Performance Evaluation of Carbon Fiber Fabric-Reinforced Formaldehyde-Free High-Strength Plywood

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Production of Plywood

2.3. Characterization

2.3.1. Mechanical Properties

2.3.2. SEM Analysis

2.3.3. Finite Element Simulation Analysis

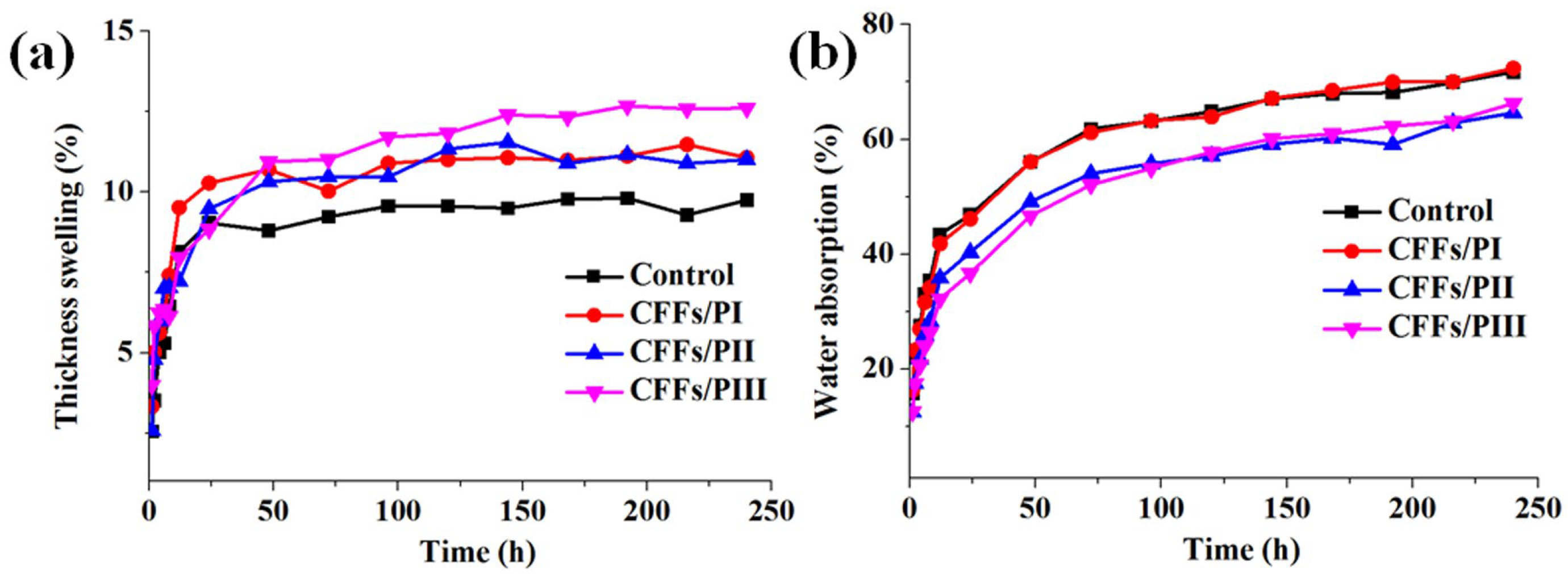

2.3.4. Water Resistance

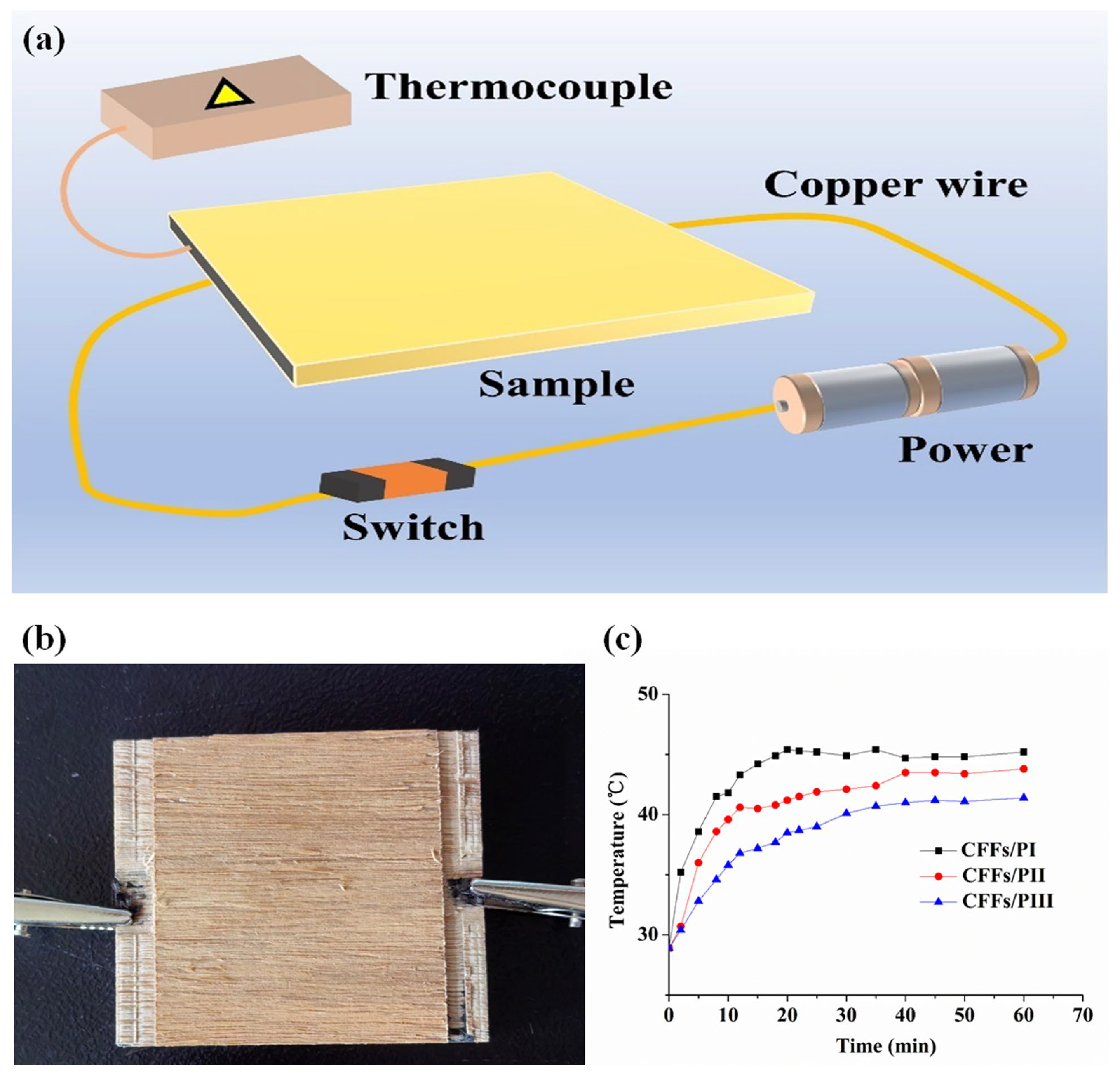

2.3.5. Electrothermal Properties

