Influence of NR/MWCNT Blending on Rotor Metal Friction and Wear during Mixing Process

Abstract

1. Introduction

2. Experiment

2.1. Formulation and Mixing Process

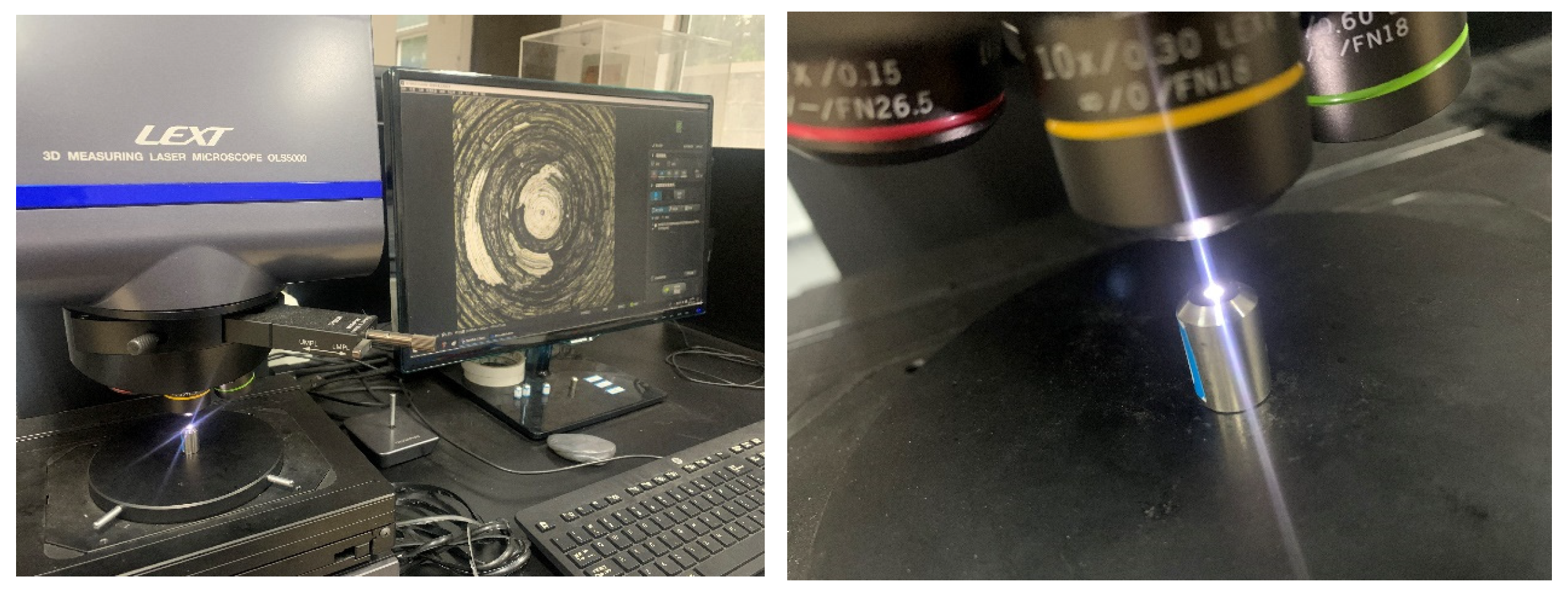

2.2. Testing Methods

3. Mechanism of Silanization Reaction

4. Experimental Results

