Investigation of the Weldability of 3D-Printed Multi-Material Materials (PLA and PLA Wood) Using Friction Stir Welding

Abstract

1. Introduction

2. Material and Methods

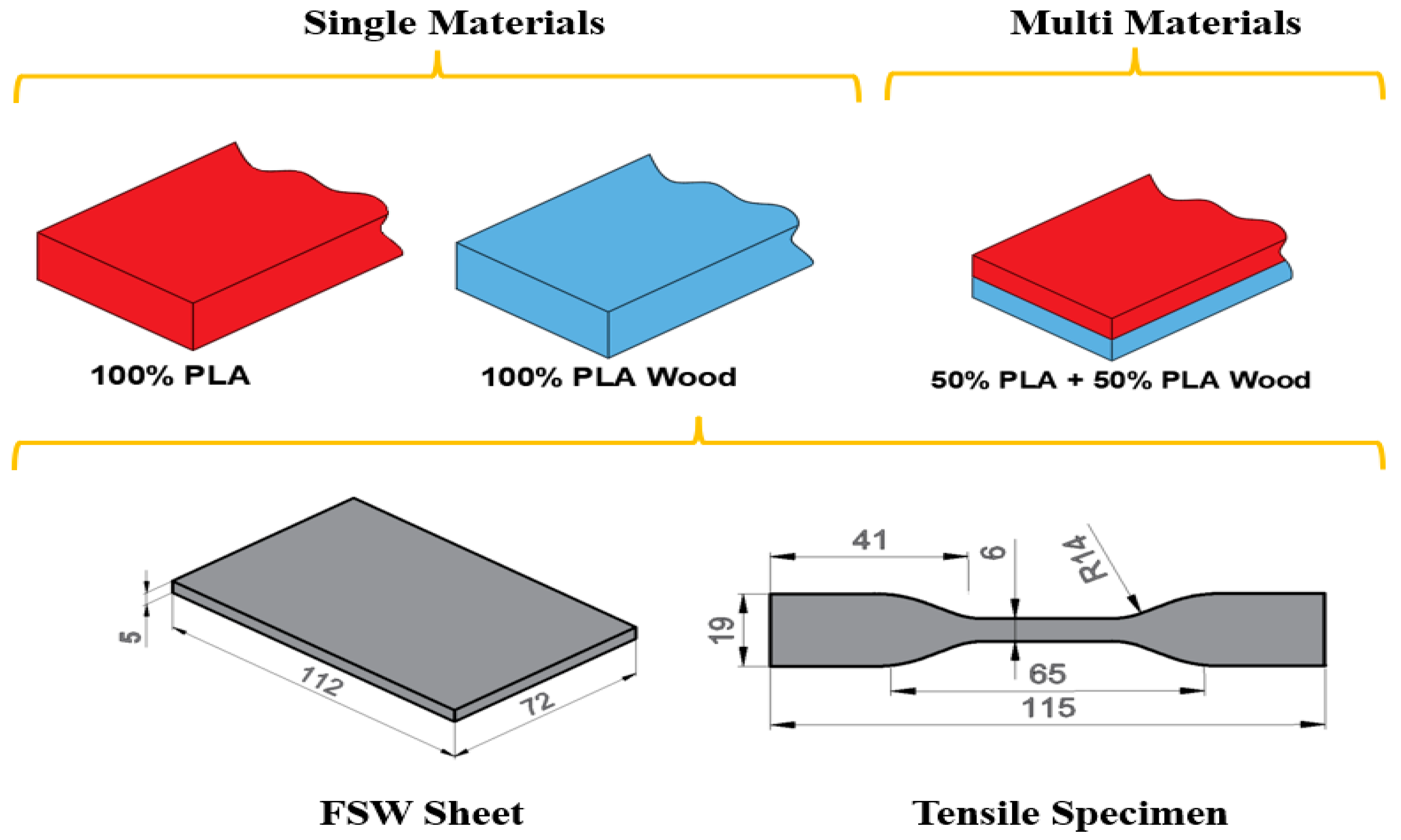

2.1. Materials

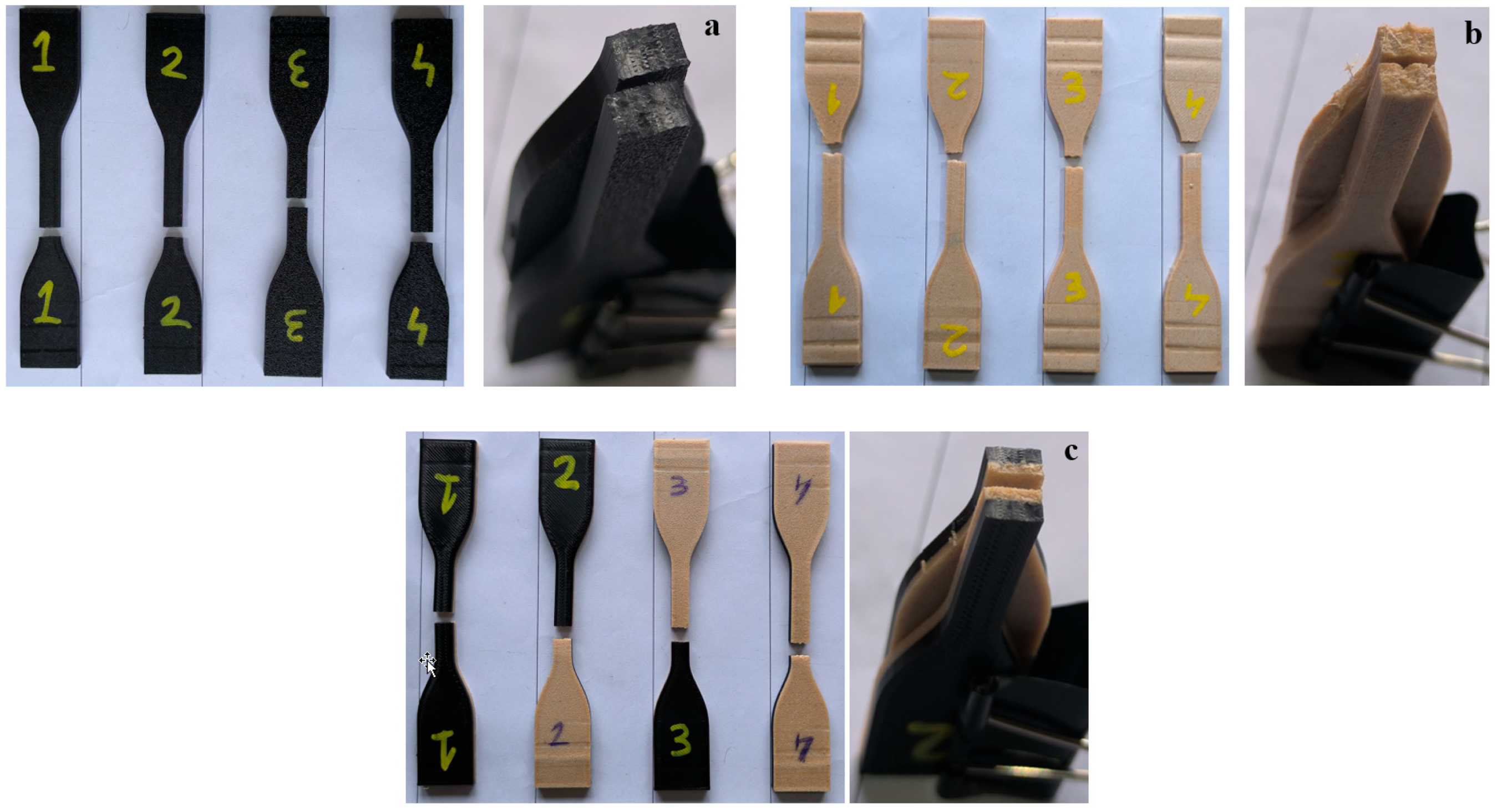

2.2. Printing Samples from 3D Printer

2.3. Experimental Design

