The Quest for the Holy Grail Of 3D Printing: A Critical Review of Recycling in Polymer Powder Bed Fusion Additive Manufacturing

Abstract

1. Introduction

1.1. Polymers

1.2. Additive Manufacturing Methods

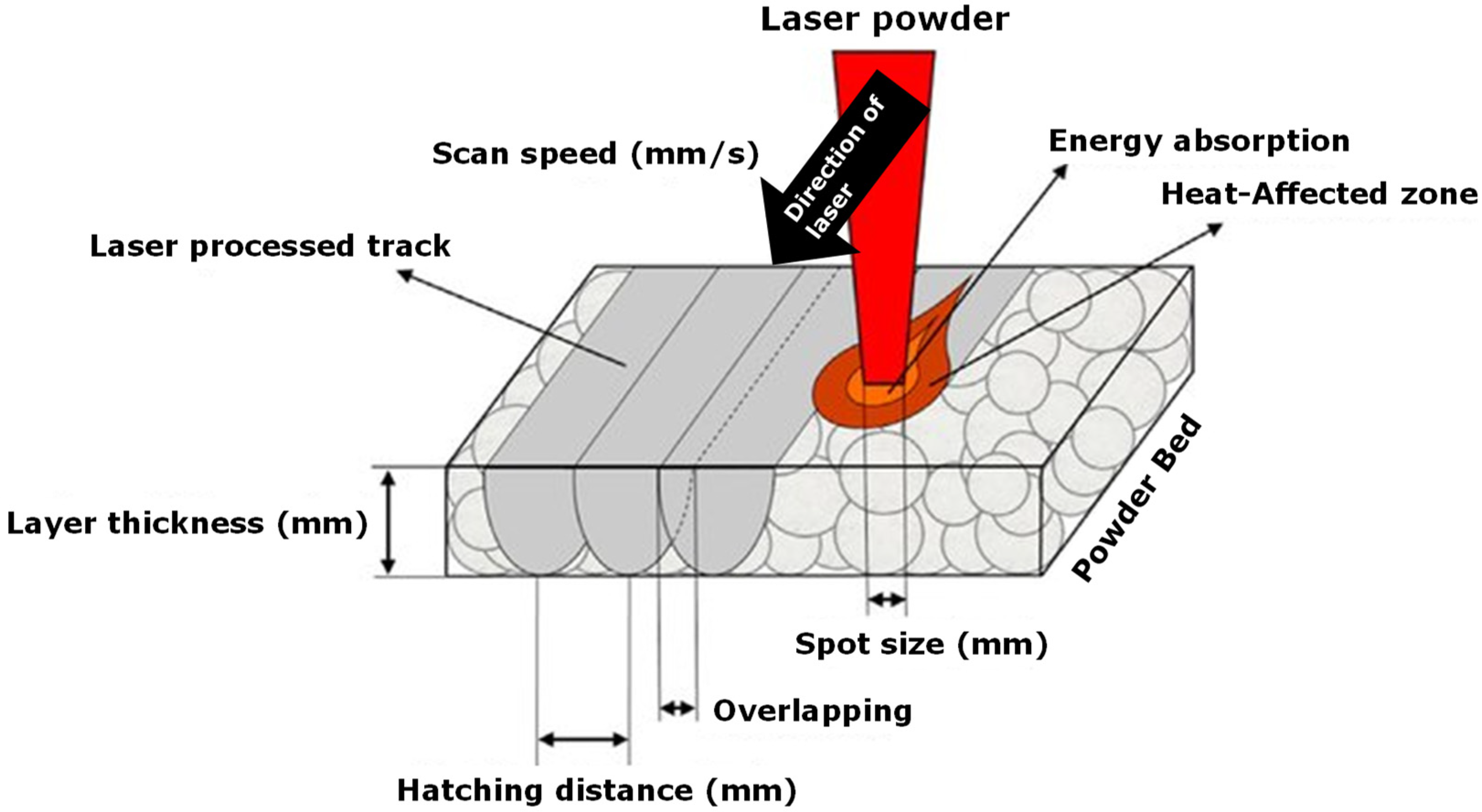

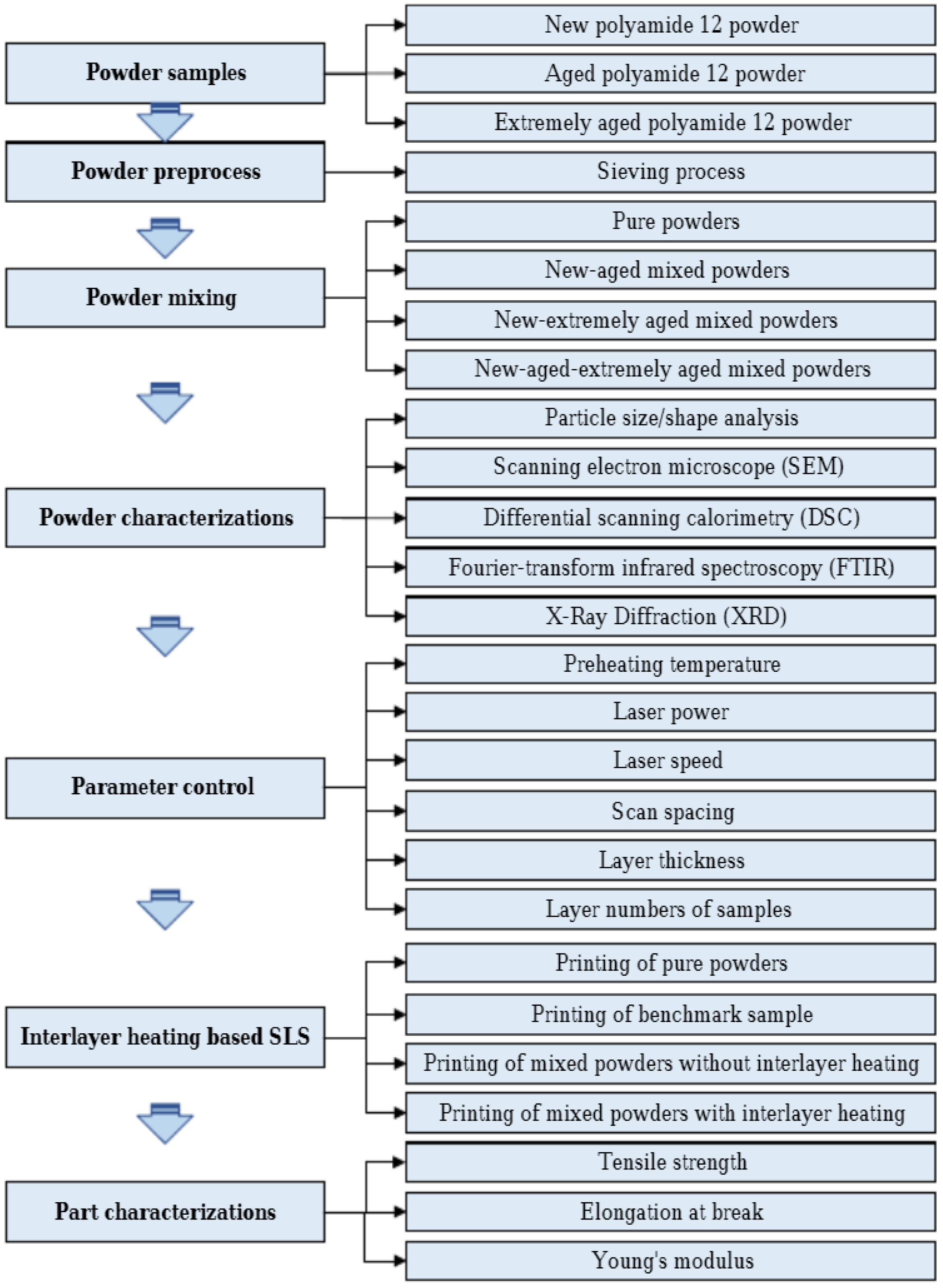

1.3. Challenges and Opportunities for Powder Bed Fusion Sustainability

2. Sustainability and Circular Economy of Additive Manufacturing

3. Polymeric Material Recycling Methods for 3D Printing

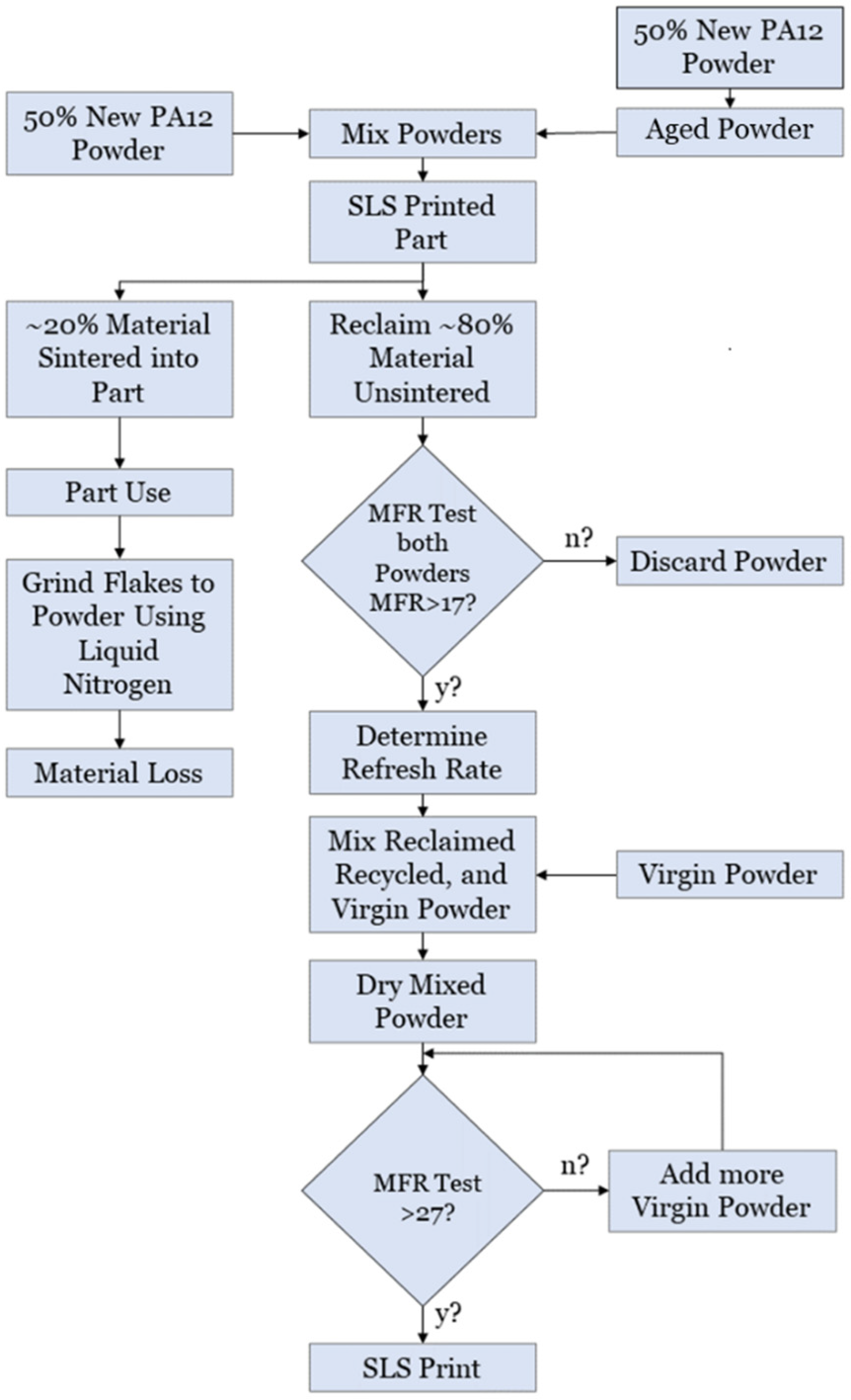

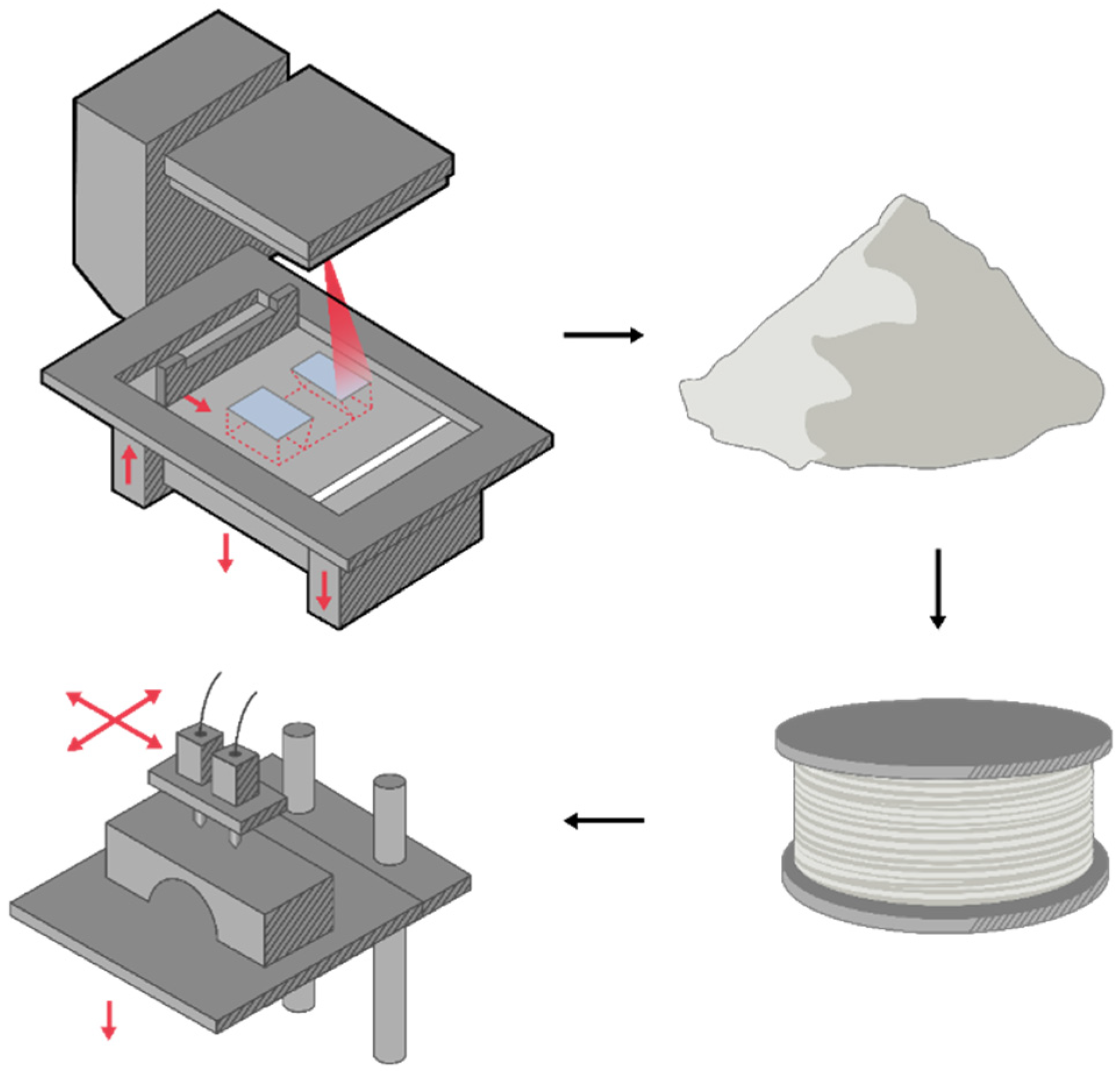

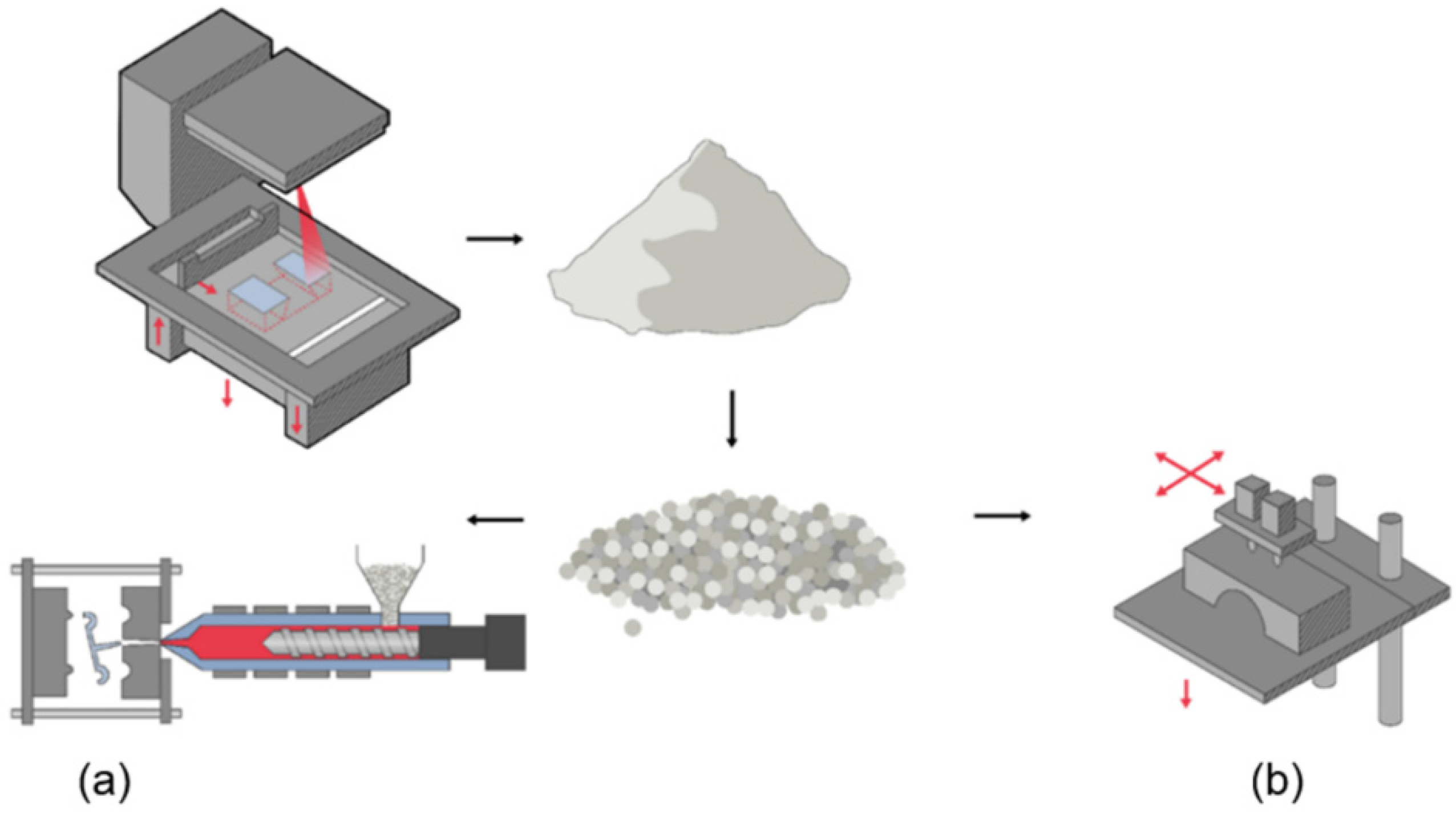

Use of Filaments

4. Methods for Recycling to 3D Printing

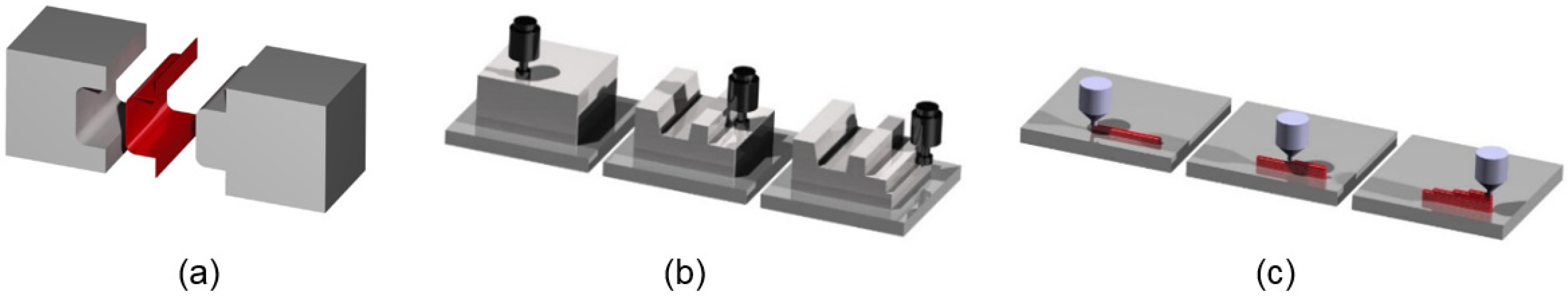

Alternative Methods for Recycling

5. Recycling of Materials Used in Additive Manufacturing

6. Discussion and Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ranjan Madhu, N.; Erfani, H.; Jadoun, S.; Amir, M.; Thiagarajan, Y.; Pal Singh Chauhan, N. Fused Deposition Modelling Approach Using 3D Printing and Recycled Industrial Materials for a Sustainable Environment: A Review. Int. J. Adv. Manuf. Technol. 2022, 122, 2125–2138. [Google Scholar] [CrossRef] [PubMed]