4.1. Filler Dispersion Analysis

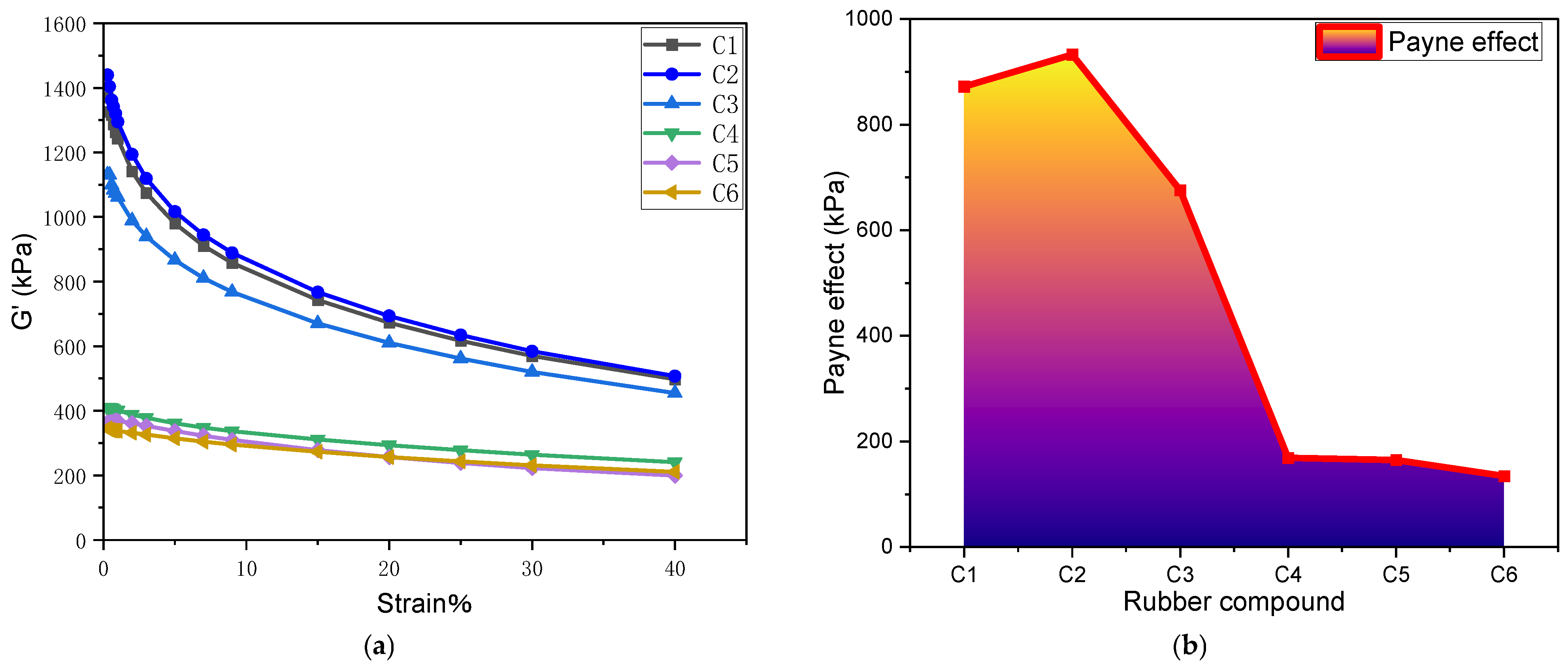

4.1.1. Payne Effect

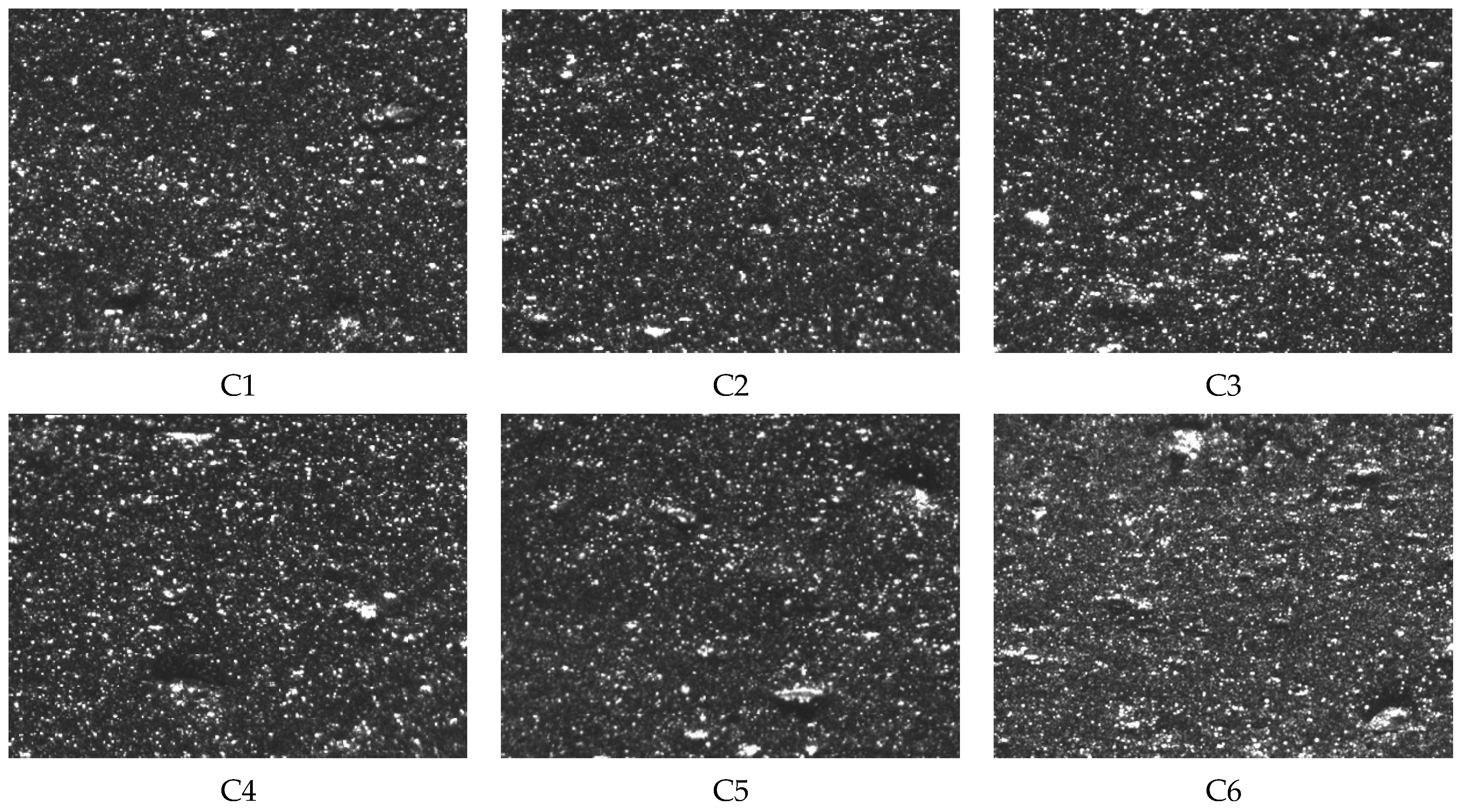

4.1.2. Dispersion Comparison

4.2. Wear Analysis

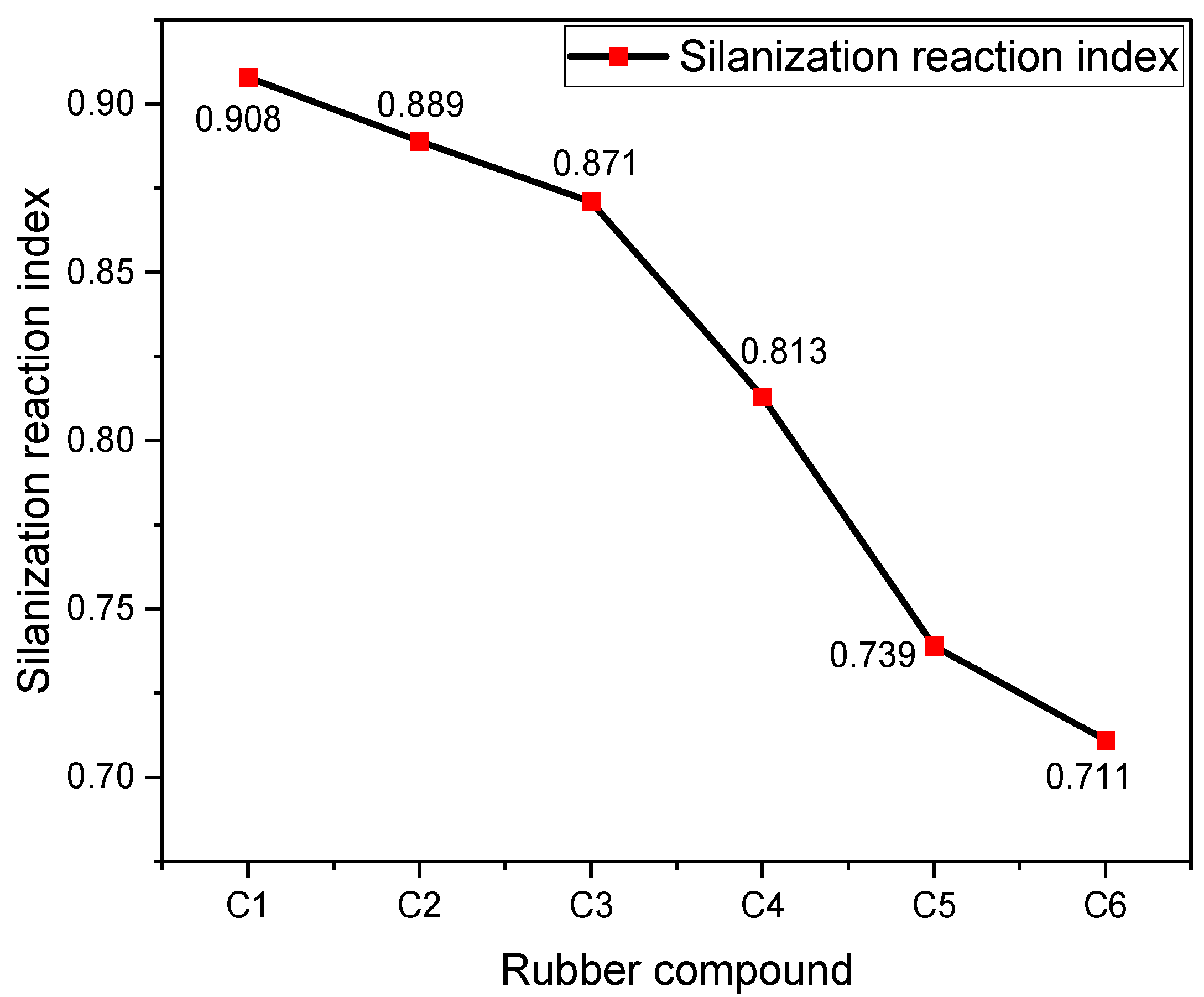

4.2.1. Silanization Reaction Index

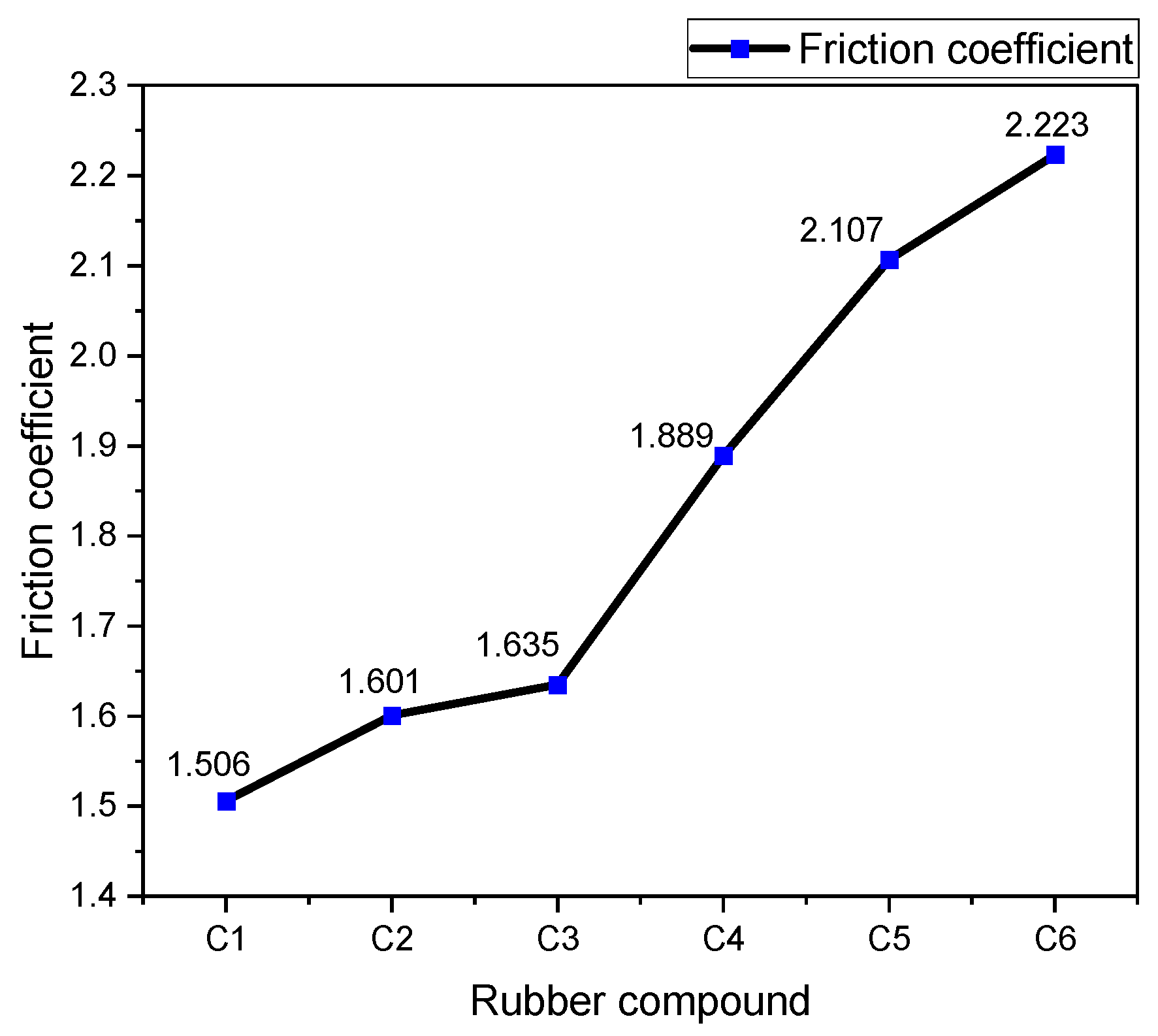

