Effect of Melamine Formaldehyde Resin Encapsulated UV Acrylic Resin Primer Microcapsules on the Properties of UV Primer Coating

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Equipment

2.2. Process of UV Primer Microcapsules Preparing

2.3. Method of UV Primer Coating Preparing

2.4. Test and Characterization

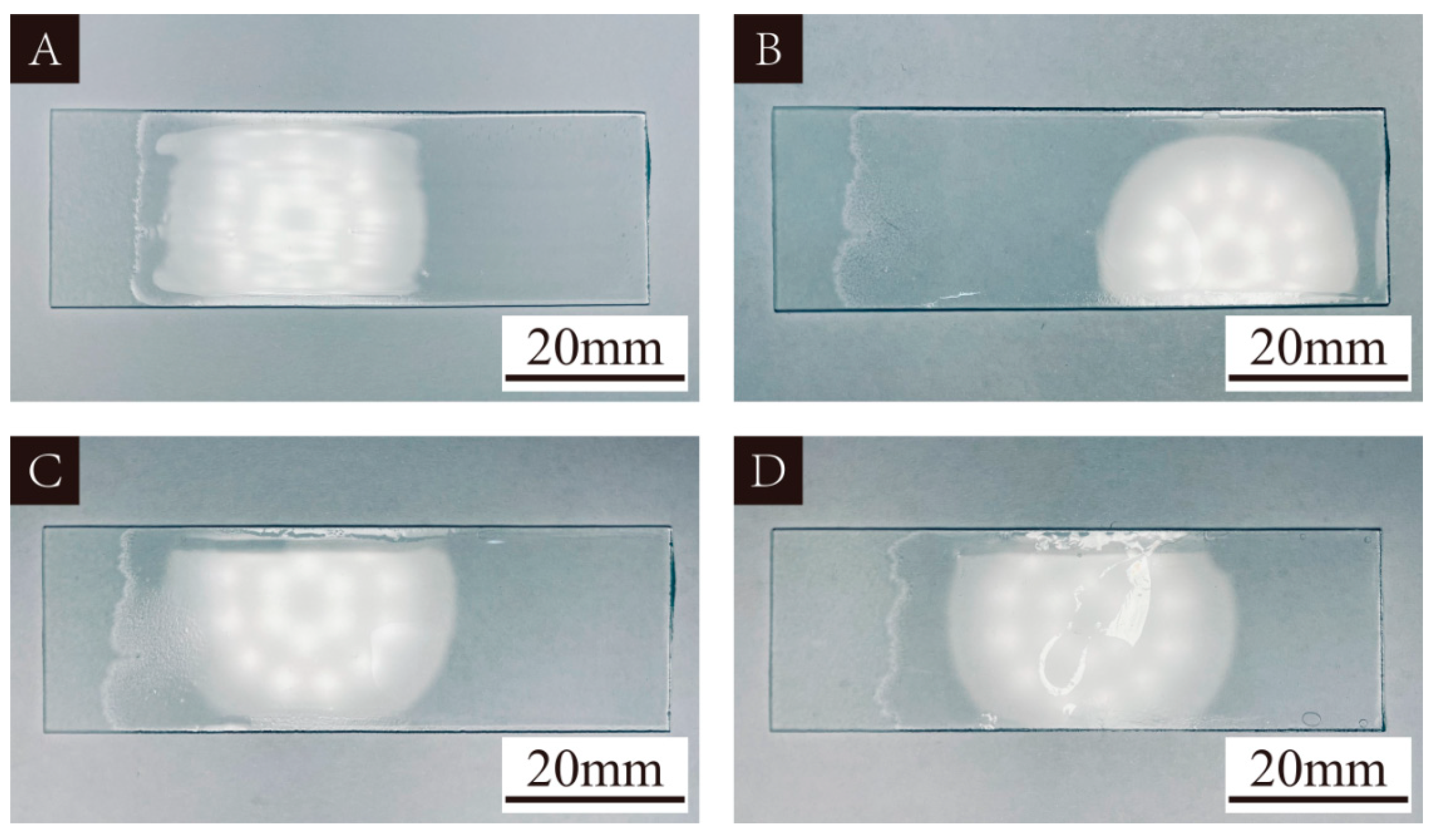

2.4.1. UV Primer Curing Test

2.4.2. Yield Rate and Encapsulation Rate

2.4.3. Microscopic Characterization

2.4.4. Chemical Composition

2.4.5. Optical Properties

2.4.6. Mechanical Properties

2.4.7. Self-Healing Property

3. Results and Discussion

