Examining the Flexural Behavior of Thermoformed 3D-Printed Wrist–Hand Orthoses: Role of Material, Infill Density, and Wear Conditions

Abstract

1. Introduction

2. Materials and Methods

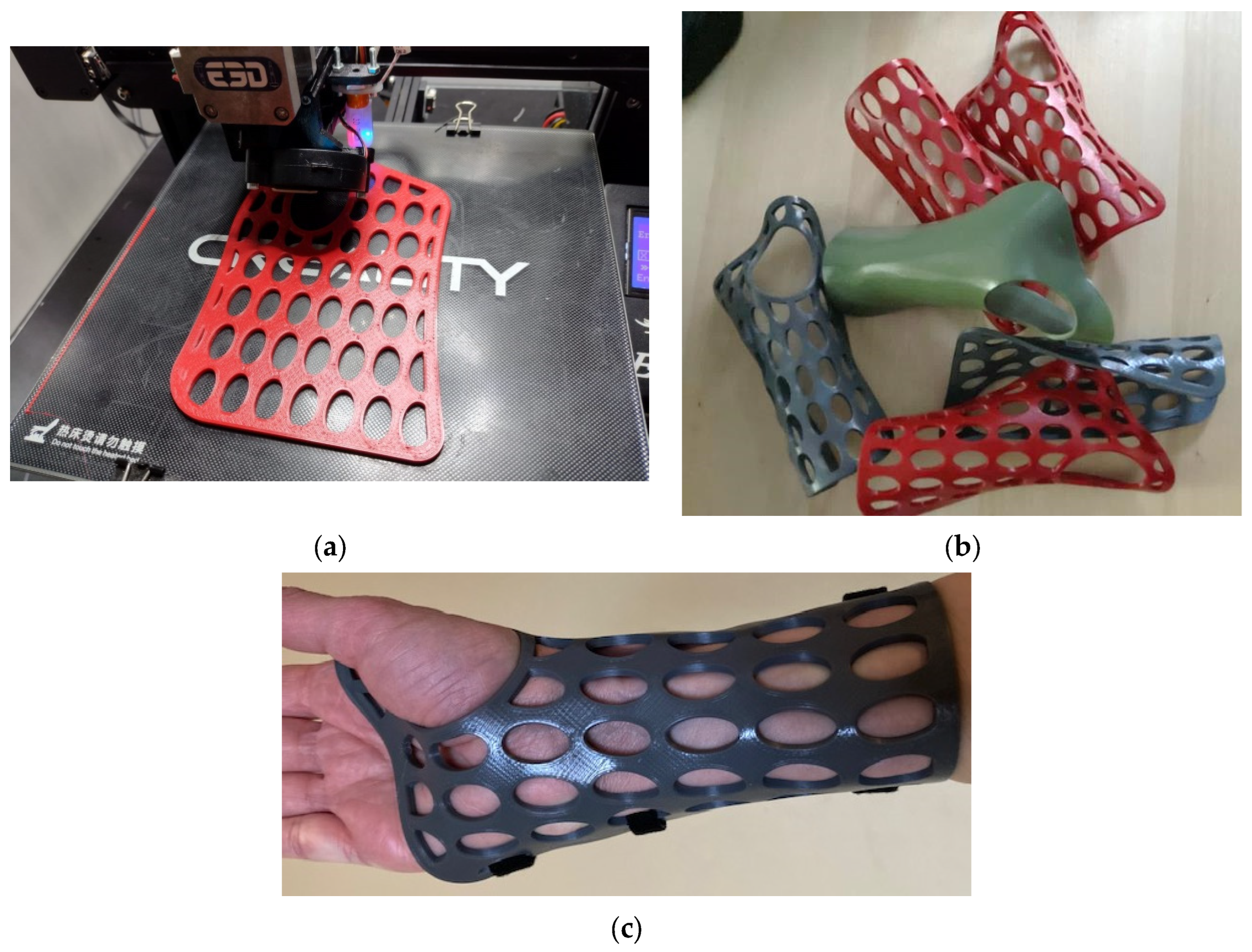

2.1. WHOs and Specimens Design and 3D Printing

- Layer thickness: 0.2 mm

- Printing temperature: 215 °C (PLA), 230 °C (PETG)

- Platform temperature: 50 °C (PLA), 85 °C (PETG)

