Sustainable Thermoplastic Material Selection for Hybrid Vehicle Battery Packs in the Automotive Industry: A Comparative Multi-Criteria Decision-Making Approach

Abstract

1. Introduction

2. Literature Review

3. Material and Methods

3.1. Material Alternatives

3.2. Criteria

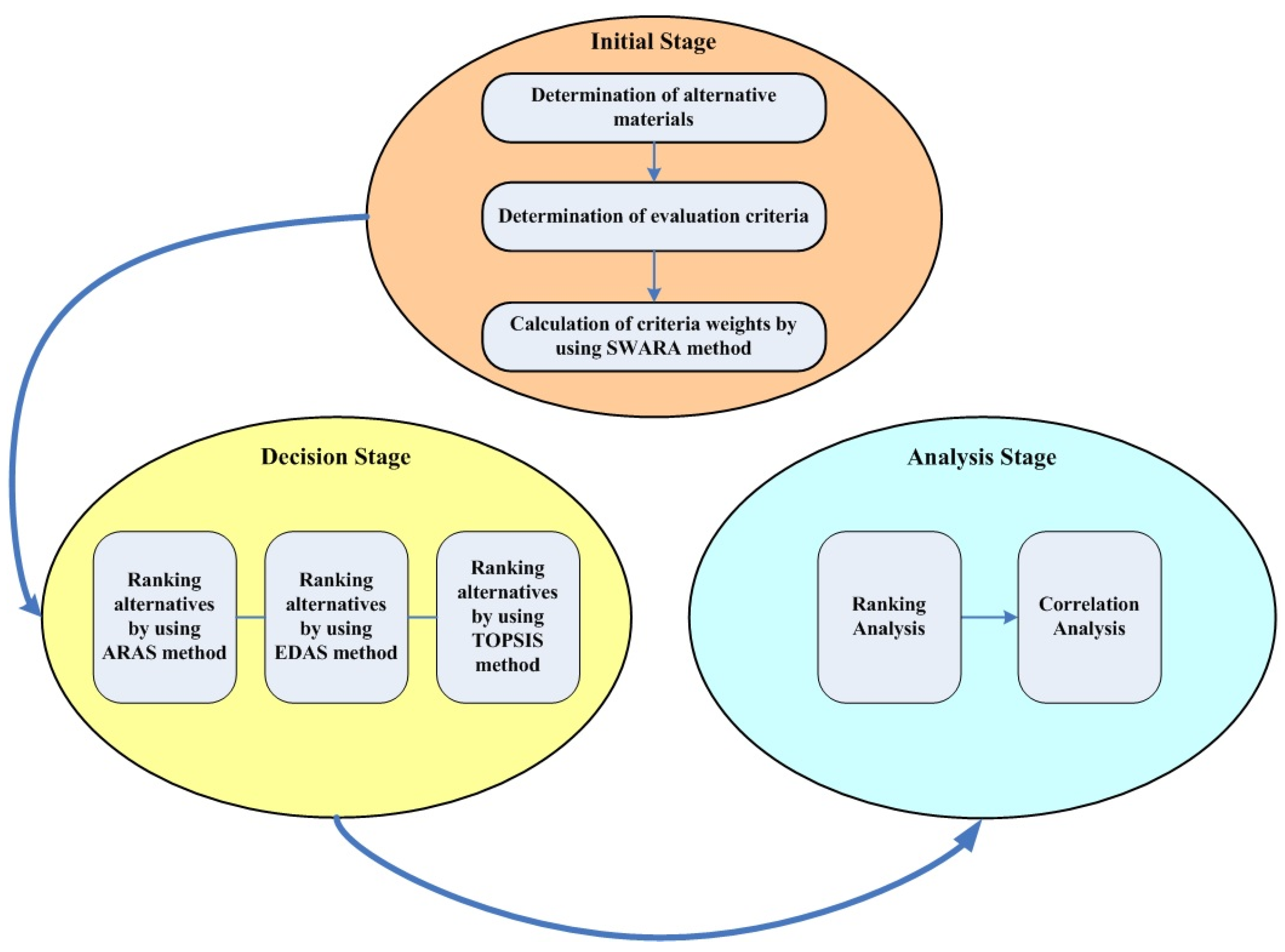

3.3. A Comparative Multi-Criteria Decision-Making Approach

3.3.1. Step-Wise Weight Assessment Ratio Analysis (SWARA) Approach for Weighting Criteria

3.3.2. Additive Ratio Assessment (ARAS) Approach

3.3.3. Evaluation Based on Distance from Average Solution (EDAS) Approach

3.3.4. Technique for Order Preference by Similarity to Ideal (TOPSIS) Approach

4. Results and Discussion

4.1. Criterion Weights

4.2. Comparison of SWARA-Based MCDM Approaches

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Biron, M. Material Selection for Thermoplastic Parts; Elsevier: New York, NY, USA, 2016; pp. 603–653. [Google Scholar]

