Study on the Factors Affecting the Self-Healing Performance of Graphene-Modified Asphalt Based on Molecular Dynamics Simulation

Abstract

1. Introduction

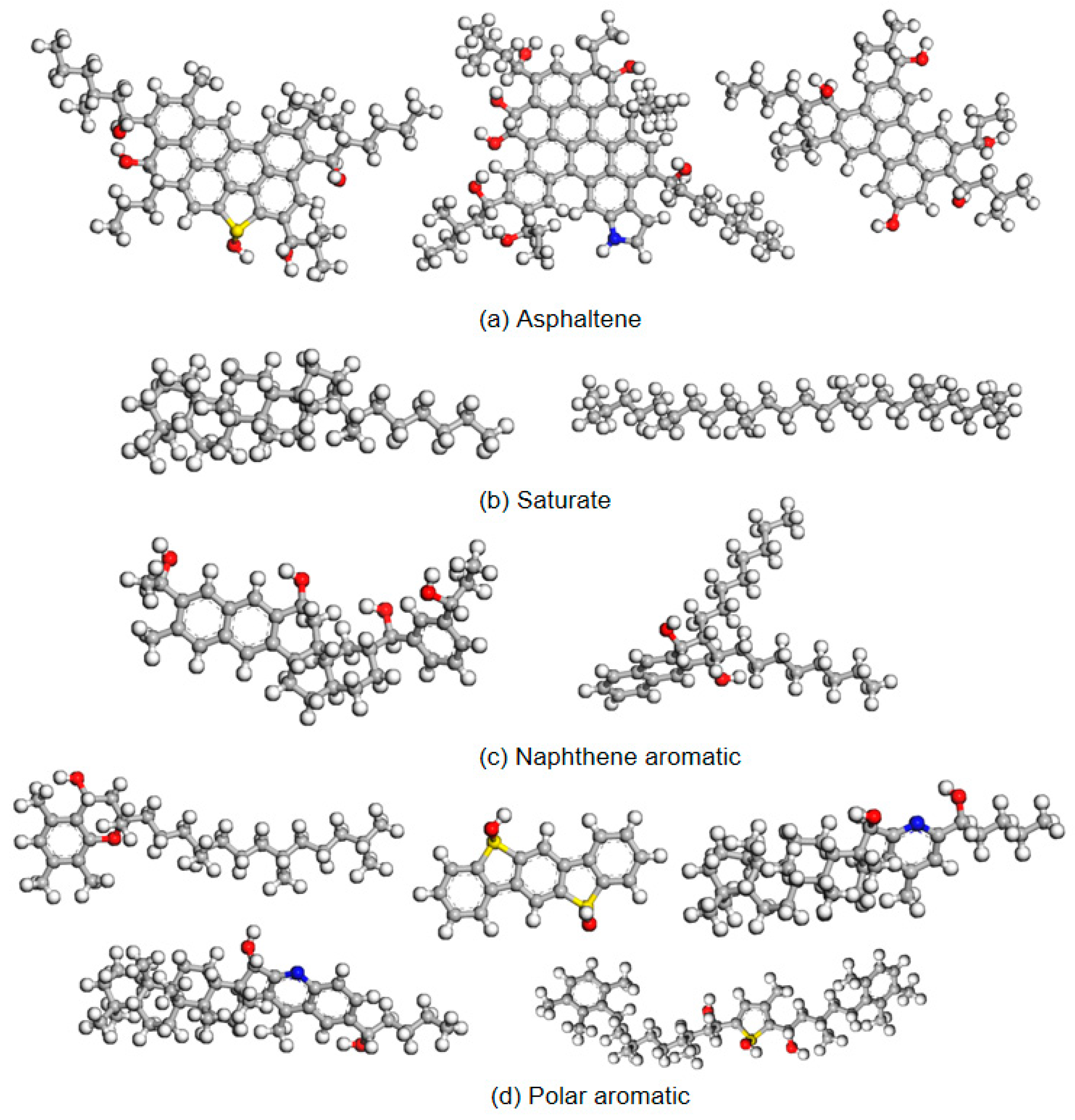

2. Establishment and Validation of Asphalt Molecular Models

2.1. Establishment of the Base Asphalt Model

- (1)