3.1. UV Primer Curing Results

3.2. UV Primer Microcapsules

3.2.1. Analysis of Yield Rate and Encapsulation Rate

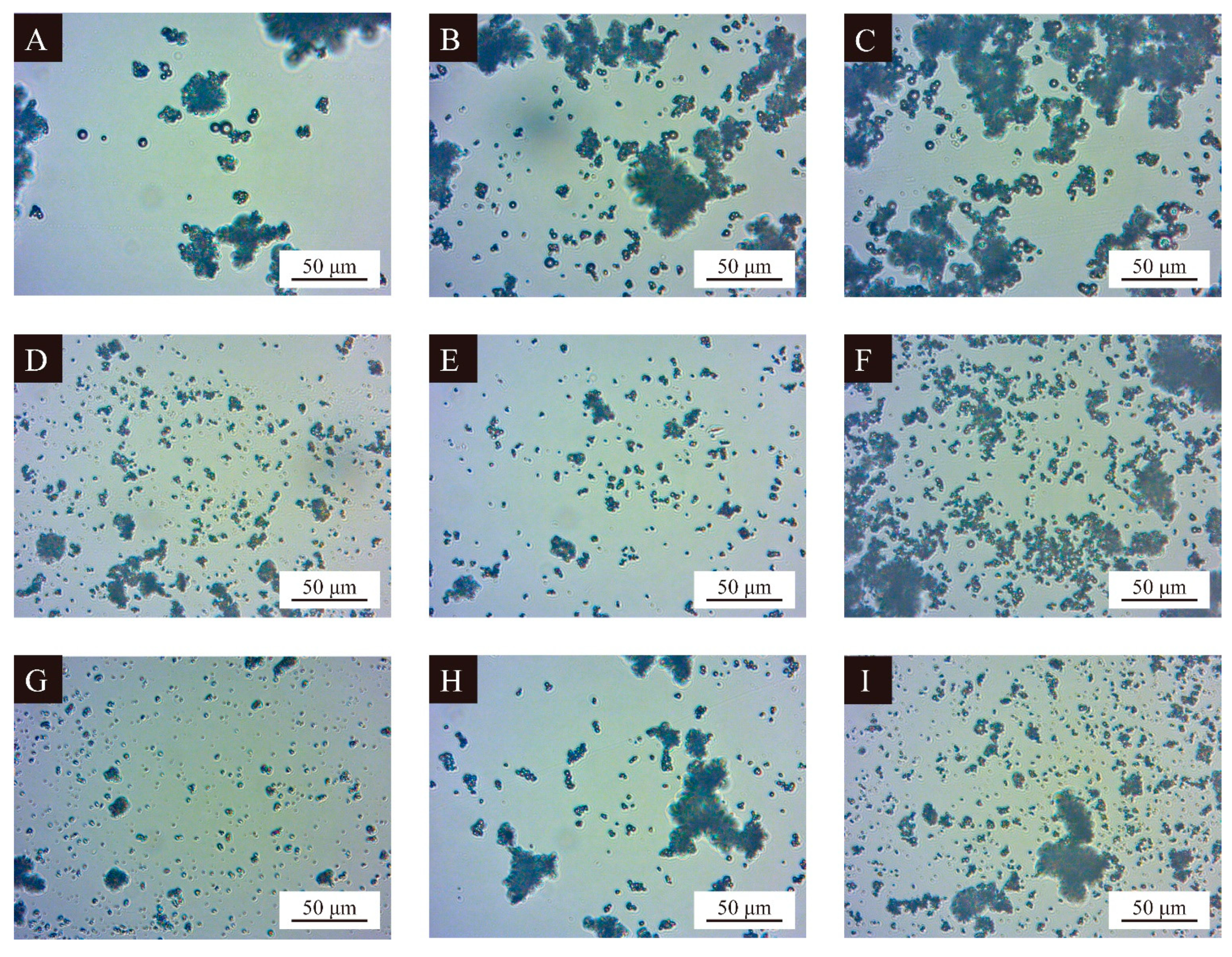

3.2.2. Microscopic Morphology of UV Primer Microcapsules

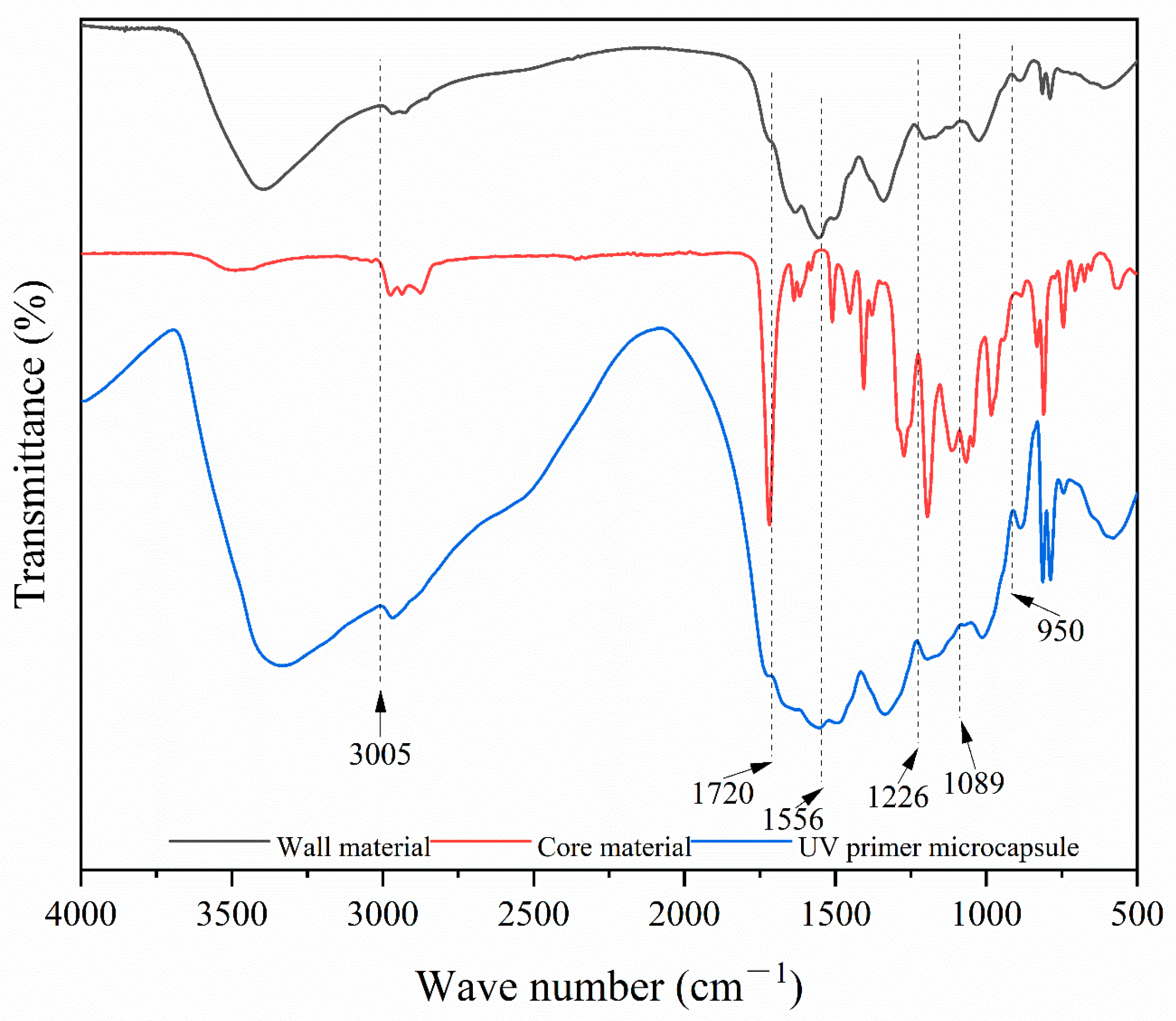

3.2.3. Chemical Composition Analysis of UV Primer Microcapsules

3.3. UV Primer Coating Property

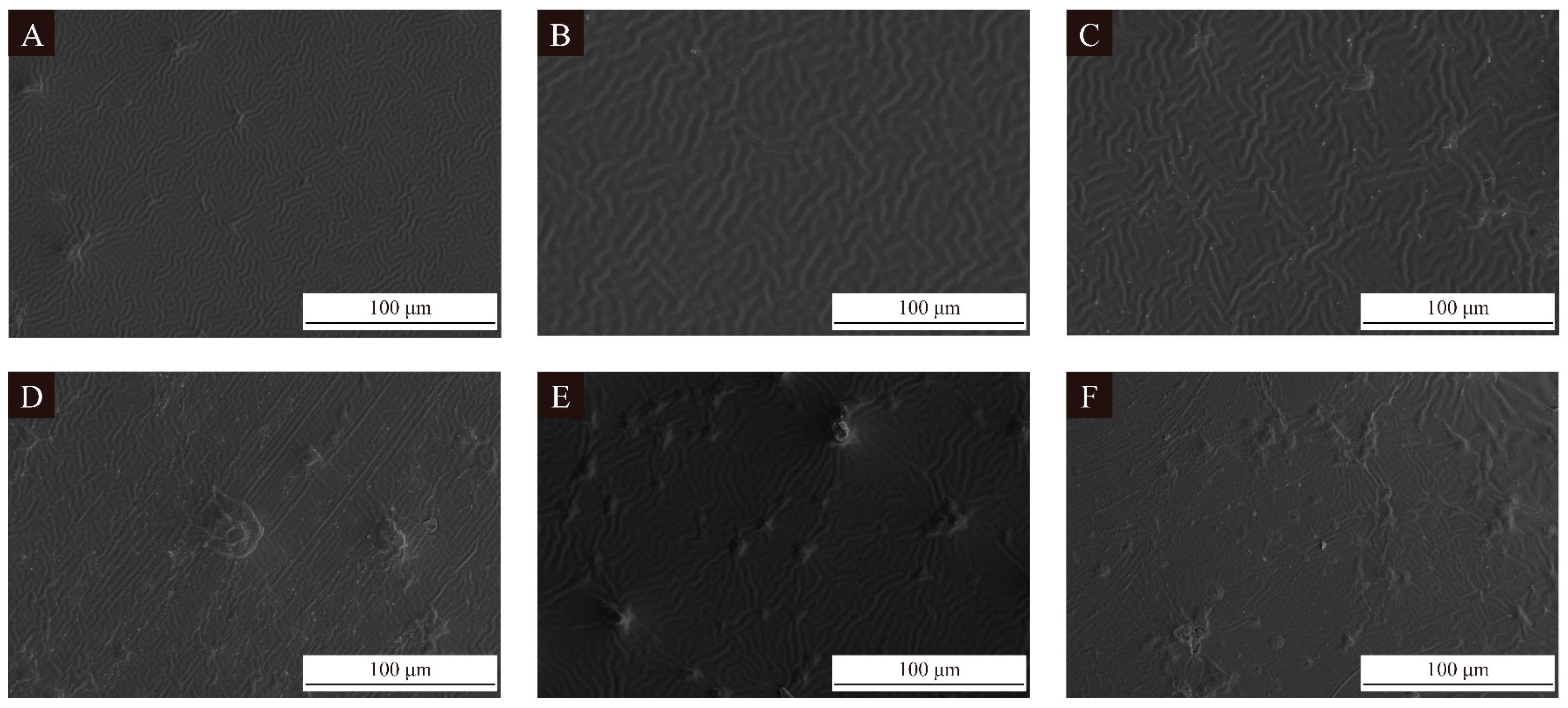

3.3.1. UV Primer Coating Morphology

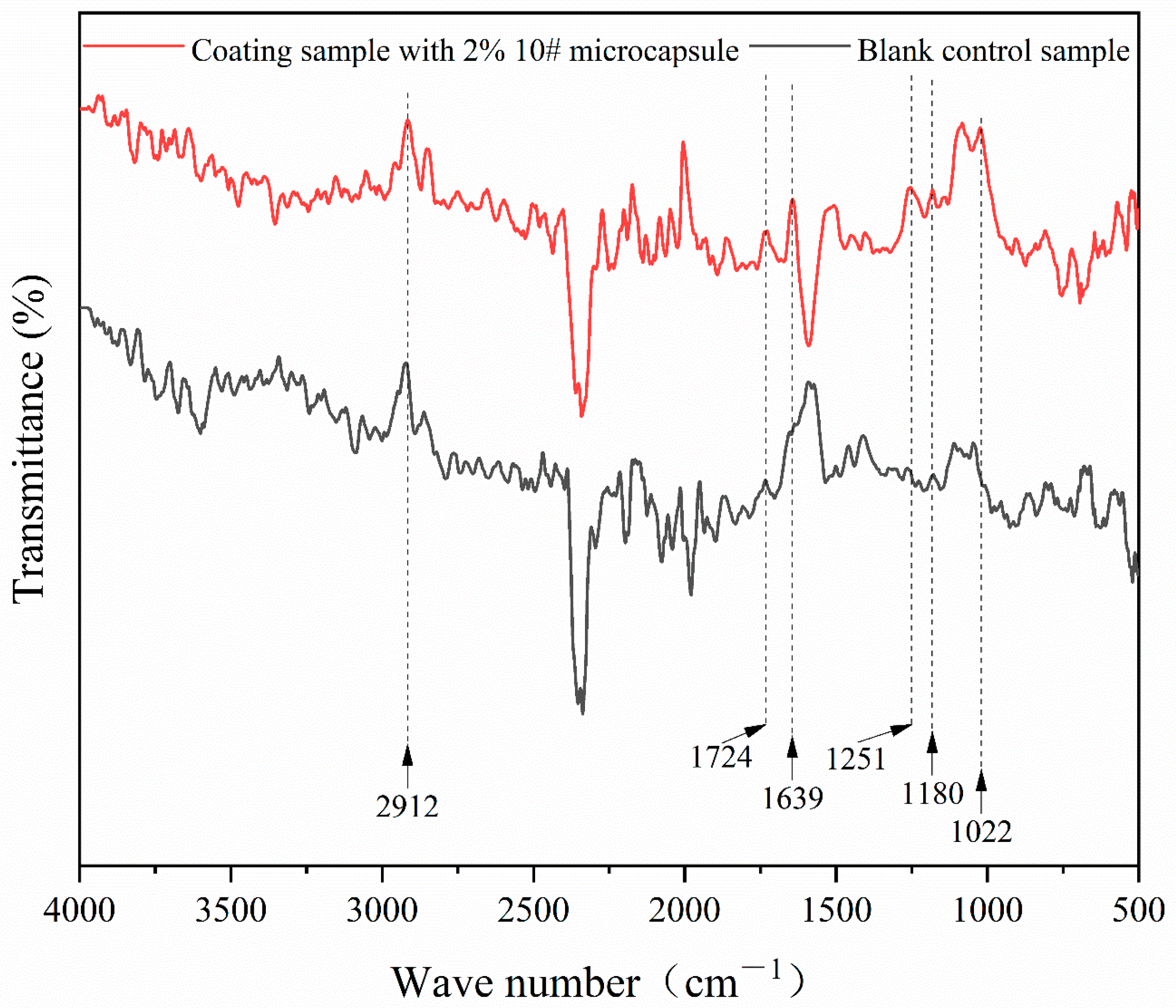

3.3.2. Chemical Composition Analysis of UV Primer Coating

3.3.3. Optical Properties of UV Primer Coating