- Dixit, S.; Rodriguez, S.; Jones, M.R.; Buzby, P.; Dixit, R.; Argibay, N.; DelRio, F.W.; Lim, H.H.; Fleming, D. Refractory High-Entropy Alloy Coatings for High-Temperature Aerospace and Energy Applications. J. Therm. Spray Technol. 2022, 31, 1021–1031. [Google Scholar] [CrossRef]

- Pillai, R.; Ren, Q.Q.; Su, Y.F.; Kurfess, Y.; Feldhausen, T.; Nag, S. Leveraging Additive Manufacturing to Fabricate High Temperature Alloys with Co-Designed Mechanical Properties and Environmental Resistance. In Proceedings of the ASME Turbo Expo 2023: Turbomachinery Technical Conference and Exposition, Boston, MA, USA, 26–30 June 2023. [Google Scholar]

- Huang, B.C.; Hung, F.Y. Effect of High Temperature and Thermal Cycle of 4043 Al Alloy Manufactured through Continuous Casting Direct Rolling. Materials 2023, 16, 7176. [Google Scholar] [CrossRef]

- Boyer, R.R.; Cotton, J.D.; Mohaghegh, M.; Schafrik, R.E. Materials Considerations for Aerospace Applications. MRS Bull. 2015, 40, 1055–1066. [Google Scholar] [CrossRef]

- McCluskey, F.P.; Podlesak, T.; Grzybowski, R. High Temperature Electronics, 1st ed.; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Pierce, D.; Haynes, A.; Hughes, J.; Graves, R.; Maziasz, P.; Muralidharan, G.; Shyam, A.; Wang, B.; England, R.; Daniel, C. High Temperature Materials for Heavy Duty Diesel Engines: Historical and Future Trends. Prog. Mater. Sci. 2019, 103, 109–179. [Google Scholar] [CrossRef]

- Belmonte, M. Advanced Ceramic Materials for High Temperature Applications. Adv. Eng. Mater. 2006, 8, 693–703. [Google Scholar] [CrossRef]

- Malik, M.; Dincer, I.; Rosen, M.A. Review on Use of Phase Change Materials in Battery Thermal Management for Electric and Hybrid Electric Vehicles. Int. J. Energy Res. 2016, 40, 1011–1031. [Google Scholar]

- Tomaszewska, A.; Chu, Z.; Feng, X.; O’kane, S.; Liu, X.; Chen, J.; Ji, C.; Endler, E.; Li, R.; Liu, L.; et al. Lithium-ion Battery Fast Charging: A Review. eTransportation 2019, 1, 100011. [Google Scholar] [CrossRef]

- Dai, H.; Jiang, B.; Hu, X.; Lin, X.; Wei, X.; Pecht, M. Advanced Battery Management Strategies for a Sustainable Energy Future: Multilayer Design Concepts and Research Trends. Renew. Sustain. Energy Rev. 2021, 138, 110480. [Google Scholar] [CrossRef]

- Kabir, M.M.; Demirocak, D.E. Degradation Mechanisms in Li-ion Batteries: A State-of-the-Art Review. Int. J. Energy Res. 2017, 41, 1963–1986. [Google Scholar] [CrossRef]

- Pollet, B.G.; Staffell, I.; Shang, J.L. Current Status of Hybrid, Battery and Fuel Cell Electric Vehicles: From Electrochemistry to Market Prospects. Electrochim. Acta 2012, 84, 235–249. [Google Scholar] [CrossRef]

- Tian, X.; Yi, Y.; Fang, B.; Yang, P.; Wang, T.; Liu, P.; Qu, L.; Li, M.; Zhang, S. Design Strategies of Safe Electrolytes for Preventing Thermal Runaway in Lithium Ion Batteries. Chem. Mater. 2020, 32, 9821–9848. [Google Scholar] [CrossRef]

