The Role of Lanthanum Stearate on Strain-Induced Crystallization and the Mechanical Properties of Whole Field Latex Rubber

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Samples

2.3. Methods

3. Results and Discussion

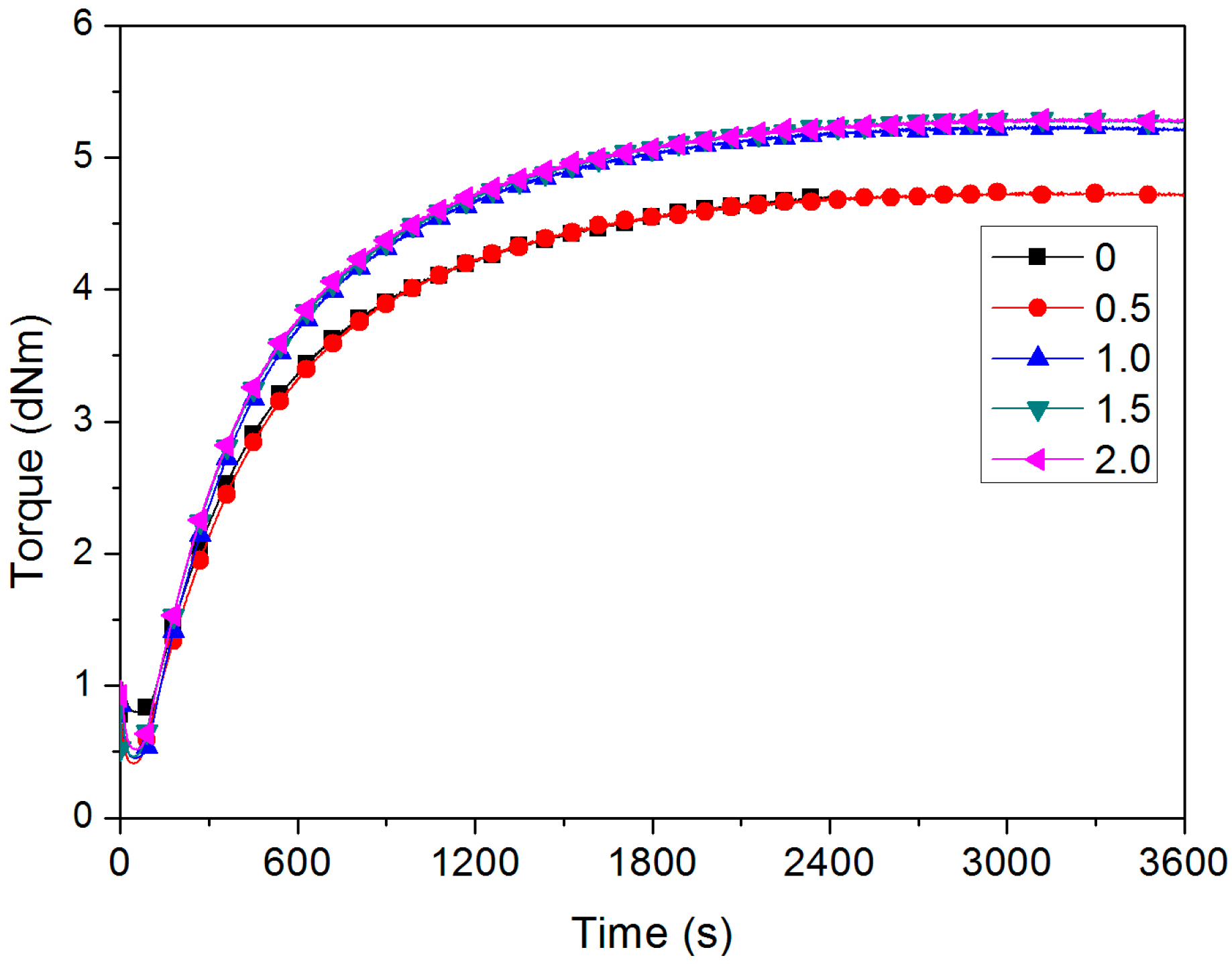

3.1. Cure Characteristics of SCR-WF with Different LaSt Loadings

3.2. Crosslink Density Measurements of SCR-WF with Different LaSt Loadings

3.3. Mechanical Properties of Vulcanized SCR-WF with Different LaSt Loadings

3.4. Strain-Induced Crystallization of Vulcanized SCR-WF with 2 phr LaSt and without LaSt

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, J.; Tang, Z.; Huang, J.; Guo, B.C.; Huang, G.S. Promoted strain-induced-crystallization in synthetic cis-1, 4-polyisoprene via constructing sacrificial bonds. Polymer 2016, 97, 580–588. [Google Scholar] [CrossRef]