3. Results

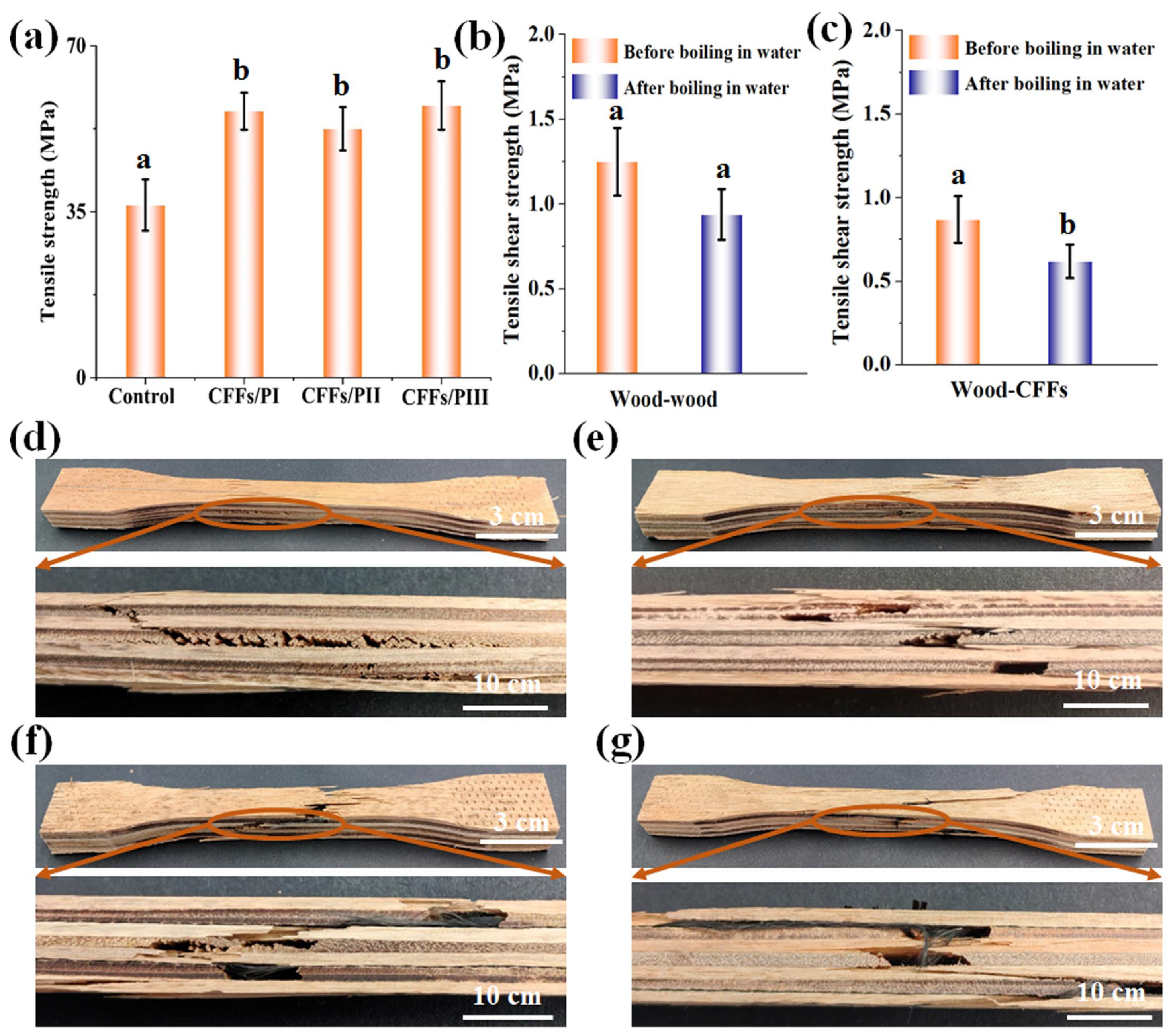

3.1. Tensile Property Analysis

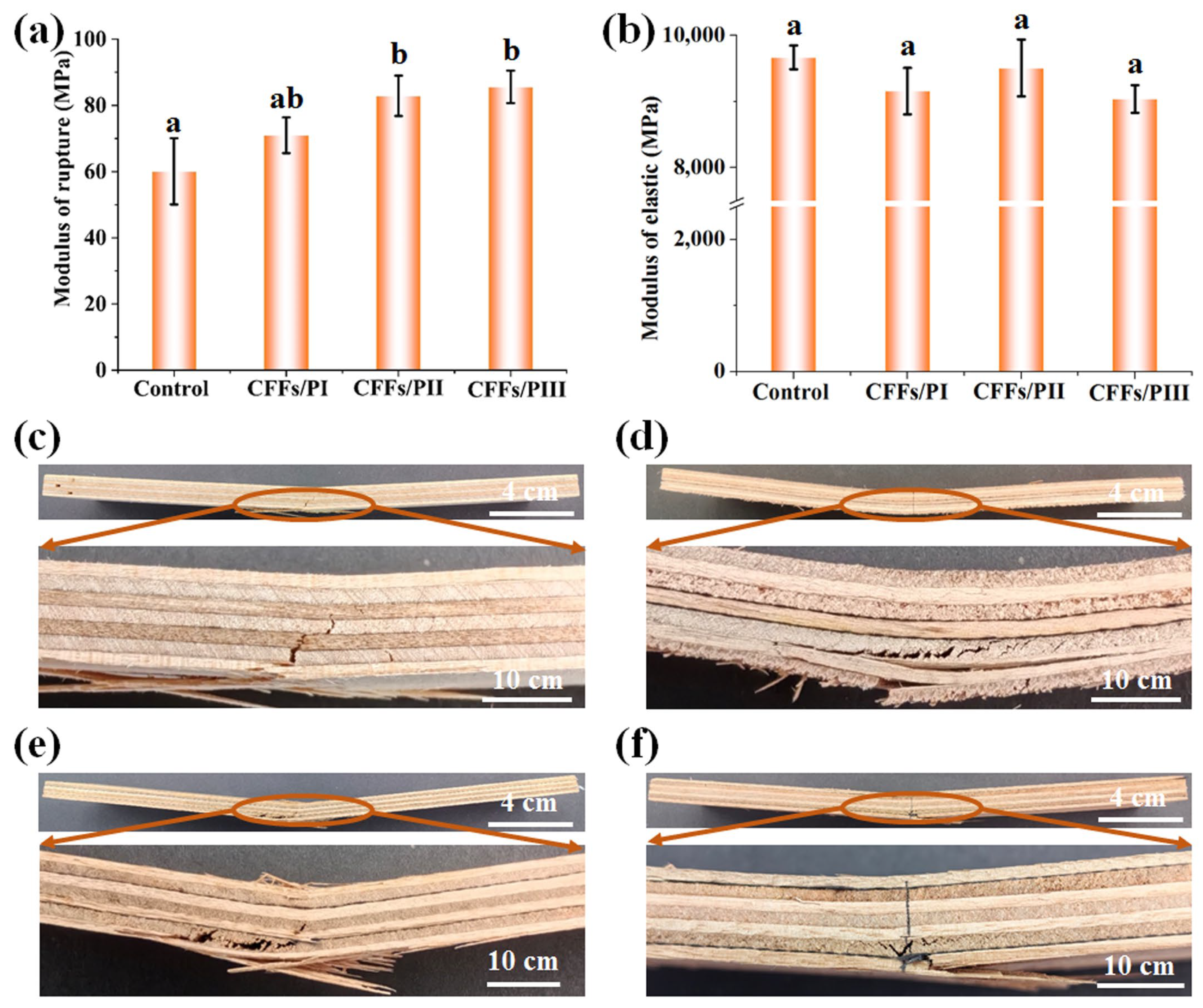

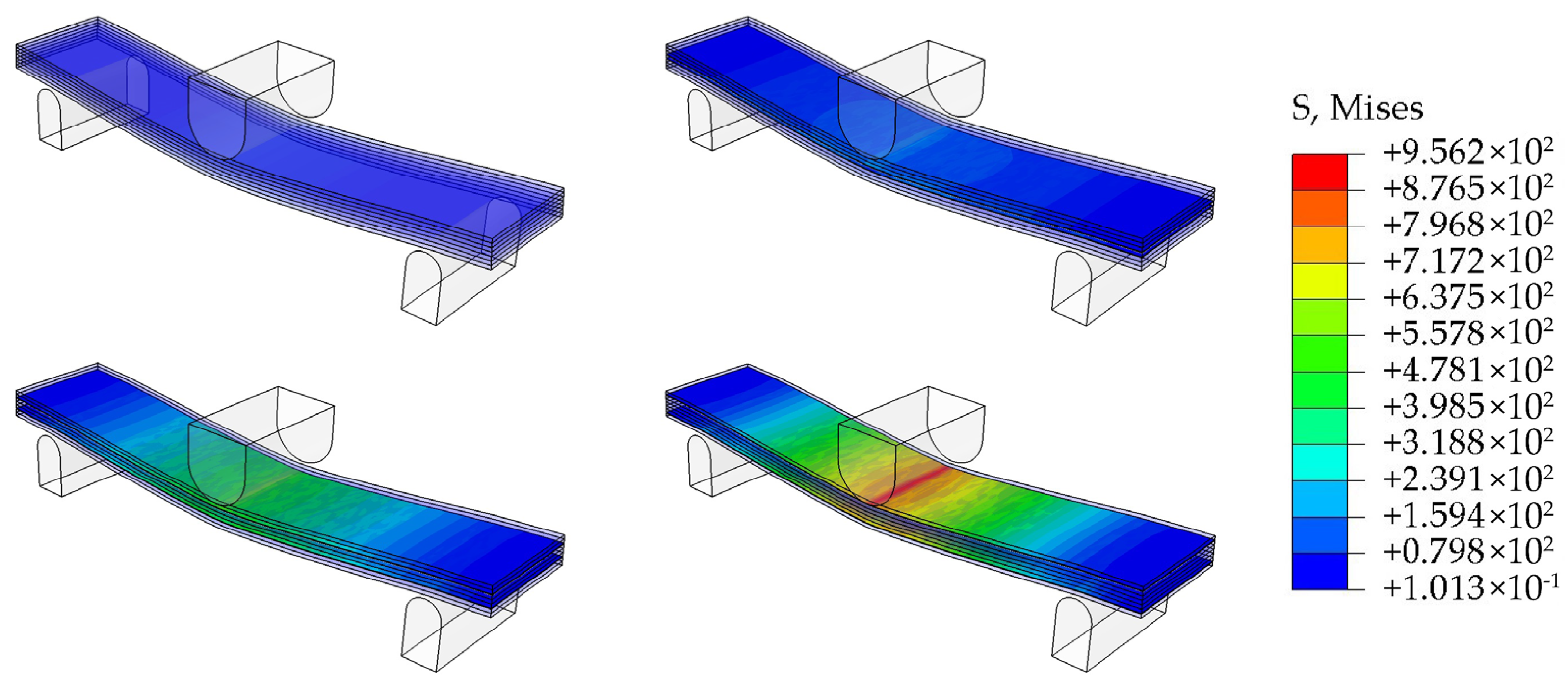

3.2. Flexural Property Analysis