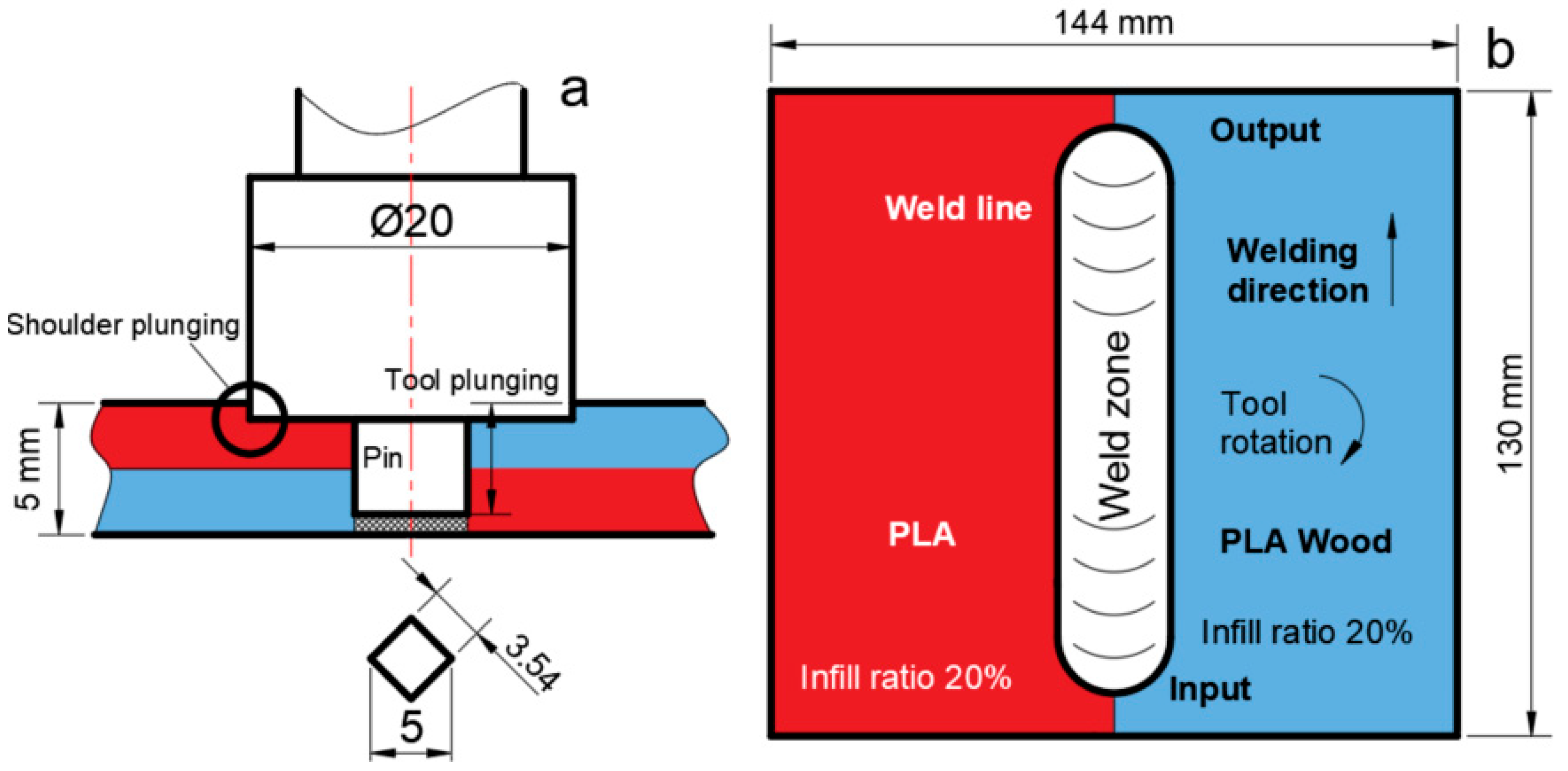

2.4. Friction Stir Welding Parameters

2.5. Determination of Mechanical Properties

3. Results and Discussion

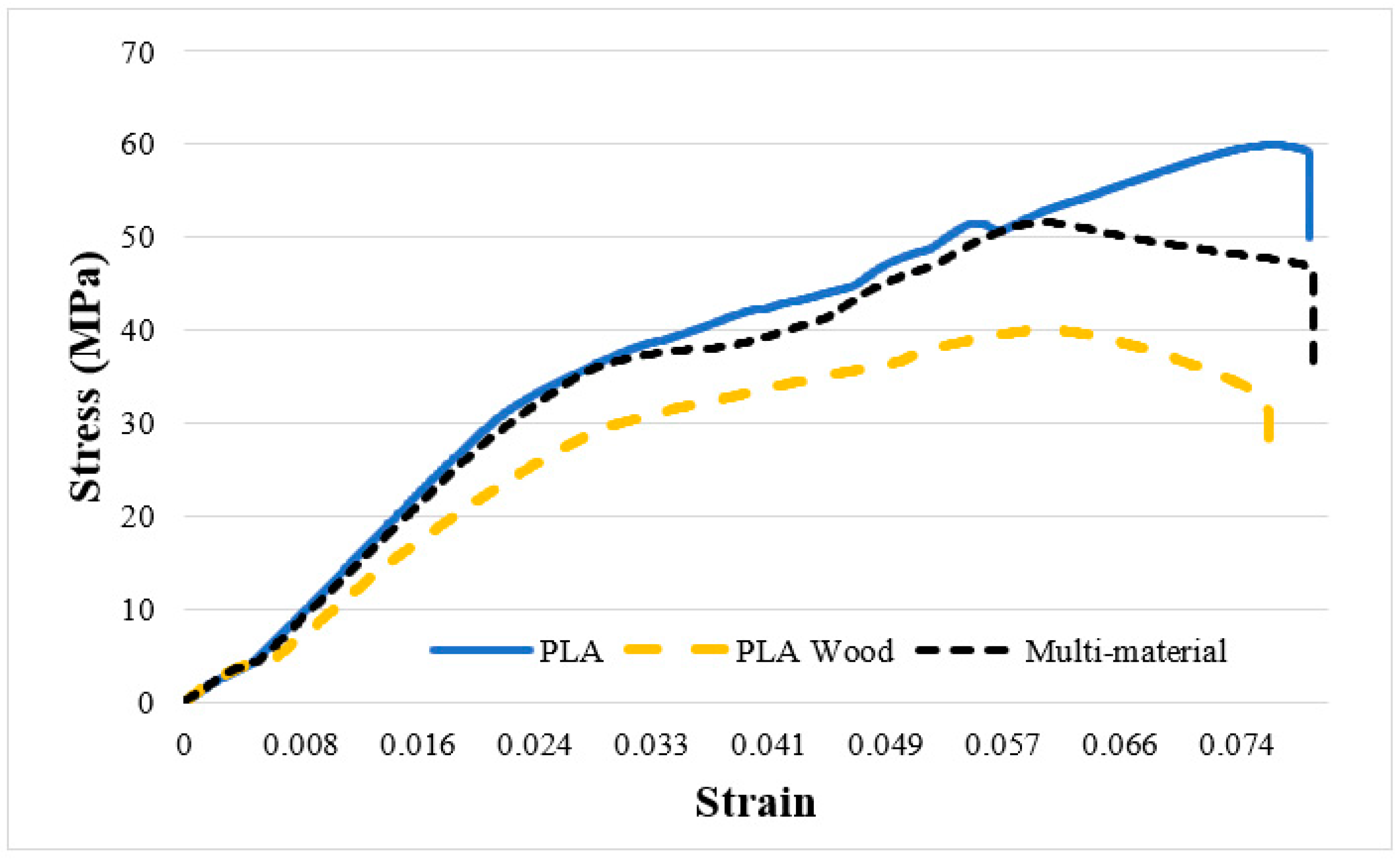

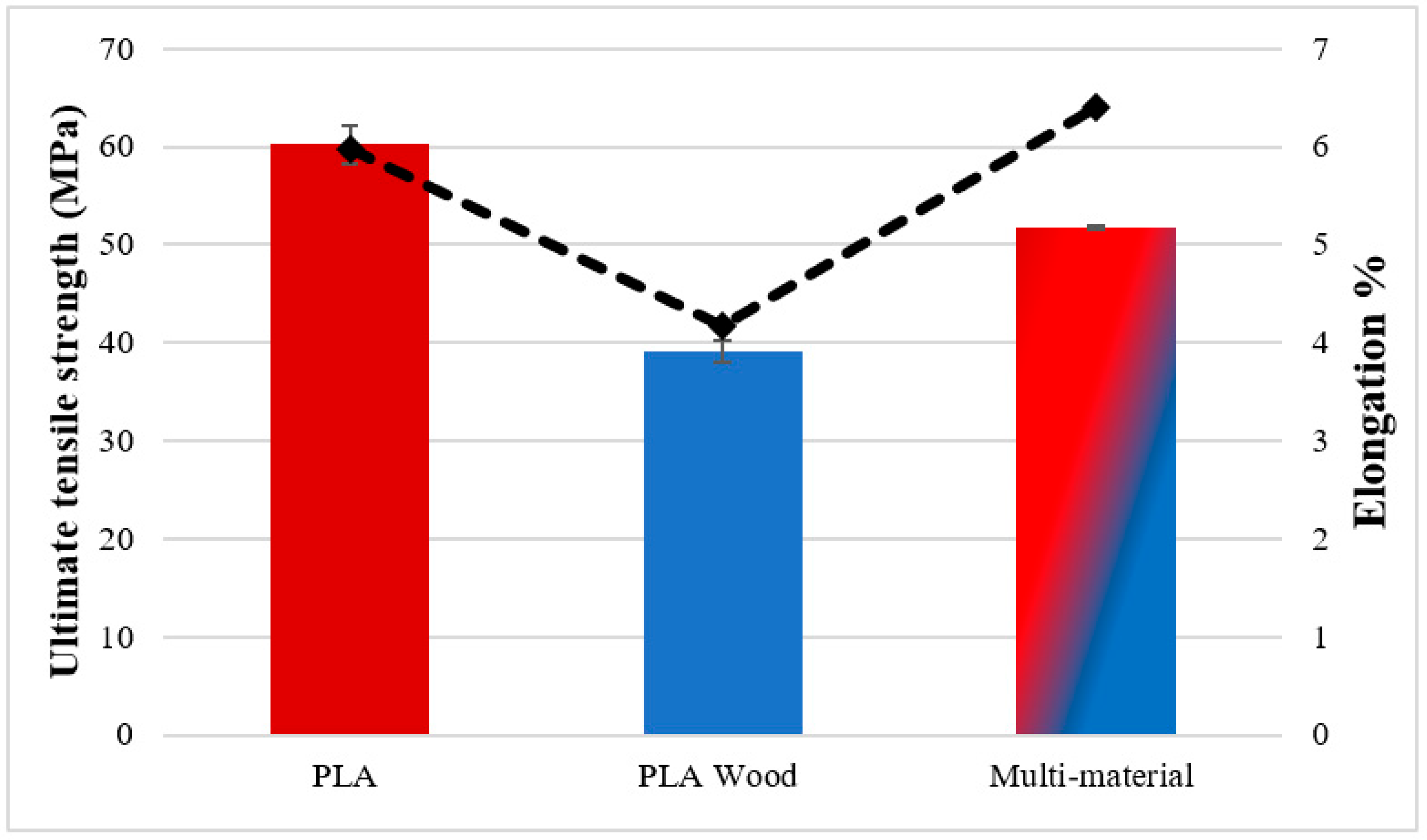

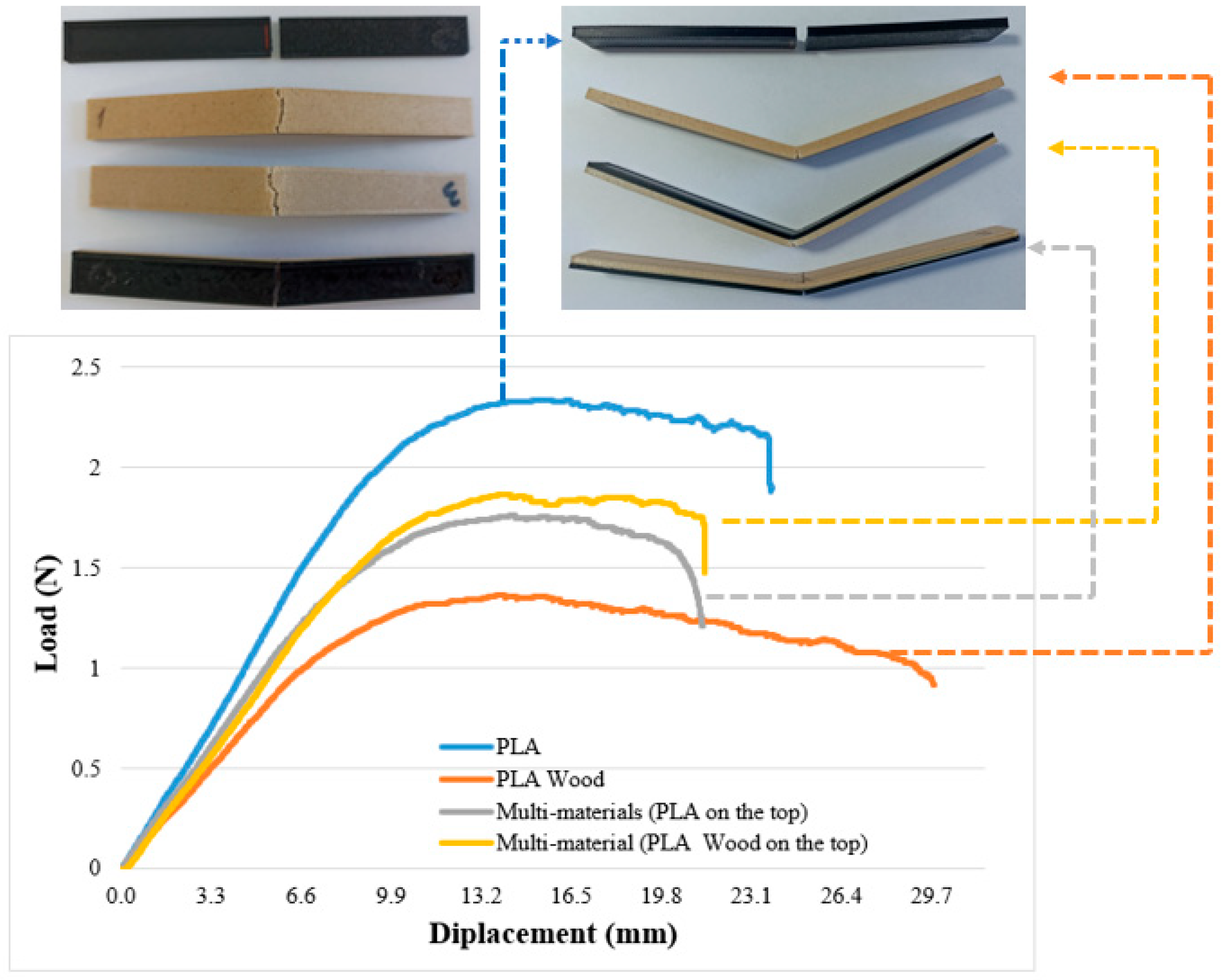

3.1. Mechanical Properties of Base Materials

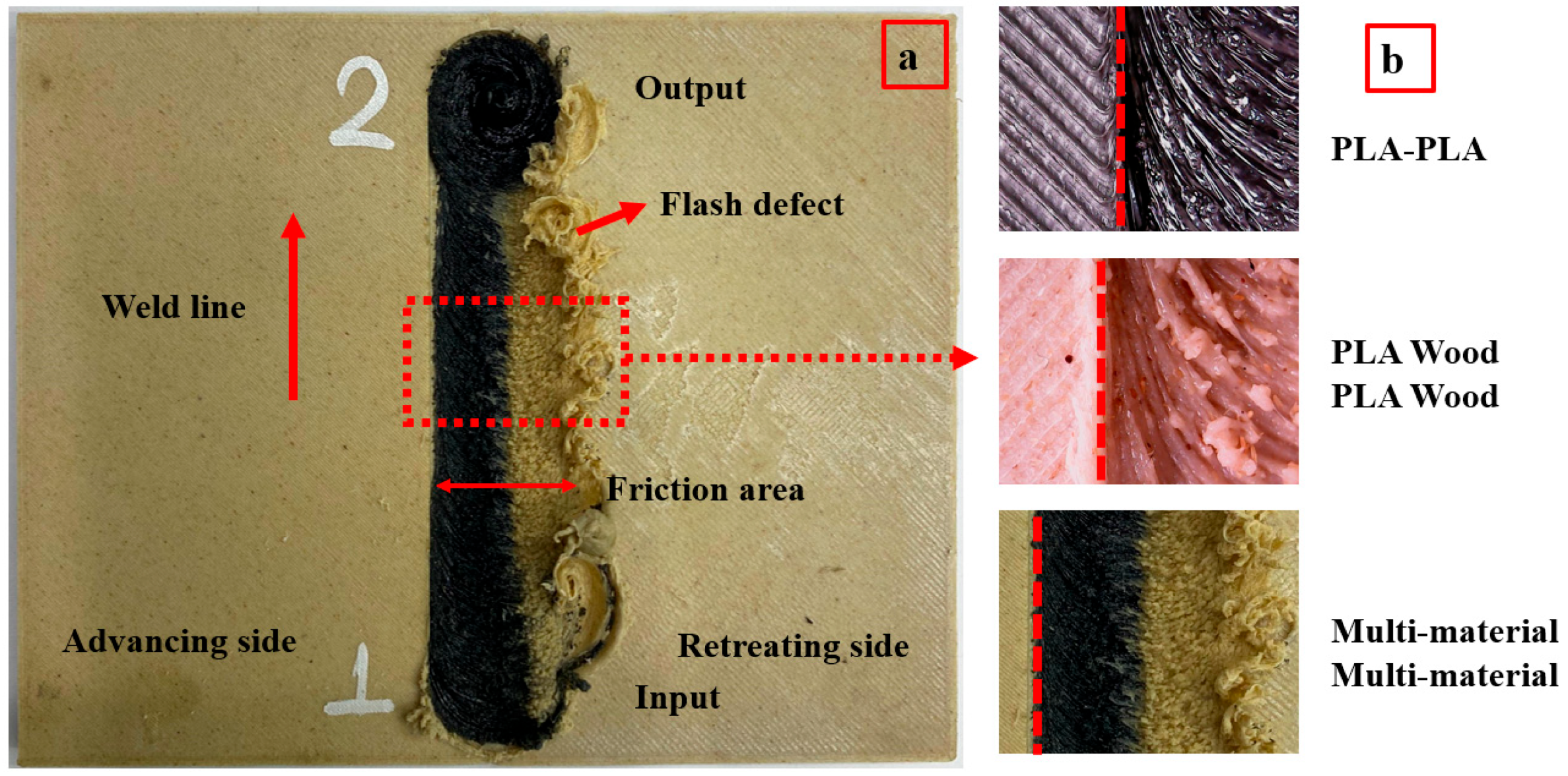