4.2.2. Coefficient of Friction

4.2.3. Morphology of Metal Surface before and after Friction

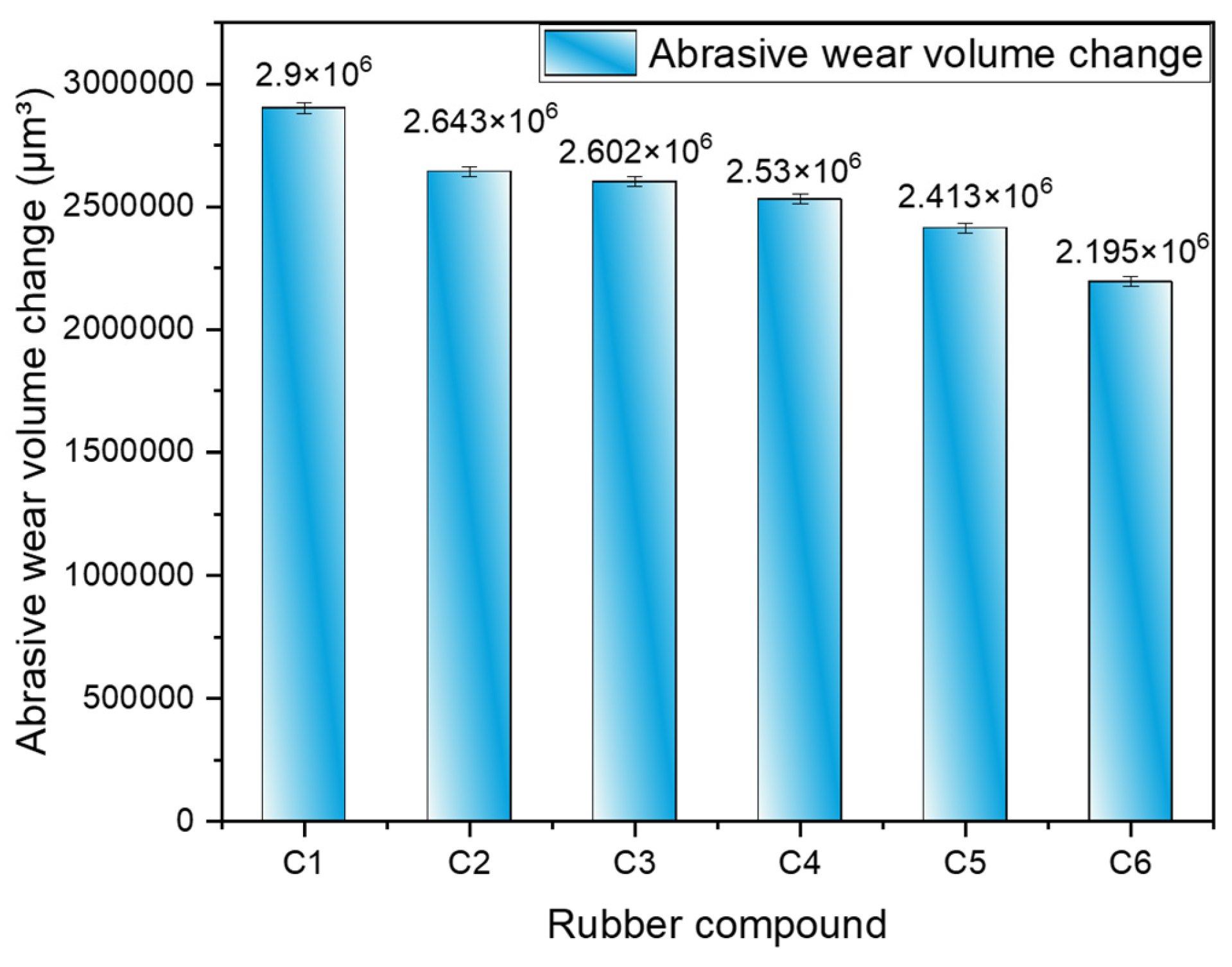

4.2.4. Metal Wear Volume

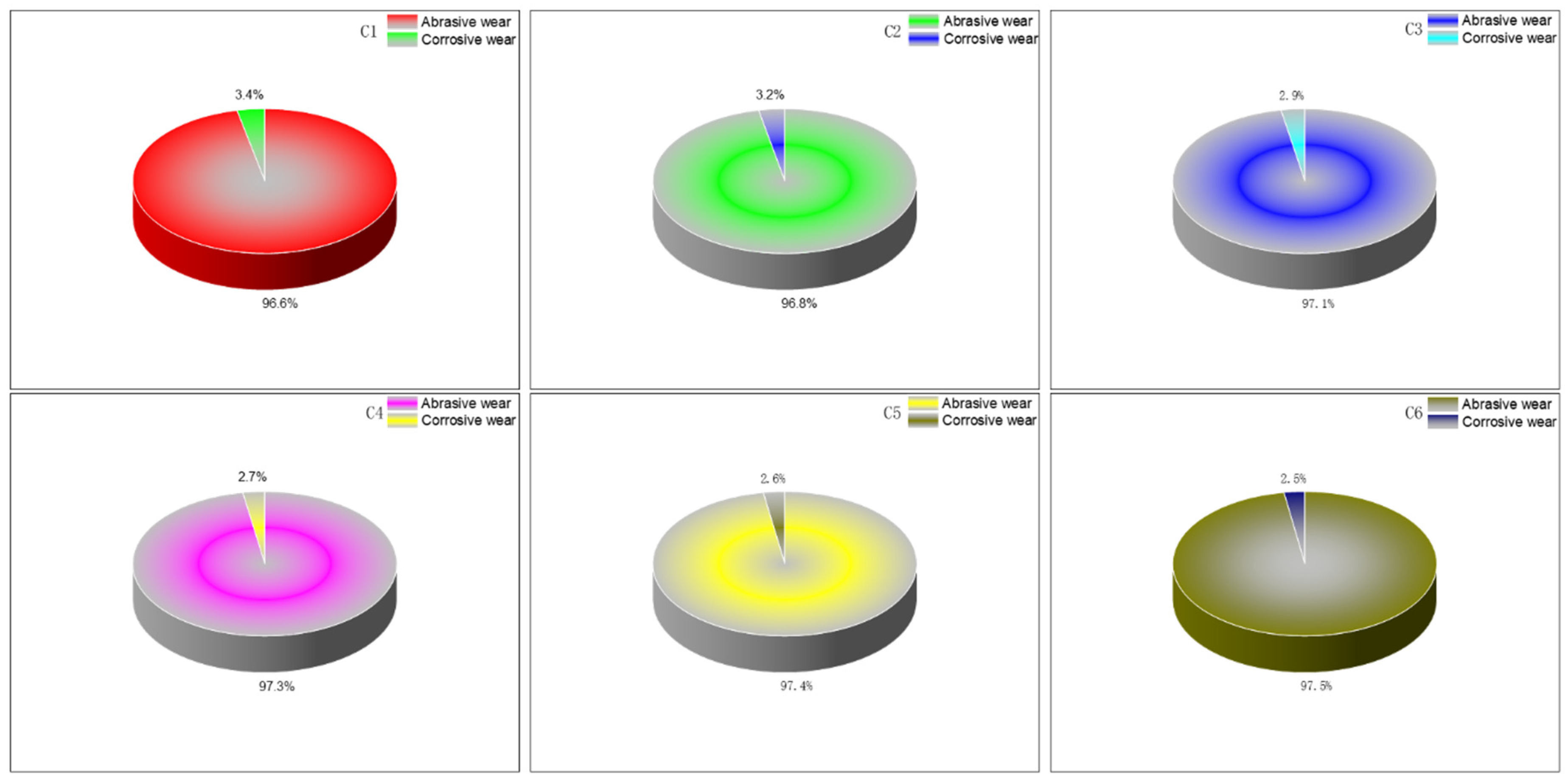

4.2.5. Proportion of Corrosive Wear and Abrasive Wear