- Kumar, A.; Sah, B.; Singh, A.R.; Deng, Y.; He, X.; Kumar, P.; Bansal, R.C. A Review of Multi Criteria Decision Making (MCDM) towards Sustainable Renewable Energy Development. Renew. Sustain. Energy Rev. 2017, 69, 596–609. [Google Scholar] [CrossRef]

- Li, L.; Duan, Y. Engineering Polymer-Based Porous Membrane for Sustainable Lithium-Ion Battery Separators. Polymers 2023, 15, 3690. [Google Scholar] [CrossRef]

- Chowdhury, P.; Paul, S.K. Applications of MCDM Methods in Research on Corporate Sustainability. Manag. Environ. Qual. Int. J. 2020, 31, 385–405. [Google Scholar] [CrossRef]

- Güner, S.; Cebeci, H.İ. Multi-Criteria Decision Making Techniques for Green Supply Chain Management: A Literature Review. In Ethics and Sustainability in Global Supply Chain Management, 1st ed.; Akküçük, U., Ed.; IGI Global: Hershey, PA, USA, 2017; pp. 261–287. [Google Scholar]

- Agarwal, A.; Pant, A.; Agarwal, M. Green Supplier Selection for Manufacturing Organization Using a Hybrid MCDM Approach. J. Stat. Manag. Syst. 2023, 26, 603–612. [Google Scholar] [CrossRef]

- Ordu, M.; Kirli Akin, H.; Demir, E. Healthcare Systems and COVID-19: Lessons to be Learnt from Efficient Countries. Int. J. Health Plan. Manag. 2021, 36, 1476–1485. [Google Scholar] [CrossRef] [PubMed]

- Moosivand, A.; Rangchian, M.; Zarei, L.; Peiravian, F.; Mehralian, G.; Sharifnia, H. An Application of Multi-Criteria Decision-Making Approach to Sustainable Drug Shortages Management: Evidence from a Developing Country. J. Pharm. Health Care Sci. 2021, 7, 14. [Google Scholar] [CrossRef]

- García-Orozco, S.; Vargas-Gutiérrez, G.; Ordóñez-Sánchez, S.; Silva, R. Using Multi-Criteria Decision Making in Quality Function Deployment for Offshore Renewable Energies. Energies 2023, 16, 6533. [Google Scholar] [CrossRef]

- Raut, R.; Kharat, M.; Kamble, S.; Kumar, C.S. Sustainable Evaluation and Selection of Potential Third-Party Logistics (3PL) Providers. Benchmarking Int. J. 2018, 25, 76–97. [Google Scholar] [CrossRef]

- Göncü, K.K.; Çetin, O. A Decision Model for Supplier Selection Criteria in Healthcare Enterprises with Dematel ANP Method. Sustainability 2022, 14, 13912. [Google Scholar] [CrossRef]

- Van Nguyen, T.; Cong Pham, H.; Nhat Nguyen, M.; Zhou, L.; Akbari, M. Data-Driven Review of Blockchain Applications in Supply Chain Management: Key Research Themes and Future Directions. Int. J. Prod. Res. 2023, 61, 8213–8235. [Google Scholar] [CrossRef]

- Ordu, M.; Fedai, Y. A Novel Decision Support System Based on Fuzzy Multi Criteria Decision Making for Optimizing Machining Parameters. J. Eng. Res. 2023, 11, 228–237. [Google Scholar] [CrossRef]

- Mayyas, A.; Omar, M.A.; Hayajneh, M.T. Eco-Material Selection Using Fuzzy TOPSIS Method. Int. J. Sustain. Eng. 2016, 9, 292–304. [Google Scholar] [CrossRef]

- Huang, X.; Fan, Y.; Zhang, J.; Jiang, P. Polypropylene Based Thermoplastic Polymers for Potential Recyclable HVDC Cable Insulation Applications. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1446–1456. [Google Scholar] [CrossRef]

- Larson, E.R. Thermoplastic Material Selection; Elsevier: New York, NY, USA, 2015; pp. 1–18. [Google Scholar]

- Emovon, I.; Oghenenyerovwho, O.S. Application of MCDM Method in Material Selection for Optimal Design: A Review. Results Mater. 2020, 7, 100115. [Google Scholar] [CrossRef]

