Evaluating the Piezoelectric Energy Harvesting Potential of 3D-Printed Graphene Prepared Using Direct Ink Writing and Fused Deposition Modelling

Abstract

1. Introduction

- (i)

- Vat photopolymerization;

- (ii)

- Material extrusion;

- (iii)

- Material jetting;

- (iv)

- Binder jetting;

- (v)

- Powder bed fusion;

- (vi)

- Direct energy deposition;

- (vii)

- Sheet lamination.

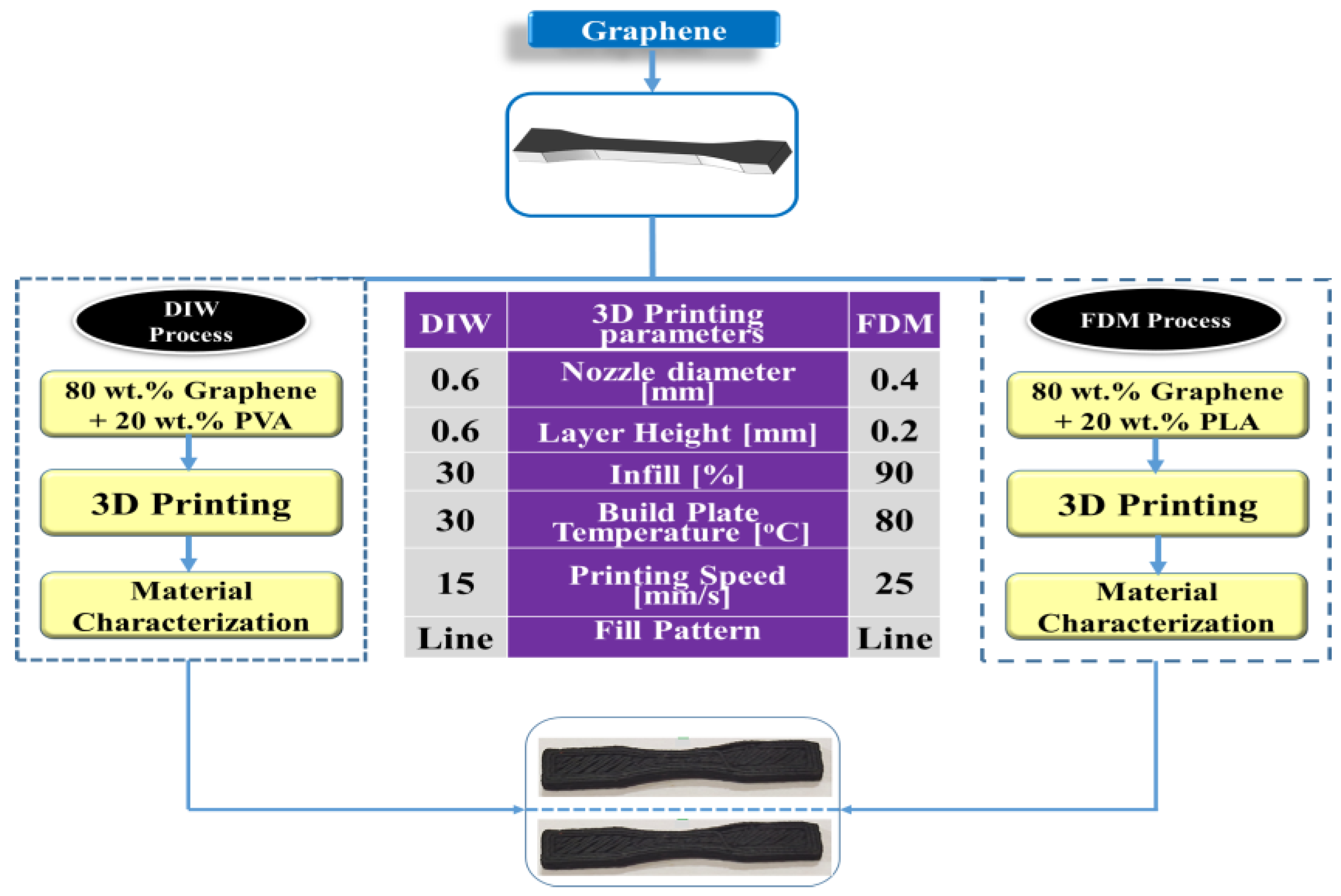

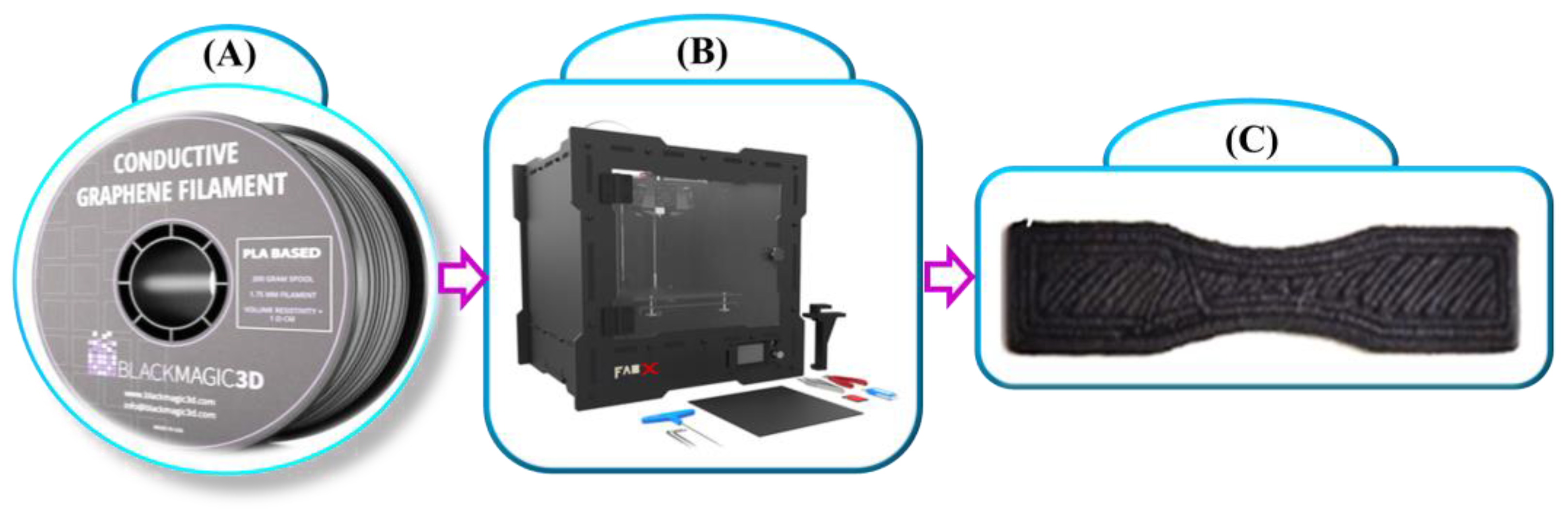

2. Materials and Methods