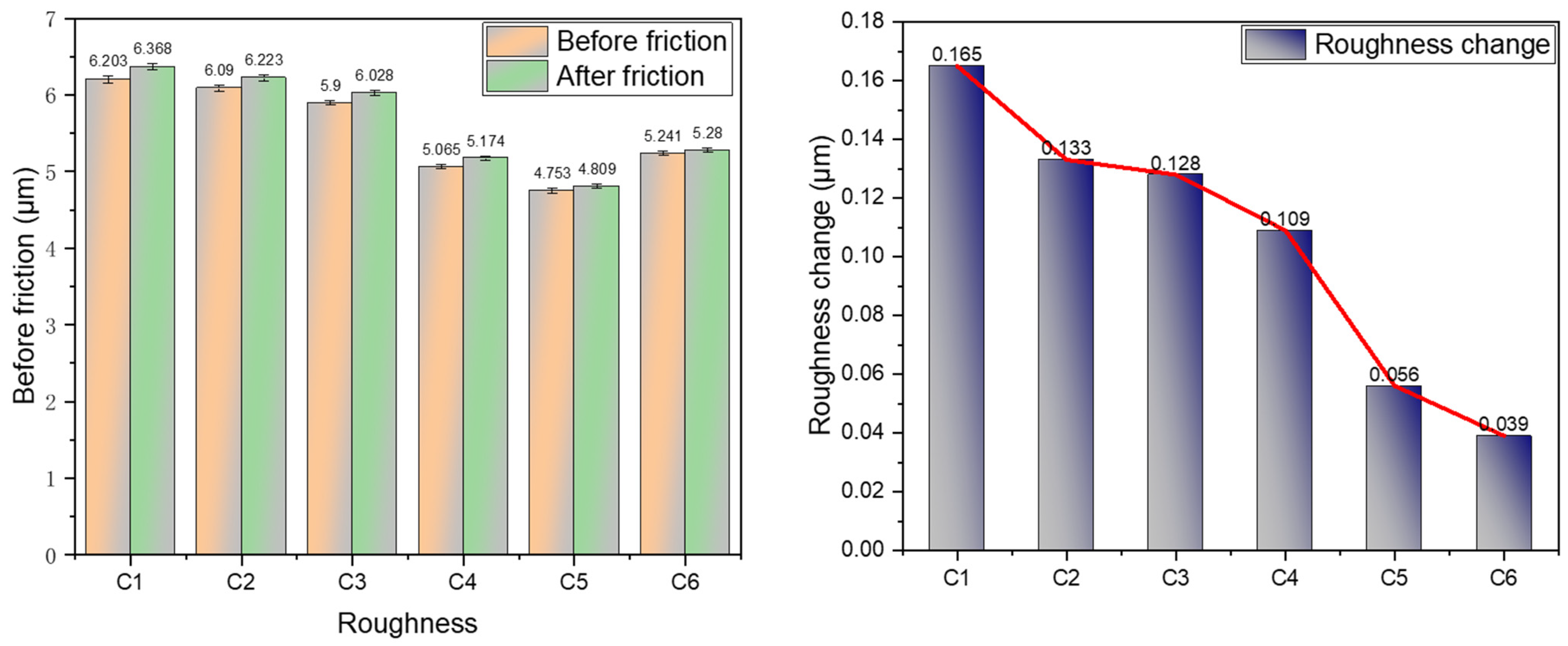

4.2.6. Roughness Changes before and after Friction

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Cataldo, F.; Ursini, O.; Angelini, G. MWCNTs Elastomer Nanocomposite, Part 1: The Addition of MWCNTs to a Natural Rubber-based Carbon Black-filled Rubber Compound. Fuller. Nanotub. Carbon Nanostructures 2009, 17, 38–54. [Google Scholar] [CrossRef]

- Eghbalinia, S.; Katbab, A.; Nazockdast, H.; Katbab, P. Highly compressible piezoresistive strain sensor with a semi-IPN structure based on PU sponge/RTV silicone rubber/MWCNTs. J. Polym. Res. 2022, 29, 471. [Google Scholar] [CrossRef]

- Han, D.S.; Liu, C.X.; Wang, L.; Wang, C.S. Investigation of NR, BR, and SBR composite material properties and internal mixer Wear under various lubricating oil media during mixing process. Surf. Coat. Technol. 2024, 480, 130611. [Google Scholar] [CrossRef]