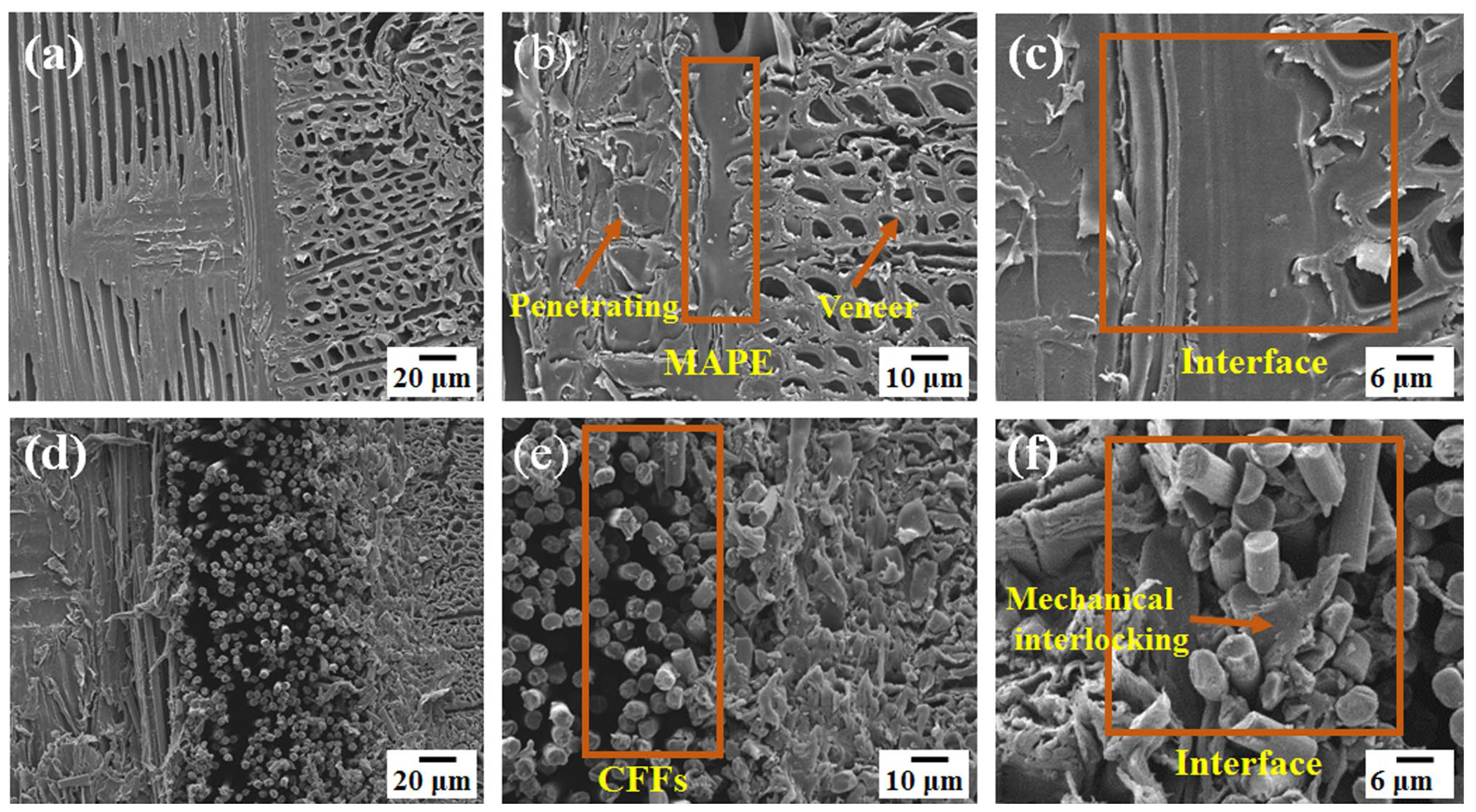

3.3. Microstructure Analysis

3.4. Water-Resistant Property Analysis

3.5. Electrothermal Property Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Auriga, R.; Gumowska, A.; Szymanowski, K.; Wronka, A.; Robles, E.; Ocipka, P.; Kowaluk, G. Performance properties of plywood composites reinforced with carbon fibers. Compos. Struct. 2020, 248, 112533. [Google Scholar] [CrossRef]