3.3.4. Mechanical Properties of UV Primer Coating

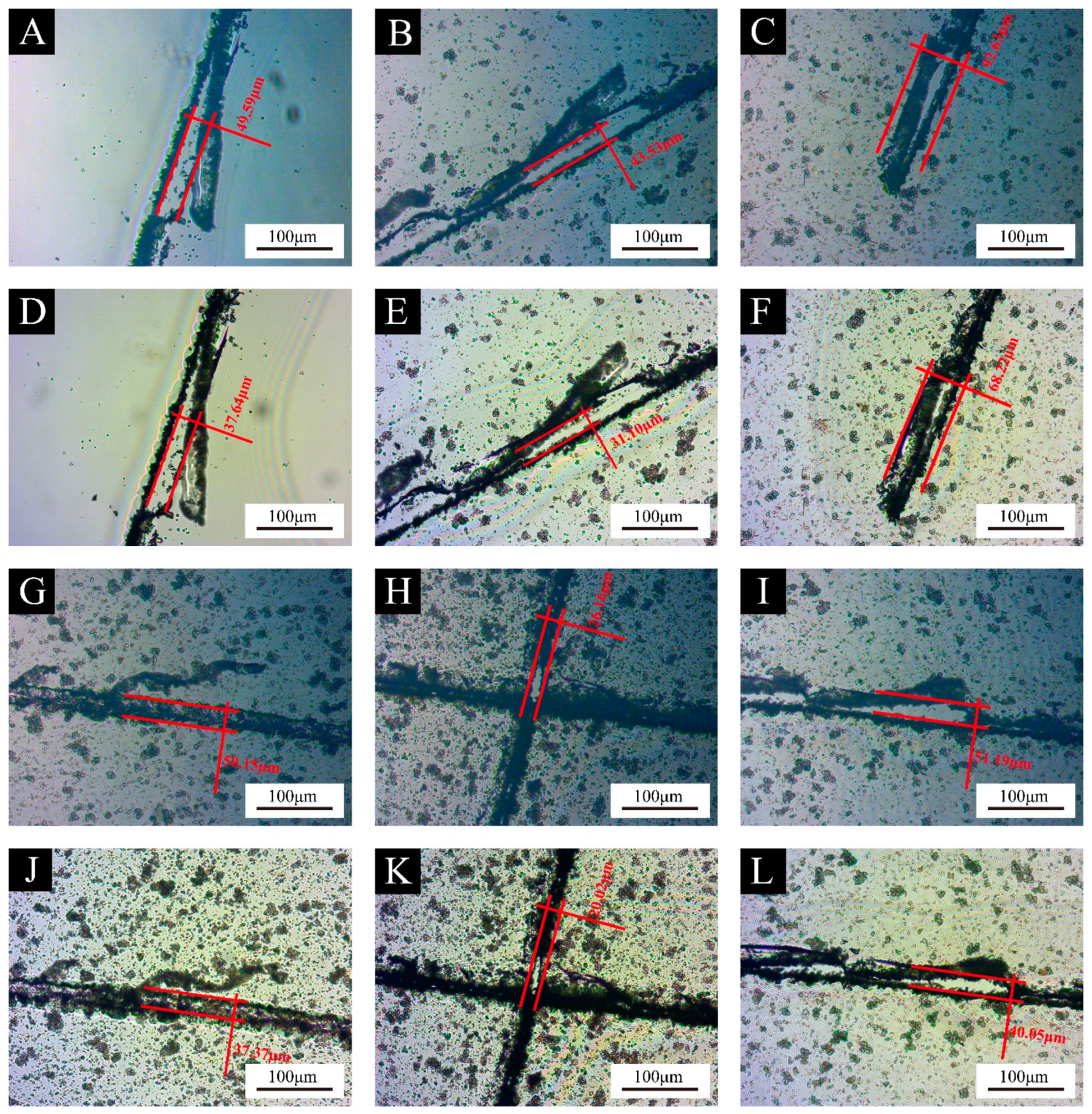

3.3.5. Self-Healing Property of UV Primer Coating

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, J.G.; Niu, J.Y. Green Material Characteristics Applied to Office Desk Furniture. Bioresources 2022, 17, 2228–2242. [Google Scholar] [CrossRef]

- Zhu, H.L.; Luo, W.; Ciesielski, P.N.; Fang, Z.Q.; Zhu, J.Y.; Henriksson, G.; Himmel, M.E.; Hu, L.B. Wood-Derived Materials for Green Electronics, Biological Devices, and Energy Applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef]

- Feil, A.A.; Reiter, I.D.; Oberherr, R.; Strasburg, V.J.; Schreiber, D. Analysis and measurement of the sustainability level in the furniture industry. Environ. Dev. Sustain. 2022, 24, 13657–13682. [Google Scholar] [CrossRef]

- Zhang, N.; Xu, W.; Tan, Y. Multi-attribute hierarchical clustering for product family division of customized wooden doors. Bioresources 2023, 18, 7889–7904. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Xu, W.; Li, R.R.; Zhou, J.C.; Luo, Z.Y. Study on sustainable lightweight design of airport waiting chair frame structure based on ANSYS workbench. Sustainability 2024, 16, 5350. [Google Scholar] [CrossRef]