- Ikeda, Y.; Yasuda, Y.; Makino, S.; Yamamoto, S.; Tosaka, M.; Senoo, K.; Kohjiya, S. Strain-induced crystallization of peroxide-crosslinked natural rubber. Polymer 2007, 48, 1171–1175. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Liao, L.; Wang, R.; Yu, H.P.; Zheng, T.; Lian, Y.; Luo, M.C.; Liao, S.Q.; Liu, H.C.; Peng, Z. Research of strain induced crystallization and tensile properties of vulcanized natural rubber based on crosslink densities. Ind. Crop. Prod. 2023, 2, 117070. [Google Scholar] [CrossRef]

- Kitamura, Y.; Okada, K.; Masunaga, H.; Hikosaka, M. Role of strain rate in the strain-induced crystallization (SIC) of natural and synthetic isoprene rubber. Polym. J. 2019, 51, 221–226. [Google Scholar] [CrossRef]

- Katz, J.R. Röntgenspektrographische Untersuchungen am gedehnten Kautschuk und ihre mögliche Bedeutung für das Problem der Dehnungseigenschaften dieser Substanz. Naturwissenschaften 1925, 13, 410–416. [Google Scholar] [CrossRef]

- Healey, A.M.; Hendra, P.J.; West, Y.D. A Fourier-transform Raman study of the strain-induced crystallization and cold crystallization of natural rubber. Polymer 1996, 37, 4009–4024. [Google Scholar] [CrossRef]

- Tanaka, Y. Structural characterization of natural polyisoprenes: Solve the mystery of natural rubber based on structural study. Rubber Chem. Technol. 2001, 74, 355–375. [Google Scholar] [CrossRef]

- Rault, J.; Marchal, J.; Judeinstein, P.; Albouy, P.A. Chain orientation in natural rubber, Part II: 2H-NMR study. Eur. Phys. J. E Soft Matter 2006, 21, 243–261. [Google Scholar] [CrossRef]

- Bekkedahl, N.; Wood, L.A. Crystallization of vulcanized rubber. Ind. Eng. Chem. 1941, 33, 381–384. [Google Scholar] [CrossRef]

- Cam, J.-B.L. A review of volume changes in rubbers: The effect of stretching. Rubber Chem. Technol. 2010, 83, 247–269. [Google Scholar] [CrossRef]

- Tosaka, M.; Kohjiya, S.; Ikeda, Y.; Toki, S.; Hsiao, B.S. Molecular orientation and stress relaxation during strain-induced crystallization of vulcanized natural rubber. Polymer 2010, 42, 474–481. [Google Scholar] [CrossRef]

- Trabelsi, S.; Albouy, P.-A.; Rault, J. Crystallization and melting processes in vulcanized stretched natural rubber. Macromolecules 2003, 36, 7624–7639. [Google Scholar] [CrossRef]

- Candau, N.; Chazeau, L.; Chenal, J.-M.; Gauthier, C.; Ferreira, J.; Munch, E. Strain induced crystallization and melting of natural rubber during dynamic cycles. Phys. Chem. Chem. Phys. 2015, 17, 15331–15338. [Google Scholar] [CrossRef] [PubMed]

- Toki, S.; Che, J.; Rong, L.; Hsiao, B.S.; Amnuaypornsri, S.; Nimpaiboon, A.; Sakdapipanich, J. Entanglements and networks to strain-induced crystallization and stress–strain relations in natural rubber and synthetic polyisoprene at various temperatures. Macromolecules 2013, 46, 5238–5248. [Google Scholar] [CrossRef]

