High Speed Sintering of Polyamide 12: From Powder to Part Properties

Abstract

1. Introduction

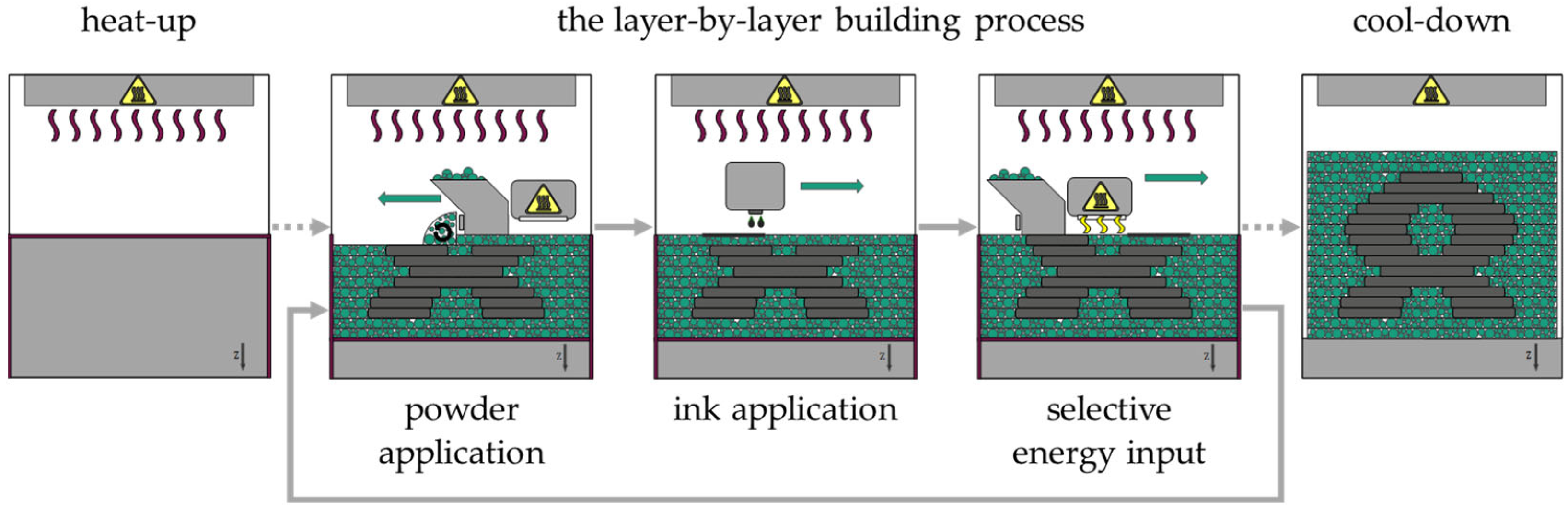

1.1. Process of the HSS

1.2. Potential of the HSS

1.3. State of the Research on HSS

1.4. Need for Action

2. Experimental Methodology

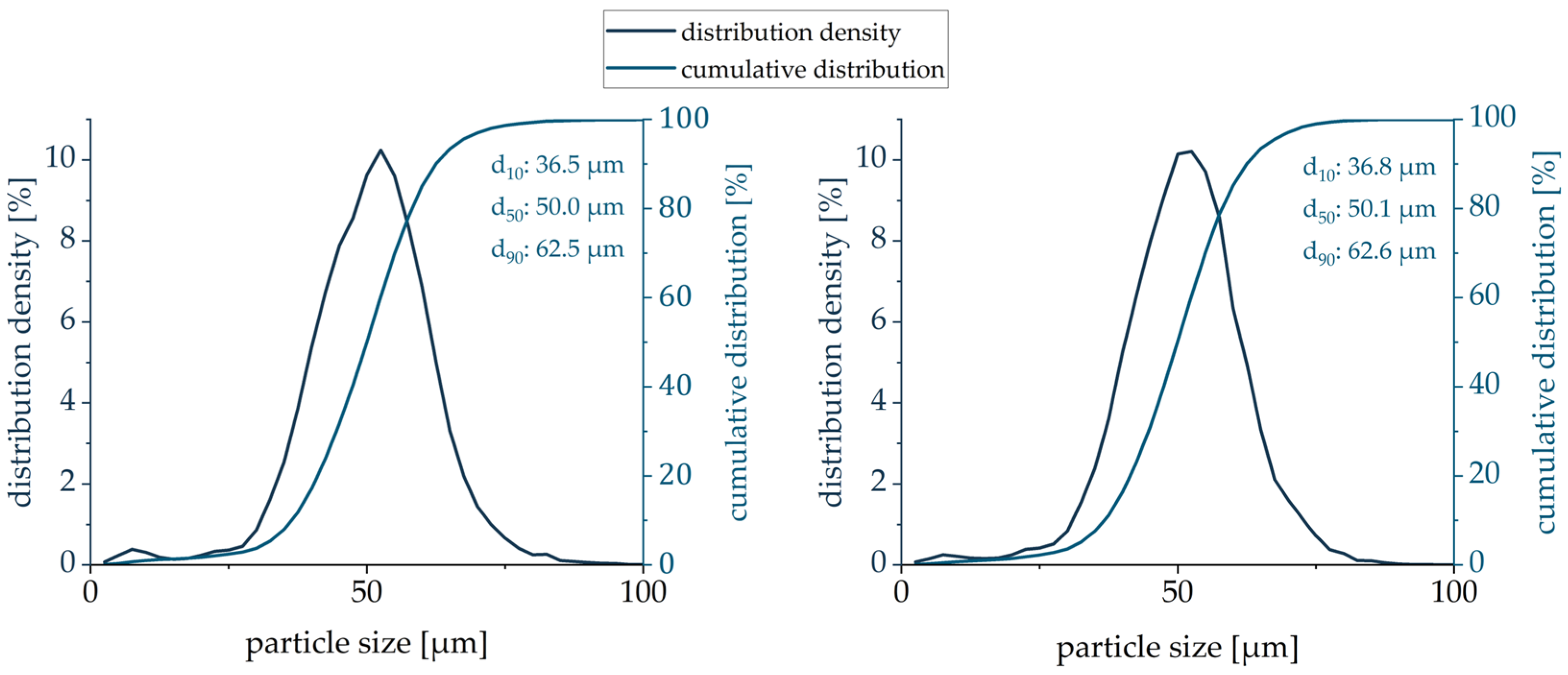

2.1. PA 12 Powder and Ink

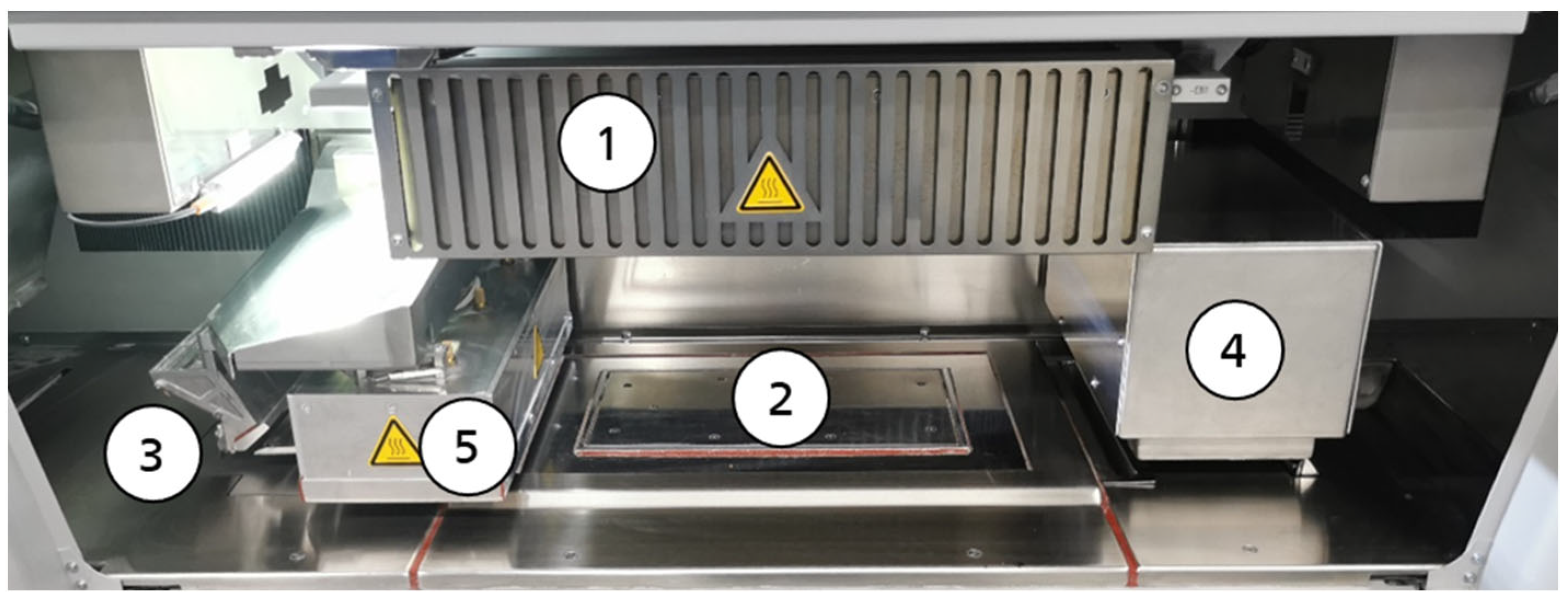

2.2. HSS System and Process Parameters

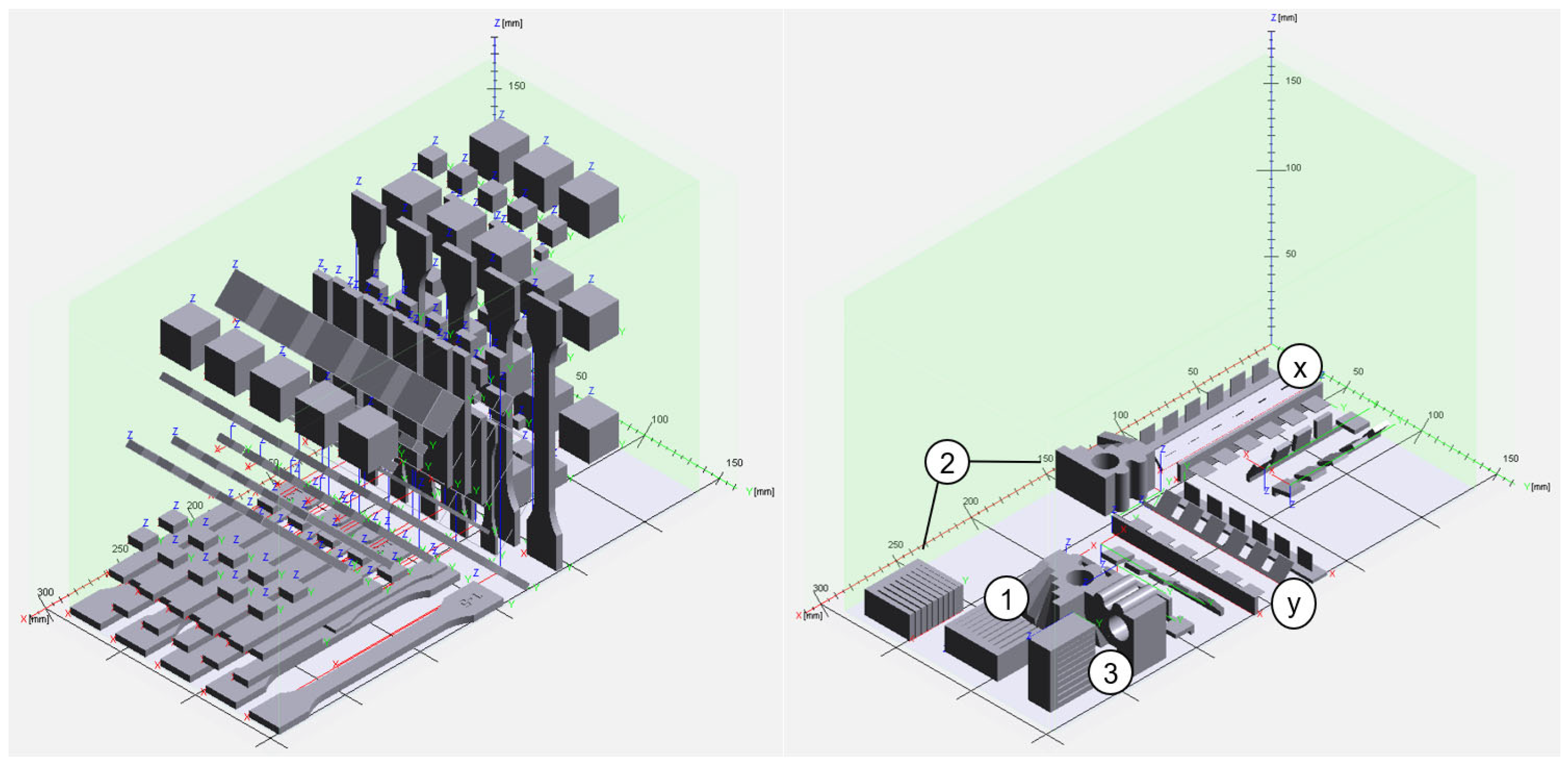

2.3. Specimens and Build Job

3. Powder and Sample Analysis Methods

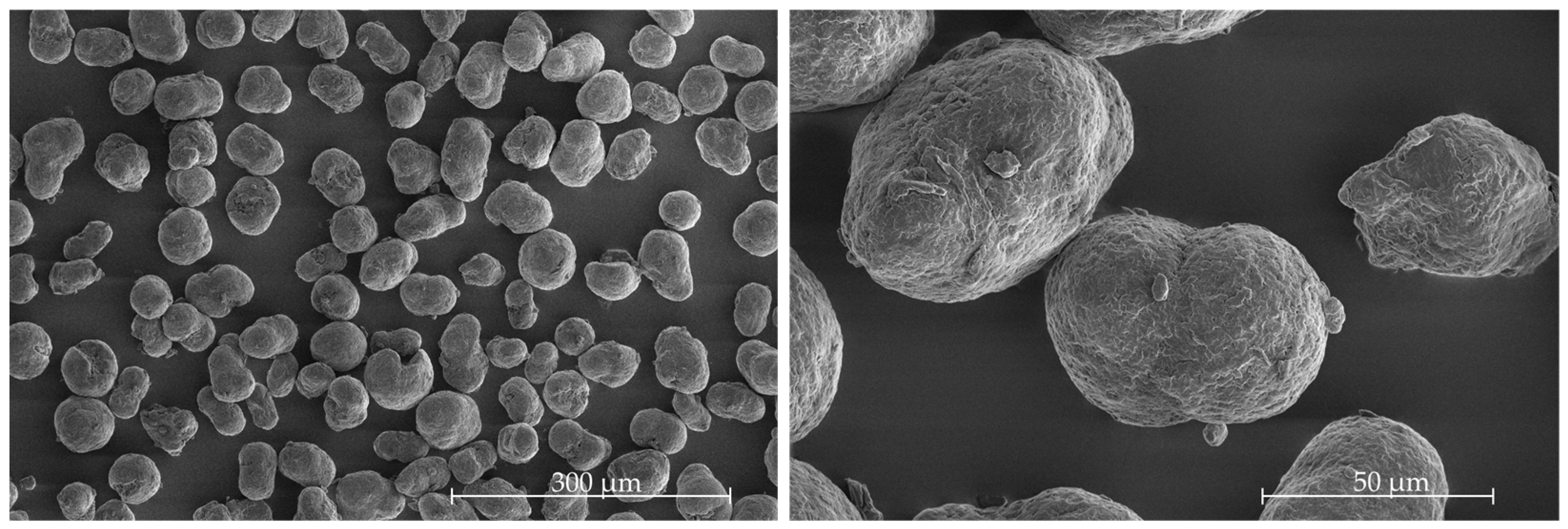

3.1. Particle Analysis

3.2. Powder Flowability Analysis

3.3. Thermal Analysis

3.4. Density Analysis

3.5. Mechanical Analysis

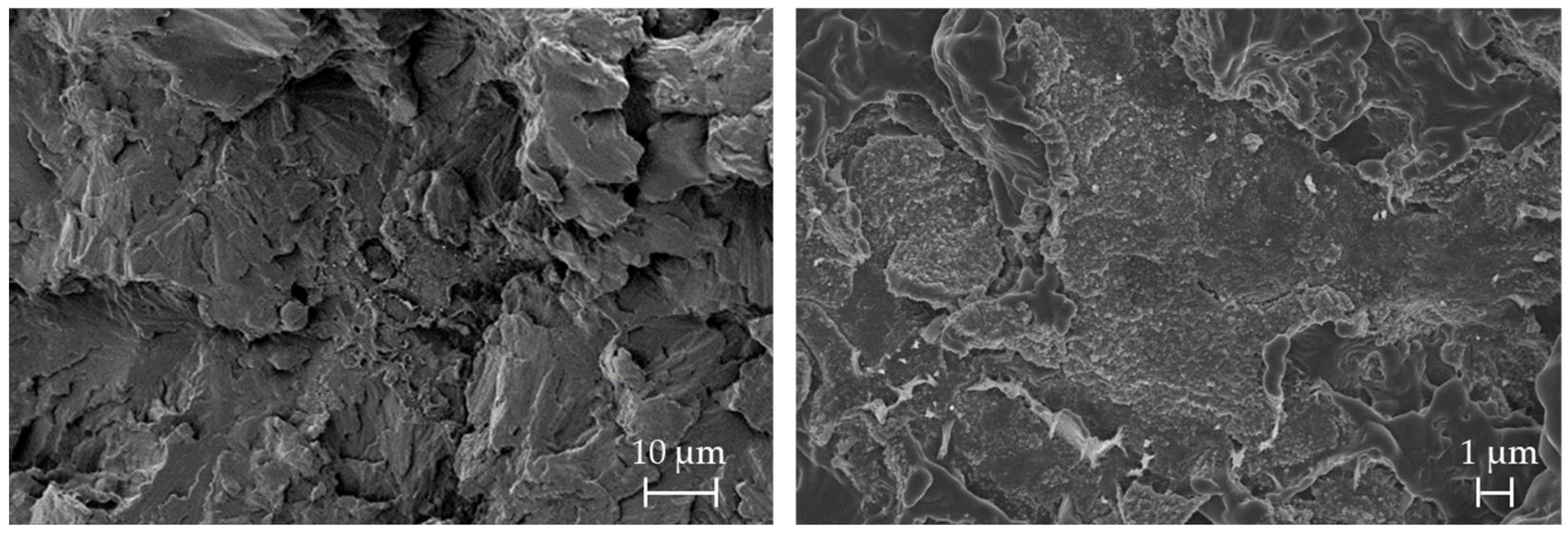

3.6. Fractured Surface Analysis

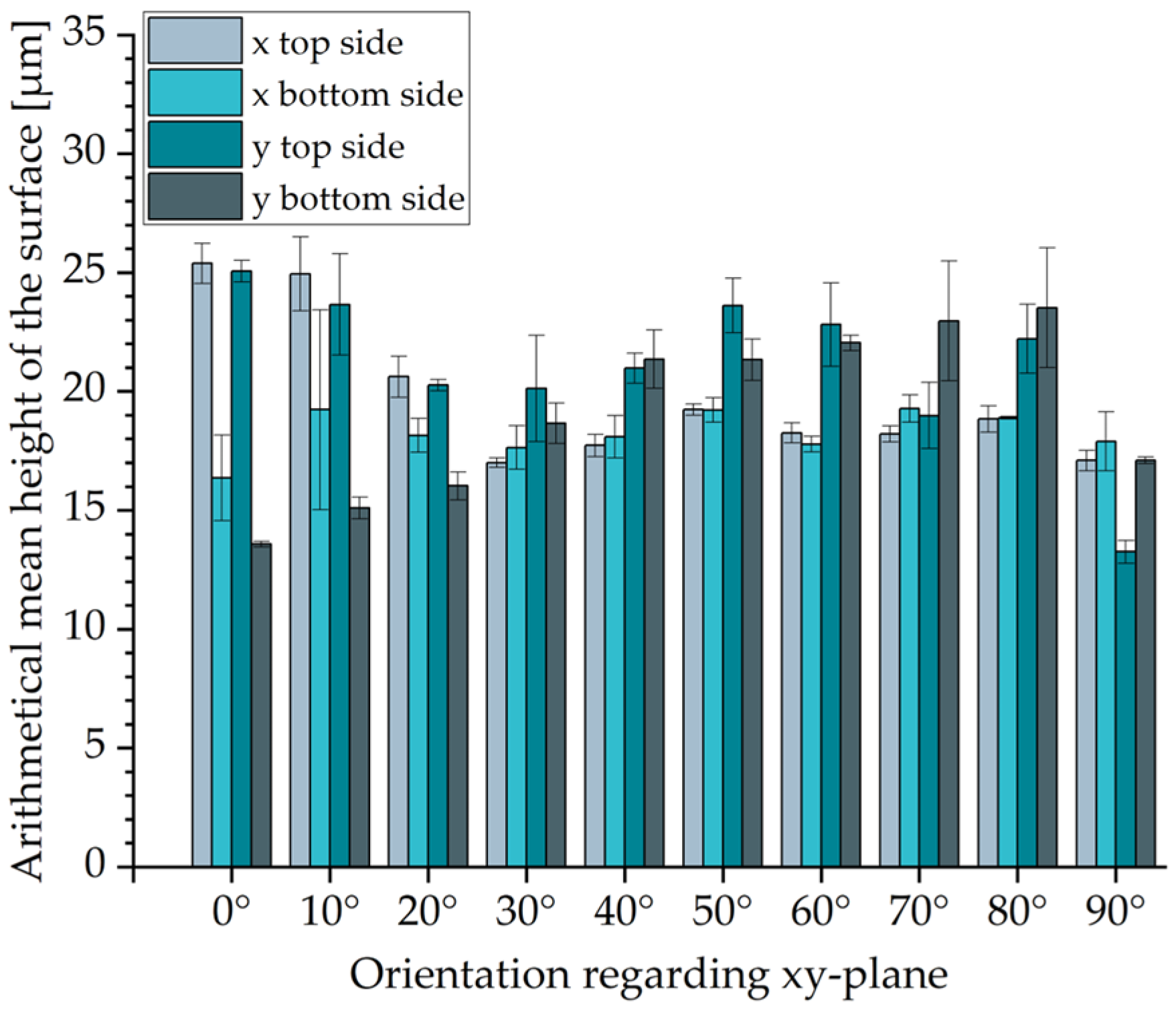

3.7. Surface Roughness Analysis