- Wang, W.; Zammarano, M.; Shields, J.R.; Knowlton, E.D.; Kim, I.; Gales, J.A.; Hoehler, M.S.; Li, J. A novel application of silicone-based flame-retardant adhesive in plywood. Constr. Build. Mater. 2018, 189, 448–459. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; He, Y.; Yu, J.; Lu, Y.; Zhang, X.; Fang, L. Fabrication and characterization of EVA resins as adhesives in plywood. Polymers 2023, 15, 1834. [Google Scholar] [CrossRef] [PubMed]

- Zuo, S.; Liang, Y.; Wu, Y.; Ge, S.; Shi, J.; Ma, X.; Cai, L.; Li, J.; Lam, S.S.; Xia, C. Using environmentally friendly technology for fabricating special plywood with ultra-high strength. J. Clean. Prod. 2023, 396, 136462. [Google Scholar] [CrossRef]

- Xia, C.; Ren, H.; Shi, S.Q.; Zhang, H.; Cheng, J.; Cai, L.; Chen, K.; Tan, H.-S. Natural fiber composites with EMI shielding function fabricated using VARTM and Cu film magnetron sputtering. Appl. Surf. Sci. 2016, 362, 335–340. [Google Scholar] [CrossRef]

- Tang, J.; Zhang, X.; Wang, J.; Zou, R.; Wang, L. Achieving flexible and durable electromagnetic interference shielding fabric through lightweight and mechanically strong aramid fiber wrapped in highly conductive multilayer metal. Appl. Surf. Sci. 2021, 565, 150577. [Google Scholar] [CrossRef]

- Chang, L.; Guo, W.; Tang, Q. Assessing the tensile shear strength and interfacial bonding mechanism of poplar plywood with high-density polyethylene films as adhesive. BioResources 2017, 12, 571–585. [Google Scholar] [CrossRef]

- Chang, L.; Tang, Q.; Gao, L.; Fang, L.; Wang, Z.; Guo, W. Fabrication and characterization of HDPE resins as adhesives in plywood. Eur. J. Wood Wood Prod. 2018, 76, 325–335. [Google Scholar] [CrossRef]

- Zhang, Y.; Fang, L.; Chen, J. Influence of micron-sized oligomeric semisiloxane modification on surface properties of veneer and interfacial adhesion of EVA film/poplar plywood. Wood Mater. Sci. Eng. 2024, 19, 1–10. [Google Scholar] [CrossRef]

- Lu, F.; Chang, L.; Wen-jing, G.; Yi-ping, R.; Wang, Z. Preparation and characterization of wood-plastic plywood bonded with high density polyethylene film. Eur. J. Wood Wood Prod. 2013, 71, 739–746. [Google Scholar] [CrossRef]

- Li, J.; Xu, Q.; Wang, J.; Jiao, J.; Zhang, Z. Controlled synthesis of monolithic hierarchical porous materials using wood as a template with assistance of supercritical carbon dioxide. Ind. Eng. Chem. Res. 2008, 47, 7680–7685. [Google Scholar] [CrossRef]

- Bekhta, P.; Müller, M.; Hunko, I. Properties of thermoplastic-bonded plywood: Effects of the wood species and types of the thermoplastic films. Polymers 2020, 12, 2582. [Google Scholar] [CrossRef] [PubMed]

- Temiz, A.; Akbas, S.; Aydin, I.; Demirkir, C. The effect of plasma treatment on mechanical properties, surface roughness and durability of plywood treated with copper-based wood preservatives. Wood Sci. Technol. 2016, 50, 179–191. [Google Scholar] [CrossRef]

- Bekhta, P.; Sedliačik, J.; Kusniak, I.; Gryc, V.; Pipíška, T.; Ráheľ, J.; Lepcio, P.; Pavliňák, D.; Tymyk, D.; Chernetskyi, O. Enhancing the properties of thermoplastic-bonded plywood by treating the birch veneers with citric acid. Int. J. Adhes. Adhes. 2024, 134, 103781. [Google Scholar] [CrossRef]