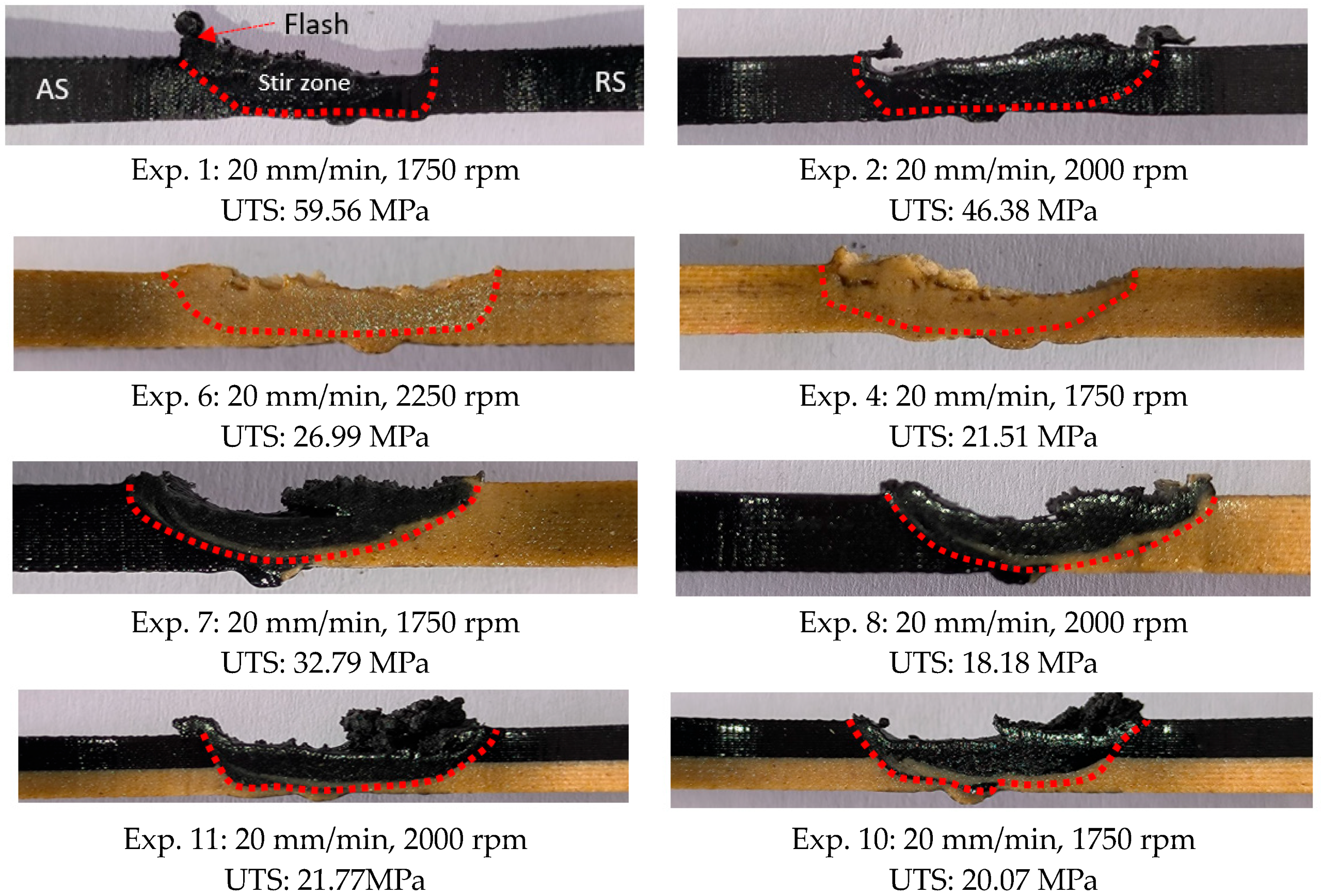

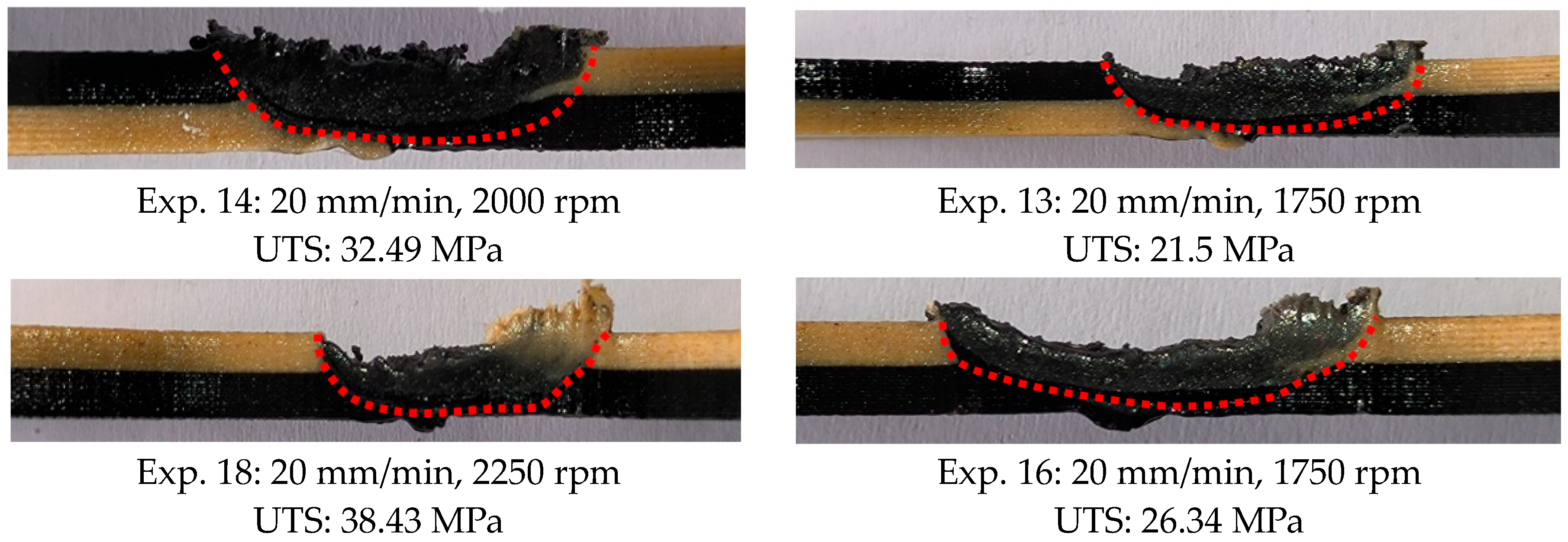

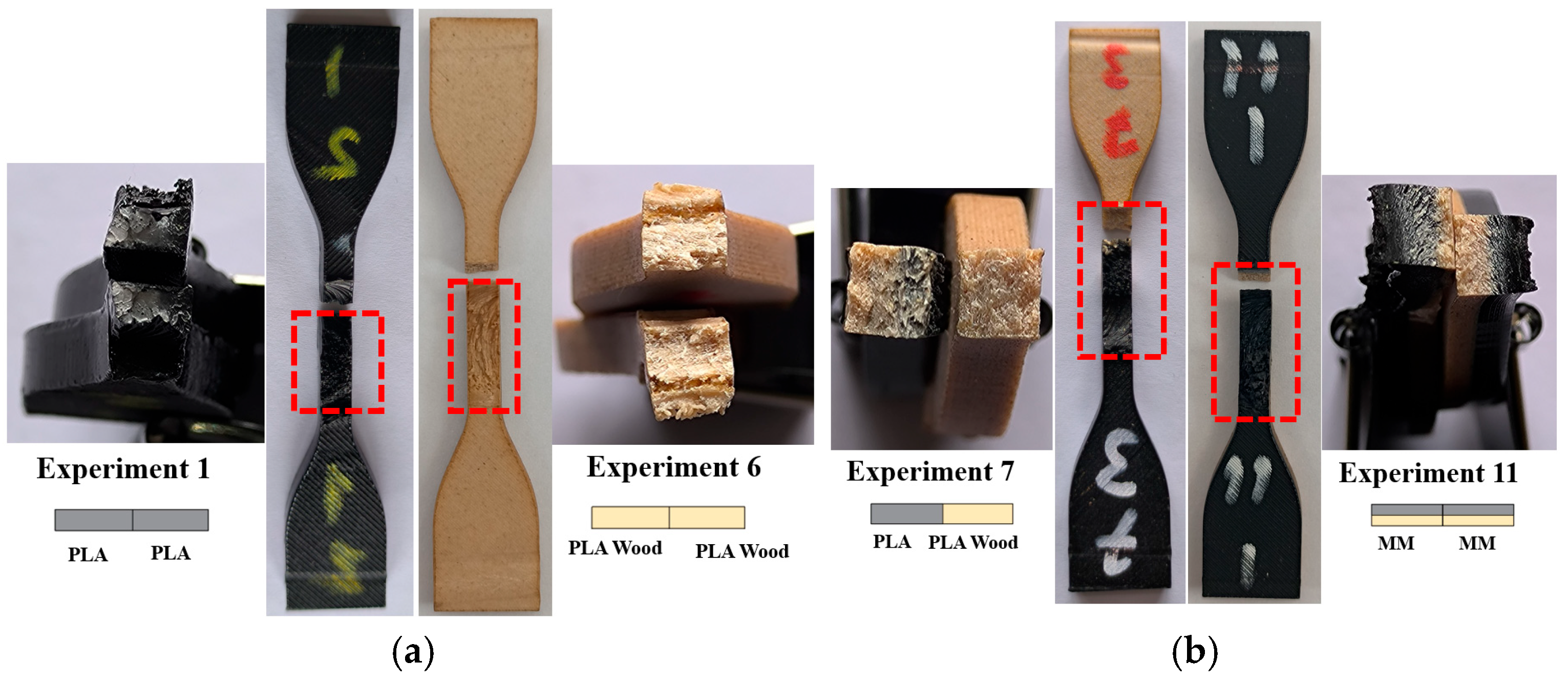

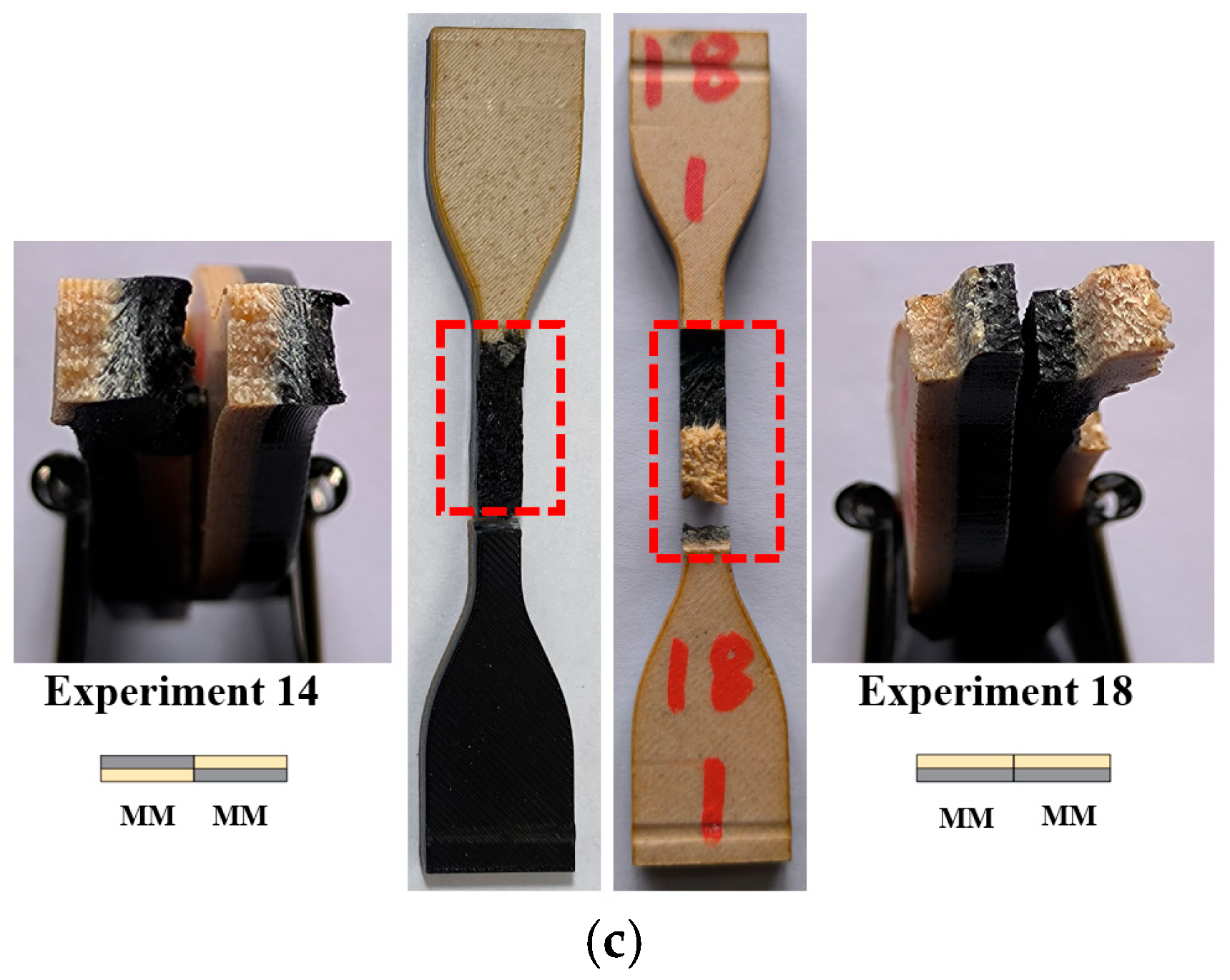

3.2. Visual Inspection of Welding Area

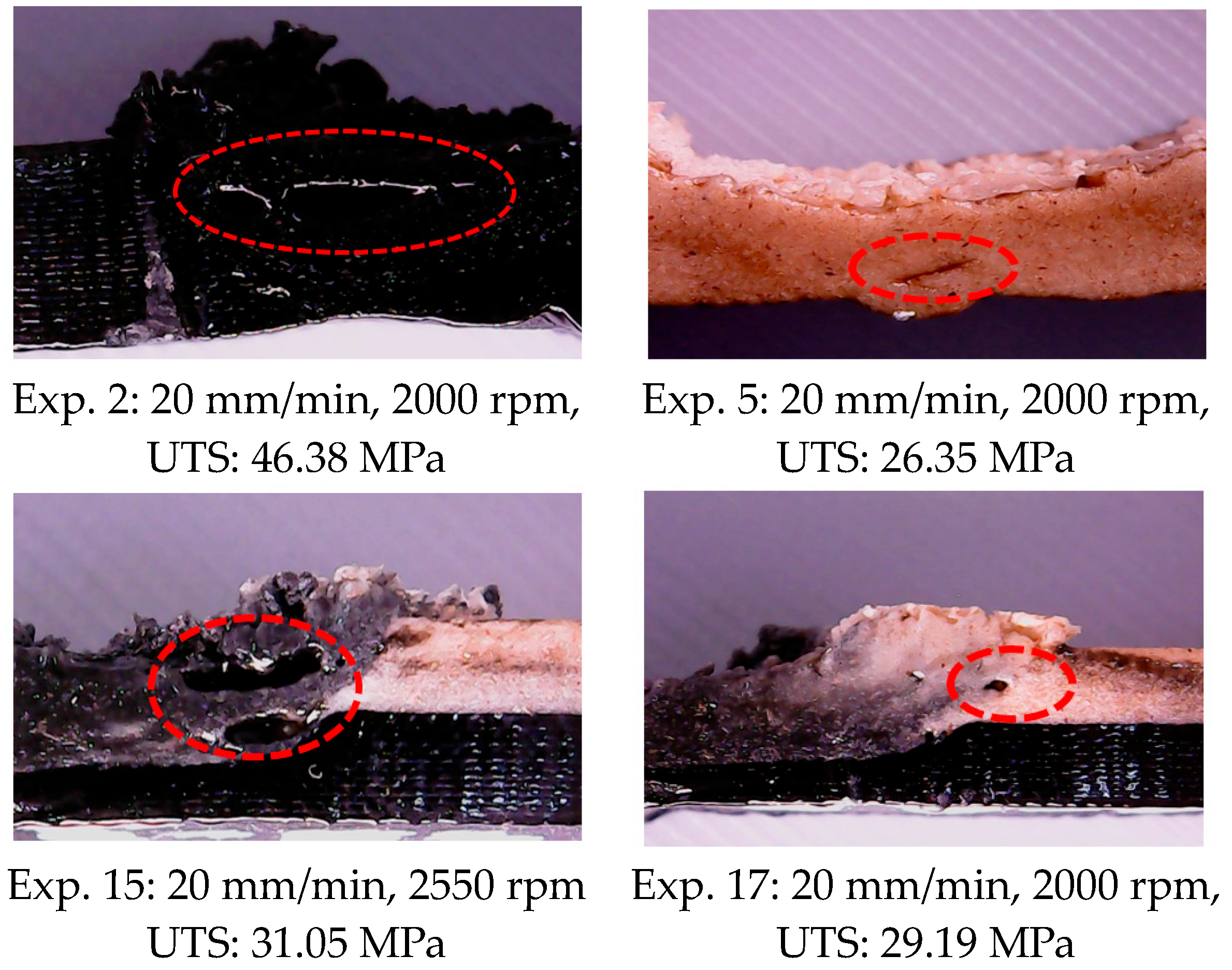

3.3. Result of FSW Strength

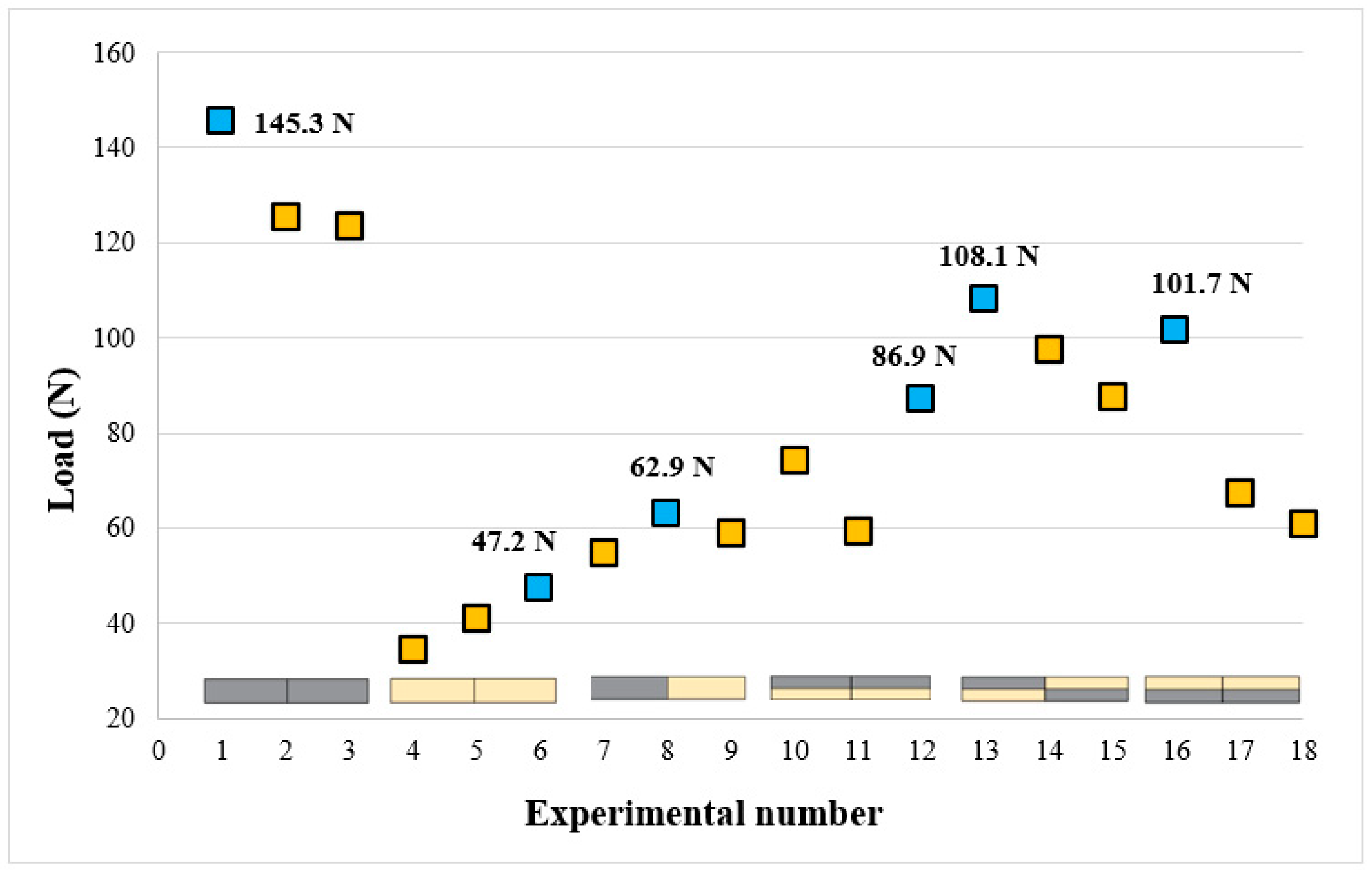

3.4. Bending Test Results