3.8. Geometric Accuracy Analysis

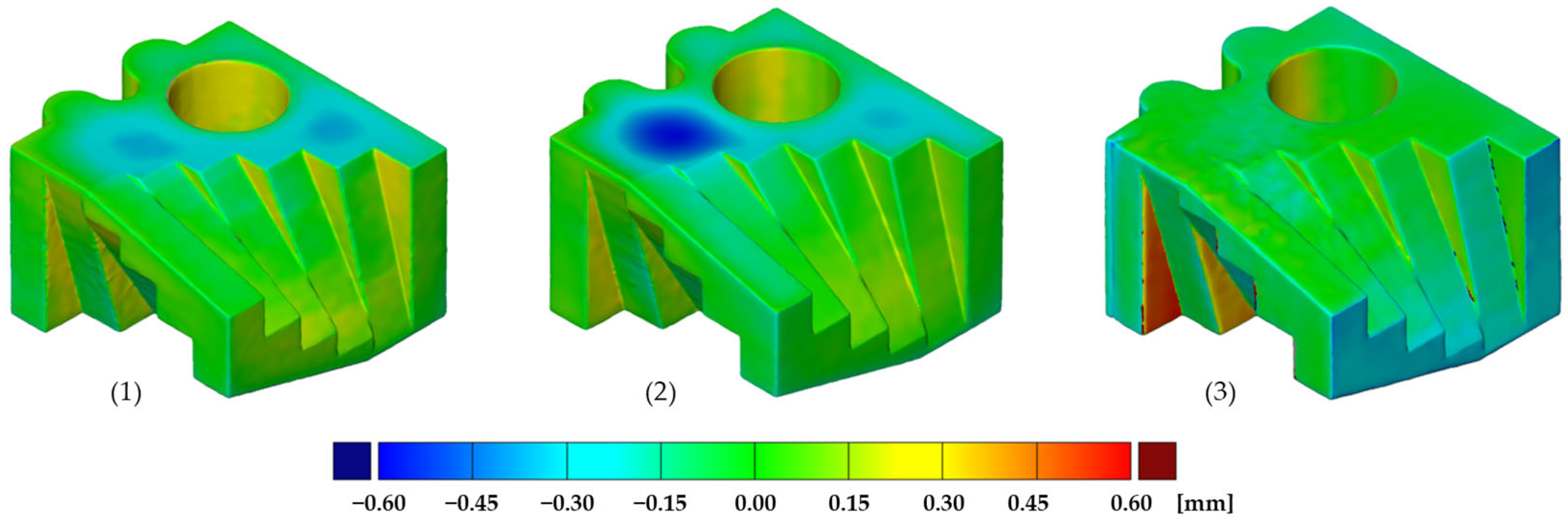

3.9. Feasible Geometries Analysis

4. Results and Discussion

4.1. Characterization of Powder

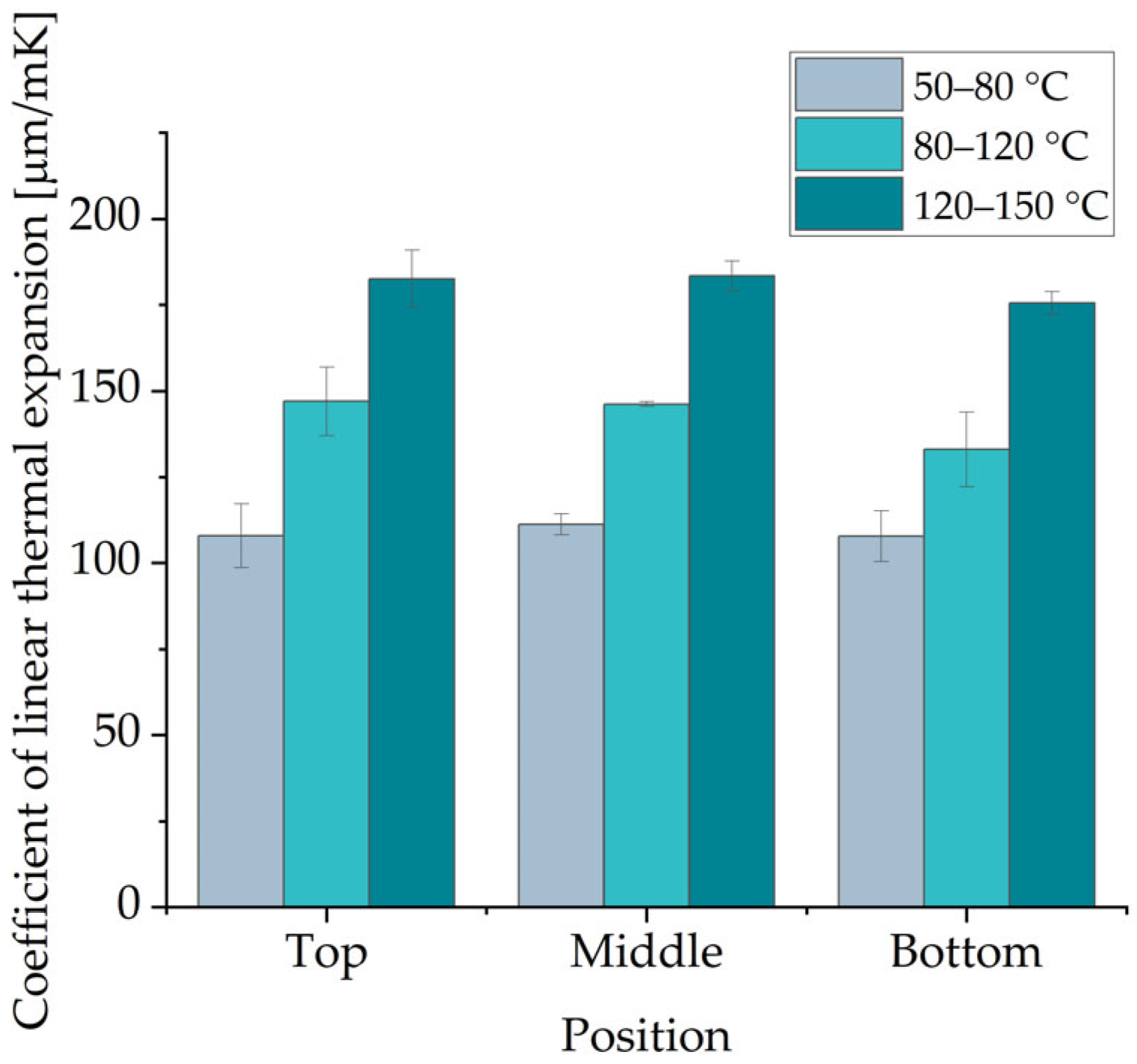

4.2. Thermal Behavior of Powder and Parts

4.3. Density and Porosity of Parts

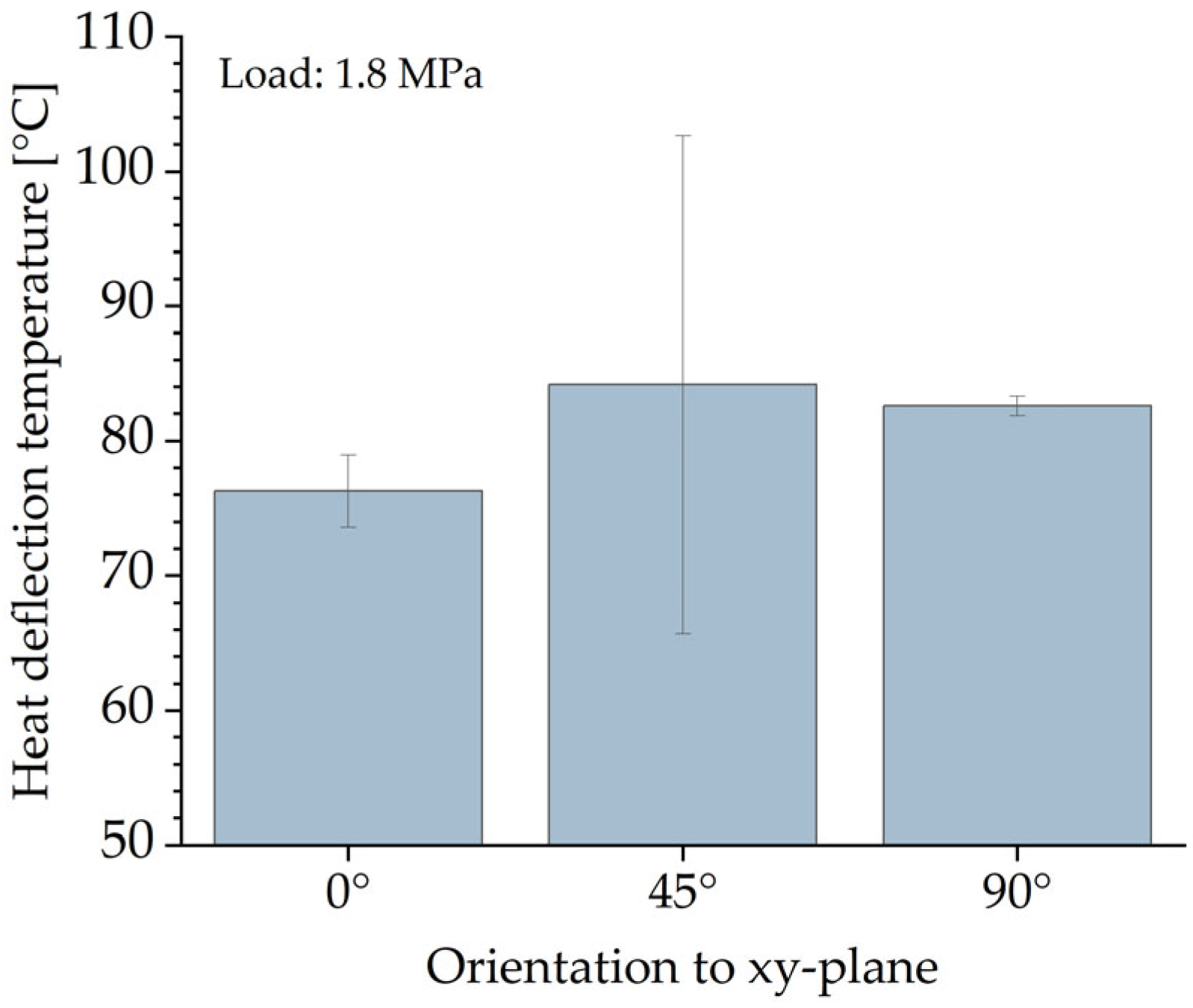

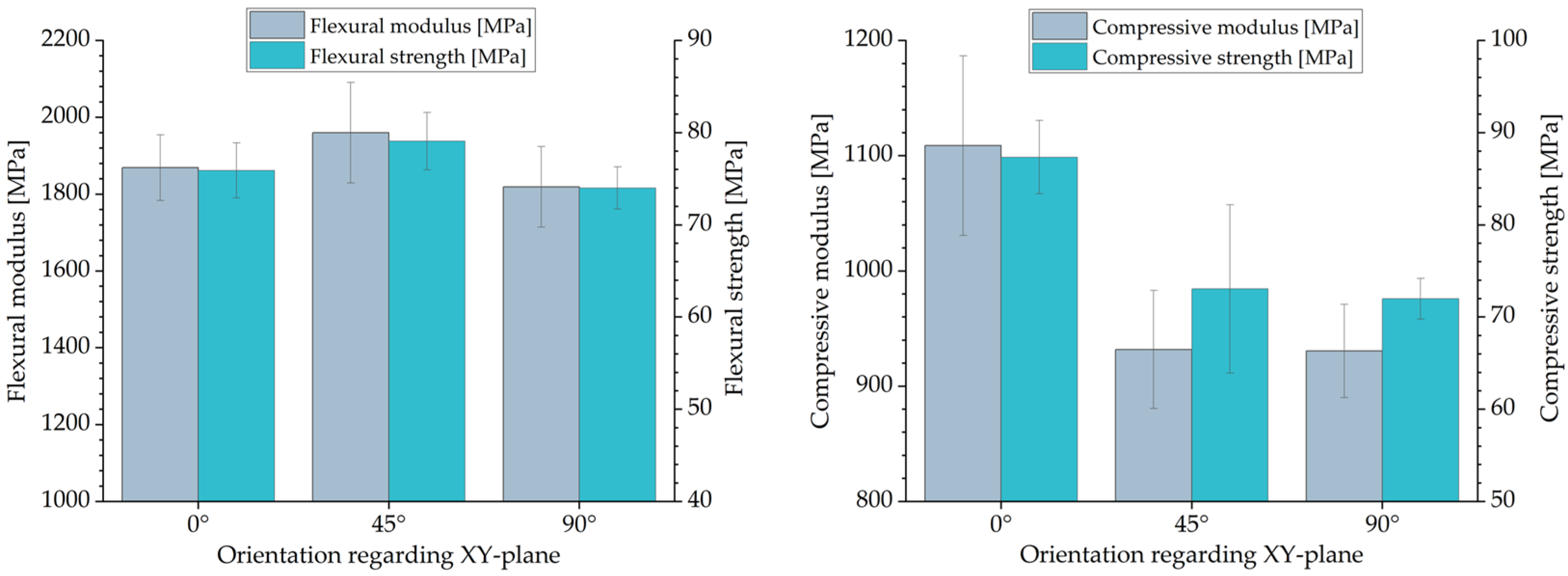

4.4. Mechanical Properties of Parts

| Young’s Modulus [MPa] | Ultimate Tensile Strength [MPa] | Elongation at Break [%] | ||||

|---|---|---|---|---|---|---|

| xy | z | xy | z | xy | z | |

| LS [53] | 1674 ± 15 | 1713 ± 14 | 45.58 ± 0.36 | 46.92 ± 0.20 | 13.07 ± 1.88 | 14.41 ± 1.46 |

| LS [54] | 2070 ± 60 | 2035 ± 32 | 53.22 ± 1.14 | 50.70 ± 0.71 | 9.66 ± 3.47 | 8.70 ± 1.84 |

| MJF [53] | 1466 ± 20 | 1810 ± 25 | 42.95 ± 1.09 | 51.59 ± 0.60 | 15.80 ± 1.39 | 17.77 ± 0.49 |