- 3D Printing Market Size, Share & Trends Analysis Report 2030. Available online: https://www.grandviewresearch.com/industry-analysis/3d-printing-industry-analysis (accessed on 5 August 2024).

- 3D Printing Market Size to Surpass USD 87.2 Billion by 2030. Available online: https://www.acumenresearchandconsulting.com/3d-printing-market (accessed on 5 August 2024).

- DePalma, K.; Walluk, M.R.; Murtaugh, A.; Hilton, J.; McConky, S.; Hilton, B. Assessment of 3D Printing Using Fused Deposition Modeling and Selective Laser Sintering for a Circular Economy. J. Clean. Prod. 2020, 264, 121567. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A.E. A Review on Hot Stamping. J. Mater. Process Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Kauffer, P.H. Injection Molding: Process, Design and Applications; Nova Science Publishers: New York, NY, USA, 2021. [Google Scholar]

- Throne, J. Thermoforming. In Applied Plastics Engineering Handbook: Processing, Materials, and Applications, 2nd ed.; William Andrew: Washington, DC, USA, 2017. [Google Scholar]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Yang, F.; Zobeiry, N.; Mamidala, R.; Chen, X. A Review of Aging, Degradation, and Reusability of PA12 Powders in Selective Laser Sintering Additive Manufacturing. Mater. Today Commun. 2023, 34, 105279. [Google Scholar] [CrossRef]

- Fernández De Velasco-Ruiz, M.; Quijada-Garrido, I.; Benavente, R.; Barrales-Rienda, J.M. Miscibility Studies of Erucamide (13-Cis-Docosenamide)/Poly(Laurolactam) (Nylon 12) (PA-12) Blends. Polymer 2000, 41, 5819–5828. [Google Scholar] [CrossRef]

- (9) (PDF) Polyamide (Nylon) 12 Degradation during the Selective Laser Sintering (SLS) Process: A Quantification for Recycling Optimization. Available online: https://www.researchgate.net/publication/281078350_Polyamide_Nylon_12_Degradation_during_the_Selective_Laser_Sintering_SLS_Process_A_Quantification_for_Recycling_Optimization?channel=doi&linkId=55d3efb108ae0b8f3ef9351e&showFulltext=true (accessed on 5 August 2024).

