Effects of Macro Fibers on Crack Opening Reduction in Fiber Reinforced Concrete Overlays

Abstract

:1. Introduction

2. Fiber Reinforcements for Pavement Structures

2.1. Steel

2.2. Synthetic

2.3. Other Fibers

2.4. Hybrid Fibers

3. Design of FRC Overlays and Crack Opening Width Prediction

3.1. Design Methods Applicable to FRC Overlays

3.2. Residual Strength Ratio

3.3. Crack Opening Width Prediction in FRC Overlays

4. Effect of Fiber Types on Crack Opening Reduction and Comparison of Macro Fibers to Dowel Bars

4.1. Effects of Fiber Types and Volume Contents on Crack Width Reduction in FRC Pavements

4.2. Comparison of Macro Fibers to Dowel Bars

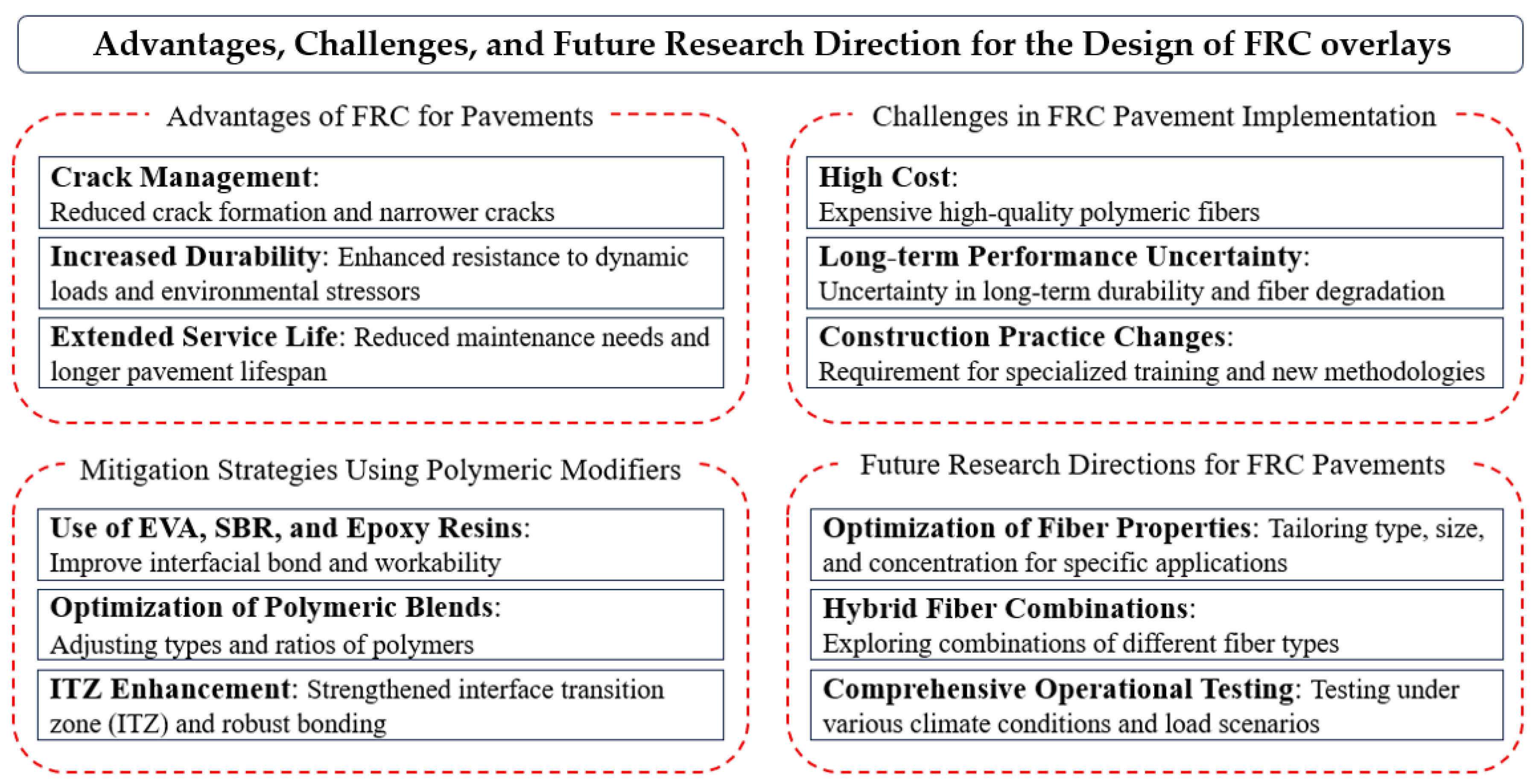

5. Limitations and Future Studies

6. Conclusions

- Steel fibers demonstrate superior effectiveness in reducing the crack opening width compared to polypropylene (PP) fibers, offering significant durability and performance benefits for concrete overlays. However, cost considerations and potential corrosion issues must be carefully managed.

- Hybrid systems combining macro and micro fibers exhibit excellent properties for reducing the crack opening width. Integrating different fiber types into hybrid systems is a promising strategy for improving both the structural performance and cost-effectiveness of concrete overlays. The combination of the high strength of macro fibers and the fine size of micro fibers maximizes the crack reduction effect, enhancing long-term performance.

- Designing FRC overlays involves numerous complex variables beyond those of traditional overlay methods, including fiber type, volume content, and overlay thickness. With the proper design and material selection, FRC overlays can achieve outstanding performance.