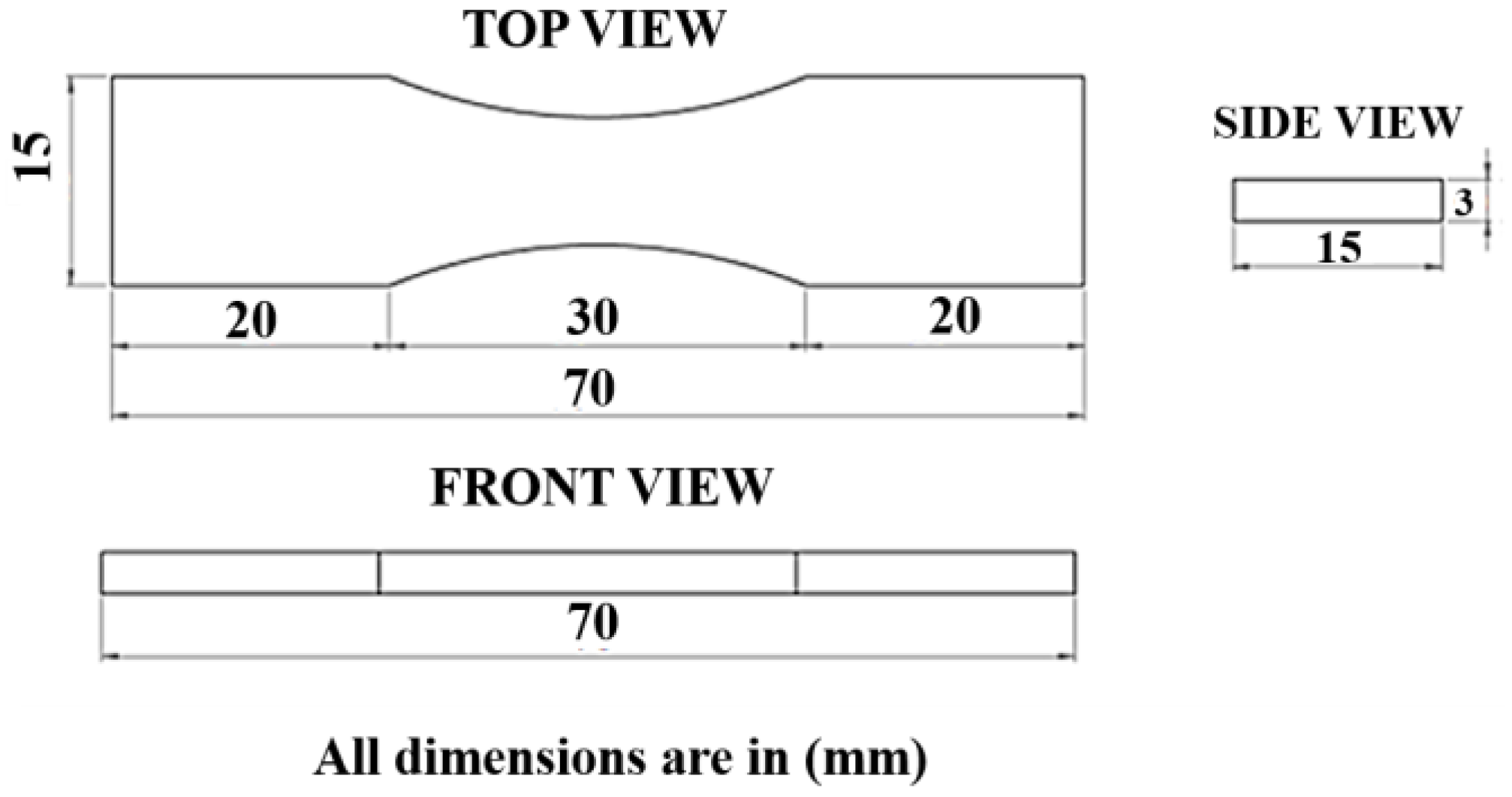

2.1. Proposed Design

2.2. Materials

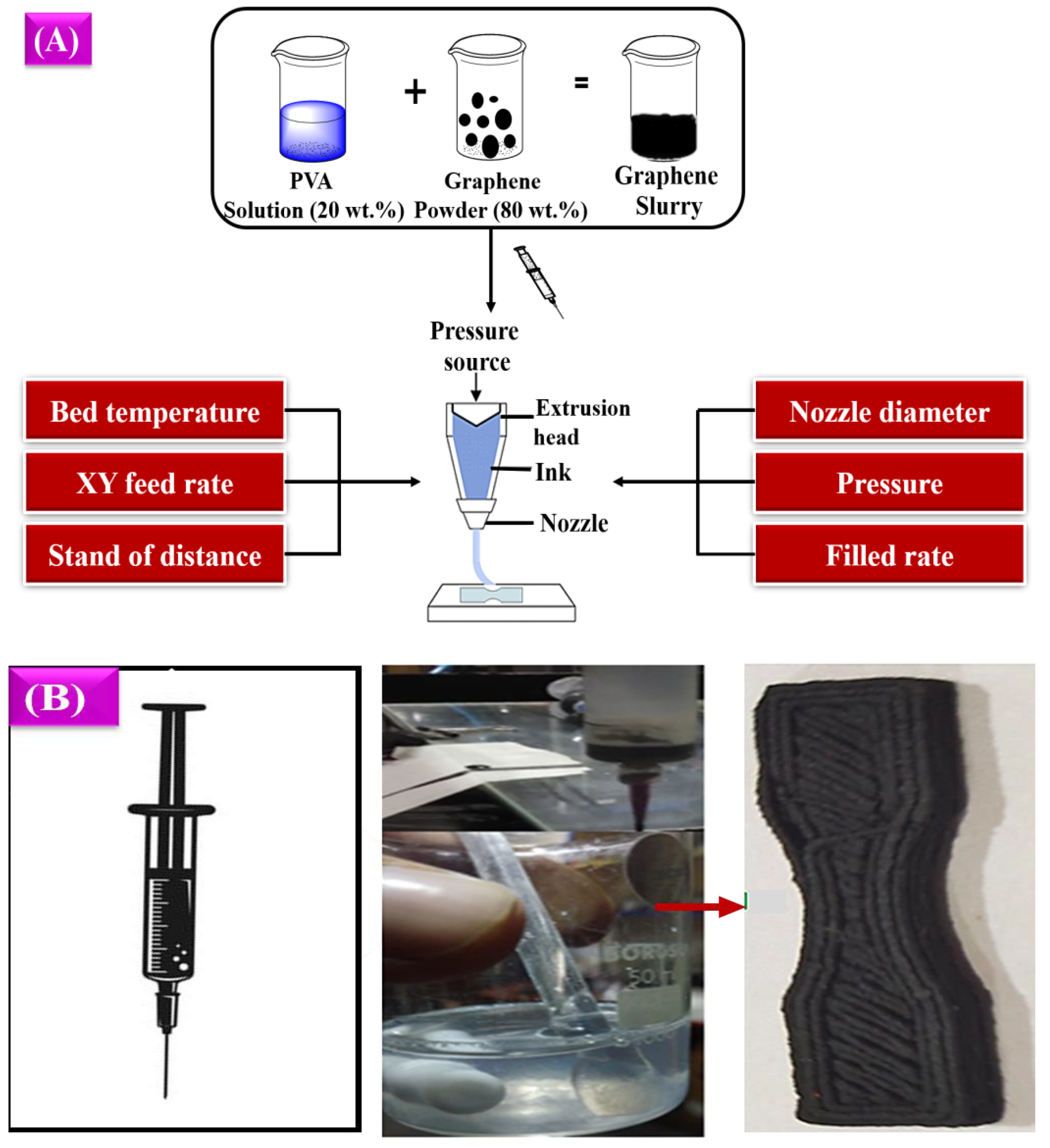

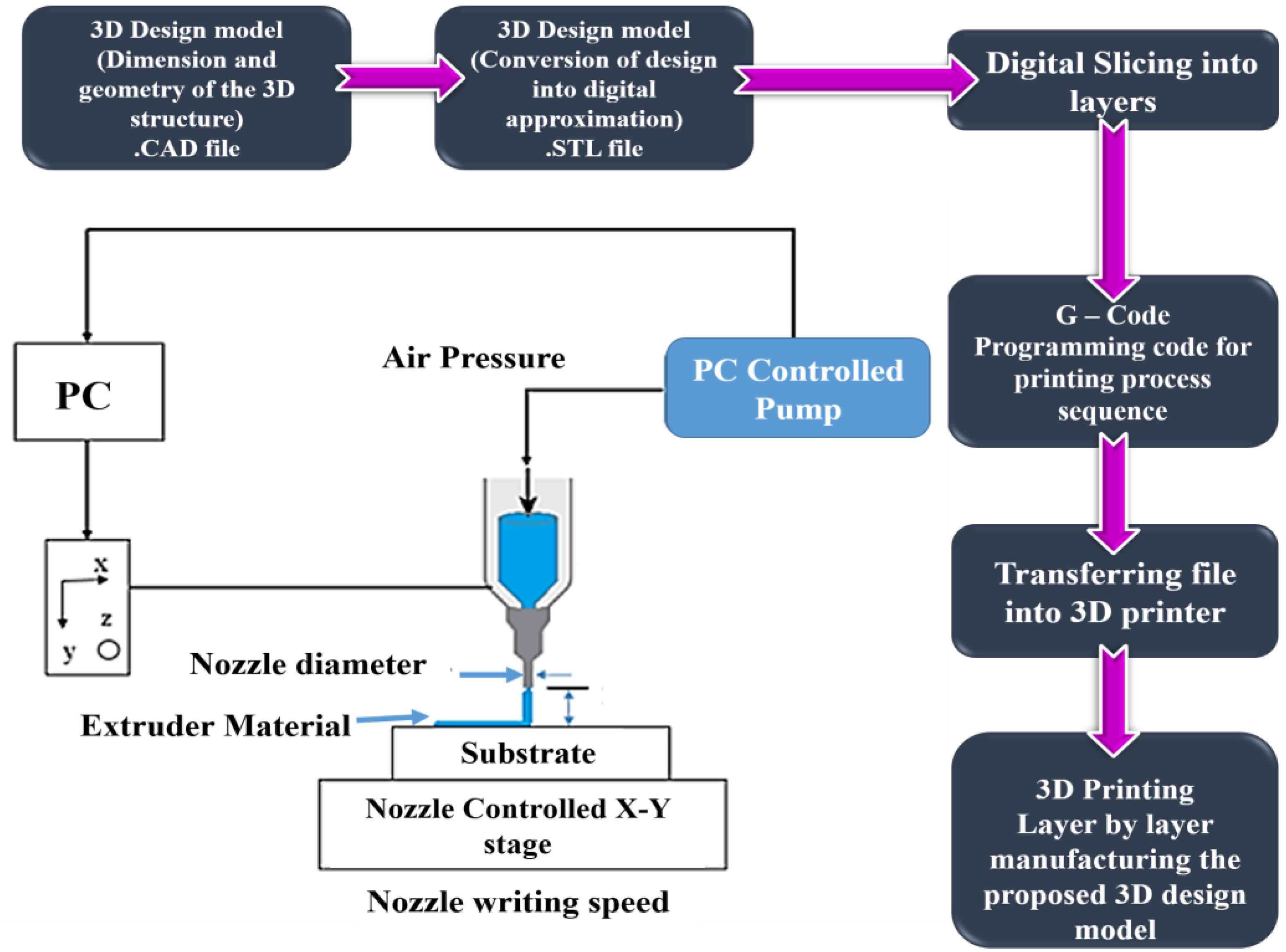

2.3. Preparation of 3D-Printed Graphene-Based Composite Using the DIW Process

2.4. Preparation of 3D-Printed Graphene-Based Composite Using the FDM Process

- Volume resistivity: 0.6 ohm-cm;

- Colour: black;

- Diameter: 1.75 mm;

- Weight: 100 g;

- Graphene for superior conductivity and improved mechanical properties;

- PLA-based.