| MJF [55] | 1128 ± 68 | 1337 ± 98 | 45.80 ± 3.50 | 47.90 ± 0.90 | 11.20 ± 1.80 | 11.40 ± 1.30 |

| MJF [51] | 1242 ± 28 | 1246 ± 37 | 47.00 ± 0.90 | 49.00 ± 0.60 | 19.00 ± 2.80 | 16.00 ± 1.90 |

| HSS [8] | 1400 | - | 34 | - | 10 | - |

| HSS [19] | 1793 | - | 44.40 | - | 13.50 | - |

| HSS [23] | 1720 | - | 42.20 | - | 11.70 | - |

| HSS [24] | 1127 & 1615 | - | 37.30 & 42.70 | - | 20.80 & 18.60 | - |

| HSS MDS [56] | 1716 ± 89 | 1725 ± 59 | 52.00 ± 1.00 | 46.00 ± 2.00 | 10.00 ± 1.00 | 5.00 ± 1.00 |

| HSS current work Type 1A | 1876 ± 40 | 1979 ± 56 | 49.81 ± 2.45 | 48.86 ± 1.99 | 6.90 ± 2.47 | 3.99 ± 0.32 |

| HSS current work Type 1BA | 1820 ± 41 | 1840 ± 50 | 48.39 ± 0.51 | 45.67 ± 0.50 | 6.08 ± 0.61 | 4.47 ± 0.35 |

4.5. Fractured Surface of Parts

4.6. Surface Roughness of Parts

4.7. Geometric Accuracy of Parts