- Infill pattern: grid

- Perimeters: 2

- Top/bottom layers: 2

- Infill density: 55%, 80%

- Printing speed: 100 mm/s for layers, 60 mm/s for perimeters

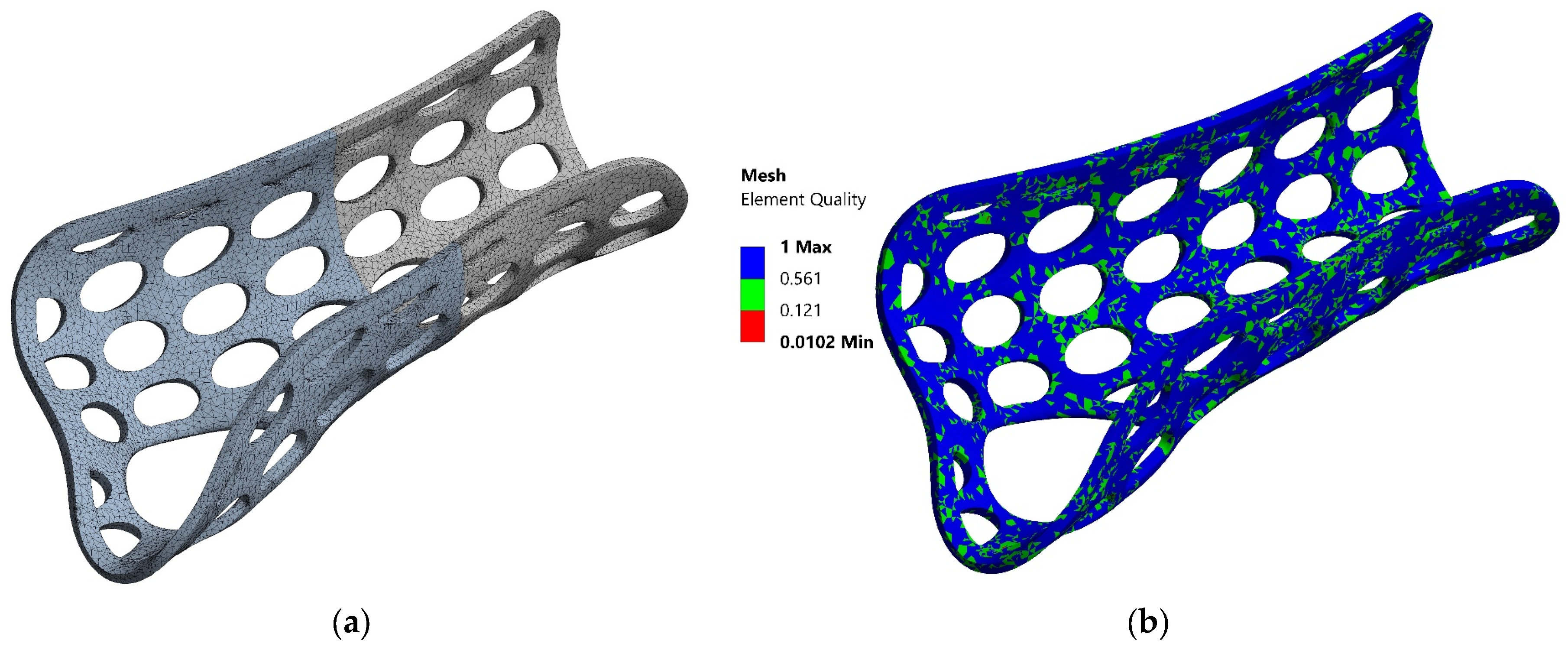

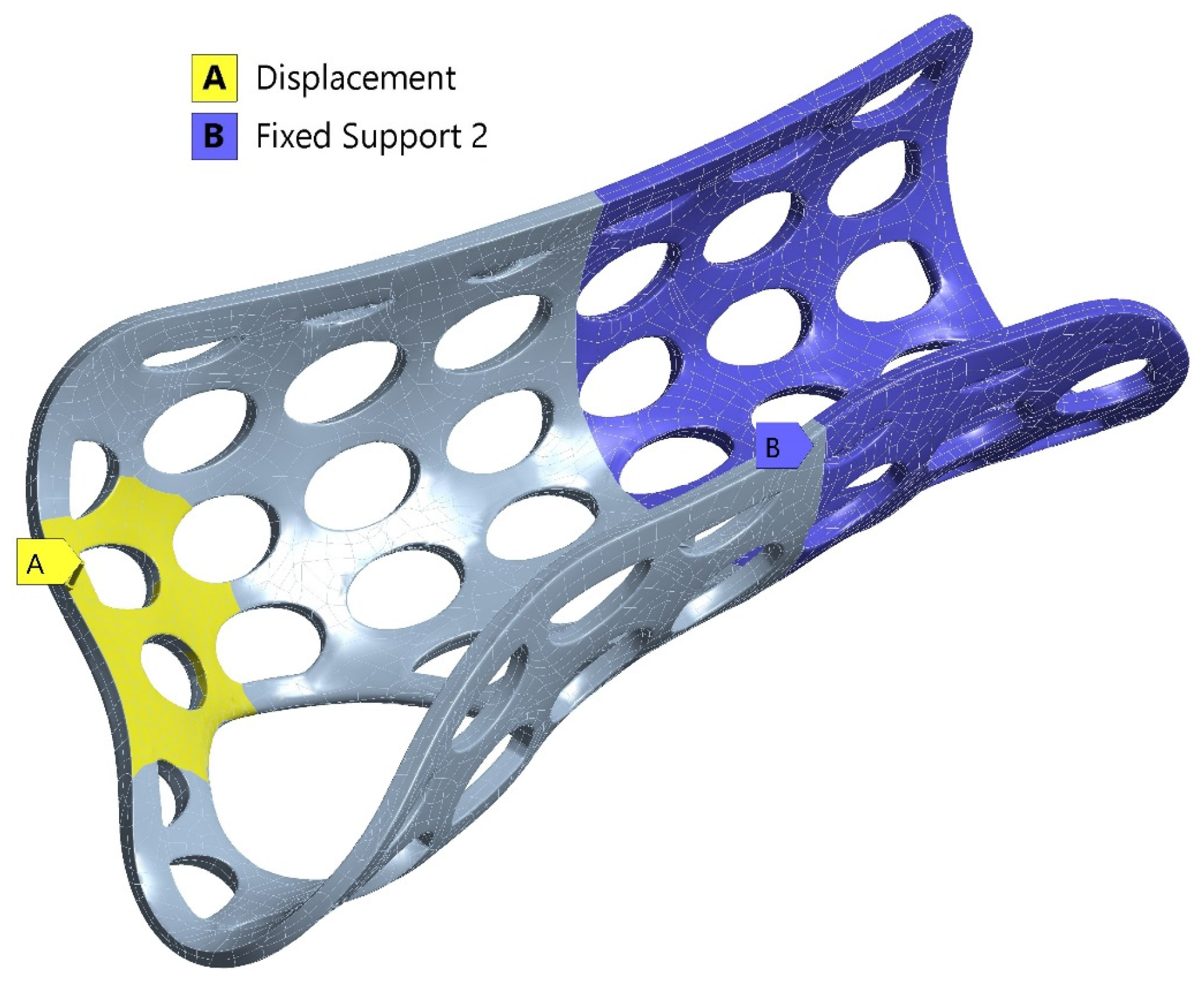

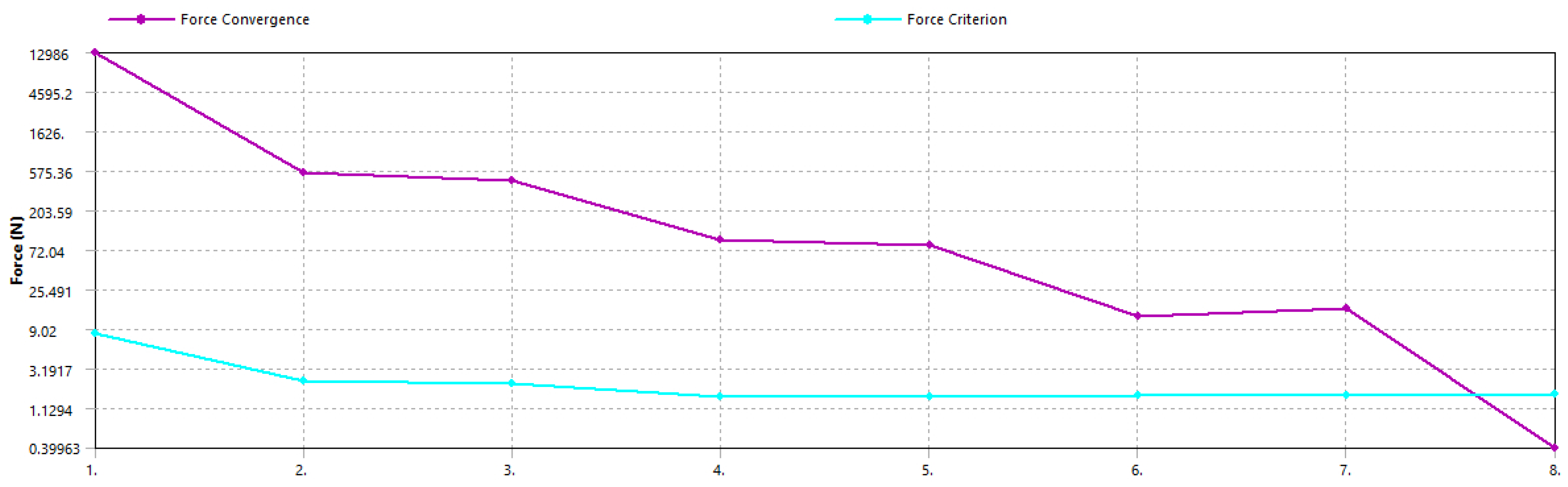

2.2. Finite Element Analysis of 3DP-WHOs

2.3. Experimental Tests

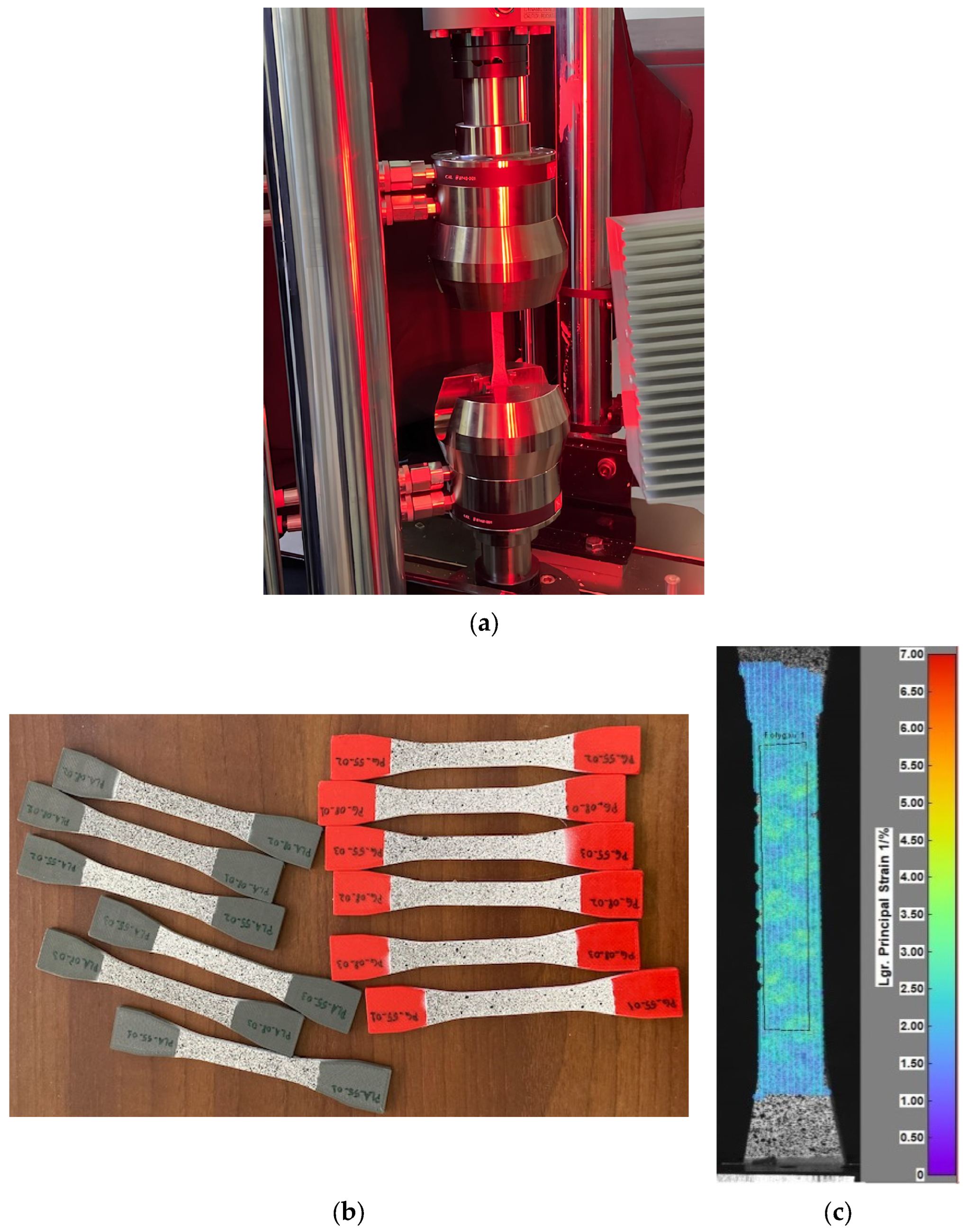

2.3.1. Determination of PLA and PETG Material Properties

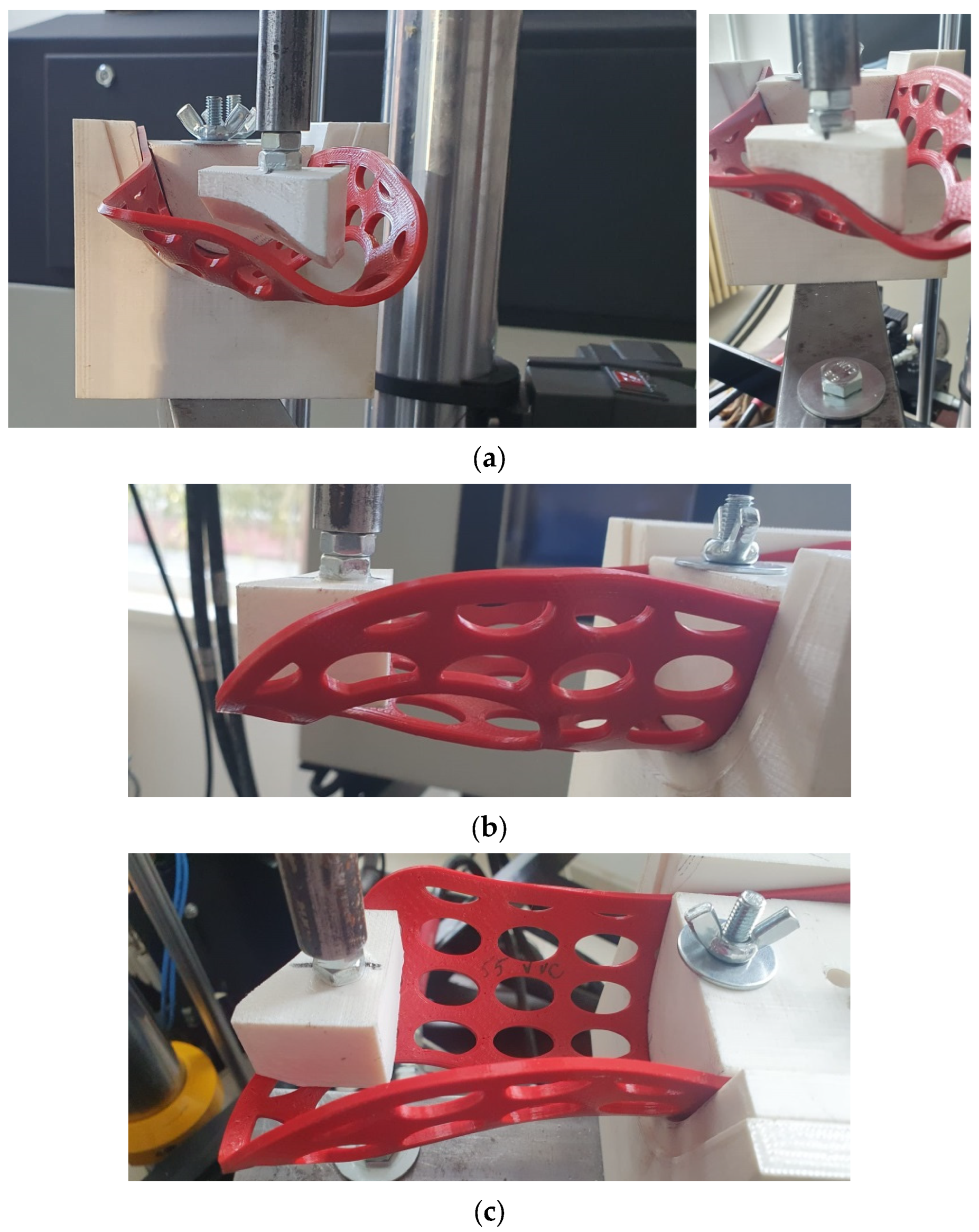

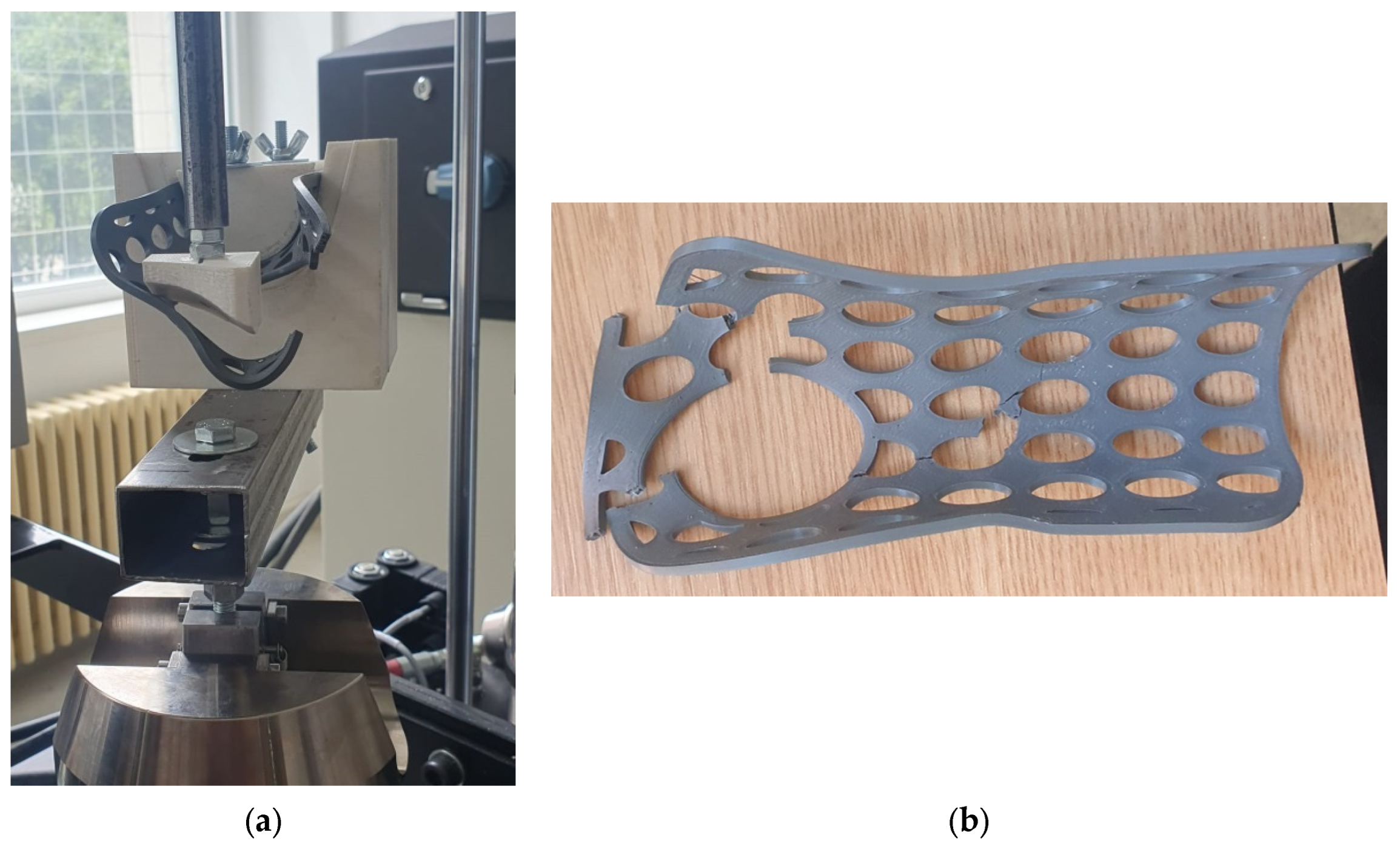