- Kallakas, H.; Rohumaa, A.; Vahermets, H.; Kers, J. Effect of different hardwood species and lay-up schemes on the mechanical properties of plywood. Forests 2020, 11, 649. [Google Scholar] [CrossRef]

- Chen, X.; Sun, C.; Wang, Q.; Tan, H.; Zhang, Y. Preparation of glycidyl methacrylate grafted starch adhesive to apply in high-performance and environment-friendly plywood. Int. J. Biol. Macromol. 2022, 194, 954–961. [Google Scholar] [CrossRef]

- Ansell, M.P. 16—Hybrid wood composites—Integration of wood with other engineering materials. In Wood Composites; Elsevier: Amsterdam, The Netherlands, 2015; pp. 411–426. [Google Scholar]

- Rescalvo, F.J.; Valverde-Palacios, I.; Suarez, E.; Gallego, A. Experimental and analytical analysis for bending load capacity of old timber beams with defects when reinforced with carbon fiber strips. Compos. Struct. 2018, 186, 29–38. [Google Scholar] [CrossRef]

- Raftery, G.M.; Harte, A.M. Low-grade glued laminated timber reinforced with FRP plate. Compos. Part B Eng. 2011, 42, 724–735. [Google Scholar] [CrossRef]

- Bal, B.C. Flexural properties, bonding performance and splitting strength of LVL reinforced with woven glass fiber. Constr. Build. Mater. 2014, 51, 9–14. [Google Scholar] [CrossRef]

- Zhang, P.; Shijie, S. Strengthening mechanical properties of glulam with basalt fiber. Adv. Nat. Sci. 2011, 4, 130–133. [Google Scholar] [CrossRef]

- Kim, D.-H.; Kim, H.-G.; Kim, H.-S. Design optimization and manufacture of hybrid glass/carbon fiber reinforced composite bumper beam for automobile vehicle. Compos. Struct. 2015, 131, 742–752. [Google Scholar] [CrossRef]

- Rui, Y. The Application of Deformable Carbon Fiber Reinforced PVC Plastic Building Template in Building Wall. China Plast. Ind. 2017, 9, 106–109, 139. [Google Scholar] [CrossRef]

- Bakalarz, M.; Kossakowski, P. Mechanical properties of laminated veneer lumber beams strengthened with CFRP sheets. Arch. Civ. Eng. 2019, 65, 57–66. [Google Scholar] [CrossRef]

- Rescalvo, F.J.; Duriot, R.; Pot, G.; Gallego, A.; Denaud, L. Enhancement of bending properties of Douglas-fir and poplar laminate veneer lumber (LVL) beams with carbon and basalt fibers reinforcement. Constr. Build. Mater. 2020, 263, 120185. [Google Scholar] [CrossRef]

- Mercimek, Ö.; Ghoroubi, R.; Akkaya, S.T.; Türer, A.; Anıl, Ö.; İşleyen, Ü.K. Flexural behavior of finger joint connected glulam wooden beams strengthened with CFRP strips. Structures 2024, 66, 106853. [Google Scholar] [CrossRef]

- Gallego Molina, A.; Rescalvo Fernández, F.J.; Suárez Vargas, E. CHOPO. Madera microlaminada estructural de chopo reforzada con tejidos de carbono o basalto. Alzada 2020, 120, 32–43. Available online: http://hdl.handle.net/20.500.12251/1682 (accessed on 1 October 2020).

- GBT1447-2005; Fiber-Reinforced Plastics Composites—Determination of Tensile Properties. National Standardization Administration: Beijing, China, 2005.

- GB/T 17657-2022; Test Methods of Evaluating the Properties of Wood-Based Panels and Surface Decorated Wood-Based Panels. National Standardization Administration: Beijing, China, 2022.

- GB/T 9846.3-2015; Plywood for General Use. National Standardization Administration: Beijing, China, 2015.

- Dölling, S.; Hahn, J.; Felger, J.; Bremm, S.; Becker, W. A scaled boundary finite element method model for interlaminar failure in composite laminates. Compos. Struct. 2020, 241, 111865. [Google Scholar] [CrossRef]

- Xiao, J.; Li, H.; Lu, M.; Wang, Y.; Jiang, J.; Yang, W.; Qu, S.; Lu, W. Enhancing the Interfacial Shear Strength and Tensile Strength of Carbon Fibers through Chemical Grafting of Chitosan and Carbon Nanotubes. Polymers 2023, 15, 2147. [Google Scholar] [CrossRef]