- Chatterjee, S.; Chakraborty, S. Material Selection of a Mechanical Component Based on Criteria Relationship Evaluation and MCDM Approach. Mater. Today Proc. 2021, 44, 1621–1626. [Google Scholar] [CrossRef]

- Mathiyazhagan, K.; Gnanavelbabu, A.; Prabhuraj, B.L. A Sustainable Assessment Model for Material Selection in Construction Industries Perspective Using Hybrid MCDM Approaches. J. Adv. Manag. Res. 2019, 16, 234–259. [Google Scholar] [CrossRef]

- Ordu, M.; Der, O. Polymeric Materials Selection for Flexible Pulsating Heat Pipe Manufacturing Using a Comparative Hybrid MCDM Approach. Polymers 2023, 15, 2933. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.H. Compromise Solution by MCDM Methods: A Comparative Analysis of VIKOR and TOPSIS. Eur. J. Oper. Res. 2004, 156, 445–455. [Google Scholar] [CrossRef]

- Vinodh, S.; Manjunatheshwara, K.J. Grey-Based Decision-Making Method for Sustainable Material Selection of Tablet Device Enclosure. Clean Technol. Environ. Policy 2018, 20, 2345–2356. [Google Scholar]

- Liu, J.; Yang, C.; Wu, H.; Lin, Z.; Zhang, Z.; Wang, R.; Li, B.; Kang, F.; Shi, L.; Wong, C.P. Future Paper-Based Printed Circuit Boards for Green Electronics: Fabrication and Life Cycle Assessment. Energy Environ. Sci. 2014, 7, 3674–3682. [Google Scholar] [CrossRef]

- Ordu, M.; Der, O. Yeşil Üretim için Çevresel Etki Temelli Termoplastik Malzeme Seçimi: Karşılaştırmalı Bir Hibrid ÇKKV Yaklaşımı. Erciyes Üniv. Fen Bilim. Enst. Fen Bilim. Derg. 2023, 39, 100–115. [Google Scholar]

- Nisticò, R. Polyethylene Terephthalate (PET) in the Packaging Industry. Polym. Test. 2020, 90, 106707. [Google Scholar] [CrossRef]

- Simari, C.; Lufrano, E.; Brunetti, A.; Barbieri, G.; Nicotera, I. Highly-Performing and Low-Cost Nanostructured Membranes Based on Polysulfone and Layered Doubled Hydroxide for High-Temperature Proton Exchange Membrane Fuel Cells. J. Power Sources 2020, 471, 228440. [Google Scholar] [CrossRef]

- Paszkiewicz, S.; Lesiak, P.; Walkowiak, K.; Irska, I.; Miadlicki, K.; Królikowski, M.; Piesowicz, E.; Figiel, P. The Mechanical, Thermal, and Biological Properties of Materials Intended for Dental Implants: A Comparison of Three Types of Poly(aryl-ether-ketones) (PEEK and PEKK). Polymers 2023, 15, 3706. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Cao, J.H.; Wang, Y.; Shen, S.G.; Liang, W.H.; Wu, D.A. Colorless Polyamide–Imide Films with Enhanced Thermal and Dimensional Stability and Their Application in Flexible OLED Devices. ACS Appl. Polym. Mater. 2022, 4, 7664–7673. [Google Scholar] [CrossRef]

- Chen, G.; Mohanty, A.K.; Misra, M. Progress in Research and Applications of Polyphenylene Sulfide Blends and Composites with Carbons. Compos. Part B Eng. 2021, 209, 108553. [Google Scholar] [CrossRef]

- Sabet, M. The Impact of Graphene Oxide on the Mechanical and Thermal Strength Properties of Polycarbonate. J. Elastomers Plast. 2023, 55, 511–525. [Google Scholar] [CrossRef]

- Haque, S.M.; Ardila-Rey, J.A.; Umar, Y.; Mas’ud, A.A.; Muhammad-Sukki, F.; Jume, B.H.; Rahman, H.; Bani, N.A. Application and Suitability of Polymeric Materials as Insulators in Electrical Equipment. Energies 2021, 14, 2758. [Google Scholar] [CrossRef]

- Der, O.; Alqahtani, A.A.; Marengo, M.; Bertola, V. Characterization of Polypropylene Pulsating Heat Stripes: Effects of Orientation, Heat Transfer Fluid, and Loop Geometry. Appl. Therm. Eng. 2021, 184, 116304. [Google Scholar] [CrossRef]

