Low-Velocity Impact Resistance and Compression After Impact Strength of Thermoplastic Nanofiber Toughened Carbon/Epoxy Composites with Different Layups

Abstract

1. Introduction

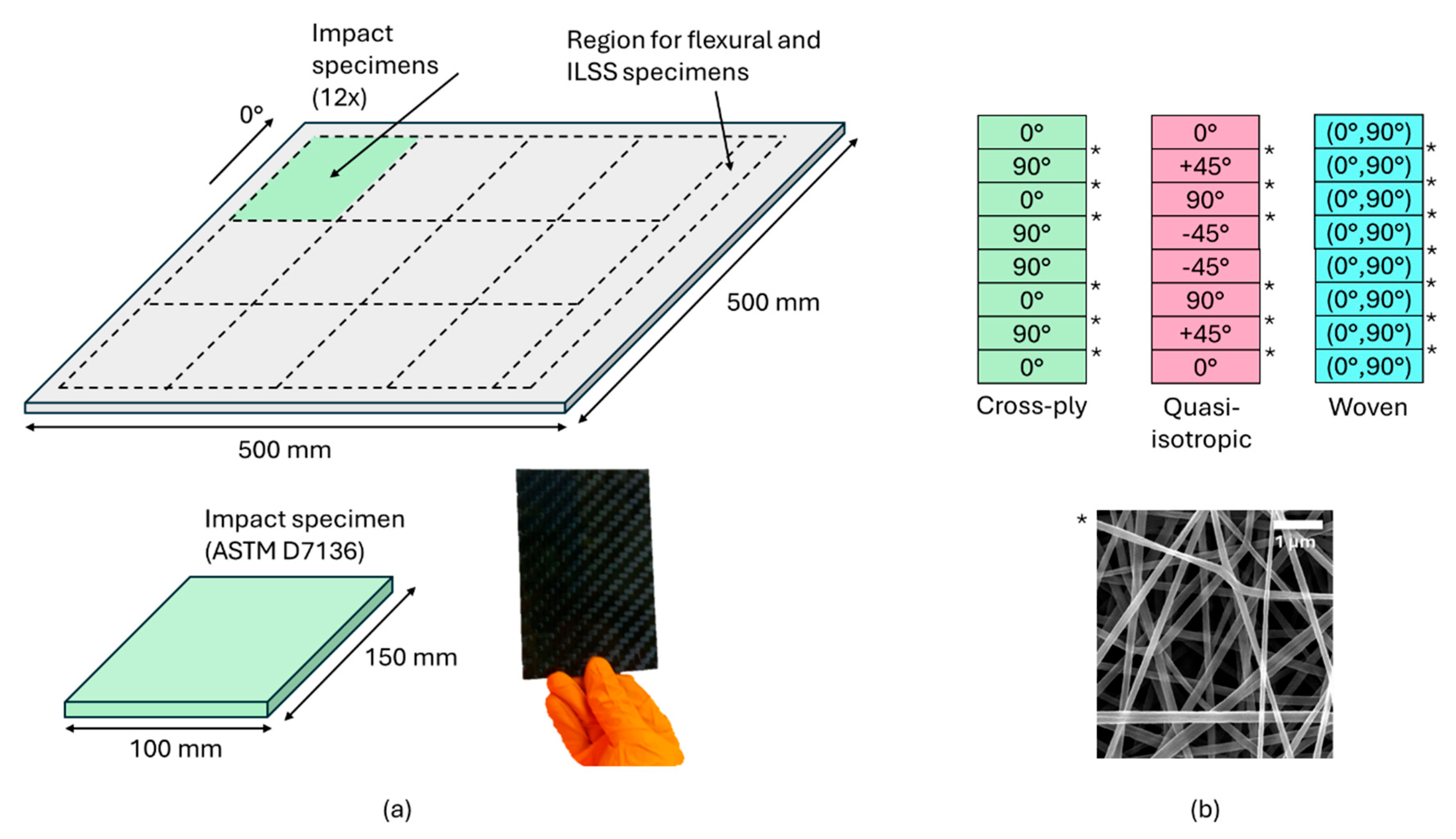

2. Materials and Methods

2.1. Nanofiber Interleave Production

2.2. Composites Production

2.3. Flexural and Interlaminar Shear Strength Testing

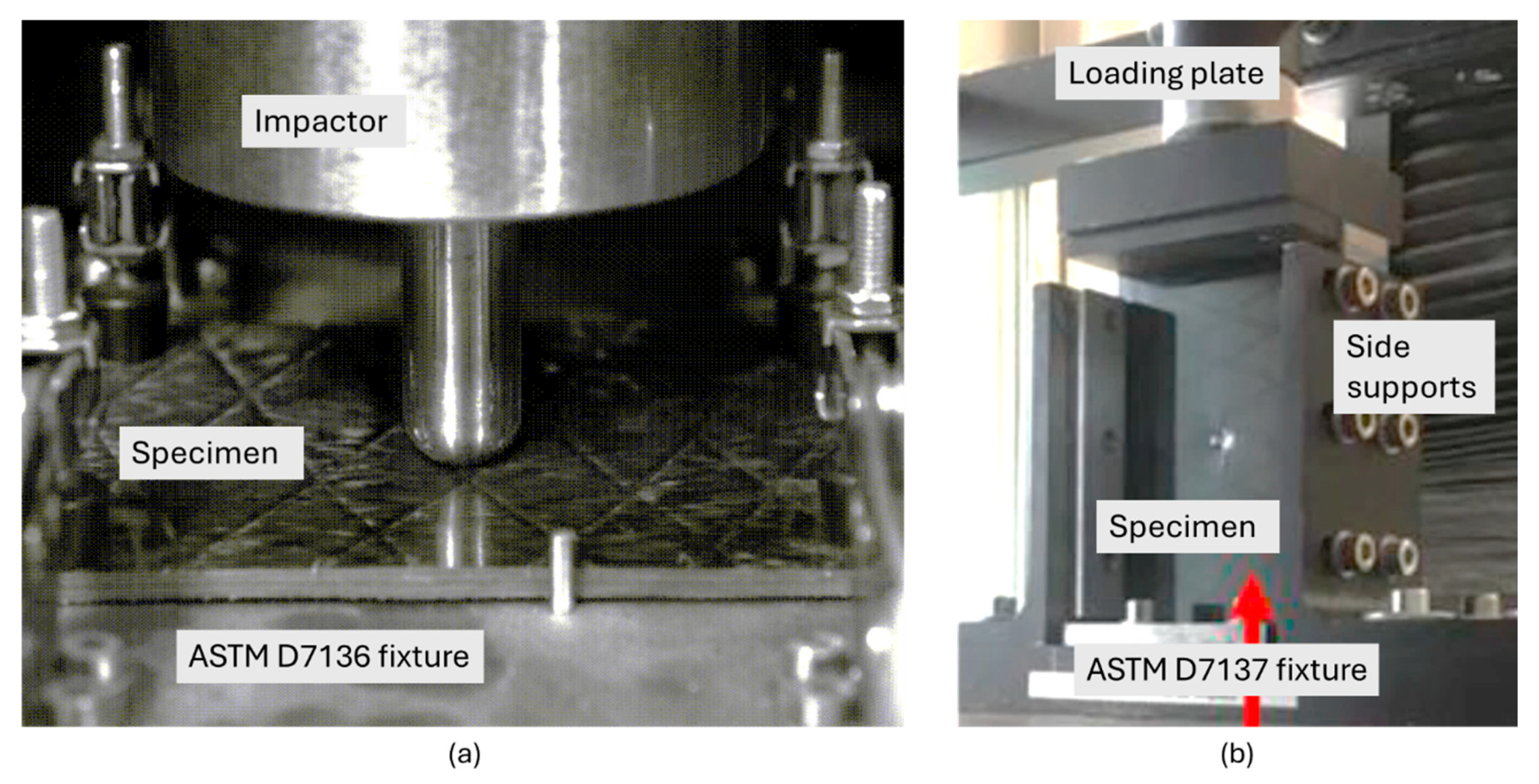

2.4. Low-Velocity Impact Testing

2.5. Compression After Impact Testing

3. Results and Discussion