- Hu, W.G.; Yu, R.Z. Mechanical and acoustic characteristics of four wood species subjected to bending load. Maderas-Cienc. Tecnol. 2023, 25, 39. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.Y.; Zhu, Y. Reverse design and additive manufacturing of furniture protective foot covers. Bioresources 2024, 19, 4670–4678. [Google Scholar] [CrossRef]

- Hu, W.G.; Luo, M.Y.; Hao, M.M.; Tang, B.; Wan, C. Study on the effects of selected factors on the diagonal tensile strength of oblique corner furniture joints constructed by wood dowel. Forests 2023, 14, 1149. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, W.G.; Kasal, A.; Erdil, Y.Z. The State of the Art of Biomechanics Applied in Ergonomic Furniture Design. Appl. Sci. 2023, 13, 12120. [Google Scholar] [CrossRef]

- Hu, W.G.; Luo, M.Y.; Liu, Y.Q.; Xu, W.; Konukcu, A.C. Experimental and numerical studies on the mechanical properties and behaviors of a novel wood dowel reinforced dovetail joint. Eng. Fail. Anal. 2023, 152, 107440. [Google Scholar] [CrossRef]

- Zhang, S.W.; Yu, A.X.; Song, X.Q.; Liu, X.Y. Synthesis and characterization of waterborne UV-curable polyurethane nanocomposites based on the macromonomer surface modification of colloidal silica. Prog. Org. Coat. 2013, 76, 1032–1039. [Google Scholar] [CrossRef]

- Marrot, L.; Zouari, M.; Schwarzkopf, M.; DeVallance, D.B. Sustainable biocarbon/tung oil coatings with hydrophobic and UV-shielding properties for outdoor wood substrates. Prog. Org. Coat. 2023, 177, 107428. [Google Scholar] [CrossRef]

- Invernizzi, C.; Fiocco, G.; Iwanicka, M.; Targowski, P.; Piccirillo, A.; Vagnini, M.; Licchelli, M.; Malagodi, M.; Bersani, D. Surface and Interface Treatments on Wooden Artefacts: Potentialities and Limits of a Non-Invasive Multi-Technique Study. Coatings 2021, 11, 29. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Zhu, J.G.; Qi, Q. Research on the Recyclable Design of Wooden Furniture Based on the Recyclability Evaluation. Sustainability 2023, 15, 16758. [Google Scholar] [CrossRef]

- Hu, W.G.; Fu, W.J.; Zhao, Y. Optimal design of the traditional Chinese wood furniture joint based on experimental and numerical method. Wood Res. 2024, 69, 50–59. [Google Scholar] [CrossRef]

- Xiong, X.Q.; Yue, X.Y.; Dong, W.H.; Xu, Z.Z. Current status and system construction of used-furniture recycling in China. Environ. Sci. Pollut. Res. 2022, 29, 82729–82739. [Google Scholar] [CrossRef] [PubMed]

- Chu, J.; Kumar, A. Assessment of wood industrial pollutants based on emission coefficients in China. Holzforschung 2020, 74, 1071–1078. [Google Scholar] [CrossRef]

- Yang, D.R.; Zhu, J.G. Recycling and Value-added Design of Discarded Wooden Furniture. Bioresources 2022, 16, 6953–6963. [Google Scholar] [CrossRef]

- Pan, N.N.; Fan, C.L.; Quan, Q.; Zhu, M.H.; Zhou, X.Y.; Chen, M.Z. Preparation and performance of high energy storage cellulose-based phase change Pickering emulsion. J. For. Eng. 2023, 8, 101–112. [Google Scholar]

- Lin, J.; Zhang, Q.; Wei, X.Y.; Sun, F.W. Preparation and characterization of modified polyethylene glycol/phenolic foam filled with phase change microcapsules. J. For. Eng. 2023, 8, 102–109. [Google Scholar]

- Ghiman, R.; Pop, R.; Rugina, D.; Focsan, M. Recent progress in preparation of microcapsules with tailored structures for bio-medical applications. J. Mol. Struct. 2022, 1248, 131366. [Google Scholar] [CrossRef]

- Taheri-Boroujeni, M.; Ashrafi, M.J. Self-healing performance of a microcapsule-based structure reinforced with pre-strained shape memory alloy wires: 3-D FEM/XFEM modeling. J. Intel. Mat. Syst. Str. 2023, 34, 2192–2206. [Google Scholar] [CrossRef]

- Hu, H.L.; Zhang, L.; Yu, R.L.; Yuan, L.Y.; Yang, Y.H.; He, X.D.; Wang, J.M.; Li, Z.P. Microencapsulation of ethylenediamine and its application in binary self-healing system using dual-microcapsule. Mater. Design 2020, 189, 108535. [Google Scholar] [CrossRef]

- Wang, H.P.; Rong, M.Z.; Zhang, M.Q. Self-Healing Polymers and Polymer-Based Composites Containing Microcapsules. Prog. Chem. 2010, 22, 2397–2407. [Google Scholar]

- Wang, T.H.; Liu, X.B.; Luo, J.; Sun, G.Q.; Liu, R. Interfacial polymerization for preparation of capsaicin microcapsules: Achieving sustained release in UV-curable coatings on plastic substrates. Colloid Surface A 2024, 696, 134379. [Google Scholar] [CrossRef]

- Wang, S.P.; Wu, Y.G.; Dai, J.Y.; Teng, N.; Peng, Y.Y.; Cao, L.J.; Liu, X.Q. Making organic coatings greener: Renewable resource, solvent-free synthesis, UV curing and repairability. Eur. Polym. J. 2020, 123, 109439. [Google Scholar] [CrossRef]

- Noè, C.; Tonda-Turo, C.; Carmagnola, I.; Hakkarainen, M.; Sangermano, M. UV-Cured Biodegradable Methacrylated Starch-Based Coatings. Coatings 2021, 11, 127. [Google Scholar] [CrossRef]

- Kupikowska-Stobba, B.; Lewinska, D. Polymer microcapsules and microbeads as cell carriers for in vivo biomedical applications. Biomater. Sci. 2020, 8, 1536–1574. [Google Scholar] [CrossRef]