- US11491726B2—Method for the Treatment of Residual Thermoplastic Powders—Google Patents. Available online: https://patents.google.com/patent/US11491726B2/en?inventor=bruno+alves&oq=bruno+alves&page=4 (accessed on 5 August 2024).

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Recycling in Additive Manufacturing: A Systematic Literature Review and Opportunities for the Circular Economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- The Evolution of SLS: New Technologies, Materials and Applications—AMFG. Available online: https://amfg.ai/2020/01/21/the-evolution-of-sls-new-technologies-materials-and-applications/ (accessed on 5 August 2024).

- Maines, E.M.; Porwal, M.K.; Ellison, C.J.; Reineke, T.M. Sustainable Advances in SLA/DLP 3D Printing Materials and Processes. Green Chem. 2021, 23, 6863–6897. [Google Scholar] [CrossRef]

- Professional 3D Printing Solutions|EOS|EOS GmbH. Available online: https://www.eos.info/en-us (accessed on 5 August 2024).

- Fina, F.; Gaisford, S.; Basit, A.W. Powder Bed Fusion: The Working Process, Current Applications and Opportunities. In AAPS Advances in the Pharmaceutical Sciences Series; Springer: Cham, Switzerland, 2018; Volume 31. [Google Scholar]

- The Life and Times of a Selective Laser Sintering Powder—TCT Magazine. Available online: https://www.tctmagazine.com/additive-manufacturing-3d-printing-news/life-times-selective-laser-sintering-powder/ (accessed on 5 August 2024).

- Yang, F.; Jiang, T.; Lalier, G.; Bartolone, J.; Chen, X. Process Control of Surface Quality and Part Microstructure in Selective Laser Sintering Involving Highly Degraded Polyamide 12 Materials. Polym. Test. 2021, 93, 106920. [Google Scholar] [CrossRef]

- 3D Printers, Software, Manufacturing & Digital Healthcare|3D Systems. Available online: https://www.3dsystems.com/?smtNoRedir=1 (accessed on 5 August 2024).

- Chen, P.; Tang, M.; Zhu, W.; Yang, L.; Wen, S.; Yan, C.; Ji, Z.; Nan, H.; Shi, Y. Systematical Mechanism of Polyamide-12 Aging and Its Micro-Structural Evolution during Laser Sintering. Polym. Test. 2018, 67, 370–379. [Google Scholar] [CrossRef]

- Kellens, K.; Renaldi, R.; Dewulf, W.; Kruth, J.P.; Duflou, J.R. Environmental Impact Modeling of Selective Laser Sintering Processes. Rapid Prototyp. J. 2014, 20, 459–470. [Google Scholar] [CrossRef]

- PA12 Smooth—Nylon-12 Powder|Filament2Print. Available online: https://filament2print.com/gb/powders/1085-pa12-smooth-nylon-powder.html (accessed on 5 August 2024).

- Babagowda; Kadadevara Math, R.S.; Goutham, R.; Srinivas Prasad, K.R. Study of Effects on Mechanical Properties of PLA Filament Which Is Blended with Recycled PLA Materials. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 310. [Google Scholar]

- Dotchev, K.; Yusoff, W. Recycling of Polyamide 12 Based Powders in the Laser Sintering Process. Rapid Prototyp. J. 2009, 15, 192–203. [Google Scholar] [CrossRef]

- Li, Z.; Zhu, F.; Xu, H.; Li, Z.; Teng, B.; Zhang, X. Effect of Powder Recycling on Hardness and Impact Toughness of Polyamide Formed by Selective Laser Sintering. Zhongguo Jiguang/Chin. J. Lasers 2018, 45, 0502010. [Google Scholar] [CrossRef]

- Talebi, F.A.; Haydari, Z.; Salehi, H.; Mehrabi, M.; Gardy, J.; Bradley, M.; Bayly, A.; Hassanpour, A. Spreadability of Powders for Additive Manufacturing: A Critical Review of Characterisation Methods. Particuology 2024, 93, 211–234. [Google Scholar] [CrossRef]

- du Maire, P.; Sert, E.; Deckert, M.; Johlitz, M.; Öchsner, A. Characterisation of the Thermal Ageing Effects on the Mechanical Properties When Reusing Polyamide 12 in the Selective Laser Sintering Process. Materwiss Werksttech 2022, 53, 503–508. [Google Scholar] [CrossRef]

- Yaragatti, N.; Patnaik, A. A Review on Additive Manufacturing of Polymers Composites. Mater. Today Proc. 2020, 44, 4150–4157. [Google Scholar] [CrossRef]

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of Additive Manufacturing: An Overview on Its Energy Demand and Environmental Impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- Rett, J.P.; Traore, Y.L.; Ho, E.A. Sustainable Materials for Fused Deposition Modeling 3D Printing Applications. Adv. Eng. Mater. 2021, 23, 694–704. [Google Scholar] [CrossRef]

- Pham, D.T.; Dotchev, K.D.; Yusoff, W.A.Y. Deterioration of Polyamide Powder Properties in the Laser Sintering Process. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2008, 222, 2163–2176. [Google Scholar] [CrossRef]

- Grossin, D.; Montón, A.; Navarrete-Segado, P.; Özmen, E.; Urruth, G.; Maury, F.; Maury, D.; Frances, C.; Tourbin, M.; Lenormand, P.; et al. A Review of Additive Manufacturing of Ceramics by Powder Bed Selective Laser Processing (Sintering/Melting): Calcium Phosphate, Silicon Carbide, Zirconia, Alumina, and Their Composites. Open Ceram. 2021, 5, 100073. [Google Scholar] [CrossRef]

- Jabri, F.E.; Ouballouch, A.; Lasri, L.; Alaiji, R.E. A Comprehensive Review of Polymer Materials and Selective Laser Sintering Technology for 3D Printing. J. Achiev. Mater. Manuf. Eng. 2023, 118, 5–17. [Google Scholar] [CrossRef]

- Josupeit, S.; Schmid, H.J. Experimental Analysis and Modeling of Local Ageing Effects during Laser Sintering of Polyamide 12 in Regard to Individual Thermal Histories. J. Appl. Polym. Sci. 2017, 134, 45435. [Google Scholar] [CrossRef]

- Sanchez-Rexach, E.; Johnston, T.G.; Jehanno, C.; Sardon, H.; Nelson, A. Sustainable Materials and Chemical Processes for Additive Manufacturing. Chem. Mater. 2020, 32, 7105–7119. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Kechagias, J.D. Sustainable Additive Manufacturing: Mechanical Response of Polyamide 12 over Multiple Recycling Processes. Materials 2021, 14, 466. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; Núñez, P.J.; García-Plaza, E.; García-Moreno, I.; Reverte, J.M. Additive Manufacturing of Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties. Compos. Sci. Technol. 2019, 181, 107688. [Google Scholar] [CrossRef]

- Cress, A.K.; Huynh, J.; Anderson, E.H.; O’neill, R.; Schneider, Y.; Keleş, Ö. Effect of Recycling on the Mechanical Behavior and Structure of Additively Manufactured Acrylonitrile Butadiene Styrene (ABS). J. Clean. Prod. 2021, 279, 123689. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Arrieta, M.P.; Moreno, E.; Gaspar, G.; Muneta, L.M.; Carrasco-Gallego, R.; Yáñez, S.; Hidalgo-Carvajal, D.; de la Orden, M.U.; Martínez Urreaga, J. Evaluation of the Technical Viability of Distributed Mechanical Recycling of PLA 3D Printing Wastes. Polymers 2021, 13, 1247. [Google Scholar] [CrossRef]