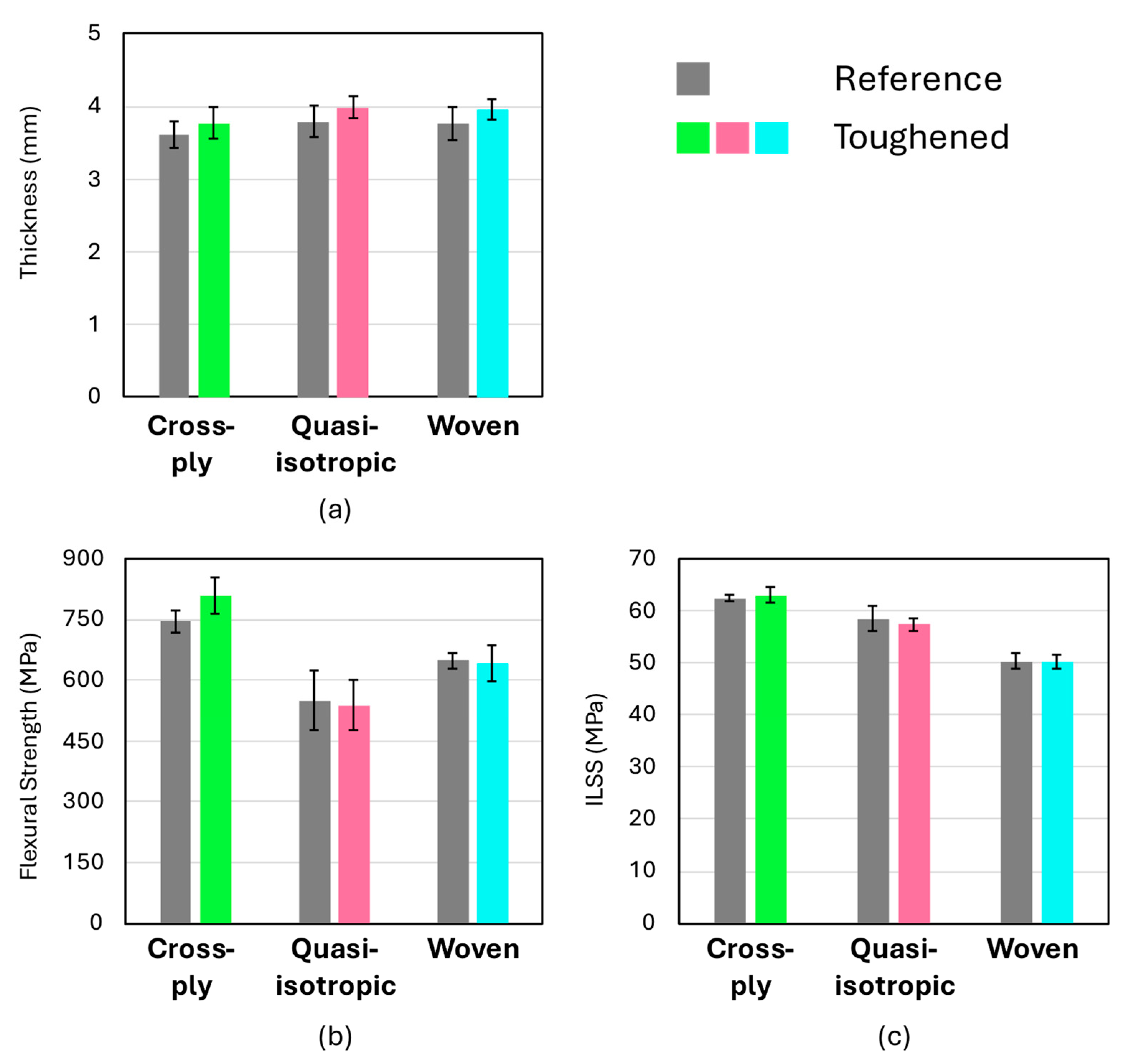

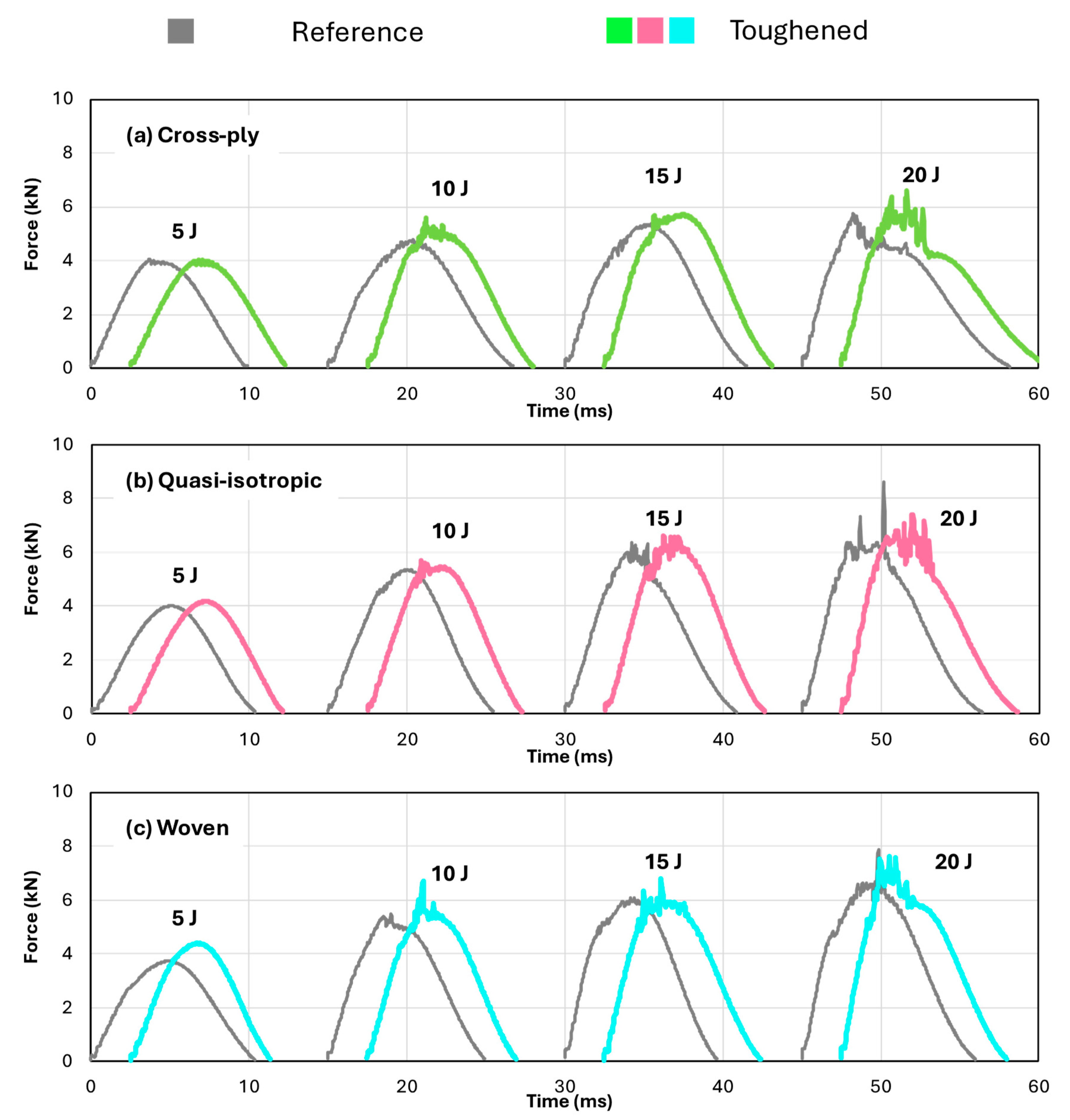

3.1. Laminate Quality and Low-Velocity Impact Response

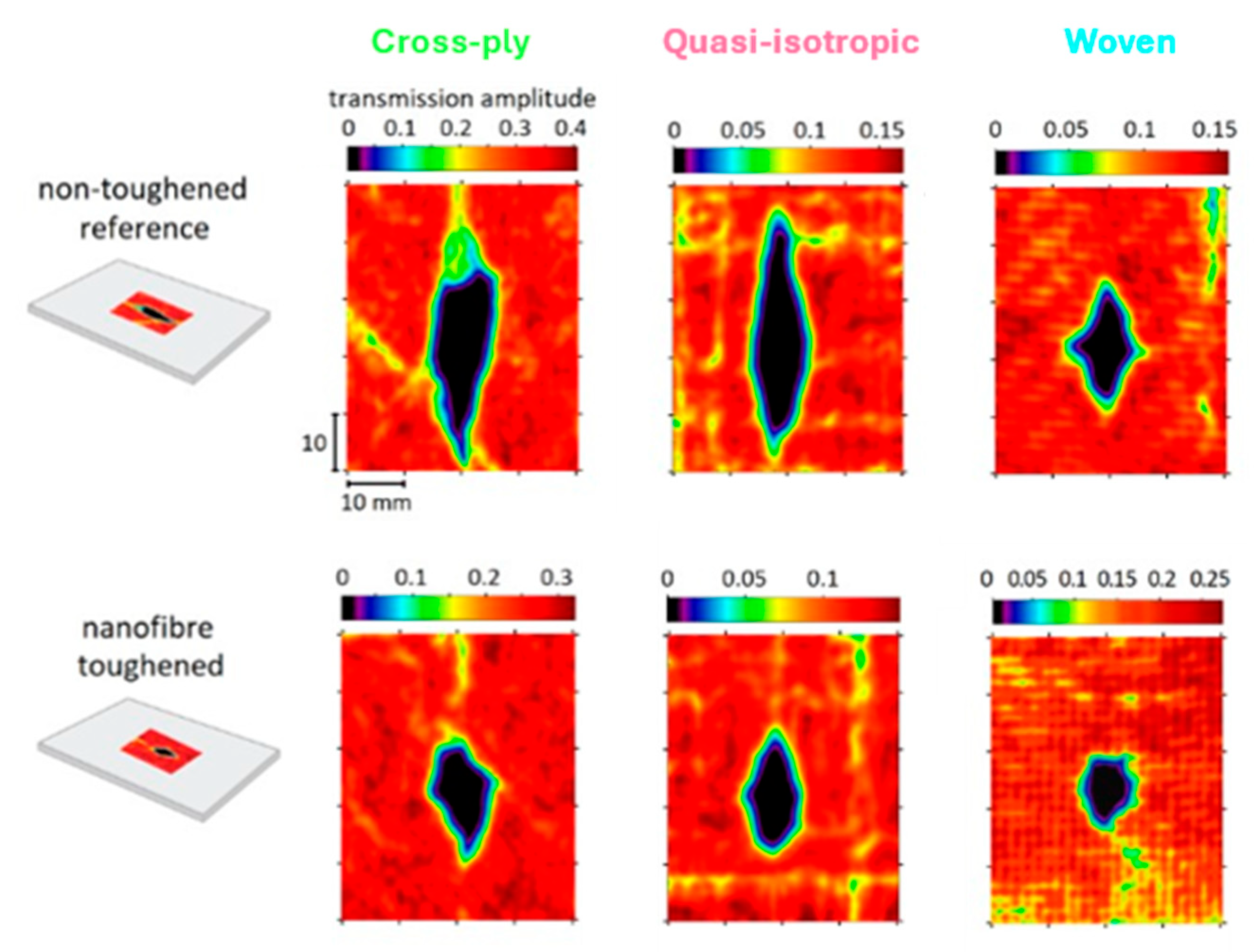

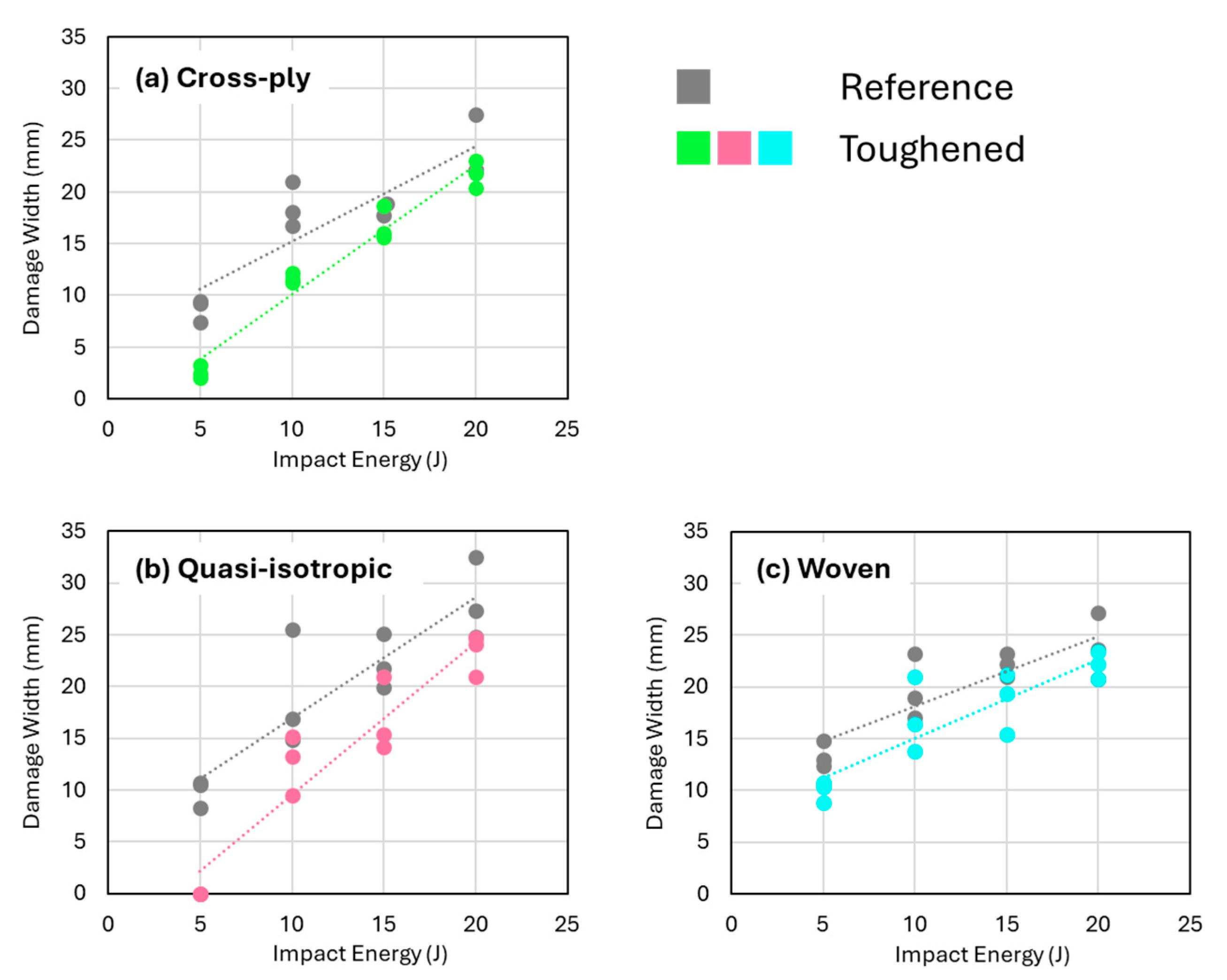

3.2. Damage Area in Toughened and Non-Toughened Specimens After Impact

3.3. Cross-Sectional Examination of Impacted Specimens

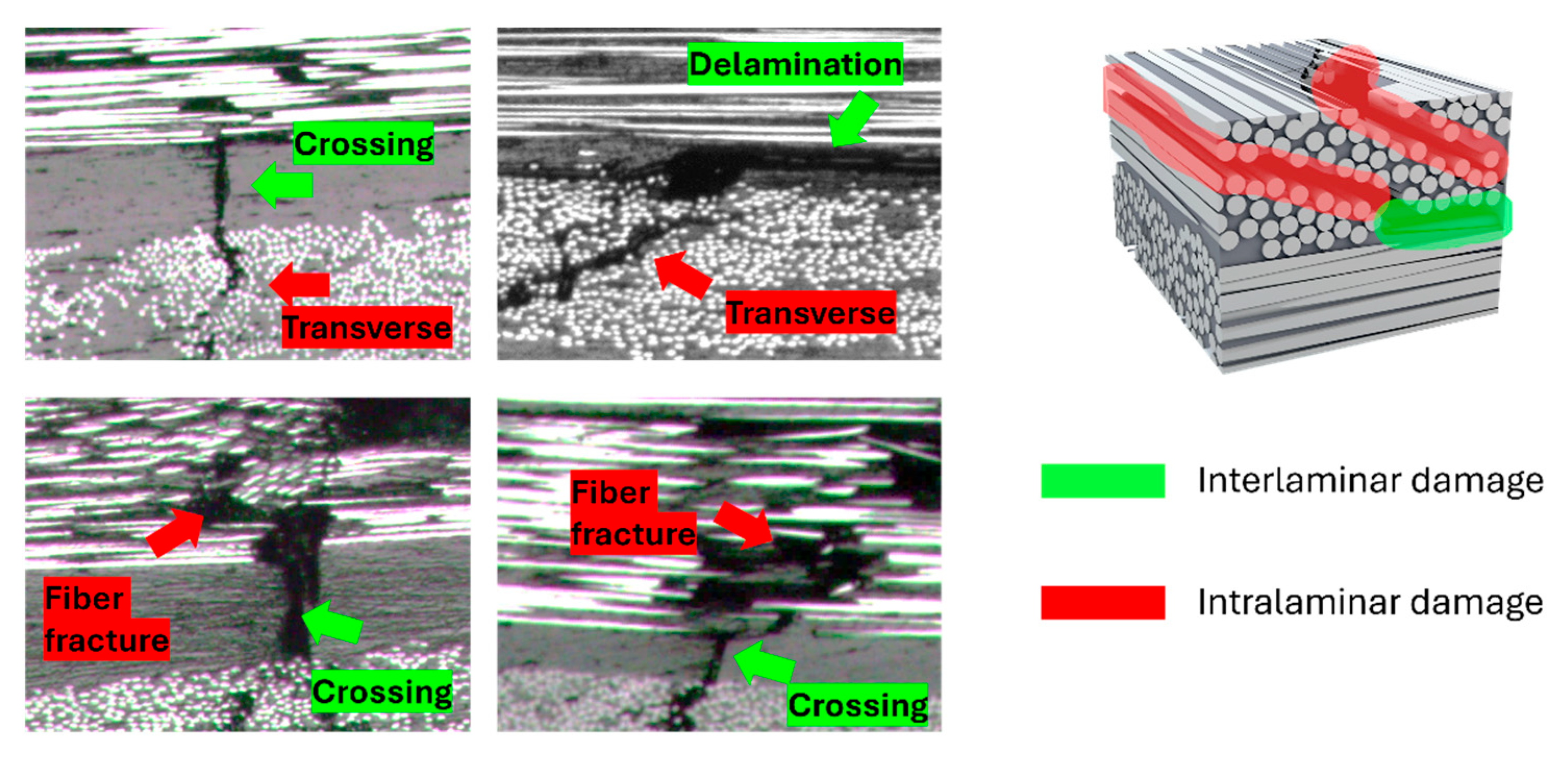

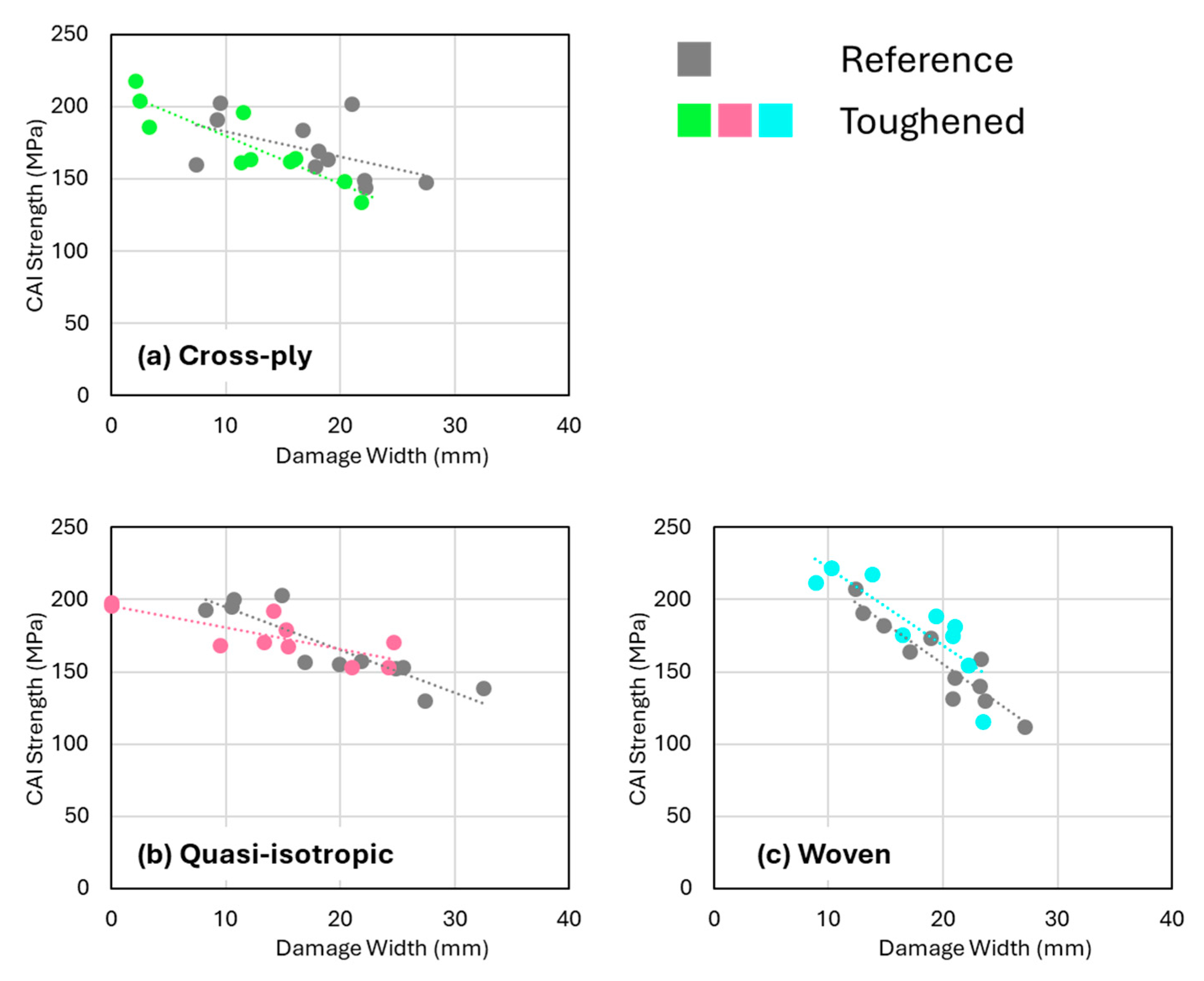

3.4. Compression After Impact Strength

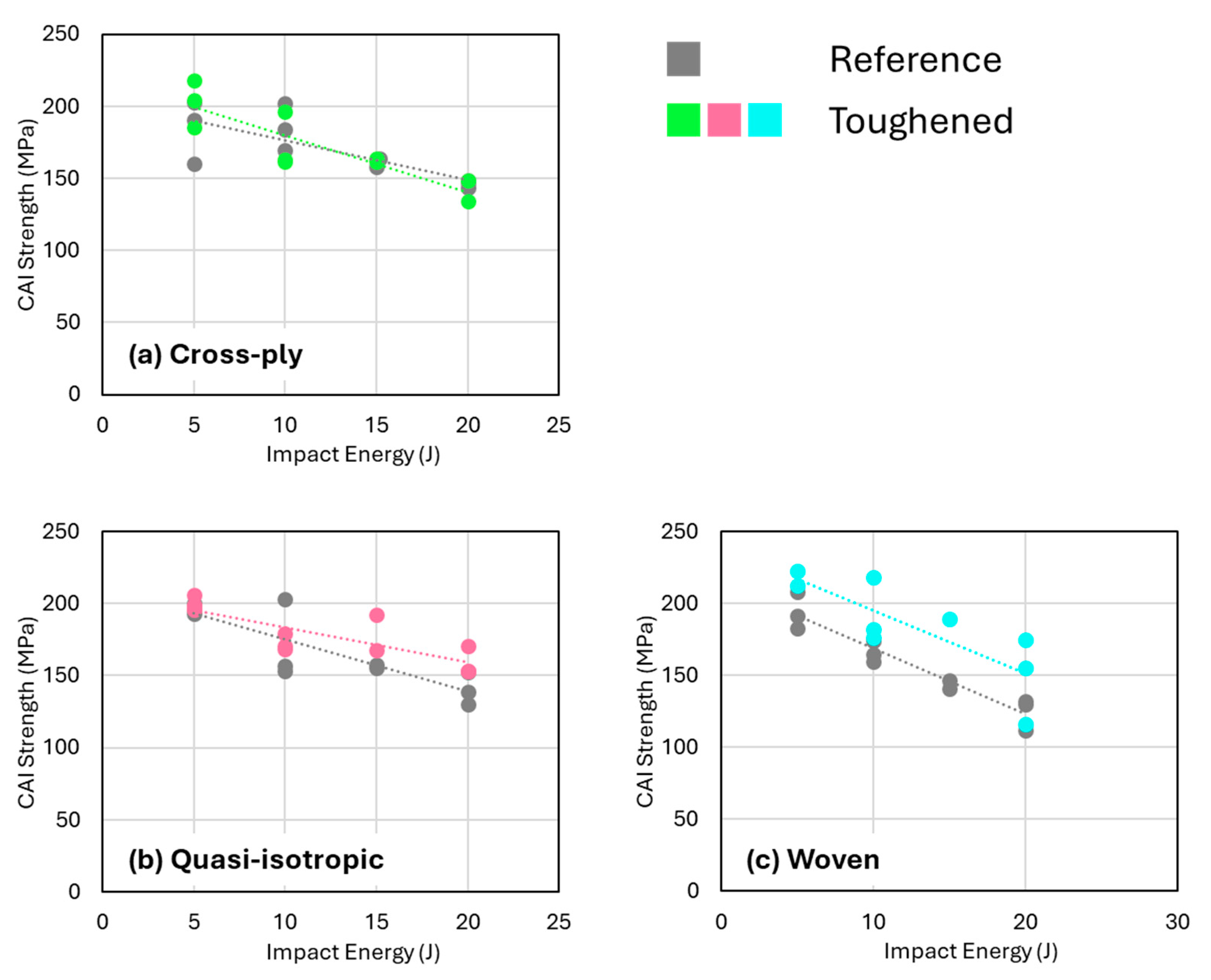