2.3.2. 3D-Printed PLA and PETG Orthoses Testing

3. Results and Discussion

3.1. Moldability Evaluation of 3DP-WHO Materials

3.2. Mechanical Tests Results

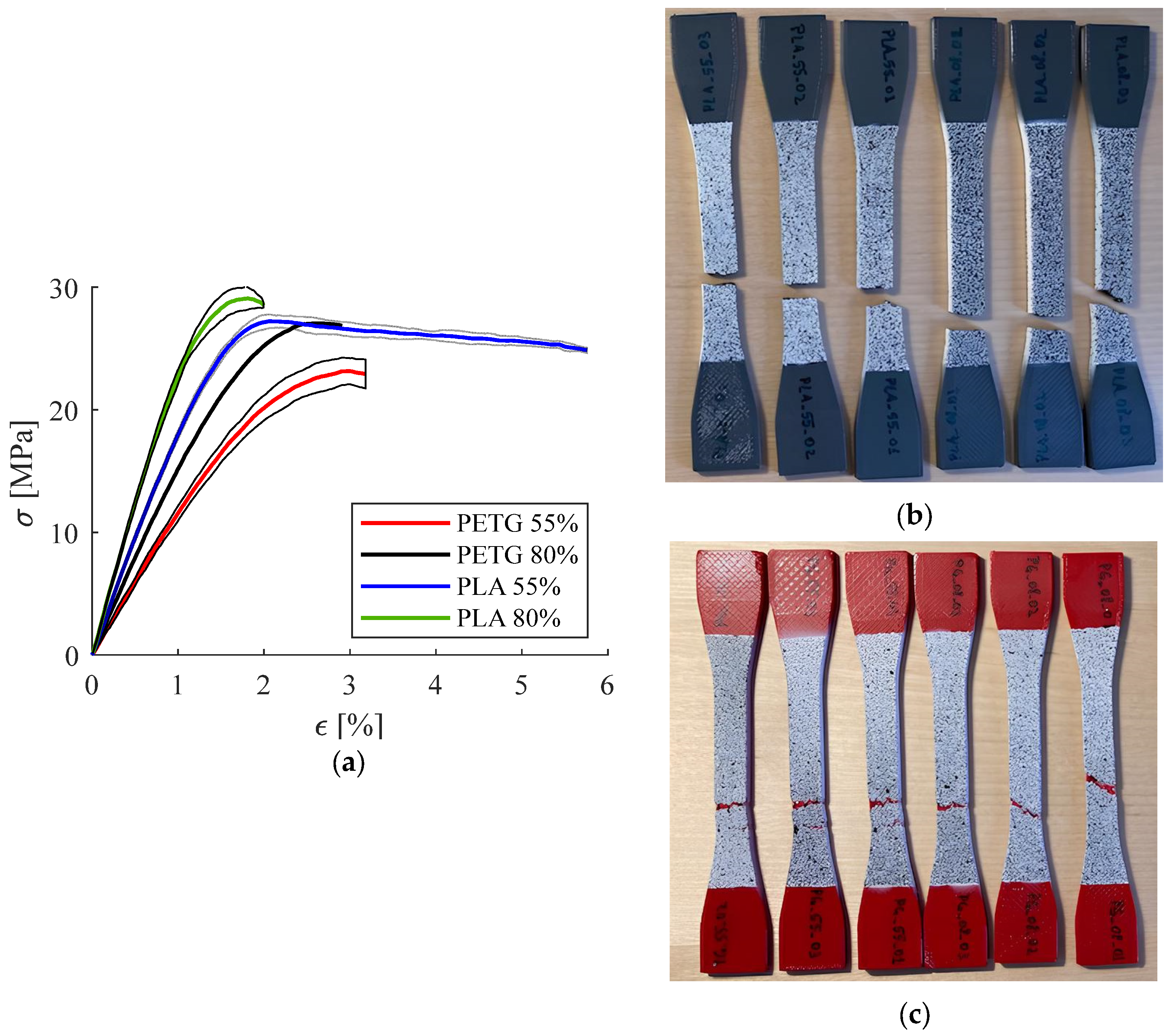

3.2.1. Results of Mechanical Tests Performed on Specimens

- -

- Comparison between PLA and PETG: Significant differences (p < 0.5) were found in the Young’s modulus (p = 0.000480), Poisson coefficient (p = 0.020117), and apparent yield stress (p = 0.004521). However, when comparing the ultimate tensile strength (UTS), no significant difference was found (p = 0.430554).

- -

- Comparison between 80% and 55% infill density:

- ○

- PLA specimens: Significant differences were found in the Young’s modulus (p = 0.000121) and Poisson coefficient (p = 0.011542), but no significant differences were observed for the apparent yield stress (p = 0.090911) and UTS (p = 0.774743).

- ○

- PETG specimens: Significant differences were found in all properties, particularly in the Young’s modulus (p = 0.006105), Poisson coefficient (p = 0.025838), apparent yield stress (p = 0.002054), and UTS (p = 0.017380).