4.8. Feasible Geometries of Parts

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Newton, R.; van Rensburg, J.; Scott, C.; Campbell, R.; Diegel, O.; Huff, R.; Kowen, J. Wohlers Report 2023: 3D Printing and Additive Manufacturing: Global State of the Industry; Wohlers Associates, ASTM International: Fort Collins, CO, USA, 2023; ISBN 978-1-6220-4966-0. [Google Scholar]

- Ellis, A. High Speed Sintering: The Next Generation of Manufacturing. In Nanomaterials for 2D and 3D Printing; Shlomo, M., Alexander, K., Eds.; Wiley-VCH: Weinheim, Germany, 2017; pp. 107–118. ISBN 9783527338191. [Google Scholar]

- Zapka, W. Handbook of Industrial Inkjet Printing; Wiley: Weinheim, Germany, 2017; ISBN 9783527338320. [Google Scholar]

- Hopkinson, N.; Erasenthiran, P. High Speed Sintering-Early Research into a New Rapid Manufacturing Process. In Proceedings of the 15th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 2–4 August 2004. [Google Scholar]

- Thomas, H.R.; Hopkinson, N.; Erasenthiran, P. High Speed Sintering—Continuing Research into a New Rapid Manufacturing Process, Solid Freeform Fabrication. In Proceedings of the 17th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 14–16 August 2006. [Google Scholar] [CrossRef]

- Hopkinson, N.; Thomas, H.U.S. Methods and Apparatus for Selectively Combining Particulate Material. Loughborough University: London, UK. Patent Application EP2739457A1, 19 June 2019. [Google Scholar]

- Günther, D.; Scheck, C.; Brüller, L.; Reevers, J.U.S. voxeljet AG: Method and Device for 3D Printing with a Narrow Wavelength Spectrum. Patent Application EP3377321A1, 20 April 2022. [Google Scholar]

- Majewski, C.E.; Hobbs, B.S.; Hopkinson, N. Effect of bed temperature and infra-red lamp power on the mechanical properties of parts produced using high-speed sintering. Virtual Phys. Prototyp. 2007, 2, 103–110. [Google Scholar] [CrossRef]

- Majewski, C.E.; Oduye, D.; Thomas, H.R.; Hopkinson, N. Effect of infra-red power level on the sintering behaviour in the high speed sintering process. Rapid Prototyp. J. 2008, 14, 155–160. [Google Scholar] [CrossRef]

- Norazman, F.; Hopkinson, N. Effect of Sintering Parameters and Flow Agent on the Mechanical Properties of High Speed Sintered Elastomer. J. Manuf. Sci. Eng. 2014, 136, 061006. [Google Scholar] [CrossRef]

- Ellis, A.; Noble, C.J.; Hopkinson, N. High Speed Sintering: Assessing the influence of print density on microstructure and mechanical properties of nylon parts. Addit. Manuf. 2014, 1, 48–51. [Google Scholar] [CrossRef]