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Saghafi, H.; Fotouhi, M.; Minak, G. Improvement of the impact properties of composite laminates by means of nano-modification of the matrix-A review. Appl. Sci. 2018, 8, 2406. [Google Scholar] [CrossRef]

- Zhang, D.; Gu, Y.; Zhang, Z.; Jia, M.; Yue, S.; Li, G. Effect of off-axis angle on low-velocity impact and compression after impact damage mechanisms of 3D woven composites. Mater. Des. 2020, 192, 108672. [Google Scholar] [CrossRef]

- Di Benedetto, R.M.; Haque, B.Z.; Ali, M.A.; Tierney, J.; Heider, D. Energy absorption study considering crush test on carbon fiber/epoxy and carbon fiber/polyurethane structural composite beams. Compos. Struct. 2018, 203, 242–253. [Google Scholar] [CrossRef]

- Wronkowicz-Katunin, A.; Dragan, K. Evaluation of impact damage in composite structures using ultrasonic testing. Fatigue Aircr. Struct. 2018, 2018, 82–92. [Google Scholar] [CrossRef]

- Segers, J.; Hedayatrasa, S.; Verboven, E.; Poelman, G.; Van Paepegem, W.; Kersemans, M. In-plane local defect resonances for efficient vibrothermography of impacted carbon fiber-reinforced polymers (CFRP). NDT E Int. 2019, 102, 218–225. [Google Scholar] [CrossRef]

- Daelemans, L.; Cohades, A.; Meireman, T.; Beckx, J.; Spronk, S.; Kersemans, M.; De Baere, I.; Rahier, H.; Michaud, V.; Van Paepegem, W.; et al. Electrospun nanofibrous interleaves for improved low velocity impact resistance of glass fibre reinforced composite laminates. Mater. Des. 2018, 141, 170–184. [Google Scholar] [CrossRef]

- Liu, H.; Falzon, B.G.; Tan, W. Composites: Part A Predicting the Compression-After-Impact ( CAI ) strength of damage-tolerant hybrid unidirectional/woven carbon-fibre reinforced composite laminates. Compos. Part A 2018, 105, 189–202. [Google Scholar] [CrossRef]

- Fotouhi, S.; Clamp, J.; Bolouri, A.; Pozegic, T.R.; Fotouhi, M. Investigating polyethersulfone interleaved Glass/Carbon hybrid composite under impact and its comparison with GLARE. Compos. Struct. 2019, 226, 111268. [Google Scholar] [CrossRef]