- Further field testing is necessary. Future research should assess the long-term performance and durability of concrete overlays with various fiber types and volume contents under realistic environmental conditions. Field test results will complement laboratory findings and bolster confidence in their real-world applications.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tatnall, P.C.; Kuitenbouwer, L. Steel Fiber Reinforced Concrete in Industrial Floors. Concr. Int. 1992, 14, 43–47. [Google Scholar]

- Tiberti, G.; Minelli, F.; Plizzari, G. Reinforcement optimization of fiber reinforced concrete linings for conventional tunnels. Compos. Part B Eng. 2014, 58, 199–207. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- Brandt, A.M. Fibre Reinforced Cement-Based (FRC) Composites after over 40 Years of Development in Building and Civil Engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, P.; Wang, J.; Hu, S. Influence of fibers on the mechanical properties and durability of ultra-high-performance concrete: A review. J. Build. Eng. 2022, 52, 104370. [Google Scholar] [CrossRef]

- Hosseinzadeh, H.; Salehi, A.M.; Mehraein, M.; Asadollahfardi, G. The effects of steel, polypropylene, and high-performance macro polypropylene fibers on mechanical properties and durability of high-strength concrete. Constr. Build. Mater. 2023, 386, 131589. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, C.; Gao, Z.; Wang, F. A review on fracture properties of steel fiber reinforced concrete. J. Build. Eng. 2023, 67, 105975. [Google Scholar] [CrossRef]

- Zeng, W.; Wang, W.; Pan, J.; Liu, G. Effect of steel fiber on the permeability of freeze-thaw damaged concrete under splitting tensile and compressive loads. J. Build. Eng. 2023, 80, 108086. [Google Scholar] [CrossRef]

- Zeng, W.; Zhao, X.; Zou, B.; Chen, C. Topographical characterization and permeability correlation of steel fiber reinforced concrete surface under freeze-thaw cycles and NaCl solution immersion. J. Build. Eng. 2023, 80, 108042. [Google Scholar] [CrossRef]

- Rocha, T.d.S.; Cardoso, D.C.; Bitencourt, L.A., Jr. Macro synthetic fiber pullout behavior in short- and long-term tests. Constr. Build. Mater. 2023, 384, 131491. [Google Scholar] [CrossRef]

- Zainal, S.M.I.S.; Hejazi, F.; Mafaileh, A.M.A. Strengthening of Reinforced Concrete slabs using macro and micro synthetic fibers. Structures 2023, 51, 1579–1590. [Google Scholar] [CrossRef]

- Yıldırım, M.; Özhan, H.B. Durability properties of basalt fiber-reinforced mortars with different mineral admixtures exposed to high temperatures. Constr. Build. Mater. 2023, 400, 132574. [Google Scholar] [CrossRef]

- Wang, X.; Li, L.; Xiang, Y.; Wu, Y.; Wei, M. The influence of basalt fiber on the mechanical performance of concrete-filled steel tube short columns under axial compression. Front. Mater. 2024, 10, 1332269. [Google Scholar] [CrossRef]

- Hasan, R.; Sobuz, M.H.R.; Akid, A.S.M.; Awall, M.R.; Houda, M.; Saha, A. Eco-friendly self-consolidating concrete production with reinforcing jute fiber. J. Build. Eng. 2023, 63, 105519. [Google Scholar] [CrossRef]

- Yuan, H.; Fan, Y.; You, X.; Fu, B.; Zou, Q. Pullout behavior of recycled macro fibers in the cementitious matrix: Analytical model and experimental validation. Compos. Struct. 2024, 328, 117690. [Google Scholar] [CrossRef]

- Islam, M.J.; Islam, K.; Shahjalal, M.; Khatun, E.; Islam, S.; Razzaque, A.B. Influence of different types of fibers on the mechanical properties of recycled waste aggregate concrete. Constr. Build. Mater. 2022, 337, 127577. [Google Scholar] [CrossRef]

- Niyasom, S.; Tangboriboon, N. Development of biomaterial fillers using eggshells, water hyacinth fibers, and banana fibers for green concrete construction. Constr. Build. Mater. 2021, 283, 122627. [Google Scholar] [CrossRef]

- Khan, M.; Cao, M.; Xie, C.; Ali, M. Effectiveness of Hybrid Steel-Basalt Fiber Reinforced Concrete under Compression. Case Stud. Constr. Mater. 2022, 16, e00941. [Google Scholar] [CrossRef]

- Yuan, Z.; Jia, Y. Mechanical properties and microstructure of glass fiber and polypropylene fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2021, 266, 121048. [Google Scholar] [CrossRef]

- Cecconello, V.; Poletto, M. Assessment of graphene oxide coated polyester fiber reinforced cementitious composites. J. Mater. Res. Technol. 2023, 27, 8216–8227. [Google Scholar] [CrossRef]

- Paewchompoo, N.; Yodsudjai, W.; Chindaprasirt, P. Corrosion-Induced Cracking Time in Steel Fiber-Reinforced Concrete: Experiment and Finite Element Method. ACI Mater. J. 2020, 117, 3–12. [Google Scholar]

- Mangat, P.; Gurusamy, K. Permissible crack widths in steel fibre reinforced marine concrete. Mater. Struct. 1987, 20, 338–347. [Google Scholar] [CrossRef]