- Candau, N.; Chazeau, L.; Chenal, J.M.; Gauthier, C.; Munch, E. A comparison of the abilities of natural rubber (NR) and synthetic polyisoprene cis-1,4 rubber (IR) to crystallize under strain at high strain rates. Phys. Chem. Chem. Phys. 2016, 18, 3472–3481. [Google Scholar] [CrossRef]

- Yang, C.J.; Luo, Y.Y.; Peng, Z.; Xu, K.; Zhong, J. Comparison effects of lanthanum stearate and antioxidants in epoxidized natural rubber. J. Rare Earths 2015, 33, 1236–1240. [Google Scholar] [CrossRef]

- Qiu, G.M.; Zhou, L.X.; Zhang, M.; Nakakita, S.; Inoue, S.; Okamoto, H. Thermal oxidation resistance of rare earth containing composite Elastomer. J. Chin. Soc. Rare Earths 2001, 19, 192–197. (In Chinese) [Google Scholar]

- Qiu, G.M.; Zhou, L.X.; Zhang, M. Preparation and mechanical performance of rare earth- containing composite elastomer. J. Rare Earths 2001, 19, 260–265. [Google Scholar]

- Xie, C.; Jia, Z.X.; Jia, D.M.; Luo, Y.F.; You, C.J. The effect of Dy(III) complex with 2-mercaptobenzimidazole on the thermo-oxidation aging behavior of natural rubber vulcanizates. Int. J. Polym. Mater. 2010, 59, 663–679. [Google Scholar] [CrossRef]

- Zheng, W.; Liu, L.; Zhao, X.; He, J.; Wang, A.; Chan, T.W.; Wu, S.Z. Effects of lanthanum complex on the thermo-oxidative aging of natural rubber. Polym. Degrad. Stabil. 2015, 120, 377–383. [Google Scholar] [CrossRef]

- Fang, L.; Song, Y.; Zhu, X.; Zheng, Q. Influence of lanthanum stearate as a co-stabilizer on stabilization efficiency of calcium/zinc stabilizers to polyvinyl chloride. Polym. Degrad. Stabil. 2009, 94, 845–850. [Google Scholar] [CrossRef]

- Luo, Y.Y.; Yang, C.J.; Wang, Y.Q.; He, C.Z.; Zhong, J.P.; Liao, S.Q.; Peng, Z.; Liu, X.X. Effect of neodymium stearate on cure and mechanical properties of epoxidized natural rubber. J. Rare Earth 2012, 30, 721–724. [Google Scholar] [CrossRef]

- Luo, Y.Y.; Yang, C.J.; Chen, B.Q.; Xu, K.; Zhong, J.P.; Peng, Z.; Lü, Z.; Wang, Q.H. Thermal degradation of epoxidized natural rubber in presence of neodymium stearate. J. Rare Earths 2013, 31, 526–530. [Google Scholar] [CrossRef]

- Bin Othman, A.; Chan, B.L. Effect of pH coagulation and sulphuric acid as a coagulant on natural rubber properties. J. Rubber Res. Inst. Malays. 1980, 28, 109–118. [Google Scholar]

- Chukwu, M.N.; Idiagha, J.A.; Ihuezor, M.O. Effect of acid coagulation level on the plasticity retention index (PRI) of natural rubber. Multidiscip. J. Res. Dev. 2010, 15, 1–4. [Google Scholar]

- Ng, J.W.; Othman, N.; Yusof, N.H. Various coagulation techniques and their impacts towards the properties of natural rubber latex from Hevea brasiliensis—A comprehensive review related to type application. Ind. Crops Prod. 2022, 181, 114835. [Google Scholar] [CrossRef]

- Li, S.D.; Chen, J.; Li, L.F.; Wang, Z.F.; Zhong, J.P.; Yang, L. Vulcanization characteristics of natural rubber coagulated by microorganisms. Rubber Chem. Technol. 2018, 91, 64–78. [Google Scholar] [CrossRef]

- ASTM D2084-01; Standard Test Method for Rubber Property—Vulcanization Using Oscillating Disk Cure Meter. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D412-06; Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers-Tension. ASTM International: West Conshohocken, PA, USA, 2017.