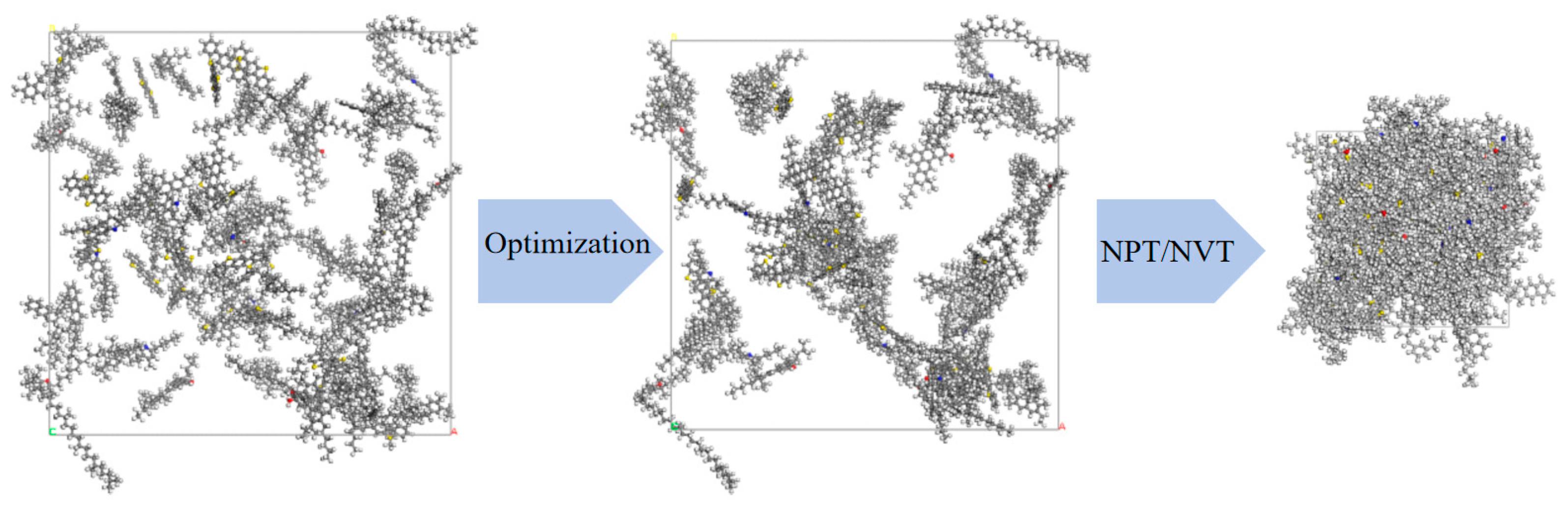

- Using Materials Studio 2019 software, the molecular structures of twelve types of asphalt molecules were drawn, as shown in Figure 1. All the drawn molecular structures were imported into the Amorphous Cell module. According to the parameters in Table 1, the number of each type of molecule in a unit cell was input into the software. The initial density was set to 0.1 g/cm3, and the initial temperature was set to 295.15 K. Due to the presence of long-chain structures among the twelve types of asphalt molecules, setting a low initial density ensures ample space within the unit cell, keeping the molecules sufficiently dispersed to prevent entanglement, which could affect subsequent molecular dynamics simulations;

- (2)

- The asphalt molecular model established in the previous step was subjected to geometry optimization and annealing, both performed within the COMPASSⅡ force field. During the geometry optimization process, the step number was set to 100,000. For the annealing process, the temperature ranged from 300 K to 500 K, with 10 cycles;

- (3)

- After geometry optimization and annealing, the asphalt molecular model was subjected to a 1 ns dynamics calculation within the Canonical Ensemble (NVT) at a temperature of 298.15 K to obtain a uniform asphalt molecular model. Subsequently, a 1 ns dynamics calculation was performed within the Isothermal-Isobaric Ensemble (NPT) at a temperature of 298.15 K and a pressure of 1 standard atmosphere to compress the volume of the asphalt molecular model. The final molecular model is shown in Figure 2.