- Hwang, J.P.; Jung, M.S.; Kim, M.; Ann, K.Y. Corrosion risk of steel fibre in concrete. Constr. Build. Mater. 2015, 101, 239–245. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Maluk, C.; Bisby, L.; Terrasi, G.P. Effects of polypropylene fibre type and dose on the propensity for heat-induced concrete spalling. Eng. Struct. 2017, 141, 584–595. [Google Scholar] [CrossRef]

- Nobili, A.; Lanzoni, L.; Tarantino, A.M. Experimental investigation and monitoring of a polypropylene-based fiber reinforced concrete road pavement. Constr. Build. Mater. 2013, 47, 888–895. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, H.; Zhao, B.; Wang, B.; Zhao, Q.; Sun, M. Experimental investigation on physical properties of concrete containing polypropylene fiber and water-borne epoxy for pavement. Coatings 2023, 13, 452. [Google Scholar] [CrossRef]

- Hussain, I.; Ali, B.; Akhtar, T.; Jameel, M.S.; Raza, S.S. Comparison of mechanical properties of concrete and design thickness of pavement with different types of fiber-reinforcements (steel, glass, and polypropylene). Case Stud. Constr. Mater. 2020, 13, e00429. [Google Scholar] [CrossRef]

- Ali, B.; Qureshi, L.A.; Kurda, R. Environmental and economic benefits of steel, glass, and polypropylene fiber reinforced cement composite application in jointed plain concrete pavement. Compos. Commun. 2020, 22, 100437. [Google Scholar] [CrossRef]

- Yu, J.; Yi, Z.; Zhang, Z.; Liu, D.; Ran, J. The Effects of Hybrid Steel/Basalt Fibers on the Durability of Concrete Pavement against Freeze–Thaw Cycles. Materials 2023, 16, 7137. [Google Scholar] [CrossRef] [PubMed]

- Krayushkina, K.; Khymeryk, T.; Bieliatynskyi, A. Basalt fiber concrete as a new construction material for roads and airfields. IOP Conf. Ser. Mater. Sci. Eng. 2019, 708, 012088. [Google Scholar] [CrossRef]

- Ozturk, O.; Ozyurt, N. Sustainability and cost-effectiveness of steel and polypropylene fiber reinforced concrete pavement mixtures. J. Clean. Prod. 2022, 363, 132582. [Google Scholar] [CrossRef]

- Achilleos, C.; Hadjimitsis, D.; Neocleous, K.; Pilakoutas, K.; Neophytou, P.O.; Kallis, S. Proportioning of steel fibre reinforced concrete mixes for pavement construction and their impact on environment and cost. Sustainability 2011, 3, 965–983. [Google Scholar] [CrossRef]

- Shakir, H.M.; Al-Tameemi, A.F.; Al-Azzawi, A.A. A review on hybrid fiber reinforced concrete pavements technology. J. Phys. Conf. Ser. 2021, 1895, 012053. [Google Scholar] [CrossRef]

- Chanvillard, G.; Aitcin, P.C.; Lupien, C. Field evaluation of steel-fiber reinforced concrete overlay with various bonding mechanisms. Transp. Res. Rec. 1989, 1226, 48–56. [Google Scholar]

- Granju, J.L. Thin bonded overlays: About the role of fiber reinforcement on the limitation of their debonding. Adv. Cem. Based Mater. 1996, 4, 21–27. [Google Scholar] [CrossRef]

- Pourjahanshahi, A.; Madani, H.; Emadi, M. Assessing flexural and permeability performance of roller-compacted concrete pavement (RCCP) reinforcing with different types of synthetic fibres and crimped steel fibre. Aust. J. Civ. Eng. 2023, 21, 167–181. [Google Scholar] [CrossRef]

- Carlswärd, J. Shrinkage Cracking of Steel Fibre Reinforced Self-Compacting Concrete Overlays Test Methods and Theoretical Modelling: Test Methods and Theoretical Modelling. Doctoral Dissertation, Luleå Tekniska Universitet, Luleå, Sweden, 2006. [Google Scholar]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Kayali, O.; Haque, M.; Zhu, B. Some characteristics of high strength fiber reinforced lightweight aggregate concrete. Cem. Concr. Compos. 2003, 25, 207–213. [Google Scholar] [CrossRef]

- Hsie, M.; Tu, C.; Song, P.S. Mechanical properties of polypropylene hybrid fiber-reinforced concrete. Mat. Sci. Eng. A-Struct. 2008, 494, 153–157. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Pereira, E.B.; Fischer, G.; Barros, J.A. Effect of hybrid fiber reinforcement on the cracking process in fiber reinforced cementitious composites. Cem. Concr. Compos. 2012, 34, 1114–1123. [Google Scholar] [CrossRef]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Arisoy, B.; Wu, H.-C. Material characteristics of high performance lightweight concrete reinforced with PVA. Constr. Build. Mater. 2008, 22, 635–645. [Google Scholar] [CrossRef]

- Sun, W.; Chen, H.; Luo, X.; Qian, H. The effect of hybrid fibers and expansive agent on the shrinkage and permeability of high-performance concrete. Cem. Concr. Res. 2001, 31, 595–601. [Google Scholar] [CrossRef]

- Banyhussan, Q.S.; Yıldırım, G.; Bayraktar, E.; Demirhan, S.; Şahmaran, M. Deflection-hardening hybrid fiber reinforced concrete: The effect of aggregate content. Constr. Build. Mater. 2016, 125, 41–52. [Google Scholar] [CrossRef]