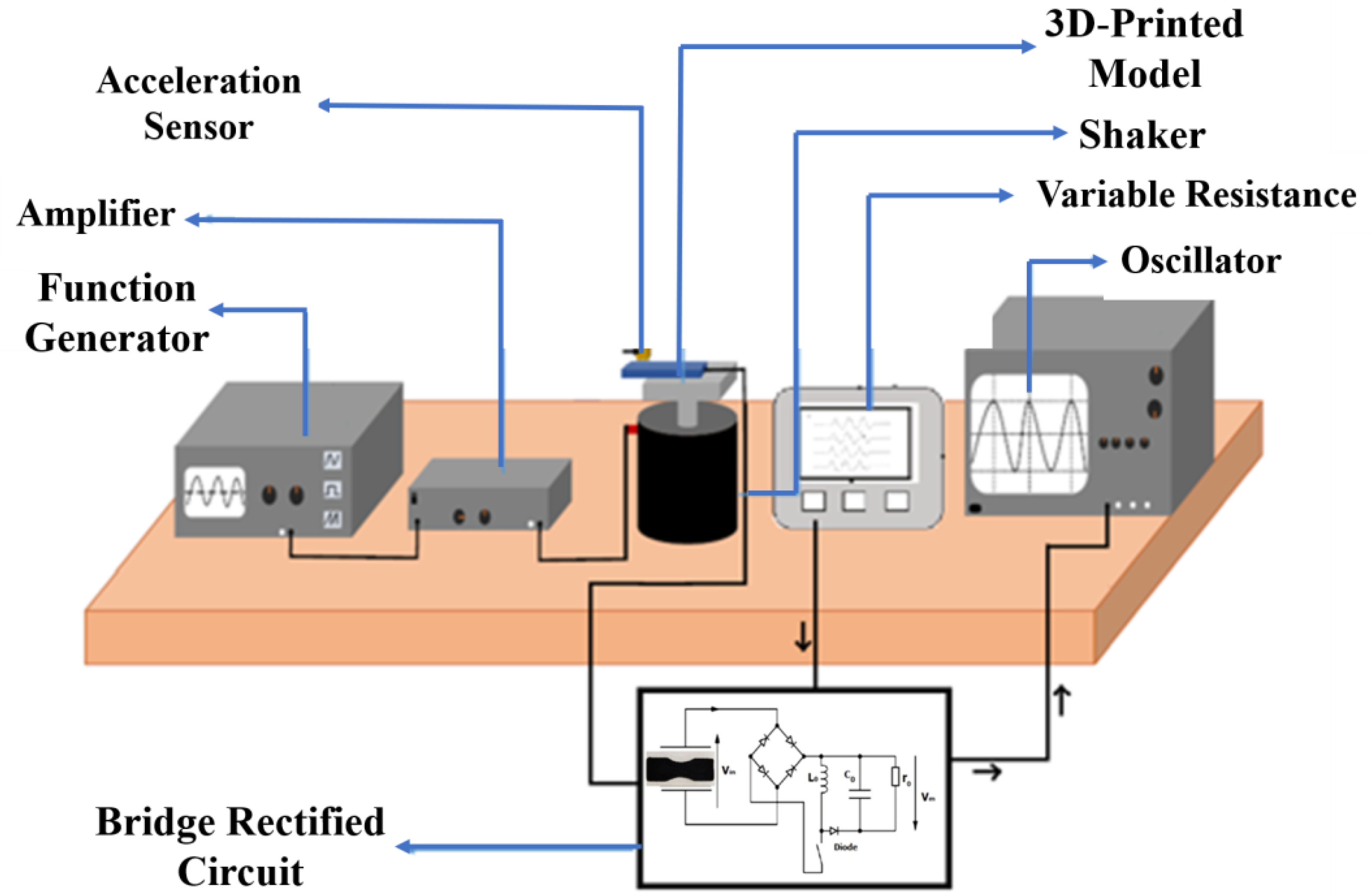

3. Testing Approaches

3.1. Microstructural Analysis

3.2. Experimental Analysis of Vibration-Based Energy Harvesting Method

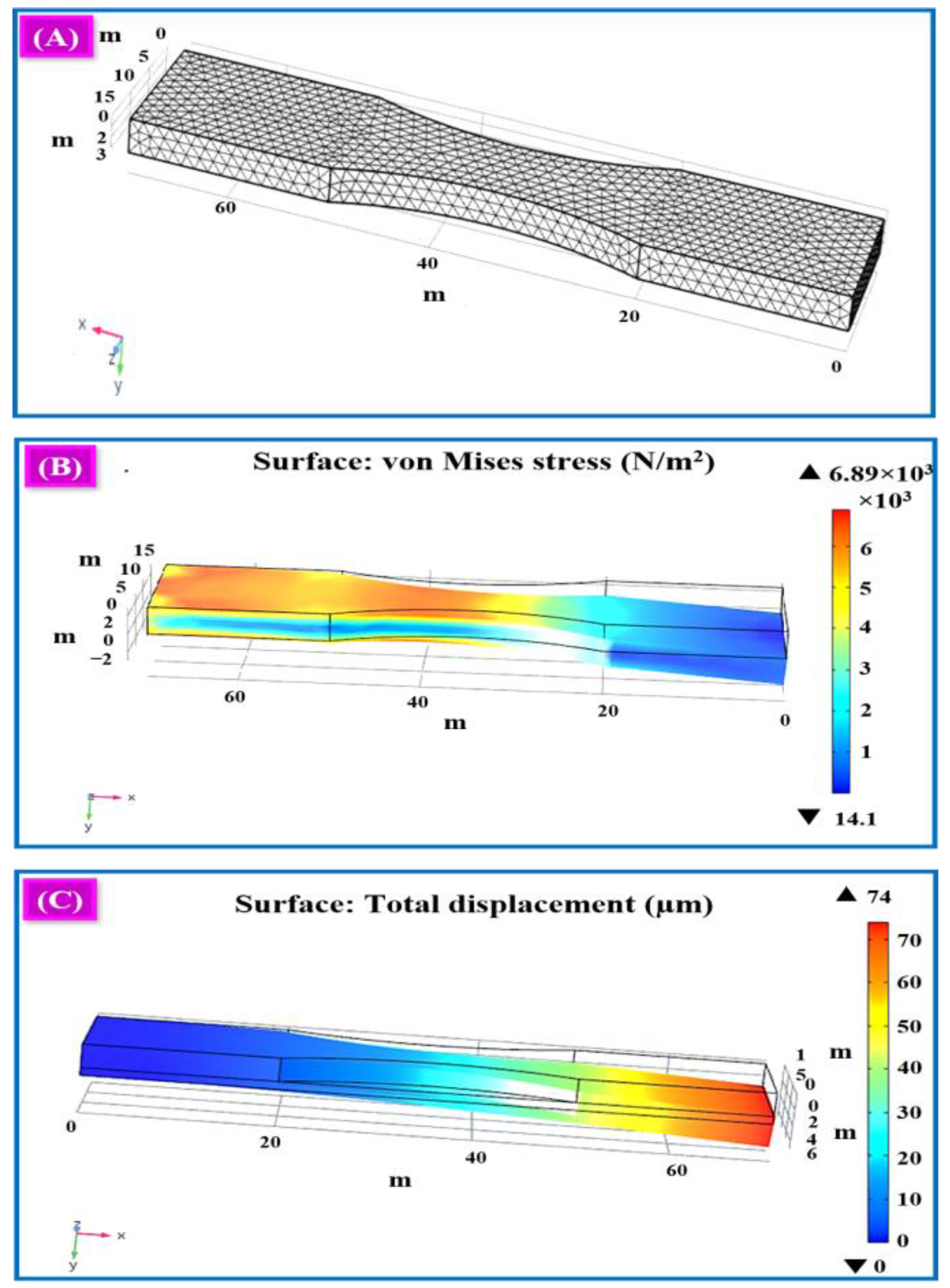

3.3. Simulation

4. Results and Discussion

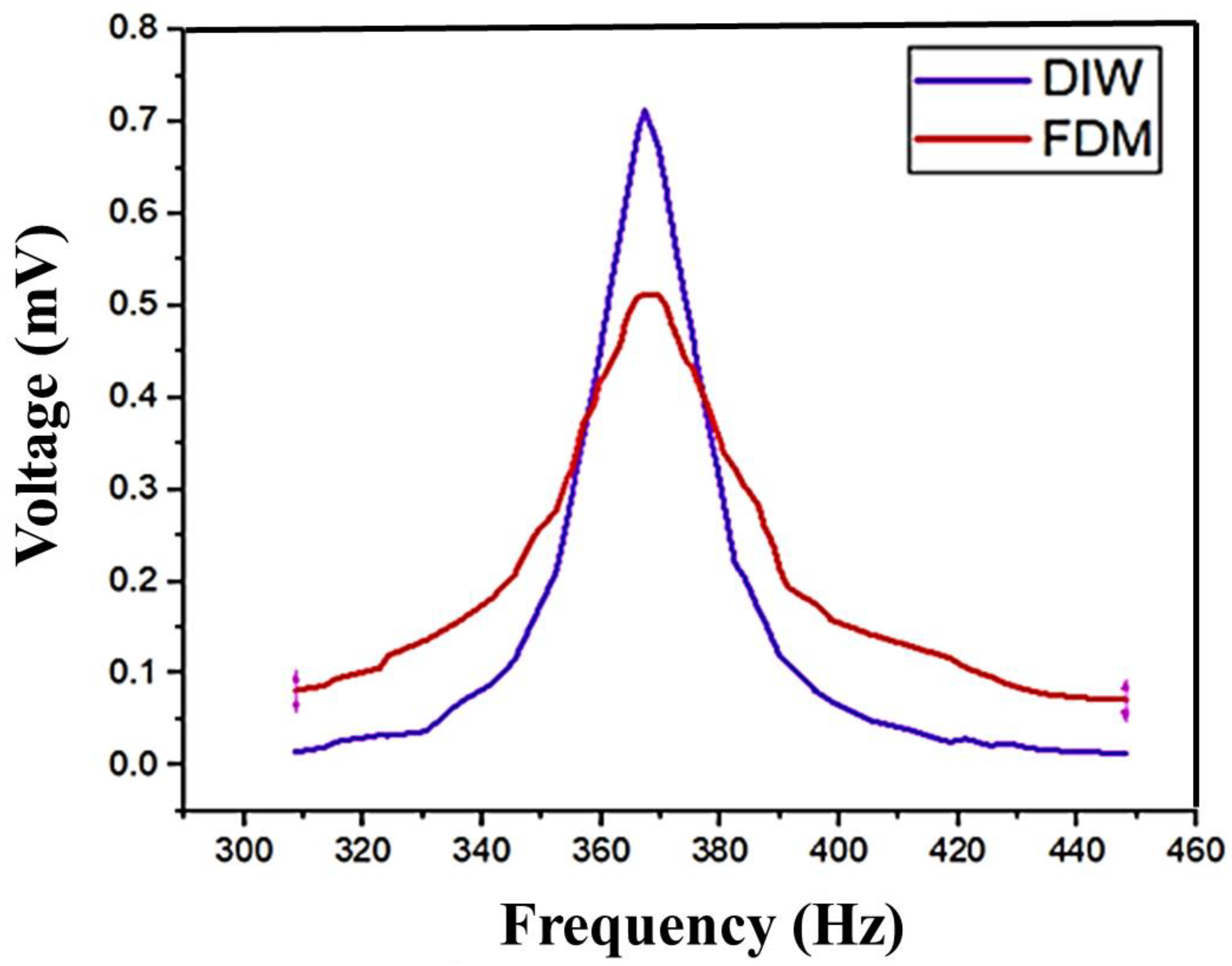

4.1. Experimental Analysis of Cantilever Beam Technique

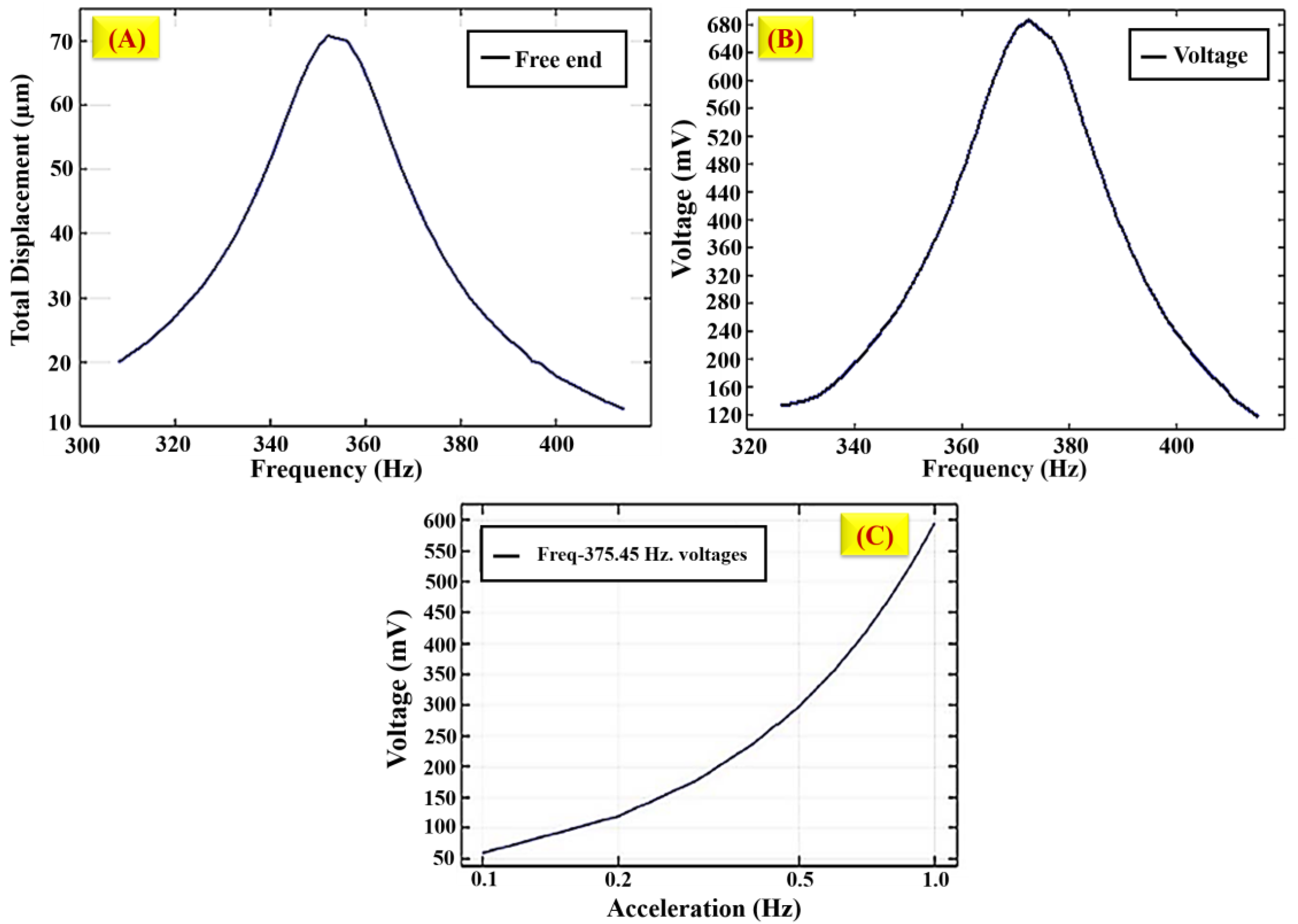

4.1.1. Voltage and Frequency

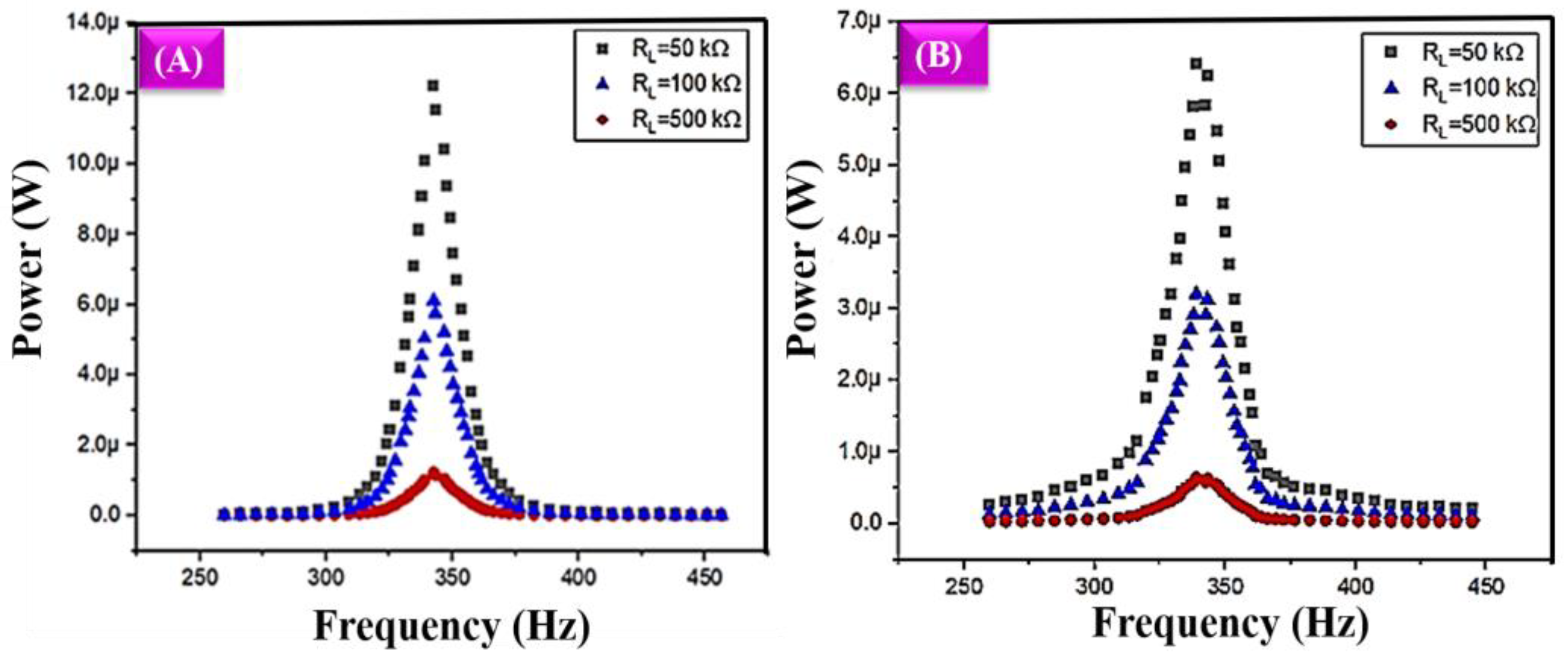

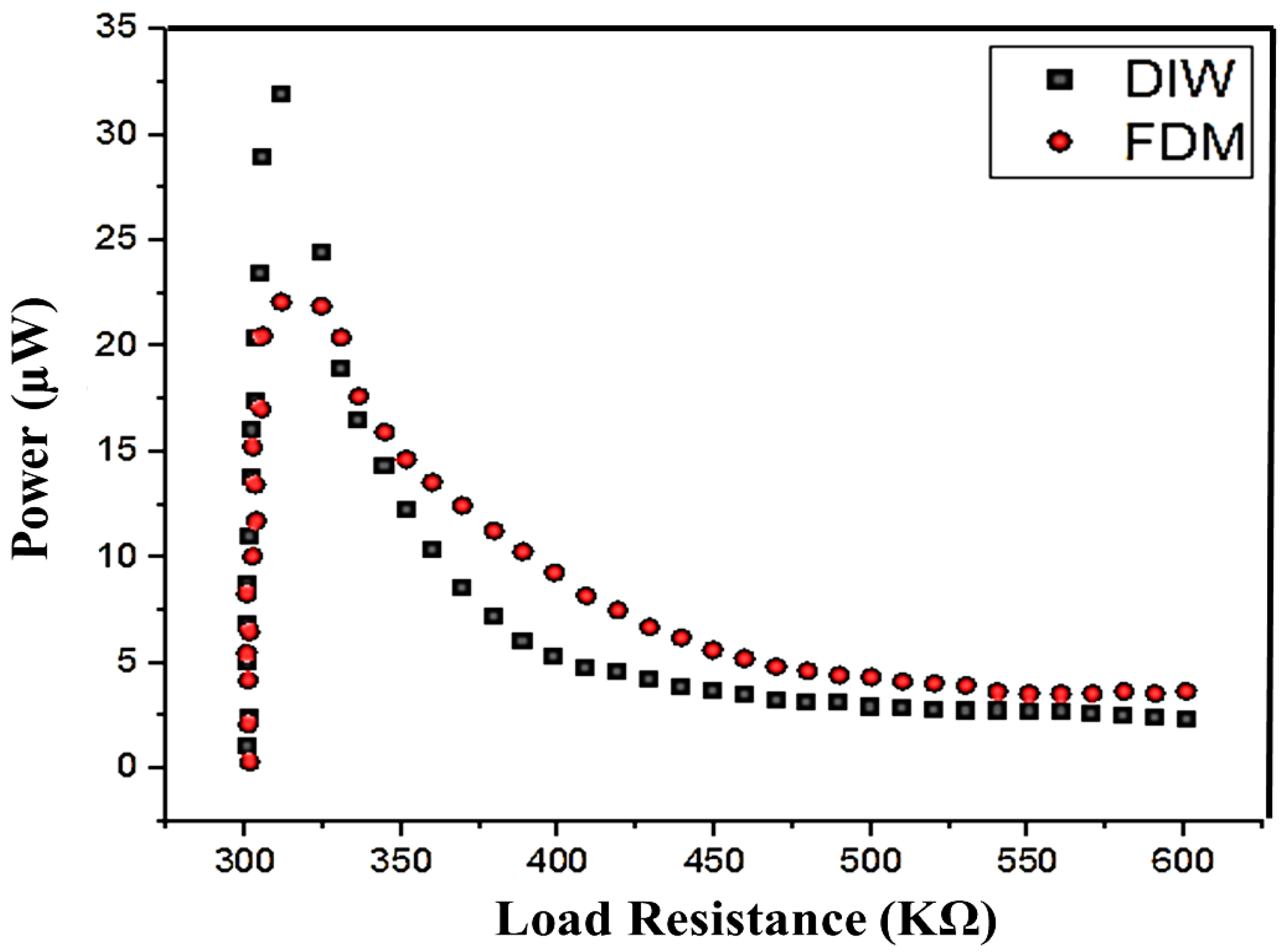

4.1.2. Power and Frequency

4.2. Microstructure Analysis

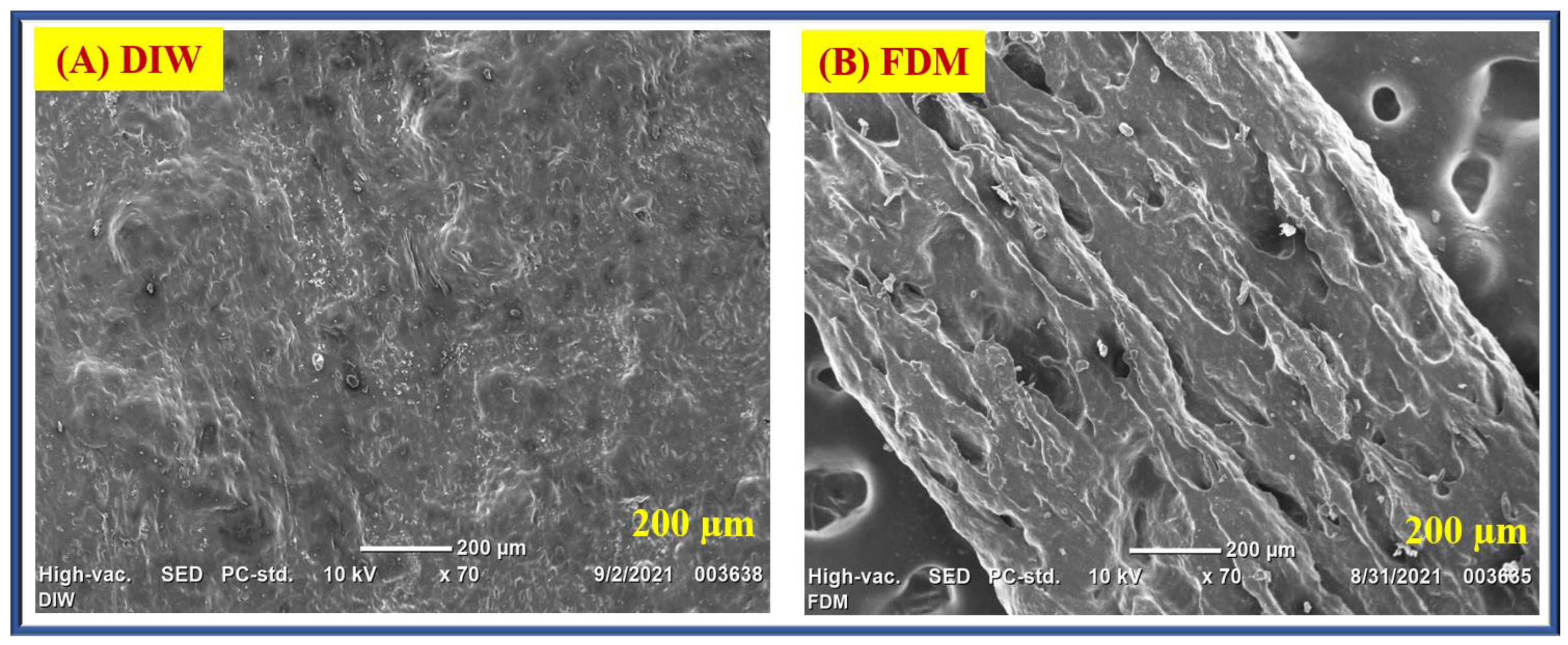

4.2.1. SEM Analysis

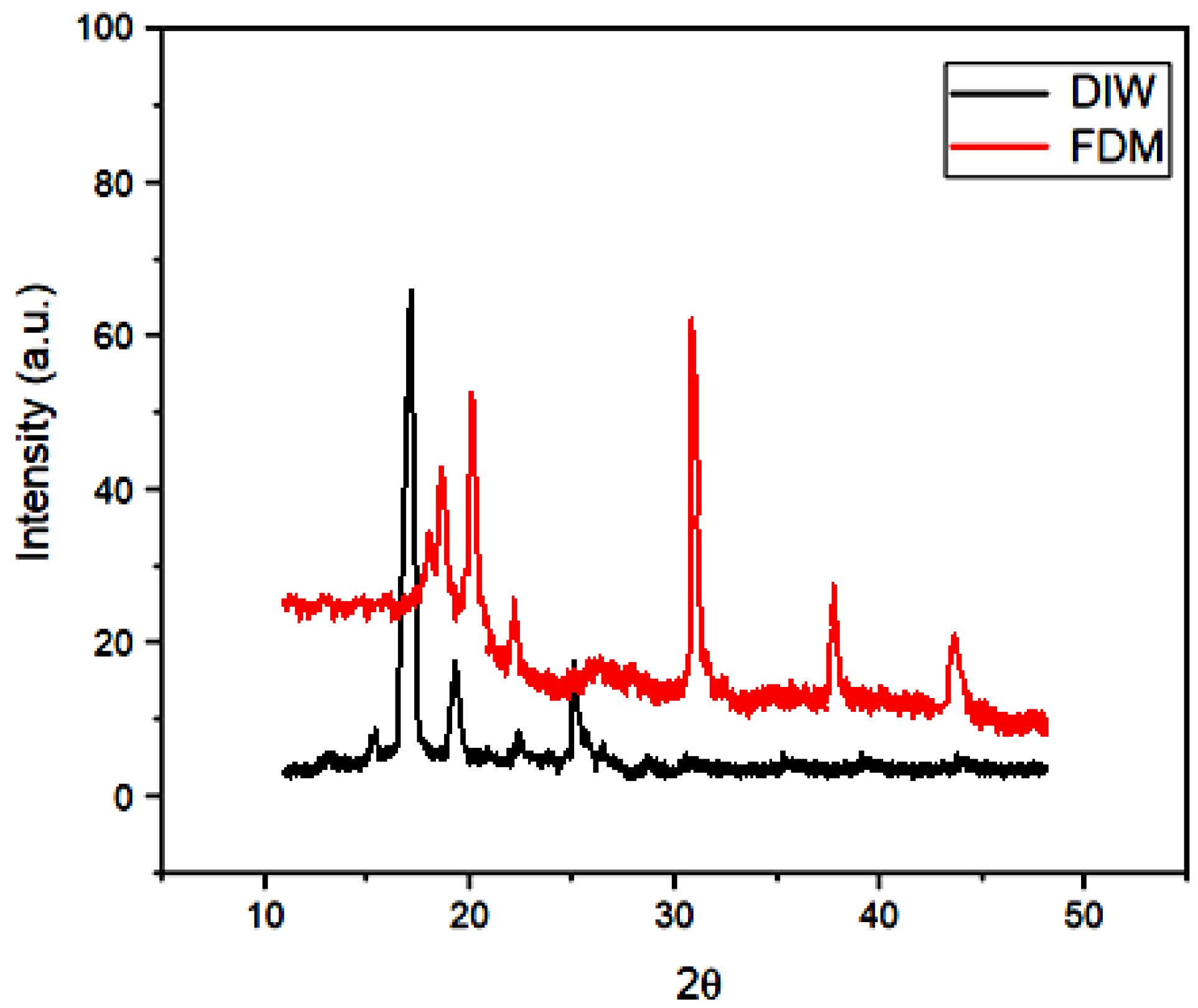

4.2.2. XRD Analysis

4.3. COMSOL Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jaisingh Sheoran, A.; Kumar, H. Fused Deposition modeling process parameters optimization and effect on mechanical properties and part quality: Review and reflection on present research. Mater. Today 2020, 21, 1659–1672. [Google Scholar] [CrossRef]

- Beaman, J.J.; Bourell, D.L.; Seepersad, C.C.; Kovar, D. Additive manufacturing review: Early past to current practice. J. Manuf. Sci. Eng. 2020, 142, 110812. [Google Scholar] [CrossRef]