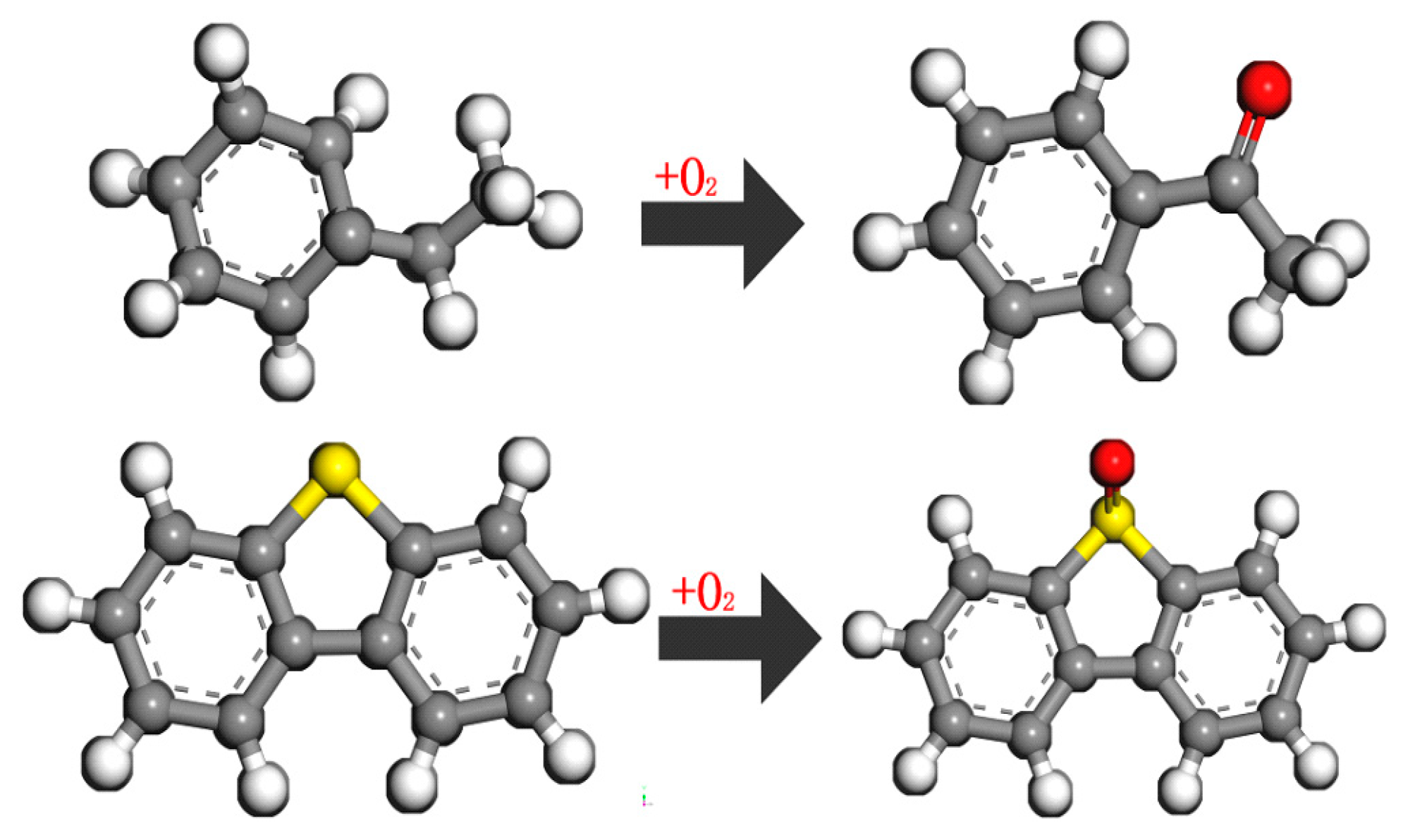

2.2. Establishment of Oxidized Aging Asphalt Model

2.3. Establishment of Graphene-Modified Asphalt Model

2.4. Validation of the Asphalt Molecular Model

2.4.1. Density

2.4.2. Cohesion Energy Density

2.4.3. Radial Distribution Function

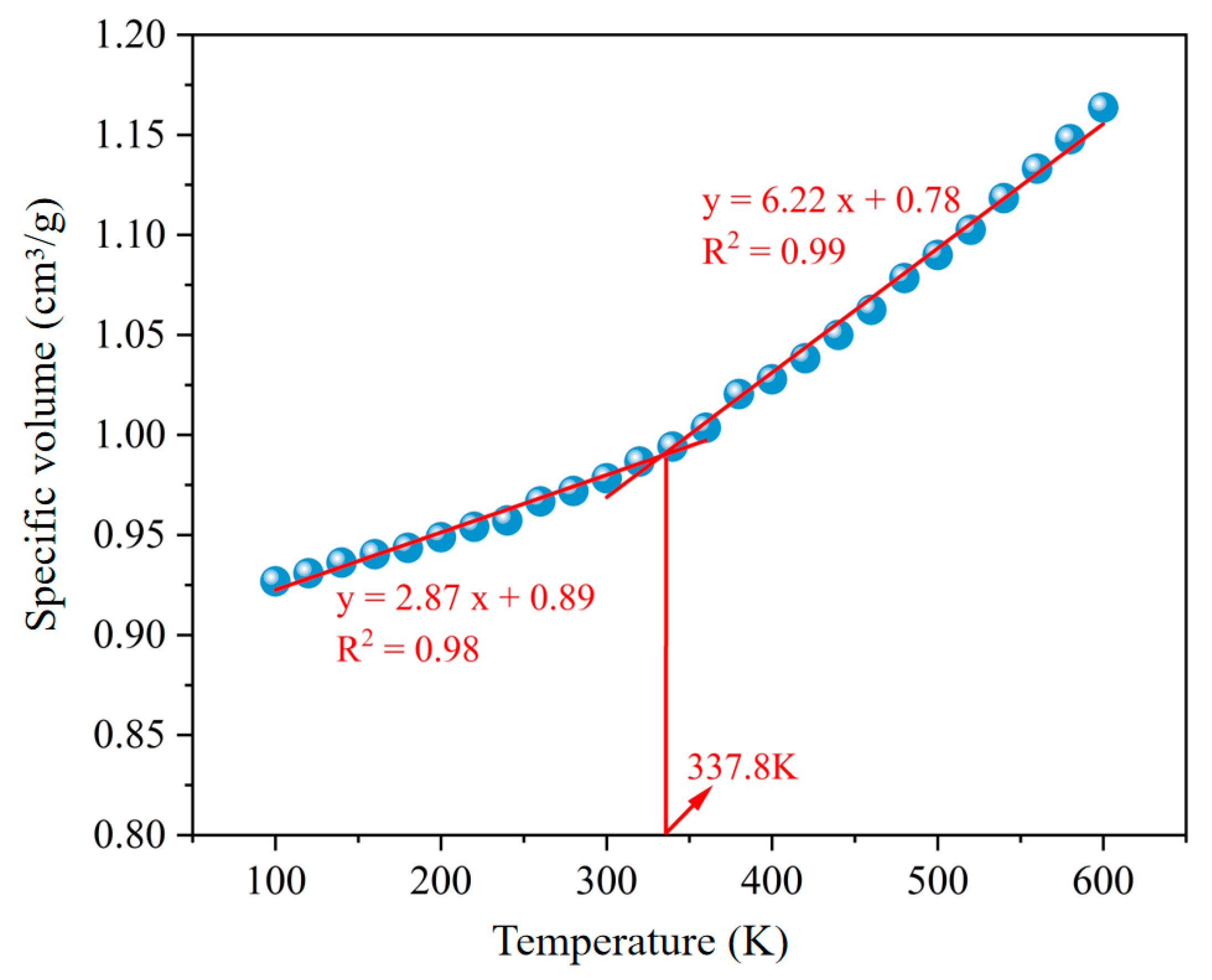

2.4.4. Glass Transition Temperature

3. Construction of Asphalt Crack Model

4. Molecular Dynamics Simulation Results

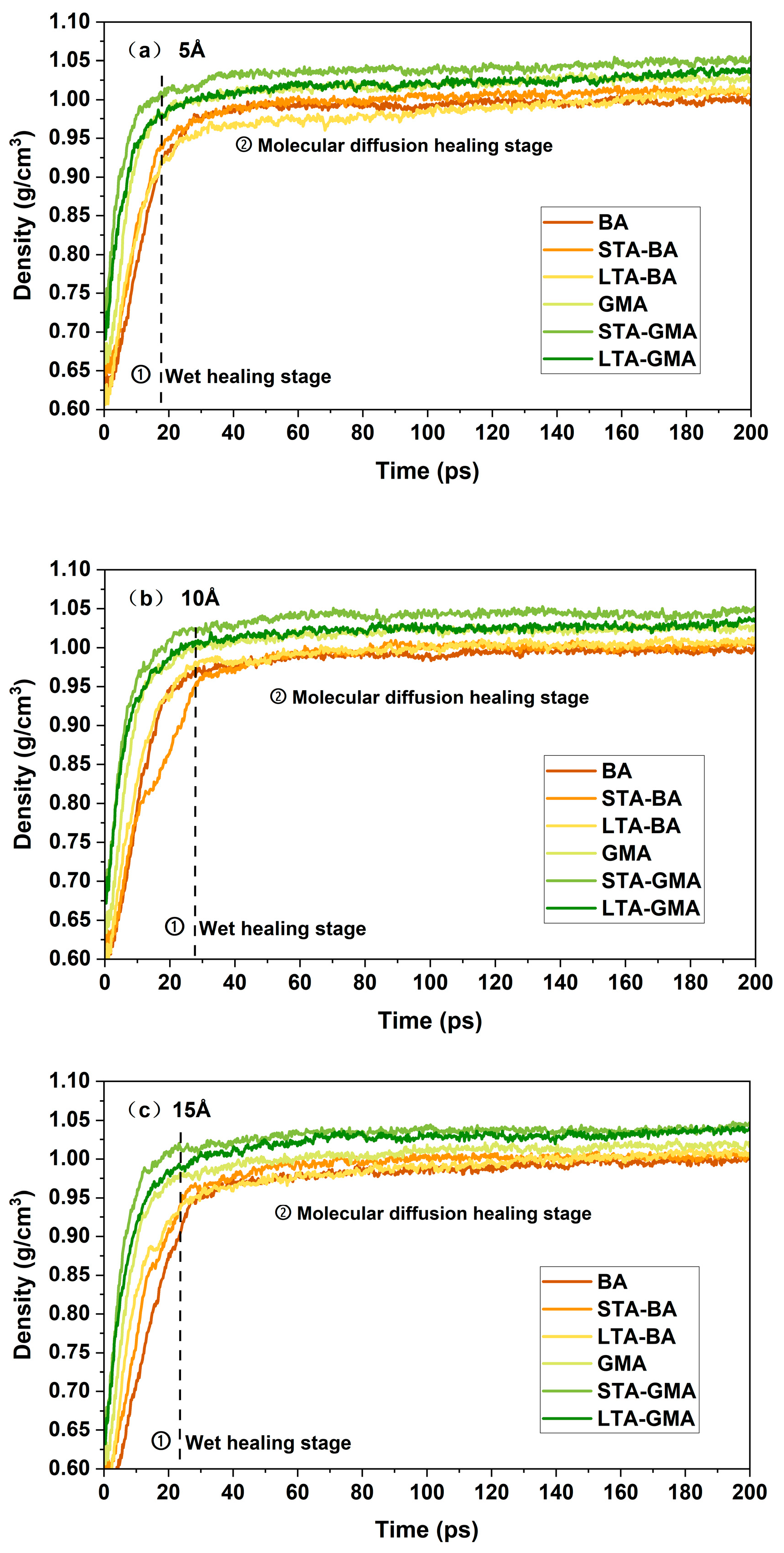

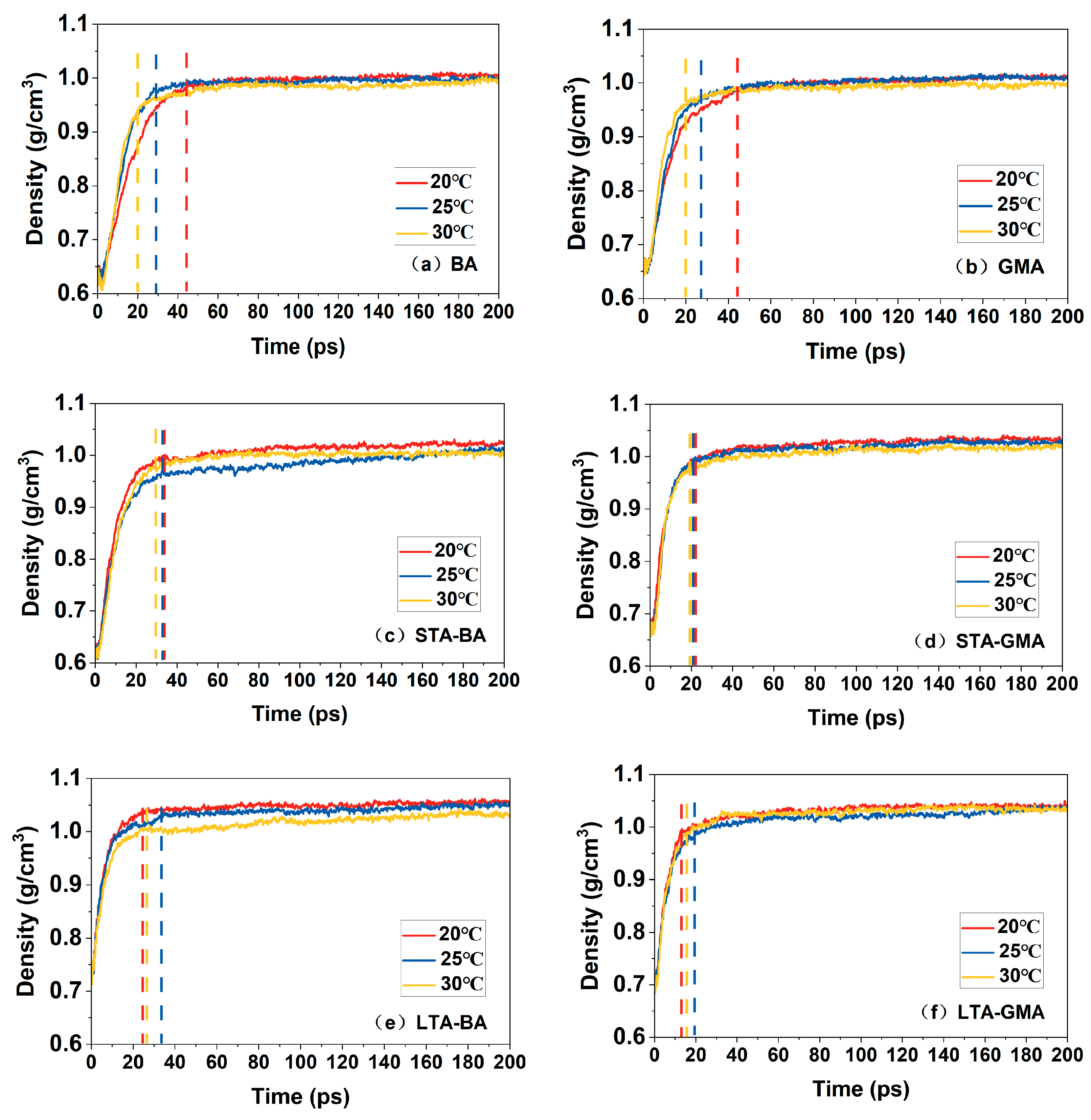

4.1. Density

4.2. Mean Square Displacement and Diffusion Coefficient

5. Conclusions

- (1)

- The healing simulation process can be divided into two stages: the wetting healing stage and the molecular diffusion healing stage. It was found that temperature changes have a greater impact on the healing effect of unaged asphalt. When other conditions remain constant, an increase in healing temperature shortens the duration of the first stage, indicating that the healing process is accelerated to some extent with higher environmental temperatures.

- (2)

- During oxidative aging, the chemical composition of asphalt undergoes oxidation and dehydrogenation, with oxygen atoms in some groups replacing hydrogen atoms on the phenyl carbon. This hinders molecular migration within the asphalt crack model, reducing the relaxation ability of asphalt molecules and ultimately worsening the healing effect. Oxidative aging has a negative impact on self-healing efficiency, showing a higher degree of influence compared to healing temperature.