- Atahan, H.N.; Pekmezci, B.Y.; Tuncel, E.Y. Behavior of PVA Fiber-Reinforced Cementitious Composites Under Static and Impact Flexural Effects. J. Mater. Civ. Eng. 2013, 25, 1438–1445. [Google Scholar] [CrossRef]

- Kumar, A.; Walia, B.S.; Bajaj, A. Influence of fly ash, lime, and polyester fibers on compaction and strength properties of expansive soil. J. Mater. Civ. Eng. 2007, 19, 242–248. [Google Scholar] [CrossRef]

- Gupta, S.; Rao, V.K.; Sengupta, J. Evaluation of polyester fiber reinforced concrete for use in cement concrete pavement works. Road Mater. Pavement Des. 2008, 9, 441–461. [Google Scholar] [CrossRef]

- Martínez-Barrera, G.; Gencel, O.; Martínez-López, M. Polyester polymer concrete modified by polyester fibers and gamma rays. Constr. Build. Mater. 2022, 356, 129278. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C. On the mechanical properties and fracture behavior of polyolefin fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2014, 55, 274–288. [Google Scholar] [CrossRef]

- Xu, H.; Shao, Z.; Wang, Z.; Cai, L.; Li, Z.; Jin, H.; Chen, T. Experimental study on mechanical properties of fiber reinforced concrete: Effect of cellulose fiber, polyvinyl alcohol fiber and polyolefin fiber. Constr. Build. Mater. 2020, 261, 120610. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Galvez, J.C. Improving the reinforcement of polyolefin fiber reinforced concrete for infrastructure applications. Fibers 2015, 3, 504–522. [Google Scholar] [CrossRef]

- Ahmad, J.; Zaid, O.; Aslam, F.; Martínez-García, R.; Alharthi, Y.M.; Hechmi EI Ouni, M.; Faisal Tufail, R.; Sharaky, I.A. Mechanical properties and durability assessment of nylon fiber reinforced self-compacting concrete. J. Eng. Fibers Fabr. 2021, 16, 1–13. [Google Scholar] [CrossRef]

- Sarkar, A.; Hajihosseini, M. The effect of basalt fibre on the mechanical performance of concrete pavement. Road Mater. Pavement Des. 2020, 21, 1726–1737. [Google Scholar] [CrossRef]

- Kos, Ž.; Kroviakov, S.; Kryzhanovskyi, V.; Hedulian, D. Strength, Frost Resistance, and Resistance to Acid Attacks on Fiber-Reinforced Concrete for Industrial Floors and Road Pavements with Steel and Polypropylene Fibers. Materials 2022, 15, 8339. [Google Scholar] [CrossRef] [PubMed]

- Fattouh, M.S.; Tayeh, B.A.; Agwa, I.S.; Elsayed, E.K. Improvement in the flexural behaviour of road pavement slab concrete containing steel fibre and silica fume. Case Stud. Constr. Mater. 2023, 18, e01720. [Google Scholar] [CrossRef]

- Kos, Ž.; Kroviakov, S.; Mishutin, A.; Poltorapavlov, A. An Experimental Study on the Properties of Concrete and Fiber-Reinforced Concrete in Rigid Pavements. Materials 2023, 16, 5886. [Google Scholar] [CrossRef] [PubMed]

- Arce, G.A.; Noorvand, H.; Hassan, M.M.; Rupnow, T.; Dhakal, N. Feasibility of low fiber content PVA-ECC for jointless pavement application. Constr. Build. Mater. 2021, 268, 121131. [Google Scholar] [CrossRef]

- Lee, S.J.; Shin, H.J.; Park, C.G. Strength and durability of hybrid fiber-reinforced latex-modified rapid-set cement preplaced concrete for emergency concrete pavement repair. Appl. Sci. 2021, 11, 4595. [Google Scholar] [CrossRef]

- Kori, K.; Goliya, S.S. Use of Discrete fiber in road pavement. Mater. Today Proc. 2022, 65, 1856–1860. [Google Scholar] [CrossRef]

- Smirnova, O.; Kharitonov, A.; Belentsov, Y. Influence of polyolefin fibers on the strength and deformability properties of road pavement concrete. J. Traffic Transp. Eng. 2019, 6, 407–417. [Google Scholar] [CrossRef]

- Ayub, T.; Shafiq, N.; Nuruddin, M.F. Mechanical properties of high-performance concrete reinforced with basalt fibers. Procedia Eng. 2014, 77, 131–139. [Google Scholar] [CrossRef]

- Song, P.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Kim, H.R.; Han, S.J.; Yun, H.D. Compressive Properties of High Strength Steel Fiber Reinforced Concrete with Different Fiber Volume Fractions. Appl. Mech. Mater. 2013, 372, 215–218. [Google Scholar] [CrossRef]

- Ulu, A.; Tutar, A.I.; Kurklu, A.; Cakir, F. Effect of excessive fiber reinforcement on mechanical properties of chopped glass fiber reinforced polymer concretes. Constr. Build. Mater. 2022, 359, 129486. [Google Scholar] [CrossRef]

- Destrée, X.; Yao, Y.; Mobasher, B. Sequential cracking and their openings in steel-fiber-reinforced joint-free concrete slabs. J. Mater. Civ. Eng. 2015, 28, 04015158. [Google Scholar] [CrossRef]