- Das, P.; Gabriel, J.C.P.; Tay, C.Y.; Lee, J.M. Value-Added Products from Thermochemical Treatments of Contaminated e-Waste Plastics. Chemosphere 2021, 269, 129409. [Google Scholar] [CrossRef]

- Abdel-Gawad, N.M.K.; El Dein, A.Z.; Mansour, D.A.; Ahmed, H.M.; Darwish, M.M.F.; Lehtonen, M. PVC Nanocomposites for Cable Insulation with Enhanced Dielectric Properties, Partial Discharge Resistance and Mechanical Performance. High Volt. 2020, 5, 463–471. [Google Scholar] [CrossRef]

- Balasubramaniam, S.; Mohanty, A.; Balasingam, S.K.; Kim, S.J.; Ramadoss, A. Comprehensive Insight into the Mechanism, Material Selection and Performance Evaluation of Supercapatteries. Nano-Micro Lett. 2020, 12, 85. [Google Scholar] [CrossRef] [PubMed]

- Guan, Q.F.; Yang, H.B.; Han, Z.M.; Zhou, L.C.; Zhu, Y.B.; Ling, Z.C.; Jiang, H.B.; Wang, P.F.; Ma, T.; Wu, H.A.; et al. LightWeight, Tough, and Sustainable Cellulose Nanofiber-Derived Bulk Structural Materials with Low Thermal Expansion Coefficient. Sci. Adv. 2020, 6, eaaz1114. [Google Scholar] [CrossRef] [PubMed]

- Burd, J.T.J.; Moore, E.A.; Ezzat, H.; Kirchain, R.; Roth, R. Improvements in Electric Vehicle Battery Technology Influence Vehicle Lightweighting and Material Substitution Decisions. Appl. Energy 2021, 283, 116269. [Google Scholar] [CrossRef]

- Rojas, O.E.; Khan, M.A. A Review on Electrical and Mechanical Performance Parameters in Lithium-ion Battery Packs. J. Clean. Prod. 2022, 378, 134381. [Google Scholar] [CrossRef]

- Okokpujie, I.P.; Tartibu, L.K.; Musa-Basheer, H.O.; Adeoye, A.O.M. Effect of Coatings on Mechanical, Corrosion and Tribological Properties of Industrial Materials: A Comprehensive Review. J. Bio-Tribo-Corros. 2024, 10, 2. [Google Scholar] [CrossRef]

- Rana, S.; Kumar, R.; Bharj, R.S. Current Trends, Challenges, and Prospects in Material Advances for Improving the Overall Safety of Lithium-ion Battery Pack. Chem. Eng. J. 2023, 463, 142336. [Google Scholar] [CrossRef]

- Mayandi, K.; Rajini, N.; Ayrilmis, N.; Indira Devi, M.P.; Siengchin, S.; Mohammad, F.; Al-Lohedan, H.A. An Overview of Endurance and Ageing Performance Under Various Environmental Conditions of Hybrid Polymer Composites. J. Mater. Res. Technol. 2020, 9, 15962–15988. [Google Scholar] [CrossRef]

- Zhang, X.; Chao, X.; Lou, L.; Fan, J.; Chen, Q.; Li, B.; Ye, L.; Shou, D. Personal Thermal Management by Thermally Conductive Composites: A Review. Compos. Commun. 2021, 23, 100595. [Google Scholar] [CrossRef]

- Andrady, A.L.; Heikkilä, A.M.; Pandey, K.K.; Bruckman, L.S.; White, C.C.; Zhu, M.; Zhu, L. Effects of UV Radiation on Natural and Synthetic Materials. Photochem. Photobiol. Sci. 2023, 22, 1177–1202. [Google Scholar] [CrossRef]

- Zavadskas, E.K.; Turskis, Z. A New Additive Ratio Assessment (ARAS) Method in Multicriteria Decision-Making. Technol. Econ. Dev. Econ. 2010, 16, 159–172. [Google Scholar] [CrossRef]

- Keshavarz Ghorabaee, M.; Zavadskas, E.K.; Olfat, L.; Turskis, Z. Multi-Criteria Inventory Classification Using a New Method of Evaluation Based on Distance from Average Solution (EDAS). Informatica 2015, 26, 435–451. [Google Scholar] [CrossRef]