- (3)

- Under unaged and short-term aging conditions, the healing performance of graphene-modified asphalt is similar to that of base asphalt. However, under long-term aging conditions, the healing performance of graphene-modified asphalt is superior. As the years of use increase, the decline in the healing performance of graphene-modified asphalt is slower than that of base asphalt, indicating stronger anti-aging properties for graphene-modified asphalt.

- (4)

- When the crack width is small, factors such as temperature and aging degree have less impact on the diffusion coefficient results of the asphalt crack model, resulting in similar curves. As the crack width increases, the influence of these factors on the diffusion coefficient becomes more significant. When the crack width is large, the healing effect of asphalt is more dependent on various influencing factors. Increasing crack width amplifies the impact of various factors on the self-healing process, thereby reducing self-healing efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Men, B.; Li, X.; Sha, T.; Guo, F.; Tang, G.; Yue, J. Research on Fatigue Performance of Fast-Melting SBS/Epoxy Resin Composite-Modified Asphalt. Coatings 2024, 14, 789. [Google Scholar] [CrossRef]

- Men, B.; Guo, F.; Kang, X.; Yue, J. Research on the Adhesion Properties of Fast-Melting SBS-Modified Asphalt–Aggregate Based on Surface Free Energy Theory. Materials 2023, 16, 7601. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.; Amirkhanian, S. Investigation of the Graphene Oxide and Asphalt Interaction and Its Effect on Asphalt Pavement Performance. Constr. Build. Mater. 2018, 165, 572–584. [Google Scholar] [CrossRef]

- Almutairi, H.; Baaj, H. Evaluating Self-Healing Behaviour of Asphalt Binders Modified with Phase-Change Materials, Polymers and Recycled Glass Powder. Polymers 2023, 15, 1934. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Lin, T.; Zhu, X.; Tian, Y.; Liu, F. Indices for Self-Healing Performance Assessments Based on Molecular Dynamics Simulation of Asphalt Binders. Comput. Mater. Sci. 2016, 114, 86–93. [Google Scholar] [CrossRef]

- Long, Z.; You, L.; Tang, X.; Ma, W.; Ding, Y.; Xu, F. Analysis of interfacial adhesion properties of nano-silica modified asphalt mixtures using molecular dynamics simulation. Constr. Build. Mater. 2020, 255, 119354. [Google Scholar] [CrossRef]

- Hajj, R.; Bhasin, A. The search for a measure of fatigue cracking in asphalt binders-a review of different approaches. Int. J. Pavement Eng. 2018, 19, 205–219. [Google Scholar] [CrossRef]

- Zhu, Q.; Liu, C.; Wang, Y.; Su, Y.; Li, M. Effect of Modifiers on Self-Healing and Rheological Properties of Asphalt Binder. Materials 2024, 17, 3304. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Sun, Y.; Kong, L.; Cannone Falchetto, A.; Yuan, D.; Wang, W. Study on Multiple Effects of Self-Healing Properties and Thermal Characteristics of Asphalt Pavement. Buildings 2024, 14, 1313. [Google Scholar] [CrossRef]

- Xu, S.; Liu, X.; Tabaković, A.; Schlangen, E. Experimental Investigation of the Performance of a Hybrid Self-Healing System in Porous Asphalt under Fatigue Loadings. Materials 2021, 14, 3415. [Google Scholar] [CrossRef]

- Li, J.; Ji, X.-P.; Fang, X.-Z.; Hu, Y.-L.; Hua, W.-L.; Zhang, Z.-M.; Shao, D.-Y. Self-healing performance and prediction model of microcapsule asphalt. Constr. Build. Mater. 2022, 330, 127085. [Google Scholar] [CrossRef]

- de Oliveira, L.S.; Júnior, J.L.O.L.; Babadopulos, L.F.A.L.; Soares, J.B. Stiffness and fatigue evaluation in cyclic tests with rest periods for asphalt mixtures with or without fly ash. Constr. Build. Mater. 2022, 322, 126426. [Google Scholar] [CrossRef]

- Xu, S.; Tabaković, A.; Liu, X.; Palin, D.; Schlangen, E. Optimization of the Calcium Alginate Capsules for Self-Healing Asphalt. Appl. Sci. 2019, 9, 468. [Google Scholar] [CrossRef]

- Nalbandian, K.M.; Carpio, M.; González, A. Analysis of the scientific evolution of self-healing asphalt pavements: Toward sustainable road materials. J. Clean. Prod. 2021, 293, 126107. [Google Scholar] [CrossRef]

- Li, R.; Yu, S.; Chen, H.; Wu, J.; Chen, Y.; Yue, J. Effects of a Complex Environment on Fatigue and Self-Healing Characterization of Asphalt Composites Containing Rock Asphalt. Materials 2024, 17, 2453. [Google Scholar] [CrossRef]