- Lau, C.K.; Chegenizadeh, A.; Htut, T.N.S.; Nikraz, H. Performance of the steel fibre reinforced rigid concrete pavement in fatigue. Buildings 2020, 10, 186. [Google Scholar] [CrossRef]

- Chen, Y.; Cen, G.P.; Cui, Y.H. Comparative analysis on the anti-wheel impact performance of steel fiber and reticular polypropylene synthetic fiber reinforced airport pavement concrete under elevated temperature aging environment. Constr. Build. Mater. 2018, 192, 818–835. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Ozbakkaloglu, T. Synthetic fibers for cementitious composites: A critical and in-depth review of recent advances. Constr. Build. Mater. 2019, 207, 491–518. [Google Scholar] [CrossRef]

- Chen, Y.; Cen, G.P.; Cui, Y.H. Comparative study on the effect of synthetic fiber on the preparation and durability of airport pavement concrete. Constr. Build. Mater. 2018, 184, 34–44. [Google Scholar] [CrossRef]

- Merhej, T.; Cheng, L.L.; Feng, D.C. Polypropylene fiber reinforced concrete for rigid airfield pavement. Adv. Mater. Res. 2011, 228, 627–633. [Google Scholar] [CrossRef]

- Hasani, M.; Nejad, F.M.; Sobhani, J.; Chini, M. Mechanical and durability properties of fiber reinforced concrete overlay: Experimental results and numerical simulation. Constr. Build. Mater. 2021, 268, 121083. [Google Scholar] [CrossRef]

- Barman, M.; Hansen, B. Comparison of Performances of Structural Fibers and Development of a Specification for Using Them in Thin Concrete Overlays; Minnesota Department of Transportation: St. Paul, MN, USA, 2018.

- Roesler, J.R.; Altoubat, S.A.; Lange, D.A.; Rieder, K.A.; Ulreich, G.R. Effect of synthetic fibers on structural behavior of concrete slabs-on-ground. ACI Mater. J. 2006, 103, 3–10. [Google Scholar]

- Ali, S.; Liu, X.M.; Thambiratnam, D.P.; Fawzia, S. Enhancing the impact performance of runway pavements with improved composition. Eng. Fail. Anal. 2021, 130, 105739. [Google Scholar] [CrossRef]

- Al-Rousan, R.; Alhassan, M.; Al-Salman, H. Impact resistance of polypropylene fiber reinforced concrete two-way slabs. Struct. Eng. Mech. 2017, 62, 373–380. [Google Scholar] [CrossRef]

- Choi, S.Y.; Park, J.S.; Jung, W.T. A study on the shrinkage control of fiber reinforced concrete pavement. Procedia Eng. 2011, 14, 2815–2822. [Google Scholar] [CrossRef]

- Folliard, K.J.; Berke, N.S. Properties of high-performance concrete containing shrinkage-reducing admixture. Cem. Concr. Res. 1997, 27, 1357–1364. [Google Scholar] [CrossRef]

- Grzybowski, M.; Shah, S.P. Shrinkage Cracking of Fiber Reinforced Concrete. ACI Mater. J. 1990, 87, 138–148. [Google Scholar]

- Wang, Z.H.; Guo, R.X.; Liu, G.S.; Guo, L.X.; Yan, Y. Study on Flexural Fatigue Properties of POM Fiber Airport Pavement Concrete. Polymers 2022, 14, 2979. [Google Scholar] [CrossRef] [PubMed]

- Banthia, N.; Bindiganavile, V.; Azhari, F.; Zanotti, C. Curling control in concrete slabs using fiber reinforcement. J. Test. Eval. 2014, 42, 390–397. [Google Scholar] [CrossRef]

- Khan, M.; Ali, K. Effectiveness of hair and wave polypropylene fibers for concrete roads. Constr. Build. Mater. 2018, 166, 581–591. [Google Scholar] [CrossRef]

- Bolat, H.; Simsek, O.; Çullu, M.; Durmus, G.; Can, Ö. The effects of macro synthetic fiber reinforcement use on physical and mechanical properties of concrete. Compos. Part B Eng. 2014, 61, 191–198. [Google Scholar] [CrossRef]

- Westergaard, H.M. Stresses in Concrete Pavements Computed by Theoretical Analysis. Public Roads 1926, 7, 25–35. [Google Scholar]

- Johansen, K.W. Yield-Line Theory; Cement and Concrete Association: London, UK, 1962. [Google Scholar]

- ACI 544.4R-88; Design Considerations for Steel Fiber Reinforced Concrete. ACI Committee: Farmington Hills, MI, USA, 1999; Volume 88, p. 18.