- Neisiany, R.E.; Khorasani, S.N.; Lee, J.K.Y.; Naeimirad, M.; Ramakrishna, S. Interfacial toughening of carbon/epoxy composite by incorporating styrene acrylonitrile nanofibers. Theor. Appl. Fract. Mech. 2018, 95, 242–247. [Google Scholar] [CrossRef]

- Liu, H.; Falzon, B.G.; Li, S.; Tan, W.; Liu, J.; Chai, H.; Blackman, B.R.K.; Dear, J.P. Compressive failure of woven fabric reinforced thermoplastic composites with an open-hole: An experimental and numerical study. Compos. Struct. 2019, 213, 108–117. [Google Scholar] [CrossRef]

- Furtado, C.; Tavares, R.P.; Arteiro, A.; Xavier, J.; Linde, P.; Wardle, B.L.; Camanho, P.P. Effects of ply thickness and architecture on the strength of composite sub-structures. Compos. Struct. 2021, 256, 113061. [Google Scholar] [CrossRef]

- Goodarz, M.; Bahrami, S.H.; Sadighi, M.; Saber-Samandari, S. Low-velocity impact performance of nanofiber-interlayered aramid/epoxy nanocomposites. Compos. B Eng. 2019, 173, 106975. [Google Scholar] [CrossRef]

- Francesconi, L.; Aymerich, F. Effect of Z-pinning on the impact resistance of composite laminates with different layups. Compos. Part A Appl. Sci. Manuf. 2018, 114, 136–148. [Google Scholar] [CrossRef]

- Kallagunta, H.; Tate, J.S. Low-velocity impact behavior of glass fiber epoxy composites modified with nanoceramic particles. J. Compos. Mater. 2020, 54, 2217–2228. [Google Scholar] [CrossRef]

- Shakil, U.A.; Hassan, S.B.A.; Yahya, M.Y.; Nauman, S. Mechanical properties of electrospun nanofiber reinforced/interleaved epoxy matrix composites—A review. Polym. Compos. 2020, 41, 2288–2315. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; Bavasso, I.; Bracciale, M.P.; Sbardella, F.; Lampani, L.; Cicala, G. Effect of electrospun nanofibres and MWCNTs on the low velocity impact response of carbon fibre laminates. Compos. Struct. 2020, 234, 111776. [Google Scholar] [CrossRef]

- Goodarz, M.; Bahrami, H.; Sadighi, M.; Saber-Samandari, S. Quasi-static indentation response of aramid fiber/epoxy composites containing nylon 66 electrospun nano-interlayers. J. Ind. Text. 2018, 47, 960–977. [Google Scholar] [CrossRef]

- Saghafi, H.; Minak, G.; Zucchelli, A.; Brugo, T.M.; Heidary, H. Comparing various toughening mechanisms occurred in nanomodified laminates under impact loading. Compos. B Eng. 2019, 174, 106964. [Google Scholar] [CrossRef]

- Yademellat, H.; Nikbakht, A.; Saghafi, H.; Sadighi, M. Experimental and numerical investigation of low velocity impact on electrospun nanofiber modified composite laminates. Compos. Struct. 2018, 200, 507–514. [Google Scholar] [CrossRef]

- Saghafi, H.; Ghaffarian, S.R.; Salimi-Majd, D.; Saghafi, H.A. Investigation of interleaf sequence effects on impact delamination of nano-modified woven composite laminates using cohesive zone model. Compos. Struct. 2017, 166, 49–56. [Google Scholar] [CrossRef]

- Daelemans, L.; Van Der Heijden, S.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Damage-Resistant Composites Using Electrospun Nanofibers: A Multiscale Analysis of the Toughening Mechanisms. ACS Appl. Mater. Interfaces 2016, 8, 11806–11818. [Google Scholar] [CrossRef] [PubMed]

- Saghafi, H.; Palazzetti, R.; Heidary, H.; Brugo, T.M.; Zucchelli, A.; Minak, G. Toughening Behavior of Carbon/Epoxy Laminates Interleaved by PSF/PVDF Composite Nanofibers. Appl. Sci. 2020, 10, 5618. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Neisiany, R.E.; Razavi, M.; Fakhar, A.; Shanmugam, V.; Alagumalai, V.; Försth, M.; Sas, G.; Das, O. Efficient Improvement in Fracture Toughness of Laminated Composite by Interleaving Functionalized Nanofibers. Polymers 2021, 13, 2509. [Google Scholar] [CrossRef] [PubMed]

- Zhu, X.; Li, Y.; Yu, T.; Zhang, Z. Enhancement of the interlaminar fracture toughness and damping properties of carbon fiber reinforced composites using cellulose nanofiber interleaves. Compos. Commun. 2021, 28, 100940. [Google Scholar] [CrossRef]

- Song, X.; Gao, J.; Zheng, N.; Zhou, H.; Mai, Y.W. Interlaminar toughening in carbon fiber/epoxy composites interleaved with CNT-decorated polycaprolactone nanofibers. Compos. Commun. 2021, 24, 100622. [Google Scholar] [CrossRef]

- Vallack, N.; Sampson, W.W. Materials systems for interleave toughening in polymer composites. J. Mater. Sci. 2022, 57, 6129–6156. [Google Scholar] [CrossRef]

- Akangah, P.; Shivakumar, K. Assessment of Impact Damage Resistance and Tolerance of Polymer Nanofiber Interleaved Composite Laminates. J. Chem. Sci. Technol. 2013, 2, 39–52. [Google Scholar]

- Akangah, P.; Lingaiah, S.; Shivakumar, K. Effect of Nylon-66 nano-fiber interleaving on impact damage resistance of epoxy/carbon fiber composite laminates. Compos. Struct. 2010, 92, 1432–1439. [Google Scholar] [CrossRef]

- Palazzetti, R.; Zucchelli, A.; Trendafilova, I. The self-reinforcing effect of Nylon 6,6 nano-fibres on CFRP laminates subjected to low velocity impact. Compos. Struct. 2013, 106, 661–671. [Google Scholar] [CrossRef]

- Zarei, H.; Brugo, T.; Belcari, J.; Bisadi, H.; Minak, G.; Zucchelli, A. Low velocity impact damage assessment of GLARE fiber-metal laminates interleaved by Nylon 6,6 nanofiber mats. Compos. Struct. 2017, 167, 123–131. [Google Scholar] [CrossRef]

- Anand, A.; Kumar, N.; Harshe, R.; Joshi, M. Glass/epoxy structural composites with interleaved nylon 6/6 nanofibers. J. Compos. Mater. 2017, 51, 3291–3298. [Google Scholar] [CrossRef]

