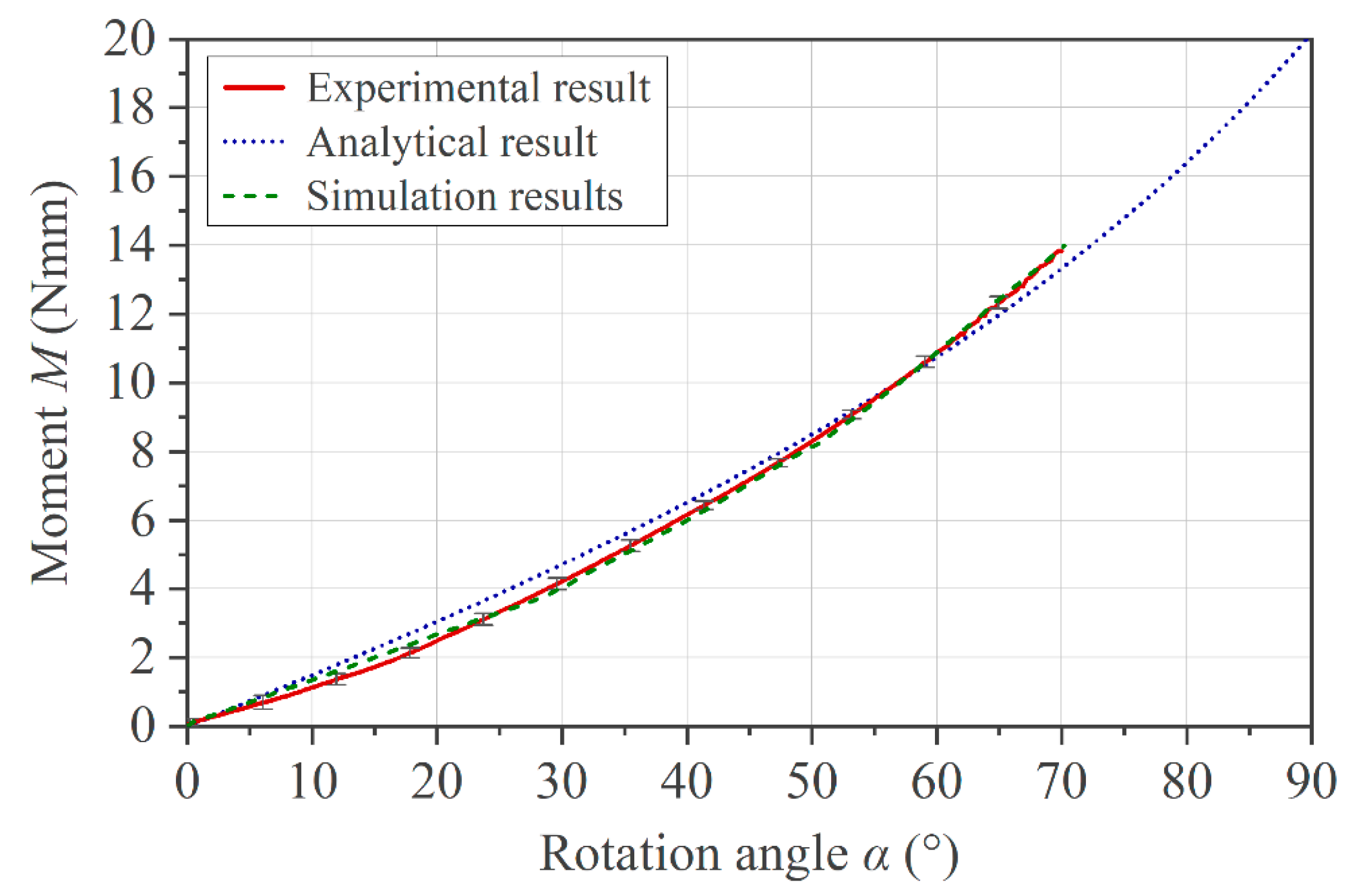

Table 1, was tested at room temperature. The experimental results were compared with the numerical results obtained from an FE model of the test set-up, using identical mechanical properties for the specimen. Following the first batch of experiments, we concluded from the good agreement of the two result sets (experimental and numerical) that the installed set-up was performing as expected, which confirmed the applicability for the determination of material properties.