- Zhang, L.; Hoff, I.; Zhang, X.; Liu, J.; Yang, C.; Wang, F. A Methodological Review on Development of Crack Healing Technologies of Asphalt Pavement. Sustainability 2023, 15, 9659. [Google Scholar] [CrossRef]

- Fan, S.; Zhu, H.; Yuan, H.; Chen, C. Fracture-healing properties of asphalt mixtures and microwave heating thermo-sensitivity analysis of their constituent materials. J. Clean. Prod. 2021, 312, 127763. [Google Scholar] [CrossRef]

- Bhasin, A.; Ganesan, V. Preliminary investigation of using a multi-component phase field model to evaluate microstructure of asphalt binders. Int. J. Pavement Eng. 2017, 18, 775–782. [Google Scholar] [CrossRef]

- Sun, D.; Sun, G.; Zhu, X.; Pang, Q.; Yu, F.; Lin, T. Identification of wetting and molecular diffusion stages during self-healing process of asphalt binder viafluorescence microscope. Constr. Build. Mater. 2017, 132, 230–239. [Google Scholar] [CrossRef]

- Zhang, D.-R.; Luo, R.; Chen, Y.; Zhang, S.-Z.; Sheng, Y. Performance Analysis of DCLR-modified Asphalt Based on Surface Free Energy. Zhongguo GongluXuebao/China J. Highw. Transp. 2016, 29, 22–28. [Google Scholar]

- Xiao, M.; Guo, X.; Dong, J.; Li, C.; Ren, J. Microscopic self-healing of multi-walled carbon nanotube-modified asphalt based on the dual diffusion-energy theory. Can. J. Civ. Eng. 2024, 51, 434–448. [Google Scholar] [CrossRef]

- Qu, X.; Wang, D.; Wang, L.; Huang, Y.; Hou, Y.; Oeser, M. The state-of-the-art review on molecular dynamics simulation of asphalt binder. Adv. Civ. Eng. 2018, 2018, 4546191. [Google Scholar] [CrossRef]

- Li, C.; Wu, S.; Chen, Z.; Tao, G.; Xiao, Y. Improved Microwave Heating and Healing Properties of Bitumen by Using Nanometer Microwave-Absorbers. Constr. Build. Mater. 2018, 189, 757–767. [Google Scholar] [CrossRef]

- Liu, J.; Hao, P.; Dou, Z.; Wang, J.; Ma, L. Rheological, Healing and Microstructural Properties of Unmodified and Crumb Rubber Modified Asphalt Incorporated with Graphene/Carbon Black Composite. Constr. Build. Mater. 2021, 305, 124512. [Google Scholar] [CrossRef]

- Wang, R.; An, X. An Optimized Fatigue Model of Asphalt Binder Combining Nonlinear Viscoelastic and Intrinsic Healing Characteristics. Constr. Build. Mater. 2024, 424, 135946. [Google Scholar] [CrossRef]

- Wang, R.; Qi, Z.; Li, R.; Yue, J. Investigation of the Effect of Aging on the Thermodynamic Parameters and the Intrinsic Healing Capability of Graphene Oxide Modified Asphalt Binders. Constr. Build. Mater. 2020, 230, 116984. [Google Scholar] [CrossRef]

- Gong, Y.; Xu, J.; Yan, E.-h.; Cai, J.-h. The self-healing performance of carbon-based nanomaterials modified asphalt binders based on molecular dynamics simulations. Front. Mater. 2021, 7, 599551. [Google Scholar] [CrossRef]

- Qu, X.; Wang, D.; Hou, Y.; Liu, Q.; Oeser, M.; Wang, L. Investigation on self-healing behavior of asphalt binder using a six-fraction molecular model. J. Mater. Civ. Eng. 2019, 31, 04019046. [Google Scholar] [CrossRef]

- Sun, W.; Wang, H. Self-healing of asphalt binder with cohesive failure: Insights from molecular dynamics simulation. Constr. Build. Mater. 2020, 262, 120538. [Google Scholar] [CrossRef]

- Trong, D.N.; Long, V.C.; Ţălu, Ş. The Influence of Shape and Matrix Size on the Mechanical Properties of the 2D Epoxy Thin Film by Monte Carlo Simulation Method. J. Appl. Polym. Sci. 2020, 137, 48274. [Google Scholar] [CrossRef]

- Xu, H.; Xu, W.; Zheng, X.; Cao, K. A Multistage Analysis of Asphalt Binder Nanocrack Generation and Self-Healing Behavior Based on Molecular Dynamics. Polymers 2022, 14, 3581. [Google Scholar] [CrossRef] [PubMed]

- You, Z.; Mills-Beale, J.; Foley, J.M.; Roy, S.; Odegard, G.M.; Dai, Q.; Goh, S.W. Nanoclay-modified asphalt materials: Preparation and characterization. Constr. Build. Mater. 2011, 25, 1072–1078. [Google Scholar] [CrossRef]