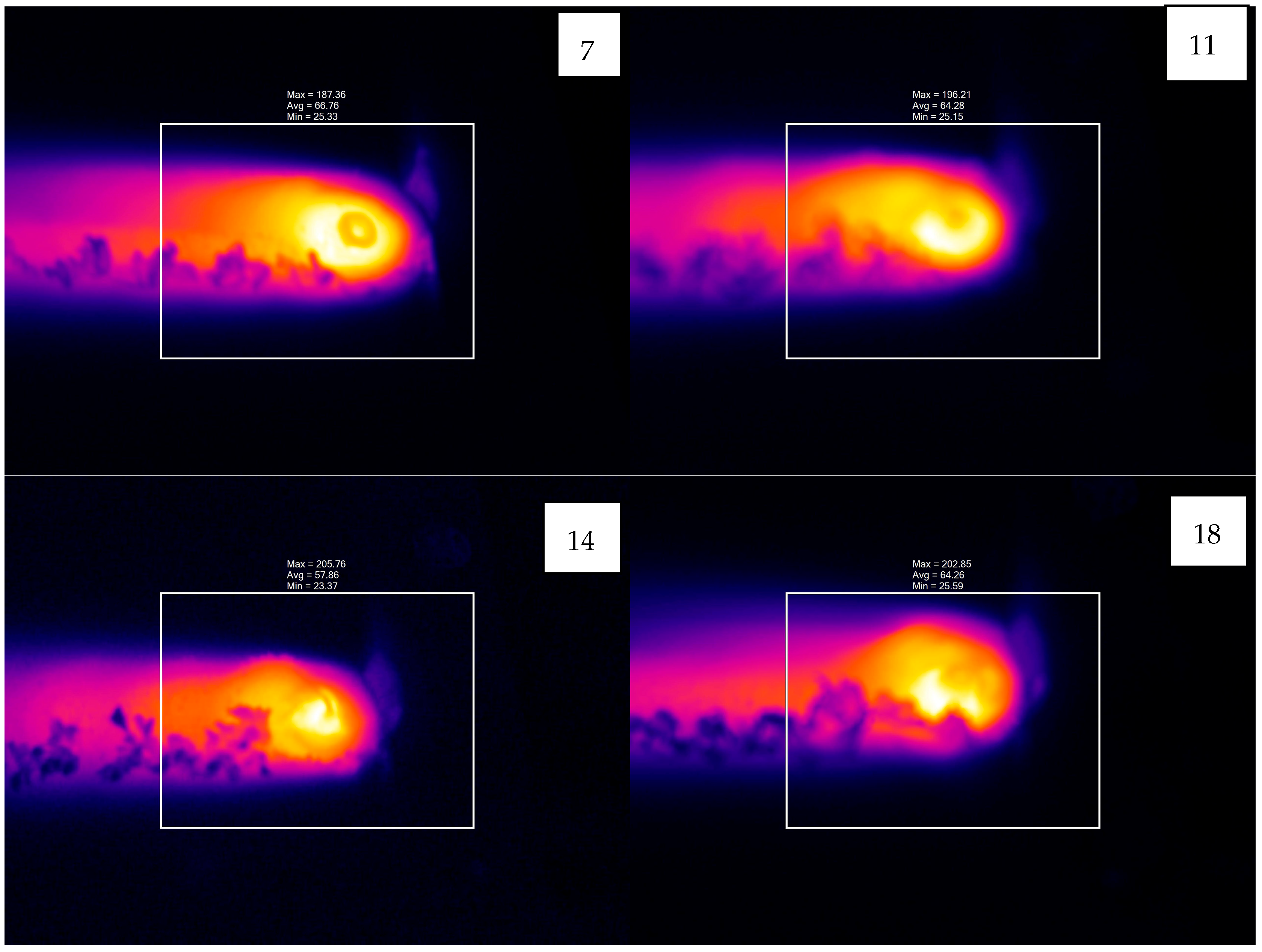

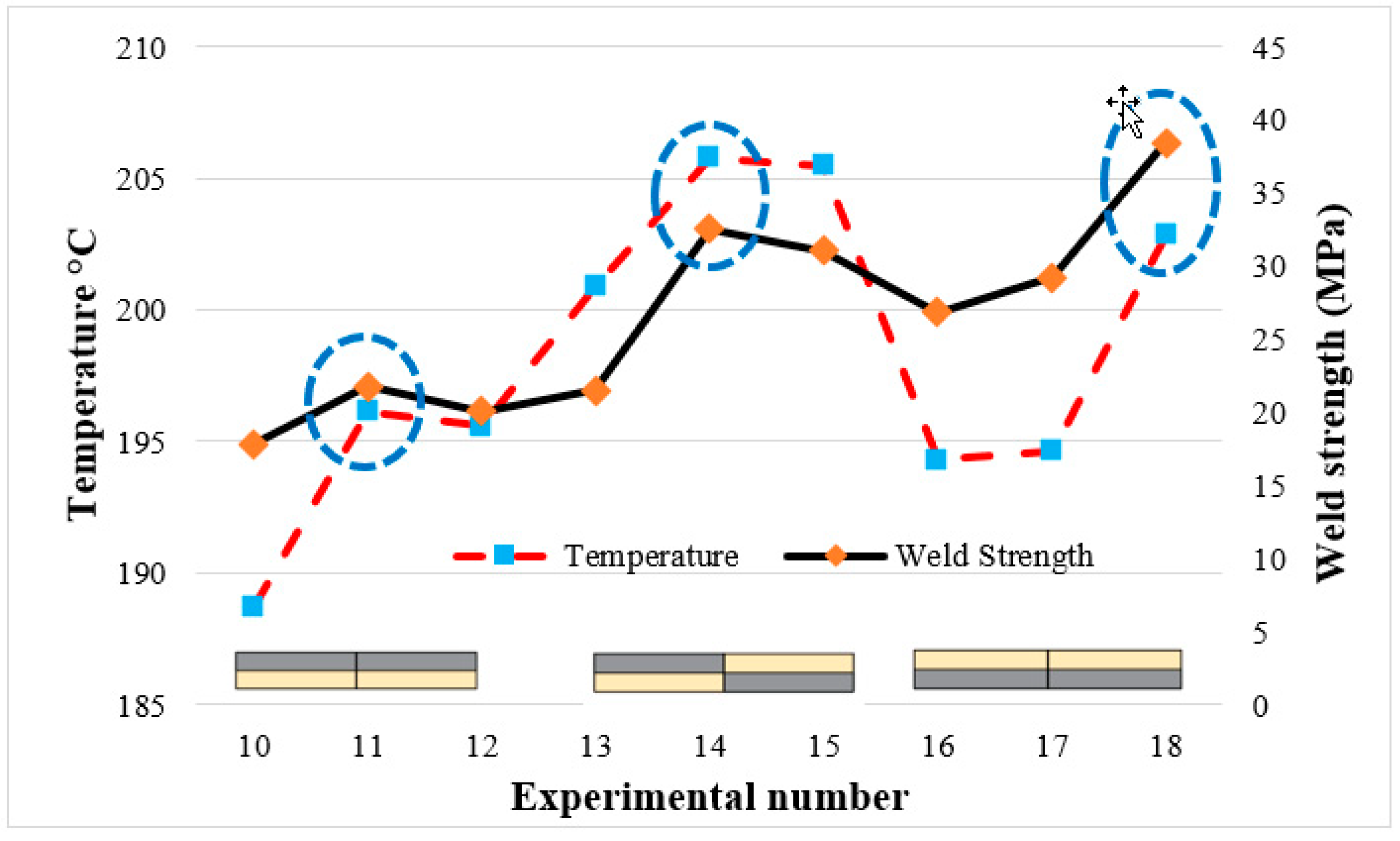

3.5. Evaluation of Temperature Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baca, D.; Ahmad, R. The impact on the mechanical properties of multi-material polymers fabricated with a single mixing nozzle and multi-nozzle systems via fused deposition modeling. Int. J. Adv. Manuf. Technol. 2020, 106, 4509–4520. [Google Scholar] [CrossRef]

- Arifvianto, B.; Satiti, B.E.; Salim, U.A.; Suyitno; Nuryanti, A.; Mahardika, M. Mechanical properties of the FFF sandwich-structured parts made of PLA/TPU multi-material. Prog. Addit. Manuf. 2022, 7, 1213–1223. [Google Scholar] [CrossRef]

- Lopes, L.; Silva, A.; Carneiro, O. Multi-material 3D printing: The relevance of materials affinity on the boundary interface performance. Addit. Manuf. 2018, 23, 45–52. [Google Scholar] [CrossRef]

- Ribeiro, M.; Sousa Carneiro, O.; Ferreira da Silva, A. Interface geometries in 3D multi-material prints by fused filament fabrication. Rapid Prototyp. J. 2019, 25, 38–46. [Google Scholar] [CrossRef]