- Han, D.S.; Wang, L.; Zhang, S.F.; Zhang, Q.Z.; Wang, C.S.; Li, W. The impact of synergistic action of methacrylic acid/zinc oxide/carbon nanotubes on metal Friction and wear. Wear 2024, 546–547, 205342. [Google Scholar] [CrossRef]

- Gu, H.S.; Itoh, Y. Ageing Behaviour of Natural Rubber and High Damping Rubber Materials Used in Bridge Rubber Bearings. Adv. Struct. Eng. 2010, 13, 1105–1113. [Google Scholar] [CrossRef]

- Hasan, A.; Rochmadi; Sulistyo, H.; Honggokusumo, S. Effect of Rubber Mixing Sequence Variation Upon Bound Rubber Formation and Its Physical Properties. Asian J. Chem. 2013, 25, 5203–5207. [Google Scholar] [CrossRef]

- Hayeemasae, N.; Salleh, S.Z.; Ismail, H. Sustainable Use of Chloroprene Rubber Waste as Blend Component with Natural Rubber, Epoxidized Natural Rubber and Styrene Butadiene Rubber. J. Polym. Environ. 2019, 27, 2119–2130. [Google Scholar] [CrossRef]

- Kaliyathan, A.V.; Varghese, K.M.; Nair, A.S.; Thomas, S. Rubber–rubber blends: A critical review. Prog. Rubber Plast. Recycl. Technol. 2020, 36, 196–242. [Google Scholar] [CrossRef]

- Tang, C.; Yang, M.; Fang, Y.; Luo, Y.; Gao, S.; Xiao, X.; An, Z.; Zhou, B.; Zhang, B.; Tan, X.; et al. The rubber tree genome reveals new insights into rubber production and species adaptation. Nat. Plants 2016, 2, 16073. [Google Scholar] [CrossRef]

- Perera, K.; Edirisinghe, D.G.; Karunanayake, L. Characterization of blends of virgin nitrile rubber and compounded nitrile rubber latex waste reclaimed with urea. Part 1: Cure characteristics. Prog. Rubber Plast. Recycl. Technol. 2021, 37, 115–130. [Google Scholar] [CrossRef]

- Sarkar, P.; Bhowmick, A.K. Sustainable rubbers and rubber additives. J. Appl. Polym. Sci. 2018, 135, 45701. [Google Scholar] [CrossRef]

- Gao, J.S.; He, Y.; Gong, X.B. Effect of electric field induced alignment and dispersion of functionalized carbon nanotubes on properties of natural rubber. Results Phys. 2018, 9, 493–499. [Google Scholar] [CrossRef]

- Felhös, D.; Karger-Kocsis, J. Friction and Wear of Rubber Nanocomposites Containing Layered Silicates and Carbon Nanotubes; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Kueseng, P.; Sae-oui, P.; Sirisinha, C.; Jacob, K.I.; Rattanasom, N. Anisotropic studies of multi-wall carbon nanotube (MWCNT)-filled natural rubber (NR) and nitrile rubber (NBR) blends. Polymer Testing 2013, 32, 1229–1236. [Google Scholar] [CrossRef]

- Foitzik, M.J.; Unrau, H.J.; Gauterin, F.; Dörnhöfer, J.; Koch, T. Investigation of ultra fine particulate matter emission of ruber tires. Wear 2018, 394–395, 87–95. [Google Scholar] [CrossRef]

- Gao, J.; Dong, X.; Tian, Q.; He, Y. Carbon nanotubes reinforced proton exchange membranes in fuel cells: An overview. Int. J. Hydrogen Energy 2022, 48, 3216–3231. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.; Li, J.; Li, F.; Fang, Y. An on-line imaging sensor based on magnetic deposition and flowing dispersion for wear debris feature monitoring. Mech. Syst. Signal Process. 2024, 212, 111321. [Google Scholar] [CrossRef]

- Wu, Q.; Zhou, X.; Pan, X. Cutting tool wear monitoring in milling processes by integrating deep residual convolution network and gated recurrent unit with an attention mechanism. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2022, 237, 1171–1181. [Google Scholar] [CrossRef]

- Hou, F.Y.; Song, Y.H.; Zheng, Q. Payne effect of thermo-oxidatively aged isoprene rubber vulcanizates. Polymer 2020, 195, 122432. [Google Scholar] [CrossRef]

- Narayan, S.P.A.; Palade, L.I. Modeling Payne effect with a framework of multiple natural configurations. Int. J. Eng. Sci. 2020, 157, 103396. [Google Scholar] [CrossRef]

- Song, Y.H.; Xu, Z.J.; Wang, W.J.; Zheng, Q. Payne effect of carbon black filled natural rubber nanocomposites: Influences of extraction, crosslinking, and swelling. J. Rheol. 2021, 65, 807–820. [Google Scholar] [CrossRef]