- Meda, A. On the extension of the yield-line method to the design of SFRC slabs on grade. Stud. Res. Politec. Milano 2003, 24, 223–239. [Google Scholar]

- Meda, A.; Plizzari, G.A.; Riva, P. Fracture behavior of SFRC slabs on grade. Mater. Struct. Constr. 2004, 37, 405–411. [Google Scholar] [CrossRef]

- Masad, E.; Taha, R.; Muhunthan, B. Finite-element analysis of temperature effects on plain-jointed concrete pavements. J. Transp. Eng. 1996, 122, 388–398. [Google Scholar] [CrossRef]

- Shoukry, S.N.; William, G.W.; Riad, M. Nonlinear temperature gradient effects in dowel jointed concrete slabs. Int. J. Pavement Eng. 2003, 4, 131–142. [Google Scholar] [CrossRef]

- Shoukry, S.N.; William, G.W.; Riad, M.Y. Effect of thermal stresses on mid-slab cracking in dowel jointed concrete pavements. Struct. Infra. Eng. 2007, 3, 43–51. [Google Scholar] [CrossRef]

- Shoukry, S.N.; Fahmy, M.; Prucz, J.; William, G. Validation of 3DFE analysis of rigid pavement dynamic response to moving traffic and nonlinear temperature gradient effects. Int. J. Geomech. 2007, 7, 16–24. [Google Scholar] [CrossRef]

- Mackiewicz, P. Thermal stress analysis of jointed plane in concrete pavements. Appl. Therm. Eng. 2014, 73, 1169–1176. [Google Scholar] [CrossRef]

- Altoubat, S.A.; Roesler, J.R.; Lange, D.A.; Rieder, K.-A. Simplified method for concrete pavement design with discrete structural fibers. Constr. Build. Mater. 2008, 22, 384–393. [Google Scholar] [CrossRef]

- ASTM C1609/C1609M-12; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading). ASTM: West Conshohocken, PA, USA, 2012.

- Japan Concrete Inst. JSCE-SF4; Standard for Flexural Strength and Flexural Toughness, Method of Tests for Steel Fiber Reinforced Concrete. Japan Society of Civil Engineers: Tokyo, Japan, 1984; pp. 58–61.

- ASTM C1550-20; Method for Flexural Toughness of Fiber Reinforced Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- ASTM C1399/C1399M-10; Standard Test Method for Obtaining Average Residual-Strength of Fiber-Reinforced Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- National Cooperative Highway Research Program (NCHRP). Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures; National Cooperative Highway Research Program 1-37 A; NCHRP: Washington, DC, USA, 2004. [Google Scholar]

- Darter, M.I.; Barenberg, E.J. Design of Zero-Maintenance Plain Jointed Concrete Pavement; Report no. FHWA-RD-77-111; Federal Highway Administration: Washington, DC, USA, 1977; Volume 1. [Google Scholar]

- AASHTO. Guide for the Design of Pavement Structures; AASHTO: Washington, WA, USA, 1993. [Google Scholar]

- RILEM TC 162-TDF, Test and design methods for steel fibre reinforced concrete, σ-ε design method. Mater. Struct. 2003, 36, 560–567. [CrossRef]

- EN 1992-1-1; Eurocode 2. Design of Concrete Structures. Part 1-1: General Rules and Rules for Building. CEN: Brussels, Belgium, 2004.

- Löfgren, I. Calculation of crack width and crack spacing. In Fiber Reinforced Concrete; Nordic Mini Seminar: Trondheim, Norway, 2007; pp. 1–12. [Google Scholar]

- Jansson, A.; Löfgren, I.; Gylltoft, K. Flexural behavior of members with a combination of steel fibres and conventional reinforcement. Nord. Concr. Res. 2010, 2, 155–171. [Google Scholar]

- Hussain, Z.; Pu, Z.; Hussain, A.; Ahmed, S.; Shah, A.U.; Ali, A.; Ali, A. Effect of fiber dosage on water permeability using a newly designed apparatus and crack monitoring of steel fiber–reinforced concrete under direct tensile loading. Struct. Health Monit. 2022, 21, 2083–2096. [Google Scholar] [CrossRef]

- Gali, S.; Subramaniam, K.V. Multi-linear stress-crack separation relationship for steel fiber reinforced concrete: Analytical framework and experimental evaluation. Theor. Appl. Fract. Mech. 2018, 93, 33–43. [Google Scholar] [CrossRef]

- Saradar, A.; Tahmouresi, B.; Mohseni, E.; Shadmani, A. Restrained shrinkage cracking of fiber-reinforced high-strength concrete. Fibers 2018, 6, 12. [Google Scholar] [CrossRef]

- Oh, H.J.; Cho, Y.K.; Kim, S.M. Experimental evaluation of crack width movement of continuously reinforced concrete pavement under environmental load. Constr. Build. Mater. 2017, 137, 85–95. [Google Scholar] [CrossRef]

- Reddy, K.C.; Subramaniam, K.V. Analysis for multi-linear stress-crack opening cohesive relationship: Application to macro-synthetic fiber reinforced concrete. Eng. Fract. Mech. 2017, 169, 128–145. [Google Scholar] [CrossRef]

- Passuello, A.; Moriconi, G.; Shah, S.P. Cracking behavior of concrete with shrinkage reducing admixtures and PVA fibers. Cem. Concr. Compos. 2009, 31, 699–704. [Google Scholar] [CrossRef]

- Nunes, L.C.S.; Reis, J.M.L. Estimation of crack-tip-opening displacement and crack extension of glass fiber reinforced polymer mortars using digital image correlation method. Mater. Des. 2012, 33, 248–253. [Google Scholar] [CrossRef]

- Mirza, F.A.; Soroushian, P. Effects of alkali-resistant glass fiber reinforcement on crack and temperature resistance of lightweight concrete. Cem. Concr. Compos. 2002, 24, 223–227. [Google Scholar] [CrossRef]

- Caggiano, A.; Gambarelli, S.; Martinelli, E.; Nisticò, N.; Pepe, M. Experimental characterization of the post-cracking response in hybrid steel/polypropylene fiber-reinforced concrete. Constr. Build. Mater. 2016, 125, 1035–1043. [Google Scholar] [CrossRef]