- Noble, C.J.; Ellis, A.; Hopkinson, N. Effect of Greyscale/Print Density on the Properties of High Speed Sintered Nylon 12, Solid Freeform Fabrication. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 4–6 August 2014. [Google Scholar]

- Ellis, A.; Hartley, L.; Hopkinson, N. Effect of Print Density on the Properties of High Speed Sintered Elastomers. Met. Mat. Trans. A 2015, 46, 3883–3886. [Google Scholar] [CrossRef]

- Rouholamin, D.; Hopkinson, N. Understanding the efficacy of micro-CT to analyse high speed sintering parts. Rapid Prototyp. J. 2016, 22, 152–161. [Google Scholar] [CrossRef]

- Norazman, F. Realising the Potential of the High Speed Sintering Process for Industrial Implementation. Ph.D. Thesis, University of Sheffield, London, UK, 2018. [Google Scholar]

- Brown, R.; Morgan, C.T.; Majewski, C.E. Not just Nylon… Improving the Range of Materilas for High Speed Sintering, Solid Freeform Fabrication. In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 13–15 August 2018; pp. 1487–1498. [Google Scholar]

- Bharaj, K.; Paul, S.; Mumtaz, K.A.; Chisholm, M.; Hopkinson, N. Fabricating poly(methyl methacrylate) parts using high-speed sintering, Proceedings of the Institution of Mechanical Engineers, Part B. J. Eng. Manuf. 2020, 234, 118–125. [Google Scholar] [CrossRef]

- Fox, L. Investigation into the Use of Polypropylene in High Speed Sintering. Ph.D. Thesis, University of Sheffield, London, UK, 2018. [Google Scholar]

- Zhu, Z.; Majewski, C. Understanding pore formation and the effect on mechanical properties of High Speed Sintered polyamide-12 parts: A focus on energy input. Mater. Des. 2020, 194, 108937. [Google Scholar] [CrossRef]

- Zhu, Z.; Lou, S.; Majewski, C. Characterisation and correlation of areal surface texture with processing parameters and porosity of High Speed Sintered parts. Addit. Manuf. 2020, 36, 101402. [Google Scholar] [CrossRef]

- Pezold, D. Einfluss Infrarotstrahlungsabsorbierender Partikel auf die Bauteileigenschaften im High Speed Sintering; University of Bayreuth: Bayreuth, Germany, 2024. [Google Scholar]

- Pezold, D.; Schorzmann, J.; Waldmüller, P.; Kemnitzer, J.; Döpper, F. Systematic evaluation of the part properties through combination of different greyscales in one part in High Speed Sintering. Procedia CIRP 2023, 118, 729–734. [Google Scholar] [CrossRef]

- Norazman, F.; Patrick, S.; Hopkinson, N. Spectral Analysis of Infrared Lamps for Use in the High Speed Sintering Process. In Proceedings of the 2016 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2016; Available online: https://hdl.handle.net/2152/89704 (accessed on 30 October 2024).

- Fox, L.; Adam, N. Hopkinson: Use of an Alternative Ink in the High Speed Sintering Process, 2015 International Solid Freeform Fabrication Symposium. 2015. Available online: https://hdl.handle.net/2152/89342 (accessed on 30 October 2024).

- Fahad, M.; Hopkinson, N. Evaluation of Parts Produced by a Novel Additive Manufacturing Process. Appl. Mech. Mater. 2013, 315, 63–67. [Google Scholar] [CrossRef]

- Fahad, M.; Hopkinson, N. Evaluation and comparison of geometrical accuracy of parts produced by sintering-based additive manufacturing processes. Int. J. Adv. Manuf. Technol. 2017, 88, 3389–3394. [Google Scholar] [CrossRef]

- Ellis, A.; Brown, R.; Hopkinson, N. The effect of build orientation and surface modification on mechanical properties of high speed sintered parts. Surf. Topogr. Metrol. Prop. 2015, 3, 034005. [Google Scholar] [CrossRef]

- Schmid, M. Laser Sintering with Plastics Technology, Processes, and Materials, 2nd ed.; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2024; ISBN 978-1-56990-921-8. [Google Scholar]

- VDI 3405 Blatt 1.1; Additive Manufacturing Processes—Laser Sintering of Polymer Parts. VDI Verein Deutscher Ingenieure e.V.: Berlin, Germany, 2018.

- ISO 11357-1:2009; Plastics—Differential Scanning Calorimetry (DSC): Part 1: General Principles. DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2017.

- Gogolewski, S.; Czerntawska, K.; Gastorek, M. Effect of annealing on thermal properties and crystalline structure of polyamides. Nylon 12 (polylaurolactam). Colloid Polym. Sci. 1980, 258, 1130–1136. [Google Scholar] [CrossRef]

- Shah, V. Handbook of Plastics Testing and Failure Analysis; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- ISO 868:2003; Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2003.

- ISO 1183-1:2019; Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pyknometer Method and Titration Method. DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2018.

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2018.

- ISO 178:2010; Plastics—Determination of Flexural Properties. DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2013.

- ISO 604:2002; Plastics—Determination of Compressive Properties. DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2003.

- ISO 25178-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2012.

- VDI 3405 Blatt 3.2; Additive Manufacturing Processes—Design Rules—Test Artefacts and Test Features for Limiting Geometric Elements. VDI Verein Deutscher Ingenieure e.V.: Berlin, Germany, 2019.

- Riedelbauch, J.; Rietzel, D.; Witt, G. Analysis of material aging and the influence on the mechanical properties of polyamide 12 in the Multi Jet Fusion process. Addit. Manuf. 2019, 27, 259–266. [Google Scholar] [CrossRef]

- Craft, G.; Nussbaum, J.; Crane, N.; Harmon, J.P. Impact of extended sintering times on mechanical properties in PA-12 parts produced by powderbed fusion processes. Addit. Manuf. 2018, 22, 800–806. [Google Scholar] [CrossRef]

- Cai, C.; Tey, W.S.; Chen, J.; Zhu, W.; Liu, X.; Liu, T.; Zhao, L.; Zhou, K. Comparative study on 3D printing of polyamide 12 by selective laser sintering and multi jet fusion. J. Mater. Process. Technol. 2021, 288, 116882. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Y.; Wu, D.; Ananth, K.P.; Bai, J. The process and performance comparison of polyamide 12 manufactured by multi jet fusion and selective laser sintering. J. Manuf. Process. 2019, 47, 419–426. [Google Scholar] [CrossRef]

- Zarringhalam, H.; Majewski, C.; Hopkinson, N. Degree of particle melt in Nylon-12 selective laser-sintered parts. Rapid Prototyp. J. 2009, 15, 126–132. [Google Scholar] [CrossRef]

- Rosso, S.; Meneghello, R.; Biasetto, L.; Grigolato, L.; Concheri, G.; Savio, G. In-depth comparison of polyamide 12 parts manufactured by Multi Jet Fusion and Selective Laser Sintering. Addit. Manuf. 2020, 36, 1–13. [Google Scholar] [CrossRef]