- Saghafi, H.; Brugo, T.; Minak, G.; Zucchelli, A. Improvement the impact damage resistance of composite materials by interleaving polycaprolactone nanofibers. Eng. Solid Mech. 2015, 3, 21–26. [Google Scholar] [CrossRef]

- Beylergil, B.; Tanoǧlu, M.; Aktaş, E. Modification of carbon fibre/epoxy composites by polyvinyl alcohol (PVA) based electrospun nanofibres. Adv. Compos. Lett. 2016, 25, 69–76. [Google Scholar] [CrossRef]

- Molnár, K.; Košt’áková, E.; Mészáros, L. The effect of needleless electrospun nanofibrous interleaves on mechanical properties of carbon fabrics/epoxy laminates. Express Polym. Lett. 2014, 8, 62–72. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hosur, M.; Hsiao, K.T.; Wallace, L.; Jeelani, S. Low velocity impact properties of carbon nanofibers integrated carbon fiber/epoxy hybrid composites manufactured by OOA-VBO process. Compos. Struct. 2015, 120, 32–40. [Google Scholar] [CrossRef]

- Liotier, P.J.; Alain, V.; Christine, D. Characterization of 3D morphology and microcracks in composites reinforced by multi-axial multi-ply stitched preforms. Compos. Part A Appl. Sci. Manuf. 2010, 41, 653–662. [Google Scholar] [CrossRef]

- Meireman, T.; Daelemans, L.; Van Verre, E.; Van Paepegem, W.; De Clerck, K. Nanofibre toughening of dissimilar interfaces in composites. Mater. Des. 2020, 195, 109050. [Google Scholar] [CrossRef]

- Meireman, T.; Daelemans, L.; Rijckaert, S.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Delamination resistant composites by interleaving bio-based long-chain polyamide nanofibers through optimal control of fiber diameter and fiber morphology. Compos. Sci. Technol. 2020, 193, 108126. [Google Scholar] [CrossRef]

- ASTM D7264M-21; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: Pennsylvania, PA, USA, 2021.

- ASTM D2344M-22; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM International: Pennsylvania, PA, USA, 2022.

- ASTM D7136M-20; Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event. ASTM International: Pennsylvania, PA, USA, 2020.

- ASTM D7137M-23; Standard Test Method for Compressive Residual Strength Properties of Damaged Polymer Matrix Composite Plates. ASTM International: Pennsylvania, PA, USA, 2023.

- van der Heijden, S.; Daelemans, L.; Meireman, T.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Interlaminar toughening of resin transfer molded laminates by electrospun polycaprolactone structures: Effect of the interleave morphology. Compos. Sci. Technol. 2016, 136, 10–17. [Google Scholar] [CrossRef]

- Xue, J.H.; Luo, Q.Z.; Han, F.; Liu, R.H. Two-dimensional analyses of delamination buckling of symmetrically cross-ply rectangular laminates. Appl. Math. Mech. (Engl. Ed.) 2013, 34, 597–612. [Google Scholar] [CrossRef]

- Aslan, Z.; Daricik, F. Effects of multiple delaminations on the compressive, tensile, flexural, and buckling behaviour of E-glass/epoxy composites. Compos. B Eng. 2016, 100, 186–196. [Google Scholar] [CrossRef]

- Wang, R.G.; Zhang, L.; Liu, W.B.; Zhang, J.; Sui, X.D.; Zheng, D.; Fang, Y.F. Numerical analysis of delamination behavior in laminated composite with double delaminations embedded in different depth positions. Polym. Polym. Compos. 2011, 19, 213–222. [Google Scholar] [CrossRef]

- Yang, F.; Xu, Z.; Zhang, L.; Jiao, W.; Liu, W.; Sui, X.; Zhang, J.; Wang, R. Prediction of delamination buckling and growth behavior in laminated composites with coexisting delaminations. Polym. Polym. Compos. 2014, 22, 299–308. [Google Scholar] [CrossRef]

- Damghani, M.; Kennedy, D.; Featherston, C. Critical buckling of delaminated composite plates using exact stiffness analysis. Comput. Struct. 2011, 89, 1286–1294. [Google Scholar] [CrossRef]

- Wysmulski, P.; Falkowicz, K.; Filipek, P. Buckling state analysis of compressed composite plates with cut-out. Compos. Struct. 2021, 274, 114345. [Google Scholar] [CrossRef]

- Wysmulski, P.; Debski, H. Stability Analysis of Composite Columns under Eccentric Load. Appl. Compos. Mater. 2019, 26, 683–692. [Google Scholar] [CrossRef]

- Li, D.; Tang, G.; Zhou, J.; Lei, Y. Buckling analysis of a plate with built-in rectangular delamination by strip distributed transfer function method. Acta Mech. 2005, 176, 231–243. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meireman, T.; Verboven, E.; Kersemans, M.; Van Paepegem, W.; De Clerck, K.; Daelemans, L. Low-Velocity Impact Resistance and Compression After Impact Strength of Thermoplastic Nanofiber Toughened Carbon/Epoxy Composites with Different Layups. Polymers 2024, 16, 3060. https://doi.org/10.3390/polym16213060

Meireman T, Verboven E, Kersemans M, Van Paepegem W, De Clerck K, Daelemans L. Low-Velocity Impact Resistance and Compression After Impact Strength of Thermoplastic Nanofiber Toughened Carbon/Epoxy Composites with Different Layups. Polymers. 2024; 16(21):3060. https://doi.org/10.3390/polym16213060

Chicago/Turabian StyleMeireman, Timo, Erik Verboven, Mathias Kersemans, Wim Van Paepegem, Karen De Clerck, and Lode Daelemans. 2024. "Low-Velocity Impact Resistance and Compression After Impact Strength of Thermoplastic Nanofiber Toughened Carbon/Epoxy Composites with Different Layups" Polymers 16, no. 21: 3060. https://doi.org/10.3390/polym16213060

APA StyleMeireman, T., Verboven, E., Kersemans, M., Van Paepegem, W., De Clerck, K., & Daelemans, L. (2024). Low-Velocity Impact Resistance and Compression After Impact Strength of Thermoplastic Nanofiber Toughened Carbon/Epoxy Composites with Different Layups. Polymers, 16(21), 3060. https://doi.org/10.3390/polym16213060