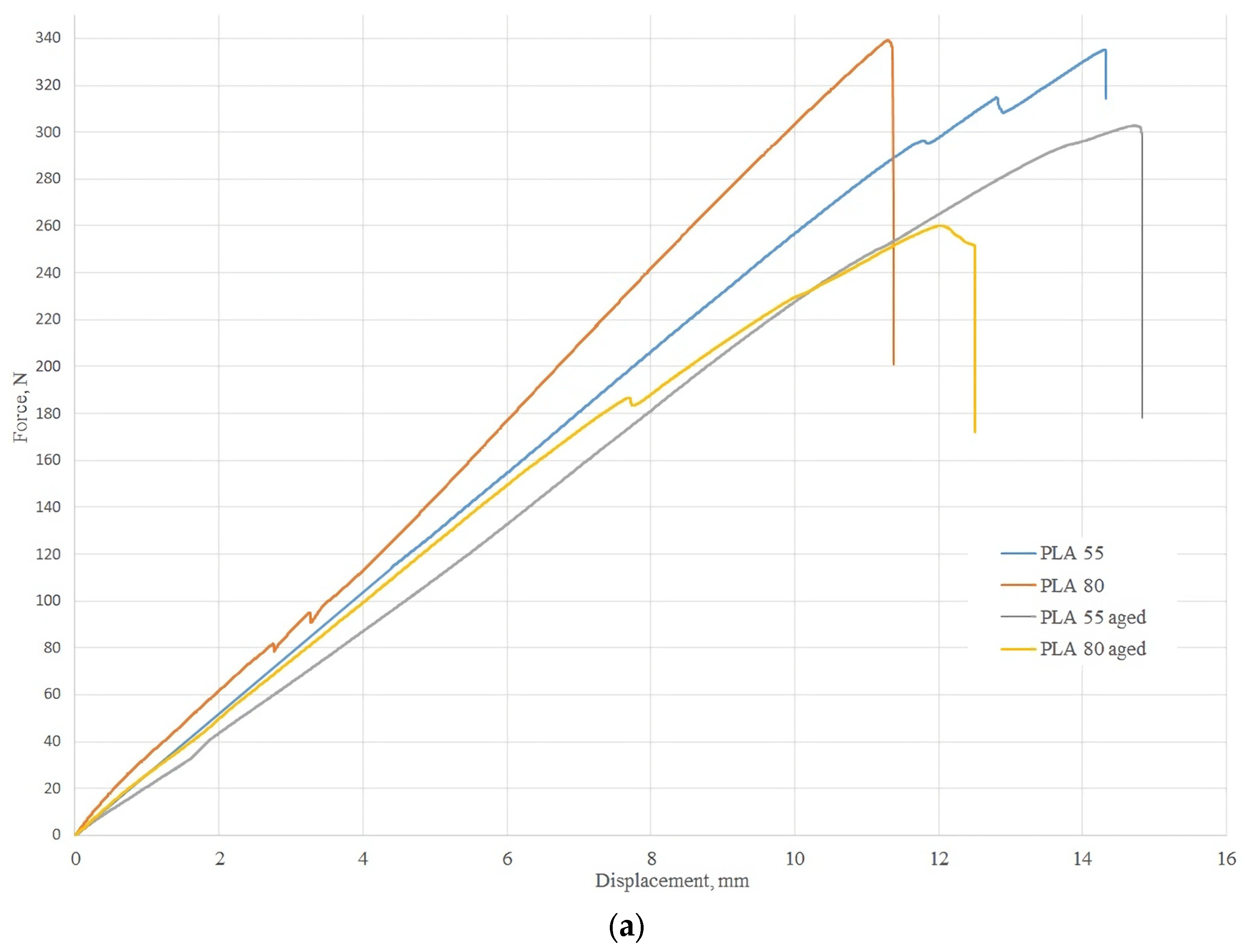

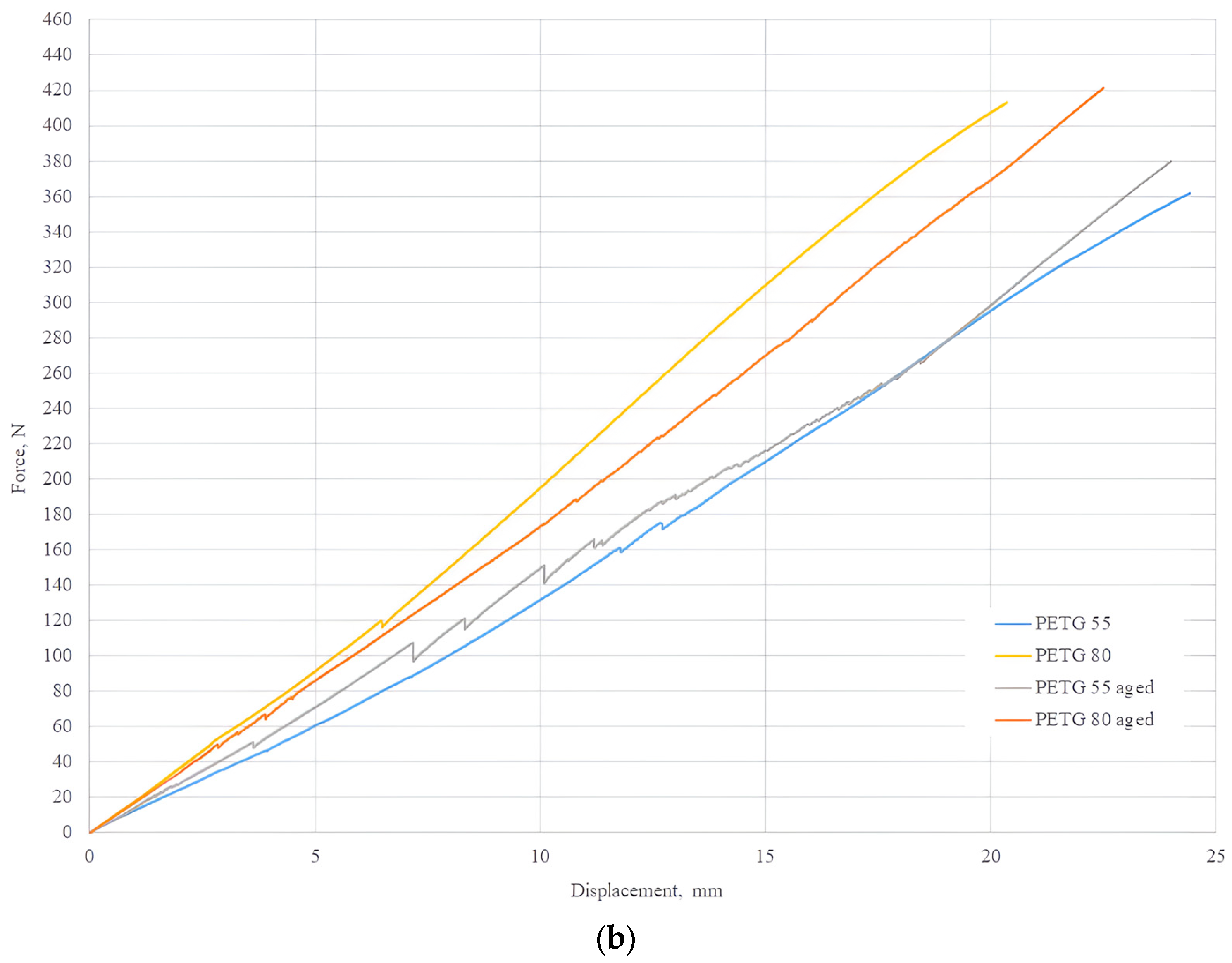

3.2.2. Mechanical Tests Results Conducted on 3DP-WHOs

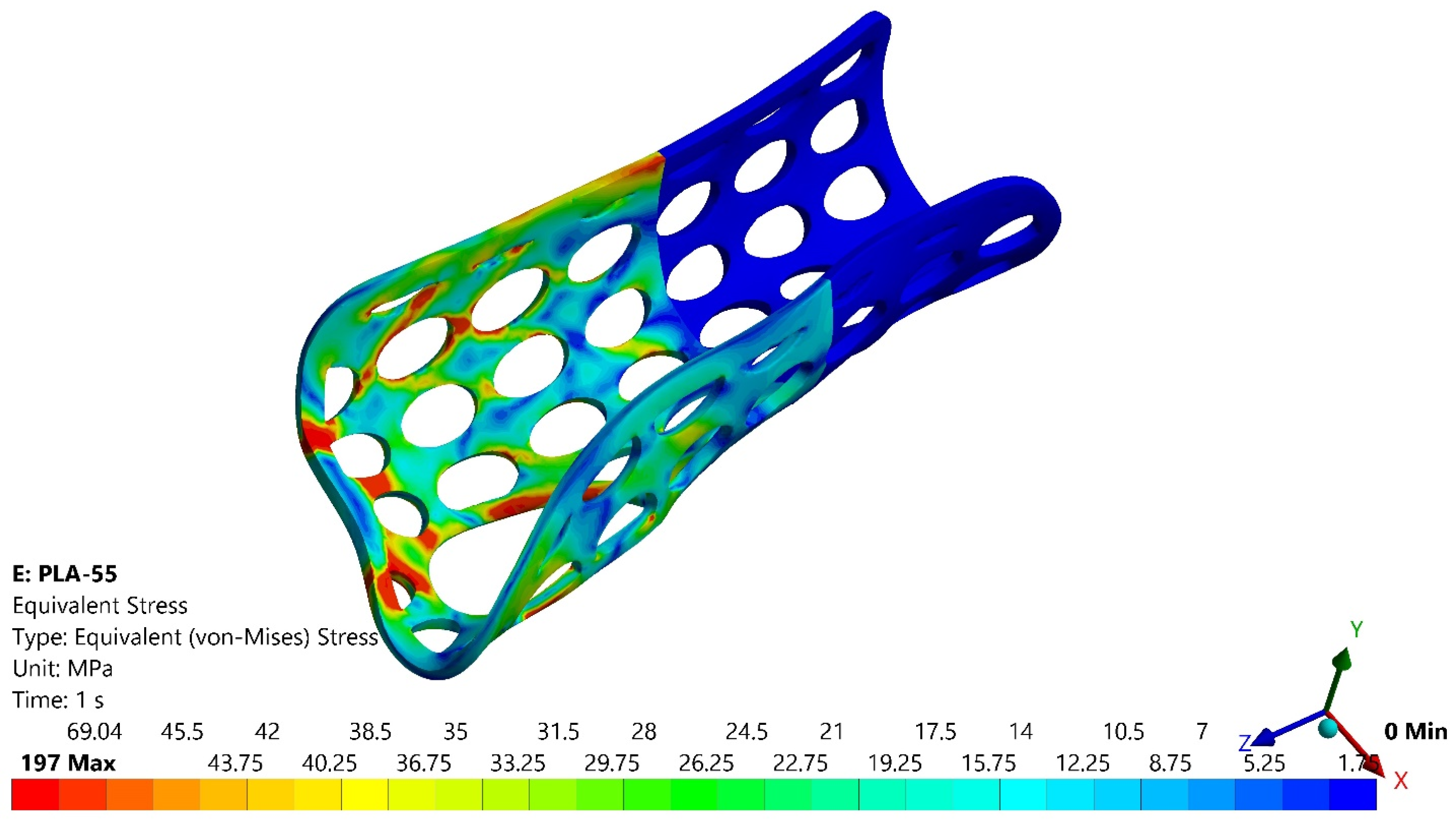

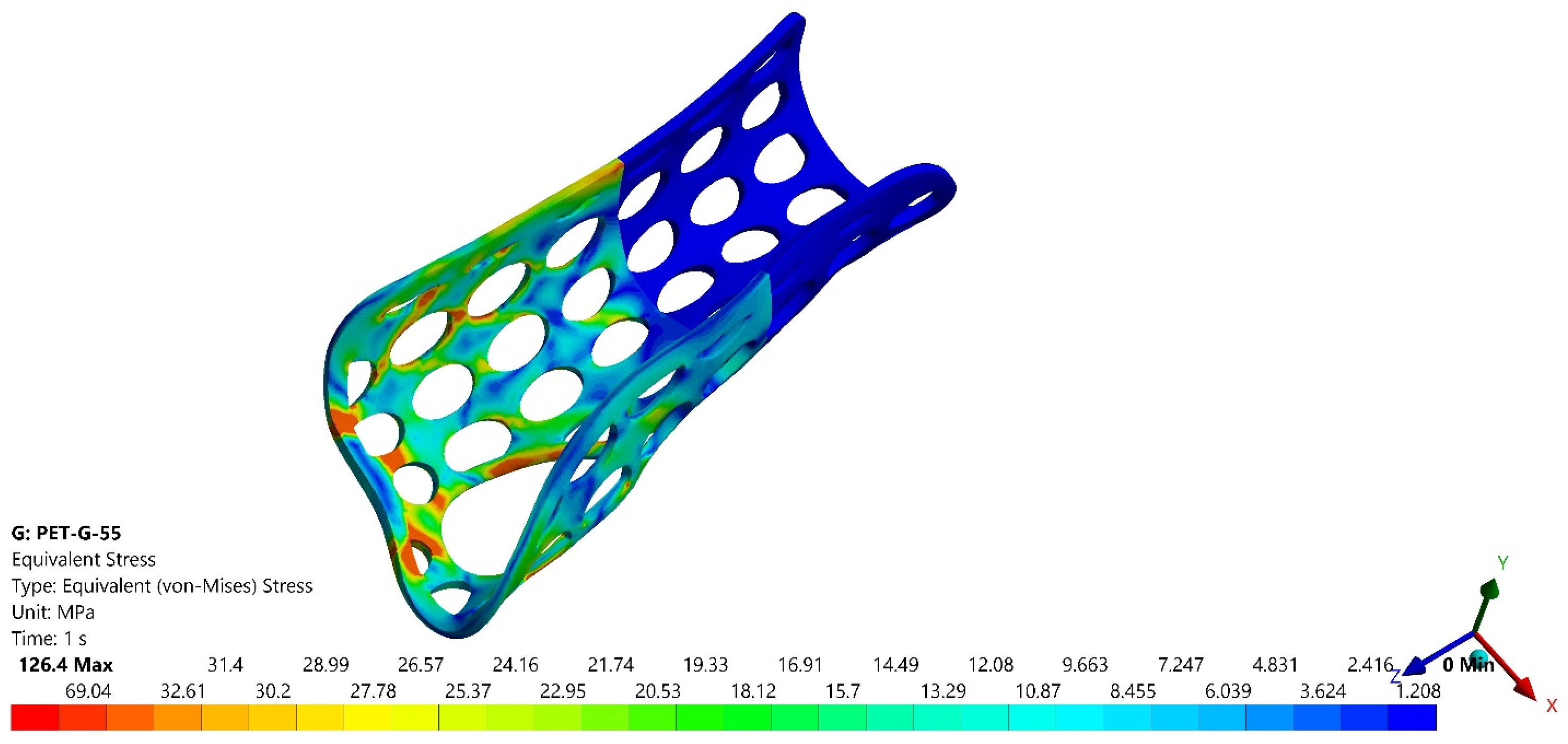

3.3. FEA Results

4. Conclusions and Further Work

- -

- Thermoformed 3D-printed orthoses made from both PLA and PETG demonstrated superior flexural resistance, even after being subjected to moisture and long-term aging. This shows that the thermoforming method can produce orthoses that are not only more easily customizable to the user’s hand and fulfil the immobilization functional criterion but also withstand aging and moisture. No such research has been conducted so far, thus opening up a new perspective for manufacturing orthotic products in 3DP-PoC.

- -

- PLA orthoses were easier to thermoform, while the PETG material provided better elasticity and stability of the orthotic properties over time. Thermoforming was simpler for the PLA orthoses than PETG orthoses, requiring higher temperatures and faster cooling rates, complicating the molding process. After one year of shelf life and exposure to moisture, the PETG orthoses with 55% infill density showed properties almost identical to their initial status, likely due to thermoforming (acting as successive annealing), stress relaxation, and additional crosslinking over time. Conversely, the PLA orthoses experienced a more significant decrease in mechanical properties after aging, with the 55% dense orthoses being less affected than the 80% dense orthoses.