- Bhagia, S.; Bornani, K.; Agarwal, R.; Satlewal, A.; Ďurkovič, J.; Lagaňa, R.; Bhagia, M.; Yoo, C.G.; Zhao, X.; Kunc, V.; et al. Critical Review of FDM 3D Printing of PLA Biocomposites Filled with Biomass Resources, Characterization, Biodegradability, Upcycling and Opportunities for Biorefineries. Appl. Mater. Today 2021, 24, 101078. [Google Scholar] [CrossRef]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-Looped Recycling of Polylactic Acid Used in 3D Printing: An Experimental Investigation and Life Cycle Assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

- Zhao, X.G.; Hwang, K.J.; Lee, D.; Kim, T.; Kim, N. Enhanced Mechanical Properties of Self-Polymerized Polydopamine-Coated Recycled PLA Filament Used in 3D Printing. Appl. Surf. Sci. 2018, 441, 381–387. [Google Scholar] [CrossRef]

- Yao, Y.; Li, M.; Lackner, M.; Herfried, L. A Continuous Fiber-Reinforced Additive Manufacturing Processing Based on PET Fiber and PLA. Materials 2020, 13, 3044. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer Recycling in an Open-Source Additive Manufacturing Context: Mechanical Issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Anderson, I. Mechanical Properties of Specimens 3D Printed with Virgin and Recycled Polylactic Acid. 3D Print. Addit. Manuf. 2017, 4, 110–115. [Google Scholar] [CrossRef]

- Tanney, D.; Meisel, N.A.; Moore, J. Investigating Material Degradation through the Recycling of PLA in Additively Manufactured Parts. In Proceedings of the 2017 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Lanzotti, A.; Martorelli, M.; Maietta, S.; Gerbino, S.; Penta, F.; Gloria, A. A Comparison between Mechanical Properties of Specimens 3D Printed with Virgin and Recycled PLA. Procedia CIRP 2019, 79, 143–146. [Google Scholar] [CrossRef]

- Wu, M.Y.T.; Mak, S.L.; Tang, W.F.; Li, C.H.; Chan, T.W. A Review on Melt Flow Index Characteristics of Polylactide (PLA) for Recycle Use in 3-D Printing. J. Test. Eval. 2022, 50, 2260–2267. [Google Scholar] [CrossRef]

- Pernica, J.; Vodák, M.; Šarocký, R.; Šustr, M.; Dostál, P.; Černý, M.; Dobrocký, D. Mechanical Properties of Recycled Polymer Materials in Additive Manufacturing. Manuf. Technol. 2022, 22, 200–203. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, R.; Singh, T.P.; Batish, A.; Singh, M. Multi-Stage Primary and Secondary Recycled PLA Composite Matrix for 3D Printing Applications. Proc. Natl. Acad. Sci. India Sect. A: Phys. Sci. 2022, 92, 677–698. [Google Scholar] [CrossRef]

- Atakok, G.; Kam, M.; Koc, H.B. Tensile, Three-Point Bending and Impact Strength of 3D Printed Parts Using PLA and Recycled PLA Filaments: A Statistical Investigation. J. Mater. Res. Technol. 2022, 18, 1542–1554. [Google Scholar] [CrossRef]

- Singh, R.; Barwar, A.; Kumar, A. Investigations on Primary and Secondary Recycling of PLA and Its Composite for Biomedical and Sensing Applications. J. Inst. Eng. 2022, 103, 821–836. [Google Scholar] [CrossRef]

- Pillin, I.; Montrelay, N.; Bourmaud, A.; Grohens, Y. Effect of Thermo-Mechanical Cycles on the Physico-Chemical Properties of Poly(Lactic Acid). Polym. Degrad. Stab. 2008, 93, 321–328. [Google Scholar] [CrossRef]

- le Duigou, A.; Pillin, I.; Bourmaud, A.; Davies, P.; Baley, C. Effect of Recycling on Mechanical Behaviour of Biocompostable Flax/Poly(l-Lactide) Composites. Compos. Part. A Appl. Sci. Manuf. 2008, 39, 1471–1478. [Google Scholar] [CrossRef]

- Lopez, J.P.; Girones, J.; Mendez, J.A.; Puig, J.; Pelach, M.A. Recycling Ability of Biodegradable Matrices and Their Cellulose-Reinforced Composites in a Plastic Recycling Stream. J. Polym. Env. 2012, 20, 96–103. [Google Scholar] [CrossRef]

- Zenkiewicz, M.; Richert, J.; Rytlewski, P.; Moraczewski, K.; Stepczyńska, M.; Karasiewicz, T. Characterisation of Multi-Extruded Poly(Lactic Acid). Polym. Test. 2009, 28, 412–418. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Karlsson, S.; Ribes-Greus, A. Material Valorisation of Amorphous Polylactide. Influence of Thermo-Mechanical Degradation on the Morphology, Segmental Dynamics, Thermal and Mechanical Performance. Polym. Degrad. Stab. 2012, 97, 670–678. [Google Scholar] [CrossRef]

- Hamad, K.; Kaseem, M.; Deri, F. Effect of Recycling on Rheological and Mechanical Properties of Poly(Lactic Acid)/Polystyrene Polymer Blend. J. Mater. Sci. 2011, 46, 3013–3019. [Google Scholar] [CrossRef]

- Stephens, B.; Azimi, P.; el Orch, Z.; Ramos, T. Ultrafine Particle Emissions from Desktop 3D Printers. Atmos. Env. 2013, 79, 334–339. [Google Scholar] [CrossRef]

- Kim, Y.; Yoon, C.; Ham, S.; Park, J.; Kim, S.; Kwon, O.; Tsai, P.J. Emissions of Nanoparticles and Gaseous Material from 3D Printer Operation. Env. Sci. Technol. 2015, 49, 12044–12053. [Google Scholar] [CrossRef] [PubMed]

- Steinle, P. Characterization of Emissions from a Desktop 3D Printer and Indoor Air Measurements in Office Settings. J. Occup. Env. Hyg. 2016, 13, 121–132. [Google Scholar] [CrossRef]

- Azimi, P.; Zhao, D.; Pouzet, C.; Crain, N.E.; Stephens, B. Emissions of Ultrafine Particles and Volatile Organic Compounds from Commercially Available Desktop Three-Dimensional Printers with Multiple Filaments. Env. Sci. Technol. 2016, 50, 1260–1268. [Google Scholar] [CrossRef]

- Giani, N.; Mazzocchetti, L.; Benelli, T.; Picchioni, F.; Giorgini, L. Towards Sustainability in 3D Printing of Thermoplastic Composites: Evaluation of Recycled Carbon Fibers as Reinforcing Agent for FDM Filament Production and 3D Printing. Compos. Part. A Appl. Sci. Manuf. 2022, 159, 107002. [Google Scholar] [CrossRef]

- Al Zahmi, S.; Alhammadi, S.; Elhassan, A.; Ahmed, W. Carbon Fiber/PLA Recycled Composite. Polymers 2022, 14, 2194. [Google Scholar] [CrossRef]

- Omar, N.W.Y.; Shuaib, N.A.; Hadi, M.H.J.A.; Azmi, A.I.; Misbah, M.N. Mechanical and Physical Properties of Recycled-Carbon-Fiber-Reinforced Polylactide Fused Deposition Modelling Filament. Materials 2022, 15, 190. [Google Scholar] [CrossRef]

- Li, H.; Zhao, W.; Wu, X.; Tang, H.; Li, Q.; Tan, J.; Wang, G. 3D Printing and Solvent Dissolution Recycling of Polylactide-Lunar Regolith Composites by Material Extrusion Approach. Polymer 2020, 12, 1724. [Google Scholar] [CrossRef] [PubMed]