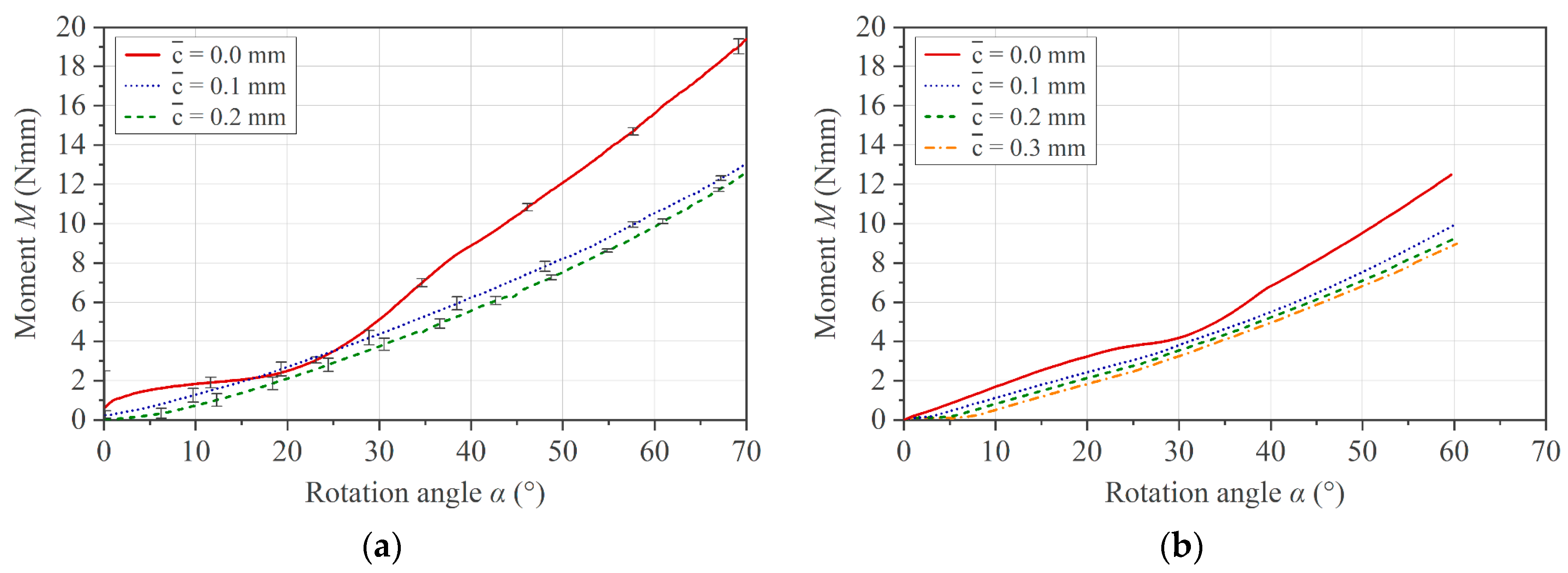

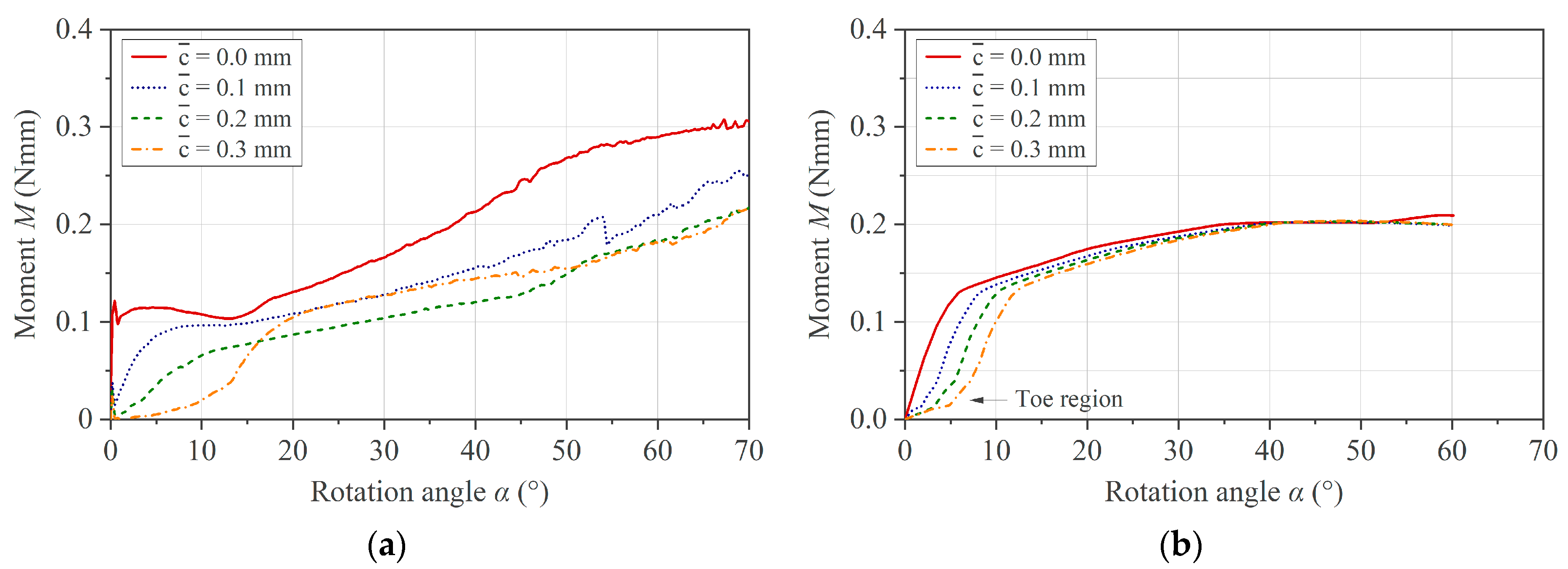

The second experimental activity was aimed at investigating the influence of the effective clearance on the experimental results. This was conducted with test batches on brass specimens at room temperature and on PC/CF specimens at 250 °C with different clearance c settings of the test set-up. Following the second experimental activity, we could select an appropriate setting and derive a data evaluation procedure for the following experiments.