- Zhong, X.K.; Song, Y.H.; Zheng, Q.; Wang, W.J. Influence of coagents on Payne effect of butadiene rubber vulcanizates. Polymer 2021, 212, 123298. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Wang, Q.T.; Fang, H. Experimental study on the continuous preparation of high-performance thermal conductivity CNTs/EG/SSBR composite based on the shear and elongation flow fields with the assistance of the silanization reaction. Polym. Compos. 2024, 28697. [Google Scholar] [CrossRef]

- Neethirajan, J.; Natarajan, T.S.; Dayalan, S.; Patel, B.; Rajasekar, V.; Kuriakose, J.; Krishnan, S.R.; Naskar, K. Screening of mixing parameters based on their significance on the extent of silanization and energy consumption of silica-filled S-SBR elastomer compounds for fuel-saving tyre application. Polym. Eng. Sci. 2022, 62, 2779–2792. [Google Scholar] [CrossRef]

- Ohser, J.; Lacayo-Pineda, J.; Putman, M.; Rack, A.; Dobrovolskij, D. Estimation of filler macro-dispersion in rubber matrix by radiometric stereo microscopy. J. Microsc. 2019, 274, 32–44. [Google Scholar] [CrossRef]

- ASTM D7723-19; Standard Test Method for Rubber Property—Macro-Dispersion of Fillers in Compounds. ASTM International: West Conshohocken, PA, USA, 2024.

- Harsha, Y.M.; Mohana, K.N.S.; Sunilkumar, M.C.; Hithesh, M.C.; Sreelakshmi, M.; Madhusudhana, A.M. Syntheses of diphenolic resin based anti-corrosion coating material and reinforce its performance through MWCNT-Ag and MWCNT-Ag/ PANI nanofillers. Surf. Coat. Technol. 2024, 485, 130871. [Google Scholar] [CrossRef]

- Drozd, D.; Zhang, H.Y.; Goryacheva, I.; De Saeger, S.; Beloglazova, N.V. Silanization of quantum dots: Challenges and perspectives. Talanta 2019, 205, 120164. [Google Scholar] [CrossRef] [PubMed]

- Lucia, A.; Bacher, M.; van Herwijnen, H.W.G.; Rosenau, T. A Direct Silanization Protocol for Dialdehyde Cellulose. Molecules 2020, 25, 2458. [Google Scholar] [CrossRef]

- Vistas, C.R.; Aguas, A.C.P.; Ferreira, G.N.M. Silanization of glass chips—A factorial approach for optimization. Appl. Surf. Sci. 2013, 286, 314–318. [Google Scholar] [CrossRef]

- Zhang, C.F.; Yu, S.J.; Tang, Z.H.; Guo, B.C. Catalyzed silanization by supporting ceria on silica towards rubber composites with improved mechanical properties. Compos. Commun. 2022, 32, 101168. [Google Scholar] [CrossRef]

| Rubber | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|

| Payne Effect (kPa) | 872.17 | 932.55 | 675.74 | 168.89 | 164.73 | 134.41 |

| Rubber Compound | C1 | C2 | C3 | C4 | C5 | C6 |

|---|---|---|---|---|---|---|

| Dispersion | 7.52 | 7.01 | 6.8 | 6.54 | 5.98 | 5.56 |

| Rubber Compound | Before Friction | After Friction | Volume Change |

|---|---|---|---|

| C1 | 29,840,232.73 | 26,837,912.37 | 3,002,320.358 |

| C2 | 13,426,579.44 | 10,696,922.25 | 2,729,657.189 |

| C3 | 20,724,015.27 | 18,043,812.31 | 2,680,202.955 |

| C4 | 16,598,935.15 | 13,999,310.09 | 2,599,625.051 |

| C5 | 28,768,615.15 | 26,290,460.59 | 2,478,154.554 |

| C6 | 21,440,262.44 | 19,188,570.74 | 2,251,691.703 |

| Rubber Compound | Abrasive Wear Volume Change |

|---|---|

| C1 | 2,900,841.93 |

| C2 | 2,642,581.125 |

| C3 | 2,602,477.069 |

| C4 | 2,529,955.1 |

| C5 | 2,413,474.72 |

| C6 | 2,194,723.903 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, D.; Zhang, Q.; Zhao, W.; Liu, C.; Wang, L. Influence of NR/MWCNT Blending on Rotor Metal Friction and Wear during Mixing Process. Polymers 2024, 16, 2294. https://doi.org/10.3390/polym16162294

Han D, Zhang Q, Zhao W, Liu C, Wang L. Influence of NR/MWCNT Blending on Rotor Metal Friction and Wear during Mixing Process. Polymers. 2024; 16(16):2294. https://doi.org/10.3390/polym16162294

Chicago/Turabian StyleHan, Deshang, Quanzhong Zhang, Weifu Zhao, Changxia Liu, and Lin Wang. 2024. "Influence of NR/MWCNT Blending on Rotor Metal Friction and Wear during Mixing Process" Polymers 16, no. 16: 2294. https://doi.org/10.3390/polym16162294

APA StyleHan, D., Zhang, Q., Zhao, W., Liu, C., & Wang, L. (2024). Influence of NR/MWCNT Blending on Rotor Metal Friction and Wear during Mixing Process. Polymers, 16(16), 2294. https://doi.org/10.3390/polym16162294