- Chen, W.D.; Hu, H.S.; Qian, S.X.; Zhu, D.K. Research on energy harvesting behaviors of different shapes of piezoelectric vibrator. Appl. Mech. Mater. 2012, 164, 441–445. [Google Scholar] [CrossRef]

- Ng, T.H.; Liao, W.H. Sensitivity analysis and energy harvesting for a self-powered piezoelectric sensor. J. Intell. Mater. Syst. Struct. 2005, 16, 785–797. [Google Scholar] [CrossRef]

- Sun, C.; Shang, G. Multi-direction piezoelectric energy harvesting techniques. J. Power. Energy. Eng. 2019, 7, 52–59. [Google Scholar] [CrossRef]

- Čeponis, A.; Mažeika, D.; Kilikevičius, A. Bi-directional piezoelectric multi-modal energy harvester based on saw-tooth cantilever array. Sensors 2022, 22, 2880. [Google Scholar] [CrossRef]

- Gedeon, D.; Meyer, S.T.; Rupitsch, S.J.; Lerch, R. D7. 1—A hybrid simulation approach for piezoelectric vibration energy harvesting. In Proceedings of the SENSOR 2015, Nürnberg, Germany, 19–21 May 2015; pp. 621–625. [Google Scholar] [CrossRef]

- Shi, J.; Akbarzadeh, A.H. Architected cellular piezoelectric metamaterials: Thermo-electro-mechanical properties. Acta. Mater. 2019, 163, 91–121. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO: Geneva, Switzerland, 2021.