- Greensmith, H.W. Rupture of rubber. X. The change in stored energy on making a small cut in a test piece held in simple extension. J. Appl. Polym. Sci. 1963, 7, 993–1002. [Google Scholar] [CrossRef]

- Ellis, B.; Welding, G. Estimation, from swelling, of the structural contribution of chemical reactions to the vulcanization of natural rubber. Part II. Estimation of equilibrium degree of swelling. Rubber Chem. Technol. 1964, 37, 571–575. [Google Scholar] [CrossRef]

- Albouy, P.-A.; Guillier, G.; Petermann, D.; Vieyres, A.; Sanseau, O.; Sotta, P. A stroboscopic X-ray apparatus for the study of the kinetics of strain-induced crystallization in natural rubber. Polymer 2012, 53, 3313–3324. [Google Scholar] [CrossRef]

- Albouy, P.-A.; Vieyres, A.; Pérez-Aparicio, R.; Sanséau, O.; Sotta, P. The impact of strain-induced crystallization on strain during mechanical cycling of cross-linked natural rubber. Polymer 2014, 55, 4022–4031. [Google Scholar] [CrossRef]

- Mitchell, G. A wide-angle X-ray study of the development of molecular orientation in crosslinked natural rubber. Polymer 1984, 25, 1562–1572. [Google Scholar] [CrossRef]

- Ismail, H.; Poh, B.T. Cure and tear properties of ENR 25/SMR L and ENR 50/SMR L blends. Eur. Polym. J. 2000, 36, 2403–2408. [Google Scholar] [CrossRef]

- Tarachiwin, L.; Sakdapipanich, J.; Ute, K.; Kitayama, T.; Bamba, T.; Fukusaki, E.; Kobayashi, A.; Tanaka, Y. Structural characterization of α-terminal group of natural rubber. 1. Decomposition of branch-points by lipase and phosphatase treatments. Biomacromolecules 2005, 6, 1851–1857. [Google Scholar] [CrossRef]

- Huang, Y.; King, D.R.; Sun, T.L.; Nonoyama, T.; Kurokawa, T.; Nakajima, T.; Gong, J.P. Energy-dissipative matrices enable synergistic toughening in fiber reinforced soft composites. Adv. Funct. Mater. 2017, 27, 1605350–1605359. [Google Scholar] [CrossRef]

- Zhang, X.; Niu, K.J.; Song, W.X.; Yan, S.K.; Zhao, X.Y.; Lu, Y.L.; Zhang, L.Q. The effect of epoxidation on strain-induced crystallization of epoxidized natural rubber. Macromol. Rapid. Comm. 2019, 40, 1900042. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, J.; Xu, Z.Q.; Yue, D.M.; Wu, S.Z.; Yan, S.K.; Lu, Y.L.; Zhang, L.Q. Comparative study on the molecular chain orientation and strain-induced crystallization behaviors of HNBR with different acrylonitrile content under uniaxial stretching. Polymer 2021, 219, 123520. [Google Scholar] [CrossRef]

- Imbernon, L.; Pauchet, R.; Pire, M.; Albouy, P.-A.; Tencé-Girault, S.; Norvez, S. Strain-induced crystallization in sustainably crosslinked epoxidized natural rubber. Polymer 2016, 3, 189–197. [Google Scholar] [CrossRef]

- Tosaka, M.; Murakami, S.; Poompradub, S.; Kohjiya, S.; Ikeda, Y.; Toki, S.; Sics, I.; Hsiao, B.S. Orientation and crystallization of natural rubber network as revealed by WAXD using synchrotron radiation. Macromolecules 2004, 37, 3299–3309. [Google Scholar] [CrossRef]

- Fu, X.; Huang, G.; Xie, Z.; Xing, W. New insights into reinforcement mechanism of nanoclay-filled isoprene rubber during uniaxial deformation by in situ synchrotron X-ray diffraction. RSC Adv. 2015, 5, 25171–25182. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, L.; Chen, X.; Wang, Y.; Zhao, F.; Luo, M.; Liao, S. The role of non-rubber components on molecular network of natural rubber during accelerated storage. Polymers 2020, 12, 2880. [Google Scholar] [CrossRef]