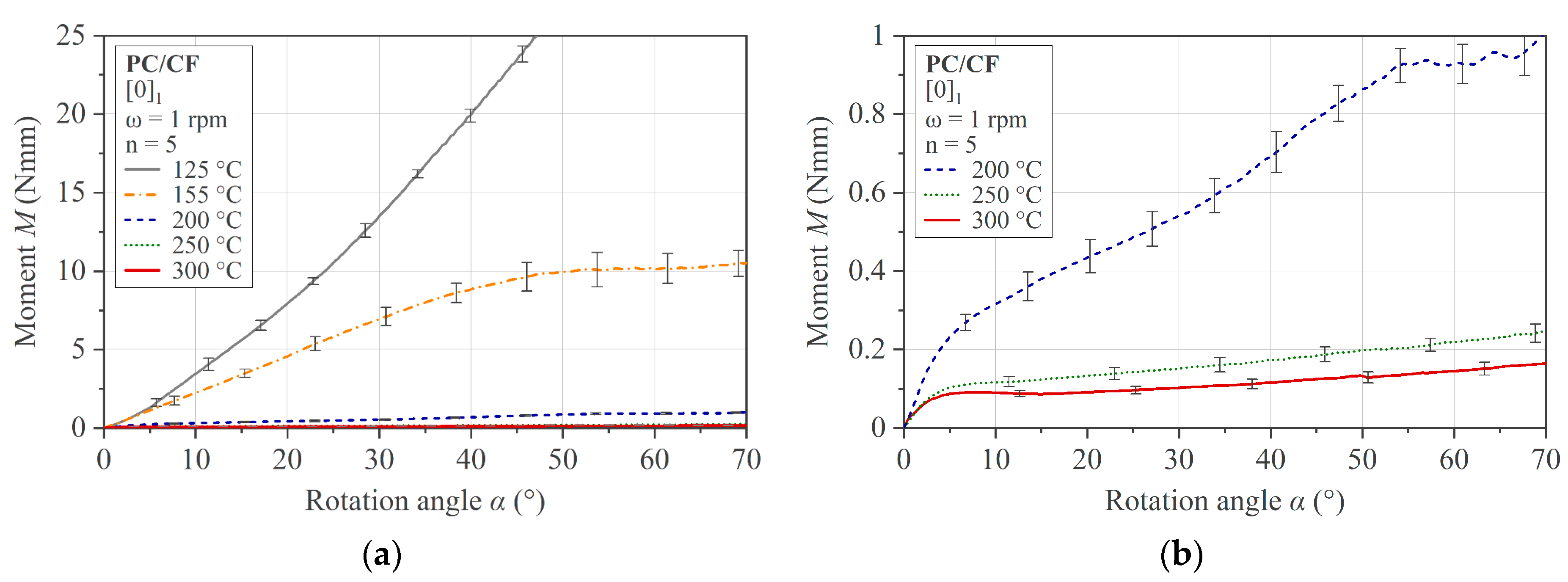

The third experimental activity was the characterization of both single- and multi-ply PC/CF specimens at different temperatures. Based on the experimental results, the temperature-dependent bending resistance was extracted. All tests were performed at a constant deflection rate of 6°/s. The test program used is summarized in

Table 3. The thickness dimensions given were determined with a micrometer screw gauge, and the set clearance dimensions were checked with a thickness gauge for each test set.