- Pérez, M.; Carou, D.; Rubio, E.M.; Teti, R. Current advances in additive manufacturing. Procedia Cirp. 2020, 88, 439–444. [Google Scholar] [CrossRef]

- Mercado Rivera, F.J.; Rojas Arciniegas, A.J. Additive manufacturing methods: Techniques, materials, and closed-loop control applications. Int. J. Adv. Manuf. Technol. 2020, 109, 17–31. [Google Scholar] [CrossRef]

- Martínez-García, A.; Monzón, M.; Paz, R. Standards for additive manufacturing technologies: Structure and impact. Handbooks in Advanced Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 395–408. [Google Scholar] [CrossRef]

- Maurya, D.; Khaleghian, S.; Sriramdas, R.; Kumar, P.; Kishore, R.A.; Kang, M.G.; Kumar, V.; Song, H.C.; Lee, S.Y.; Yan, Y.; et al. 3D printed graphene-based self-powered strain sensors for smart tires in autonomous vehicles. Nat. Commun. 2020, 11, 5392. [Google Scholar] [CrossRef]

- Kim, H.; Torres, F.; Villagran, D.; Stewart, C.; Lin, Y.; Tseng, T.B. 3D printing of BaTiO3 /PVDF composites with electric in situ poling for pressure sensor applications. Macromol. Mater. Eng. 2017, 302, 1700229. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Pang, Y.; Cao, Y.; Chu, Y.; Liu, M.; Snyder, K.; MacKenzie, D.; Cao, C. Additive manufacturing of batteries. Adv. Funct. Mater. 2020, 30, 1906244. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; De Cillis, F. Mechanical comparison of new composite materials for aerospace applications. Compos. B Eng. 2019, 162, 122–128. [Google Scholar] [CrossRef]

- Gnanasekaran, K.; Heijmans, T.; van Bennekom, S.; Woldhuis, H.; Wijnia, S.; de With, G.; Friedrich, H. 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modelling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Echeverry Velasquez, A.; Velez Quintana, M.; Posada-Montoya, J.A.; Palacio-Fernandez, J.A. Design, construction and evaluation of an energy harvesting prototype built with piezoelectric materials. Rev. Fac. Ing. Univ. Antioq. 2020, 97, 56–64. [Google Scholar] [CrossRef]

- Zou, A.; Li, J.; Han, X.; Wang, Q. Segmented cantilever and array configurations for wider frequency band and higher power generation in piezoelectric vibration energy harvester. Wirel. Commun. Mob. Comput. 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Bayati, A.; Khajepour, M.; Mirasadi, K.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Poly (ethylene terephthalate) glycol/carbon black composites for 4D printing. Mater. Chem. Phys. 2024, 325, 129737. [Google Scholar] [CrossRef]