- Behzadian, M.; Khanmohammadi Otaghsara, S.; Yazdani, M.; Ignatius, J. A State-of the-Art Survey of TOPSIS Applications. Expert Syst. Appl. 2012, 39, 13051–13069. [Google Scholar] [CrossRef]

- Keršulienė, V.; Zavadskas, E.K.; Turskis, Z. Selection of Rational Dispute Resolution Method by Applying New Step-Wise Weight Assessment Ratio Analysis (SWARA). J. Bus. Econ. Manag. 2010, 11, 243–258. [Google Scholar] [CrossRef]

- Zhao, D.; Bezgans, Y.; Vdonin, N.; Du, W. The Use of TOPSIS-Based-Desirability Function Approach to Optimize the Balances Among Mechanical Performances, Energy Consumption, and Production Efficiency of the Arc Welding Process. Int. J. Adv. Manuf. Technol. 2021, 112, 3545–3559. [Google Scholar] [CrossRef]

- Shukla, A.; Agarwal, P.; Rana, R.S.; Purohit, R. Applications of TOPSIS Algorithm on Various Manufacturing Processes: A Review. Mater. Today Proc. 2017, 4, 5320–5329. [Google Scholar] [CrossRef]

- Ordu, M. Evaluating Occupational Accidents and Diseases-Based Sustainable Performances of the Turkish Development Regions Using a Hybrid MCDM Approach. In Intelligent Engineering Applications and Applied Sciences for Sustainability, 1st ed.; Mishra, B.K., Ed.; IGI Global: Hershey, PA, USA, 2023; pp. 190–207. [Google Scholar]

- Der, O.; Ordu, M.; Basar, G. Multi-Objective Optimization of Cutting Parameters for Polyethylene Thermoplastic Material by Integrating Data Envelopment Analysis and SWARA-Based CoCoSo Approach. Osman. Korkut Ata Üniv. Fen Bilim. Enst. Derg. 2024, 7, 638–661. [Google Scholar] [CrossRef]

- Der, O.; Ordu, M.; Basar, G. Optimization of Cutting Parameters in Manufacturing of Polymeric Materials for Flexible Two-Phase Thermal Management Systems. Mater. Test. 2024. [Google Scholar] [CrossRef]

| Criteria | Unit | Abbreviations |

|---|---|---|

| Maximum Temperature Resistance | °C | MTR |

| Mechanical Strength | MPa | MS |

| Chemical Resistance | - | CR |

| Wear Resistance | mm3 | WR |

| Elastic Modulus | GPa | EM |

| Thermal Expansion | µm/m/°C | TE |

| Thermal Conductivity | W/mK | TC |

| UV Resistance | - | UVR |

| Moisture Absorption Rate | % | MAR |

| Density | kg/m3 | D |

| Criteria | sj | kj | qj | wj |

|---|---|---|---|---|

| Maximum Temperature Resistance | 1.00 | 1.000 | 0.1930 | |

| Mechanical Strength | 0.10 | 1.10 | 0.909 | 0.1755 |

| Chemical Resistance | 0.50 | 1.50 | 0.606 | 0.1170 |

| Wear Resistance | 0.05 | 1.05 | 0.577 | 0.1114 |

| Elastic Modulus | 0.20 | 1.20 | 0.481 | 0.0928 |

| Thermal Expansion | 0.15 | 1.15 | 0.418 | 0.0807 |

| Thermal Conductivity | 0.20 | 1.20 | 0.349 | 0.0673 |

| UV Resistance | 0.15 | 1.15 | 0.303 | 0.0585 |

| Moisture Absorption Rate | 0.10 | 1.10 | 0.276 | 0.0532 |

| Density | 0.05 | 1.05 | 0.262 | 0.0506 |

| Criteria | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| MTE | MS | CS | WR | EM | TE | TC | UVR | MAR | D | ||