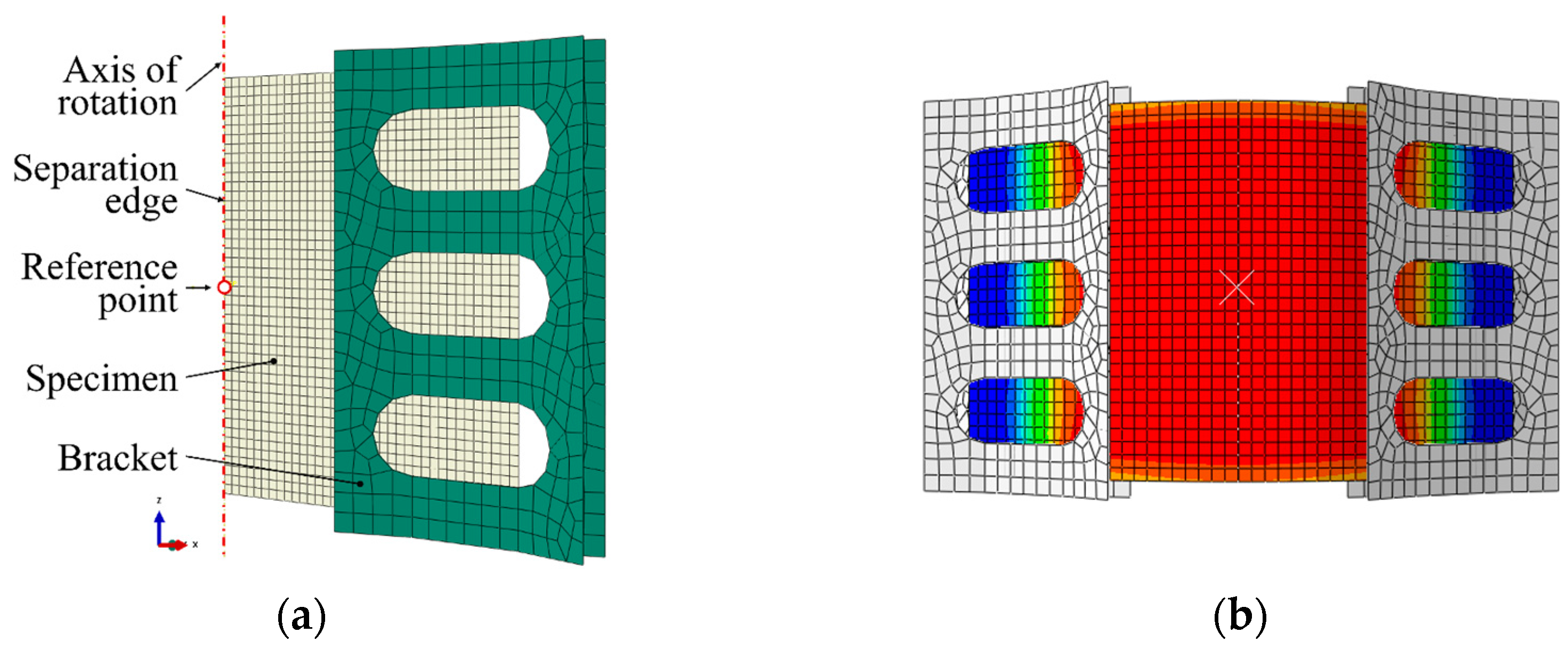

3.4. Simulation Model

For numerical investigations, a finite element (FE) simulation in ABAQUS/Standard (Simulia-Dassault Systems, Providence, RI, USA; Version: Abaqus/CAE 2020) according to the set-up presented in

Section 3.1 was modeled. For a simple but representative model and to optimize the calculation time, it was reduced to one-half and to the relevant sections, as illustrated in

Figure 9a. To ensure a kinematic motion corresponding to the experiment, the rotational degrees of freedom UR2 = UR3 = 0 and the translational degree of freedom U1 = 0 are constrained at the separation edge of the specimen. The vertical position of the specimen was ensured by the constrained translational degree of freedom U3 = 0, which was assigned to the segment of the lower edge of the specimen inside the clamp. The rotational movement of the fixture was controlled by a rotational boundary condition at a reference point (RP) located on the axis of rotation, coupled to the corresponding bracket. This same reference point was used to gather the reaction moment during the deflection. The brackets are discretized by rigid elements of type R3D4 and the specimen by S4 shell elements with a mesh size of 0.75 mm. Contact between specimen and fixture is modeled as a surface-to-surface contact interaction. An illustration of a representative solution of the FE model is given in

Figure 9b.