- Delatte, N. Concrete Pavement Design, Construction, and Performance; Taylor & Francis: Abingdon, UK; New York, NY, USA, 2008; pp. 25–27. [Google Scholar]

- Rao, S.; Hoegh, K.; Yu, T.; Khazanovich, L. Evaluation of dowel alignment constructability in Portland cement concrete pavements. J. Transp. Res. Board. 2009, 2098, 86–93. [Google Scholar] [CrossRef]

- Tayabji, S. Dowel placement tolerances for concrete pavements. J. Transp. Res. Board. 1986, 10625, 47–54. [Google Scholar]

- Xu, F.; Zhou, M.; Chen, J.; Ruan, S. Mechanical performance evaluation of polyester fiber and SBR latex compound-modified cement concrete road overlay material. Constr. Build. Mater. 2014, 63, 142–149. [Google Scholar] [CrossRef]

| Property | Fiber Type | |||||||

|---|---|---|---|---|---|---|---|---|

| Steel [39,40] | PP 1 [40,41,42,43] | PE 2 [39,44] | PVA 3 [45,46,47,48] | Polyester [49,50,51] | Polyolefin [52,53,54] | Nylon [42,55] | Basalt [12,56] | |

| Specific gravity | 7.84 | 0.91 | 0.92–0.96 | 1.20–1.30 | 1.33–1.40 | 0.91–0.97 | 1.10–1.16 | 2.52–2.97 |

| Modulus of elasticity (GPa) | 200 | 1.5–12 | 5–100 | 20–43 | 8–20 | >9 | 4–5.3 | 85–110 |

| Tensile strength (MPa) | 500–2000 | 240–900 | 80–600 | 1000–1600 | 400–750 | >500 | 450–919 | 1100–4840 |

| Elongation at break (%) | 0.5–3.5 | 15–80 | 4–100 | 6–7 | 12–20 | 15–30 | 15–28 | 3.15 |

| Acid and Alkali Resistance | Varied | High | High | High | High | High | Moderate | High |

| Cost ($/kg) | 1.0–8.0 | 1.0–2.5 | 2.0–20 | 1.0–15 | 1.2–1.5 | 1.0–10 | 2.0–2.5 | 4.5–5.0 |

| Fiber Type | Strength Improvement | Thickness Reduction and Other Effects | Refs. |

|---|---|---|---|

| Steel (Hooked or Wave) | Compressive strength 10% ↑ *, Flexural strength 80% ↑ | Improved residual strength and toughness, Reduced thickness by 63 mm at 1.0% Vf ** | [28] |

| Flexural strength 25% ↑ at 0.5% Vf and 47% at 1.0% Vf, Improved residual strength | Contributed to reduced thickness, Prevent micro cracking due to drying shrinkage | [29] | |

| Improved compressive and flexural strength | Improved cold, wear, and acid resistances | [57] | |

| Compressive strength 25% ↑ at 7 and 28 days | Increased ultimate load with the addition steel fibers and silica fume (confirmed through SEM *** & TGA ****) | [58] | |

| PP | Tensile strength 20% ↑ | Thickness reduced by 21mm at 1.0% Vf | [28] |

| Flexural strength 9% ↑ at 0.5% Vf and 18% ↑ at 1.0% Vf | Contributes to reduced thickness | [29] | |

| Compressive strength 5 to 6% ↑, Flexural strength 8 to 12% ↑ | Improved wear and frost resistances (at 50 cycles) | [59] | |

| PVA | Improved flexural and tensile strength values with increased Vf | Prevents brittle failure of pavement in case of overload or subgrade support loss | [60] |

| Improved compressive and flexural strength | Improved wear resistance by 44% and impact resistance more than doubled | [61] | |

| Polyester | Improved strength compared to PP fibers | – | [62] |

| Polyolefin | Improved tensile strength | Reduced stress concentration and prevents counter cracks | [63] |

| Similar strength and elastic modulus to unreinforced concrete Improved tensile strength | Improved load-bearing capacity | [54] | |

| Nylon | Compressive strength 2.62 to 5.01% ↑ Flexural strength 12.31% ↑ | Improved wear resistance (7.30%), Reduced permeability (37.5%) | [61] |

| Basalt | Highest compressive strength at 2.0% Vf, Increased splitting tensile strength | Strength increased with the addition of kaolin or silica fume | [64] |

| Hybrid (Steel and Basalt) | Reduced compressive strength at freeze-thaw condition, but less compared to single fiber | Improved freeze-thaw resistance, increased pavement structure life | [30] |

| Hybrid (PP and Polyester) | Strength significantly increased compared to single fiber | – | [62] |

| Hybrid (PVA and Nylon) | Higher compressive and flexural strength compared to a single fiber | Suitable for emergency packaging repairs | [61] |

| Feature | Linear Elastic | Non-Linear Fracture Mechanics | |

|---|---|---|---|

| Elastic Response | Yield Line | ||

| Approach | Elastic foundation with constant subgrade contacts and a circular wheel load contact area | Based on yield line theory, focuses on ultimate load capacity | Analyzes post-cracking behavior, particularly for strain-softening materials |

| Based on | Westergaard stress formulation [86] | Yield line theory [87] | NLFM principles |

| Pros | Traditionally used for straightforward scenarios | Offering precise design calculations for ultimate load | Accurate, providing detailed predictions and enhances durability |