- Baghi, F.; Gharsallaoui, A.; Dumas, E.; Ghnimi, S. Advancements in Biodegradable Active Films for Food Packaging: Effects of Nano/Microcapsule Incorporation. Foods 2022, 11, 760. [Google Scholar] [CrossRef]

- Nandy, A.; Saremi, R.; Lee, E.; Sharma, S. Stability and Applicability of Retinyl Palmitate Loaded Beeswax Microcapsules for Cosmetic Use Material Properties and Stability of Microencapsulated Actives. Johns. Matthey Tech. 2022, 66, 316–325. [Google Scholar] [CrossRef]

- Chen, K.L.; Zhou, J.L.; Che, X.G.; Zhao, R.Y.; Gao, Q. One-step synthesis of core shell cellulose-silica/n-octadecane microcapsules and their application in waterborne self-healing multiple protective fabric coatings. J. Colloid Interf. Sci. 2020, 566, 401–410. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.Y.; Li, X.Y.; Hu, J.J.; Guo, X.; Zhang, Y.J.; Zhang, Y.; Sun, W.S. Influence of metal oxide doping on waterborne UV polyurethane coating. J. For. Eng. 2023, 8, 190–197. [Google Scholar]

- Sang, R.J.; Fan, Z.X. Effect of surface treatment of poplar substrate on the characterization performance of UV inkjet coating. J. For. Eng. 2022, 7, 177–182. [Google Scholar]

- Wu, Z.H.; Zhang, H.Q. Research progress on waterborne UV-curable coatings and their applications for furniture and wood products. J. For. Eng. 2023, 8, 1–12. [Google Scholar]

- Li, P.H.; Lu, Z.; Ma, K.X.; Zou, G.F.; Chang, L.; Guo, W.C.; Tian, K.S.; Li, X.A.; Wang, H.Y. UV-triggered self-healing SiO2/PDA hybrid microcapsules with both enhanced UV-shielding ability and improved compatibility for epoxy resin coating. Prog. Org. Coat. 2022, 163, 106636. [Google Scholar] [CrossRef]

- Xia, Y.X.; Yan, X.X. Preparation of UV Topcoat Microcapsules and Their Effect on the Properties of UV Topcoat Paint Film. Polymers 2024, 16, 1410. [Google Scholar] [CrossRef]

- Wu, S.S.; Zhou, J.C.; Xu, W. A convenient approach to manufacturing lightweight and high-sound-insulation plywood using furfuryl alcohol/multilayer graphene oxide as a shielding layer. Wood Mater. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- GB/T 11186.3-1989; Methods for Measuring the Colour of Coating Films. Part III: Calculation of Colour Differences. Standardization Administration of the People’s Republic of China: Beijing, China, 1990.

- Wang, C.; Zhou, Z.Y. Optical properties and lampshade design applications of PLA 3D printing materials. Bioresources 2023, 18, 1545–1553. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Wang, J.X.; Xu, W. Study of selective modification effect of constructed structural color layers on European beech wood surfaces. Forests 2024, 15, 261. [Google Scholar] [CrossRef]

- Hu, J.; Liu, Y.; Xu, W. Influence of Cell Characteristics on the Construction of Structural Color Layers on Wood Surfaces. Forests 2024, 15, 676. [Google Scholar] [CrossRef]

- GB/T 4893.6-2013; Test of Surface Coatings of Furniture-Part 6: Determination of Gloss Value. Standardization Administration of the People’s Republic of China: Beijing, China, 2013.

- Hu, J.; Liu, Y.; Xu, W. Impact of cellular structure on the thickness and light reflection properties of structural color layers on diverse wood surfaces. Wood Mater. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- Wang, C.; Yu, J.H.; Jiang, M.H.; Li, J.Y. Effect of slicing parameters on the light transmittance of 3D-printed polyethylene terephthalate glycol products. Bioresources 2024, 19, 500–509. [Google Scholar] [CrossRef]

- Hu, W.G.; Luo, M.Y.; Yu, R.Z.; Zhao, Y. Effects of the selected factors on cyclic load performance of T-shaped mortise-and-tenon furniture joints. Wood Mater. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- Wang, C.; Yu, J.H.; Jiang, M.H.; Li, J.Y. Effect of selective enhancement on the bending performance of fused deposition methods 3D-printed PLA models. Bioresources 2024, 19, 2660–2669. [Google Scholar] [CrossRef]

- Hu, W.G.; Yu, R.Z. Study on the strength mechanism of the wooden round-end mortise-and-tenon joint using the digital image correlation method. Holzforschung 2024. [Google Scholar] [CrossRef]

- Wu, W.; Xu, W.; Wu, S.S. Mechanical performance analysis of double-dovetail joint applied to furniture T-shaped components. BioResources 2024, 19, 5862–5879. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, C.Y.; Ding, K.Q.; Jiang, M.H. Immersion polishing post-treatment of PLA 3D printed formed parts on its surface and mechanical performance. BioResources 2023, 18, 7995–8006. [Google Scholar] [CrossRef]

| Experimental Materials | Molecular Mass (g/mol) | CAS | Producer |

|---|---|---|---|

| 37% formaldehyde | 30.03 | 50-00-0 | Wuxi Yatai United Chemical Co., Ltd., Wuxi, China |

| Melamine | 126.12 | 108-78-1 | Nanjing Quanlong Biotechnology Co., Ltd., Nanjing, China |

| Triethanolamine | 149.19 | 102-71-6 | Nanjing Houxin Biotechnology Co., Ltd., Nanjing, China |

| Span-20 | 346.459 | 133-39-2 | Nanjing Houxin Biotechnology Co., Ltd., Nanjing, China |

| Triton X-100 | 646.85 | 9002-93-1 | Hangzhou Chicheng Pharmaceutical Technology Co., Ltd., Hangzhou, China |

| Absolute ethanol | 46.07 | 64-17-5 | Sichuan Kelun Pharmaceutical Co., Ltd., Chengdu, China |

| UV primer | - | - | Guangdong Huankai Microbial Technology Co., Ltd., Guangzhou, China |

| Citric acid monohydrate | 210.139 | 5949-29-1 | Jinan Xiaoshi Chemical Co., Ltd., Jinan, China |

| Equipment | Model | Manufacturer |

|---|---|---|

| Water bath | LC-OB-5L | Shangpin Bense Smart Home Co., Ltd., Zaozhuang, China |