- Ermolai, V.; Nagîţ, G.; Sover, A.; Surugiu, I. Design and Testing of Multi-Material Shape-Changing Flexure Hinges for Fused Filament Fabrication. Bull. Polytech. Inst. Iași. Mach. Constr. Sect. 2022, 68, 19–30. [Google Scholar] [CrossRef]

- Brancewicz-Steinmetz, E.; Valverde Vergara, R.; Buzalski, V.; Sawicki, J. Study of the adhesion between TPU and PLA in multi-material 3D printing. J. Achiev. Mater. Manuf. Eng. 2022, 115, 49–56. [Google Scholar] [CrossRef]

- Ermolai, V.; Sover, A.; Nagit, G. Strength of Contact Geometry for Multi-material 3D-Printed Samples. In Macromolecular Symposia; Wiley Online Library: New York, NY, USA, 2022; p. 2100320. [Google Scholar]

- Benli, İ.K.; Anaç, N.; Koçar, O.; da Silva, L.F. The effects of material type and temperature factors on the adhesive bonding strength of 3D printed multi-material plastic structures. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2024, 14644207241275821. [Google Scholar] [CrossRef]

- Koçar, O.; Anaç, N.; Baysal, E. A New Approach in Part Design for Friction Stir Welding of 3D-Printed Parts with Different Infill Ratios and Colors. Polymers 2024, 16, 1790. [Google Scholar] [CrossRef]

- Koçar, O.; Anaç, N.; Palaniappan, S.K.; Doğan, M.; Siengchin, S. Effect of process parameters on the mechanical behavior of additively manufactured and FSW joined PLA wood sheets. Polym. Compos. 2024, 45, 1568–1584. [Google Scholar] [CrossRef]

- Anaç, N.; Koçar, O.; Baysal, E. Estimation of friction stir welding parameters of 3D printed sheets using ANN. Niğde Ömer Halisdemir Univ. J. Eng. Sci. 2024, 13, 176–187. [Google Scholar]

- Anaç, N. Assessment of adhesively bonded joints of similar and dissimilar materials: Industrial case study. Processes 2023, 11, 1312. [Google Scholar] [CrossRef]

- Polat, N.; Nergizhan, A.; Faruk, M. Investigation of the Effect of Bonding Parameters on the Mechanical Strength of the Adhesive Bonding PLA Parts Produced by Additive Manufacturing. J. Polytech. 2021, 27, 1143–1154. [Google Scholar]

- Frascio, M.; Mandolfino, C.; Moroni, F.; Jilich, M.; Lagazzo, A.; Pizzorni, M.; Bergonzi, L.; Morano, C.; Alfano, M.; Avalle, M. Appraisal of surface preparation in adhesive bonding of additive manufactured substrates. Int. J. Adhes. Adhes. 2021, 106, 102802. [Google Scholar] [CrossRef]

- Garcia, R.; Prabhakar, P. Bond interface design for single lap joints using polymeric additive manufacturing. Compos. Struct. 2017, 176, 547–555. [Google Scholar] [CrossRef]

- Ribeiro, T.; Campilho, R.; Pinto, R.; Rocha, R. Structural behaviour of adhesive bonds in 3D printed adherends. J. Adhes. Sci. Technol. 2024, 1–25. [Google Scholar] [CrossRef]

- Sharma, A.K.R.; Roy Choudhury, M.; Debnath, K. Experimental investigation of friction stir welding of PLA. Weld. World 2020, 64, 1011–1021. [Google Scholar] [CrossRef]

- Incorporated. P.S. 3 Types of Plastic Used in 3D Printing. Available online: https://www.polymersolutions.com/blog/plastic-in-3d-printing/ (accessed on 12 February 2023).

- Kyutoku, H.; Maeda, N.; Sakamoto, H.; Nishimura, H.; Yamada, K. Effect of surface treatment of cellulose fiber (CF) on durability of PLA/CF bio-composites. Carbohydr. Polym. 2019, 203, 95–102. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kariz, M.; Kwon, J.H.; Kitek Kuzman, M. Effect of printing layer thickness on water absorption and mechanical properties of 3D-printed wood/PLA composite materials. Int. J. Adv. Manuf. Technol. 2019, 102, 2195–2200. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Microstructure and mechanical performance of 3D printed wood-PLA/PHA using fused deposition modelling: Effect of printing temperature. Polymers 2019, 11, 1778. [Google Scholar] [CrossRef]

- Ultimaker. Ultimaker PLA TDS. Available online: https://support.makerbot.com/s/article/1667410781972 (accessed on 11 October 2022).

- Filameon. PLA Wood. Available online: https://www.filameon.com/urun/filameon-pla-wood-filament/ (accessed on 5 November 2022).

- Creality. Ender 3-S1. Available online: https://www.creality.com/ (accessed on 1 October 2023).

- ASTM 638-10; Standard Test Method for Tensile Properties of Plastics. American Society for Testing Materials: West Conshohocken, PA, USA, 2010.

- Günay, M.; Gündüz, S.; Yilmaz, H.; Yaşar, N.; Kaçar, R. PLA esaslı numunelerde çekme dayanımı için 3D baskı işlem parametrelerinin optimizasyonu. Politek. Derg. 2020, 23, 73–79. [Google Scholar] [CrossRef]

- Bilgin, M. Abs Esasli Numunelerin 3d Yazici İle Üretilmesinde İşlem Parametrelerinin Optimizasyonu. Int. J. 3d Print. Technol. Digit. Ind. 2022, 6, 236–249. [Google Scholar]

- Chacón, J.; Caminero, M.A.; García-Plaza, E.; Núnez, P.J. Additive manufacturing of PLA structures using fused deposition modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Ahmed, S.W.; Hussain, G.; Altaf, K.; Ali, S.; Alkahtani, M.; Abidi, M.H.; Alzabidi, A. On the effects of process parameters and optimization of interlaminate bond strength in 3D printed ABS/CF-PLA composite. Polymers 2020, 12, 2155. [Google Scholar] [CrossRef] [PubMed]

- Devuri, V.; Mahapatra, M.; Harsha, S.; Mandal, N. Effect of shoulder surface dimension and geometries on FSW of AA7039. J. Manuf. Sci. Prod. 2014, 14, 183–194. [Google Scholar] [CrossRef]

- Sun, T.; Reynolds, A.; Roy, M.; Withers, P.; Prangnell, P. The effect of shoulder coupling on the residual stress and hardness distribution in AA7050 friction stir butt welds. Mater. Sci. Eng. A 2018, 735, 218–227. [Google Scholar] [CrossRef]

- Sharma, N.; Siddiquee, A.N.; Khan, Z.A.; Mohammed, M.T. Material stirring during FSW of Al–Cu: Effect of pin profile. Mater. Manuf. Process. 2018, 33, 786–794. [Google Scholar] [CrossRef]

- Hynes, N.R.J.; Velu, P.S. Effect of rotational speed on Ti-6Al-4V-AA 6061 friction welded joints. J. Manuf. Process. 2018, 32, 288–297. [Google Scholar] [CrossRef]

- Buffa, G.; Baffari, D.; Campanella, D.; Fratini, L. An innovative friction stir welding based technique to produce dissimilar light alloys to thermoplastic matrix composite joints. Procedia Manuf. 2016, 5, 319–331. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Ahuja, I. Mechanical, thermal and micrographic investigations of friction stir welded: 3D printed melt flow compatible dissimilar thermoplastics. J. Manuf. Process. 2019, 38, 387–395. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Ahuja, I.; Fortunato, A. Thermo-mechanical investigations for the joining of thermoplastic composite structures via friction stir spot welding. Compos. Struct. 2020, 253, 112772. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Ahuja, I.S. Joining of 3D printed dissimilar thermoplastics with consumable tool through friction stir spot welding: A case study. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 91–96. [Google Scholar]

- Şık, A.; Ertürk, İ.; Önder, M. A Study Into Effects of Different Parameters on Mechanical Properties in Friction Stir Welding of AA 2024 Aluminium Alloy. Pamukkale Univ. J. Eng. Sci. 2010, 16, 139–147. [Google Scholar]

- ASTM D2240-15(2021); Standard Test Method for Rubber Property-Durometer Hardness. ASTM: West Conshohocken, PA, USA, 2000.

- Parmaksız, F.; Anaç, N.; Koçar, O.; Erdogan, B. Investigation of mechanical properties and thermal conductivity coefficients of 3D printer materials. Int. Adv. Res. Eng. J. 2023, 7, 146–156. [Google Scholar] [CrossRef]

- Hanon, M.M.; Dobos, J.; Zsidai, L. The influence of 3D printing process parameters on the mechanical performance of PLA polymer and its correlation with hardness. Procedia Manuf. 2021, 54, 244–249. [Google Scholar] [CrossRef]

- Li, B.; Shen, Y.; Hu, W. The study on defects in aluminum 2219-T6 thick butt friction stir welds with the application of multiple non-destructive testing methods. Mater. Des. 2011, 32, 2073–2084. [Google Scholar] [CrossRef]

- Rao, H.; Jordon, J.; Boorgu, S.; Kang, H.; Yuan, W.; Su, X. Influence of the key-hole on fatigue life in friction stir linear welded aluminum to magnesium. Int. J. Fatigue 2017, 105, 16–26. [Google Scholar] [CrossRef]

- Khan, N.Z.; Siddiquee, A.N.; Khan, Z.A.; Shihab, S.K. Investigations on tunneling and kissing bond defects in FSW joints for dissimilar aluminum alloys. J. Alloys Compd. 2015, 648, 360–367. [Google Scholar] [CrossRef]