- Sugimoto, Y.; Shimamoto, D.; Imai, Y.; Hotta, Y. Simultaneous evaluation of tensile strength and interfacial shear strength of short length carbon fibers using fragmentation test. Carbon 2020, 161, 83–88. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, L.; Nie, H.; Sheng, H.; Li, H. Balanced mechanical and biotribological properties of polymer composites reinforced by a 3D interlocked Si3N4 nanowire membrane. ACS Appl. Mater. Interfaces 2022, 14, 56203–56212. [Google Scholar] [CrossRef]

| Type | Squares | df | Mean Square | F Value | Pr |

|---|---|---|---|---|---|

| Tensile property | 1029.27 | 20 | 282.39 | 12.41 | 0.002 |

| Type | Mean Difference | q | Pr |

|---|---|---|---|

| Control/CFFsPI | 19.8 | 7.19 | 0.004 |

| Control/CFFsPII | 16.1 | 5.85 | 0.008 |

| Control/CFFsPIII | −3.7 | 1.34 | 0.0029 |

| CFFsPI/CFFsPII | 20.97 | 7.61 | 0.7801 |

| CFFsPI/CFFsPIII | 1.17 | 0.42 | 0.9899 |

| CFFsPII/CFFsPIII | 4.87 | 1.77 | 0.6196 |

| Type | Mean Difference | q | Pr |

|---|---|---|---|

| Wood–wood before boiling in water/ Wood–wood after boiling in water | −0.38 | 3.81 | 0.0543 |

| Wood–CFFs before boiling in water/ Wood–CFFs after boiling in water | −0.32 | 4.34 | 0.0371 |

| Type | Squares | df | Mean Square | F Value | Pr |

|---|---|---|---|---|---|

| MOR | 1618.98 | 20 | 412.74 | 8.67 | 0.007 |

| MOE | 1,548,100 | 20 | 26,010 | 2.71 | 0.1152 |

| Type | Mean Difference | q | Pr |

|---|---|---|---|

| Control/CFFsPI | 10.9 | 2.73 | 0.2870 |

| Control/CFFsPII | 22.8 | 5.72 | 0.0156 |

| Control/CFFsPIII | 25.5 | 6.40 | 0.008 |

| CFFsPI/CFFsPII | 11.9 | 2.99 | 0.2279 |

| CFFsPI/CFFsPIII | 14.6 | 3.67 | 0.1182 |

| CFFsPII/CFFsPIII | 2.7 | 0.68 | 0.9616 |

| Type | Mean Difference | q | Pr |

|---|---|---|---|

| Control/CFFsPI | −510 | 2.85 | 0.2586 |

| Control/CFFsPII | −160 | 0.89 | 0.9186 |

| Control/CFFsPIII | −630 | 3.52 | 0.1362 |

| CFFsPI/CFFsPII | 350 | 1.96 | 0.5417 |

| CFFsPI/CFFsPIII | −120 | 0.67 | 0.9627 |

| CFFsPII/CFFsPIII | −470 | 2.63 | 0.3152 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Tang, Q.; Chen, X.; Luo, X.; Zhang, F.; Zhou, G.; Zhang, J.; Zhang, L.; Meng, Y.; Ren, Y.; et al. Performance Evaluation of Carbon Fiber Fabric-Reinforced Formaldehyde-Free High-Strength Plywood. Polymers 2024, 16, 2637. https://doi.org/10.3390/polym16182637

Wang Y, Tang Q, Chen X, Luo X, Zhang F, Zhou G, Zhang J, Zhang L, Meng Y, Ren Y, et al. Performance Evaluation of Carbon Fiber Fabric-Reinforced Formaldehyde-Free High-Strength Plywood. Polymers. 2024; 16(18):2637. https://doi.org/10.3390/polym16182637

Chicago/Turabian StyleWang, Yuanwu, Qiheng Tang, Xueqi Chen, Xiaoxi Luo, Fenghao Zhang, Guanwu Zhou, Jie Zhang, Lei Zhang, Yuan Meng, Yiping Ren, and et al. 2024. "Performance Evaluation of Carbon Fiber Fabric-Reinforced Formaldehyde-Free High-Strength Plywood" Polymers 16, no. 18: 2637. https://doi.org/10.3390/polym16182637

APA StyleWang, Y., Tang, Q., Chen, X., Luo, X., Zhang, F., Zhou, G., Zhang, J., Zhang, L., Meng, Y., Ren, Y., Chang, L., & Guo, W. (2024). Performance Evaluation of Carbon Fiber Fabric-Reinforced Formaldehyde-Free High-Strength Plywood. Polymers, 16(18), 2637. https://doi.org/10.3390/polym16182637