- Plavec, R.; Horváth, V.; Hlaváčiková, S.; Omaníková, L.; Repiská, M.; Medlenová, E.; Feranc, J.; Kruželák, J.; Přikryl, R.; Figalla, S.; et al. Influence of Multiple Thermomechanical Processing of 3D Filaments Based on Polylactic Acid and Polyhydroxybutyrate on Their Rheological and Utility Properties. Polymer 2022, 14, 1947. [Google Scholar] [CrossRef]

- Razali, M.S.; Khimeche, K.; Melouki, R.; Boudjellal, A.; Vroman, I.; Alix, S.; Ramdani, N. Preparation and Properties Enhancement of Poly(Lactic Acid)/Calcined-Seashell Biocomposites for 3D Printing Applications. J. Appl. Polym. Sci. 2022, 139, 51591. [Google Scholar] [CrossRef]

- Morsidi, M.; Mativenga, P.T.; Fahad, M. Fused Deposition Modelling Filament with Recyclate Fibre Reinforcement. Procedia CIRP 2020, 85, 353–358. [Google Scholar] [CrossRef]

- Marciniak, D.; Czyżewski, P.; Sykutera, D.; Bieliński, M. Recycling of ABS Operating Elements Obtained from Industry 3D Printing Machines. Polim. Polym. 2021, 64, 803–810. [Google Scholar] [CrossRef]

- Turku, I.; Kasala, S.; Kärki, T. Characterization of Polystyrene Wastes as Potential Extruded Feedstock Filament for 3D Printing. Recycling 2018, 3, 57. [Google Scholar] [CrossRef]

- Kumar, V.; Singh, R.; Ahuja, I.P.S. Effect of Extrusion Parameters on Primary Recycled ABS: Mechanical, Rheological, Morphological and Thermal Properties. Mater. Res. Express 2020, 7, 015208. [Google Scholar] [CrossRef]

- Mohammed, M.I.; Wilson, D.; Gomez-Kervin, E.; Tang, B.; Wang, J. Investigation of Closed-Loop Manufacturing with Acrylonitrile Butadiene Styrene over Multiple Generations Using Additive Manufacturing. ACS Sustain. Chem. Eng. 2019, 7, 13955–13969. [Google Scholar] [CrossRef]

- Di, L.; Yang, Y. Towards Closed-Loop Material Flow in Additive Manufacturing: Recyclability Analysis of Thermoplastic Waste. J. Clean. Prod. 2022, 362, 132427. [Google Scholar] [CrossRef]

- Chawla, K.; Singh, R.; Singh, J. On Recyclability of Thermoplastic ABS Polymer as Fused Filament for FDM Technique of Additive Manufacturing. World J. Eng. 2022, 19, 352–360. [Google Scholar] [CrossRef]

- Kumar, V.; Singh, R.; Ahuja, I.P.S. On Correlation of Rheological, Thermal, Mechanical and Morphological Properties of Chemical Assisted Mechanically Blended ABS-Graphene Composite as Tertiary Recycling for 3D Printing Applications. Adv. Mater. Process. Technol. 2021, 8, 2476–2495. [Google Scholar] [CrossRef]

- Alduais, A.; Kazanç, F.; Bayram, G.; Özerinç, S. ABS-Fly Ash Composite Filaments for Fused Deposition Modeling. In Recent Advances in Manufacturing Processes and Systems; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2022. [Google Scholar]

- Borkar, A.; Hendlmeier, A.; Simon, Z.; Randall, J.D.; Stojcevski, F.; Henderson, L.C. A Comparison of Mechanical Properties of Recycled High-Density Polyethylene/Waste Carbon Fiber via Injection Molding and 3D Printing. Polym. Compos. 2022, 43, 2408–2418. [Google Scholar] [CrossRef]

- Bremer, M.; Janoschek, L.; Kaschta, D.; Schneider, N.; Wahl, M. Influence of Plastic Recycling—A Feasibility Study for Additive Manufacturing Using Glycol Modified Polyethylene Terephthalate (PETG). SN Appl. Sci. 2022, 4, 156. [Google Scholar] [CrossRef]

- Bergonzi, L.; Vettori, M. Mechanical Properties Comparison between New and Recycled Polyethylene Terephthalate Glycol Obtained from Fused Deposition Modelling Waste. Mater. Des. Process. Commun. 2021, 3, e250. [Google Scholar] [CrossRef]

- Zander, N.E. Recycled Polymer Feedstocks for Material Extrusion Additive Manufacturing. In ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2019; Volume 1315. [Google Scholar]

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled Polypropylene Blends as Novel 3D Printing Materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Zander, N.E.; Boelter, Z.R. Rubber Toughened Recycled Polyethylene Terephthalate for Material Extrusion Additive Manufacturing. Polym. Int. 2021, 70, 742–748. [Google Scholar] [CrossRef]

- Zander, N.E.; Gillan, M.; Lambeth, R.H. Recycled Polyethylene Terephthalate as a New FFF Feedstock Material. Addit. Manuf. 2018, 21, 174–182. [Google Scholar] [CrossRef]

- Tylman, I.; Dzierzek, K. Filament for a 3D Printer from Pet Bottles-Simple Machine. Int. J. Mech. Eng. Robot. Res. 2020, 9, 1386–1392. [Google Scholar] [CrossRef]

- Ronkay, F.; Molnar, B.; Gere, D.; Czigany, T. Plastic Waste from Marine Environment: Demonstration of Possible Routes for Recycling by Different Manufacturing Technologies. Waste Manag. 2021, 119, 101–110. [Google Scholar] [CrossRef] [PubMed]

- Oussai, A.; Bártfai, Z.; Kátai, L. Development of 3d Printing Raw Materials from Plastic Waste. A Case Study on Recycled Polyethylene Terephthalate. Appl. Sci. 2021, 11, 7338. [Google Scholar] [CrossRef]

- Idrees, M.; Jeelani, S.; Rangari, V. Three-Dimensional-Printed Sustainable Biochar-Recycled PET Composites. ACS Sustain. Chem. Eng. 2018, 6, 13940–13948. [Google Scholar] [CrossRef]

- Ferrari, F.; Corcione, C.E.; Montagna, F.; Maffezzoli, A. 3D Printing of Polymer Waste for Improving People’s Awareness about Marine Litter. Polymers 2020, 12, 1738. [Google Scholar] [CrossRef] [PubMed]

- Little, H.A.; Tanikella, N.G.; Reich, M.J.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks. Materials 2020, 13, 4273. [Google Scholar] [CrossRef]

- Patra, N.R.; Negi, Y.S. Thermal, Structural, and Rheological Modifications in Recycled Polyethylene Terephthalate for a Sustainable Alternative Source for Additive Manufacturing. Polym. Eng. Sci. 2022, 62, 2486–2497. [Google Scholar] [CrossRef]

- Pricop, B.; Sava, Ș.D.; Lohan, N.M.; Bujoreanu, L.G. DMA Investigation of the Factors Influencing the Glass Transition in 3D Printed Specimens of Shape Memory Recycled PET. Polymers 2022, 14, 2248. [Google Scholar] [CrossRef] [PubMed]

- Development of 3D Printing Filament Material Using Recycled Polyethylene Terephthalate Reinforced with Sugar Palm Fiber | SpringerLink. Available online: https://link.springer.com/chapter/10.1007/978-981-19-3179-6_4 (accessed on 20 October 2022).