- Karimi, A.; Rahmatabadi, D.; Baghani, M. Direct pellet three-dimensional printing of polybutylene adipate-co-terephthalate for a greener future. Polymers 2024, 16, 267. [Google Scholar] [CrossRef]

- Sang, M.; Shin, J.; Kim, K.; Yu, K. Electronic and thermal properties of graphene and recent advances in graphene based electronics applications. Nanomaterials 2019, 9, 374. [Google Scholar] [CrossRef]

- Morozovska, A.N.; Kurchak, A.I.; Strikha, M.V. Graphene separation and stretching induced by piezoelectric effect of ferroelectric domains: Impact on the conductance of graphene channel. arXiv 2017, arXiv:1706.00486. [Google Scholar]

- da Cunha Rodrigues, G.; Zelenovskiy, P.S.; Romanyuk, K.; Luchkin, S.Y.; Kopelevich, Y.; Kholkin, A.L. Strong piezoelectricity in single-layer graphene deposited on SiO2 grating substrates. Nat. Commun. 2015, 6, 7572. [Google Scholar] [CrossRef]

- Xu, K.; Wang, K.; Zhao, W.; Bao, W.; Liu, E.; Ren, Y.; Wang, M.; Fu, Y.; Zeng, J.; Li, Z.; et al. The positive piezoconductive effect in graphene. Nat. Commun. 2015, 6, 8119. [Google Scholar] [CrossRef]

- Larraza, I.; Vadillo, J.; Calvo-Correas, T.; Tejado, A.; Olza, S.; Peña-Rodríguez, C.; Arbelaiz, A.; Eceiza, A. Cellulose and graphene based polyurethane nanocomposites for FDM 3D printing: Filament properties and printability. Polymers 2021, 13, 839. [Google Scholar] [CrossRef]

- Mallineni, S.S.; Dong, Y.; Behlow, H.; Rao, A.M.; Podila, R. A wireless triboelectric nanogenerator. Adv. Energy Mater. 2018, 8, 1702736. [Google Scholar] [CrossRef]

- Achour, M.A.; Rguiti, M.; Samuel, C.; Barrau, S.; Lacrampe, M.F.; Courtois, C. Energy harvesting by uniaxially-stretched poly (lactide) films at low tensile strain frequencies for powering wearable sensors: Experimental results and theoretical extrapolation. Smart Mater. Struct. 2023, 32, 075009. [Google Scholar] [CrossRef]

- Oumghar, K.; Chakhchaoui, N.; Farhan, R.; Eddiai, A.; Meddad, M.; Cherkaoui, O.; Mazroui, M.; Van Langenhove, L. Piezoelectric β-polymorph enhancement in graphene oxide-PLA nanocomposite films. IOP Conf. Ser. Mater. Sci. Eng. 2020, 948, 012024. [Google Scholar] [CrossRef]

- Amini, S.; Ahmed, R.F.; Ankanathappa, S.M.; Sannathammegowda, K. Polyvinyl alcohol-based economical triboelectric nanogenerator for self-powered energy harvesting applications. Nanotechnology 2023, 35, 035403. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Jin, Z.; Liu, Y.; Ning, H.; Liu, X.; Alamusi, H.N. Recent advances in the preparation of PVDF-based piezoelectric materials. Nanotechnol. Rev. 2022, 25, 1386–1407. [Google Scholar] [CrossRef]

- Kwon, J.; Sharma, B.K.; Ahn, J.H. Graphene based nanogenerator for energy harvesting. Jpn. J. Appl. Phy. 2013, 52, 06GA02. [Google Scholar] [CrossRef]

- Ma, J.; Wang, P.; Dong, L.; Ruan, Y.; Lu, H. Highly conductive, mechanically strong graphene monolith assembled by three-dimensional printing of large graphene oxide. J. Colloid. Interface. Sci. 2018, 534, 12–19. [Google Scholar] [CrossRef]

- Safaei, M.; Sodano, H.A.; Anton, S.R. A review of energy harvesting using piezoelectric materials: State-of-the-art a decade later (2008–2018). Smart Mater. Struct. 2019, 28, 113001. [Google Scholar] [CrossRef]

- Schouten, M.; Wolterink, G.; Dijkshoorn, A.; Kosmas, D.; Stramigioli, S.; Krijnen, G. A review of extrusion-based 3D printing for the fabrication of electro- and biomechanical sensors. IEEE Sens. J. 2021, 21, 12900–12912. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. 3D-printed sensors: Current progress and future challenges. Sens. Actuators. A Phys. 2020, 305, 111916. [Google Scholar] [CrossRef]

- Tarelho, J.P.G.; Soares dos Santos, M.P.; Ferreira, J.A.F.; Ramos, A.; Kopyl, S.; Kim, S.O.; Hong, S.; Kholkin, A. Graphene-based materials and structures for energy harvesting with fluids—A review. Mater. Today 2018, 21, 1019–1041. [Google Scholar] [CrossRef]

- Cho, J.; Lee, H.; Nam, K.H.; Yeo, H.; Yang, C.M.; Seong, D.G.; Lee, D.; Kim, S.Y. Enhanced electrical conductivity of polymer nanocomposite based on edge-selectively functionalized graphene nanoplatelets. Compos. Sci. Technol. 2020, 189, 108001. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, D.; Kwon, Y.; Kim, T.W.; Kim, K.; Kim, H.J. Enhanced electrochemical oxygen reduction reaction performance with Pt nanocluster catalysts supported on microporous graphene-like 3D carbon. J. Electroanal. Chem. 2019, 838, 89–93. [Google Scholar] [CrossRef]

- Chen, J.; Li, H.; Zhang, L.; Du, C.; Fang, T.; Hu, J. Direct reduction of graphene oxide/nanofibrillated cellulose composite film and its electrical conductivity research. Sci. Rep. 2020, 10, 3124. [Google Scholar] [CrossRef]

- Mansour, M.; Tsongas, K.; Tzetzis, D. Measurement of the mechanical and dynamic properties of 3D printed polylactic acid reinforced with graphene. Polym.-Plast. Technol. Mater. 2019, 58, 1234–1244. [Google Scholar] [CrossRef]

- Cao, S. Investigation on thermal conductivity of dimethyl silicone oil modified by graphene nanosheets. Carbon. Lett. 2023, 33, 2153–2159. [Google Scholar] [CrossRef]

- Kil, M.S.; Park, H.J.; Yoon, J.H.; Jang, J.; Lee, K.G.; Choi, B.G. Stretchable graphene conductor based on fluid dynamics and its application to flexible conductometric sensor. Carbon. Lett. 2022, 32, 1791–1798. [Google Scholar] [CrossRef]

- Yi, Y.; Wang, B.; Liu, X.; Li, C. Flexible piezoresistive strain sensor based on CNTs–polymer composites: A brief review. Carbon. Lett. 2022, 32, 713–726. [Google Scholar] [CrossRef]

- Sabarish, K.V.; Parvati, T.S. An experimental investigation on L9 orthogonal array with various concrete materials. Mater. Today 2021, 37, 3045–3050. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Kinloch, I.A.; Young, R.J. Mechanical properties of graphene and graphene-based nanocomposites. Prog. Mater. Sci. 2017, 90, 75–127. [Google Scholar] [CrossRef]

- Bouakaz, B.S.; Habi, A.; Grohens, Y.; Pillin, I. Organomontmorillonite/graphene-PLA/PCL nanofilled blends: New strategy to enhance the functional properties of PLA/PCL blend. Appl. Clay. Sci. 2017, 39, 81–91. [Google Scholar] [CrossRef]

- Tsang, C.H.A.; Huang, H.; Xuan, J.; Wang, H.; Leung, D.Y.C. Graphene materials in green energy applications: Recent development and future perspective. Renew. Sustain. Energy Rev. 2020, 120, 109656. [Google Scholar] [CrossRef]

- Foster, C.W.; Down, M.P.; Zhang, Y.; Ji, X.; Rowley-Neale, S.J.; Smith, G.C.; Kelly, P.J.; Banks, C.E. 3D printed graphene-based energy storage devices. Sci. Rep. 2017, 7, 42233. [Google Scholar] [CrossRef]

- Ye, M.; Zhang, Z.; Zhao, Y.; Qu, L. Graphene platforms for smart energy generation and storage. Joule 2018, 2, 245–268. [Google Scholar] [CrossRef]

- Rafiee, M.; Farahani, R.D.; Therriault, D. Multi-material 3D and 4D printing: A survey. Adv. Sci. 2020, 7, 1902307. [Google Scholar] [CrossRef]

- Quintanilla, A.; Carbajo, A.; Casas, J.A.; Miranzo, P.; Osendi, M.I.; Belmonte, M. Graphene-based nanostructures as catalysts for wet peroxide oxidation treatments: From nanopowders to 3D printed porous monoliths. Catal. Today 2020, 356, 197–204. [Google Scholar] [CrossRef]

- Alafaghani, A.; Qattawi, A.; Alrawi, B.; Guzman, A. Experimental optimization of fused deposition modelling processing parameters: A design-for-manufacturing approach. Procedia. Manuf. 2017, 10, 791–803. [Google Scholar] [CrossRef]