- -

- The 3D-printed orthoses with 55% infill density can be produced as flat shapes easily, quickly, and with sufficient mechanical resistance. Given the challenges of 3D printing orthoses in their final, ready-to-use form at this infill density, the thermoforming approach provides significant advantages.

- -

- The numerical and experimental analysis conducted in this study provides valuable insights into optimizing the material selection and design parameters, filling a gap in the existing literature.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Kouzani, A.Z.; Khoo, S.Y.; Moghadam, A.A.A.; Gibson, I.; Kaynak, A. Evolution of 3D printed soft actuators. Sens. Actuators A Phys. 2016, 250, 258–272. [Google Scholar] [CrossRef]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Dias, S.; Espadinha-Cruz, P.; Matos, F. Understanding how Additive Manufacturing influences organizations’ strategy in knowledge economy. Procedia Comput. Sci. 2022, 200, 1318–1327. [Google Scholar] [CrossRef]

- Bastawrous, S.; Wu, L.; Liacouras, P.C.; Levin, D.B.; Ahmed, M.T.; Strzelecki, B.; Amendola, M.F.; Lee, J.T.; Coburn, J.; Ripley, B. Establishing 3D Printing at the Point of Care: Basic Principles and Tools for Success. RadioGraphics 2022, 42, 451–468. [Google Scholar] [CrossRef]

- Daoud, G.E.; Pezzutti, D.L.; Dolatowski, C.J.; Carrau, R.L.; Pancake, M.; Herderick, E.; VanKoevering, K.K. Establishing a point-of-care additive manufacturing workflow for clinical use. J. Mater. Res. 2021, 36, 3761–3780. [Google Scholar] [CrossRef] [PubMed]

- Beitler, B.G.; Abraham, P.F.; Glennon, A.R.; Tommasini, S.M.; Lattanza, L.L.; Morris, J.M.; Wiznia, D.H. Interpretation of regulatory factors for 3D printing at hospitals and medical centers, or at the point of care. 3D Print. Med. 2022, 8, 7. [Google Scholar] [CrossRef]

- Teo, A.Q.A.; Ng, D.Q.K.; Lee, P.; O’Neill, G.K. Point-of-Care 3D Printing: A Feasibility Study of Using 3D Printing for Orthopaedic Trauma. Injury 2021, 52, 3286–3292. [Google Scholar] [CrossRef]

- Murtezani, I.; Sharma, N.; Thieringer, F.M. Medical 3D printing with a focus on Point-of-Care in Cranio- and Maxillofacial Surgery. A systematic review of literature. Ann. 3D Print. Med. 2022, 6, 100059. [Google Scholar] [CrossRef]

- Radfar, P.; Bazaz, S.R.; Mirakhorli, F.; Warkiani, M.E. The role of 3D printing in the fight against COVID-19 outbreak. J. 3D Print. Med. 2021, 5, 51–60. [Google Scholar] [CrossRef]

- Choo, Y.J.; Boudier-Revéret, M.; Chang, M.C. 3D printing technology applied to orthosis manufacturing: Narrative review. Ann. Palliat. Med. 2020, 9, 4262–4270. [Google Scholar] [CrossRef] [PubMed]

- Keller, M.; Guebeli, A.; Thieringer, F.; Honigmann, P. In-hospital professional production of patient-specific 3D-printed devices for hand and wrist rehabilitation. Hand Surg. Rehabil. 2021, 40, 126–133. [Google Scholar] [CrossRef] [PubMed]

- Oud, T.A.M.; Lazzari, E.; Gijsbers, H.J.H.; Gobbo, M.; Nollet, F.; Brehm, M.A. Effectiveness of 3D-printed orthoses for traumatic and chronic hand conditions: A scoping review. PLoS ONE 2021, 16, e0260271. [Google Scholar] [CrossRef]

- Huisstede, B.M.; Bierma-Zeinstra, S.M.; Koes, B.W.; Verhaar, J.A. Incidence and prevalence of upper-extremity musculoskeletal disorders. A systematic appraisal of the literature. BMC Musculoskelet. Disord. 2006, 7, 7. [Google Scholar] [CrossRef]

- Kim, S.J.; Kim, S.J.; Cha, Y.H.; Lee, K.H.; Kwon, J.Y. Effect of personalized wrist orthosis for wrist pain with three-dimensional scanning and printing technique: A preliminary, randomized, controlled, open-label study. Prosthet. Orthot. Int. 2018, 42, 636–643. [Google Scholar] [CrossRef] [PubMed]

- Guida, P.; Casaburi, A.; Busiello, T.; Lamberti, D.; Sorrentino, A.; Iuppariello, L.; D’albore, M.; Colella, F.; Clemente, F. An alternative to plaster cast treatment in a pediatric trauma center using the CAD/CAM technology to manufacture customized three-dimensional-printed orthoses in a totally hospital context: A feasibility study. J. Pediatr. Orthop. B 2019, 28, 248–255. [Google Scholar] [CrossRef] [PubMed]

- Popescu, D.; Iacob, M.C.; Tarbă, C.; Lăptoiu, D.; Cotruţ, C.M. Exploring a Novel Material and Approach in 3D-Printed Wrist-Hand Orthoses. J. Manuf. Mater. Process. 2024, 8, 29. [Google Scholar] [CrossRef]

- Bauwens, P.; Bossuyt, F.; Deckers, J.P.; Vanfleteren, J. Vacuum Lamination of a Stretchable Sensor System in PolyPropylene. In Proceedings of the IEEE 8th Electronics System-Integration Technology Conference (ESTC) 2020, Tønsberg, Norway, 15–18 September 2020; pp. 1–4. [Google Scholar]

- Wang, G.; Yang, Y.; Guo, M.; Zhu, K.; Yan, Z.; Cui, Q.; Zhou, Z.; Ji, J.; Li, J.; Luo, D.; et al. ThermoFit: Thermoforming Smart Orthoses via Metamaterial Structures for Body-Fitting and Component-Adjusting. Proc. ACM Interact. Mob. Wearable Ubiquitous Technol. 2023, 7, 31. [Google Scholar] [CrossRef]

- Popescu, D.; Baciu, F.; Vlăsceanu, D.; Marinescu, R.; Lăptoiu, D. Investigations on the Fatigue Behavior of 3D-Printed and Thermoformed Polylactic Acid Wrist–Hand Orthoses. Polymers 2023, 15, 2737. [Google Scholar] [CrossRef]

- Kelly, S.; Paterson, A.M.J.; Bibb, R.J. A review of wrist splint designs for additive manufacture. Proceedings of 2015 14th Rapid Design, Prototyping and Manufacture Conference (RDPM 14) 2015, Loughborough, UK, 15–16 December 2015. [Google Scholar]

- Górski, F.; Wichniarek, R.; Kuczko, W.; Żukowska, M.; Lulkiewicz, M.; Zawadzki, P. Experimental Studies on 3D Printing of Automatically Designed Customized Wrist-Hand Orthoses. Materials 2020, 13, 4091. [Google Scholar] [CrossRef] [PubMed]

- Łukaszewski, K.; Raj, R.; Karwasz, A. Mechanical Evaluation of PET-G 3D-Printed Wrist-Hand Orthosis: An Integrated Experimental and Numerical Approach. Materials 2023, 16, 6132. [Google Scholar] [CrossRef]

- Sedlak, J.; Joska, Z.; Jansky, J.; Zouhar, J.; Kolomy, S.; Slany, M.; Svasta, A.; Jirousek, J. Analysis of the Mechanical Properties of 3D-Printed Plastic Samples Subjected to Selected Degradation Effects. Materials 2023, 16, 3268. [Google Scholar] [CrossRef] [PubMed]

- Nieto, D.M.; Alonso-García, M.; Pardo-Vicente, M.-A.; Rodríguez-Parada, L. Product design by additive manufacturing for water environments: Study of degradation and absorption behavior of PLA and PETG. Polymers 2021, 13, 1036. [Google Scholar] [CrossRef]

- Amza, C.G.; Zapciu, A.; Baciu, F.; Vasile, M.I.; Nicoara, A.I. Accelerated Aging Effect on Mechanical Properties of Common 3D-Printing Polymers. Polymers 2021, 13, 4132. [Google Scholar] [CrossRef]

- Guo, J.; Xiao, R.; Tian, C.; Jiang, M. Optimizing physical aging in poly(ethylene terephthalate)-glycol (PETG). J. Non-Cryst. Solids 2018, 502, 15–21. [Google Scholar] [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022. Available online: https://www.astm.org/d0638-22.html (accessed on 15 March 2024).