- Weinmann, S.; Bonten, C. Recycling of Pa12 Powder for Selective Laser Sintering. In AIP Conference Proceedings; AIP Publishing: College Park, MD, USA, 2020; Volume 2289. [Google Scholar]

- Kumar, S.; Czekanski, A. Development of Filaments Using Selective Laser Sintering Waste Powder. J. Clean. Prod. 2017, 165, 1188–1196. [Google Scholar] [CrossRef]

- Al-Mazrouei, N.; Al-Marzouqi, A.H.; Ahmed, W. Characterization and Sustainability Potential of Recycling 3D-Printed Nylon Composite Wastes. Sustainability 2022, 14, 10458. [Google Scholar] [CrossRef]

- Pickering, K.L.; Stoof, D.B. Sustainable Composite Fused Deposition Modelling Filament Using Post-Consumer Recycled Polypropylene. J. Compos. Sci. 2017, 1, 17. [Google Scholar] [CrossRef]

- Spoerk, M.; Arbeiter, F.; Raguž, I.; Holzer, C.; Gonzalez-Gutierrez, J. Mechanical Recyclability of Polypropylene Composites Produced by Material Extrusion-Based Additive Manufacturing. Polymers 2019, 11, 1318. [Google Scholar] [CrossRef] [PubMed]

- Prihandana, D.B.; Kuswanto, D. Analysis of Angle Comparison for the “Kawung” Pattern Module Development Based on Additive Manufacturing Method Using 3D Filament from Recycled Plastic Waste Material. In IOP Conference Series: Earth and Environmental Science; IOP Publishing Ltd.: Bristol, UK, 2021; Volume 649. [Google Scholar]

- Dobránsky, J.; Pollák, M.; Běhálek, L.; Svetlík, J. Implementation of a Recycled Polypropylene Homopolymer Material for Use in Additive Manufacturing. Sustainability 2021, 13, 4990. [Google Scholar] [CrossRef]

- Kristiawan, R.B.; Rusdyanto, B.; Imaduddin, F.; Ariawan, D. Glass Powder Additive on Recycled Polypropylene Filaments: A Sustainable Material in 3d Printing. Polymers 2022, 14, 5. [Google Scholar] [CrossRef]

- Bartolomei, S.S.; da Silva, F.L.F.; de Moura, E.A.B.; Wiebeck, H. Recycling Expanded Polystyrene with a Biodegradable Solvent to Manufacture 3D Printed Prototypes and Finishing Materials for Construction. J. Polym. Env. 2022, 30, 3701–3717. [Google Scholar] [CrossRef]

- Gaikwad, V.; Ghose, A.; Cholake, S.; Rawal, A.; Iwato, M.; Sahajwalla, V. Transformation of E-Waste Plastics into Sustainable Filaments for 3D Printing. ACS Sustain. Chem. Eng. 2018, 6, 14432–14440. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef]

- Meyer, T.K.; Tanikella, N.G.; Reich, M.J.; Pearce, J.M. Potential of Distributed Recycling from Hybrid Manufacturing of 3-D Printing and Injection Molding of Stamp Sand and Acrylonitrile Styrene Acrylate Waste Composite. Sustain. Mater. Technol. 2020, 25, e00169. [Google Scholar] [CrossRef]

- Calvo-Correas, T.; Benitez, M.; Larraza, I.; Ugarte, L.; Peña-Rodríguez, C.; Eceiza, A. Advanced and Traditional Processing of Thermoplastic Polyurethane Waste. Polym. Degrad. Stab. 2022, 198, 109880. [Google Scholar] [CrossRef]

- Immonen, K.; Metsä-Kortelainen, S.; Nurmio, J.; Tribot, A.; Turpeinen, T.; Mikkelson, A.; Kalpio, T.; Kaukoniemi, O.V.; Kangas, H. Recycling of 3D Printable Thermoplastic Cellulose-Composite. Sustainability 2022, 14, 2734. [Google Scholar] [CrossRef]

- Kumar, V.; Singh, R.; Ahuja, I.S. Tertiary Recycling of Plastic Solid Waste for Additive Manufacturing. In Additive Manufacturing for Plastic Recycling: Efforts in Boosting A Circular Economy; CRC Press: Boca Raton, FL, USA, 2022; pp. 93–109. [Google Scholar] [CrossRef]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. Comprehensive Characterization of Polymeric Composites Reinforced with Silica Microparticles Using Leftover Materials of Fused Filament Fabrication 3D Printing. Polymers 2021, 13, 2423. [Google Scholar] [CrossRef]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. 3d Printing Pla Waste to Produce Ceramic Based Particulate Reinforced Composite Using Abundant Silica-Sand: Mechanical Properties Characterization. Polymers 2020, 12, 2579. [Google Scholar] [CrossRef]

- Siraj, S.; Al-Marzouqi, A.; Ahmed, W. Processing Biodegradable Fused Filament Fabrication Waste with Micro-Silica Particles. Key Eng. Mater. 2022, 907, 156–162. [Google Scholar] [CrossRef]

- Pinho, A.C.; Amaro, A.M.; Piedade, A.P. 3D Printing Goes Greener: Study of the Properties of Post-Consumer Recycled Polymers for the Manufacturing of Engineering Components. Waste Manag. 2020, 118, 426–434. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; de Carolis, V.; Montagna, F.; Esposito Corcione, C. Sustainable Polymer Composites Manufacturing through 3D Printing Technologies by Using Recycled Polymer and Filler. Polymers 2022, 14, 3756. [Google Scholar] [CrossRef]

- Sauerwein, M.; Zlopasa, J.; Doubrovski, Z.; Bakker, C.; Balkenende, R. Reprintable Paste-Based Materials for Additive Manufacturing in a Circular Economy. Sustainability 2020, 12, 8032. [Google Scholar] [CrossRef]

- Skibicki, S.; Pułtorak, M.; Kaszyńska, M.; Hoffmann, M.; Ekiert, E.; Sibera, D. The Effect of Using Recycled PET Aggregates on Mechanical and Durability Properties of 3D Printed Mortar. Constr. Build. Mater. 2022, 335, 127443. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Mechanical and Thermal Study of 3D Printing Composite Filaments from Wind Turbine Waste. Polym. Compos. 2021, 42, 2305–2316. [Google Scholar] [CrossRef]

- Tahir, M.; Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Experimental and Analytical Investigation of 3D Printed Specimens Reinforced by Different Forms of Recyclates from Wind Turbine Waste. Polym. Compos. 2021, 42, 4533–4548. [Google Scholar] [CrossRef]

- Domingues, J.; Marques, T.; Mateus, A.; Carreira, P.; Malça, C. An Additive Manufacturing Solution to Produce Big Green Parts from Tires and Recycled Plastics. Procedia Manuf. 2017, 12, 242–248. [Google Scholar] [CrossRef]

- Kuo, C.C.; Chen, J.Y.; Chang, Y.H. Optimization of Process Parameters for Fabricating Polylactic Acid Filaments Using Design of Experiments Approach. Polymers 2021, 13, 1222. [Google Scholar] [CrossRef]

- Cisneros-López, E.O.; Pal, A.K.; Rodriguez, A.U.; Wu, F.; Misra, M.; Mielewski, D.F.; Kiziltas, A.; Mohanty, A.K. Recycled Poly(Lactic Acid)–Based 3D Printed Sustainable Biocomposites: A Comparative Study with Injection Molding. Mater. Today Sustain. 2020, 7–8, 100027. [Google Scholar] [CrossRef]

- Alves, B. Apparatus for Treatment of Residual Thermoplastic Powder. U.S. Patent 11,046,004, 29 June 2021. [Google Scholar]

- He, D.; Kim, H.C.; de Kleine, R.; Soo, V.K.; Kiziltas, A.; Compston, P.; Doolan, M. Life Cycle Energy and Greenhouse Gas Emissions Implications of Polyamide 12 Recycling from Selective Laser Sintering for an Injection-Molded Automotive Component. J. Ind. Ecol. 2022, 26, 1378–1388. [Google Scholar] [CrossRef]

- Woern, A.L.; Pearce, J.M. 3-D Printable Polymer Pelletizer Chopper for Fused Granular Fabrication-Based Additive Manufacturing. Inventions 2018, 3, 78. [Google Scholar] [CrossRef]

- Woern, A.L.; Byard, D.J.; Oakley, R.B.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Fused Particle Fabrication 3-D Printing: Recycled Materials’ Optimization and Mechanical Properties. Materials 2018, 11, 1413. [Google Scholar] [CrossRef] [PubMed]

- Global Primary Plastic Production by Polymer, 1990 to 2019. Available online: https://ourworldindata.org/grapher/plastic-production-polymer?time=earliest.2019 (accessed on 5 August 2024).