| Cons | Not fully capture the role of fibers, especially in crack openings | Requires adjustments for fatigue, temperature curling stresses | Complex and requires detailed material data |

| Limitation | Not useful for complex stress conditions or advanced material behaviors including fibers | Does not account for material behavior beyond initial yielding | Challenging to integrate into existing design frameworks |

| Other | Used primarily for initial design estimates | Modifications needed in elastic design procedures to account for FRC | Beneficial for analyzing thermal stress distribution, deformation, and the effects of dowel bars |

| No. | Equation | Symbols | Refs. |

|---|---|---|---|

| 1 | cw is 0, if cw is less than 0 | cw = crack width at the depth of the steel, CC = local calibration constant (1 is recommended in MEPDG [83] based on global calibration), L = mean crack spacing, εshr = drying shrinkage coefficient of Portland cement concrete (PCC), αPCC = coefficient of thermal expansion (CTE) of PCC, ΔT = drop in PCC temperature from the concrete set temperature at the depth of the steel, c2 = second bond stress coefficient increment, fσ = maximum longitudinal tensile stress in PCC at the steel level, EPCC = elastic modulus of PCC | [101] |

| 2 | ∆L = joint opening width, C = adjustment factor (0.65 is a typical), L = joint spacing or slab length, αt = coefficient of thermal expansion, ∆T = temperature differences at placement, ε = drying shrinkage coefficient | [102,103] | |

| 3 | w = crack width, β = coefficient relating the average crack width to a structural design, εsm = mean strain between the cracks in the tensile reinforcement, k1 and k2 = non-dimensional geometric coefficients, ϕb = structural tensile reinforcement bar diameter, ρr = tensile reinforcement ratio, Lf/Df = fiber aspect ratio | [104,105] | |

| 4 | Ɛsm = mean strain in the structural tensile reinforcement, Ɛcm = mean strain in the remaining concrete between the cracks, c = concrete cover depth, k1 and k2 = non-dimensional geometric coefficients, fresidual = measured residual flexural stress of SFRC, fctm = measured flexural strength of SFRC, ϕ = structural tensile reinforcement bar diameter, ρs,eff = effective structural tensile reinforcement ratio | [106,107] |

| Fiber Type | Fiber Volume, Vf | Effect on Crack Opening Width Reduction | Refs. |

|---|---|---|---|

| Steel | 0 to 1.0% | Restrain crack development, improve crack resistance, load transfer, and enhanced structural durability | [35] |

| 0.75% | Effectively limit crack opening width, well-distributed micro-cracks, contribute to high bond strength | [38] | |

| 0 to 1.25% | Increased first cracking load with higher Vf, The first cracking load increased by 21% at 1.25% Vf | [108] | |

| 0 to 0.75% | Improved cracking resistance and load transfer capacity with higher Vf, enhanced durability | [109] | |

| 0.1% | Initial crack width reduced by 50%, Crack width increased over time with signs of corrosion observed | [110] | |

| 0.6 to 0.8% | Reduced crack opening width with increased Vf | [111] | |

| PP | 0.1% | Reduced crack width by 84% and initial crack age increased by 62% No full-depth cracks observed after 28 days | [110] |

| 0 to 0.88% | Improved cracking resistance and load bearing capacity | [112] | |

| Polyolefin | 0.1% | Delayed initial crack age, but no significant effect on crack width | [110] |

| 0 to 0.88% | Contribute to better load recovery with maintaining greater load-carrying capacity | [112] | |

| PVA | 0.25 to 0.50% | Reduced crack width by 70% for macro fibers and 90% for micro fibers, shrinkage reducing admixtures (SRA) applied | [113] |

| Glass | 0 to 10% | Reduced crack opening widths with increased Vf | [114] |

| 0.125 to 0.75% | Reduce crack width, but promote multiple cracks, Effective at 0.25% Vf | [115] | |

| 0.1% | Delayed initial crack age, but no significant effect on crack width | [110] | |

| Basalt | 0.1% | Delayed initial crack age, but no significant effect on crack width | [110] |

| Hybrid (Steel and PP) | 0.75% (Steel: 0 to 60 kg/m3) (PP: 0 to 6.8 kg/m3) | Hybrid fibers reduce crack width and enhance post-cracking behavior, with steel fibers increasing toughness and polypropylene fibers reducing variability | [116] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, S.; Bordelon, A.C.; Kim, M.O. Effects of Macro Fibers on Crack Opening Reduction in Fiber Reinforced Concrete Overlays. Polymers 2024, 16, 2282. https://doi.org/10.3390/polym16162282

Cho S, Bordelon AC, Kim MO. Effects of Macro Fibers on Crack Opening Reduction in Fiber Reinforced Concrete Overlays. Polymers. 2024; 16(16):2282. https://doi.org/10.3390/polym16162282

Chicago/Turabian StyleCho, Sanghwan, Amanda C. Bordelon, and Min Ook Kim. 2024. "Effects of Macro Fibers on Crack Opening Reduction in Fiber Reinforced Concrete Overlays" Polymers 16, no. 16: 2282. https://doi.org/10.3390/polym16162282

APA StyleCho, S., Bordelon, A. C., & Kim, M. O. (2024). Effects of Macro Fibers on Crack Opening Reduction in Fiber Reinforced Concrete Overlays. Polymers, 16(16), 2282. https://doi.org/10.3390/polym16162282