- Kim, Y.; Fujii, H.; Tsumura, T.; Komazaki, T.; Nakata, K. Three defect types in friction stir welding of aluminum die casting alloy. Mater. Sci. Eng. A 2006, 415, 250–254. [Google Scholar] [CrossRef]

- Kim, J.-D.; Murugan, S.P.; Kim, J.W.; Chun, C.-K.; Kim, S.W.; Hong, J.-K.; Choi, S.-W.; Ji, C.; Kim, J.-U.; Park, Y.-D. α/β phase transformation and dynamic recrystallization induced microstructure development in fine-grained Ti-6Al-4V friction stir weld. Mater. Charact. 2021, 178, 111300. [Google Scholar] [CrossRef]

- Vijendra, B.; Sharma, A. Induction heated tool assisted friction-stir welding (i-FSW): A novel hybrid process for joining of thermoplastics. J. Manuf. Process. 2015, 20, 234–244. [Google Scholar] [CrossRef]

| Mechanical properties | PLA [22] | PLA Wood [23] |

|---|---|---|

| Diameter (mm) | 1.75 | 1.75 |

| Brand | Filameon | Filameon |

| Color | Black | Light Brown |

| Tensile strength (MPa) | 53 | 47 |

| Elongation at break (%) | 6 | - |

| Density (g/cm3) | 1.24 | 1.13 |

| Material | PLA | PLA Wood |

|---|---|---|

| Infill ratio (%) | 100 | 100 |

| Printing temperature (°C) | 205 | 220 |

| Build plate temperature (°C) | 60 | 65 |

| Print speed (mm/s) | 60 | 45 |

| Material | Material | FSW | Feed Rate (mm/min) | Rotational Speed (rpm) |

|---|---|---|---|---|

| PLA | PLA |  | 20 | 1750 |

| PLA Wood | PLA Wood |  | ||

| PLA | PLA Wood |  | 2000 | |

| Multi-material | Multi-material |  | ||

| 2250 | |||

|

| Exp. | Material | Material | Figural Representation | UTS (MPa) | FR (mm/min) | RS (rpm) | Welding Efficiency (%) | ||

|---|---|---|---|---|---|---|---|---|---|

| PLA | PLA Wood | MM | |||||||

| Ref. | PLA |  | 60.20 ± 1.95 | -- | -- | -- | -- | -- | |

| Ref. | PLA Wood |  | 39.12 ± 1.17 | -- | -- | -- | -- | -- | |

| Ref. | Multi-material |  | 51.71 ± 3.4 | -- | -- | -- | -- | -- | |

| 1 | PLA | PLA |  | 59.56 ± 2.40 | 20 | 1750 | 98.94 | -- | -- |

| 2 | PLA | PLA | 46.38 ± 4.60 | 20 | 2000 | 77.04 | -- | -- | |

| 3 | PLA | PLA | 48.18 ± 3.30 | 20 | 2250 | 80.03 | -- | -- | |

| 4 | PLA Wood | PLA Wood |  | 21.51 ± 0.10 | 20 | 1750 | -- | 54.98 | -- |

| 5 | PLA Wood | PLA Wood | 26.35 ± 4.40 | 20 | 2000 | -- | 67.36 | -- | |

| 6 | PLA Wood | PLA Wood | 26.99 ± 0.40 | 20 | 2250 | -- | 68.99 | -- | |

| 7 | PLA | PLA Wood |  | 32.79 ± 2.70 | 20 | 1750 | 54.47 | 83.82 | -- |

| 8 | PLA | PLA Wood | 18.88 ± 2.50 | 20 | 2000 | 31.36 | 48.26 | -- | |

| 9 | PLA | PLA Wood | 21.27 ± 2.40 | 20 | 2250 | 35.33 | 54.37 | -- | |

| 10 | Multiple | Multiple |  | 17.80 ± 1.80 | 20 | 1750 | -- | -- | 34.4 |

| 11 | Multiple | Multiple | 21.77 ± 1.30 | 20 | 2000 | -- | -- | 41.9 | |

| 12 | Multiple | Multiple | 20.07 ± 1.20 | 20 | 2250 | -- | -- | 38.8 | |

| 13 | Multiple | Multiple |  | 21.50 ± 1.40 | 20 | 1750 | -- | -- | 41.5 |

| 14 | Multiple | Multiple | 32.49 ± 2.20 | 20 | 2000 | -- | -- | 62.8 | |

| 15 | Multiple | Multiple | 31.05 ± 1.80 | 20 | 2250 | -- | -- | 60.0 | |

| 16 | Multiple | Multiple |  | 26.84 ± 4.10 | 20 | 1750 | -- | -- | 51.9 |

| 17 | Multiple | Multiple | 29.19 ± 2.90 | 20 | 2000 | -- | -- | 56.4 | |

| 18 | Multiple | Multiple | 38.43 ± 4.30 | 20 | 2250 | -- | -- | 74.3 | |

| Exp. | Material | Figural Representation | Load (N) | FR (mm/min) | RS (rpm) | Welding Efficiency (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| PLA | PLA Wood | MM 1 | MM2 | ||||||

| Ref. | PLA |  | 103.32 ± 2.5 | -- | -- | -- | -- | -- | -- |

| Ref. | PLA Wood |  | 61.45 ± 1.25 | -- | -- | -- | -- | -- | -- |

| Ref. | MM 1 |  | 75.81 ± 0.21 | -- | -- | -- | -- | -- | -- |

| Ref. | MM 2 |  | 81.41 ± 2.7 | -- | -- | -- | -- | -- | -- |

| 1 | PLA–PLA |  | 145.36 ± 5.3 | 20 | 1750 | 140.68 | -- | -- | -- |

| 2 | 125.51 ± 8.2 | 20 | 2000 | 121.47 | -- | -- | -- | ||

| 3 | 123.71 ± 0.7 | 20 | 2250 | 119.73 | -- | -- | -- | ||

| 4 | PLA Wood–PLA Wood |  | 34.54 ± 1.3 | 20 | 1750 | -- | 56.20 | -- | -- |

| 5 | 41.18 ± 6.0 | 20 | 2000 | -- | 67.01 | -- | -- | ||

| 6 | 47.27 ± 4.7 | 20 | 2250 | -- | 76.92 | -- | -- | ||

| 7 | PLA–PLA Wood |  | 54.93 ± 1.5 | 20 | 1750 | 53.16 | 89.38 | -- | -- |

| 8 | 62.99 ± 5.8 | 20 | 2000 | 60.96 | 102.5 | -- | -- | ||

| 9 | 58.85 ± 1.1 | 20 | 2250 | 56.95 | 95.76 | -- | -- | ||

| 10 | MM1–MM1 |  | 74.39 ± 7.9 | 20 | 1750 | -- | -- | 98.12 | -- |

| 11 | 59.25 ± 2.1 | 20 | 2000 | -- | -- | 78.15 | -- | ||

| 12 | 86.95 ± 1.0 | 20 | 2250 | -- | -- | 114.69 | -- | ||

| 13 | MM1–MM2 |  | 108.17 ± 2.5 | 20 | 1750 | -- | -- | 142.68 | 132.87 |

| 14 | 97.52 ± 4.6 | 20 | 2000 | -- | -- | 128.63 | 119.78 | ||

| 15 | 87.71 ± 0.4 | 20 | 2250 | -- | -- | 115.69 | 107.73 | ||

| 16 | MM2–MM2 |  | 101.71 ± 1.9 | 20 | 1750 | -- | -- | -- | 124.93 |

| 17 | 67.53 ± 0.4 | 20 | 2000 | -- | -- | -- | 82.95 | ||

| 18 | 60.98 ± 5.9 | 20 | 2250 | -- | -- | -- | 74.90 | ||

| Material Pair | Lowest Temperature (°C) | Highest Temperature (°C) | Temperature of Best Welding Strength (°C) | Temperature Difference (°C) |

|---|---|---|---|---|

| 194.30 (Exp. 3) | 205.44 (Exp. 2) | 201.87 (Exp. 1) | 11.14 |

| 174.44 (Exp. 4) | 187.38 (Exp. 6) | 187.38 (Exp. 6) | 12.94 |

| 171.60 (Exp. 8) | 194.16 (Exp. 9) | 187.36 (Exp. 7) | 22.56 |

| 188.72 (Exp. 10) | 196.12 (Exp. 11) | 196.12 (Exp. 11) | 7.40 |

| 200.88 (Exp. 13) | 205.76 (Exp. 14) | 205.76 (Exp. 14) | 4.88 |

| 194.30 (Exp. 16) | 202.85 (Exp. 18) | 202.85 (Exp. 18) | 8.55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Şahin, G.; Anaç, N.; Koçar, O. Investigation of the Weldability of 3D-Printed Multi-Material Materials (PLA and PLA Wood) Using Friction Stir Welding. Polymers 2024, 16, 3249. https://doi.org/10.3390/polym16233249

Şahin G, Anaç N, Koçar O. Investigation of the Weldability of 3D-Printed Multi-Material Materials (PLA and PLA Wood) Using Friction Stir Welding. Polymers. 2024; 16(23):3249. https://doi.org/10.3390/polym16233249

Chicago/Turabian StyleŞahin, Gökhan, Nergizhan Anaç, and Oğuz Koçar. 2024. "Investigation of the Weldability of 3D-Printed Multi-Material Materials (PLA and PLA Wood) Using Friction Stir Welding" Polymers 16, no. 23: 3249. https://doi.org/10.3390/polym16233249

APA StyleŞahin, G., Anaç, N., & Koçar, O. (2024). Investigation of the Weldability of 3D-Printed Multi-Material Materials (PLA and PLA Wood) Using Friction Stir Welding. Polymers, 16(23), 3249. https://doi.org/10.3390/polym16233249