| Scanning electron microscope | Zeiss Sigma 300 | FEI Company, Hillsboro, OR, USA |

| Powder tablet press | HY-12 | Tianjin Tianguang Optical Instrument Co., Ltd., Tianjin, China |

| Infrared spectrometer | VERTEX 80V | Germany BRUKER Co., Ltd., Karlsruhe, Germany |

| Color difference meter | 3nhYS3010 | Shenzhen Linshang Technology Co., Ltd., Shenzhen, China |

| Glossmeter | 3nhYG60S | Shenzhen Linshang Technology Co., Ltd., Shenzhen, China |

| Ultraviolet spectrophotometer | U-3900 | Hitachi High-Tech Co., Ltd., Beijing, China |

| Universal mechanical testing machine | 5000N | Zhejiang Wanxiong Instrument Manufacturing Co., Ltd., Ningbo, China |

| Coating roughness tester | SJ-411 | Shanghai Taiming Optical Instrument Co., Ltd., Shanghai, China |

| Single-lamp curing machine | 620# | Huzhou Tongxu Machinery Equipment Co., Ltd., Huzhou, China |

| Levels | Factor A Wall-Core Mass Ratio | Factor B Emulsifier HLB Value | Factor C Temperature (°C) | Factor D Time (h) |

|---|---|---|---|---|

| 1 | 1:0.60 | 8.60 | 60 | 1.0 |

| 2 | 1:0.70 | 10.04 | 70 | 2.0 |

| 3 | 1:0.80 | 13.40 | 80 | 3.0 |

| Sample (#) | Factor A Wall-Core Mass Ratio | Factor B Emulsifier HLB Value | Factor C Temperature (°C) | Factor D Time (h) |

|---|---|---|---|---|

| 1 | 1:0.60 | 8.60 | 60 | 1.0 |

| 2 | 1:0.60 | 10.04 | 70 | 2.0 |

| 3 | 1:0.60 | 13.40 | 80 | 3.0 |

| 4 | 1:0.70 | 8.60 | 70 | 3.0 |

| 5 | 1:0.70 | 10.04 | 80 | 1.0 |

| 6 | 1:0.70 | 13.40 | 60 | 2.0 |

| 7 | 1:0.80 | 8.60 | 80 | 2.0 |

| 8 | 1:0.80 | 10.04 | 60 | 3.0 |

| 9 | 1:0.80 | 13.40 | 70 | 1.0 |

| Sample (#) | Triton X-100 (g) | Span-20 (g) | Ethanol (mL) | Primer (g) | Formaldehyde (g) | Melamine (g) | Deionized Water (mL) |

|---|---|---|---|---|---|---|---|

| 1 | 0.00 | 0.30 | 78.90 | 4.40 | 9.01 | 4.00 | 20.00 |

| 2 | 0.08 | 0.22 | 78.90 | 4.40 | 9.01 | 4.00 | 20.00 |

| 3 | 0.30 | 0.00 | 78.90 | 4.40 | 9.01 | 4.00 | 20.00 |

| 4 | 0.00 | 0.30 | 78.90 | 4.40 | 7.72 | 3.43 | 17.50 |

| 5 | 0.08 | 0.22 | 78.90 | 4.40 | 7.72 | 3.43 | 17.50 |

| 6 | 0.30 | 0.00 | 78.90 | 4.40 | 7.72 | 3.43 | 17.50 |

| 7 | 0.00 | 0.30 | 78.90 | 4.40 | 6.76 | 3.00 | 15.00 |

| 8 | 0.08 | 0.22 | 78.90 | 4.40 | 6.76 | 3.00 | 15.00 |

| 9 | 0.30 | 0.00 | 78.90 | 4.40 | 6.76 | 3.00 | 15.00 |

| Sample (#) | Triton X-100 (g) | Span-20 (g) | Ethanol (mL) | Primer (g) | Formaldehyde (g) | Melamine (g) | Deionized Water (mL) |

|---|---|---|---|---|---|---|---|

| 10 | 0.08 | 0.22 | 78.90 | 4.40 | 10.81 | 4.80 | 24.00 |

| 11 | 0.08 | 0.22 | 78.90 | 4.40 | 9.83 | 4.36 | 21.82 |

| 12 | 0.08 | 0.22 | 78.90 | 4.40 | 9.01 | 4.00 | 20.00 |

| 13 | 0.08 | 0.22 | 78.90 | 4.40 | 8.32 | 3.69 | 18.46 |

| 14 | 0.08 | 0.22 | 78.90 | 4.40 | 7.72 | 3.43 | 17.50 |

| Sample (#) | Factor A Wall-Core Mass Ratio | Factor B Emulsifier HLB Value | Factor CTemperature (°C) | Factor DTime (h) | P (%) |

|---|---|---|---|---|---|

| 1 | 1:0.60 | 8.60 | 60 | 1.0 | 22.17 |

| 2 | 1:0.60 | 10.04 | 70 | 2.0 | 26.42 |

| 3 | 1:0.60 | 13.40 | 80 | 3.0 | 32.22 |

| 4 | 1:0.70 | 8.60 | 70 | 3.0 | 27.65 |

| 5 | 1:0.70 | 10.04 | 80 | 1.0 | 22.32 |

| 6 | 1:0.70 | 13.40 | 60 | 2.0 | 21.29 |

| 7 | 1:0.80 | 8.60 | 80 | 2.0 | 11.86 |

| 8 | 1:0.80 | 10.04 | 60 | 3.0 | 23.38 |

| 9 | 1:0.80 | 13.40 | 70 | 1.0 | 15.32 |

| Mean value 1 | 26.937 | 20.560 | 22.280 | 19.937 | |

| Mean value 2 | 23.753 | 24.040 | 23.130 | 19.857 | |

| Mean value 3 | 16.853 | 22.943 | 22.133 | 27.750 | |

| Range | 10.084 | 3.480 | 0.997 | 7.893 | |

| Order of influencing factors | A > D > B > C | ||||

| Optimal level | A1 | B2 | C2 | D3 | |

| Recommended preparation process | A1B2C2D3 | ||||

| Factors | Quadratic Sum | Free Degree | F-Ratio | F-Critical Value | Significance |