- Li, D.D.; Greenfield, M.L. Chemical compositions of improved model asphalt systems for molecular simulations. Fuel 2014, 115, 347–356. [Google Scholar] [CrossRef]

- He, L.; Li, G.; Lv, S.; Gao, J.; Kowalski, K.J.; Valentin, J.; Alexiadis, A. Self-healing behavior of asphalt system based on molecular dynamics simulation. Constr. Build. Mater. 2020, 254, 119225. [Google Scholar] [CrossRef]

- Agzenai, Y.; Pozuelo, J.; Sanz, J.; Perez, I.; Baselga, J. Advanced self-healing asphalt composites in the pavement performance field: Mechanisms at the nano level and new repairing methodologies. Recent Pat. Nanotechnolog. 2015, 9, 43–50. [Google Scholar] [CrossRef]

- Ayar, P.; Moreno-Navarro, F.; Rubio-Gámez, M.C. The healing capability of asphalt pavements: A state of the art review. J. Clean. Prod. 2016, 113, 28–40. [Google Scholar] [CrossRef]

- Sun, D.; Lin, T.; Zhu, X.; Cao, L. Calculation and evaluation of activation energy as a self healing indication of asphalt mastic. Constr. Build. Mater. 2015, 95, 431–436. [Google Scholar] [CrossRef]

- Bhasin, A.; Little, D.N.; Bommavaram, R.; Vasconcelos, K.; Little, D.N.; Bommavaram, R.; Vasconcelos, K. A Framework to Quantify the Effect of Healing in Bituminous Materials Using Material Properties. Road Mater. Pavement Des. 2008, 9, 219–242. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Wu, Z.; Sun, B. Influencing Factors and Evaluation of the Self-Healing Behavior of Asphalt Binder Using Molecular Dynamics Simulation Method. Molecules 2023, 28, 2860. [Google Scholar] [CrossRef] [PubMed]

- Ren, S.; Liu, X.; Lin, P.; Gao, Y.; Erkens, S. Review on the Diffusive and Interfacial Performance of Bituminous Materials: From a Perspective of Molecular Dynamics Simulation. J. Mol. Liq. 2022, 366, 120363. [Google Scholar] [CrossRef]

| Molecular Name | Molecular Formula | Atomic Number | Molar Mass (g/mol) | Mass Fraction (%) |

|---|---|---|---|---|

| Squalane | C30H62 | 92 | 422.8 | 5.19 |

| Hopane | C35H62 | 97 | 482.9 | 5.93 |

| PHPN | C35H44 | 79 | 464.7 | 15.68 |

| DOCHN | C30H46 | 76 | 406.7 | 16.22 |

| Quinolinohopane | C40H59N | 100 | 553.9 | 6.79 |

| Thioisorenieratane | C40H60S | 101 | 573 | 7.03 |

| Trimethylbenzeneoxane | C29H50O | 80 | 414.7 | 6.36 |

| Pyridinohopane | C36H57N | 94 | 503.9 | 6.18 |

| Benzobisbenzothiophene | C18H10S2 | 30 | 290.4 | 13.36 |

| Asphaltene-phenol | C42H54O | 97 | 574.9 | 5.29 |

| Asphaltene-pyrrole | C66H81N | 148 | 888.4 | 5.45 |

| Asphaltene-thiophene | C51H62S | 114 | 707.1 | 6.51 |

| Asphalt Type | Simulated Density | Measured Density |

|---|---|---|

| 70# | 0.995 | 1.016 |

| GMA | 1.007 | 1.023 |

| RTFOT-70# | 1.019 | 1.074 |

| RTFOT-GMA | 1.025 | 1.076 |

| PAV-70# | 1.054 | 1.082 |

| PAV-GMA | 1.04 | 1.091 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, F.; Li, X.; Wang, Z.; Chen, Y.; Yue, J. Study on the Factors Affecting the Self-Healing Performance of Graphene-Modified Asphalt Based on Molecular Dynamics Simulation. Polymers 2024, 16, 2482. https://doi.org/10.3390/polym16172482

Guo F, Li X, Wang Z, Chen Y, Yue J. Study on the Factors Affecting the Self-Healing Performance of Graphene-Modified Asphalt Based on Molecular Dynamics Simulation. Polymers. 2024; 16(17):2482. https://doi.org/10.3390/polym16172482

Chicago/Turabian StyleGuo, Fei, Xiaoyu Li, Ziran Wang, Yijun Chen, and Jinchao Yue. 2024. "Study on the Factors Affecting the Self-Healing Performance of Graphene-Modified Asphalt Based on Molecular Dynamics Simulation" Polymers 16, no. 17: 2482. https://doi.org/10.3390/polym16172482

APA StyleGuo, F., Li, X., Wang, Z., Chen, Y., & Yue, J. (2024). Study on the Factors Affecting the Self-Healing Performance of Graphene-Modified Asphalt Based on Molecular Dynamics Simulation. Polymers, 16(17), 2482. https://doi.org/10.3390/polym16172482