- Cazon, A.; Kelly, S.; Paterson, A.M.; Bibb, R.J.; Campbell, R.I. Analysis and comparison of wrist splint designs using the finite element method: Multi-material three-dimensional printing compared to typical existing practice with thermoplastics. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2017, 231, 881–897. [Google Scholar] [CrossRef] [PubMed]

- Alexandru, T.G.; Popescu, D.; Constantin, S.; Baciu, F. Experimental and numerical investigations on the thermoforming of 3D-printed polylactic acid parts. Rapid Prototyp. J. 2024, 30, 928–946. [Google Scholar] [CrossRef]

- Ronca, A.; Abbate, V.; Redaelli, D.F.; Storm, F.A.; Cesaro, G.; De Capitani, C.; Sorrentino, A.; Colombo, G.; Fraschini, P.; Ambrosio, L. A Comparative Study for Material Selection in 3D Printing of Scoliosis Back Brace. Materials 2022, 15, 5724. [Google Scholar] [CrossRef]

- Johnson, G.; French, J.J. Evaluation of infill effect on mechanical properties of consumer 3D printing materials. DOAJ (Dir. Open Access J.) Adv. Technol. Innov. 2018, 3, 179–184. Available online: https://core.ac.uk/download/pdf/228834597.pdf (accessed on 10 January 2024).

- Hsueh, M.-H.; Lai, C.-J.; Wang, S.-H.; Zeng, Y.-S.; Hsieh, C.-H.; Pan, C.-Y.; Huang, W.-C. Effect of Printing Parameters on the Thermal and Mechanical Properties of 3D-Printed PLA and PETG, Using Fused Deposition Modeling. Polymers 2021, 13, 1758. [Google Scholar] [CrossRef] [PubMed]

- Valvez, S.; Reis, P.N.; Ferreira, J.A. Effect of annealing treatment on mechanical properties of 3D-Printed composites. J. Mater. Res. Technol. 2023, 23, 2101–2115. [Google Scholar] [CrossRef]

- Shi, Q.; Xiao, R.; Yang, H.; Lei, D. Effects of physical aging on thermomechanical behaviors of poly(ethylene terephthalate)-glycol (PETG). Polym. Technol. Mater. 2019, 59, 835–846. [Google Scholar] [CrossRef]

- Banjo, A.D.; Agrawal, V.; Auad, M.L.; Celestine, A.-D.N. Moisture-induced changes in the mechanical behavior of 3D printed polymers. Compos. Part C Open Access 2022, 7, 100243. [Google Scholar] [CrossRef]

- Breger-Lee, D.E.; Bufford, W.L. Properties of Thermoplastic Splinting Materials. J. Hand Ther. 1992, 5, 202–211. [Google Scholar] [CrossRef]

- Schlégl, T.; Told, R.; Kardos, K.; Szőke, A.; Ujfalusi, Z.; Maróti, P. Evaluation and Comparison of Traditional Plaster and Fiberglass Casts with 3D-Printed PLA and PLA–CaCO3 Composite Splints for Bone-Fracture Management. Polymers 2022, 14, 3571. [Google Scholar] [CrossRef]

- Łukaszewski, K.; Wichniarek, R.; Górski, F. Determination of the Elasticity Modulus of Additively Manufactured Wrist Hand Orthoses. Materials 2020, 13, 4379. [Google Scholar] [CrossRef]

| 3DP-WHOs Based on 3D Scanning | 3DP-WHOs Based on Thermoforming | |

| Strengths |

|

|

| ||

| Weaknesses |

|

|

| Opportunities |

| |

| Threads |

| |

| Specimen | Young’s Modulus [MPa] | Poisson Coefficient | Apparent Yield Stress [MPa] | UTS [MPa] | Mean Young’s Modulus [MPa] | Mean Poisson Coefficient [-] | Mean Apparent Yield Stress [MPa] | Mean UTS [MPa] |

|---|---|---|---|---|---|---|---|---|

| [-] | ||||||||

| PLA_80_01 | 2420 | 0.337 | 28.09 | 29.99 | 2384 ± 35.08 | 0.348 ± 0.01 | 27.3 ± 1.12 | 26.39 ± 5.14 |

| PLA_80_02 | 2381 | 0.349 | - | 20.5 | ||||

| PLA_80_03 | 2350 | 0.357 | 26.51 | 28.67 | ||||

| PLA_55_01 | 1842 | 0.389 | 24.61 | 27.24 | 1864 ± 20.66 | 0.383 ± 0.01 | 24.4 ± 1.1 | 27.36 ± 0.57 |

| PLA_55_02 | 1883 | 0.378 | 25.39 | 27.98 | ||||

| PLA_55_03 | 1867 | 0.383 | 23.21 | 26.86 | ||||

| PETG_80_01 | 1581 | 0.381 | 22.88 | 27.96 | 1538 ± 54.12 | 0.381 ± 0.0 | 22.86 ± 0.72 | 27.61 ± 0.32 |

| PETG_80_02 | 1477 | 0.379 | 23.57 | 27.55 | ||||

| PETG_80_03 | 1555 | 0.382 | 22.14 | 27.33 | ||||

| PETG_55_01 | 1115 | 0.425 | 18.04 | 22.17 | 1190 ± 83.52 | 0.419 ± 0.01 | 18.52 ± 0.42 | 23.36 ± 1.14 |

| PETG_55_02 | 1175 | 0.406 | 18.85 | 23.46 | ||||

| PETG_55_03 | 1280 | 0.426 | 18.66 | 24.45 |

| Orthosis | PLA | PET-G | ||

|---|---|---|---|---|

| PLA 80 | PLA 55 | PETG 80 | PETG 55 | |

| Fexp [N] | 303.43 | 259.13 | 195.54 | 156.65 |

| FFEA [N] | 319.26 | 250.25 | 206.45 | 160.18 |

| Error [%] | 5.21 | 3.42 | 5.57 | 2.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vlăsceanu, D.; Popescu, D.; Baciu, F.; Stochioiu, C. Examining the Flexural Behavior of Thermoformed 3D-Printed Wrist–Hand Orthoses: Role of Material, Infill Density, and Wear Conditions. Polymers 2024, 16, 2359. https://doi.org/10.3390/polym16162359

Vlăsceanu D, Popescu D, Baciu F, Stochioiu C. Examining the Flexural Behavior of Thermoformed 3D-Printed Wrist–Hand Orthoses: Role of Material, Infill Density, and Wear Conditions. Polymers. 2024; 16(16):2359. https://doi.org/10.3390/polym16162359

Chicago/Turabian StyleVlăsceanu, Daniel, Diana Popescu, Florin Baciu, and Constantin Stochioiu. 2024. "Examining the Flexural Behavior of Thermoformed 3D-Printed Wrist–Hand Orthoses: Role of Material, Infill Density, and Wear Conditions" Polymers 16, no. 16: 2359. https://doi.org/10.3390/polym16162359

APA StyleVlăsceanu, D., Popescu, D., Baciu, F., & Stochioiu, C. (2024). Examining the Flexural Behavior of Thermoformed 3D-Printed Wrist–Hand Orthoses: Role of Material, Infill Density, and Wear Conditions. Polymers, 16(16), 2359. https://doi.org/10.3390/polym16162359