|---|---|---|---|---|---|

| A | 159.417 | 2 | 2.101 | 4.460 | |

| B | 18.993 | 2 | 0.250 | 4.460 | |

| C | 1.737 | 2 | 0.023 | 4.460 | |

| D | 123.359 | 2 | 1.626 | 4.460 | |

| Error | 303.51 | 8 |

| Sample (#) | Factor A Wall-Core Mass Ratio | Factor B Emulsifier HLB Value | Factor CTemperature (°C) | Factor DTime (h) | Pe (%) |

|---|---|---|---|---|---|

| 1 | 1:0.60 | 8.60 | 60 | 1.0 | 48.15 |

| 2 | 1:0.60 | 10.04 | 70 | 2.0 | 50.85 |

| 3 | 1:0.60 | 13.40 | 80 | 3.0 | 48.01 |

| 4 | 1:0.70 | 8.60 | 70 | 3.0 | 46.06 |

| 5 | 1:0.70 | 10.04 | 80 | 1.0 | 45.14 |

| 6 | 1:0.70 | 13.40 | 60 | 2.0 | 42.35 |

| 7 | 1:0.80 | 8.60 | 80 | 2.0 | 45.83 |

| 8 | 1:0.80 | 10.04 | 60 | 3.0 | 47.67 |

| 9 | 1:0.80 | 13.40 | 70 | 1.0 | 43.11 |

| Mean value 1 | 49.003 | 46.680 | 46.057 | 45.467 | |

| Mean value 2 | 44.517 | 47.887 | 46.673 | 46.343 | |

| Mean value 3 | 45.537 | 44.490 | 46.327 | 47.247 | |

| Range | 4.486 | 3.397 | 0.616 | 1.780 | |

| Order of influencing factors | A > B > D > C | ||||

| Optimal level | A1 | B2 | C2 | D3 | |

| Recommended preparation process | A1B2C2D3 | ||||

| Factors | Quadratic Sum | Free Degree | F-Ratio | F-Critical Value | Significance |

|---|---|---|---|---|---|

| A | 33.188 | 2 | 2.358 | 4.460 | |

| B | 17.789 | 2 | 1.264 | 4.460 | |

| C | 0.573 | 2 | 0.041 | 4.460 | |

| D | 4.753 | 2 | 0.338 | 4.460 | |

| Error | 56.30 | 8 |

| Sample (#) | Factor A Wall-Core Mass Ratio | P (%) | Pe (%) |

|---|---|---|---|

| 10 | 1:0.50 | 34.48 | 20.03 |

| 11 | 1:0.55 | 32.33 | 19.86 |

| 12 | 1:0.60 | 30.67 | 19.55 |

| 13 | 1:0.65 | 29.98 | 18.78 |

| 14 | 1:0.70 | 27.85 | 18.57 |

| Sample 10 UV Primer Microcapsules (%) | L | a | b | ΔE |

|---|---|---|---|---|

| 0 | 82.13 | 0.40 | 0.03 | - |

| 2.0 | 80.53 | 0.67 | 0.57 | 1.71 |

| 4.0 | 80.73 | 0.70 | 1.03 | 1.75 |

| 6.0 | 80.07 | 0.50 | 1.17 | 2.36 |

| 8.0 | 79.03 | 0.67 | 1.47 | 3.43 |

| 10.0 | 76.97 | 0.90 | 3.27 | 6.12 |

| Sample 10 UV Primer Microcapsules (%) | Gloss (GU) | Transmittance (%) | ||

|---|---|---|---|---|

| 20° | 60° | 85° | ||

| 0 | 162.47 | 165.93 | 110.33 | 87.51 |

| 2.0 | 91.63 | 106.63 | 82.77 | 78.80 |

| 4.0 | 71.73 | 95.83 | 73.33 | 66.39 |

| 6.0 | 48.87 | 102.77 | 87.60 | 52.39 |

| 8.0 | 36.07 | 80.00 | 74.33 | 51.84 |

| 10.0 | 43.57 | 82.83 | 72.60 | 45.37 |

| Sample 10 UV Primer Microcapsules (%) | Elongation at Break (%) |

|---|---|

| 0 | 2.67 |

| 2.0 | 3.62 |

| 4.0 | 1.19 |

| 6.0 | 1.53 |

| 8.0 | 1.36 |

| 10.0 | 0.99 |

| Sample 10 UV Primer Microcapsules (%) | Roughness (μm) |

|---|---|

| 0 | 0.030 |

| 2.0 | 0.204 |

| 4.0 | 0.232 |

| 6.0 | 0.234 |

| 8.0 | 0.287 |

| 10.0 | 0.442 |

| Sample 10 UV Primer Microcapsules (%) | Crack Width (μm) | Self-Healing Rate (%) | |

|---|---|---|---|

| After Cutting | One Week Later | ||

| 0 | 49.59 | 37.64 | 24.10 |

| 2.0 | 43.53 | 31.10 | 28.56 |

| 4.0 | 92.63 | 68.22 | 26.35 |

| 6.0 | 50.15 | 37.37 | 25.49 |

| 8.0 | 26.16 | 20.02 | 23.48 |

| 10.0 | 51.19 | 40.05 | 21.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, Y.; Xia, Y.; Yan, X. Effect of Melamine Formaldehyde Resin Encapsulated UV Acrylic Resin Primer Microcapsules on the Properties of UV Primer Coating. Polymers 2024, 16, 2308. https://doi.org/10.3390/polym16162308

Zou Y, Xia Y, Yan X. Effect of Melamine Formaldehyde Resin Encapsulated UV Acrylic Resin Primer Microcapsules on the Properties of UV Primer Coating. Polymers. 2024; 16(16):2308. https://doi.org/10.3390/polym16162308

Chicago/Turabian StyleZou, Yuming, Yongxin Xia, and Xiaoxing Yan. 2024. "Effect of Melamine Formaldehyde Resin Encapsulated UV Acrylic Resin Primer Microcapsules on the Properties of UV Primer Coating" Polymers 16, no. 16: 2308. https://doi.org/10.3390/polym16162308

APA StyleZou, Y., Xia, Y., & Yan, X. (2024). Effect of Melamine Formaldehyde Resin Encapsulated UV Acrylic Resin Primer Microcapsules on the Properties of UV Primer Coating. Polymers, 16(16), 2308. https://doi.org/10.3390/polym16162308