- Alsharari, M.; Chen, B.; Shu, W. 3D printing of highly stretchable and sensitive strain sensors using graphene based composites. Proceedings 2018, 2, 792. [Google Scholar] [CrossRef]

- Yang, L.; Li, S.; Zhou, X.; Liu, J.; Li, Y.; Yang, M.; Yuan, Q.; Zhang, W. Effects of carbon nanotube on the thermal, mechanical, and electrical properties of PLA/CNT printed parts in the FDM process. Synth. Met. 2019, 253, 122–130. [Google Scholar] [CrossRef]

- Çevik, Ü.; Kam, M. A review study on mechanical properties of obtained products by FDM method and metal/polymer composite filament production. J. Nanomater. 2020, 2020, 6187149. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Novotný, F.; Urbanová, V.; Plutnar, J.; Pumera, M. Preserving fine structure details and dramatically enhancing electron transfer rates in graphene 3D-printed electrodes via thermal annealing: Toward nitroaromatic explosives sensing. ACS Appl. Mater. Interfaces 2019, 11, 35371–35375. [Google Scholar] [CrossRef] [PubMed]

- Jing, J.; Chen, Y.; Shi, S.; Yang, L.; Lambin, P. Facile and scalable fabrication of highly thermal conductive polyethylene/graphene nanocomposites by combining solid-state shear milling and FDM 3D-printing aligning methods. Chem. Eng. J. 2020, 402, 126218. [Google Scholar] [CrossRef]

- dos Santos, P.L.; Katic, V.; Loureiro, H.C.; dos Santos, M.F.; dos Santos, D.P.; Formiga, A.L.B.; Bonacin, J.A. Enhanced performance of 3D printed graphene electrodes after electrochemical pre-treatment: Role of exposed graphene sheets. Sens. Actuators B Chem. 2019, 281, 837–848. [Google Scholar] [CrossRef]

- Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Reverte, J.M.; Becar, J.P. Additive manufacturing of PLA-based composites using fused filament fabrication: Effect of graphene nanoplatelet reinforcement on mechanical properties, dimensional accuracy and texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, L.; Jiang, Z.; Luo, G.; Yang, P.; Han, X.; Li, X.; Maeda, R. High accuracy comsol simulation method of bimorph cantilever for piezoelectric vibration energy harvesting. AIP Adv. 2019, 9, 095067. [Google Scholar] [CrossRef]

- Alsaad, A.M.; Ahmad, A.A.; Al-Bataineh, Q.M.; Daoud, N.S.; Khazaleh, M.H. Design and analysis of MEMS based aluminum nitride (AlN), lithium niobate (LiNbO3) and zinc oxide (ZnO) cantilever with different substrate materials for piezoelectric vibration energy harvesters using COMSOL multiphysics software. Open. J. Appl. Sci. 2019, 09, 181–197. [Google Scholar] [CrossRef]

- Hashim, A.A.; Mahmoud, K.I.; Ridha, H.M. Geometry and shape optimization of piezoelectric cantilever energy harvester using COMSOL multiphysics software. Int. Rev. Appl. Sci. Eng. 2021, 12, 103–110. [Google Scholar] [CrossRef]

- Xiong, Y.; Song, F.; Leng, X. A piezoelectric cantilever-beam energy harvester (PCEH) with a rectangular hole in the metal substrate. Microsyst. Technol. 2020, 26, 801–810. [Google Scholar] [CrossRef]

- Maamer, B.; Boughamoura, A.; Fath El-Bab, A.M.R.; Francis, L.A.; Tounsi, F. A review on design improvements and techniques for mechanical energy harvesting using piezoelectric and electromagnetic schemes. Energy Convers. Manag. 2019, 199, 111973. [Google Scholar] [CrossRef]

- Godard, N.; Allirol, L.; Latour, A.; Glinsek, S.; Gérard, M.; Polesel, J.; Dos Santos, F.D.; Defay, E. 1-mW vibration energy harvester based on a cantilever with printed polymer multilayers. Cell Rep. Phys. Sci. 2020, 1, 100068. [Google Scholar] [CrossRef]

- Yang, Z.; Zhou, S.; Zu, J.; Inman, D. High-performance piezoelectric energy harvesters and their applications. Joule 2018, 2, 642–697. [Google Scholar] [CrossRef]

- Tian, Y.; Li, G.; Yi, Z.; Liu, J.; Yang, B. A low-frequency MEMS piezoelectric energy harvester with a rectangular hole based on bulk PZT film. J. Phys. Chem. Solids. 2018, 117, 21–27. [Google Scholar] [CrossRef]

- Dhilipkumar, T.; Arumugam, S.; Rajesh, M.; Venkatesan, R.; Sasikumar, R.; Al-Asbahi, B.A. Evaluating the flexural and vibrational response of carbon nanotube strengthened co-cured sandwich composites. Carbon. Lett. 2024, 34, 1443–1452. [Google Scholar] [CrossRef]

- Wei, C.; Jing, X. A comprehensive review on vibration energy harvesting: Modelling and realization. Renew. Sustain. Energy. Rev. 2017, 74, 1–18. [Google Scholar] [CrossRef]

- Haque, R.I.; Farine, P.A.; Briand, D. 3D printed materials based triboelectric device for energy harvesting and sensing. Proceedings 2017, 16, 580. [Google Scholar] [CrossRef]

- Bhavanasi, V.; Kumar, V.; Parida, K.; Wang, J.; Lee, P.S. Enhanced piezoelectric energy harvesting performance of flexible PVDF-TrFE bilayer films with graphene oxide. ACS Appl. Mater. Interfaces 2016, 8, 521–529. [Google Scholar] [CrossRef]

- Karan, S.K.; Mandal, D.; Khatua, B.B. Self-powered flexible Fe-doped RGO/PVDF nanocomposite: An excellent material for a piezoelectric energy harvester. Nanoscale 2015, 24, 10655–10666. [Google Scholar] [CrossRef]

- Kwon, J.; Seung, W.; Sharma, B.K.; Kim, S.-W.; Ahn, J.-H. A high performance PZT ribbon-based nanogenerator using graphene transparent electrodes. Energ. Environ. Sci. 2012, 5, 8970–8975. [Google Scholar] [CrossRef]

| Description | Value |

|---|---|

| Number of vertex elements | 16 |

| Number of edge elements | 268 |

| Number of boundary elements | 3136 |

| Number of elements | 16,201 |

| Free meshing time | 0.80s |

| Minimum element quality | 0.2611 |

| Maximum element size | 0.082 |

| Minimum element size | 8.0 × 10−4 |

| Curvature factor | 0.23 |

| Maximum element growth rate | 1.28 |

| Predefined size | Extremely fine |

| S. No. | 3D Printing Methods | Load Resistance (kΩ) | Frequency (Hz) | Power (µW) |

|---|---|---|---|---|

| 1 | DIW | 50 | 309 | 12.22 |

| 2 | DIW | 100 | 342 | 6.11 |

| 3 | DIW | 500 | 376 | 1.24 |

| 4 | FDM | 50 | 303 | 6.4 |

| 5 | FDM | 100 | 338.89 | 3.2 |

| 6 | FDM | 500 | 372.45 | 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

R., H.; Dhilipkumar, T.; V. Shankar, K.; P, K.; Salunkhe, S.; Venkatesan, R.; Shazly, G.A.; Vetcher, A.A.; Kim, S.-C. Evaluating the Piezoelectric Energy Harvesting Potential of 3D-Printed Graphene Prepared Using Direct Ink Writing and Fused Deposition Modelling. Polymers 2024, 16, 2397. https://doi.org/10.3390/polym16172397

R. H, Dhilipkumar T, V. Shankar K, P K, Salunkhe S, Venkatesan R, Shazly GA, Vetcher AA, Kim S-C. Evaluating the Piezoelectric Energy Harvesting Potential of 3D-Printed Graphene Prepared Using Direct Ink Writing and Fused Deposition Modelling. Polymers. 2024; 16(17):2397. https://doi.org/10.3390/polym16172397

Chicago/Turabian StyleR., Hushein, Thulasidhas Dhilipkumar, Karthik V. Shankar, Karuppusamy P, Sachin Salunkhe, Raja Venkatesan, Gamal A. Shazly, Alexandre A. Vetcher, and Seong-Cheol Kim. 2024. "Evaluating the Piezoelectric Energy Harvesting Potential of 3D-Printed Graphene Prepared Using Direct Ink Writing and Fused Deposition Modelling" Polymers 16, no. 17: 2397. https://doi.org/10.3390/polym16172397

APA StyleR., H., Dhilipkumar, T., V. Shankar, K., P, K., Salunkhe, S., Venkatesan, R., Shazly, G. A., Vetcher, A. A., & Kim, S.-C. (2024). Evaluating the Piezoelectric Energy Harvesting Potential of 3D-Printed Graphene Prepared Using Direct Ink Writing and Fused Deposition Modelling. Polymers, 16(17), 2397. https://doi.org/10.3390/polym16172397