- Heinrich, G.; Vilgis, T. Contribution of entanglements to the mechanical properties of carbon black-filled polymer networks. Macromolecules 1993, 26, 1109–1119. [Google Scholar] [CrossRef]

- Nie, Y.; Huang, G.; Qu, L.; Wang, X.; Weng, G.; Wu, J. New insights into thermodynamic description of strain-induced crystallization of peroxide cross-linked natural rubber filled with clay by tube model. Polymer 2011, 52, 3234–3242. [Google Scholar] [CrossRef]

| LaSt Loading | 0 | 0.5 | 1.0 | 1.5 | 2 |

|---|---|---|---|---|---|

| ML (dNm) | 0.801 | 0.409 | 0.451 | 0.461 | 0.515 |

| MH (dNm) | 4.706 | 4.741 | 5.242 | 5.297 | 5.299 |

| MH − ML (dNm) | 3.905 | 4.332 | 4.791 | 4.836 | 4.784 |

| TS1 (min) | 3.84 | 3.13 | 3.05 | 2.87 | 2.95 |

| T90 (min) | 22.03 | 21.67 | 21.77 | 22.07 | 21.97 |

| CRI | 5.49 | 5.39 | 5.34 | 5.20 | 5.25 |

| LaSt Loading | 0 | 0.5 | 1.0 | 1.5 | 2 |

|---|---|---|---|---|---|

| Swelling rate | 5.73 ± 0.04 | 5.57 ± 0.01 | 5.54 ± 0.04 | 5.38 ± 0.01 | 5.25 ± 0.03 |

| Crosslink density (×10−5 mol·cm−3) | 10.56 ± 0.17 | 11.25 ± 0.05 | 11.44 ± 0.18 | 12.18 ± 0.06 | 12.90 ± 0.16 |

| LaSt Loading | 0 | 0.5 | 1.0 | 1.5 | 2 |

|---|---|---|---|---|---|

| Tensile strength (MPa) | 18.12 ± 0.85 | 18.98 ± 1.18 | 20.61 ± 1.04 | 22.78 ± 1.04 | 23.01 ± 0.36 |

| Elongation at break (%) | 813 ± 20 | 805 ± 14 | 797 ± 14 | 816 ± 16 | 809 ± 25 |

| Modulus (100%) (MPa) | 0.51 ± 0.03 | 0.52 ± 0.02 | 0.55 ± 0.03 | 0.58 ± 0.03 | 0.59 ± 0.04 |

| Modulus (300%) (MPa) | 1.24 ± 0.04 | 1.24 ± 0.01 | 1.33 ± 0.03 | 1.38 ± 0.04 | 1.40 ± 0.03 |

| Modulus (500%) (MPa) | 2.84 ± 0.17 | 2.97 ± 0.03 | 3.32 ± 0.12 | 3.39 ± 0.21 | 3.44 ± 0.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Luo, Y.; Li, Z.; Wei, C.; Liao, S. The Role of Lanthanum Stearate on Strain-Induced Crystallization and the Mechanical Properties of Whole Field Latex Rubber. Polymers 2024, 16, 276. https://doi.org/10.3390/polym16020276

Yang C, Luo Y, Li Z, Wei C, Liao S. The Role of Lanthanum Stearate on Strain-Induced Crystallization and the Mechanical Properties of Whole Field Latex Rubber. Polymers. 2024; 16(2):276. https://doi.org/10.3390/polym16020276

Chicago/Turabian StyleYang, Changjin, Yuhang Luo, Zechun Li, Chuanyu Wei, and Shuangquan Liao. 2024. "The Role of Lanthanum Stearate on Strain-Induced Crystallization and the Mechanical Properties of Whole Field Latex Rubber" Polymers 16, no. 2: 276. https://doi.org/10.3390/polym16020276

APA StyleYang, C., Luo, Y., Li, Z., Wei, C., & Liao, S. (2024). The Role of Lanthanum Stearate on Strain-Induced Crystallization and the Mechanical Properties of Whole Field Latex Rubber. Polymers, 16(2), 276. https://doi.org/10.3390/polym16020276