- Yang, F.; Jiang, T.; Lalier, G.; Bartolone, J.; Chen, X. A Process Control and Interlayer Heating Approach to Reuse Polyamide 12 Powders and Create Parts with Improved Mechanical Properties in Selective Laser Sintering. J. Manuf. Process 2020, 57, 828–846. [Google Scholar] [CrossRef]

- Clark, N.; Lacan, F.; Porch, A. Microwave Measurements of Nylon-12 Powder Ageing for Additive Manufacturing. In Proceedings of the Solid Freeform Fabrication 2017: The 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Sillani, F.; Kleijnen, R.G.; Vetterli, M.; Schmid, M.; Wegener, K. Selective Laser Sintering and Multi Jet Fusion: Process-Induced Modification of the Raw Materials and Analyses of Parts Performance. Addit. Manuf. 2019, 27, 32–41. [Google Scholar] [CrossRef]

- HP® | Competitive Accelerated Weathering Study between HP 3D HR PA 12 W and SLS Materials. Available online: https://reinvent.hp.com/us-en-3dprint-5420w-weathering-whitepaper?jumpid=af_daa2313d92 (accessed on 5 August 2024).

- Hesse, N.; Peukert, W.; Schmidt, J. Enhancement of Polyamide Laser Sinter Powder Reusability by Acid Catalyzed Hydrolysis. Procedia CIRP 2020, 94, 105–109. [Google Scholar] [CrossRef]

| PA-12 Powder | Peak Melting Point (°C) | Melting Enthalpy (J/g) | Peak Crystallisation Point (°C) | Crystallisation Enthalpy (J/g) | Crystallinity Xc (%) | Sintering Window * (°C) |

|---|---|---|---|---|---|---|

| New | 182.37 | 96.62 | 141.45 | −45.03 | 46.16% | 29.96 (147.15–177.11) |

| 1 time recycled | 182.53 | 95.19 | 141.94 | −44.52 | 45.48% | 29.92 (147.55–177.47) |

| 2 times recycled | 182.53 | 94.02 | 142.46 | −44.71 | 44.92% | 30.31 (147.54–177.85) |

| 3 times recycled | 182.87 | 84.07 | 142.78 | −42.88 | 40.17% | 31.00 (147.33–178.33) |

| 4 times recycled | 182.68 | 80.71 | 143.24 | −42.13 | 38.56% | 30.95 (146.72–177.67) |

| Material Recycled | Method | References |

|---|---|---|

| PLA–Poly(lactic acid) | FDM | [24,40,41,42,43,44,45,46,47,48,49,50,51,52,53] |

| PLA–Poly(lactic acid) PLA–hydroxyapatite (Hap)-chitosan (CS) composite | FDM | [53] |

| PLLA L900 | FDM | [54,55,56] |

| PLA 2002D | FDM | [57,58] |

| PLA (ESUN A-1001) | FDM | [59] |

| PLA/ABS | FDM | [60,61,62] |

| PLA/ABS/HIPS/PCTPE/Nylon/PC | FDM | [63] |

| PLA–Poly(lactic acid) + recycled Carbon Fibres (rCFs) | FDM | [64,65,66] |

| PLA/CLRS-1 c–polylactide/lunar regolith simulant | FDM | [67] |

| PLA–Poly(lactic acid) and PHB–Polyhydroxybutyrate | FDM | [68] |

| PLA–Poly(lactic acid) biocomposites filled with CSH–calcined seashell particles | FDM | [69] |

| ABS–Acrylonitrile–butadienestyrene/with recycled fiber | FDM | [70,71] |

| PS–polystyrene, ABS–Acrylonitrile–butadienestyrene and PVC polyvinylchloride | FDM | [72] |

| ABS–Acrylonitrile–butadienestyrene | FDM | [73,74,75,76] |

| ABS–Graphene composite | FDM | [77] |

| ABS–Acrylonitrile–butadienestyrene + FA fly ash (waste of coal power plants) | FDM | [78] |

| HDPE–high-density polyethylene | FDM | [79] |

| PETG–glycol modified polyethylene terephthalate | FDM | [80] |

| PETG, PET–Polyethylene Terephthalate | FDM | [81] |

| PET–Polyethylene Terephthalate, PP–Polypropylene, PS–polystyrene | FDM | [82] |

| PETG, PET–Polyethylene Terephthalate | FDM | [83] |

| PETG, PET–Polyethylene Terephthalate, SEBS–styrene ethylene-butadiene-styrene | FDM | [84] |

| PETG, PET–Polyethylene Terephthalate | FDM | [85,86,87,88,89,90,91,92,93] |

| PET–Polyethylene Terephthalate + SPF sugar palm fibre | FDM | [94] |

| PA–Polyamide 12 | FDM, SLS | [26,28,29,34,35,37,44,45,48,95,96] |

| PA–Polyamide composite (Filaments made of carbon fibre with nylon and glass fibre with nylon) | FDM | [97] |

| PP–Polypropylene | FDM | [83,98,99,100,101] |

| PP–Polypropylene + glass powder | FDM | [102] |

| PS–Polystyrene | FDM | [103] |

| PS–Polystyrene, PVC–Polyvinyl chloride | FDM | [72] |

| PC–Polycarbonate | FDM | [104,105] |

| SAG–Styrene-acrylonitrile-glycidyl methacrylate | FDM | [70] |

| ASA–Acrylonitrile styrene acrylate composites | FDM | [106] |

| TPU–Thermoplastic polyurethane | FDM | [107] |

| CAP–Cellulose Acetate Propionate | FDM | [108] |

| GNP–Graphene nanoparticles and Mn-doped ZnO powders + PVDF–recycled polyvinylidene fluoride pallets | FDM | [109] |

| Silica + PP/PVA/PLA/PA Polypropylene, polyvinyl alcohol, polylactic acid, and nylon | FDM | [110] |

| Silica + PLA Poly(lactic acid) | FDM | [111,112] |

| (PLA composites) Food packages and car dashboards | Composites | [113] |

| (PLA composites)recycled polylactic acid (PLA) and waste ceramic material from artisanal production | Composites | [114] |

| (PLA composites) Bio-based composite material consisting of ground mussel shells and alginate | Composites | [115] |

| Mortar with PET Polyethylene Terephthalate granules | Composites | [116] |

| Composites–Wind turbine waste | Composites | [117,118] |

| Mixture comprising 60% granulate tyre waste and 40% of polypropylene (PP) | Composites | [119] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Sousa Alves, B.A.; Kontziampasis, D.; Soliman, A.-H. The Quest for the Holy Grail Of 3D Printing: A Critical Review of Recycling in Polymer Powder Bed Fusion Additive Manufacturing. Polymers 2024, 16, 2306. https://doi.org/10.3390/polym16162306

de Sousa Alves BA, Kontziampasis D, Soliman A-H. The Quest for the Holy Grail Of 3D Printing: A Critical Review of Recycling in Polymer Powder Bed Fusion Additive Manufacturing. Polymers. 2024; 16(16):2306. https://doi.org/10.3390/polym16162306

Chicago/Turabian Stylede Sousa Alves, Bruno Alexandre, Dimitrios Kontziampasis, and Abdel-Hamid Soliman. 2024. "The Quest for the Holy Grail Of 3D Printing: A Critical Review of Recycling in Polymer Powder Bed Fusion Additive Manufacturing" Polymers 16, no. 16: 2306. https://doi.org/10.3390/polym16162306

APA Stylede Sousa Alves, B. A., Kontziampasis, D., & Soliman, A.-H. (2024). The Quest for the Holy Grail Of 3D Printing: A Critical Review of Recycling in Polymer Powder Bed Fusion Additive Manufacturing. Polymers, 16(16), 2306. https://doi.org/10.3390/polym16162306