- Pavan, M.; Faes, M.; Strobbe, D.; van Hooreweder, B.; Craeghs, T.; Moens, D.; Dewulf, W. On the influence of inter-layer time and energy density on selected critical-to-quality properties of PA12 parts produced via laser sintering. Polym. Test. 2017, 61, 386–395. [Google Scholar] [CrossRef]

- Mele, M.; Campana, G.; Pisaneschi, G.; Monti, G.L. Investigation into effects of cooling rate on properties of polyamide 12 parts in the multi jet fusion process. Rapid Prototyp. J. 2020, 26, 1789–1795. [Google Scholar] [CrossRef]

- Zarringhalam, H. Investigation into Crystallinity and Degree of Particle Melt in Selective Laser Sintering. Ph.D. Thesis, Loughborough University, London, UK, 2007. [Google Scholar]

- Dupin, S.; Lame, O.; Barres, C.; Charmeau, J.-Y. Microstructural origin of physical and mechanical properties of polyamide 12 processed by laser sintering. Eur. Polym. J. 2012, 48, 1611–1621. [Google Scholar] [CrossRef]

- Caulfield, B.; McHugh, P.E.; Lohfeld, S. Dependence of mechanical properties of polyamide components on build parameters in the SLS process. J. Mater. Process. Technol. 2007, 182, 477–488. [Google Scholar] [CrossRef]

- O’Connor, H.J.; Dickson, A.N.; Dowling, D.P. Evaluation of the mechanical performance of polymer parts fabricated using a production scale multi jet fusion printing process. Addit. Manuf. 2018, 22, 381–387. [Google Scholar] [CrossRef]

- Morales-Planas, S.; Minguella-Canela, J.; Lluma-Fuentes, J.; Travieso-Rodriguez, J.A.; García-Granada, A.-A. Multi Jet Fusion PA12 Manufacturing Parameters for Watertightness, Strength and Tolerances. Materials 2018, 11, 1472. [Google Scholar] [CrossRef]

- Mehdipour, F.; Gebhardt, U.; Kästner, M. Anisotropic and rate-dependent mechanical properties of 3D printed polyamide 12—A comparison between selective laser sintering and multi jet fusion. Results Mater. 2021, 11, 100213. [Google Scholar] [CrossRef]

- Lammens, N.; Kersemans, M.; De Baere, I.; Van Paepegem, W. On the visco-elasto-plastic response of additively manufactured polyamide-12 (PA-12) through selective laser sintering. Polym. Test. 2017, 57, 149–155. [Google Scholar] [CrossRef]

- Sillani, F.; Kleijnen, R.G.; Vetterli, M.; Schmida, M.; Wegener, K. Selective laser sintering and multi jet fusion: Process-induced modification of the raw materials and analyses of parts performance. Addit. Manuf. 2019, 27, 32–41. [Google Scholar] [CrossRef]

- Voxeljet, A.G. Material Data Sheets: High Speed Sintering. HSS. Available online: https://www.voxeljet.de/wp-content/uploads/2021/01/materialdatenblatt-hss.pdf (accessed on 30 November 2024).

- Tomanik, M.; Żmudzińska, M.; Wojtków, M. Mechanical and Structural Evaluation of the PA12 Desktop Selective Laser Sintering Printed Parts Regarding Printing Strategy. 3d Print. Addit. Manuf. 2021, 8, 271–279. [Google Scholar] [CrossRef]

- Ezrin, M. Plastics Failure Guide Cause and Prevention, 2nd ed.; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2013; ISBN 978-3-446-41684-0. [Google Scholar]

- Guo, B.; Xu, Z.; Luo, X.; Bai, J. A detailed evaluation of surface, thermal, and flammable properties of polyamide 12/glass beads composites fabricated by multi jet fusion. Virtual Phys. Prototyp. 2021, 16, S39–S52. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| process temperature | °C | 173 |

| floor temperature | °C | 175 |

| wall temperature | °C | 140 |

| recoater speed | m/s | 0.1 |

| recoater temperature | °C | 130 |

| recoater gap | mm | 2.8 |

| recoater intensity of vibration | % | 85 |

| sintering lamp speed | m/s | 0.15 |

| sintering lamp power | % | 100 |

| printhead speed | m/s | 0.39 |

| applied ink | pl/mm2 | 3618 |

| layer thickness | mm | 0.08 |

| empty layers start | - | 100 |

| empty layers cover | - | 40 |

| cool-down end temperature | °C | 90 |

| Specimen | Number (Total) | Position/Orientation | Build Job |

|---|---|---|---|

| cubes large (20 × 20 × 20 mm) | 6 × each (18) 5 × each (10) | bottom, middle, top 0°, 45° | I |

| cubes small (5 × 5 × 5 mm) | 5 × each (15) | bottom, middle, top | I |

| tensile bars type 1A | 5 × each (15) | 0°, 45°, 90° | I |

| tensile bars type 1BA] | 5 × each (15) | 0°, 45°, 90° | I |

| bending bars (80 × 10 × 4 mm) | 10 × each (30) | 0°, 45°, 90° | I |

| compression bars type B | 5 × each (15) | 0°, 45°, 90° | I |

| surface roughness specimens | 2 × each (4) | x- and y-orientation | II |

| geometric accuracy specimens | 1 × each (3) | orientation ➀, ➁, ➂ | II |

| minimum wall thickness specimens | 1 × each (6) | 0°, 45°, 90° for x- and y-orientation | II |

| minimum gap dimension specimens | 1 × each (3) | orientation ➀, ➁, ➂ | II |

| Sample | Melting Enthalpy Hms [J/g] | Percentage Crystallinity φc [%] |

|---|---|---|

| mixed powder | 101.9 | 48.7 |

| specimens at top | 69.3 | 33.1 |

| specimens at middle | 70.9 | 33.9 |

| specimens at bottom | 71.6 | 34.2 |

| Orientation | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wall thickness [mm] | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 |

| 90° | ■ | ■ | ■ | ■ | ■ | ■ | ■ | |||||

| 45° | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ||

| 0° | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kemnitzer, J.; Wimmer, M.; Tarasova, A.; Döpper, F. High Speed Sintering of Polyamide 12: From Powder to Part Properties. Polymers 2024, 16, 3605. https://doi.org/10.3390/polym16243605

Kemnitzer J, Wimmer M, Tarasova A, Döpper F. High Speed Sintering of Polyamide 12: From Powder to Part Properties. Polymers. 2024; 16(24):3605. https://doi.org/10.3390/polym16243605

Chicago/Turabian StyleKemnitzer, Jan, Marco Wimmer, Anna Tarasova, and Frank Döpper. 2024. "High Speed Sintering of Polyamide 12: From Powder to Part Properties" Polymers 16, no. 24: 3605. https://doi.org/10.3390/polym16243605

APA StyleKemnitzer, J., Wimmer, M., Tarasova, A., & Döpper, F. (2024). High Speed Sintering of Polyamide 12: From Powder to Part Properties. Polymers, 16(24), 3605. https://doi.org/10.3390/polym16243605