| Alternatives | PET | 1.38 | 4 | 4 | 3 | 70 | 4 | 3 | 2 | 0.24 | 4 |

| PSU | 1.24 | 5 | 5 | 4 | 55 | 5 | 4 | 3 | 0.32 | 4 | |

| PEEK | 1.32 | 5 | 5 | 5 | 47 | 5 | 5 | 2 | 0.25 | 5 | |

| PAI | 1.43 | 5 | 5 | 5 | 30 | 5 | 5 | 2 | 0.25 | 4 | |

| PPS | 1.35 | 4 | 4 | 4 | 55 | 4 | 4 | 1 | 0.24 | 4 | |

| PC | 1.20 | 3 | 4 | 3 | 65 | 3 | 3 | 3 | 0.20 | 3 | |

| PE | 0.96 | 2 | 3 | 2 | 160 | 2 | 2 | 4 | 0.42 | 2 | |

| PP | 0.91 | 3 | 3 | 2 | 125 | 3 | 2 | 4 | 0.16 | 3 | |

| PS | 1.05 | 2 | 3 | 3 | 75 | 2 | 2 | 4 | 0.04 | 2 | |

| PVC | 1.39 | 3 | 4 | 3 | 80 | 4 | 3 | 3 | 0.21 | 4 | |

| Materials | SWARA-ARAS | SWARA-EDAS | SWARA-TOPSIS | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Si | Ki | Rank | NP | NN | A | Rank | PSi | Rank | |||

| PET | 0.087 | 0.678 | 5 | 0.143 | 0.847 | 0.495 | 5 | 0.049 | 0.049 | 0.500 | 5 |

| PSU | 0.106 | 0.831 | 2 | 0.816 | 0.928 | 0.872 | 2 | 0.036 | 0.075 | 0.672 | 1 |

| PEEK | 0.109 | 0.850 | 1 | 1.000 | 0.845 | 0.922 | 1 | 0.039 | 0.079 | 0.668 | 2 |

| PAI | 0.106 | 0.824 | 3 | 0.943 | 0.775 | 0.859 | 3 | 0.044 | 0.078 | 0.637 | 3 |

| PPS | 0.089 | 0.697 | 4 | 0.280 | 0.808 | 0.544 | 4 | 0.048 | 0.053 | 0.524 | 4 |

| PC | 0.079 | 0.613 | 7 | 0.016 | 0.674 | 0.345 | 8 | 0.060 | 0.035 | 0.364 | 9 |

| PE | 0.077 | 0.599 | 8 | 0.604 | 0.096 | 0.350 | 7 | 0.076 | 0.054 | 0.416 | 7 |

| PP | 0.077 | 0.598 | 9 | 0.300 | 0.350 | 0.325 | 9 | 0.067 | 0.041 | 0.380 | 8 |

| PS | 0.062 | 0.482 | 10 | 0.102 | 0.000 | 0.051 | 10 | 0.085 | 0.024 | 0.219 | 10 |

| PVC | 0.084 | 0.653 | 6 | 0.088 | 0.792 | 0.440 | 6 | 0.055 | 0.041 | 0.426 | 6 |

| SWARA-ARAS | SWARA-EDAS | SWARA-TOPSIS | |

|---|---|---|---|

| SWARA-ARAS | 1.0000 | 0.9879 | 0.9515 |

| SWARA-EDAS | 1.0000 | 0.9758 | |

| SWARA-TOPSIS | 1.0000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bulut, M.S.; Ordu, M.; Der, O.; Basar, G. Sustainable Thermoplastic Material Selection for Hybrid Vehicle Battery Packs in the Automotive Industry: A Comparative Multi-Criteria Decision-Making Approach. Polymers 2024, 16, 2768. https://doi.org/10.3390/polym16192768

Bulut MS, Ordu M, Der O, Basar G. Sustainable Thermoplastic Material Selection for Hybrid Vehicle Battery Packs in the Automotive Industry: A Comparative Multi-Criteria Decision-Making Approach. Polymers. 2024; 16(19):2768. https://doi.org/10.3390/polym16192768

Chicago/Turabian StyleBulut, Mustafa Sefa, Muhammed Ordu, Oguzhan Der, and Gokhan Basar. 2024. "Sustainable Thermoplastic Material Selection for Hybrid Vehicle Battery Packs in the Automotive Industry: A Comparative Multi-Criteria Decision-Making Approach" Polymers 16, no. 19: 2768. https://doi.org/10.3390/polym16192768

APA StyleBulut, M. S., Ordu, M., Der, O., & Basar, G. (2024). Sustainable Thermoplastic Material Selection for Hybrid Vehicle Battery Packs in the Automotive Industry: A Comparative Multi-Criteria Decision-Making Approach. Polymers, 16(19), 2768. https://doi.org/10.3390/polym16192768